Organic Thermoelectric Nanocomposites Assembled via Spraying Layer-by-Layer Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

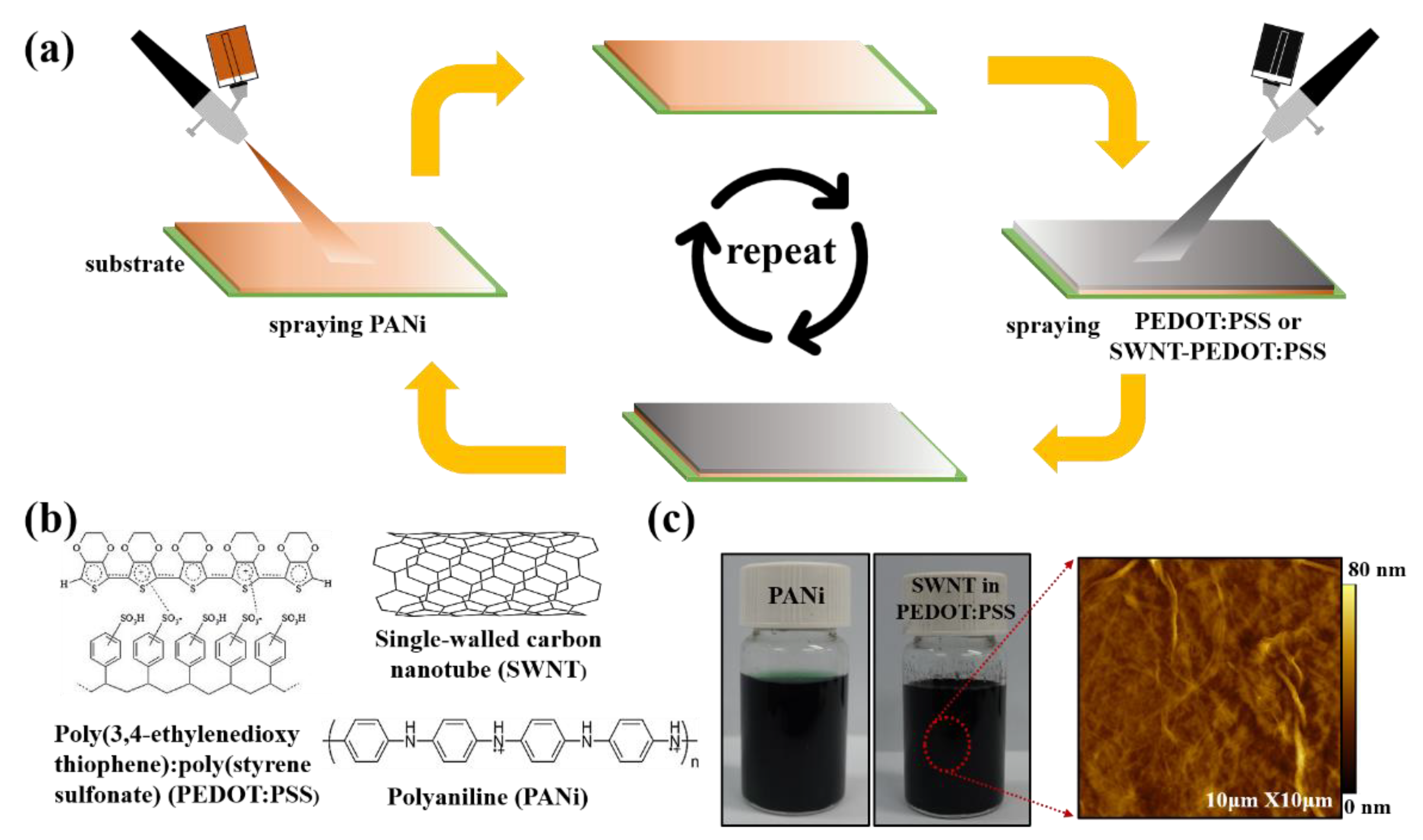

2.2. Layer-by-Layer Assembly

2.3. Thin Film Characterization

2.4. Thermoelectric Property Measurements

