Thermodynamic Analysis of a Flat Plate Solar Collector with Different Hybrid Nanofluids as Working Medium—A Thermal Modelling Approach

Abstract

:1. Introduction

2. Theoretical Background

2.1. Thermal Modeling

2.2. Entropy Analysis

- ➢

- The system is a steady flow and steady-state conditions.

- ➢

- No chemical reaction was presents.

- ➢

- Changes of potential and kinetic energy is ignored.

- ➢

- Solar irradiation intensity, IT = 1000 W/m2, and the absorbed power density by the solar panel, S = IT(τα) was considered.

- ➢

- The sun is considered as a reservoir of energy. As stated by Takashima [36], the exergy flow rate in the global solar radiation is equal to the solar flux

- ➢

- The thermo-physical properties of the nanofluids, both entering and leaving from the collector, are constant.

- ➢

- Work transfer from the system and heat transfer to the system are positive.

- ➢

- Loss coefficient is only considered for the entrance effect.

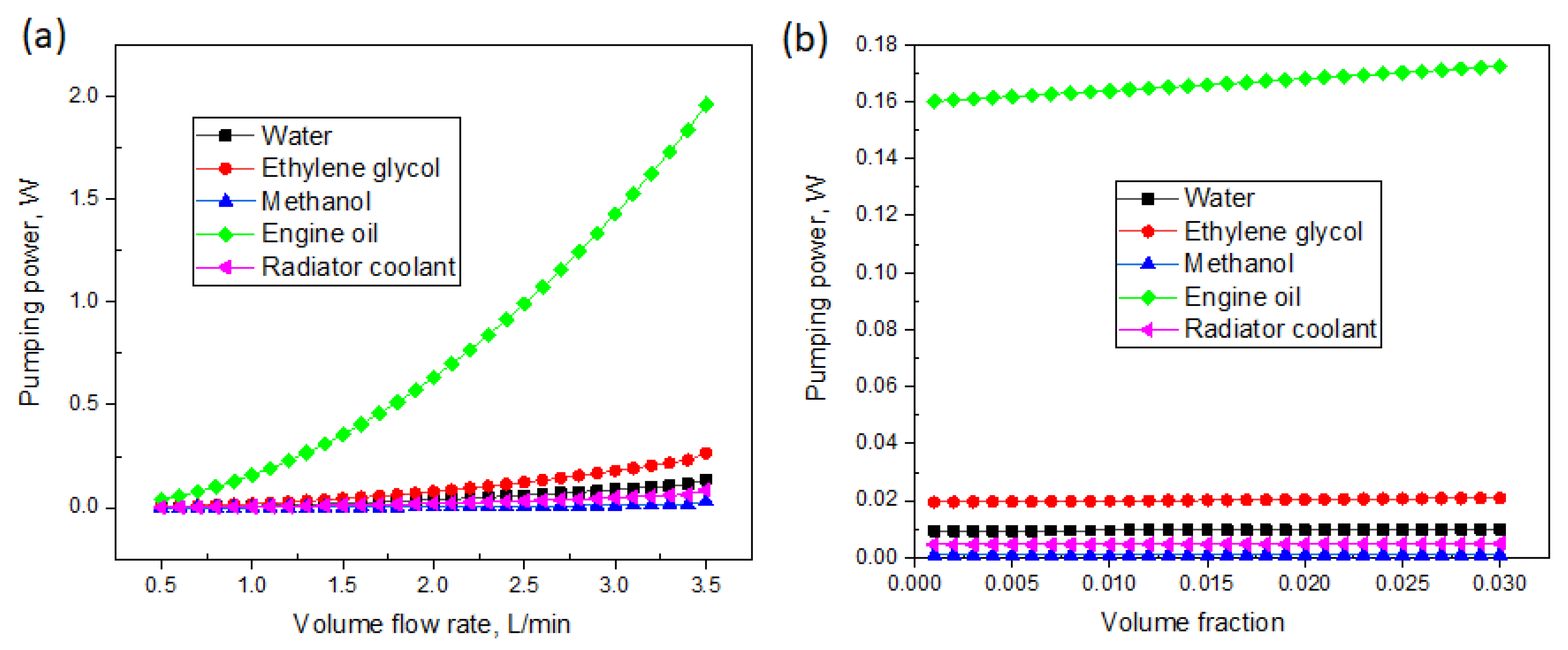

2.3. Pumping Power

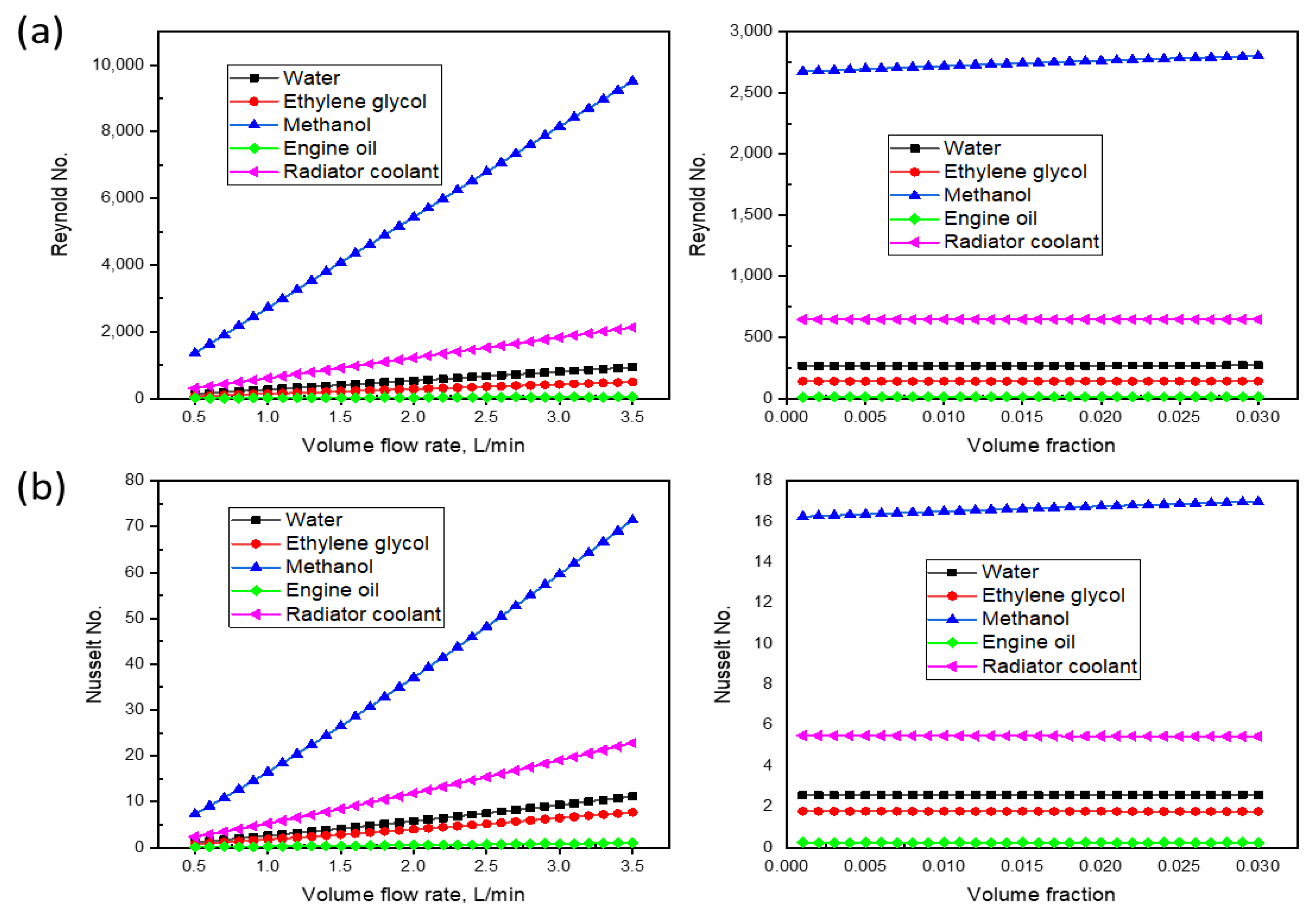

2.4. Convective Heat Transfer

2.5. Thermophysical Properties of Hybrid Nanofluids

3. Input Data and Thermal Modelling Process

3.1. Input Data

| Parameters of Collector | Value |

|---|---|

| Type | Black paint flat plate |

| Glazing | Single glass |

| Agent fluids | Water, Methanol, Radiator coolant, Ethylene glycol, Engine oil |

