Poly(lactic acid)/Plasticizer/Nano-Silica Ternary Systems: Properties Evolution and Effects on Degradation Rate

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of PLA Based Nanocomposites

- Silica nanoparticles (SiNP) were mixed with plasticizers (compositions are reported in Table 1) and were homogenized by stirring at 85 °C for 10 min, producing high silica content masterbatches;

- The masterbatches and PLA were then melt-mixed in a Plastograph EC (Brabender GmbH & Co.) batch mixer at 170 °C and 60 rpm for 10 min.

2.2. Aging

2.3. Techniques

3. Results and Discussion

3.1. Masterbatches

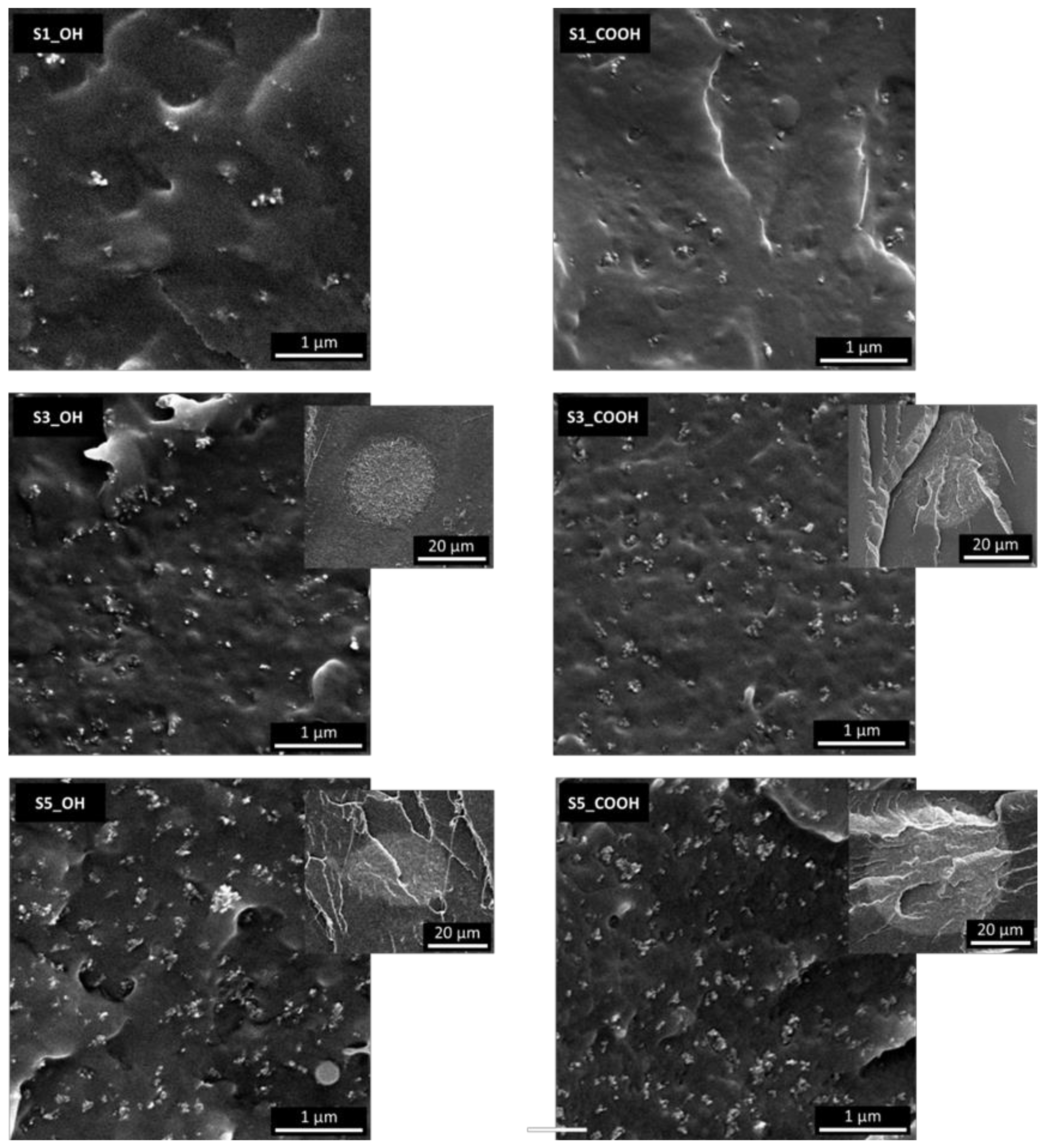

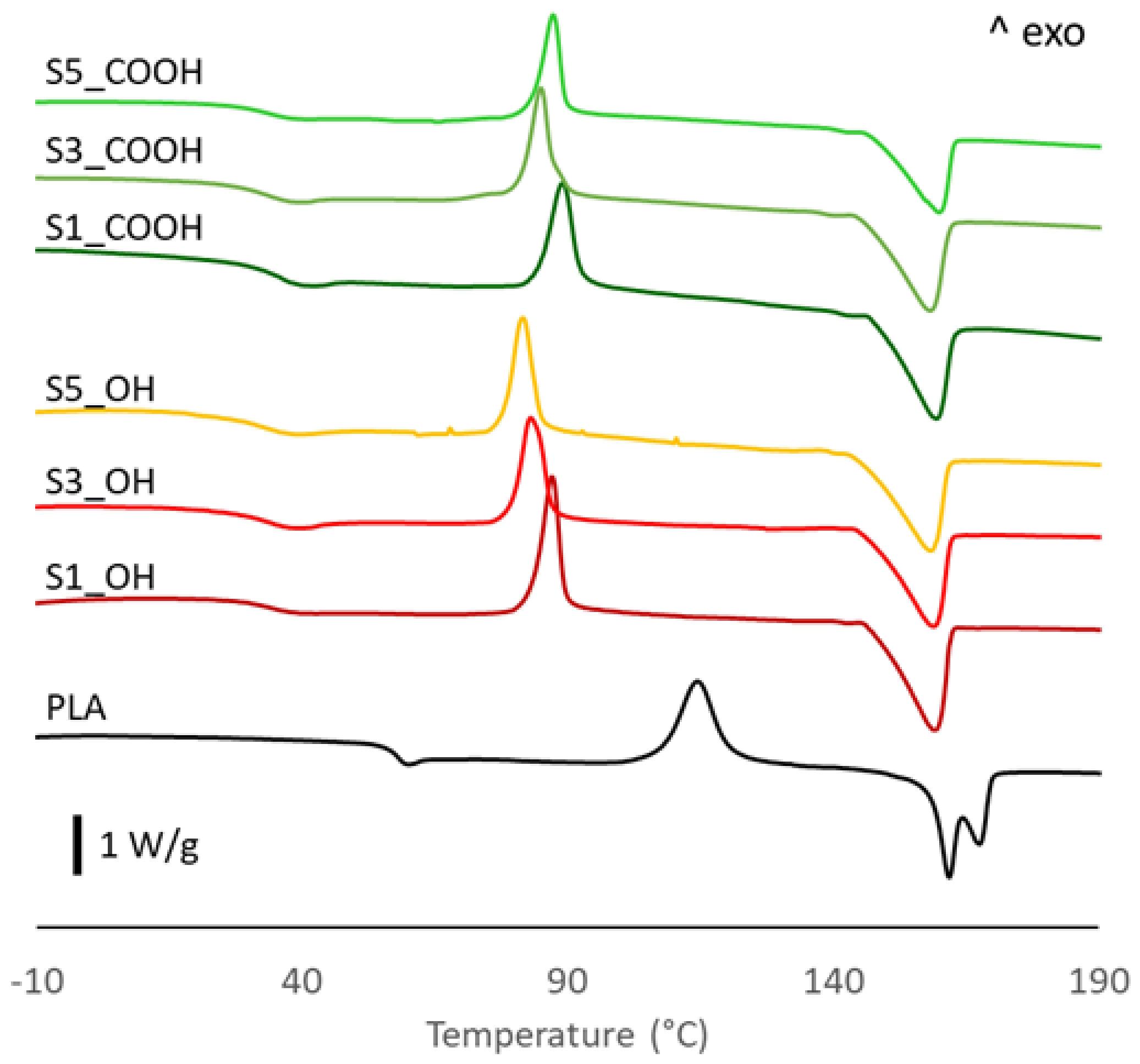

3.2. Unaged Materials

