Sustainable Microfabrication Enhancement of Graphene Nanoplatelet-Reinforced Biomedical Alumina Ceramic Matrix Nanocomposites

Abstract

1. Introduction

2. Experimental Procedure

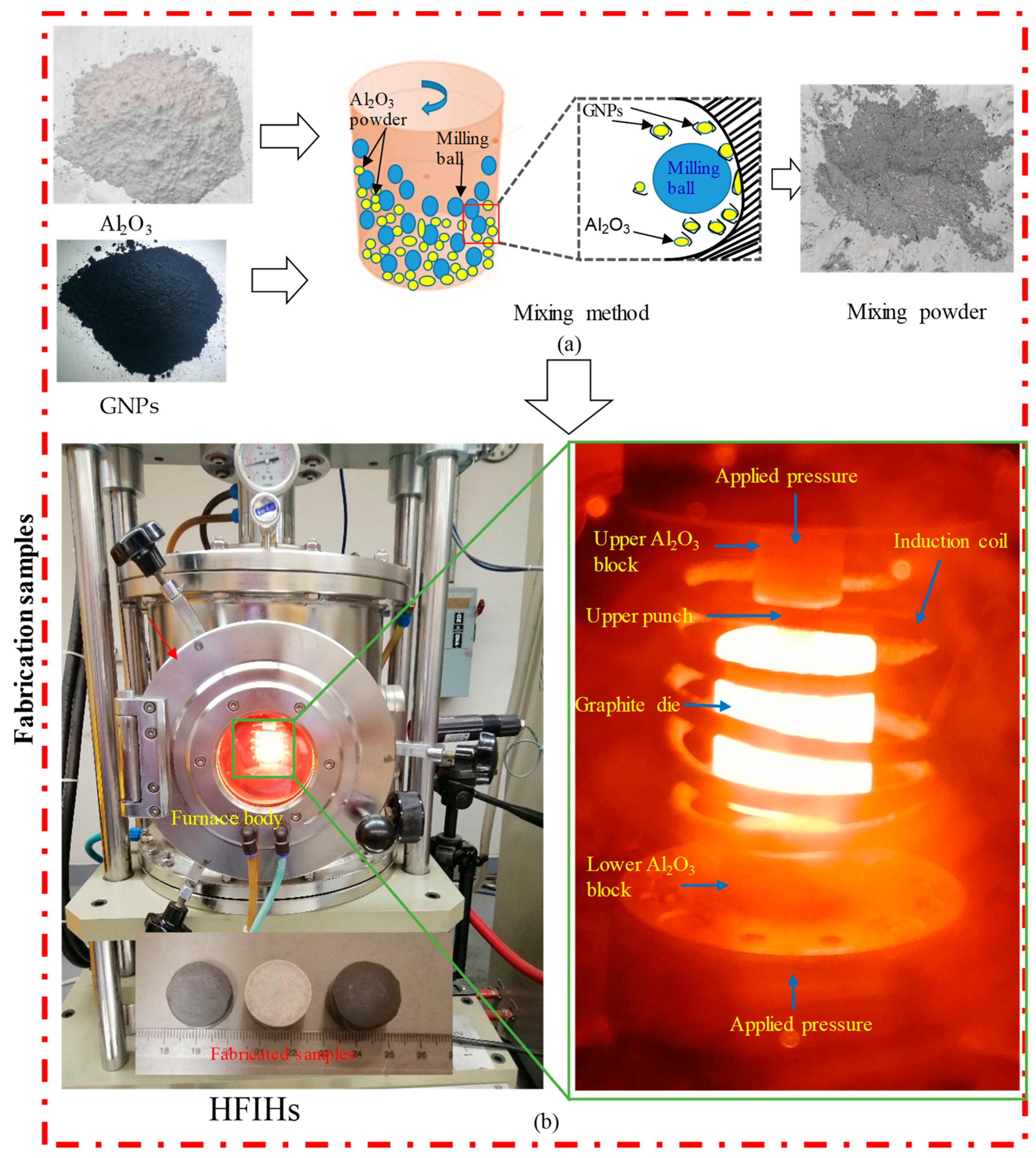

2.1. Fabrication of Nanocomposites

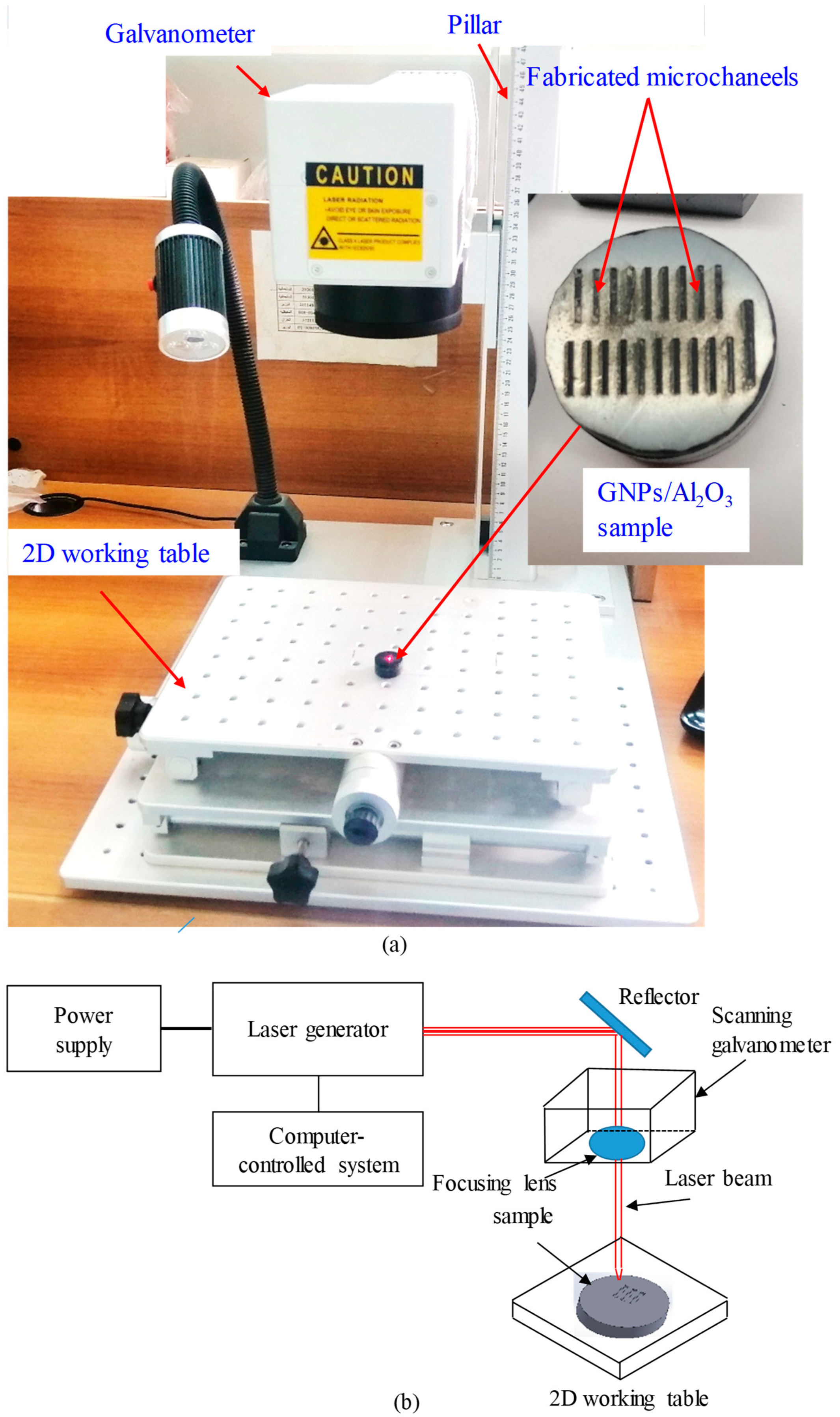

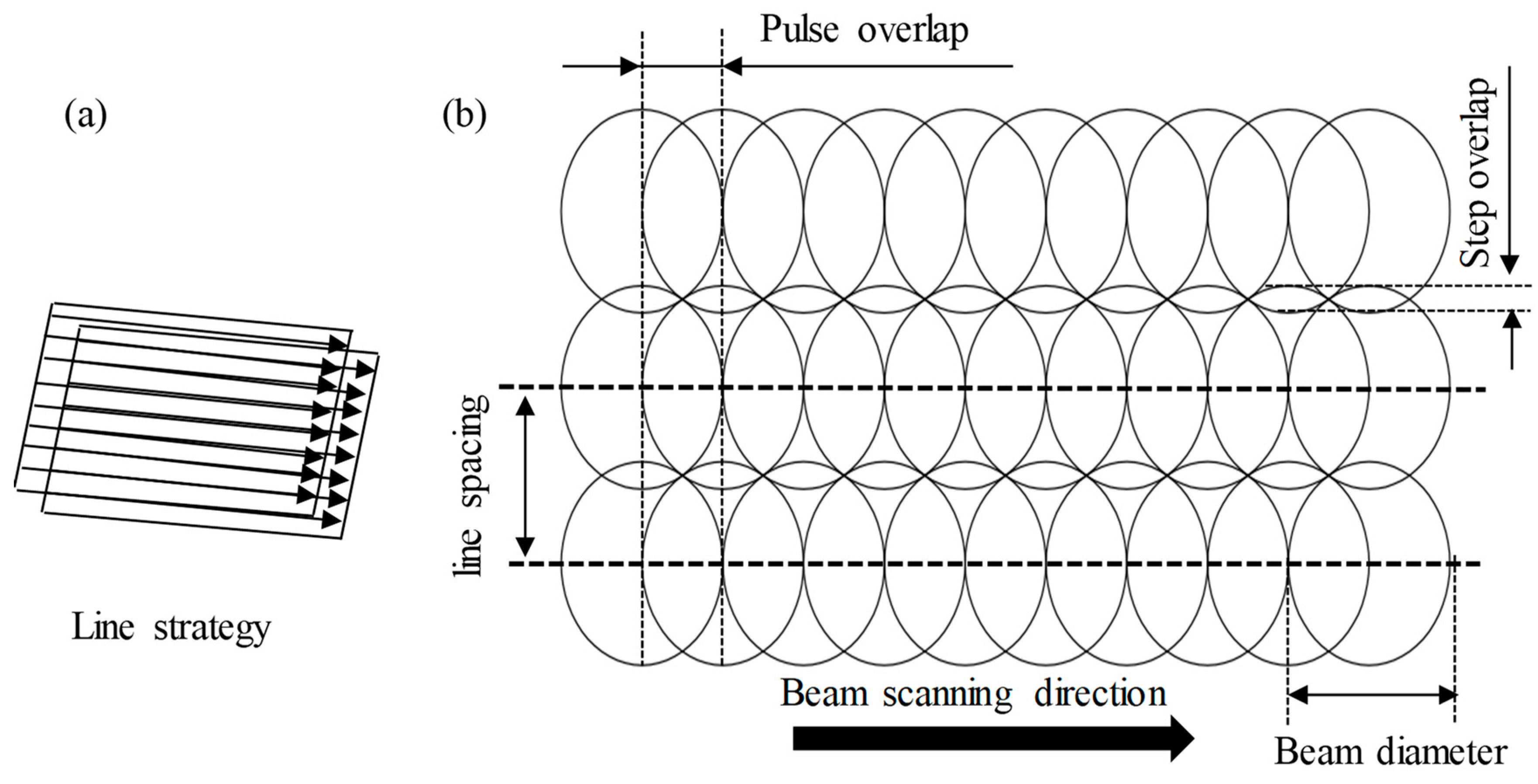

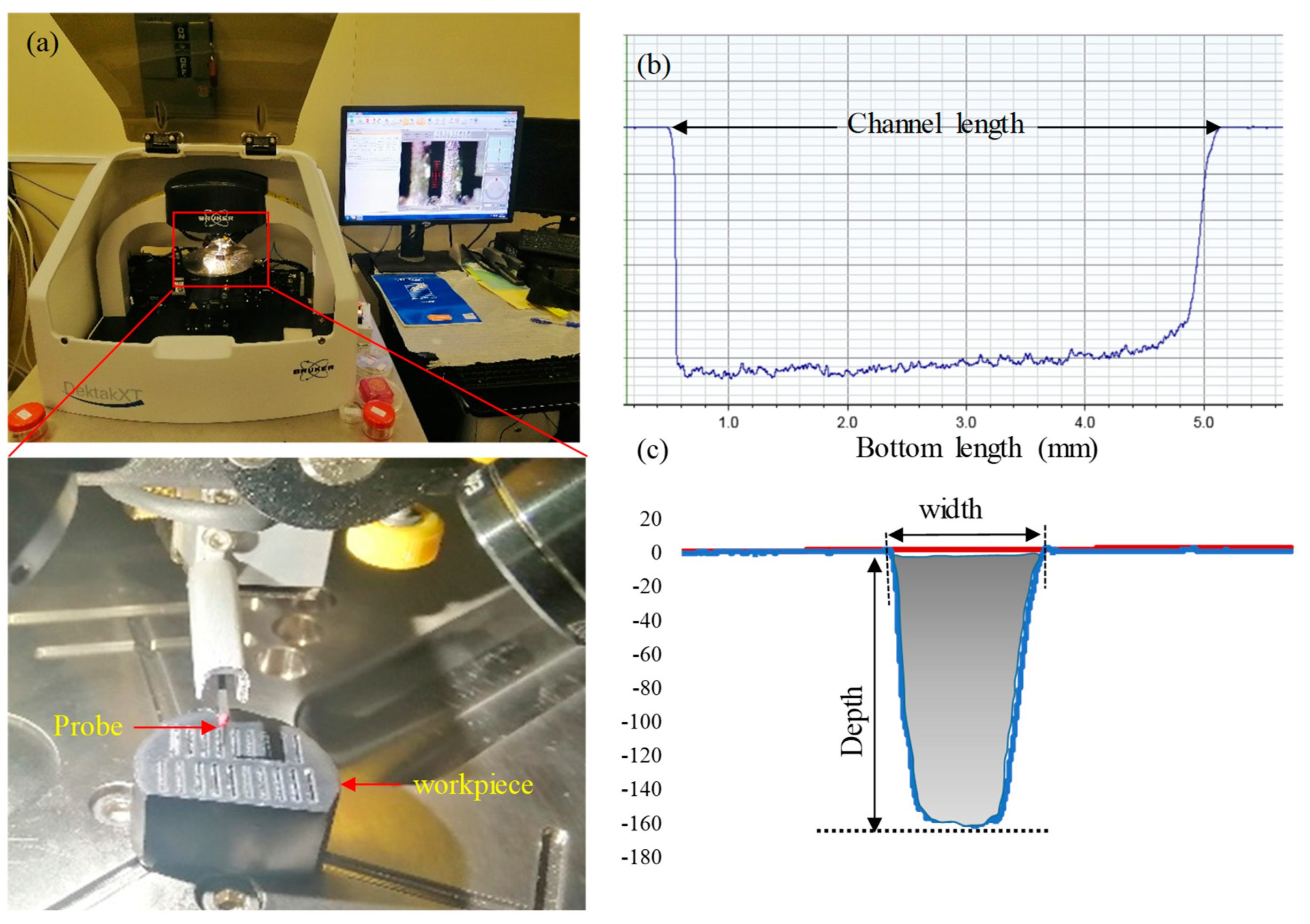

2.2. Machining and Measurements Setups

3. Results and Discussions

3.1. Characterization of the Fabricated GNP/Al2O3-Based Nanocomposites

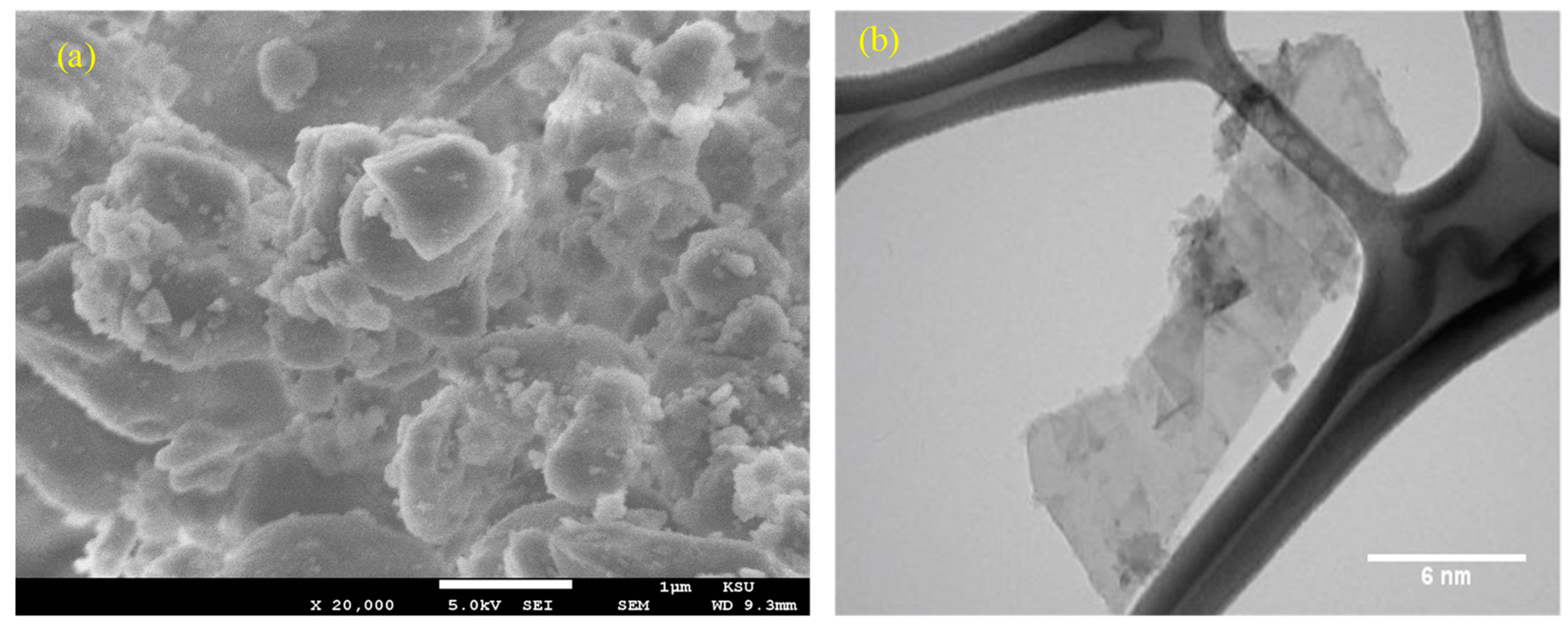