| Absorption area (m2) | 1.44 |

| Wind speed (m/s) | 20 |

| Collector tilt (°) | 20 |

| Fluid inlet and ambient temperature (K) | 300 |

| Apparent sun temperature (K) | 4350 |

| Optical efficiency | 84% |

| Emissivity of the absorber plate | 0.95 |

| Emissivity of the covers | 0.90 |

| Glass thickness (mm) | 4 |

| Insulation thermal conductivity (W/m∙K) | 0.06 |

3.2. Solution Procedure

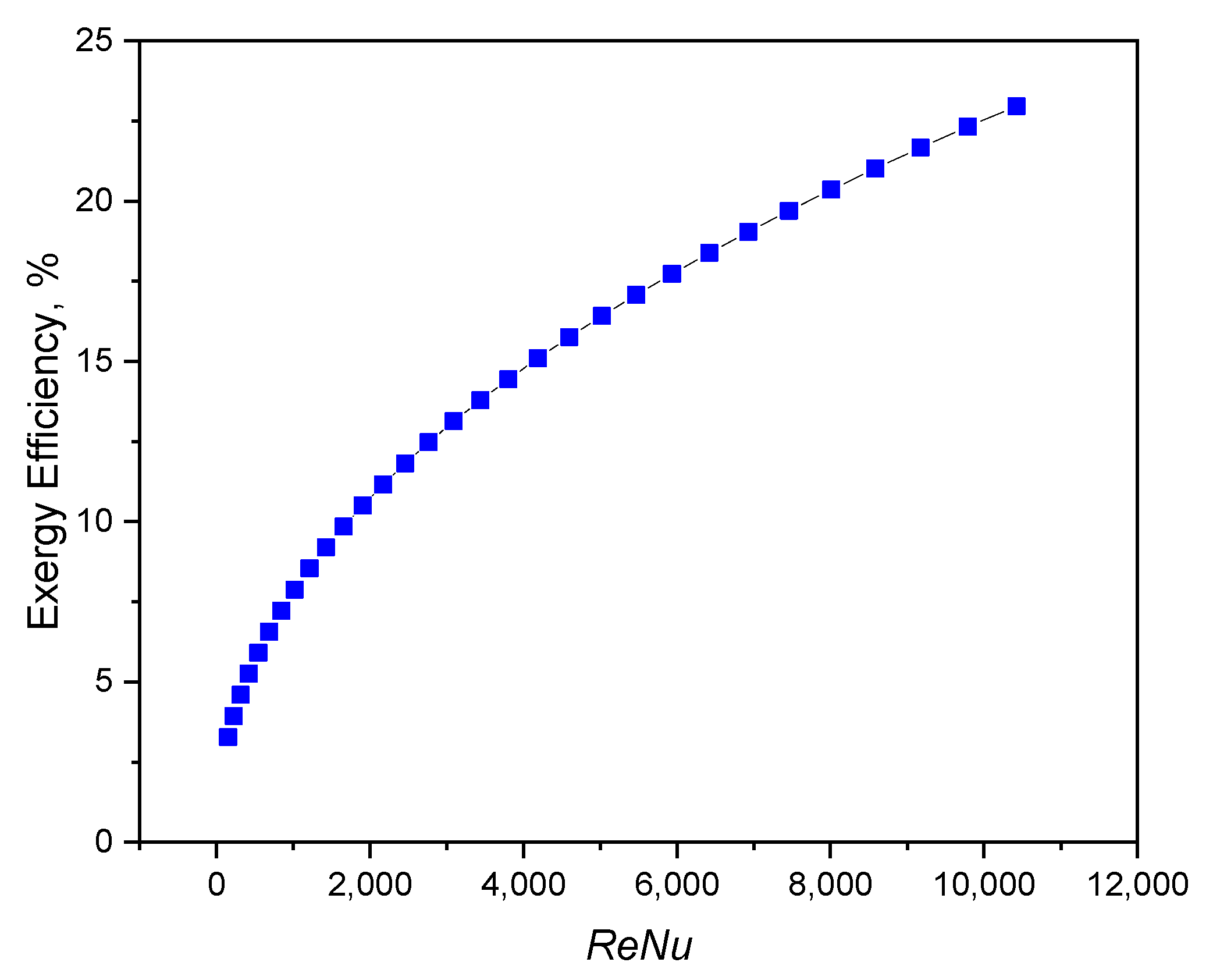

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ac | collector absorption area (m2) |

| Cp | specific heat (J/kg.K) |

| IT | incident solar energy per unit area (W/m2) |

| k | thermal conductivity (W/m.K) |

| ṁ | mass flow rate (kg/s) |

| h | heat transfer coefficient (W/m2k) |

| T | temperature (K) |

| V | mean flow velocity (m/s) |

| FPSC | flat plate solar collector |

| MWCNT | multiwalled carbon nanotube |

| EG | ethylene glycol |

| τ | transmittance |

| α | absorptance |

| ø | nanoparticles volume fraction (%) |

| ρ | density (kg/m3) |

| µ | viscosity (Pa.s) |

| Subscript | |

| a | ambient |

| bf | base fluid |

| f, in | inlet fluid |

| f, out | outlet fluid |

| np | nanoparticles |

| hnf | hybrid nanofluid |

References

- Eltaweel, M.; Abdel-Rehim, A.A. Energy and exergy analysis of a thermosiphon and forced-circulation flat-plate solar collector using MWCNT/Water nanofluid. Case Stud. Therm. Eng. 2019, 14, 100416. [Google Scholar] [CrossRef]

