Densification of Two Forms of Nanostructured TATB under Uniaxial Die Pressures: A USAXS–SAXS Study

Abstract

:1. Introduction

2. Materials and Methods

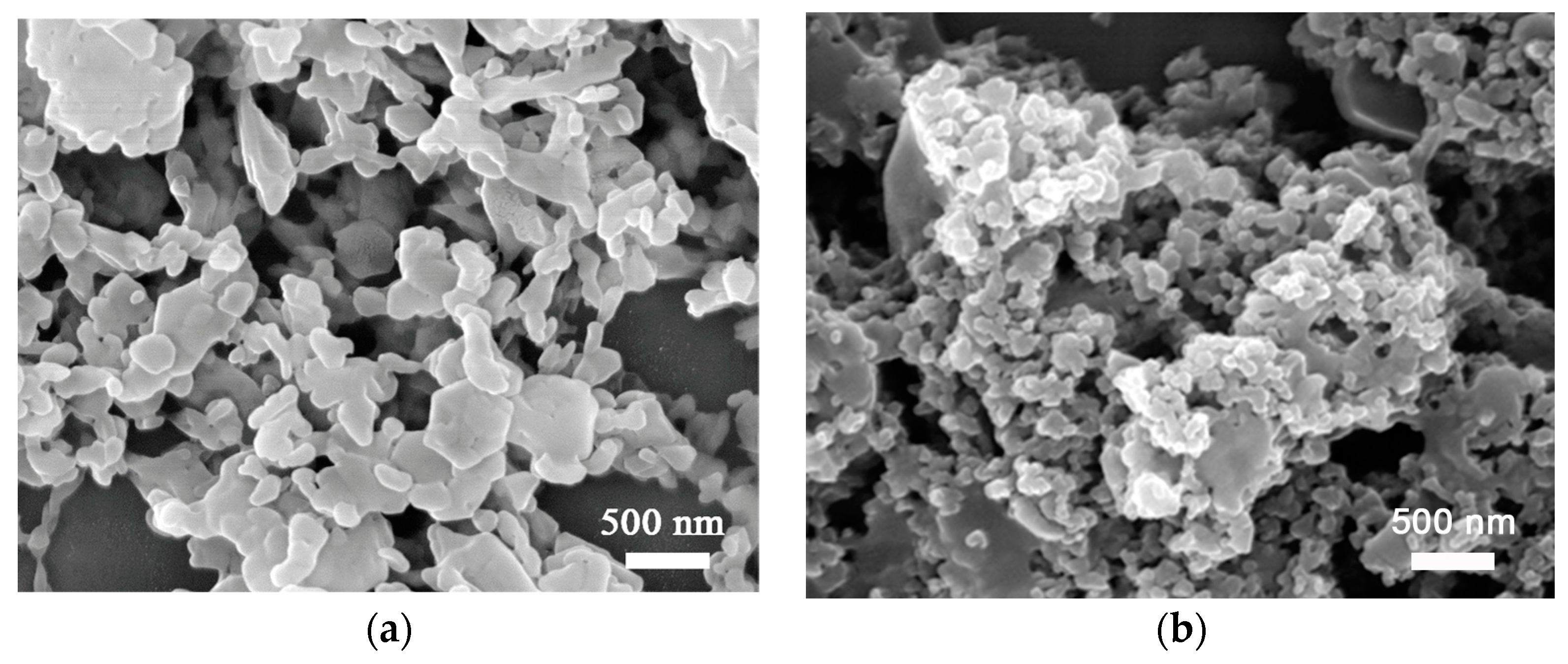

2.1. Materials

2.2. Characterization

3. Results

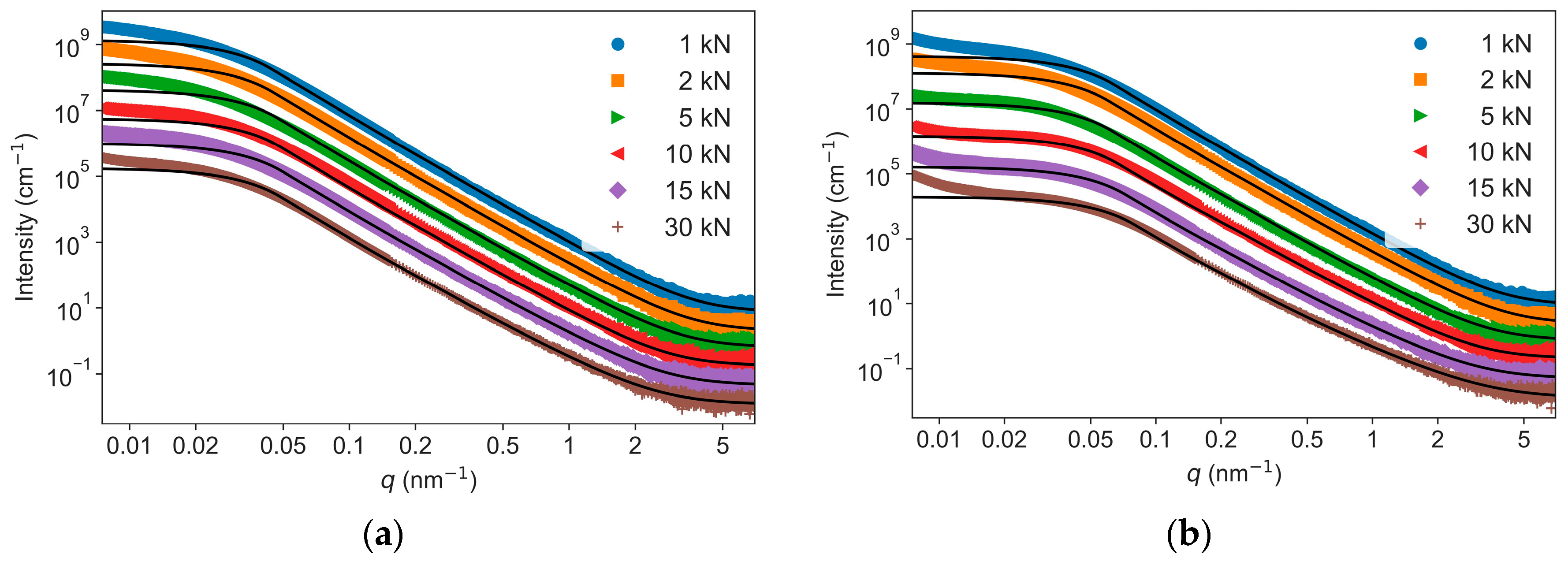

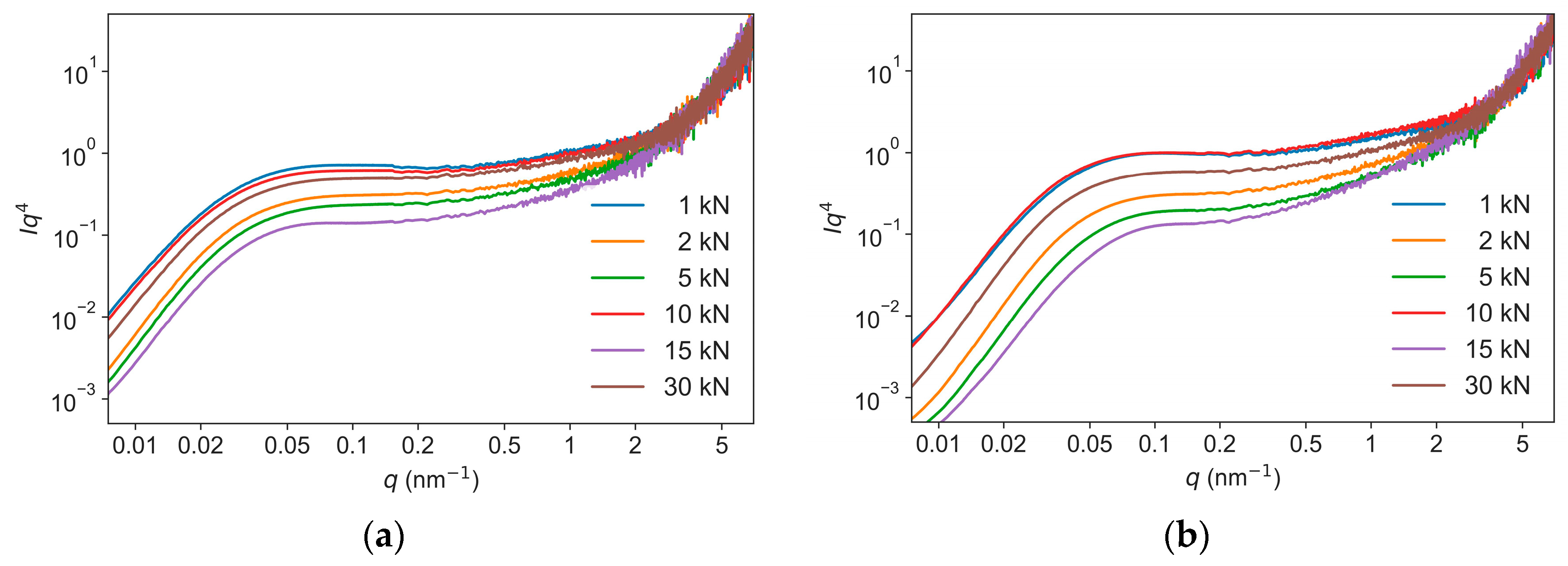

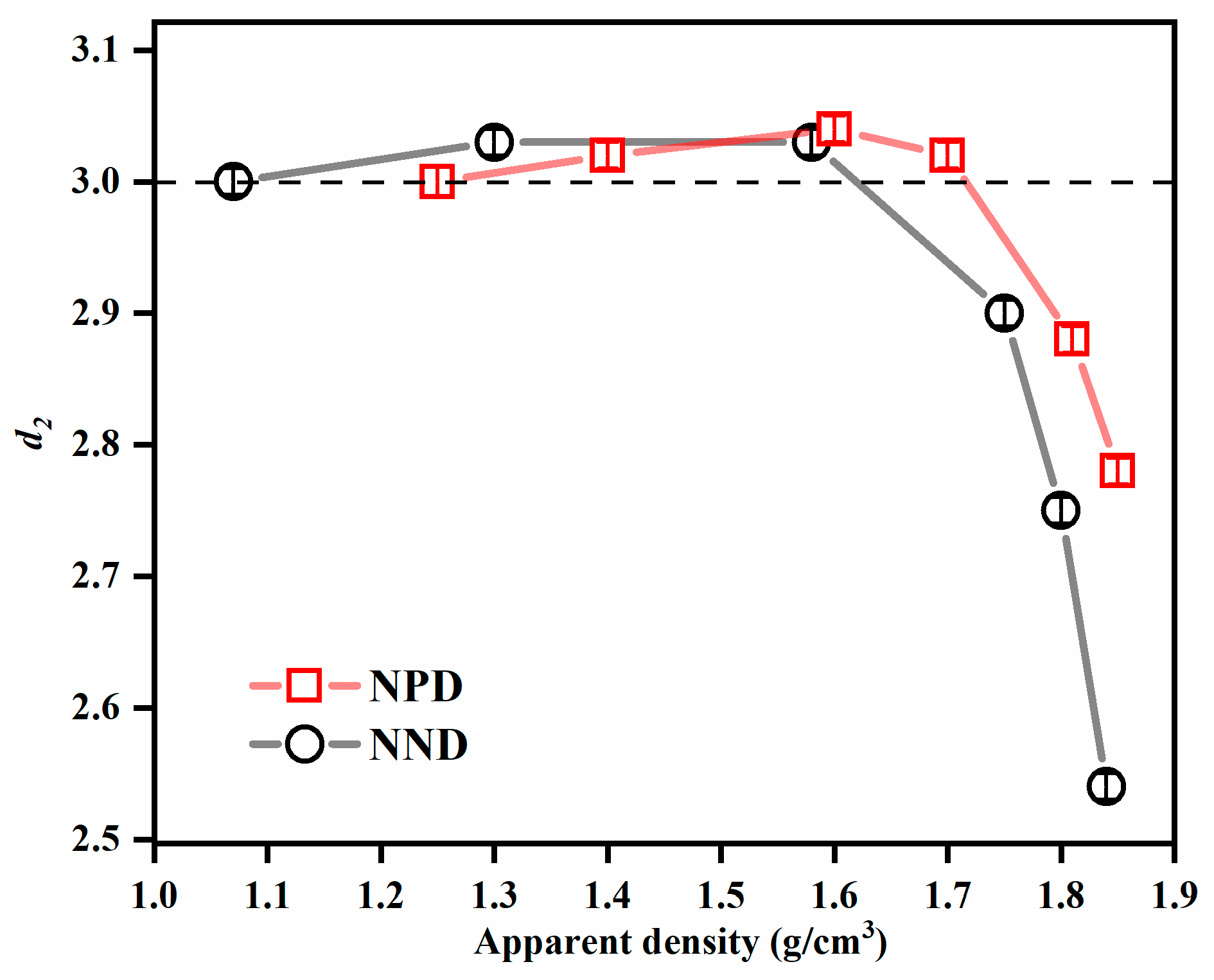

3.1. Inter- and Intra-Granular Voids

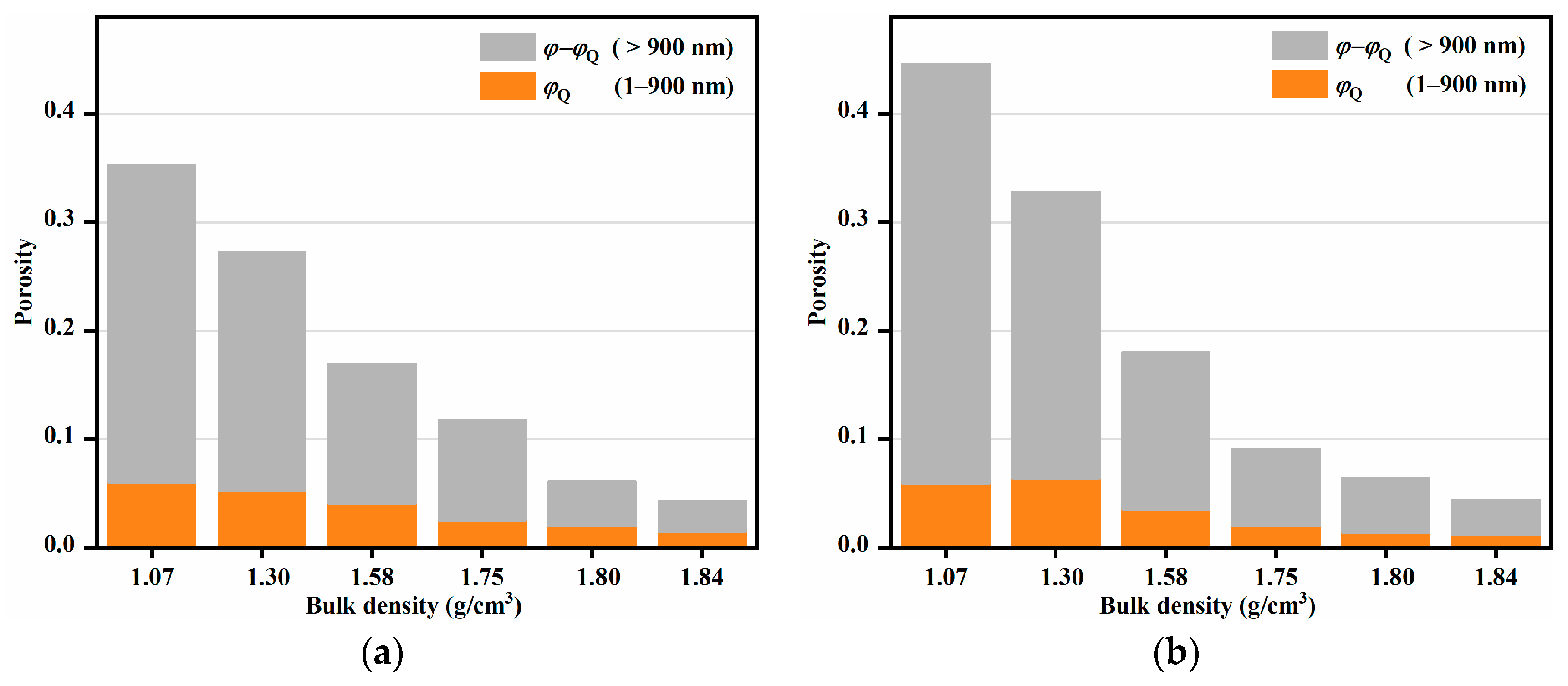

3.2. Porosity and Interfacial Area

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teipel, U. Energetic Materials: Particle Processing and Characterization; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- Mang, J.T.; Skidmore, C.B.; Hjelm, R.P.; Howe, P.M. Application of small-angle neutron scattering to the study of porosity in energetic materials. J. Mater. Res. 2000, 15, 1199–1208. [Google Scholar] [CrossRef]

- Xing, J.; Wang, W.; Huang, S.; Du, M.; Huang, B.; Liu, Y.; He, S.; Yao, T.; Li, S.; Liu, Y. Effects of grain refinement and thermal aging on atomic scale local structures of ultra-fine explosives by X-ray total scattering. Materials 2022, 15, 6835. [Google Scholar] [CrossRef]

- Luscher, D.J.; Yeager, J.D.; Clausen, B.; Vogel, S.C.; Higginbotham Duque, A.L.; Brown, D.W. Using neutron diffraction to investigate texture evolution during consolidation of deuterated triaminotrinitrobenzene (d-TATB) explosive powder. Crystals 2017, 7, 138. [Google Scholar] [CrossRef] [Green Version]

- Bai, L.; Li, X.; Li, H.; Sun, G.; Liu, D.; Su, Z.; Peng, M.; Zhu, Z.; Huang, C.; Gong, F.; et al. A review of small angle scattering, neutron reflection, and neutron diffraction techniques for microstructural characterization of polymer-bonded explosives. Energ. Mater. Front. 2023, in press. [Google Scholar] [CrossRef]