3. Results

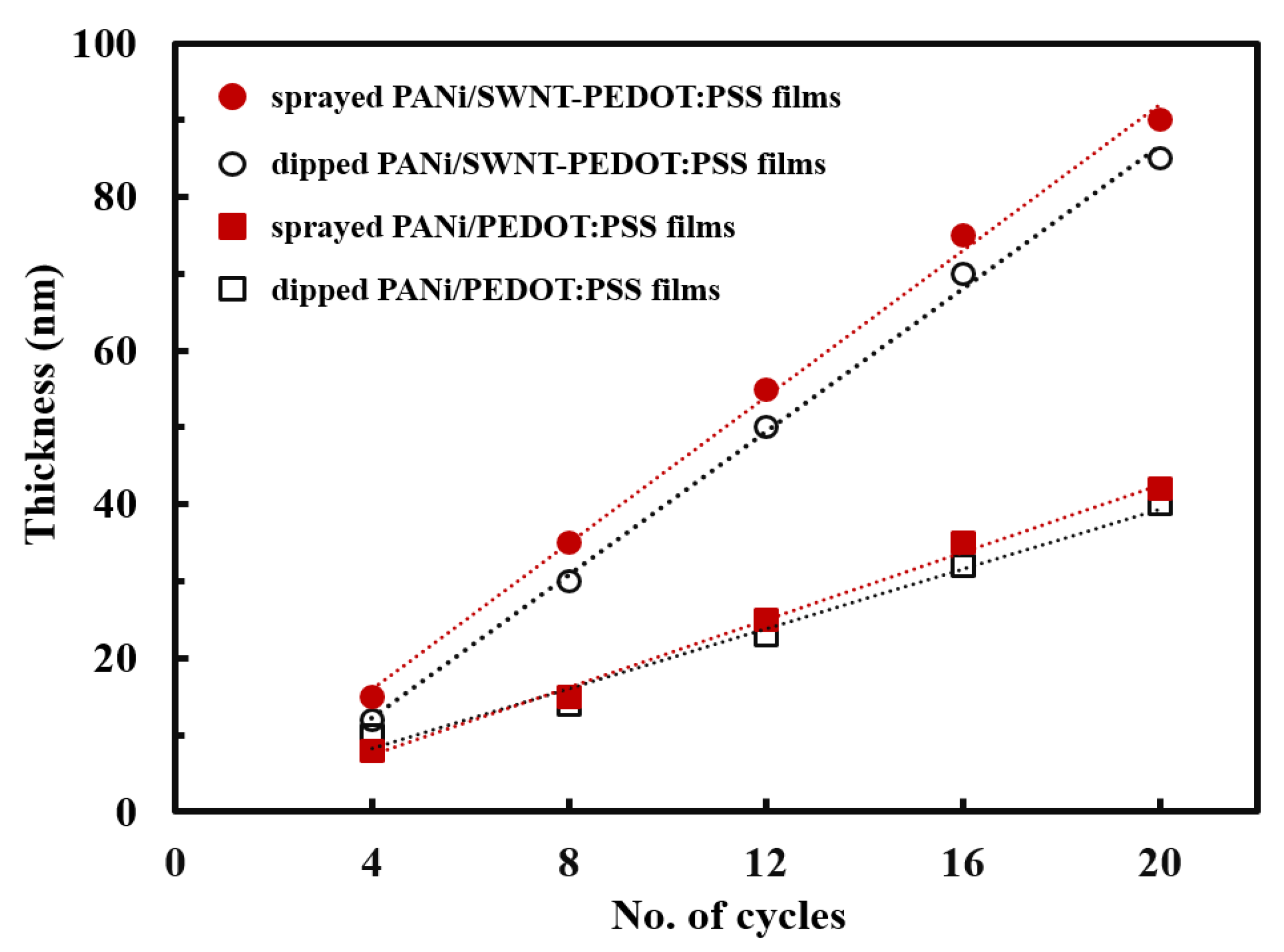

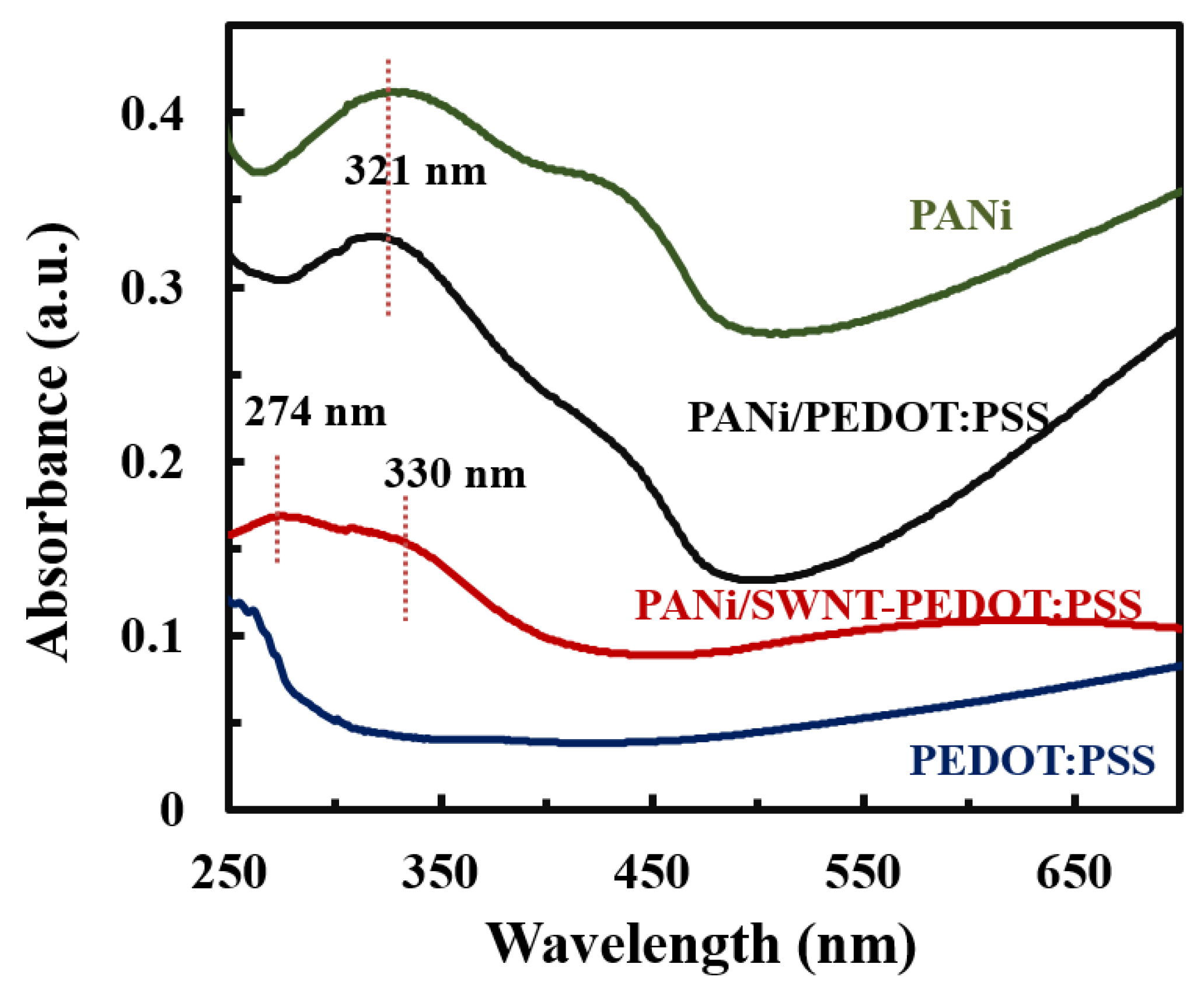

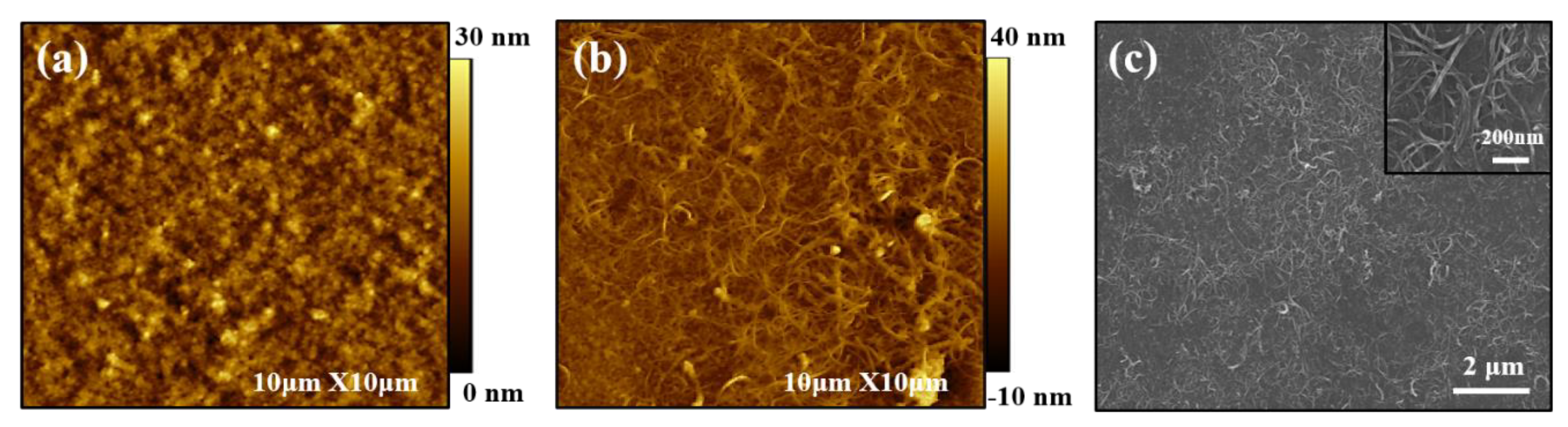

3.1. Growth Behavior

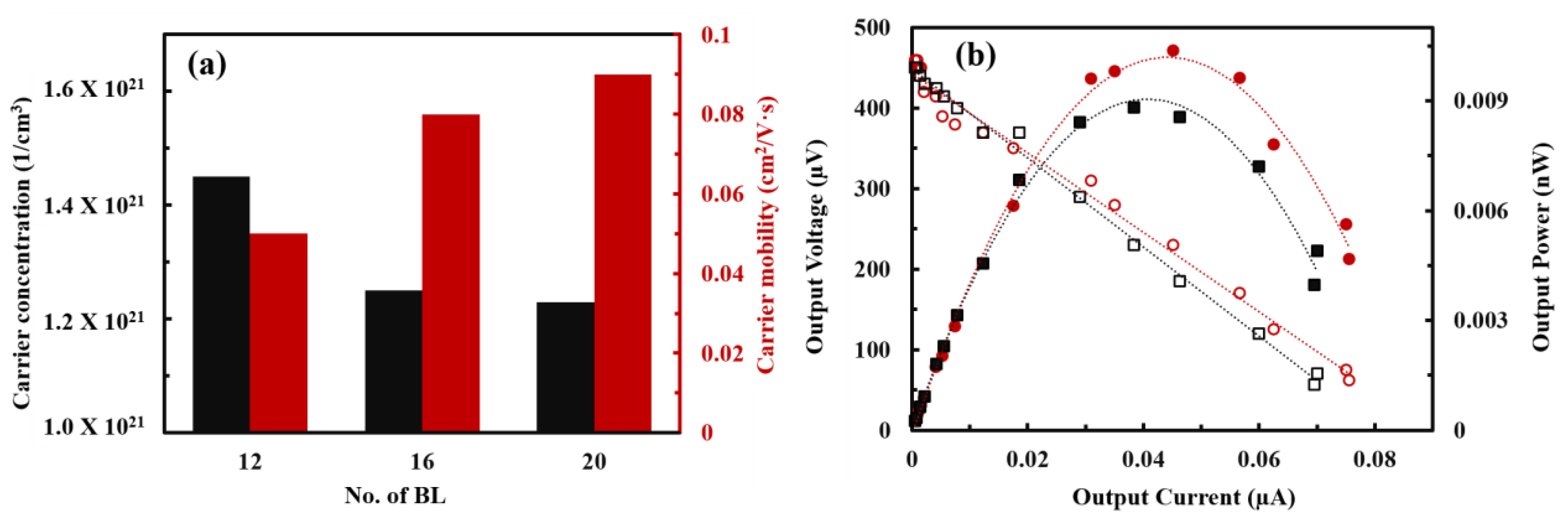

3.2. Thermoelectric Performances