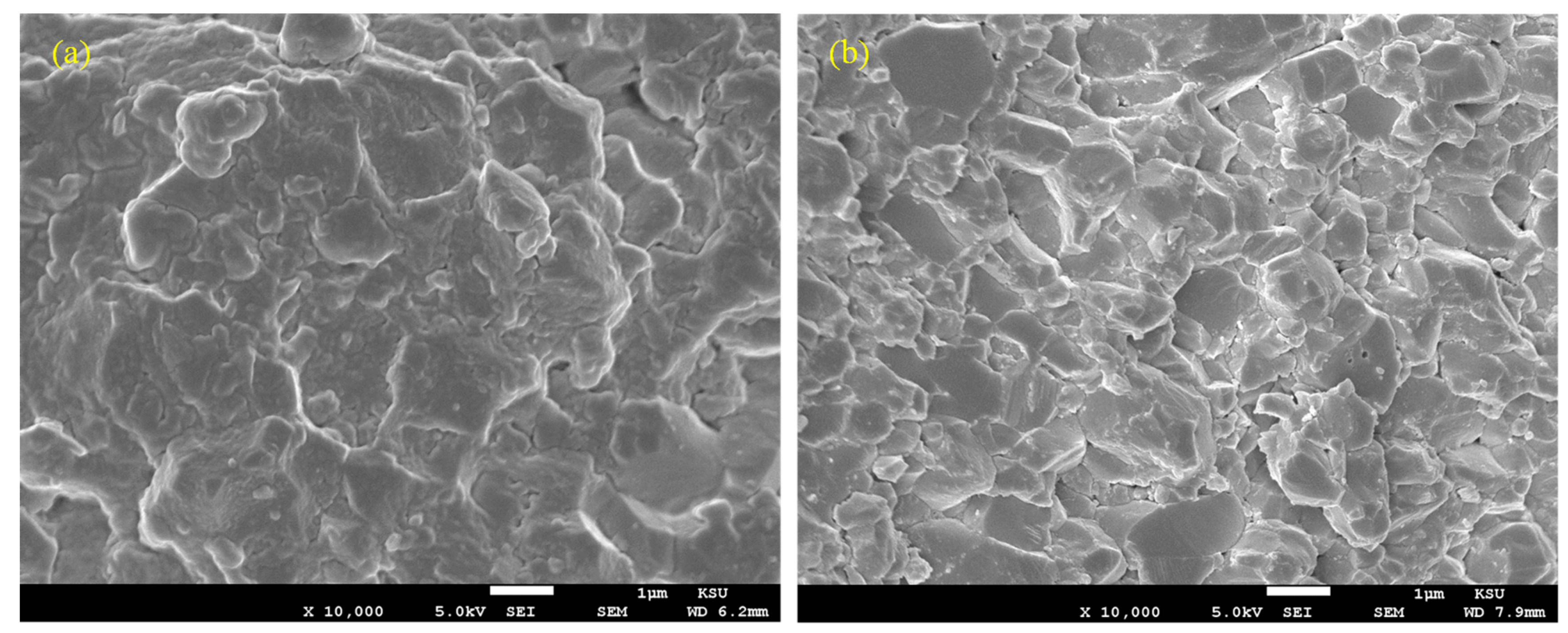

3.1.1. Microstructure Evaluation

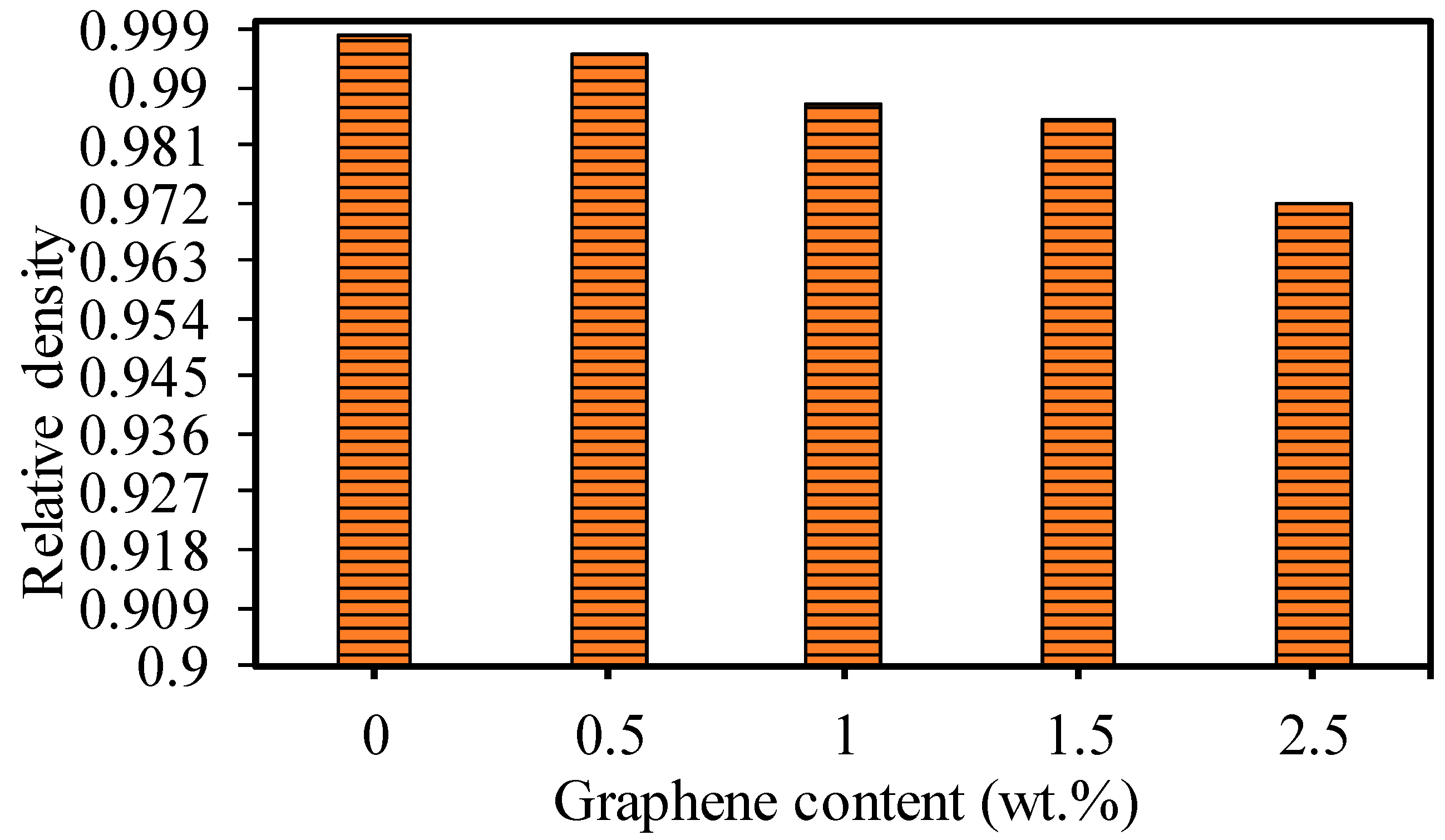

3.1.2. Density Analysis

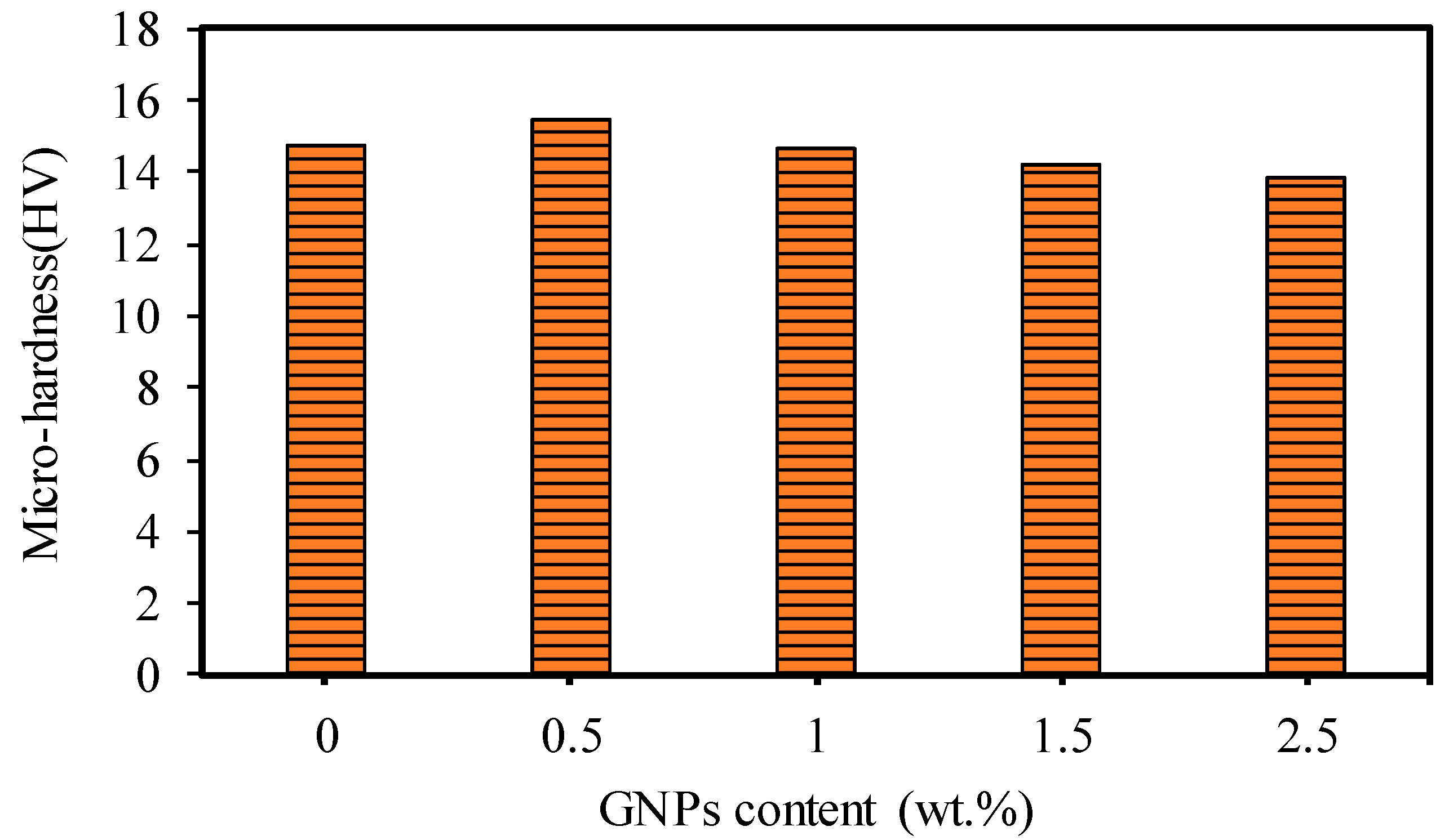

3.1.3. Hardness

3.2. Micromachining Results and Discussion

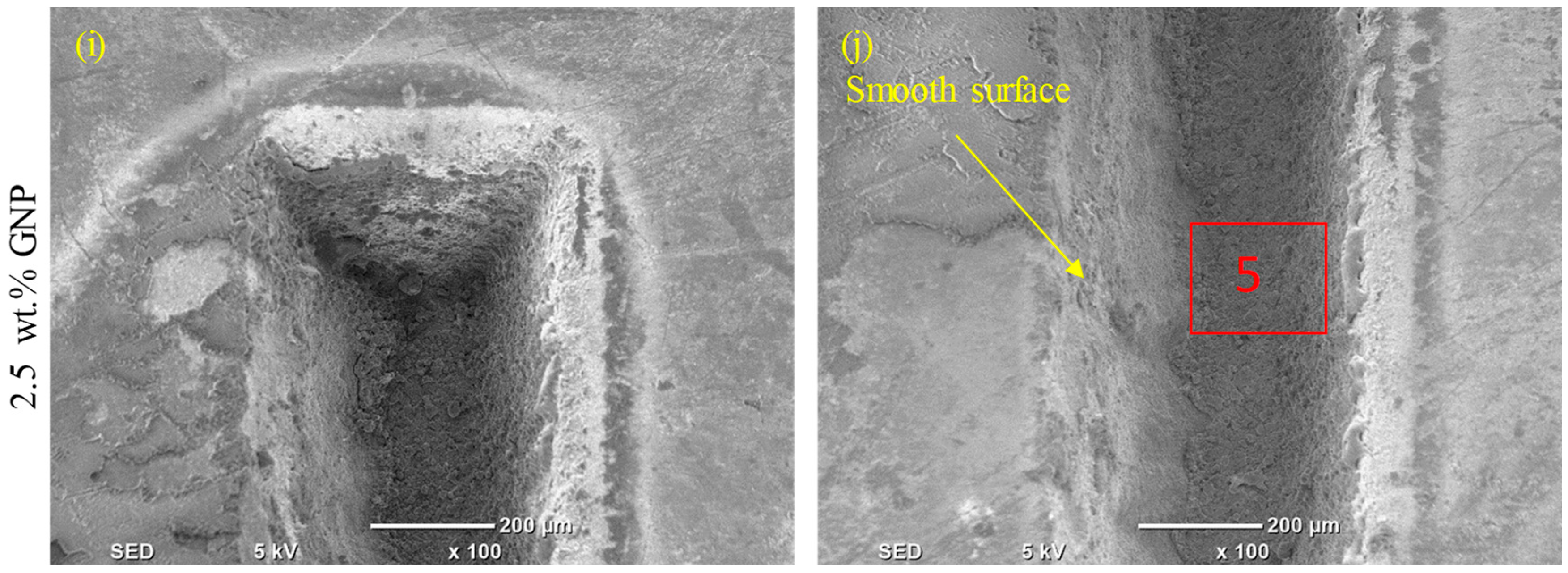

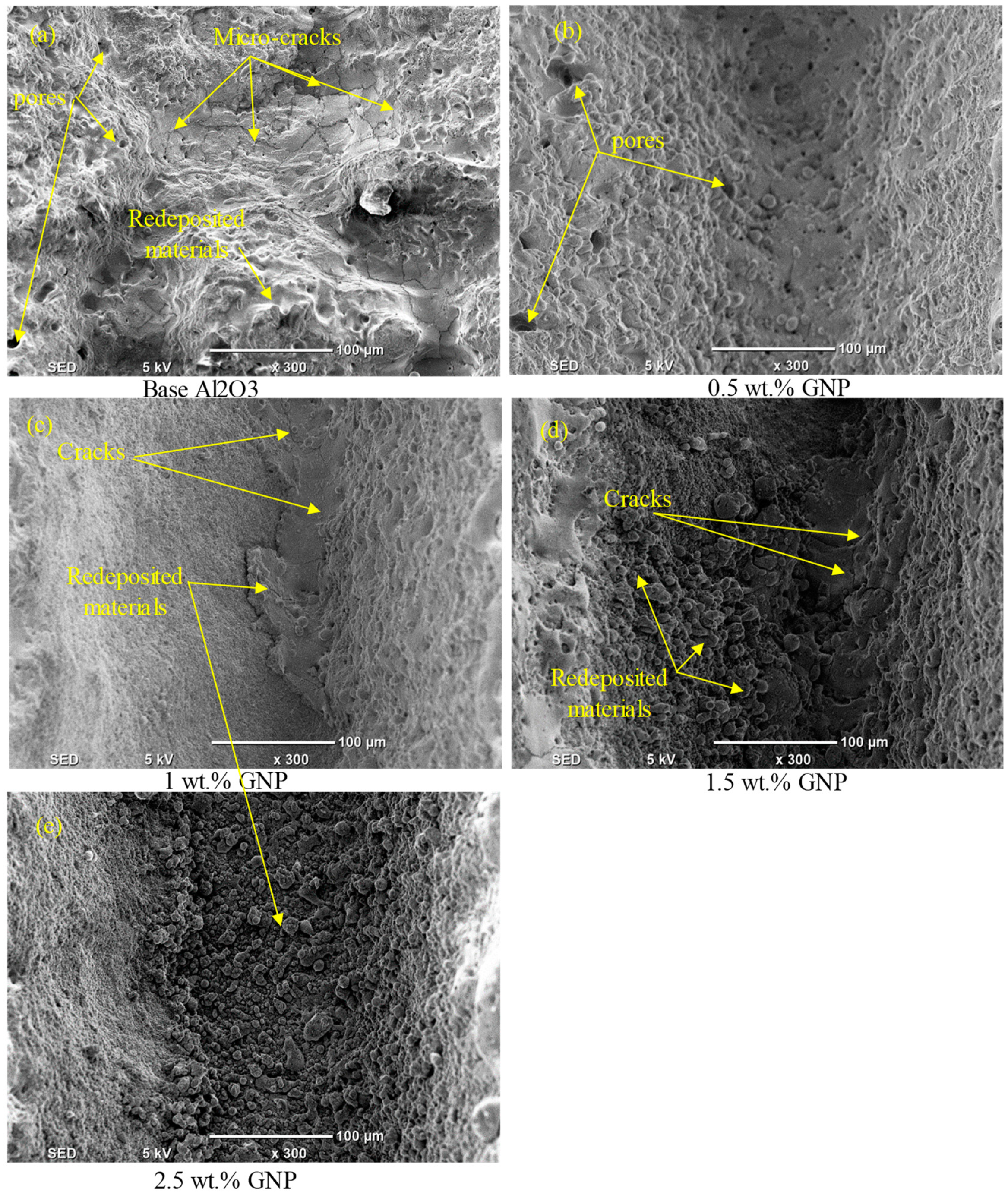

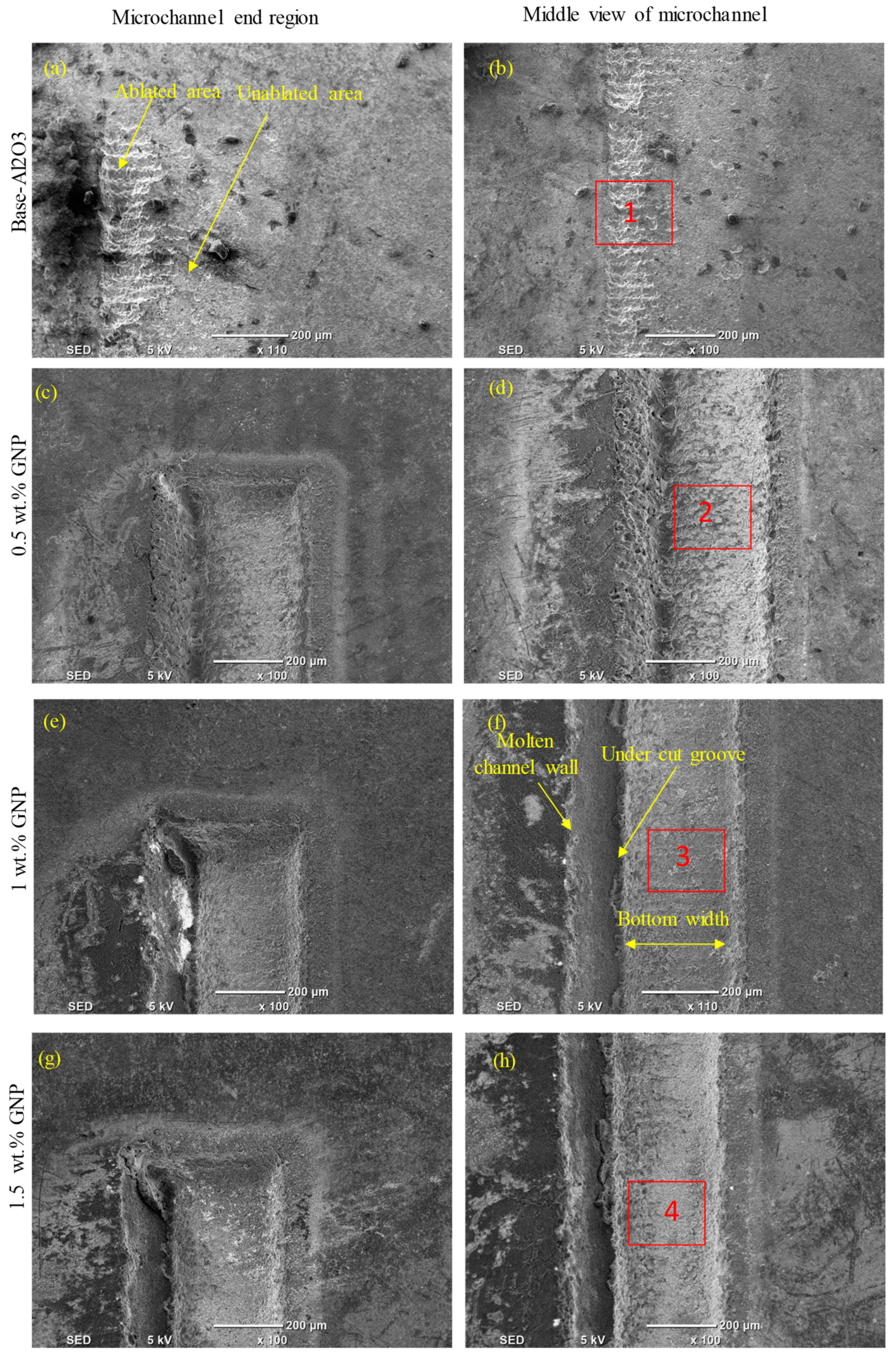

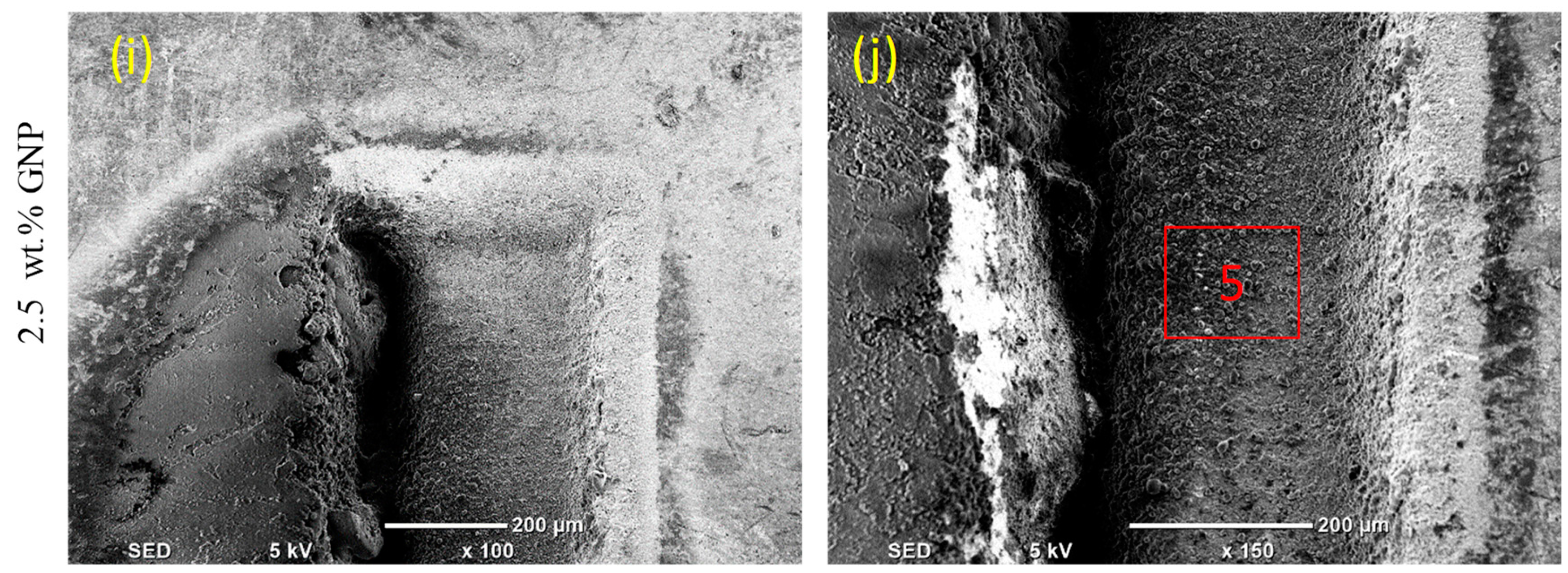

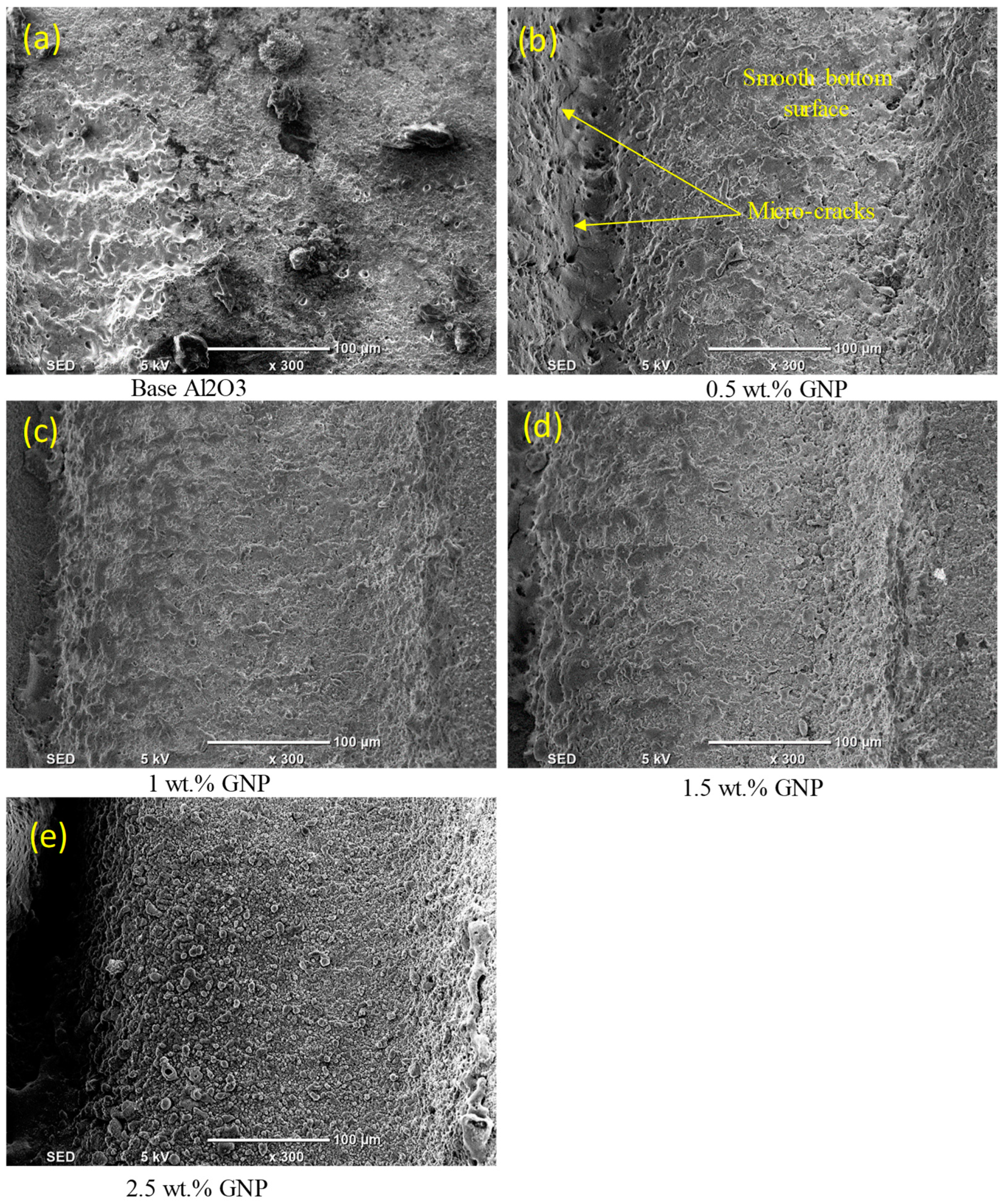

3.2.1. Surface Morphology

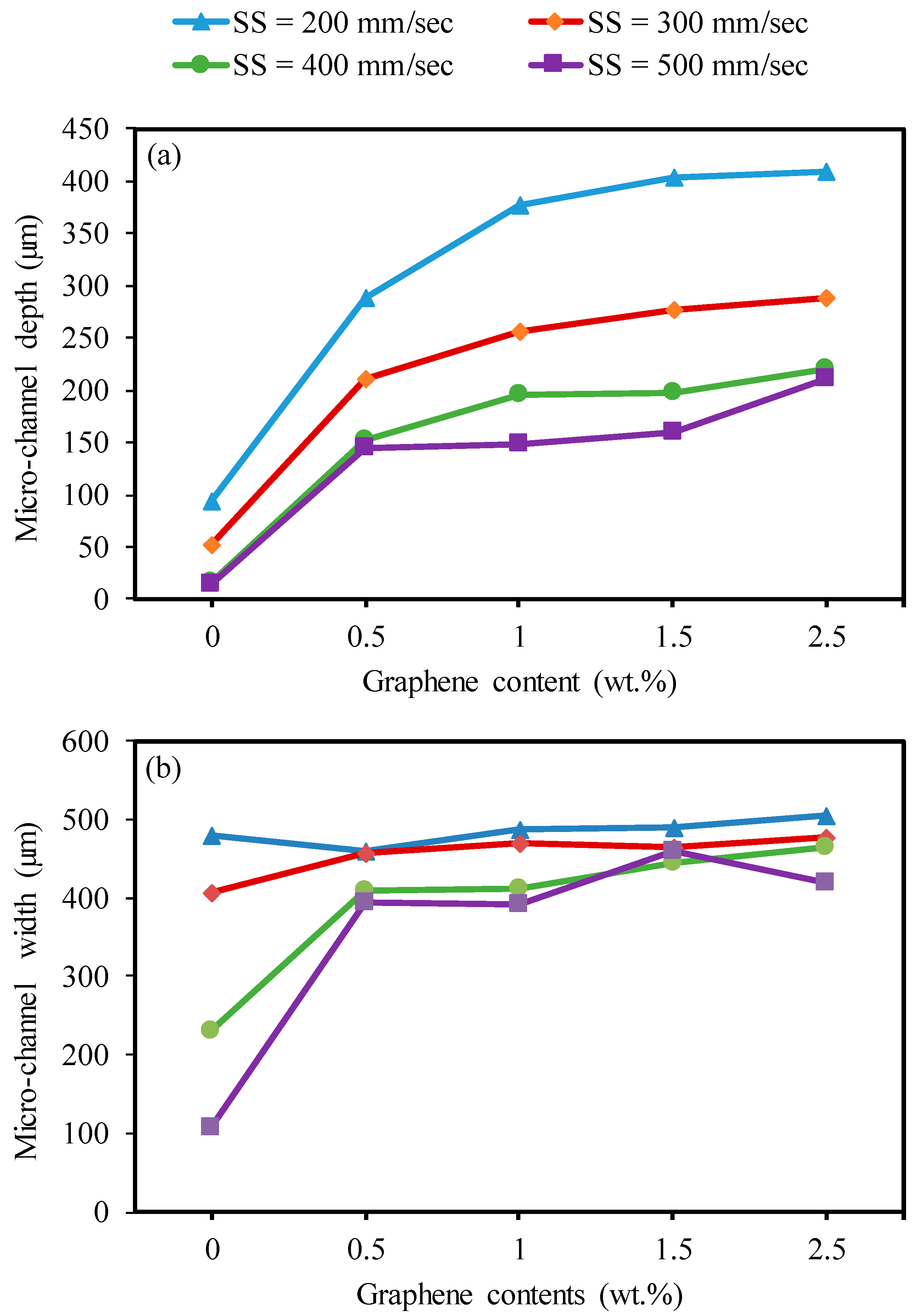

