Lead-Free Perovskite Thin Films for Gas Sensing through Surface Acoustic Wave Device Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition of Thin Films

2.2. Thin Layer Characterization

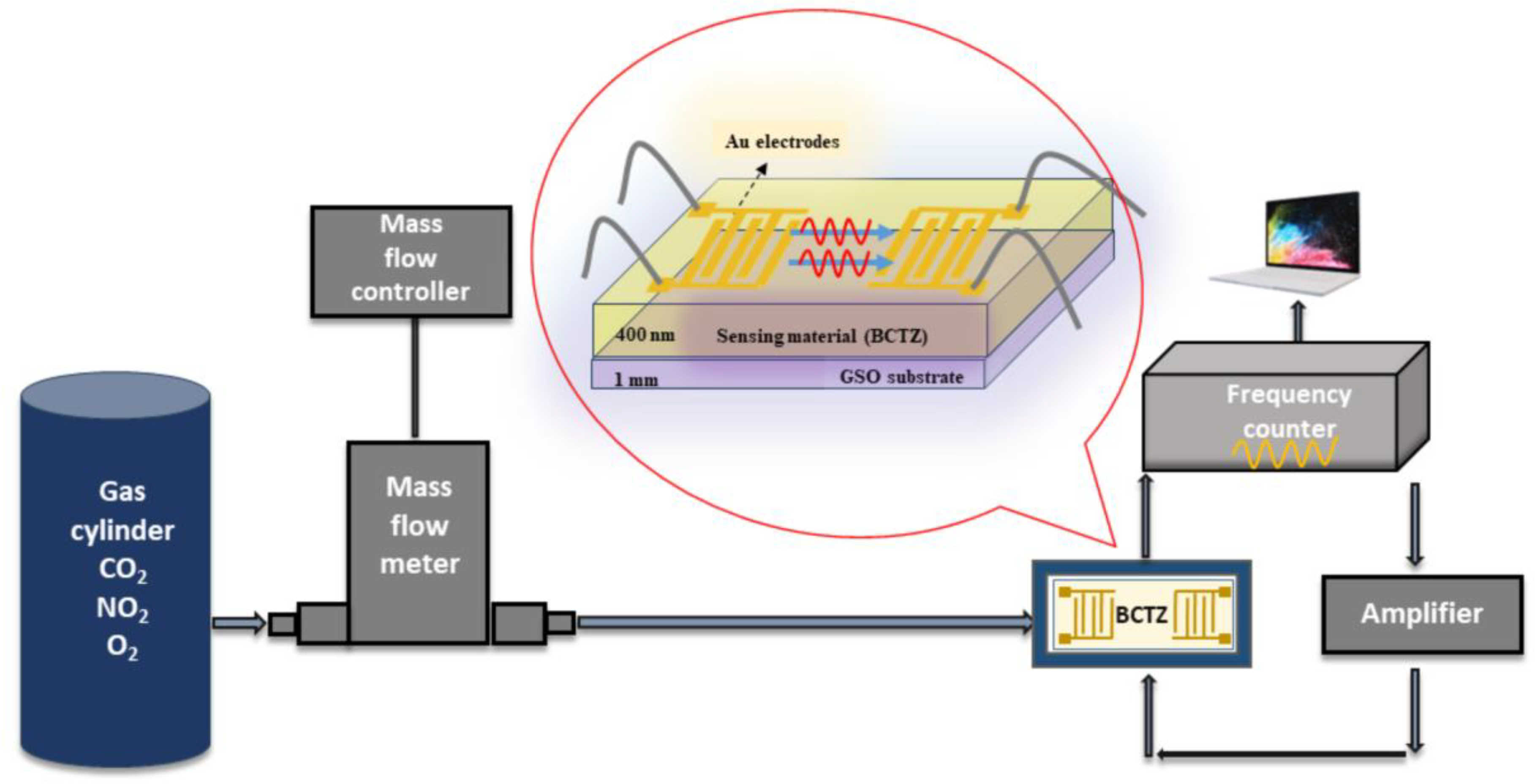

2.3. SAW Measurements

3. Results and Discussion