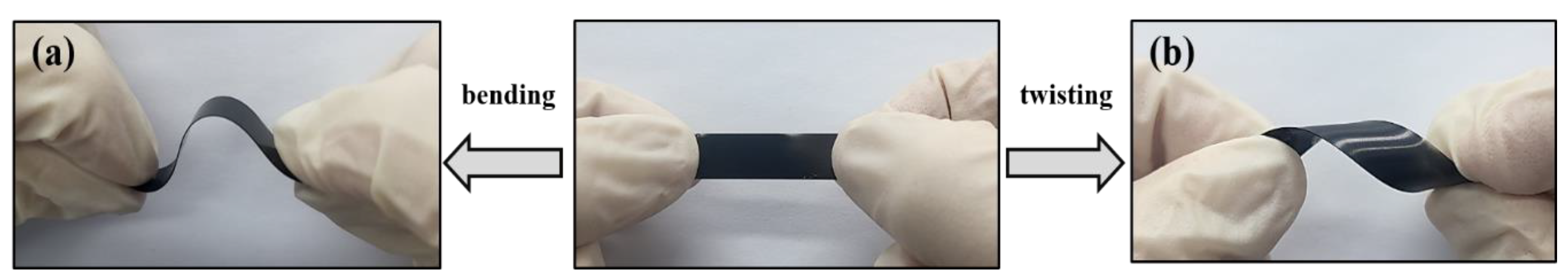

3.3. Multilayer Structure

3.4. Thermoelectric Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blackburn, J.L.; Ferguson, A.J.; Cho, C.; Grunlan, J.C. Carbon-nanotube-based thermoelectric materials and devices. Adv. Mater. 2018, 30, 1704386. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef]

- Choi, K.; Son, J.; Park, Y.T.; Cho, J.S.; Cho, C. Effect of the conformation changes of polyelectrolytes on organic thermoelectric performances. Macromol. Res. 2020, 28, 997–1002. [Google Scholar] [CrossRef]