- Peterson, P.; Mang, J.; Asay, B. Quantitative analysis of damage in an octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazonic-based composite explosive subjected to a linear thermal gradient. J. Chem. Phys. 2005, 97, 093507. [Google Scholar] [CrossRef]

- Willey, T.M.; Lauderbach, L.; Gagliardi, F.; Van Buuren, T.; Glascoe, E.A.; Tringe, J.W.; Lee, J.R.I.; Springer, H.K.; Ilavsky, J. Mesoscale evolution of voids and microstructural changes in HMX based explosives during heating through the β-δ phase transition. J. Appl. Phys. 2015, 118, 055901. [Google Scholar] [CrossRef]

- Mang, J.T.; Hjelm, R.P. Small-angle neutron scattering and contrast variation measurement of the interfacial surface area in PBX 9501 as a function of pressing conditions. Propellants Explos. Pyrotech. 2011, 36, 439–445. [Google Scholar] [CrossRef]

- Tian, Q.; Yan, G.; Bai, L.; Liu, J.; Chen, K.; Lin, C.; Chen, H.; Duan, X.; Liu, Y.; Li, J. Progress in the applied research of small-angle scattering technique in polymer bonded explosives. Chin. J. Energ. Mater. 2019, 27, 434–444. [Google Scholar]