- Kumar, K.H.; Daabo, A.M.; Karmakar, M.K.; Hirani, H. Solar parabolic dish collector for concentrated solar thermal systems: A review and recommendations. Environ. Sci. Pollut. Res. 2022, 29, 32335–32367. [Google Scholar] [CrossRef] [PubMed]

- Sansaniwal, S.K.; Sharma, V.; Mathur, J. Energy and exergy analyses of various typical solar energy applications: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 1576–1601. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W. Energetic, exergetic, economic, and environmental analysis of microchannel membrane-based absorption refrigeration system driven by various energy sources. Energy 2022, 239, 122193. [Google Scholar] [CrossRef]

- NematpourKeshteli, A.; Iasiello, M.; Langella, G.; Bianco, N. Enhancing PCMs thermal conductivity: A comparison among porous metal foams, nanoparticles and finned surfaces in triplex tube heat exchangers. Appl. Therm. Eng. 2022, 212, 118623. [Google Scholar] [CrossRef]

- Sharma, H.K.; Kumar, S.; Kumar, S.; Verma, S.K. Performance investigation of flat plate solar collector with nanoparticle enhanced integrated thermal energy storage system. J. Energy Storage 2022, 55, 105681. [Google Scholar] [CrossRef]

- Czaplicka, N.; Grzegórska, A.; Wajs, J.; Sobczak, J.; Rogala, A. Promising nanoparticle-based heat transfer fluids—Environmental and techno-economic analysis compared to conventional fluids. Int. J. Mol. Sci. 2021, 22, 9201. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Lab: Lemont, IL, USA, 1995. [Google Scholar]

