Anisotropic Resistivity Size Effect in Epitaxial Mo(001) and Mo(011) Layers

Abstract

:1. Introduction

2. Experimental and Simulation Methods

3. Results

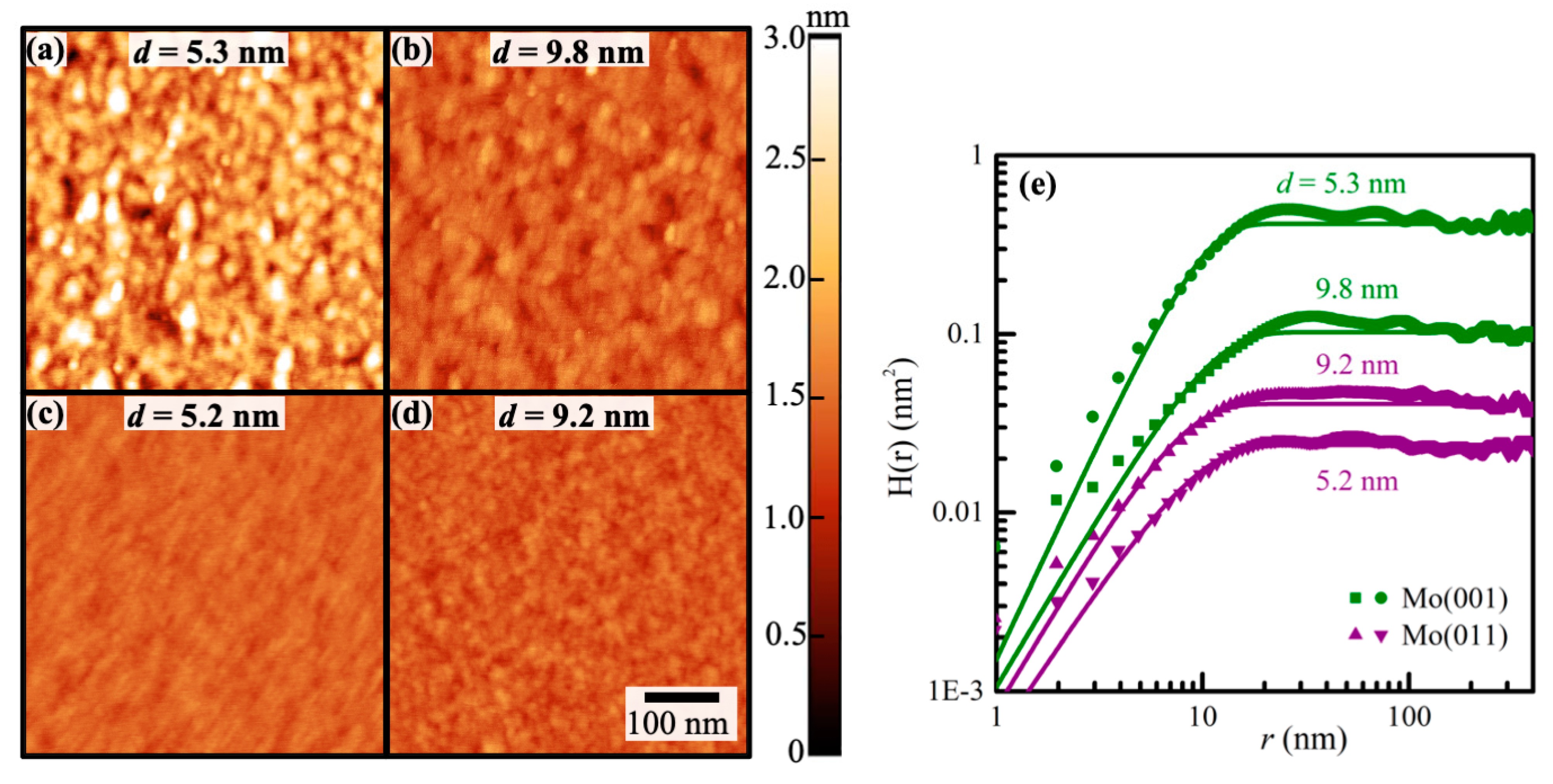

3.1. Microstructural Analysis

3.2. Electron Transport

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chawla, J.S.; Sung, S.H.; Bojarski, S.A.; Carver, C.T.; Chandhok, M.; Chebiam, R.V.; Clarke, J.S.; Harmes, M.; Jezewski, C.J.; Kobrinski, M.J.; et al. Resistance and electromigration performance of 6 nm wires. In Proceedings of the 2016 IEEE International Interconnect Technology Conference/Advanced Metallization Conference (IITC/AMC), San Jose, CA, USA, 23–26 May 2016; pp. 63–65. [Google Scholar]