- Willey, T.M.; van Buuren, T.; Lee, J.; Overturf, G.E.; Kinney, J.H.; Handly, J.; Weeks, B.L.; Ilavsky, J. Changes in pore size distribution upon thermal cycling of TATB-based explosives measured by ultra-small angle X-ray scattering. Propellants Explos. Pyrotech. 2006, 31, 466–471. [Google Scholar] [CrossRef]

- Willey, T.M.; Hoffman, D.M.; van Buuren, T.; Lauderbach, L.; Gee, R.H.; Maiti, A.; Overturf, G.E.; Fried, L.E.; Ilavsky, J. The micro-structure of TATB-based explosive formulations during temperature cycling using ultra-small-angle X-ray scattering. Propellants Explos. Pyrotech. 2009, 34, 406–414. [Google Scholar] [CrossRef]

- Perry, W.L.; Clements, B.; Ma, X.; Mang, J.T. Relating microstructure temperature, and chemistry to explosive ignition and shock sensitivity. Combust. Flame 2018, 190, 171–176. [Google Scholar] [CrossRef]

- Stoltz, C.A.; Mason, B.P.; Hooper, J. Neutron scattering study of internal void structure in RDX. J. Appl. Phys. 2010, 107, 103527. [Google Scholar] [CrossRef]

- Song, P.; Tu, X.; Bai, L.; Sun, G.; Tian, Q.; Gong, J.; Zeng, G.; Chen, L.; Qiu, L. Contrast variation small angle neutron scattering investigation of micro- and nano-sized TATB. Materials 2019, 12, 2606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bai, L.; Tian, Q.; Tu, X.; Yan, G.; Sun, G.; Gong, J.; He, G.; Chen, L.; Huang, S.; Li, X. SANS investigation on the effect of cold-pressed forming pressure on the microstructure of HMX-based PBX. Chin. J. Energ. Mater. 2019, 27, 853–860. [Google Scholar]

- Wang, H.; Xu, J.; Sun, S.; Liu, Y.; Zhang, H. Characterization of crystal microstructure based on small angle X-ray scattering (SAXS) technique. Molecules 2020, 25, 443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xing, J.; Wang, W.; Dong, J.; Yao, T.; Miao, R.; Di, M.; Wang, Z. Characterization of the internal pores of LLM-105 with different particle sizes using contrast variation small angle X-ray scattering. Propellants Explos. Pyrotech. 2022, 47, e202100199. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, B.; Zeng, G.; Luo, S.; Dong, H.; Rong, L.; Dong, B. Experimental investigation of insensitive explosive C6H6N6O6 by small angle X-ray scattering technique. Acta Phys. Sin. 2005, 54, 3273–3277. [Google Scholar]

- Liu, Y.; Fan, J.; Xue, Z.; Lu, Y.; Zhao, J.; Hui, W. Crystal structure and noncovalent interactions of heterocyclic energetic molecules. Molecules 2022, 27, 4969. [Google Scholar] [CrossRef]

- Pitt, K.; Sinka, C. Chapter 16 Tabletting. In Handbook of Powder Technology; Salman, A.D., Hounslow, M.J., Seville, J.P.K., Eds.; Elsevier Science B.V.: Hollywood, LA, USA, 2007; pp. 735–778. [Google Scholar]

- Olinger, B. Compacting Plastic-Bonded Explosive Molding Powders to Dense Solids; Technical Report LA-14173; Los Alamos National Laboratory: Santa Fe, NM, USA, 2005.

- Mang, J.T.; Hjelm, R.P. Fractal networks of inter-granular voids in pressed TATB. Propellants Explos. Pyrotech. 2013, 38, 831–840. [Google Scholar] [CrossRef]

- Mang, J.T.; Hjelm, R.P. Preferred void orientation in uniaxially pressed PBX 9502. Propellants Explos. Pyrotech. 2020, 45, 1–12. [Google Scholar] [CrossRef]