- Du, M.; Tang, G. Optical property of nanofluids with particle agglomeration. Sol. Energy 2015, 122, 864–872. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A. Energy and exergy analysis for stationary solar collectors using nanofluids: A review. Int. J. Energy Res. 2021, 45, 3643–3670. [Google Scholar] [CrossRef]

- Bejan, A. A study of entropy generation in fundamental convective heat transfer. J. Heat Transf. 1979, 101, 718–725. [Google Scholar] [CrossRef]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Henein, S.M.; Abdel-Rehim, A.A. The performance response of a heat pipe evacuated tube solar collector using MgO/MWCNT hybrid nanofluid as a working fluid. Case Stud. Therm. Eng. 2022, 33, 101957. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, S.; Kumar, S.; Dilbaghi, N.; Said, Z. Up to date review on the synthesis and thermophysical properties of hybrid nanofluids. J. Clean. Prod. 2018, 190, 169–192. [Google Scholar] [CrossRef]

- Babar, H.; Ali, H.M. Towards hybrid nanofluids: Preparation, thermophysical properties, applications, and challenges. J. Mol. Liq. 2019, 281, 598–633. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Analytical models for the computation and optimization of single and double glazing flat plate solar collectors with normal and small air gap spacing. Appl. Energy 2013, 104, 392–399. [Google Scholar] [CrossRef]

- Kuo, C.-F.J.; Su, T.-L.; Jhang, P.-R.; Huang, C.-Y.; Chiu, C.-H. Using the Taguchi method and grey relational analysis to optimize the flat-plate collector process with multiple quality characteristics in solar energy collector manufacturing. Energy 2011, 36, 3554–3562. [Google Scholar]

- Otanicar, T.P.; Phelan, P.E.; Golden, J.S. Optical properties of liquids for direct absorption solar thermal energy systems. Sol. Energy 2009, 83, 969–977. [Google Scholar] [CrossRef]

- Alim, M.A.; Abdin, Z.; Saidur, R.; Hepbasli, A.; Khairul, M.A.; Rahim, N.A. Analyses of entropy generation and pressure drop for a conventional flat plate solar collector using different types of metal oxide nanofluids. Energy Build. 2013, 66, 289–296. [Google Scholar] [CrossRef]

- Lu, L.; Liu, Z.-H.; Xiao, H.-S. Thermal performance of an open thermosyphon using nanofluids for high-temperature evacuated tubular solar collectors: Part 1: Indoor experiment. Sol. Energy 2011, 85, 379–387. [Google Scholar] [CrossRef]

- Yousefi, T.; Veysi, F.; Shojaeizadeh, E.; Zinadini, S. An experimental investigation on the effect of Al2O3–H2O nanofluid on the efficiency of flat-plate solar collectors. Renew. Energy 2012, 39, 293–298. [Google Scholar] [CrossRef]

- Saidur, R.; Meng, T.; Said, Z.; Hasanuzzaman, M.; Kamyar, A. Evaluation of the effect of nanofluid-based absorbers on direct solar collector. Int. J. Heat Mass Transf. 2012, 55, 5899–5907. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Ghosh, P.; Sarkar, J. Solar water heating using nanofluids—A comprehensive overview and environmental impact analysis. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 221–224. [Google Scholar]

- Suman, S.; Khan, M.K.; Pathak, M. Performance enhancement of solar collectors—A review. Renew. Sustain. Energy Rev. 2015, 49, 192–210. [Google Scholar] [CrossRef] [Green Version]

- Zeng, J.; Xuan, Y. Enhanced solar thermal conversion and thermal conduction of MWCNT-SiO2/Ag binary nanofluids. Appl. Energy 2018, 212, 809–819. [Google Scholar] [CrossRef]

- Alrowaili, Z.; Ezzeldien, M.; Shaaalan, N.M.; Hussein, E.; Sharafeldin, M. Investigation of the effect of hybrid CuO-Cu/water nanofluid on the solar thermal energy storage system. J. Energy Storage 2022, 50, 104675. [Google Scholar] [CrossRef]