3.3. Aging Effects on Properties

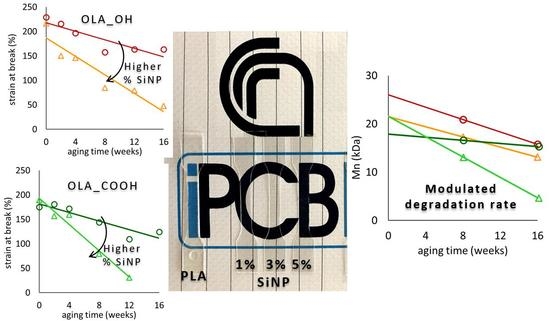

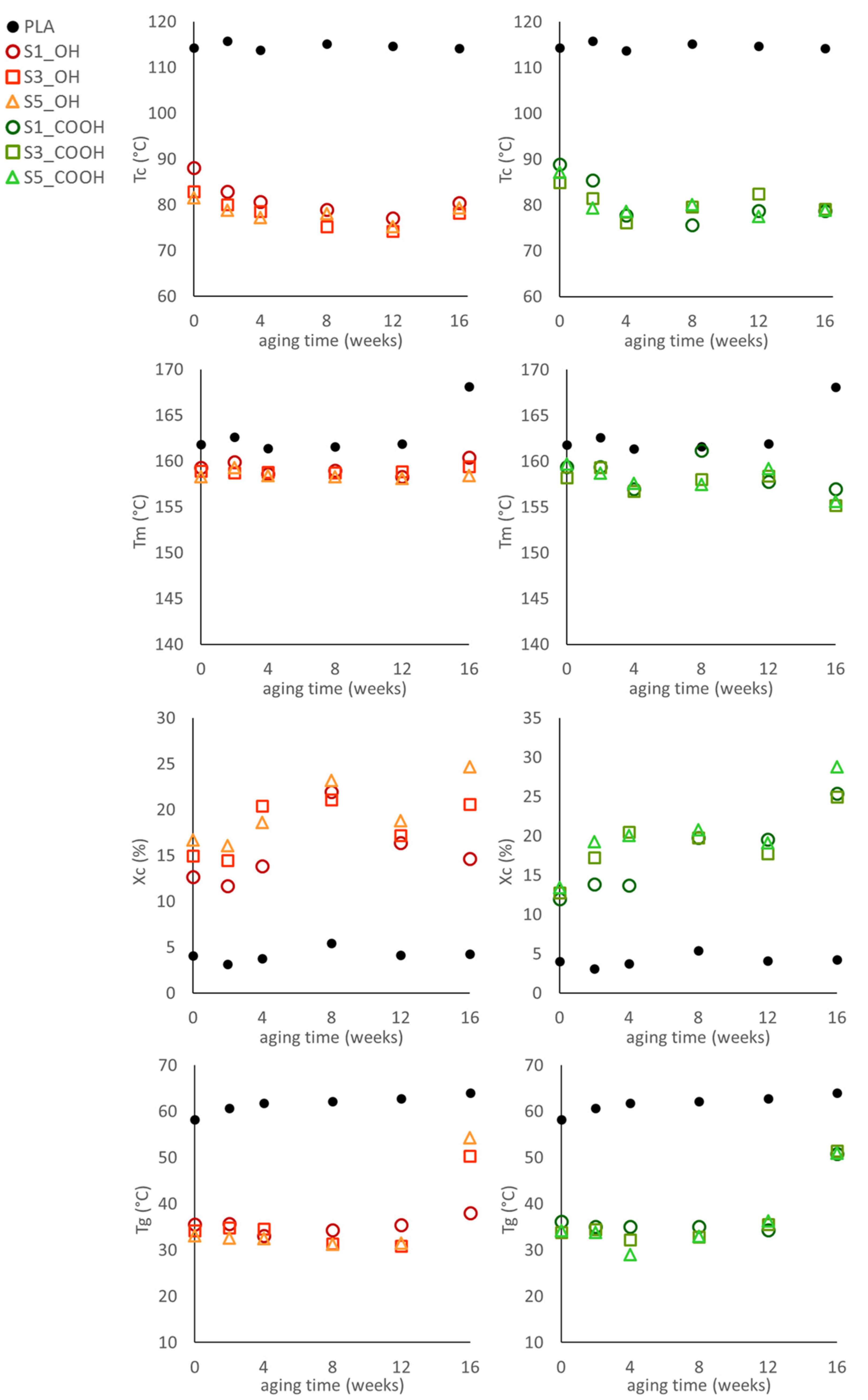

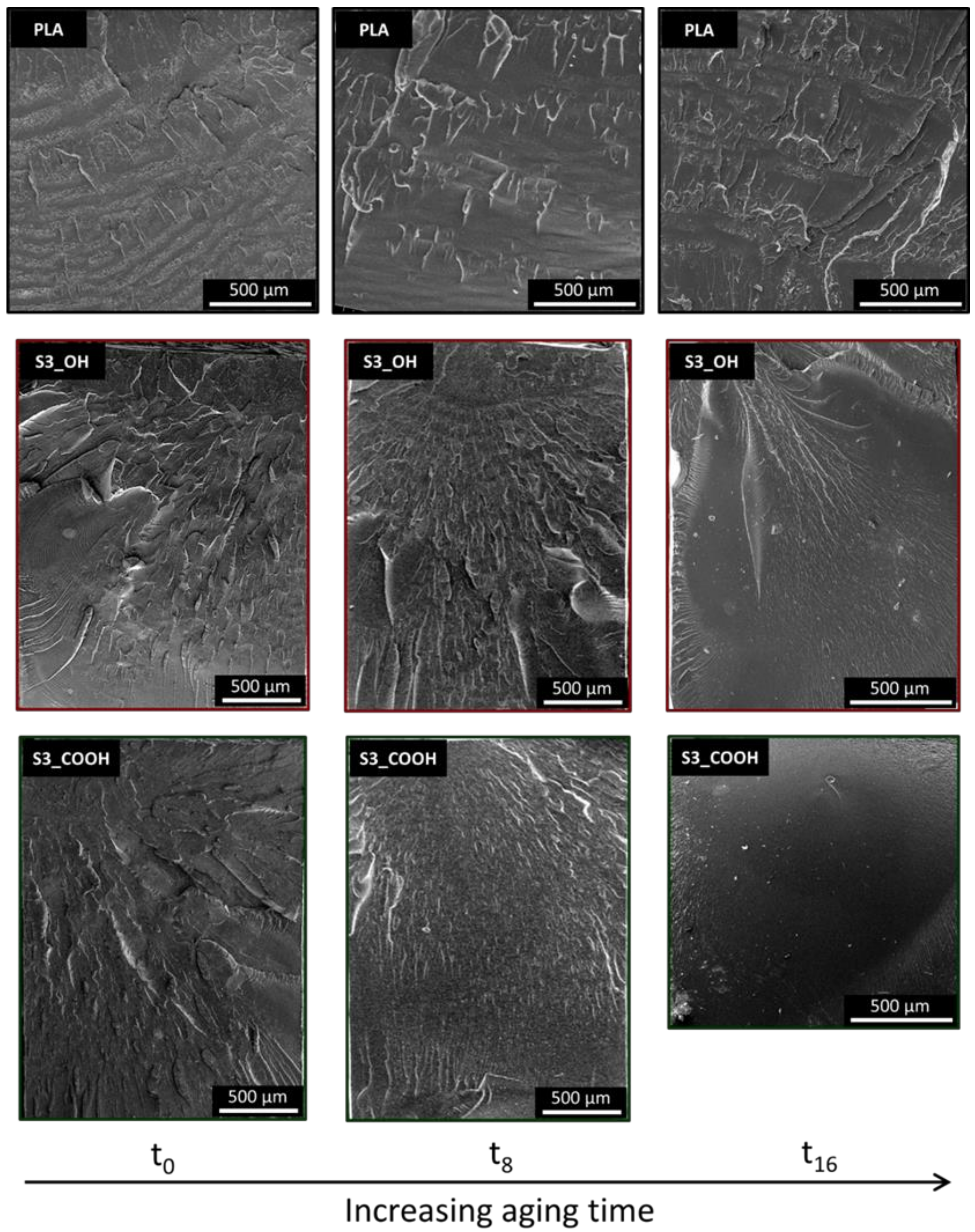

- Thermal analysis suggests the build-up of phase separation, becoming evident for most samples at 16 weeks of aging;

- The stiffness, strength, and elongation of plasticized nanocomposites are influenced by silica in a non-obvious way, with higher silica content resulting in lower stiffness at all aging times;

- The ultimate elongation declines for all samples, and this decline is enhanced by the OLA_COOH plasticizer and by a higher silica content;