- Hoffman, D.M.; Willey, T.M.; Mitchell, A.R.; Depiero, S.C. Comparison of new and legacy TATBs. J. Energ. Mater. 2008, 26, 139–162. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Wu, L.; Liu, Y.; Chen, W. In situ observation of void evolution in 1,3,5-tri-amino-2,4,6-trinitrobenzene under compression by synchrotron radiation X-ray nano-computed tomography. J. Synchrotron. Radiat. 2020, 27, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.; Zhang, W.; Lan, L.; Tian, Y. Experimental study and DEM simulation of micro-macro behavior of TATB granules during compaction using X-ray tomography. Propellants Explos. Pyrotech. 2015, 40, 688–698. [Google Scholar] [CrossRef]

- Yeager, J.D.; Kuettner, L.A.; Duque, A.L.; Hill, L.G.; Patterson, B.M. Microcomputed X-ray tomographic imaging and image processing for microstructural characterization of explosives. Materials 2020, 13, 4517. [Google Scholar] [CrossRef]

- Willey, T.M.; Lauderbach, L.; Gagliardi, F.; Cunningham, B.; Lorenz, K.T.; Lee, J.I.; Van Buuren, T.; Call, R.; Landt, L.; Overturf, G. Comprehensive characterization of voids and microstructure in TATB-based explosives from 10 nm to 1 cm: Effects of temperature cycling and compressive creep. In Proceedings of the Fourteenth International Detonation Symposium, Coeur d’Alene, ID, USA, 11–16 April 2010. [Google Scholar]

- Armstrong, C.L.; Mang, J.T. Thermally-driven changes to porosity in TATB-based high explosives. Propellants Explos. Pyrotech. 2021, 46, 1304–1312. [Google Scholar] [CrossRef]

- Gong, Z.; Tu, X.; Zeng, G.; Bai, L.; Cao, K. Aging mechanism of nano TATB explosive during storage. Chin. J. Energ. Mater. 2021, 29, 234–240. [Google Scholar]

- Yang, G.; Nie, F.; Huang, H.; Zhao, L.; Pang, W. Preparation and characterization of nano-TATB explosive. Propellants Explos. Pyrotech. 2006, 31, 390–394. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, L.; Zeng, G. The preparation of submicron TATB explosive by high-energy ball milling method. Guangzhou Chem. Indus. 2014, 42, 39–40. [Google Scholar]

- Breßler, I.; Kohlbrecher, J.; Thünemann, A.F. SASfit: A tool for small-angle scattering data analysis using a library of analytical expressions. J. Appl. Crystallogr. 2015, 48, 1587–1598. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hammouda, B. A new Guinier-Porod model. J. Appl. Crystallogr. 2010, 43, 716–719. [Google Scholar] [CrossRef]

- Glatter, O.; Kratky, O. Small Angle X-ray Scattering; Academic Press: London, UK, 1982. [Google Scholar]

- Mulford, R.N.; Romero, J.A. Sensitivity of the TATB-based explosive PBX-9502 after thermal expansion. AIP Conf. Proc. 1998, 429, 723–726. [Google Scholar]

- Burch, A.C.; Herman, M.J.; Woznick, C.S.; Nguyen, T.-A.D.; Scott, B.L.; Yeager, J.D. High-fidelity mock development for the insensitive high explosive TATB. Crystals 2022, 12, 192. [Google Scholar] [CrossRef]

- Yan, G.; Fan, Z.; Huang, S.; Liu, J.; Wang, Y.; Tian, Q.; Bai, L.; Gong, J.; Sun, G.; Wang, X. Phase retransformation and void evolution of previously heated HMX-based plastic bonded explosive in wet air. J. Phys. Chem. C 2017, 121, 20426–20432. [Google Scholar] [CrossRef]