3.1. AFM and SEM Morphological Characterization

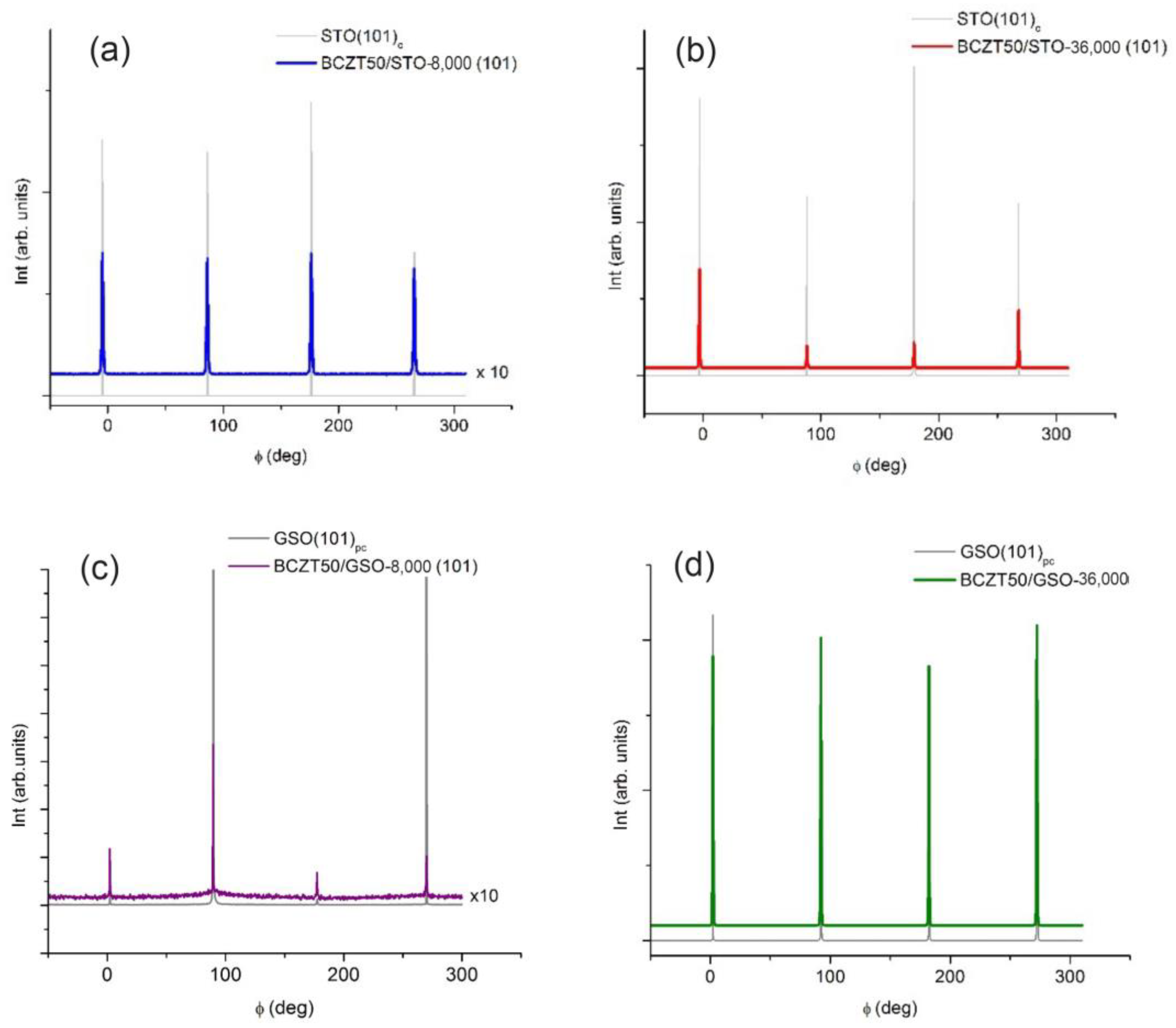

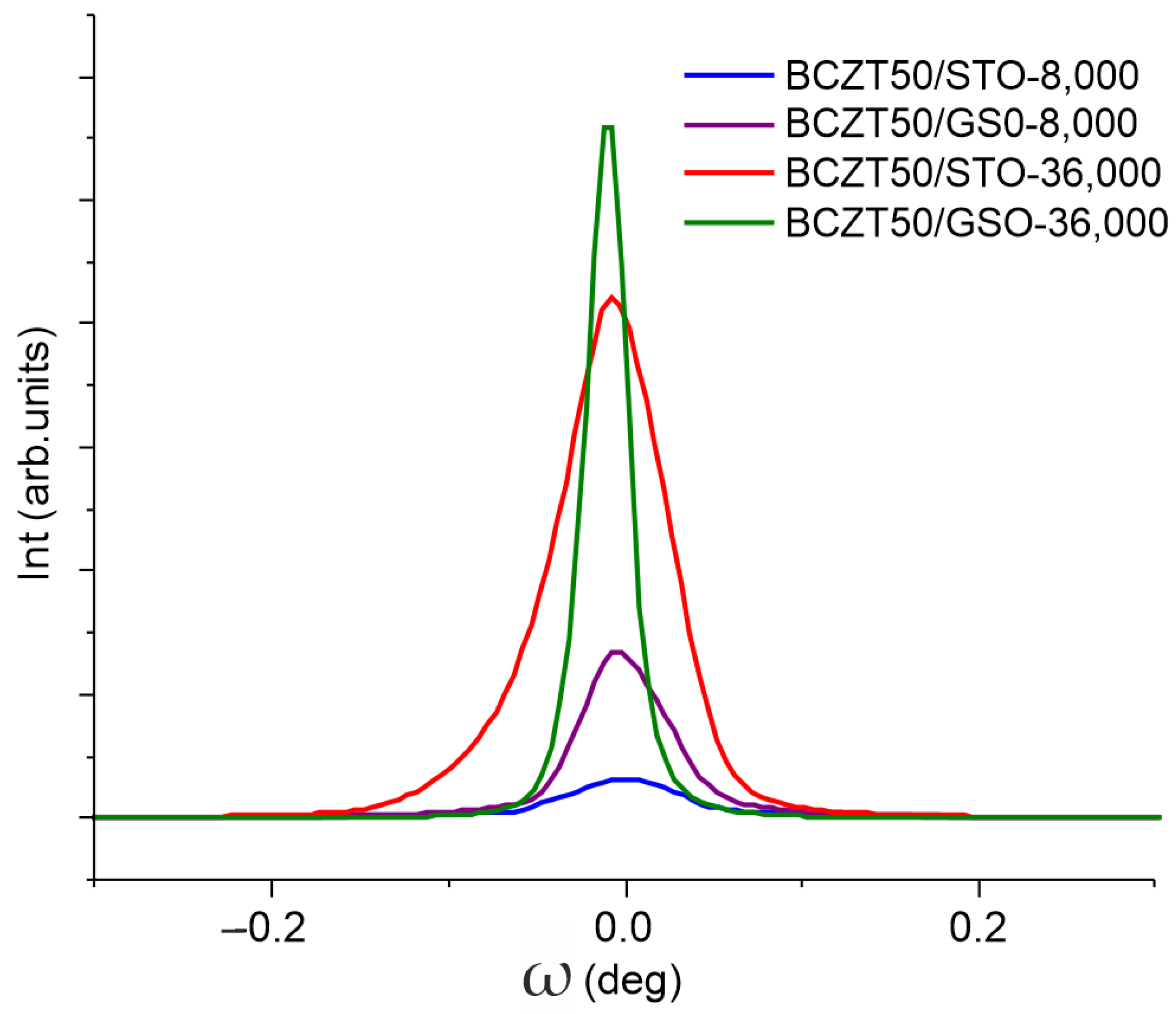

3.2. XRD Measurements

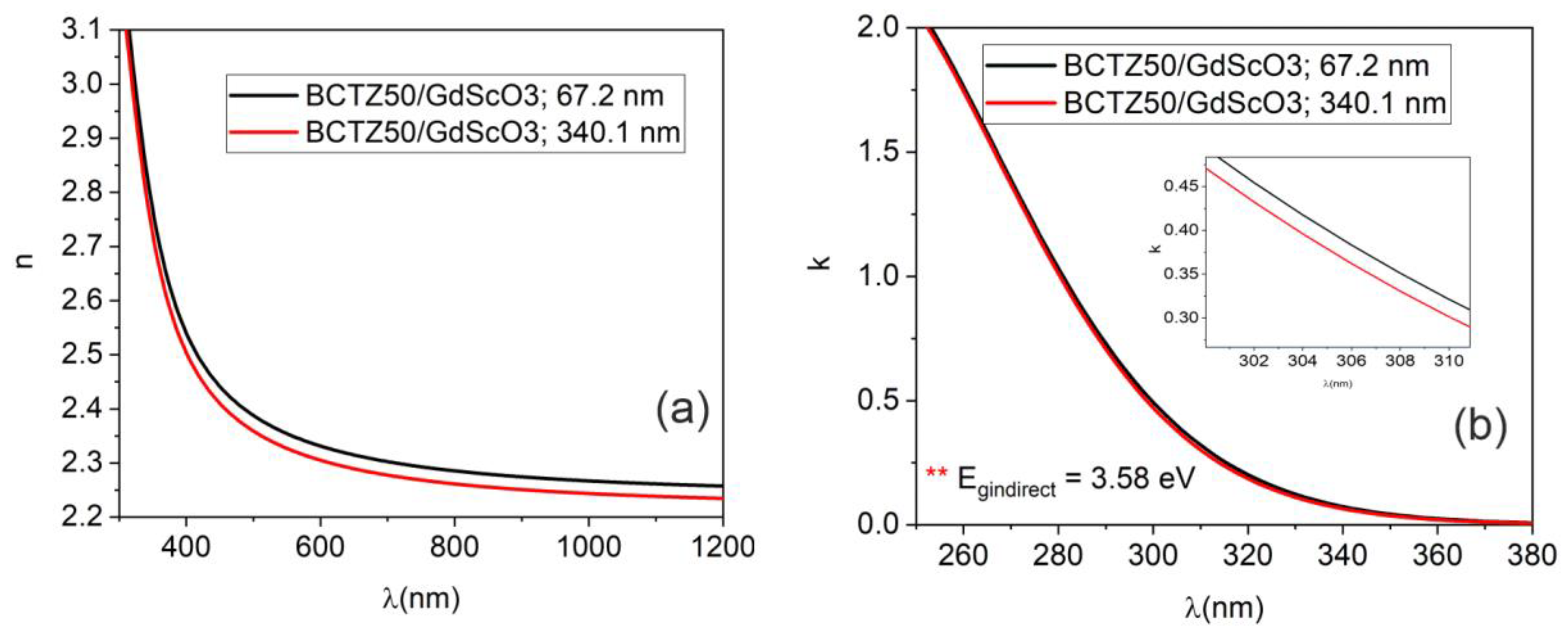

3.3. Optical Properties: Spectrometric Ellipsometry (SE)

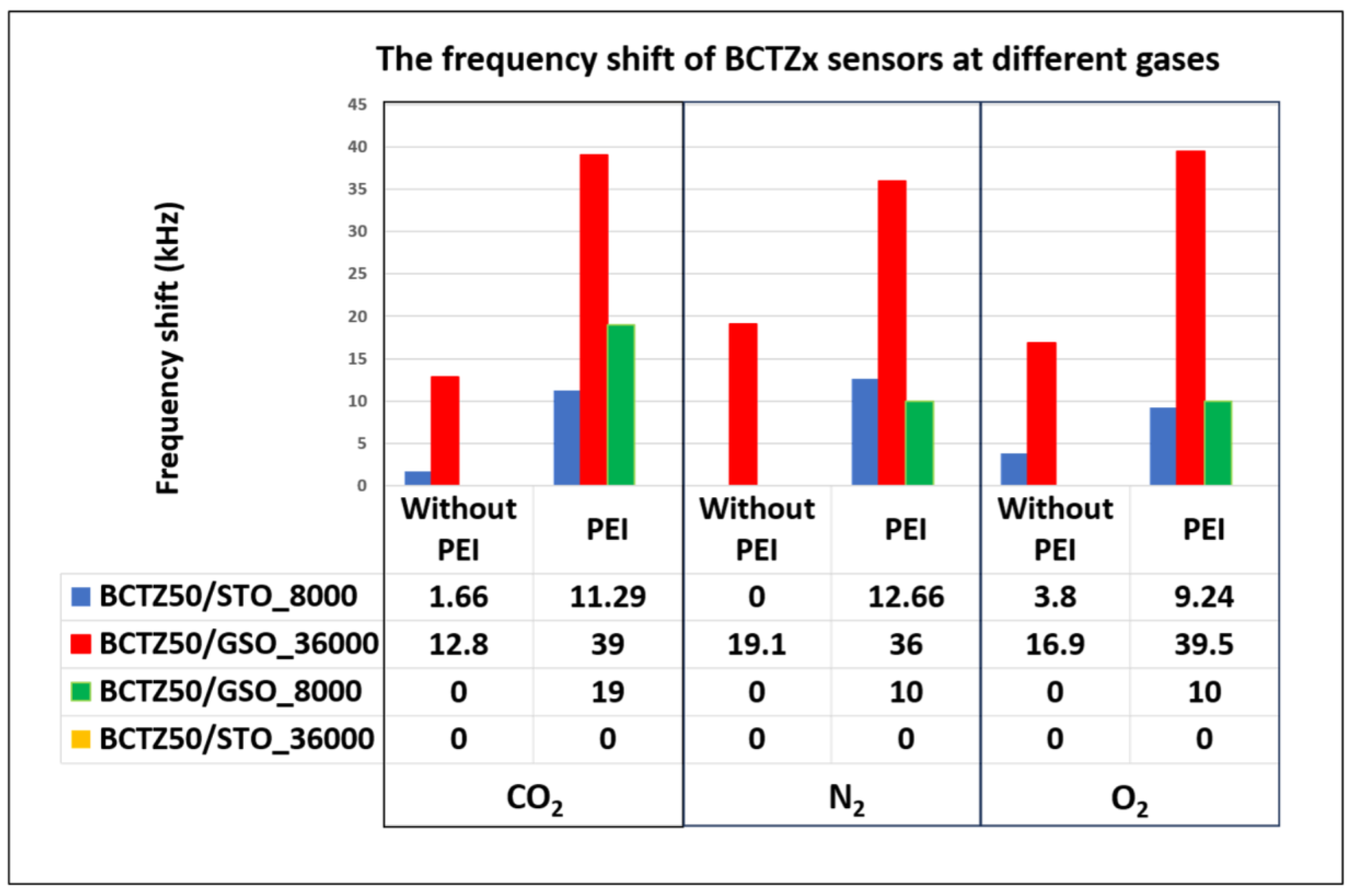