- Van der Veen, M.H.; Heyler, N.; Pedreira, O.V.; Ciofi, I.; Decoster, S.; Gonzalez, V.V.; Jourdan, N.; Struyf, H.; Croes, K.; Wilson, C.J.; et al. Damascene Benchmark of Ru, Co and Cu in scaled dimensions. In Proceedings of the 2018 IEEE International Interconnect Technology Conference (IITC), Santa Clara, CA, USA, 4–7 June 2018; pp. 172–174. [Google Scholar]

- Lin, K.; Chandhok, M.; Reshotko, M. The future of interconnects: Challenges and enabling technologies. In Proceedings of the 2018 IEEE International Interconnect Technology Conference (IITC), Santa Clara, CA, USA, 4–7 June 2018; pp. 2–3. [Google Scholar]

- Lanzillo, N.A.; Motoyama, K.; Huang, H.; Robison, R.R.; Spooner, T. Via resistance and reliability trends in copper interconnects with ultra-scaled barrier layers. Appl. Phys. Lett. 2020, 116, 164103. [Google Scholar] [CrossRef] [Green Version]

- Rosenberg, R.; Edelstein, D.C.; Hu, C.-K.; Rodbell, K.P. Copper metallization for high performance silicon technology. Annu. Rev. Mater. Res. 2000, 30, 229. [Google Scholar] [CrossRef]

- Van der Veen, M.H.; Pedreira, O.V.; Heylen, N.; Jourdan, N.; Lariviere, S.; Park, S.; Struyf, H.; Tokei, Z.; Lei, W.; Pethe, S.; et al. Exploring W-Cu hybrid dual damascene metallization for future nodes. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; pp. 1–3. [Google Scholar]

- Warashina, H.; Kawasaki, H.; Nagai, H.; Yamaguchi, T.; Sato, N.; Kikuchi, Y.; Sun, X. Advanced air gap formation scheme using volatile material. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; Volume 2, pp. 1–3. [Google Scholar]

- Park, J.; Ahn, J.H.; Yoon, Y.; Choi, Y.; Jang, J.; Lee, M. Advanced 5 nm BEOL integration development for manufacuring. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; pp. 1–3. [Google Scholar]

- You, S.; Ren, H.; Naik, M.; Chen, L.; Chen, F.; Cervantes, C.L.; Xie, X.; Kashefizadeh, K. Selective Barrier for Cu Interconnect Extension in 3nm Node and beyond. In Proceedings of the 2021 IEEE International Interconnect Technology Conference, IITC, Virtual Conference, 6–9 July 2021; pp. 3–5. [Google Scholar]

- Tabata, T.; Raynal, P.-E.; Roze, F.; Halty, S.; Thuries, L.; Cristiano, F.; Scheid, E.; Mazzamuto, F. Copper large-scale grain growth by UV nanosecond pulsed laser annealing. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; pp. 1–3. [Google Scholar]

- Zhang, X.-G.; Butler, W.H. Conductivity of metallic films and multilayers. Phys. Rev. B 1995, 51, 10085–10103. [Google Scholar] [CrossRef]

- Lucas, M.S.P. Electrical conductivity of thin metallic films with unlike surfaces. J. Appl. Phys. 1965, 36, 1632–1635. [Google Scholar] [CrossRef]

- Macdonald, D.K.C.; Sarginson, K. Size effect variation of the electrical conductivity of metals. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1950, 203, 223–240. [Google Scholar]

- Dingle, R.B. The electrical conductivity of thin wires. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1950, 201, 545–560. [Google Scholar]

- Milosevic, E.; Gall, D. Electron scattering at Co(0001) surfaces: Effects of Ti and TiN capping layers. AIP Adv. 2020, 10, 055213. [Google Scholar] [CrossRef]

- Zheng, P.Y.; Deng, R.P.; Gall, D. Ni doping on Cu surfaces: Reduced copper resistivity. Appl. Phys. Lett. 2014, 105, 131603. [Google Scholar] [CrossRef] [Green Version]