- Cui, F.; Liu, F.; Tong, Y.; Wang, S.; Guo, W.; Han, T.; Qiu, X. Energy and exergy assessment of evacuated tube solar collector using water, Fe3O4 nanofluid and Fe3O4/MWCNT hybrid nanofluid. Process Saf. Environ. Prot. 2022, 163, 236–243. [Google Scholar] [CrossRef]

- Farajzadeh, E.; Movahed, S.; Hosseini, R. Experimental and numerical investigations on the effect of Al2O3/TiO2H2O nanofluids on thermal efficiency of the flat plate solar collector. Renew. Energy 2018, 118, 122–130. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Tiwari, S.; Chauhan, D.S. Performance analysis of hybrid nanofluids in flat plate solar collector as an advanced working fluid. Sol. Energy 2018, 167, 231–241. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Chauhan, D.S. Performance augmentation in flat plate solar collector using MgO/water nanofluid. Energy Convers. Manag. 2016, 124, 607–617. [Google Scholar] [CrossRef]

- Geovo, L.; Ri, G.D.; Kumar, R.; Verma, S.K.; Roberts, J.J.; Mendiburu, A.Z. Theoretical model for flat plate solar collectors operating with nanofluids: Case study for Porto Alegre, Brazil. Energy 2023, 263, 125698. [Google Scholar] [CrossRef]

- Sint, N.K.C.; Choudhury, I.A.; Masjuki, H.H.; Aoyama, H. Theoretical analysis to determine the efficiency of a CuO-water nanofluid based-flat plate solar collector for domestic solar water heating system in Myanmar. Sol. Energy 2017, 155, 608–619. [Google Scholar] [CrossRef]

- Stalin, P.M.J.; Arjunan, T.V.; Almeshaal, M.; Murugesan, P.; Prabu, B.; Kumar, P.M. Utilization of zinc-ferrite/water hybrid nanofluids on thermal performance of a flat plate solar collector—A thermal modeling approach. Environ. Sci. Pollut. Res. 2022, 29, 78848–78861. [Google Scholar] [CrossRef] [PubMed]

- Mostafizur, R.M.; Rasul, M.G.; Nabi, M.N.; Saianand, G. Properties of Al2O3-MWCNT/radiator coolant hybrid nanofluid for solar energy applications. Energy Rep. 2022, 8, 582–591. [Google Scholar] [CrossRef]

- Hajabdollahi, Z.; Hajabdollahi, H. Thermo-economic modeling and multi-objective optimization of solar water heater using flat plate collectors. Sol. Energy 2017, 155, 191–202. [Google Scholar] [CrossRef]

- Takashima, T.; Tanaka, T.; Doi, T.; Kamoshida, J.; Tani, T.; Horigome, T. New proposal for photovoltaic-thermal solar energy utilization method. Sol. Energy 1994, 52, 241–245. [Google Scholar] [CrossRef]

- Ucar, A.; Inallı, M. Thermal and exergy analysis of solar air collectors with passive augmentation techniques. Int. Commun. Heat Mass Transf. 2006, 33, 1281–1290. [Google Scholar] [CrossRef]

- Esen, H. Experimental energy and exergy analysis of a double-flow solar air heater having different obstacles on absorber plates. Build. Environ. 2008, 43, 1046–1054. [Google Scholar] [CrossRef]

- Garg, H.; Agarwal, R. Some aspects of a PV/T collector/forced circulation flat plate solar water heater with solar cells. Energy Convers. Manag. 1995, 36, 87–99. [Google Scholar] [CrossRef]

- White, F. Fluid Mechanics, 5th ed.; McGraw-Hill Book Company: Boston, MA, USA, 2003. [Google Scholar]