- Impact toughness follows a similar trend, with an evolution towards a brittle behavior that is faster for the _COOH series and for high silica content.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiménez, A.; Peltzer, M.; Ruseckaite, R. (Eds.) Poly(lactic acid) Science and Technology; Royal Society of Chemistry: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2020, 1, 76–87. [Google Scholar] [CrossRef]

- Mohan, S.; Panneerselvam, K. A short review on mechanical and barrier properties of polylactic acid-based films. Mater. Today Proc. 2022, 56, 3241–3246. [Google Scholar] [CrossRef]

- Li, G.; Zhao, M.; Xu, F.; Yang, B.; Li, X.; Meng, X.; Teng, L.; Sun, F.; Li, Y. Synthesis and Biological Application of Polylactic Acid. Molecules 2020, 25, 5023. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Zengwen, C.; Pan, H.; Chen, Y.; Bian, J.; Han, L.; Zhang, H.; Dong, L.; Yang, Y. Transform poly (lactic acid) packaging film from brittleness to toughness using traditional industrial equipments. Polymer 2019, 180, 121728. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(lactic acid): Plasticization and properties of biodegradable multiphase systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Czogała, J.; Pankalla, E.; Turczyn, R. Recent Attempts in the Design of Efficient PVC Plasticizers with Reduced Migration. Materials 2021, 14, 844. [Google Scholar] [CrossRef] [PubMed]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Zaferani, S.H. Introduction of polymer-based nanocomposites. In Polymer-Based Nanocomposites for Energy and Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–25. [Google Scholar] [CrossRef]

- Avolio, R.; Gentile, G.; Avella, M.; Carfagna, C.; Errico, M.E. Polymer–filler interactions in PET/CaCO3 nanocomposites: Chain ordering at the interface and physical properties. Eur. Polym. J. 2013, 49, 419–427. [Google Scholar] [CrossRef]

- De Nicola, A.; Avolio, R.; Della Monica, F.; Gentile, G.; Cocca, M.; Capacchione, C.; Errico, M.E.; Milano, G. Rational design of nanoparticle/monomer interfaces: A combined computational and experimental study of in situ polymerization of silica based nanocomposites. RSC Adv. 2015, 5, 71336–71340. [Google Scholar] [CrossRef]