- Dutta, S.; Sankaran, K.; Moors, K.; Pourtois, G.; Van Elshocht, S.; Bömmels, J.; Vandervorst, W.; Tőkei, Z.; Adelmann, C. Thickness dependence of the resistivity of platinum-group metal thin films. J. Appl. Phys. 2017, 122, 025107. [Google Scholar] [CrossRef] [Green Version]

- Bishara, H.; Lee, S.; Brink, T.; Ghidelli, M.; Dehm, G. Understanding grain boundary electrical resistivity in Cu: The effect of boundary structure. ACS Nano 2021, 15, 16607–16615. [Google Scholar] [CrossRef]

- Sun, T.; Yao, B.; Warren, A.P.; Barmak, K.; Toney, M.F.; Peale, R.E.; Coffey, K.R. Surface and grain-boundary scattering in nanometric Cu films. Phys. Rev. B 2010, 81, 155454. [Google Scholar] [CrossRef] [Green Version]

- Lanzillo, N.A.; Dixit, H.; Milosevic, E.; Niu, C.; Carr, A.V.; Oldiges, P.; Raymond, M.V.; Cho, J.; Standaert, T.E.; Kamineni, V.K. Defect and grain boundary scattering in tungsten: A combined theoretical and experimental study. J. Appl. Phys. 2018, 123, 154303. [Google Scholar] [CrossRef]

- César, M.; Liu, D.; Gall, D.; Guo, H. Calculated resistances of single grain boundaries in copper. Phys. Rev. Appl. 2014, 2, 044007. [Google Scholar] [CrossRef] [Green Version]

- Rossnagel, S.M.; Kuan, T.S. Alteration of Cu conductivity in the size effect regime. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2004, 22, 240. [Google Scholar] [CrossRef]

- Chawla, J.S.; Gall, D. Specular electron scattering at single-crystal Cu(001) surfaces. Appl. Phys. Lett. 2009, 94, 252101. [Google Scholar] [CrossRef] [Green Version]

- Purswani, J.M.; Gall, D. Electron scattering at single crystal Cu surfaces. Thin Solid Films 2007, 516, 465–469. [Google Scholar] [CrossRef]

- Fuchs, K. The conductivity of thin metallic films according to the electron theory of metals. Math. Proc. Cambridge Philos. Soc. 1938, 34, 100–108. [Google Scholar] [CrossRef]

- Sondheimer, E.H. The mean free path of electrons in metals. Adv. Phys. 1952, 1, 1–42. [Google Scholar] [CrossRef]

- Mayadas, A.F.; Shatzkes, M. Electrical-resistivity model for polycrystalline films: The case of arbitrary reflection at external surfaces. Phys. Rev. B 1970, 1, 1382–1389. [Google Scholar] [CrossRef]

- Chawla, J.S.; Gstrein, F.; O’Brien, K.P.; Clarke, J.S.; Gall, D. Electron scattering at surfaces and grain boundaries in Cu thin films and wires. Phys. Rev. B 2011, 84, 235423. [Google Scholar] [CrossRef] [Green Version]

- Gall, D.; Jog, A.; Zhou, T. Narrow interconnects: The most conductive metals. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 32.3.1–32.3.4. [Google Scholar]

- Gall, D. The search for the most conductive metal for narrow interconnect lines. J. Appl. Phys. 2020, 127, 050901. [Google Scholar] [CrossRef] [Green Version]

- Gall, D.; Cha, J.J.; Chen, Z.; Han, H.; Hinkle, C.; Robinson, J.A.; Sundararaman, R.; Torsi, R. Materials for interconnects. MRS Bull. 2021, 46, 959–966. [Google Scholar] [CrossRef]

- Zhou, T.; Jog, A.; Gall, D. First-principles prediction of electron grain boundary scattering in fcc metals. Appl. Phys. Lett. 2022, 120, 241603. [Google Scholar] [CrossRef]

- Sankaran, K.; Moors, K.; Tőkei, Z.; Adelmann, C.; Pourtois, G. Ab initio screening of metallic MAX ceramics for advanced interconnect applications. Phys. Rev. Mater. 2021, 5, 056002. [Google Scholar] [CrossRef]

- Gall, D. Electron mean free path in elemental metals. J. Appl. Phys. 2016, 119, 085101. [Google Scholar] [CrossRef] [Green Version]

- Brewer, L. The Cohesive Energies of the Elements. Lawrence Berkeley National Laboratory. LBNL Report #: LBL-3720 Rev. 1977. Available online: https://escholarship.org/uc/item/08p2578m (accessed on 6 December 2017).