- Kahani, M.; Heris, S.Z.; Mousavi, S.M. Effects of curvature ratio and coil pitch spacing on heat transfer performance of Al2O3/water nanofluid laminar flow through helical coils. J. Dispers. Sci. Technol. 2013, 34, 1704–1712. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Investigation on convective heat transfer and flow features of nanofluids. J. Heat Transf. 2003, 125, 151–155. [Google Scholar] [CrossRef] [Green Version]

- Owhaib, W.; Palm, B. Experimental investigation of single-phase convective heat transfer in circular microchannels. Exp. Therm. Fluid Sci. 2004, 28, 105–110. [Google Scholar] [CrossRef]

- Takabi, B.; Salehi, S. Augmentation of the heat transfer performance of a sinusoidal corrugated enclosure by employing hybrid nanofluid. Adv. Mech. Eng. 2014, 6, 147059. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Sustain. Energy Technol. Assess. 2018, 26, 105–115. [Google Scholar] [CrossRef]

- Rasih, R.A.; Sidik, N.A.C.; Samion, S. Recent progress on concentrating direct absorption solar collector using nanofluids: A review. J. Therm. Anal. Calorim. 2019, 137, 903–922. [Google Scholar] [CrossRef]

- Mostafizur, R.; Rasul, M.; Nabi, M.N. Energy and exergy analyses of a flat plate solar collector using various nanofluids: An analytical approach. Energies 2021, 14, 4305. [Google Scholar] [CrossRef]

- Kamyar, A.; Saidur, R.; Hasanuzzaman, M. Application of computational fluid dynamics (CFD) for nanofluids. Int. J. Heat Mass Transf. 2012, 55, 4104–4115. [Google Scholar] [CrossRef]

- Namburu, P.; Kulkarni, D.; Dandekar, A.; Das, D. Experimental investigation of viscosity and specific heat of silicon dioxide nanofluids. Micro Nano Lett. 2007, 2, 67–71. [Google Scholar] [CrossRef]

- Bejan, A. Convection Heat Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Alzahrani, A.K.; Ullah, M.Z.; Alshomrani, A.S.; Gul, T. Hybrid nanofluid flow in a Darcy-Forchheimer permeable medium over a flat plate due to solar radiation. Case Stud. Therm. Eng. 2021, 26, 100955. [Google Scholar] [CrossRef]

- Aghaei, A.; Khorasanizadeh, H.; Sheikhzadeh, G.A. Measurement of the dynamic viscosity of hybrid engine oil -Cuo-MWCNT nanofluid, development of a practical viscosity correlation and utilizing the artificial neural network. Heat Mass Transf. 2018, 54, 151–161. [Google Scholar] [CrossRef]

- Mouli, K.V.V.C.; Sundar, L.S.; Alklaibi, A.M.; Said, Z.; Sharma, K.V.; Punnaiah, V.; Sousa, A.C.M. Exergy efficiency and entropy analysis of MWCNT/Water nanofluid in a thermosyphon flat plate collector. Sustain. Energy Technol. Assess. 2023, 55, 102911. [Google Scholar] [CrossRef]

- Hussein, O.A.; Habib, K.; Muhsan, A.S.; Saidur, R.; Alawi, O.A.; Ibrahim, T.K. Thermal performance enhancement of a flat plate solar collector using hybrid nanofluid. Sol. Energy 2020, 204, 208–222. [Google Scholar] [CrossRef]

- Jang, S.P.; Choi, S.U. Role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl. Phys. Lett. 2004, 84, 4316–4318. [Google Scholar] [CrossRef]

- Mahian, O.; Mahmud, S.; Heris, S.Z. Analysis of entropy generation between co-rotating cylinders using nanofluids. Energy 2012, 44, 438–446. [Google Scholar] [CrossRef]

- Dardan, E.; Afrand, M.; Meghdadi Isfahani, A.H. Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl. Therm. Eng. 2016, 109, 524–534. [Google Scholar] [CrossRef]

- Mostafizur, R.M.; Rasul, M.G.; Nabi, M.N. Effect of surfactant on stability, thermal conductivity, and viscosity of aluminium oxide—Methanol nanofluids for heat transfer applications. Therm. Sci. Eng. Prog. 2022, 31, 101302. [Google Scholar] [CrossRef]