- Avolio, R.; Castaldo, R.; Avella, M.; Cocca, M.; Gentile, G.; Fiori, S.; Errico, M.E. PLA-based plasticized nanocomposites: Effect of polymer/plasticizer/filler interactions on the time evolution of properties. Compos. Part B Eng. 2018, 152, 267–274. [Google Scholar] [CrossRef]

- Valentina, I.; Haroutioun, A.; Fabrice, L.; Vincent, V.; Roberto, P. Poly(Lactic Acid)-Based Nanobiocomposites with Modulated Degradation Rates. Materials 2018, 11, 1943. [Google Scholar] [CrossRef] [PubMed]

- Paul, U.C.; Fragouli, D.; Bayer, I.S.; Zych, A.; Athanassiou, A. Effect of Green Plasticizer on the Performance of Microcrystalline Cellulose/Polylactic Acid Biocomposites. ACS Appl. Polym. Mater. 2021, 3, 3071–3081. [Google Scholar] [CrossRef]

- Kaseem, M.; Ur Rehman, Z.; Hossain, S.; Singh, A.K.; Dikici, B. A Review on Synthesis, Properties, and Applications of Polylactic Acid/Silica Composites. Polymers 2021, 13, 3036. [Google Scholar] [CrossRef]

- Dorigato, A.; Sebastiani, M.; Pegoretti, A.; Fambri, L. Effect of Silica Nanoparticles on the Mechanical Performances of Poly(Lactic Acid). J. Polym. Environ. 2012, 20, 713–725. [Google Scholar] [CrossRef]

- Lv, H.; Song, S.; Sun, S.; Ren, L.; Zhang, H. Enhanced properties of poly(lactic acid) with silica nanoparticles. Polym. Adv. Technol. 2016, 27, 1156–1163. [Google Scholar] [CrossRef]

- Sepulveda, J.; Villegas, C.; Torres, A.; Vargas, E.; Rodriguez, F.; Baltazar, S.; Prada, A.; Rojas, A.; Romero, J.; Faba, S.; et al. Effect of functionalized silica nanoparticles on the mass transfer process in active PLA nanocomposite films obtained by supercritical impregnation for sustainable food packaging. J. Supercrit. Fluids 2020, 161, 104844. [Google Scholar] [CrossRef]

- Aragón-Gutierrez, A.; Arrieta, M.P.; López-González, M.; Fernández-García, M.; López, D. Hybrid Biocomposites Based on Poly(Lactic Acid) and Silica Aerogel for Food Packaging Applications. Materials 2020, 13, 4910. [Google Scholar] [CrossRef]

- Lai, S.-M.; Chen, J.-R.; Han, J.-L.; Yu, Y.-F.; Lai, H.-Y. Preparation and properties of melt-blended polylactic acid/polyethylene glycol-modified silica nanocomposites. J. Appl. Polym. Sci. 2013, 130, 496–503. [Google Scholar] [CrossRef]

- Avolio, R.; Castaldo, R.; Gentile, G.; Ambrogi, V.; Fiori, S.; Avella, M.; Cocca, M.; Errico, M.E. Plasticization of poly(lactic acid) through blending with oligomers of lactic acid: Effect of the physical aging on properties. Eur. Polym. J. 2015, 66, 533–542. [Google Scholar] [CrossRef]

- Avolio, R.; Gentile, G.; Avella, M.; Capitani, D.; Errico, M.E. Synthesis and characterization of poly(methylmethacrylate)/silica nanocomposites: Study of the interphase by solid-state NMR and structure/properties relationships. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 5618–5629. [Google Scholar] [CrossRef]