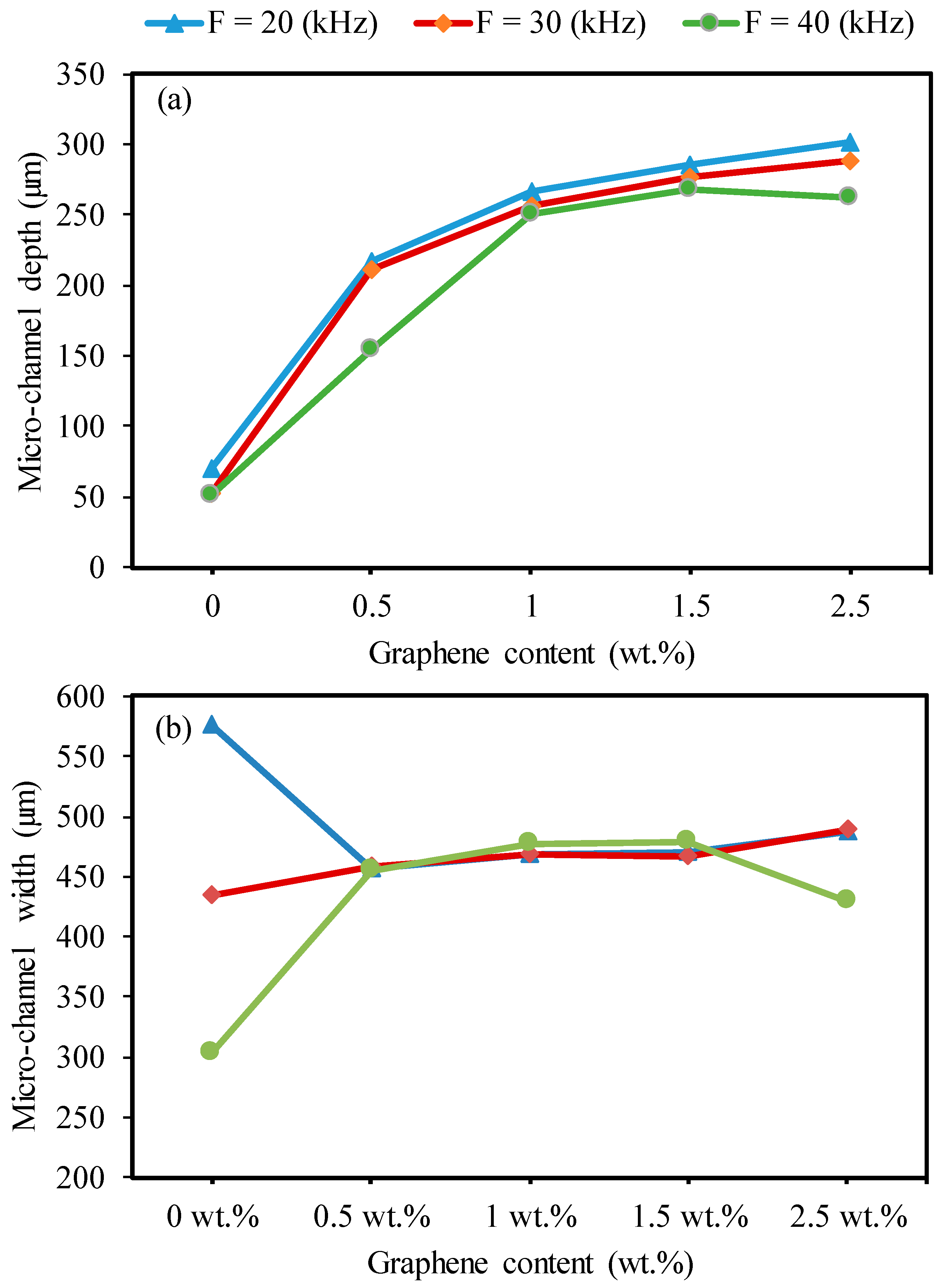

3.2.2. Microchannel Accuracy

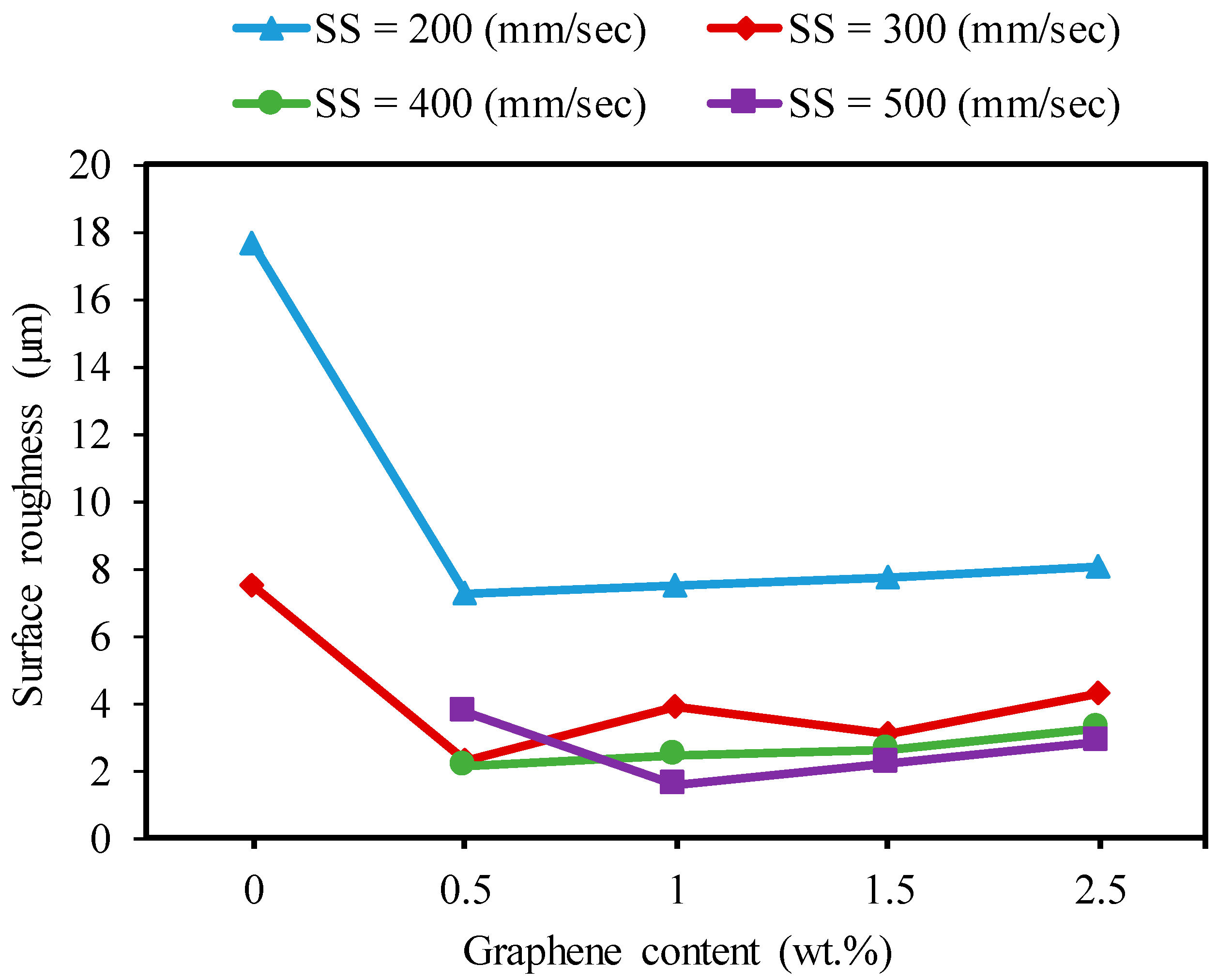

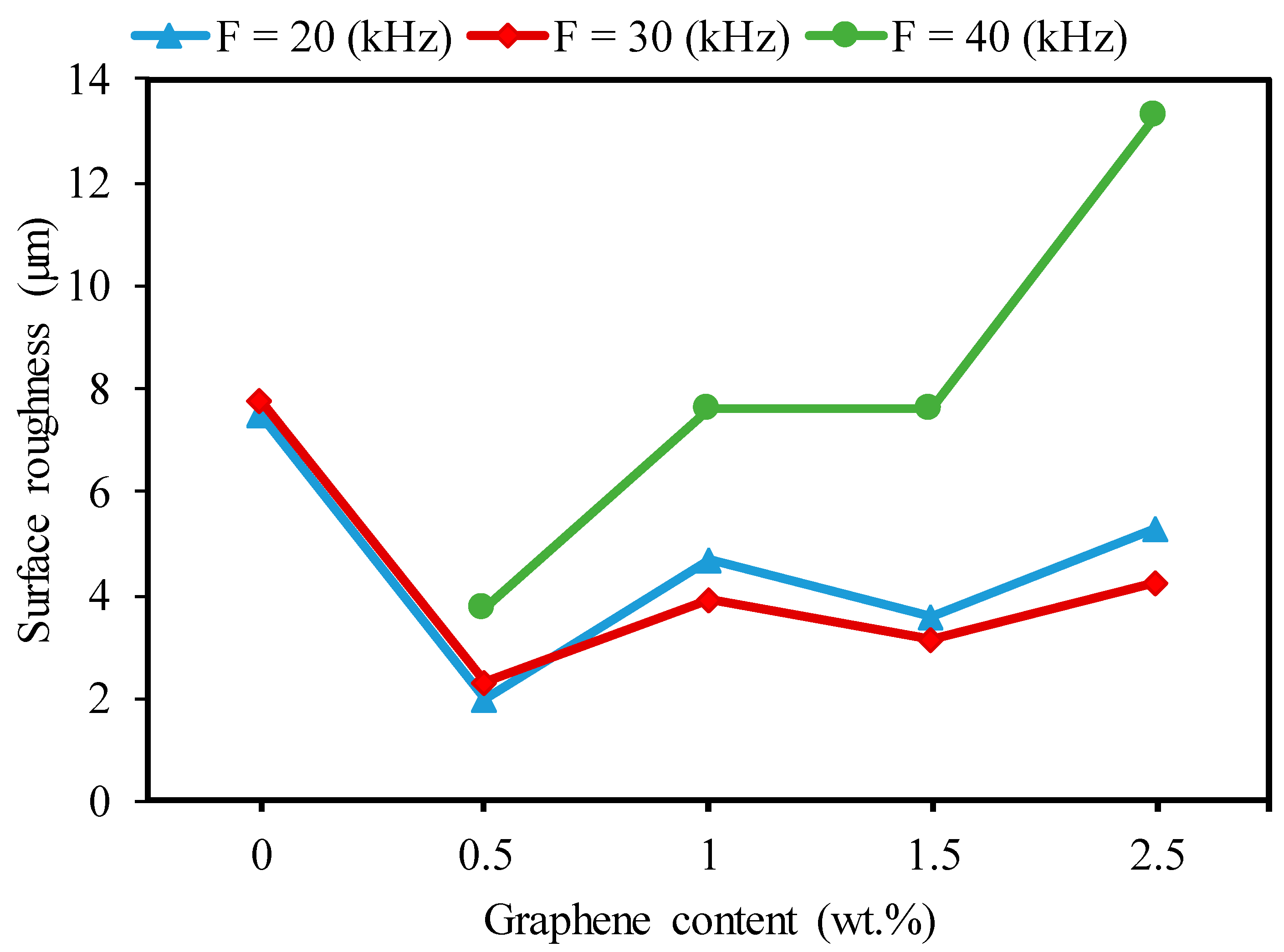

3.2.3. Surface Roughness

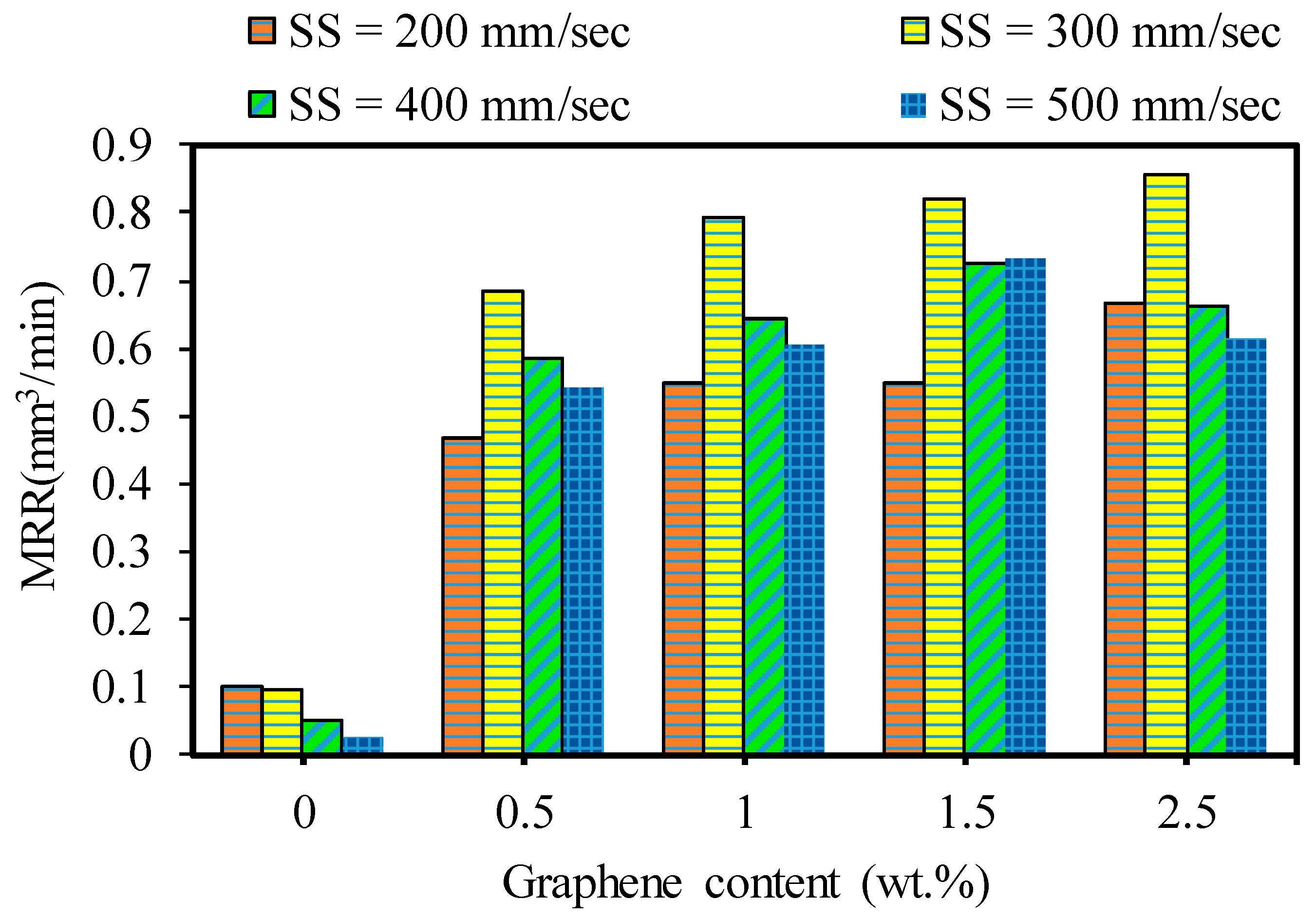

3.2.4. Material Removal Rate

4. Conclusions

- All of the produced GNP-based Al2O3 nanocomposite samples exhibited high relative densities between 97.17% and 99.79%, which indicates good bonding between the GNPs and the Al2O3 matrix without porosity or cavities.