- Hamilton, R.L.; Crosser, O. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Das, L.; Habib, K.; Irshad, K.; Saidur, R.; Algarni, S.; Alqahtani, T. Thermo-Optical Characterization of Therminol55 Based MXene–Al2O3 Hybridized Nanofluid and New Correlations for Thermal Properties. Nanomaterials 2022, 12, 1862. [Google Scholar] [CrossRef]

- Mauro, G.M.; Iasiello, M.; Bianco, N.; Chiu, W.K.S.; Naso, V. Mono- and Multi-Objective CFD Optimization of Graded Foam-Filled Channels. Materials 2022, 15, 968. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, T.; Xing, J.; Chen, J.; Fu, Z. Numerical investigation of heat-transfer enhancement in helically coiled spiral grooved tube heat exchanger. Prog. Nucl. Energy 2022, 145, 104132. [Google Scholar] [CrossRef]

- Maiga, S.E.B.; Palm, S.J.; Nguyen, C.T.; Roy, G.; Galanis, N. Heat transfer enhancement by using nanofluids in forced convection flows. Int. J. Heat Fluid Flow 2005, 26, 530–546. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A.; Kanoğlu, M. Thermodynamics: An Engineering Approach; McGraw-hill: New York, NY, USA, 2011; Volume 5. [Google Scholar]

- Kahrobaian, A.; Malekmohammadi, H. Exergy optimization applied to linear parabolic solar collectors. J. Fac. Eng. 2008, 42, 131–144. [Google Scholar]

| Physical Properties | Formula | Density, (kg/m3) @ 20 °C | Dynamic Viscosity, (N∙s/m2) @ 25 °C | Thermal Conductivity, (W/m·K) @ 25 °C | Specific Heat Capacity, (J/kg·K) @ 25 °C |

|---|---|---|---|---|---|

| Water | H2O | 1000 | 0.0008 | 0.58 | 4182 |

| Ethylene glycol | C2H6O2 | 1115 | 0.0169 | 0.258 | 2460 |

| Methanol | CH3OH | 792 | 0.000543 | 0.204 | 2520 |

| Radiator coolant | - | 1087 | 0.0038 | 0.37 | 3285 |

| Engine oil [50] | - | 872 | 0.141 | 0.15 | 1990 |

| MWCNT | - | 2100 | - | 3000 | 735 |

| Copper oxide | CuO | 6000 | - | 33 | 551 |

| Researcher | Type of Hybrid Nanofluid | Parameters | Exergy Generation Rate |

|---|---|---|---|

| Stalin et al. [33] | Zn-Fe2O4/water | 0.1 kg/s, 0.5% | 5.31 |

| Present work | CuO-MWCNT/water | 0.016 kg/s, 0.1% | 5.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostafizur, R.M.; Rasul, M.G.; Nabi, M.N.; Haque, R.; Jahirul, M.I. Thermodynamic Analysis of a Flat Plate Solar Collector with Different Hybrid Nanofluids as Working Medium—A Thermal Modelling Approach. Nanomaterials 2023, 13, 1320. https://doi.org/10.3390/nano13081320

Mostafizur RM, Rasul MG, Nabi MN, Haque R, Jahirul MI. Thermodynamic Analysis of a Flat Plate Solar Collector with Different Hybrid Nanofluids as Working Medium—A Thermal Modelling Approach. Nanomaterials. 2023; 13(8):1320. https://doi.org/10.3390/nano13081320

Chicago/Turabian StyleMostafizur, R. M., M. G. Rasul, M. N. Nabi, R. Haque, and M. I. Jahirul. 2023. "Thermodynamic Analysis of a Flat Plate Solar Collector with Different Hybrid Nanofluids as Working Medium—A Thermal Modelling Approach" Nanomaterials 13, no. 8: 1320. https://doi.org/10.3390/nano13081320