- Avolio, R.; Gentile, G.; Cocca, M.; Avella, M.; Errico, M.E. Role of silica nanoparticles on network formation and properties in thermoset polycarbonate based nanocomposites. Polym. Test. 2017, 60, 388–395. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid-Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Kawaguchi, M. Dispersion stabilities and rheological properties of fumed silica suspensions. J. Dispers. Sci. Technol. 2017, 38, 642–660. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Klonos, P.A.; Kyritsis, A.; Tziolas, A.; Avgeropoulos, A.; Papageorgiou, G.Z.; Bikiaris, D.N. Interfacial interactions, crystallization and molecular mobility in nanocomposites of Poly(lactic acid) filled with new hybrid inclusions based on graphene oxide and silica nanoparticles. Polymer 2019, 166, 1–12. [Google Scholar] [CrossRef]

- Prapruddivongs, C.; Apichartsitporn, M.; Wongpreedee, T. Effect of silica resources on the biodegradation behavior of poly (lactic acid) and chemical crosslinked poly (lactic acid) composites. Polym. Test. 2018, 71, 87–94. [Google Scholar] [CrossRef]

- Hakim, R.H.; Cailloux, J.; Santana, O.O.; Bou, J.; Sánchez-Soto, M.; Odent, J.; Raquez, J.M.; Dubois, P.; Carrasco, F.; Maspoch, M.L. PLA/SiO 2 composites: Influence of the filler modifications on the morphology, crystallization behavior, and mechanical properties. J. Appl. Polym. Sci. 2017, 134, 45367. [Google Scholar] [CrossRef]

- Gracia-Fernández, C.A.; Gómez-Barreiro, S.; López-Beceiro, J.; Naya, S.; Artiaga, R. New approach to the double melting peak of poly(l-lactic acid) observed by DSC. J. Mater. Res. 2012, 27, 1379–1382. [Google Scholar] [CrossRef]

- Cocca, M.; Di Lorenzo, M.L.; Malinconico, M.; Frezza, V. Influence of crystal polymorphism on mechanical and barrier properties of poly(l-lactic acid). Eur. Polym. J. 2011, 47, 1073–1080. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Cocca, M.; Malinconico, M. Crystal polymorphism of poly(l-lactic acid) and its influence on thermal properties. Thermochim. Acta 2011, 522, 110–117. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E. Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 2005, 46, 10290–10300. [Google Scholar] [CrossRef]

- Suksut, B.; Deeprasertkul, C. Effect of Nucleating Agents on Physical Properties of Poly(lactic acid) and Its Blend with Natural Rubber. J. Polym. Environ. 2011, 19, 288–296. [Google Scholar] [CrossRef]

- Liang, J.-Z.; Zhou, L.; Tang, C.-Y.; Tsui, C.-P. Crystalline properties of poly(L-lactic acid) composites filled with nanometer calcium carbonate. Compos. Part B Eng. 2013, 45, 1646–1650. [Google Scholar] [CrossRef]

- Tian, J.; Cao, Z.; Qian, S.; Xia, Y.; Zhang, J.; Kong, Y.; Sheng, K.; Zhang, Y.; Wan, Y.; Takahashi, J. Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose. Nanotechnol. Rev. 2022, 11, 2469–2482. [Google Scholar] [CrossRef]

- Gorrasi, G.; Pantani, R. Hydrolysis and Biodegradation of Poly(lactic acid). Rom. Rep. Phys. 2017, 54, 119–151. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, L.; Chen, J.; Jiang, Z.; Zhang, Y.; Wang, W.; Chen, H.; Shen, J.; Zhong, J.; Meng, S.; et al. Surface acidity of colloidal silica and its correlation with sapphire surface polishing. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 651, 129718. [Google Scholar] [CrossRef]