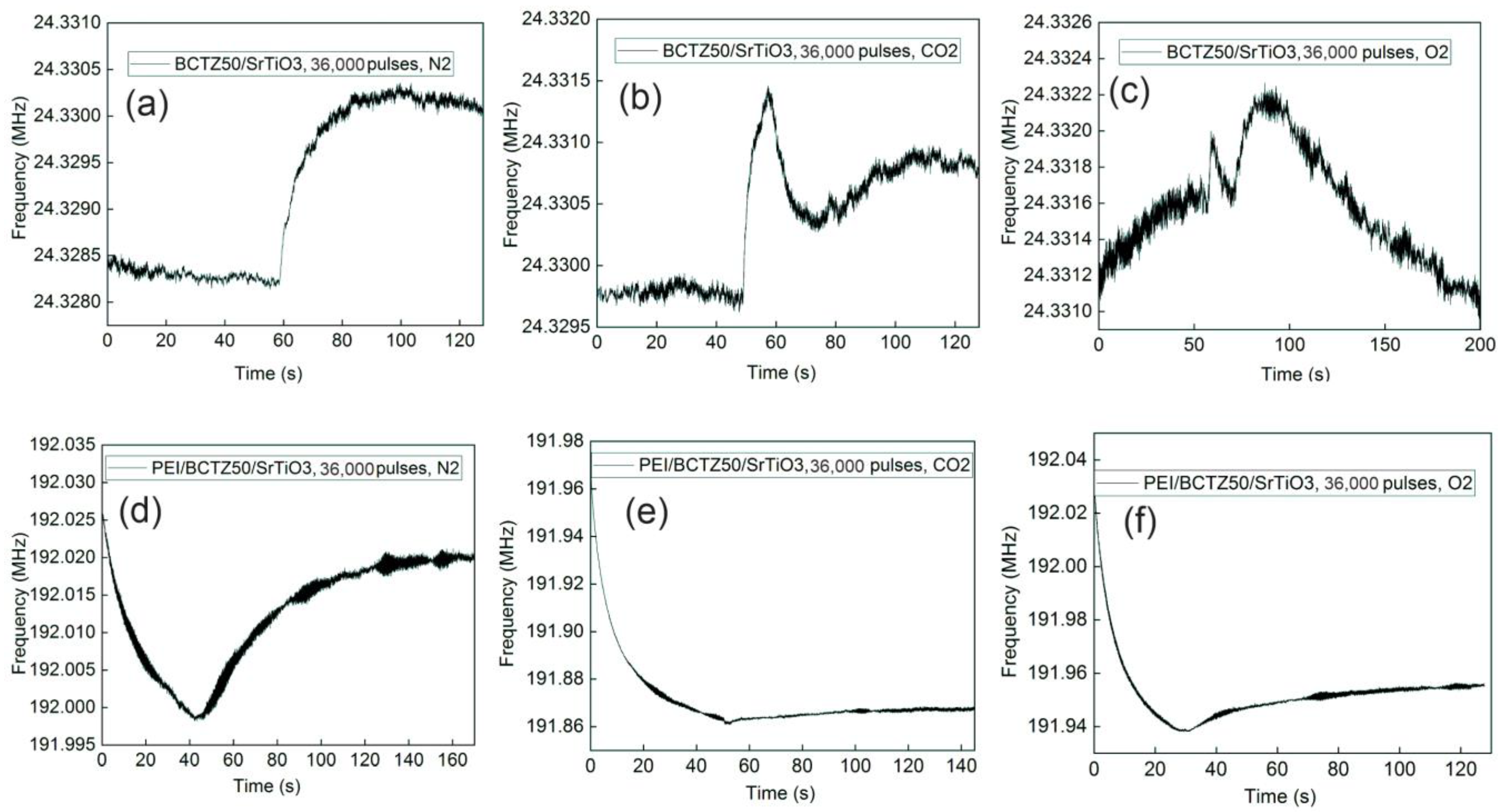

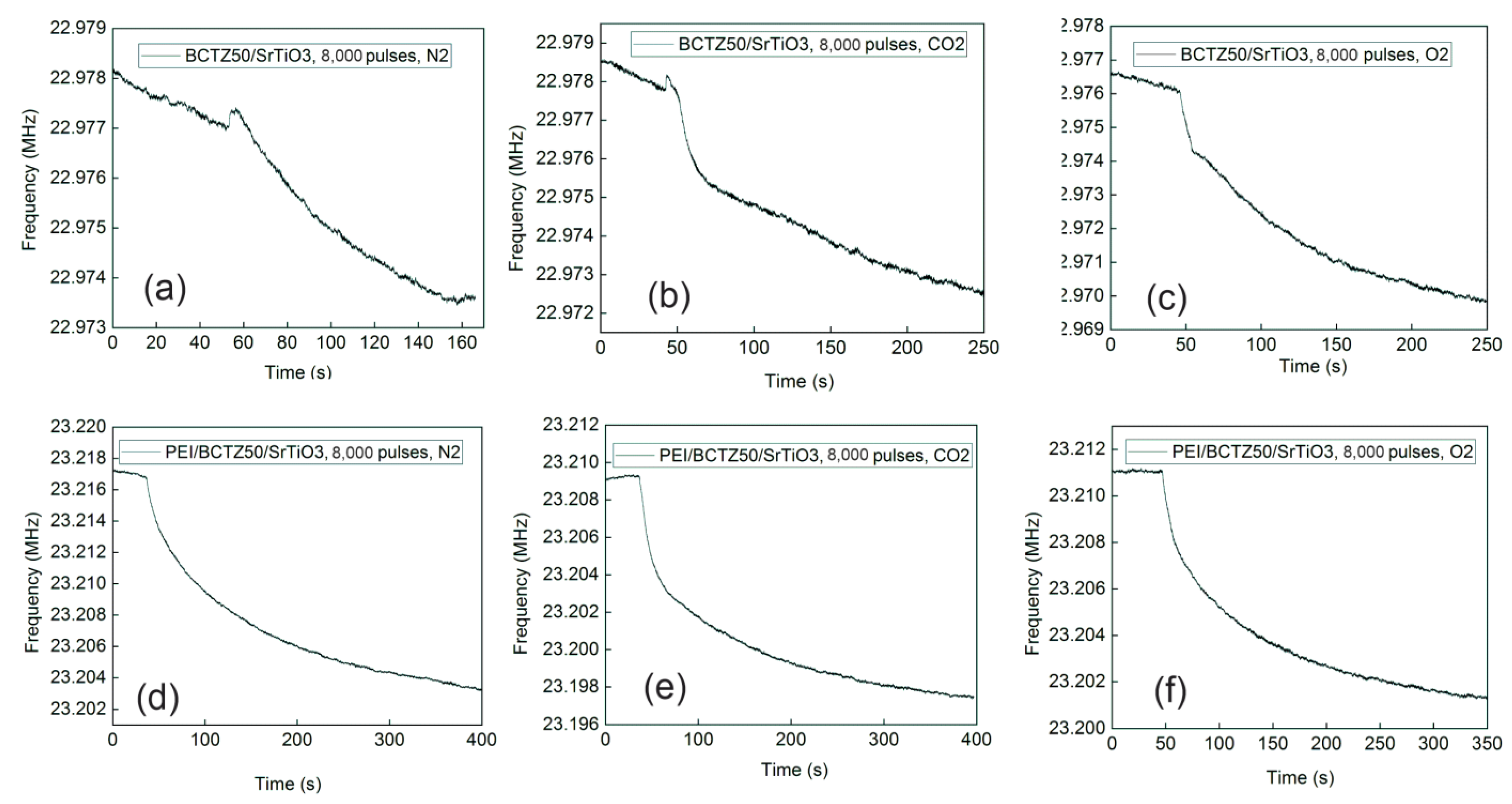

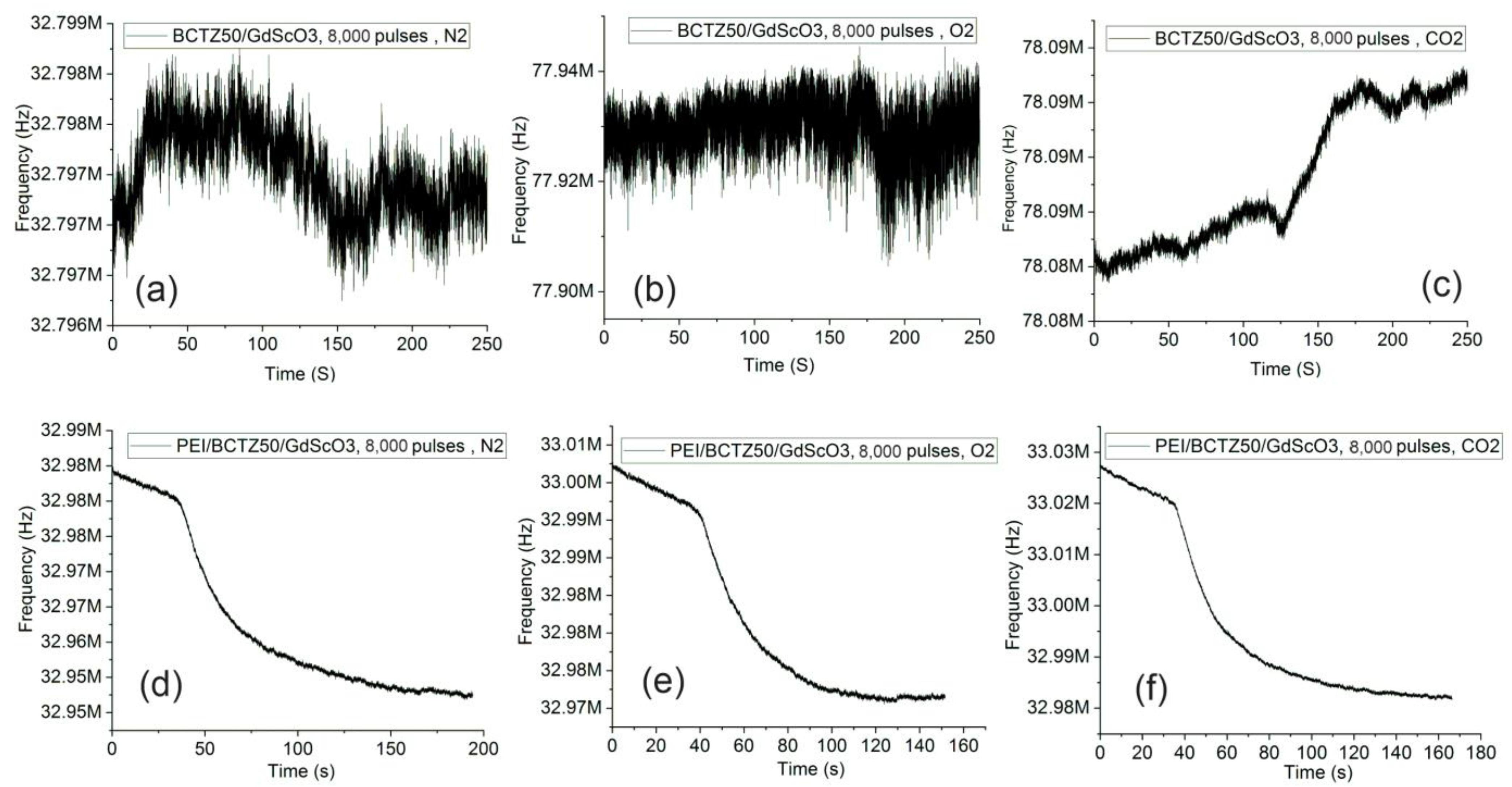

3.4. SAW Measurements

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.L.; Guo, Y.J.; Long, G.D.; Tang, Y.L.; Tang, Q.B.; Zu, X.T.; Ma, J.