- The hardness was moderately affected by the GNP reinforcement in the Al2O3 matrix. Nanocomposites with 0.5 wt.% GNPs demonstrated a slight improvement in hardness by approximately 6.3% compared to the base Al2O3. In comparison, other nanocomposites exhibited a slight decrease in hardness.

- The SEM examination revealed that the inclusion of graphene contents had a profound influence on the surface morphology of the machined microchannels. The base Al2O3 samples showed inferior surface quality, with pores, more redeposited materials, and microcracks. All of the GNP/ Al2O3 nanocomposites showed improvement in morphology compared to the base Al2O3 samples. This was due to the lower ablation threshold energy of the graphene based-nanocomposites.

- The ablation depth was significantly affected by the GNP reinforcement. The GNP/Al2O3 nanocomposites exhibited improvement in the ablation depth compared to the base Al2O3 in all machining conditions. For example, at a scanning speed of 500 mm/s, the ablation depths increased by 9.8, 10.04, 10.9, and 14.6 times, respectively, compared to the base Al2O3. This was because the graphene reinforcements reduced the ablation threshold energy required to induce the materials and increased the material removal efficiency due to higher optical absorbance, thermal conductivity, and a smaller grain size.

- The MRRs during the laser micromachining were significantly affected by the GNP reinforcement in the Al2O3 matrix. For example, at a higher scanning speed, the MRRs were increased by 2134%, 2391%, 2915%, and 2427% for the 0.5 wt.%, 1 wt.%, 1.5 wt.%, and 2.5 wt.% GNP/Al2O3 nanocomposites, respectively, compared to the base Al2O3 ceramic.