- Emmett, R.K.; Robets, M.E. Recent developments in alternative aqueous redox flow batteries for grid-scale energy storage. J. Power Sources 2021, 506, 230087. [Google Scholar] [CrossRef]

- Jung, J.-W.; Im, H.-G.; Lee, D.; Yu, S.; Jang, J.-H.; Yoon, K.R.; Kim, Y.H.; Goodenough, J.B.; Jin, J.; Kim, I.-D. Conducting nanopaper: A carbon-free cathode platform for li–o2 batteries. ACS Energy Lett. 2017, 2, 673–680. [Google Scholar] [CrossRef]

- Im, H.-G.; Jang, J.; Jeon, Y.; Noh, J.; Jin, J.; Lee, J.-Y.; Bae, B.-S. Flexible transparent crystalline-ito/ag nanowire hybrid electrode with high stability for organic optoelectronics. ACS Appl. Mater. Interfaces 2020, 12, 56462–56469. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Liu, Z.; Mei, X. Overview of Human Walking Induced Energy Harvesting Technologies and Its Possibility for Walking Robotics. Energies 2020, 13, 86. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Pan, C.; Liu, Y.; Wang, Z. Hybrid cells for simultaneously harvesting multi-type energies for self-powered micro/nanosystems. Nano Energy 2012, 1, 259–272. [Google Scholar] [CrossRef]

- Cho, C.; Song, Y.; Hsu, J.-H.; Yu, C.; Stevens, D.L.; Grunlan, J.C. Organic thermoelectric thin films with large p-type and n-type power factor. J. Mater. Sci. 2020, 56, 4291–4304. [Google Scholar] [CrossRef]

- Cho, C.; Wallace, K.L.; Tzeng, P.; Hsu, J.-H.; Yu, C.; Grunlan, J.C. outstanding low temperature thermoelectric power factor from completely organic thin films enabled by multidimensional conjugated nanomaterials. Adv. Energy Mater. 2016, 6, 1502168. [Google Scholar] [CrossRef]

- Yu, C.; Kim, Y.S.; Kim, D.; Grunlan, J.C. Thermoelectric Behavior of Segregated-Network Polymer Nanocomposites. Nano Lett. 2008, 8, 4428–4432. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.; Stevens, B.; Hsu, J.-H.; Bureau, R.; Hagen, D.A.; Regev, O.; Yu, C.; Grunlan, J.C. Completely organic multilayer thin film with thermoelectric power factor rivaling inorganic tellurides. Adv. Mater. 2015, 27, 2996–3001. [Google Scholar] [CrossRef] [PubMed]

- Jia, P.-Z.; Xie, J.-P.; Chen, X.-K.; Zhang, Y.; Yu, X.; Zeng, Y.-J.; Xie, Z.-X.; Deng, Y.-X.; Zhou, W.-X. Recent progress of two-dimensional heterostructures for thermoelectric applications. J. Phys. Condens. Matter. 2022, 35, 073001. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.-X.; Cheng, Y.; Chen, K.-Q.; Xie, G.; Wang, T.; Zhang, G. Thermal Conductivity of Amorphous Materials. Adv. Funct. Mater. 2019, 30, 1903829. [Google Scholar] [CrossRef]

- Jia, P.-Z.; Xie, Z.-X.; Deng, Y.-X.; Zhang, Y.; Tang, L.-M.; Zhou, W.-X.; Chen, K.-Q. High thermoelectric performance induced by strong anharmonic effects in monolayer (PbX)2 (X = S, Se, Te). Appl. Phys. Lett. 2022, 121, 043901. [Google Scholar] [CrossRef]

- Wu, C.-W.; Ren, X.; Xie, G.; Zhou, W.-X.; Zhang, G.; Chen, K.-Q. Enhanced High-Temperature Thermoelectric Performance by Strain Engineering in BiOCl. Phys. Rev. Appl. 2022, 18, 014053. [Google Scholar] [CrossRef]

- Choi, M.; Novak, T.G.; Byen, J.; Lee, H.; Baek, J.; Hong, S.; Kim, K.; Song, J.; Shin, H.; Jeon, S. Significantly enhanced thermoelectric performance of graphene through atomic-scale defect engineering via mobile hot-wire chemical vapor deposition systems. ACS Appl. Mater. Interfaces 2021, 13, 24304–24313. [Google Scholar] [CrossRef]

- Culebras, M.; Choi, K.; Cho, C. Recent Progress in Flexible Organic Thermoelectrics. Micromachines 2018, 9, 638. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.; Im, H.-G.; Lim, D.; Bae, B.-S. Preparation of high-performance transparent glass-fiber reinforced composites based on refractive index-tunable epoxy-functionalized siloxane hybrid matrix. Compos. Sci. Technol. 2021, 201, 108527. [Google Scholar] [CrossRef]