- De Falco, F.; Avolio, R.; Errico, M.E.; Di Pace, E.; Avella, M.; Cocca, M.; Gentile, G. Comparison of biodegradable polyesters degradation behavior in sand. J. Hazard. Mater. 2021, 416, 126231. [Google Scholar] [CrossRef] [PubMed]

| Masterbatch | OLA_OH (wt%) | OLA_COOH (wt%) | SiNP (wt%) |

|---|---|---|---|

| OLA_OH_1S | 95.2 | 4.8 | |

| OLA_OH_3S | 86.6 | 13.4 | |

| OLA_OH_5S | 79.2 | 20.8 | |

| OLA_COOH_1S | 95.2 | 4.8 | |

| OLA_COOH_3S | 86.6 | 13.4 | |

| OLA_COOH_3S | 79.2 | 20.8 |

| SiNP (wt%) | OLA_OH (wt%) | OLA_COOH (wt%) | Tg (°C) | Tc (°C) | Tm1-Tm2 (°C) | Xc (%) | |

|---|---|---|---|---|---|---|---|

| PLA | - | - | - | 58 | 114 | 162–168 | 4 |

| S1_OH | 1 | 20 | - | 36 | 88 | 159 | 13 |

| S3_OH | 3 | 20 | - | 34 | 83 | 159 | 15 |

| S5_OH | 5 | 20 | - | 33 | 82 | 159 | 17 |

| S1_COOH | 1 | - | 20 | 36 | 89 | 159 | 12 |

| S3_COOH | 3 | - | 20 | 34 | 85 | 158 | 13 |

| S5_COOH | 5 | - | 20 | 34 | 87 | 160 | 13 |

| σy (MPa) | E (MPa) | εR (%) | |

|---|---|---|---|

| PLA | 48 ± 3 | 2490 ± 90 | 6 ± 2 |

| S1_OH | 23 ± 2 | 1360 ± 60 | 230 ± 20 |

| S3_OH | 18 ± 1 | 1170 ± 60 | 240 ±20 |

| S5_OH | 15 ± 1 | 1150 ± 60 | 220 ± 30 |

| S1_COOH | 32 ± 1 | 1660 ± 60 | 150 ± 10 |

| S3_COOH | 28 ± 1 | 1620 ± 40 | 200 ± 20 |

| S5_COOH | 21 ± 1 | 1320 ± 60 | 190 ± 20 |

| ta | Molecular Weight (kDa) | ||||||

|---|---|---|---|---|---|---|---|

| S1_OH | S3_OH | S5_OH | S1_COOH | S3_COOH | S5_COOH | ||

| 8 | Mw Mn | 62.9 20.9 | 44.9 19.2 | 32.7 17.3 | 38.2 17.2 | 31.5 16.5 | 26.1 13.7 |

| 16 | Mw Mn | 48.6 15.8 | 45.6 18.2 | 25.1 13.1 | 37.3 15.9 | 14.0 5.9 | 10.6 5.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capuano, R.; Avolio, R.; Castaldo, R.; Cocca, M.; Dal Poggetto, G.; Gentile, G.; Errico, M.E. Poly(lactic acid)/Plasticizer/Nano-Silica Ternary Systems: Properties Evolution and Effects on Degradation Rate. Nanomaterials 2023, 13, 1284. https://doi.org/10.3390/nano13071284

Capuano R, Avolio R, Castaldo R, Cocca M, Dal Poggetto G, Gentile G, Errico ME. Poly(lactic acid)/Plasticizer/Nano-Silica Ternary Systems: Properties Evolution and Effects on Degradation Rate. Nanomaterials. 2023; 13(7):1284. https://doi.org/10.3390/nano13071284

Chicago/Turabian StyleCapuano, Roberta, Roberto Avolio, Rachele Castaldo, Mariacristina Cocca, Giovanni Dal Poggetto, Gennaro Gentile, and Maria Emanuela Errico. 2023. "Poly(lactic acid)/Plasticizer/Nano-Silica Ternary Systems: Properties Evolution and Effects on Degradation Rate" Nanomaterials 13, no. 7: 1284. https://doi.org/10.3390/nano13071284

APA StyleCapuano, R., Avolio, R., Castaldo, R., Cocca, M., Dal Poggetto, G., Gentile, G., & Errico, M. E. (2023). Poly(lactic acid)/Plasticizer/Nano-Silica Ternary Systems: Properties Evolution and Effects on Degradation Rate. Nanomaterials, 13(7), 1284. https://doi.org/10.3390/nano13071284