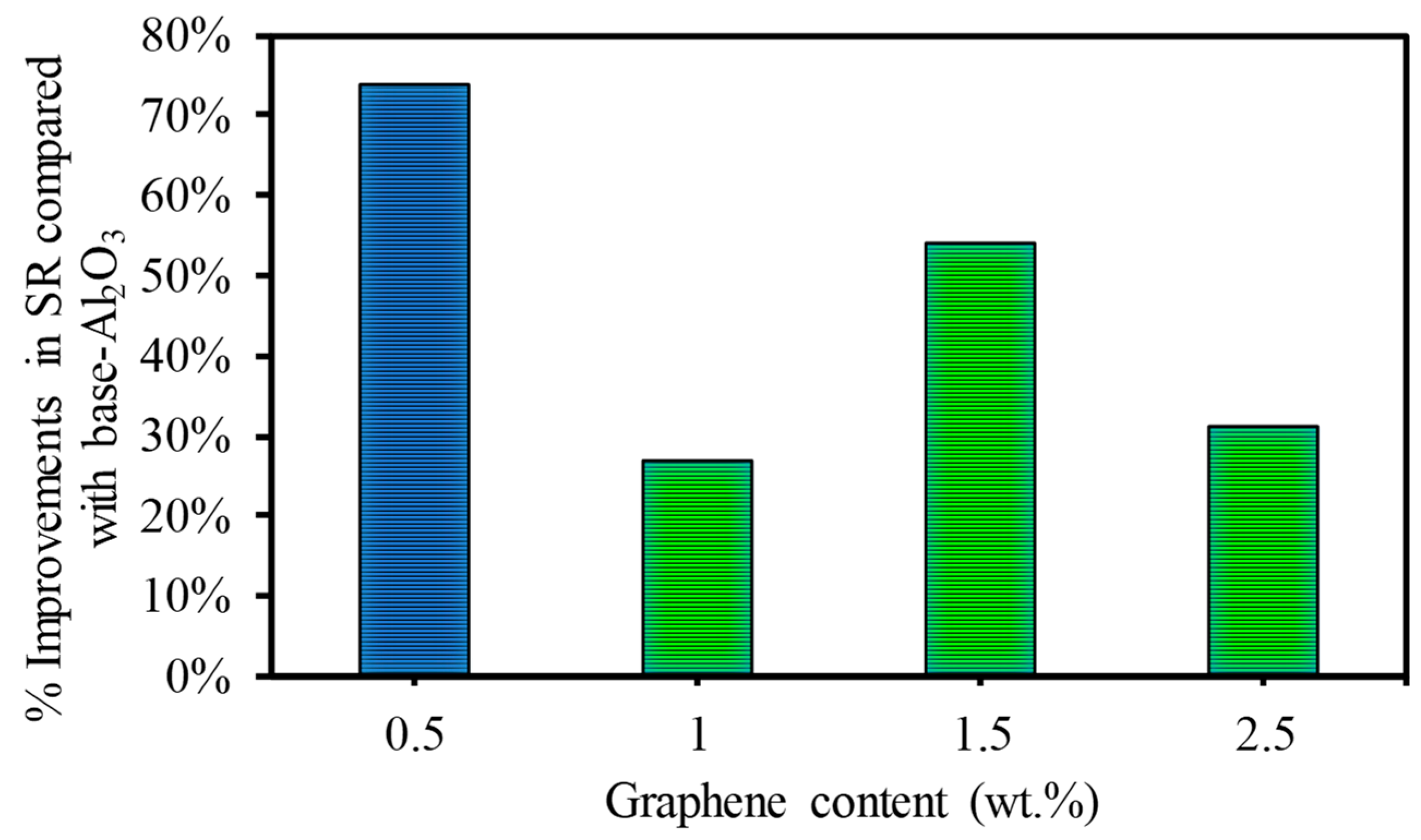

- The roughness of the machined microchannels was affected by the GNP reinforcement. The nanocomposites with lower GNP contents exhibited the lowest surface roughness compared to the other samples. Among the machined nanocomposites, the 0.5 wt.% GNP samples showed the lowest surface roughness.

- Overall, the microchannel accuracy, surface quality, and material removal rate were significantly affected by the GNP reinforcement in the alumina matrix nanocomposites during the laser micromachining. It is worth stating again that all of the GNP-reinforced alumina matrix nanocomposites showed improved micromachining performance compared to the unreinforced samples. Moreover, by comparing the influence of the GNP reinforcements on the surface roughness and surface morphology, the nanocomposites with 0.3 wt.% and 1wt.% GNPs largely showed better performance in most of the machining conditions, while the nanocomposites with 1.5 wt.% and 2.5 wt.% GNPs showed better machining performance regarding the ablation rate and material removal rate. The results show that GNP/Al2O3 nanocomposites can be machined with very good quality using a very ordinary 20 W fiber laser. In contrast, pure Al2O3 could not be machined using the same low-power and low-budget laser system. This helps in achieving the clean and sustainable manufacturing goals with reduced energy consumption for clean environment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, I.; Anwar, S.; Xu, F.; Zhu, Y. Tribological Investigation of Multilayer Graphene Reinforced Alumina Ceramic Nanocomposites. J. Tribol. 2019, 141, 022002. [Google Scholar] [CrossRef]

- Brandner, J.J. Fabrication of Microreactors Made from Metals and Ceramics. In Microreactors in Organic Synthesis and Catalysis; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; pp. 1–17. [Google Scholar]

- Abdo, B.M.A.; Anwar, S.; El-Tamimi, A.M.; Nasr, E.A. Experimental Analysis on the Influence and Optimization of μ-RUM Parameters in Machining Alumina Bioceramic. Materials 2019, 12, 616. [Google Scholar] [CrossRef] [PubMed]

- Sommers, A.; Wang, Q.; Han, X.; T’Joen, C.; Park, Y.; Jacobi, A. Ceramics and Ceramic Matrix Composites for Heat Exchangers in Advanced Thermal Systems—A Review. Appl. Therm. Eng. 2010, 30, 1277–1291. [Google Scholar] [CrossRef]

- Sternitzke, M.; Derby, B.; Brook, R.J. Alumina/Silicon Carbide Nanocomposites by Hybrid Polymer/Powder Processing: Microstructures and Mechanical Properties. J. Am. Ceram. Soc. 1998, 81, 41–48. [Google Scholar] [CrossRef]

- Morisada, Y.; Miyamoto, Y.; Takaura, Y.; Hirota, K.; Tamari, N. Mechanical Properties of SiC Composites Incorporating SiC-Coated Multi-Walled Carbon Nanotubes. Int. J. Refract. Met. Hard Mater. 2007, 25, 322–327. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solís, W.; Díaz, L.A.; Fernández, A.; Torrecillas, R. Journal of the European Ceramic Society Effect of Graphene Addition on the Mechanical and Electrical Properties of Al2O3-SiCw Ceramics. J. Eur. Ceram. Soc. 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Llorca, J.; Elices, M.; Celemín, J.A. Toughness and Microstructural Degradation at High Temperature in SiC Fiber-Reinforced Ceramics. Acta Mater. 1998, 46, 2441–2453. [Google Scholar] [CrossRef]

- Fu, Y.; Gu, Y.W.; Du, H. SiC Whisker Toughened Al2O3-(Ti,W)C Ceramic Matrix Composites. Scr. Mater. 2001, 44, 111–116. [Google Scholar] [CrossRef]

- Ahmad, I.; Islam, M.; Sayed, H.; Subhani, T.; Abdelrazek, K.; Almajid, A.A.; Yazdani, B.; Zhu, Y. Toughening Mechanisms and Mechanical Properties of Graphene Nanosheet-Reinforced Alumina. Mater. Des. 2015, 88, 1234–1243. [Google Scholar] [CrossRef]

- Shah, W.A.; Luo, X.; Guo, C.; Rabiu, B.I.; Huang, B.; Yang, Y.Q. Preparation and Mechanical Properties of Graphene-Reinforced Alumina-Matrix Composites. Chem. Phys. Lett. 2020, 754, 137765. [Google Scholar] [CrossRef]

- Nasr, M.M.; Anwar, S.; Al-Samhan, A.M.; Abdo, H.S.; Dabwan, A. On the Machining Analysis of Graphene Nanoplatelets Reinforced Ti6Al4V Matrix Nanocomposites. J. Manuf. Process. 2021, 61, 574–589. [Google Scholar] [CrossRef]

- Cygan, T.; Petrus, M.; Wozniak, J.; Cygan, S.; Teklińska, D.; Kostecki, M.; Jaworska, L.; Olszyna, A. Mechanical Properties and Tribological Performance of Alumina Matrix Composites Reinforced with Graphene-Family Materials. Ceram. Int. 2020, 46, 7170–7177. [Google Scholar] [CrossRef]

- Rivero-Antúnez, P.; Zamora-Ledezma, C.; Sánchez-Bajo, F.; Moreno-López, J.C.; Anglaret, E.; Morales-Flórez, V. Sol–Gel Method and Reactive SPS for Novel Alumina–Graphene Ceramic Composites. J. Eur. Ceram. Soc. 2023, 43, 1064–1077. [Google Scholar] [CrossRef]

- Shah, W.A.; Luo, X.; Yang, Y.Q. Mechanical and Thermal Properties of Spark Plasma Sintered Al2O3-Graphene-SiC Hybrid Composites. Ceram. Int. 2023, 49, 7987–7995. [Google Scholar] [CrossRef]

- Kuşoğlu, I.M.; Çavdar, U.; Altintaş, A. The Effects of Graphene Nanoplatelet Addition to in Situ Compacted Alumina Nanocomposites Using Ultra-High Frequency Induction Sintering System. J. Aust. Ceram. Soc. 2020, 56, 233–241. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene Reinforced Metal and Ceramic Matrix Composites: A Review. Int. Mater. Rev. 2017, 62, 241–302. [Google Scholar] [CrossRef]

- Mudra, E.; Shepa, I.; Hrubovcakova, M.; Koribanich, I.; Medved, D.; Kovalcikova, A.; Vojtko, M.; Dusza, J. Highly Wear-Resistant Alumina/Graphene Layered and Fiber-Reinforced Composites. Wear 2021, 484–485, 204026. [Google Scholar] [CrossRef]

- Shah, W.A.; Luo, X.; Rabiu, B.I.; Huang, B.; Yang, Y.Q. Toughness Enhancement and Thermal Properties of Graphene-CNTs Reinforced Al2O3 Ceramic Hybrid Nanocomposites. Chem. Phys. Lett. 2021, 781, 138978. [Google Scholar] [CrossRef]

- Duntu, S.H.; Hukpati, K.; Ahmad, I.; Islam, M.; Boakye-Yiadom, S. Deformation and Fracture Behaviour of Alumina-Zirconia Multi-Material Nanocomposites Reinforced with Graphene and Carbon Nanotubes. Mater. Sci. Eng. A 2022, 835, 142655. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, J.; Cui, E.; Tian, X.; Sun, Z. Effect of Interfacial Structure on Mechanical Properties of Graphene Reinforced Al2O3–WC Matrix Ceramic Composite. Nanomaterials 2021, 11, 1374. [Google Scholar] [CrossRef]

- Liang, L.; Huang, C.; Wang, C.; Sun, X.; Yang, M.; Wang, S.; Cheng, Y.; Ning, Y.; Li, J.; Yin, W.; et al. Ultratough Conductive Graphene/Alumina Nanocomposites. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106871. [Google Scholar] [CrossRef]

- He, T.; Li, J.; Wang, L.; Zhu, J.; Jiang, W. Preparation and Consolidation of Alumina/Graphene Composite Powders. Mater. Trans. 2009, 50, 749–751. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Fan, Z.; Yan, J.; Wei, T. Preparation of Graphene Nanosheet/Alumina Composites by Spark Plasma Sintering. Mater. Res. Bull. 2011, 46, 315–318. [Google Scholar] [CrossRef]

- Porwal, H.; Tatarko, P.; Grasso, S.; Khaliq, J.; Dlouhý, I.; Reece, M.J. Graphene Reinforced Alumina Nano-Composites. Carbon 2013, 64, 359–369. [Google Scholar] [CrossRef]

- Chen, Y.F.; Bi, J.Q.; Yin, C.L.; You, G.L. Microstructure and Fracture Toughness of Graphene Nanosheets/Alumina Composites. Ceram. Int. 2014, 40, 13883–13889. [Google Scholar] [CrossRef]

- Liu, X.; Fan, Y.-C.; Li, J.-L.; Wang, L.-J.; Jiang, W. Preparation and Mechanical Properties of Graphene Nanosheet Reinforced Alumina Composites. Adv. Eng. Mater. 2015, 17, 28–35. [Google Scholar] [CrossRef]