- Tierno, D.; Hosseini, M.; van der Veen, M.; Dangol, A.; Croes, K.; Demuynck, S.; Tokei, Z.; Litta, E.D.; Horiguchi, N. Reliability of Barrierless PVD Mo. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; pp. 1–3. [Google Scholar]

- Hegde, G.; Bowen, R.C.; Rodder, M.S. Is electron transport in nanocrystalline Cu interconnects surface dominated or grain boundary dominated? In Proceedings of the 2016 IEEE International Interconnect Technology Conference/Advanced Metallization Conference (IITC/AMC), San Jose, CA, USA, 23–26 May 2016; pp. 114–116. [Google Scholar]

- Jog, A.; Zhou, T.; Gall, D. Resistivity size effect in Epitaxial Rh(001) and Rh(111) layers. IEEE Trans. Electron Devices 2021, 68, 257–263. [Google Scholar] [CrossRef]

- Jog, A.; Gall, D. Electron scattering at surfaces and grain boundaries in Rh layers. IEEE Trans. Electron Devices 2022, 69, 3854–3860. [Google Scholar] [CrossRef]

- Jog, A.; Gall, D. Resistivity size effect in epitaxial iridium layers. J. Appl. Phys. 2021, 130, 115103. [Google Scholar] [CrossRef]

- Perez, C.; Jog, A.; Kwon, H.; Gall, D.; Asheghi, M.; Kumar, S.; Park, W.; Goodson, K.E. Dominant energy carrier transitions and thermal anisotropy in epitaxial iridium thin films. Adv. Funct. Mater. 2022, 32, 2207781. [Google Scholar] [CrossRef]

- Milosevic, E.; Kerdsongpanya, S.; Zangiabadi, A.; Barmak, K.; Coffey, K.R.; Gall, D. Resistivity size effect in epitaxial Ru(0001) layers. J. Appl. Phys. 2018, 124, 165105. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Zhang, L.; Wen, X.; Jog, A.; Kisslinger, K.; Gao, L.; Shi, J.; Gall, D.; Washington, M.A.; Wang, G.-C.; et al. Ultrathin ruthenium films on graphene buffered SiO2 via Quasi Van der Waals Epitaxy. ACS Appl. Electron. Mater. 2022, 4, 5775–5788. [Google Scholar] [CrossRef]

- Barmak, K.; Ezzat, S.; Gusley, R.; Jog, A.; Kerdsongpanya, S.; Khaniya, A.; Milosevic, E.; Richardson, W.; Sentosun, K.; Zangiabadi, A.; et al. Epitaxial metals for interconnects beyond Cu. J. Vac. Sci. Technol. A 2020, 38, 033406. [Google Scholar] [CrossRef] [Green Version]

- Lanzillo, N.A.; Edelstein, D.C. Reliability and resistance projections for rhodium and iridium interconnects from first-principles. J. Vac. Sci. Technol. B 2022, 40, 052801. [Google Scholar] [CrossRef]

- Pacco, A.; Nakano, T.; Iwasaki, A.; Iwahata, S.; Sanchez, E.A. Controlled ALE-type recess of molybdenum for future logic and memory applications. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Virtual Conference, 6–9 July 2021; pp. 1–3. [Google Scholar]

- Shao, I.; Cotte, J.M.; Haran, B.; Topol, A.W.; Simonyi, E.E.; Cabral, C.; Deligianni, H. An alternative low resistance MOL technology with electroplated rhodium as contact plugs for 32 nm CMOS and beyond. In Proceedings of the 2007 IEEE International Interconnect Technology Conference, Burlingame, CA, USA, 4–6 June 2007; Volume 10598, pp. 102–104. [Google Scholar]

- Zhang, M.; Gall, D. Resistivity scaling in Epitaxial CuAl 2 (001) layers. IEEE Trans. Electron Devices 2022, 69, 5110–5115. [Google Scholar] [CrossRef]