- Kuk, S.K.; Jang, J.; Han, H.J.; Lee, E.; Oh, H.; Kim, H.Y.; Jang, J.; Lee, K.T.; Lee, H.; Jung, Y.S.; et al. Siloxane-encapsulated upconversion nanoparticle hybrid composite with highly stable photoluminescence against heat and moisture. ACS Appl. Mater. Interfaces 2019, 11, 15952–15959. [Google Scholar] [CrossRef]

- Jang, J.; Kim, Y.; Park, S.; Yoo, D.; Cho, H.; Jang, J.; Jeong, H.; Lee, H.; Yuk, J.; Park, C.; et al. Extremely stable luminescent crosslinked perovskite nanoparticles under harsh environments over 1.5 years. Adv. Mater. 2021, 33, 2005255. [Google Scholar] [CrossRef]

- Jang, J.; Yoon, D.-E.; Kang, S.-M.; Kim, Y.H.; Lee, I.; Lee, H.; Kim, Y.H.; Lee, D.C.; Bae, B.-S. Exceptionally stable quantum dot/siloxane hybrid encapsulation material for white light-emitting diodes with a wide color gamut. Nanoscale 2019, 11, 14887–14895. [Google Scholar] [CrossRef] [PubMed]

- Nandihalli, N.; Liu, C.-J.; Mori, T. Polymer based thermoelectric nanocomposite materials and devices: Fabrication and characteristics. Nano Energy 2020, 78, 105186. [Google Scholar] [CrossRef]

- Myint, M.T.Z.; Nishikawa, T.; Inoue, H.; Omoto, K.; Kyaw, A.K.K.; Hayashi, Y. Improved room-temperature thermoelectric characteristics in F4TCNQ-doped CNT yarn/P3HT composite by controlled doping. Org. Electron. 2021, 90, 106056. [Google Scholar] [CrossRef]

- Xu, S.; Hong, M.; Shi, X.-L.; Wang, Y.; Ge, L.; Bai, Y.; Wang, L.; Dargusch, M.; Zou, J.; Chen, Z.-G. High-performance PEDOT:PSS flexible thermoelectric materials and their devices by triple post-treatments. Chem. Mater. 2019, 31, 5238–5244. [Google Scholar] [CrossRef]

- Zhang, B.; Dugas, R.; Rousse, G.; Rozier, P.; Abakumov, A.M.; Tarascon, J.-M. Insertion compounds and composites made by ball milling for advanced sodium-ion batteries. Nat. Commun. 2016, 7, 10308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, C.-J.; Zhang, H.-L.; Zhang, Q. Recent Progress in Thermoelectric Materials Based on Conjugated Polymers. Polymers 2019, 11, 107. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.; Im, H.-G.; Jin, J.; Lee, J.; Lee, J.-Y.; Bae, B.-S. A flexible and robust transparent conducting electrode platform using an electroplated silver grid/surface-embedded silver nanowire hybrid structure. ACS Appl. Mater. Interfaces 2016, 8, 27035–27043. [Google Scholar] [CrossRef]

- Cho, C.; Wallace, K.L.; Hagen, D.A.; Stevens, B.; Regev, O.; Grunlan, J.C. Nanobrick wall multilayer thin films grown faster and stronger using electrophoretic deposition. Nanotechnology 2015, 26, 185703. [Google Scholar] [CrossRef]

- Li, C.; Guan, X.; Yue, S.; Wang, X.; Li, J.; Cheng, H.; Wang, S.; Kyaw, A.K.K.; Ouyang, J. Simultaneous enhancements in the Seebeck coefficient and conductivity of PEDOT:PSS by blending ferroelectric BaTiO3 nanoparticles. J. Mater. Chem. A 2021, 9, 16952–16960. [Google Scholar] [CrossRef]

- Kim, J.; Jang, J.; Yun, S.; Kim, H.D.; Byun, Y.Y.; Park, Y.T.; Song, J.I.; Cho, C. Synergistic flame retardant effects of carbon nanotube-based multilayer nanocoatings. Macromol. Mater. Eng. 2021, 306, 2100233. [Google Scholar] [CrossRef]

- Cho, C.; Song, Y.; Allen, R.; Wallace, K.L.; Grunlan, J.C. Stretchable electrically conductive and high gas barrier nanocomposites. J. Mater. Chem. C 2018, 6, 2095–2104. [Google Scholar] [CrossRef]