- Chavez Panduro, E.A.; Beuvier, T.; Fernández Martínez, M.; Hassani, L.; Calvignac, B.; Boury, F.; Gibaud, A. Small-angle X-ray scattering analysis of porous powders of CaCO3. J. Appl. Crystallogr. 2012, 45, 881–889. [Google Scholar] [CrossRef]

| Pressure (kN) | Rg1 (nm) | Rg2 (nm) | d1 (Fixed) | d2 |

|---|---|---|---|---|

| 1 | 55.8 ± 0.1 | 7.7 ± 0.1 | 4.00 | 3.00 ± 0.01 |

| 2 | 55.1 ± 0.1 | 7.7 ± 0.1 | 4.00 | 3.00 ± 0.01 |

| 5 | 52.7 ± 0.1 | 7.7 ± 0.1 | 4.00 | 3.00 ± 0.01 |

| 10 | 50.1 ± 0.1 | 8.2 ± 0.1 | 4.00 | 3.00 ± 0.01 |

| 15 | 49.8 ± 0.1 | 8.0 ± 0.1 | 4.00 | 2.90 ± 0.01 |

| 30 | 50.0 ± 0.1 | 7.8 ± 0.1 | 4.00 | 2.80 ± 0.01 |

| Pressure (kN) | Rg1 (nm) | Rg2 (nm) | d1 (Fixed) | d2 |

|---|---|---|---|---|

| 1 | 38.7 ± 0.1 | 7.7 ± 0.1 | 4.00 | 3.00 ± 0.02 |

| 2 | 39.3 ± 0.1 | 7.1 ± 0.1 | 4.00 | 3.03 ± 0.01 |

| 5 | 38.9 ± 0.1 | 8.0 ± 0.1 | 4.00 | 3.03 ± 0.01 |

| 10 | 35.8 ± 0.1 | 8.1 ± 0.1 | 4.00 | 2.90 ± 0.01 |

| 15 | 33.1 ± 0.1 | 8.1 ± 0.1 | 4.00 | 2.75 ± 0.01 |

| 30 | 30.2 ± 0.1 | 8.0 ± 0.1 | 4.00 | 2.54 ± 0.01 |

| Pressure (kN) | dbulk (g·cm−3) | φ | ||

|---|---|---|---|---|

| NPD | NND | NPD | NND | |

| 1 | 1.25 | 1.07 | 0.35 | 0.45 |

| 2 | 1.40 | 1.30 | 0.27 | 0.33 |

| 5 | 1.60 | 1.58 | 0.17 | 0.18 |

| 10 | 1.70 | 1.75 | 0.12 | 0.09 |

| 15 | 1.81 | 1.80 | 0.06 | 0.07 |

| 30 | 1.85 | 1.84 | 0.04 | 0.05 |

| Pressure (kN) | SPorod (cm2·g−1) | SBET (cm2·g−1) | ||

|---|---|---|---|---|

| NPD | NND | NPD | NND | |

| 1 | 3.0 | 4.1 | 9.3 | 15.8 |

| 2 | 2.6 | 4.2 | 8.7 | 14.3 |

| 5 | 2.1 | 2.5 | 7.8 | 8.2 |

| 10 | 1.3 | 1.3 | 5.8 | 0.9 |

| 15 | 1.0 | 0.8 | 3.3 | 1.0 |

| 30 | 0.6 | 0.6 | 2.9 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Shi, J.; Henderson, M.J.; Li, X.; Tian, F.; Duan, X.; Tian, Q.; Almásy, L. Densification of Two Forms of Nanostructured TATB under Uniaxial Die Pressures: A USAXS–SAXS Study. Nanomaterials 2023, 13, 869. https://doi.org/10.3390/nano13050869

Zhou Y, Shi J, Henderson MJ, Li X, Tian F, Duan X, Tian Q, Almásy L. Densification of Two Forms of Nanostructured TATB under Uniaxial Die Pressures: A USAXS–SAXS Study. Nanomaterials. 2023; 13(5):869. https://doi.org/10.3390/nano13050869

Chicago/Turabian StyleZhou, Yan, Jing Shi, Mark Julian Henderson, Xiuhong Li, Feng Tian, Xiaohui Duan, Qiang Tian, and László Almásy. 2023. "Densification of Two Forms of Nanostructured TATB under Uniaxial Die Pressures: A USAXS–SAXS Study" Nanomaterials 13, no. 5: 869. https://doi.org/10.3390/nano13050869