- Zheng, P.; Gall, D. The anisotropic size effect of the electrical resistivity of metal thin films: Tungsten. J. Appl. Phys. 2017, 122, 135301. [Google Scholar] [CrossRef]

- Gall, D. Metals for low-resistivity interconnects. In Proceedings of the 2018 IEEE International Interconnect Technology Conference (IITC), Santa Clara, CA, USA, 4–6 June 2018; pp. 157–159. [Google Scholar]

- Zheng, P.; Ozsdolay, B.D.; Gall, D. Epitaxial growth of tungsten layers on MgO(001). J. Vac. Sci. Technol. A 2015, 33, 061505. [Google Scholar] [CrossRef]

- Purswani, J.M.; Gall, D. Surface morphological evolution during annealing of epitaxial Cu(001) layers. J. Appl. Phys. 2008, 104, 044305. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.Y.; Zhou, T.; Engler, B.J.; Chawla, J.S.; Hull, R.; Gall, D. Surface roughness dependence of the electrical resistivity of W(001) layers. J. Appl. Phys. 2017, 122, 095304. [Google Scholar] [CrossRef] [Green Version]

- Pelliccione, M.; Lu, T.-M. Self-affine surfaces. In Evolution of Thin Film Morphology; Springer: New York, NY, USA, 2008; pp. 29–46. [Google Scholar]

- White, G.K.; Woods, S.B. Electrical and thermal resistivity of the transition elements at low temperatures. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1959, 251, 273–302. [Google Scholar]

- Milosevic, E.; Kerdsongpanya, S.; McGahay, M.E.; Wang, B.; Gall, D. The resistivity size effect in Epitaxial Nb(001) and Nb(011) layers. IEEE Trans. Electron Devices 2019, 66, 3473–3478. [Google Scholar] [CrossRef]

- Chawla, J.S.; Zahid, F.; Guo, H.; Gall, D. Effect of O2 adsorption on electron scattering at Cu(001) surfaces. Appl. Phys. Lett. 2010, 97, 132106. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.; Zhou, T.; Gall, D. Electron channeling in TiO2 coated Cu layers. Semicond. Sci. Technol. 2016, 31, 055005. [Google Scholar] [CrossRef] [Green Version]

- Milosevic, E.; Kerdsongpanya, S.; McGahay, M.E.; Zangiabadi, A.; Barmak, K.; Gall, D. Resistivity scaling and electron surface scattering in epitaxial Co(0001) layers. J. Appl. Phys. 2019, 125, 245105. [Google Scholar] [CrossRef]

- Milosevic, E.; Zheng, P.; Gall, D. Electron scattering at Epitaxial Ni(001) surfaces. IEEE Trans. Electron Devices 2019, 66, 4326–4330. [Google Scholar] [CrossRef]

- Milosevic, E.; Gall, D. Copper interconnects: Surface state engineering to facilitate specular electron scattering. IEEE Trans. Electron Devices 2019, 66, 2692–2698. [Google Scholar] [CrossRef]

- Jog, A.; Milosevic, E.; Zheng, P.; Gall, D. Effect of electronegativity on electron surface scattering in thin metal layers. Appl. Phys. Lett. 2022, 120, 041601. [Google Scholar] [CrossRef]

- Timalsina, Y.P.; Shen, X.; Boruchowitz, G.; Fu, Z.; Qian, G.; Yamaguchi, M.; Wang, G.-C.; Lewis, K.M.; Lu, T.-M. Evidence of enhanced electron-phonon coupling in ultrathin epitaxial copper films. Appl. Phys. Lett. 2013, 103, 191602. [Google Scholar] [CrossRef]

- Kumar, S.; Multunas, C.; Defay, B.; Gall, D.; Sundararaman, R. Ultralow electron-surface scattering in nanoscale metals leveraging Fermi-surface anisotropy. Phys. Rev. Mater. 2022, 6, 085002. [Google Scholar] [CrossRef]

- Chen, L.; Kumar, S.; Yahagi, M.; Ando, D.; Sutou, Y.; Gall, D.; Sundararaman, R.; Koike, J. Interdiffusion reliability and resistivity scaling of intermetallic compounds as advanced interconnect materials. J. Appl. Phys. 2021, 129, 035301. [Google Scholar] [CrossRef]