- Kim, W.; Oh, H.S.; Shon, I.J. The Effect of Graphene Reinforcement on the Mechanical Properties of Al2O3ceramics Rapidly Sintered by High-Frequency Induction Heating. Int. J. Refract. Met. Hard Mater. 2015, 48, 376–381. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.; Hassanin, H.; Jumbu, N.; Deng, S.; Zuo, Q.; Jiang, K. Graphene–Alumina Nanocomposites with Improved Mechanical Properties for Biomedical Applications. ACS Appl. Mater. Interfaces 2016, 8, 2607–2616. [Google Scholar] [CrossRef]

- Ahmad, I.; Subhani, T.; Wang, N.; Zhu, Y. Thermophysical Properties of High-Frequency Induction Heat Sintered Graphene Nanoplatelets/Alumina Ceramic Functional Nanocomposites. J. Mater. Eng. Perform. 2018, 27, 2949–2959. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, L.; Li, J.; Li, J.; Sun, S.; Chen, F.; Chen, L.; Jiang, W. Preparation and Electrical Properties of Graphene Nanosheet/Al2O3 Composites. Carbon 2010, 48, 1743–1749. [Google Scholar] [CrossRef]

- Porwal, H.; Kasiarova, M.; Tatarko, P.; Grasso, S.; Dusza, J.; Reece, M.J. Scratch Behaviour of Graphene Alumina Nanocomposites. Adv. Appl. Ceram. 2015, 114, S34–S41. [Google Scholar] [CrossRef]

- Yazdani, B.; Porwal, H.; Xia, Y.; Yan, H.; Reece, M.J.; Zhu, Y. Role of Synthesis Method on Microstructure and Mechanical Properties of Graphene/Carbon Nanotube Toughened Al2O3 Nanocomposites. Ceram. Int. 2015, 41, 9813–9822. [Google Scholar] [CrossRef]

- Sung, J.W.; Kim, K.H.; Kang, M.C. Effects of Graphene Nanoplatelet Contents on Material and Machining Properties of GNP-Dispersed Al2O3 Ceramics for Micro-Electric Discharge Machining. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 247–252. [Google Scholar] [CrossRef]

- Nieto, A.; Zhao, J.M.; Han, Y.H.; Hwang, K.H.; Schoenung, J.M. Microscale tribological behavior and in vitro biocompatibility of graphene nanoplatelet reinforced alumina. J. Mech. Behav. Biomed. Mater. 2016, 61, 122–134. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Camfield, R. Machinability Experimental Study of Sintered Alumina (Al2O3) Ceramics Material by Chemical Vapor Deposition Diamond Coating Milling Tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1535–1546. [Google Scholar] [CrossRef]

- Abdo, B.M.A.; Ahmed, N.; El-Tamimi, A.M.; Anwar, S.; Alkhalefah, H.; Nasr, E.A. Laser Beam Machining of Zirconia Ceramic: An Investigation of Micro-Machining Geometry and Surface Roughness. J. Mech. Sci. Technol. 2019, 33, 1817–1831. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kang, M.C.; Kim, K.H.; Park, W.I.; Cho, S.H. Effects of Optical Absorbance with Ablation Characteristics in Femtosecond Laser Irradiation of Carbon Reinforced Al2O3 Composites. Adv. Appl. Ceram. 2016, 115, 123–128. [Google Scholar] [CrossRef]

- López-Pernía, C.; Muñoz-Ferreiro, C.; González-Orellana, C.; Morales-Rodríguez, A.; Gallardo-López; Poyato, R. Optimizing the Homogenization Technique for Graphene Nanoplatelet/Yttria Tetragonal Zirconia Composites: Influence on the Microstructure and the Electrical Conductivity. J. Alloys Compd. 2018, 767, 994–1002. [Google Scholar] [CrossRef]

- Abdo, B.M.A.; Anwar, S.; El-Tamimi, A.M.; Alahmari, A.M.; Abouel Nasr, E. Laser Micro-Milling of Bio-Lox Forte Ceramic: An Experimental Analysis. Precis. Eng. 2018, 53, 179–193. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Tagliaferri, F.; Palumbo, B.; Dix, M. Experimental Investigation on Laser Milling of Aluminium Oxide Using a 30 W Q-Switched Yb:YAG Fiber Laser. Opt. Laser Technol. 2016, 76, 127–137. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, L.; Zhang, L.; Wang, W.; Yan, T. Polishing of Alumina Ceramic to Submicrometer Surface Roughness by Picosecond Laser. Surf. Coat. Technol. 2020, 397, 125962. [Google Scholar] [CrossRef]

- Preusch, F.; Adelmann, B.; Hellmann, R. Micromachining of AlN and Al2O3 Using Fiber Laser. Micromachines 2014, 5, 1051–1060. [Google Scholar] [CrossRef]

- Deng, D.; Xie, Y.; Chen, L.; Chen, X. Experimental Investigation on Laser Micromilling of SiC Microchannels. Int. J. Adv. Manuf. Technol. 2019, 101, 9–21. [Google Scholar] [CrossRef]

- Agarwal, B.D.; Broutman, L.J.; Chandrashekhara, K. Analysis and Performance of Fiber Composites; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Kim, K.R.; Choi, B.D.; Yi, J.S.; Cho, S.H.; Choa, Y.H.; Shin, D.S.; Bae, D.H.; Kang, M.C.; Jeong, Y.K. Laser Micromachining of CNT/Fe/Al2O3 Nanocomposites. Trans. Nonferrous Met. Soc. China 2009, 19, s189–s193. [Google Scholar] [CrossRef]

- Kumari, L.; Zhang, T.; Du, G.H.; Li, W.Z.; Wang, Q.W.; Datye, A.; Wu, K.H. Thermal Properties of CNT-Alumina Nanocomposites. Compos. Sci. Technol. 2008, 68, 2178–2183. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Gong, H.; Sun, H.; Li, T.; Guo, X.; Ai, S. Effects of Graphene on the Thermal Conductivity of Pressureless-Sintered SiC Ceramics. Ceram. Int. 2015, 41, 13547–13552. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, L.; Wu, Z.; Wang, X.; Huang, P.; Tang, L. Fabrication and Characterization of Micro-Channels on Al2O3/TiC Ceramic Produced by Nanosecond Laser. Ceram. Int. 2018, 44, 23035–23044. [Google Scholar] [CrossRef]

- Perrie, W.; Rushton, A.; Gill, M.; Fox, P.; O’Neill, W. Femtosecond Laser Micro-Structuring of Alumina Ceramic. Appl. Surf. Sci. 2005, 248, 213–217. [Google Scholar] [CrossRef]

- Kim, K.R.; Kim, J.H.; Kim, K.H.; Niihara, K.; Jeong, Y.K. Laser Microfabrication of Alumina-Silicon Carbide Nanocomposites. J. Ceram. Process. Res. 2008, 9, 421–424. [Google Scholar]

| Ref. | CMC | Reinforcement Ratio | Preparation Method | Consolidation Method | Studied Characteristics | Machining Analysis | |

|---|---|---|---|---|---|---|---|

| Graphene-based alumina matrix nanocomposites | [31] | GNS/Al2O3 | 3, 3.5, 4, 5, 10 and 15 vol.% | Dry ball milling | SPS | Electrical conductivity | No |

| [25] | GNS/Al2O3 | 0.2, 0.5, 0.8,2 and 5 vol.% | Wet ball milling | SPS | Fracture toughness and elastic modulus | No | |

| [26] | GNS/Al2O3 | 0.1, 0.2, 0.5, and 1 wt.% | Wet ball milling | HP | Microstructure and fracture toughness | No | |

| [32] | GNP/Al2O3 | 0.5, 2, and 5 vol.% | Wet ball milling | SPS | Scratch testing | No | |

| [33] | GNP/Al2O3 CNT/Al2O3 | 1, 2 wt.% | Ultrasonic probe | HP and SPS | Morphology, grain sizes, and fracture mode | No | |

| [10] | GNS/Al2O3 | 0.25, 0.5, 1.5, 3 wt.% | Ultrasonic probe | HFIHS | Hardness, elastic modulus, and fracture toughness | No | |

| [34] | GNP/Al2O3 | 5, 10, 15, 20 vol.% | Wet ball milling | SPS | Hardness and electrical conductivity | Yes | |

| [29] | GNP/Al2O3 | 0.75, 1.17, 1.85, and 2.75 vol.% | Wet ball milling | Pressure-less sintering | Hardness, flexural strength, fracture toughness, and biocompatibility | No | |

| [35] | GNP/Al2O3 | 5, 10, 15 vol.% | Wet ball milling | SPS | Fracture toughness, wear resistance, and biocompatibility | No | |

| [30] | MLG/Al2O3 | 0.5, 1.0 vol.% | Aqueous sonic probe | HFIHS | Wear-resistance properties | No | |

| [13] | MLG/Al2O3 | 0.2, 0.5, 0.7, and 1 wt.% | Wet ball milling | SPS | Microstructure and tribological performance | No |

| Elements | Al2O3 | B2O3 | CaO | Fe2O3 | MgO | Na2O |

|---|---|---|---|---|---|---|

| Percentage (wt.%) | ≥99.9 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.03 |

| Powder | Average Diameter | Thickness | Surface Area | Density |

|---|---|---|---|---|

| GNPs | Less than 2 µm | 5–8 nm | 750 m2/g | 2.21 g/cm3 |

| Input Parameters | Values | |||

|---|---|---|---|---|

| Scanning speed, SS (mm/s) | 200 | 300 | 400 | 500 |

| Pulse frequency, F (kHz) | 20 | 30 | 40 | - |

| Power, (w) | 20 | - | - | - |

| Scanning strategy | Line | - | - | - |

| Line spacing | 17 µm | - | - | - |

| Spot diameter | 50 µm | - | - | - |

| Pulse overlap | 50% | |||

| Step overlap | 5% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasr, M.M.; Anwar, S.; Al-Samhan, A.M.; Alqahtani, K.N.; Dabwan, A.; Alhaag, M.H. Sustainable Microfabrication Enhancement of Graphene Nanoplatelet-Reinforced Biomedical Alumina Ceramic Matrix Nanocomposites. Nanomaterials 2023, 13, 1032. https://doi.org/10.3390/nano13061032

Nasr MM, Anwar S, Al-Samhan AM, Alqahtani KN, Dabwan A, Alhaag MH. Sustainable Microfabrication Enhancement of Graphene Nanoplatelet-Reinforced Biomedical Alumina Ceramic Matrix Nanocomposites. Nanomaterials. 2023; 13(6):1032. https://doi.org/10.3390/nano13061032

Chicago/Turabian StyleNasr, Mustafa M., Saqib Anwar, Ali M. Al-Samhan, Khaled N. Alqahtani, Abdulmajeed Dabwan, and Mohammed H. Alhaag. 2023. "Sustainable Microfabrication Enhancement of Graphene Nanoplatelet-Reinforced Biomedical Alumina Ceramic Matrix Nanocomposites" Nanomaterials 13, no. 6: 1032. https://doi.org/10.3390/nano13061032

APA StyleNasr, M. M., Anwar, S., Al-Samhan, A. M., Alqahtani, K. N., Dabwan, A., & Alhaag, M. H. (2023). Sustainable Microfabrication Enhancement of Graphene Nanoplatelet-Reinforced Biomedical Alumina Ceramic Matrix Nanocomposites. Nanomaterials, 13(6), 1032. https://doi.org/10.3390/nano13061032