- Byun, Y.-Y.; Jang, J.; Culebras, M.; Bae, B.-S.; Cho, J.S.; Park, Y.T.; Cho, C. Conformation-dependent thermoelectric power factor of multilayer nanocomposites. Appl. Surf. Sci. 2022, 594, 153483. [Google Scholar] [CrossRef]

- Lee, T.; Enomoto, K.; Ohshiro, K.; Inoue, D.; Kikitsu, T.; Hyeon-Deuk, K.; Pu, Y.-J.; Kim, D. Controlling the dimension of the quantum resonance in CdTe quantum dot superlattices fabricated via layer-by-layer assembly. Nat. Commun. 2020, 11, 5471. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xu, Y.; Zhang, X.; Wu, H.; Shen, J.; Chen, R.; Xiong, Y.; Li, J.; Guo, S. Progress on the layer-by-layer assembly of multilayered polymer composites: Strategy, structural control and applications. Prog. Polym. Sci. 2019, 89, 76–107. [Google Scholar] [CrossRef]

- Sato, M.; Sano, M. van der Waals Layer-by-Layer Construction of a Carbon Nanotube 2D Network. Langmuir 2005, 21, 11490–11494. [Google Scholar] [CrossRef] [PubMed]

- Cortez, M.L.; De Matteis, N.; Ceolín, M.; Knoll, W.; Battaglini, F.; Azzaroni, O. Hydrophobic interactions leading to a complex interplay between bioelectrocatalytic properties and multilayer meso-organization in layer-by-layer assemblies. Phys. Chem. Chem. Phys. 2014, 16, 20844–20855. [Google Scholar] [CrossRef]

- Cho, C.; Son, J. Organic Thermoelectric Multilayers with High Stretchiness. Nanomaterials 2019, 10, 41. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Yang, L.; Wang, Q.; Fan, Y.; Shang, J.; Qiu, S.; Li, J.; Zhang, W.; Wu, X. Supramolecular self-assembly of layer-by-layer graphene film driven by the synergism of π–π and hydrogen bonding interaction. J. Photochem. Photobiol. A Chem. 2018, 355, 249–255. [Google Scholar] [CrossRef]

- Xiang, Y.; Lu, S.; Jiang, S.P. ChemInform Abstract: Layer-by-layer self-assembly in the development of electrochemical energy conversion and storage devices from fuel cells to supercapacitors. Chem. Soc. Rev. 2012, 41, 7291–7321. [Google Scholar] [CrossRef]

- Javey, A.; Nam, S.; Friedman, R.S.; Yan, H.; Lieber, C.M. Layer-by-layer assembly of nanowires for three-dimensional, multifunctional electronics. Nano Lett. 2007, 7, 773–777. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Wang, Y.; Podsiadlo, P.; Kotov, N.A. Biomedical applications of layer-by-layer assembly: From biomimetics to tissue engineering. Adv. Mater. 2006, 18, 906. [Google Scholar] [CrossRef] [Green Version]

- Majumder, M.; Rendall, C.; Li, M.; Behabtu, N.; Eukel, J.A.; Hauge, R.H.; Schmidt, H.K.; Pasquali, M. Insights into the physics of spray coating of SWNT films. Chem. Eng. Sci. 2010, 65, 2000–2008. [Google Scholar] [CrossRef]

- Snyder, G.J.; Snyder, A.H.; Wood, M.; Gurunathan, R.; Snyder, B.H.; Niu, C. Weighted mobility. Adv. Mater. 2020, 32, 2001537. [Google Scholar] [CrossRef] [PubMed]

- Izquierdo, A.; Ono, S.S.; Voegel, J.-C.; Schaaf, P.; Decher, G. Dipping versus Spraying: Exploring the Deposition Conditions for Speeding Up Layer-by-Layer Assembly. Langmuir 2005, 21, 7558–7567. [Google Scholar] [CrossRef] [PubMed]

- Kirkpatrick, S. Percolation and conduction. Rev. Mod. Phys. 1973, 45, 574. [Google Scholar] [CrossRef]

- Kulkarni, M.V.; Kale, B.B. Studies of conducting polyaniline (pani) wrapped-multiwalled carbon nanotubes (mwcnts) nanocomposite and its application for optical ph sensing. Sens. Actuators B 2013, 187, 407–412. [Google Scholar] [CrossRef]

- Tan, H.-X.; Xu, X.-C. Conductive properties and mechanism of various polymers doped with carbon nanotube/polyaniline hybrid nanoparticles. Compos. Sci. Technol. 2016, 128, 155–160. [Google Scholar] [CrossRef]