- Zhou, T.; Gall, D. Resistivity scaling due to electron surface scattering in thin metal layers. Phys. Rev. B 2018, 97, 165406. [Google Scholar] [CrossRef] [Green Version]

- Zhou, T.; Zheng, P.; Pandey, S.C.; Sundararaman, R.; Gall, D. The electrical resistivity of rough thin films: A model based on electron reflection at discrete step edges. J. Appl. Phys. 2018, 123, 155107. [Google Scholar] [CrossRef] [Green Version]

| d (nm) | σ (nm) | ρ (µΩcm) | ||

|---|---|---|---|---|

| 295 K | 77 K | |||

| In Situ | Ex Situ | |||

| Mo(001) | ||||

| 3.9 ± 0.2 | - | 15.9 ± 0.4 | 17.9 ± 0.5 | 9.17 ± 0.27 |

| 5.3 ± 0.3 | 0.55 | 12.3 ± 0.3 | 14.4 ± 0.2 | 6.04 ± 0.16 |

| 6.4 ± 0.3 | 0.38 | 10.9 ± 0.3 | 11.5 ± 0.2 | 4.18 ± 0.07 |

| 9.8 ± 0.4 | 0.53 | 8.94 ± 0.12 | 9.49 ± 0.22 | 2.74 ± 0.03 |

| 19.7 ± 0.5 | 0.55 | 7.04 ± 0.04 | 7.32 ± 0.08 | 1.56 ± 0.03 |

| 39.3 ± 0.5 | 0.45 | 5.94 ± 0.08 | 6.19 ± 0.04 | 1.08 ± 0.01 |

| 225 ± 3 | - | 5.52 ± 0.03 | 5.65 ± 0.03 | 0.63 ± 0.01 |

| 400 ± 5 | - | 5.25 ± 0.08 | 5.50 ± 0.02 | 0.55 ± 0.02 |

| Mo(011) | ||||

| 5.2 ± 0.3 | 0.67 | 11.5 ± 0.3 | 13.3 ± 0.2 | 4.52 ± 0.12 |

| 6.4 ± 0.2 | - | 10.0 ± 0.2 | 11.1 ± 0.3 | 2.78 ± 0.11 |

| 9.2 ± 0.4 | 0.32 | 8.24 ± 0.12 | 9.15 ± 0.12 | 2.11 ± 0.05 |

| 19.3 ± 0.5 | 0.43 | 6.88 ± 0.11 | 7.16 ± 0.14 | 1.42 ± 0.04 |

| 39.2 ± 0.7 | 0.42 | 5.88 ± 0.02 | 5.99 ± 0.02 | 0.82 ± 0.01 |

| 400 ± 5 | - | 5.31 ± 0.01 | 5.46 ± 0.02 | 0.54 ± 0.02 |

| λ* (nm) | ||||

|---|---|---|---|---|

| Experiment | Mo(001) | Mo(011) | ||

| In situ | Ex situ | In situ | Ex situ | |

| 295 K | 14.4 ± 0.3 | 16.4 ± 0.2 | 11.7 ± 0.3 | 14.8 ± 0.3 |

| 77 K | 143 ± 7 | 153 ± 7 | 86 ± 3 | 106 ± 5 |

| Calculations | Mo(001) | Mo(011) Mo(011) | Mo(111) | |

| [100] | [01] | |||

| 295 K | 12.3 ± 0.1 | 8.7 ± 0.2 | 7.0 ± 0.2 | 12.4 ± 0.1 |

| 77 K | 140 ± 2 | 99 ± 2 | 79 ± 2 | 140 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jog, A.; Zheng, P.; Zhou, T.; Gall, D. Anisotropic Resistivity Size Effect in Epitaxial Mo(001) and Mo(011) Layers. Nanomaterials 2023, 13, 957. https://doi.org/10.3390/nano13060957

Jog A, Zheng P, Zhou T, Gall D. Anisotropic Resistivity Size Effect in Epitaxial Mo(001) and Mo(011) Layers. Nanomaterials. 2023; 13(6):957. https://doi.org/10.3390/nano13060957

Chicago/Turabian StyleJog, Atharv, Pengyuan Zheng, Tianji Zhou, and Daniel Gall. 2023. "Anisotropic Resistivity Size Effect in Epitaxial Mo(001) and Mo(011) Layers" Nanomaterials 13, no. 6: 957. https://doi.org/10.3390/nano13060957