- Weathers, A.; Khan, Z.U.; Brooke, R.; Evans, D.; Pettes, M.T.; Andreasen, J.W.; Crispin, X.; Shi, L. Significant electronic thermal transport in the conducting polymer poly (3, 4-ethylenedioxythiophene). Adv. Mater. 2015, 27, 2101–2106. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Wang, X.; Li, D.; Coates, N.E.; Segalman, R.A.; Cahill, D.G. Thermal Conductivity and Elastic Constants of PEDOT:PSS with High Electrical Conductivity. Macromolecules 2015, 48, 585–591. [Google Scholar] [CrossRef]

- Collins, P.G.; Bradley, K.; Ishigami, M.; Zettl, A. Extreme Oxygen Sensitivity of Electronic Properties of Carbon Nanotubes. Science 2000, 287, 1801–1804. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.-L.; Dai, R.-X.; Xin, Y.; Sun, Y.-L.; Li, X.; Yu, Y.-X.; Xiang, L.; Xie, D.; Wang, S.-D.; Ren, T.-L. Efficient and Reversible Electron Doping of Semiconductor-Enriched Single-Walled Carbon Nanotubes by Using Decamethylcobaltocene. Sci. Rep. 2017, 7, 6751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Watts, P.C.P.; Mureau, N.; Tang, Z.; Miyajima, Y.; Carey, J.D.; Silva, S.R.P. The importance of oxygen-containing defects on carbon nanotubes for the detection of polar and non-polar vapours through hydrogen bond formation. Nanotechnology 2007, 18, 175701. [Google Scholar] [CrossRef]

- Lee, H.J.; Anoop, G.; Lee, H.J.; Kim, C.; Park, J.-W.; Choi, J.; Kim, H.; Kim, Y.-J.; Lee, E.; Lee, S.-G.; et al. Enhanced thermoelectric performance of PEDOT:PSS/PANI–CSA polymer multilayer structures. Energy Environ. Sci. 2016, 9, 2806–2811. [Google Scholar] [CrossRef]

- Fan, Z.; Li, P.; Du, D.; Ouyang, J. Significantly enhanced thermoelectric properties of PEDOT:PSS films through sequential post-treatments with common acids and bases. Adv. Energy Mater. 2017, 7, 1602116. [Google Scholar] [CrossRef]

- Badre, C.; Marquant, L.; Alsayed, A.M.; Hough, L.A. Highly conductive poly (3,4-ethylenedioxythiophene): Poly (styrenesulfonate) films using 1-ethyl-3-methylimidazolium tetracyanoborate ionic liquid. Adv. Funct. Mater. 2012, 22, 2723–2727. [Google Scholar] [CrossRef]

- Saxena, N.; Pretzl, B.; Lamprecht, X.; Bießmann, L.; Yang, D.; Li, N.; Bilko, C.; Bernstorff, S.; Müller-Buschbaum, P. Ionic liquids as post-treatment agents for simultaneous improvement of seebeck coefficient and electrical conductivity in PEDOT:PSS Films. ACS Appl. Mater. Interfaces 2019, 11, 8060–8071. [Google Scholar] [CrossRef]

- Farhat, T.R.; Hammond, P.T. Engineering ionic and electronic conductivity in polymer catalytic electrodes using the layer-by-layer technique. Chem. Mater. 2006, 18, 41–49. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, Q.; Wang, L.; Wang, Y.; Sun, J.; Zeng, H.; Jin, Z.; Huang, X.; Chen, L. The synergic regulation of conductivity and seebeck coefficient in pure polyaniline by chemically changing the ordered degree of molecular chains. J. Mater. Chem. A 2014, 2, 2634–2640. [Google Scholar] [CrossRef]

- Hewitt, C.A.; Montgomery, D.S.; Barbalace, R.L.; Carlson, R.D.; Carroll, D.L. Improved thermoelectric power output from multilayered polyethylenimine doped carbon nanotube based organic composites. J. Appl. Phys. 2014, 115, 184502. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Byun, Y.Y.; Lee, I.; Cho, W.; Kim, G.; Culebras, M.; Jang, J.; Cho, C. Organic Thermoelectric Nanocomposites Assembled via Spraying Layer-by-Layer Method. Nanomaterials 2023, 13, 866. https://doi.org/10.3390/nano13050866

Kim S, Byun YY, Lee I, Cho W, Kim G, Culebras M, Jang J, Cho C. Organic Thermoelectric Nanocomposites Assembled via Spraying Layer-by-Layer Method. Nanomaterials. 2023; 13(5):866. https://doi.org/10.3390/nano13050866

Chicago/Turabian StyleKim, Seojin, You Young Byun, InYoung Lee, Woohyeon Cho, Gyungho Kim, Mario Culebras, Junho Jang, and Chungyeon Cho. 2023. "Organic Thermoelectric Nanocomposites Assembled via Spraying Layer-by-Layer Method" Nanomaterials 13, no. 5: 866. https://doi.org/10.3390/nano13050866