Y.; Du, B.; Torun, H.; Fu, Y.Q. Integrated sensing layer of bacterial cellulose and polyethyleneimine to achieve high sensitivity of ST-cut quartz surface acoustic wave formaldehyde gas sensor. J. Hazard. Mater. 2020, 388, 121743. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liu, X.; Mei, S.; Jia, Y.; Liu, M.; Xue, X.; Yang, D. Development of a Pd/Cu nanowires coated SAW hydrogen gas sensor with fast response and recovery. Sens. Actuators B Chem. 2019, 287, 157–164. [Google Scholar] [CrossRef]

- Rana, L.; Gupta, R.; Kshetrimayum, R.; Tomar, M.; Gupta, V. Fabrication of surface acoustic wave based wireless NO2 gas sensor. Surf. Coat. Technol. 2018, 343, 89–92. [Google Scholar] [CrossRef]

- Ghosh, A.; Zhang, C.; Shi, S.; Zhang, H. High temperature CO2 sensing and its cross-sensitivity towards H2 and CO gas using calcium doped ZnO thin film coated langasite SAW sensor. Sens. Actuators B Chem. 2019, 301, 126958. [Google Scholar] [CrossRef]

- Tang, Y.; Li, D.; Ao, D.; Guo, Y.; Faheem, M.B.; Khan, B.; Zu, X.; Li, S. Highly sensitive surface acoustic wave HCl gas sensors based on hydroxyl-rich sol-gel AlOxOHy films. Mater. Chem. Phys. 2020, 239, 122026. [Google Scholar] [CrossRef]

- Shu, L.; Jiang, T.; Xia, Y.; Wang, X.; Yan, D.; Wu, W. The Investigation of a SAW Oxygen Gas Sensor Operated at Room Temperature, Based on Nanostructured ZnxFeyO Films. Sensors 2019, 19, 3025. [Google Scholar] [CrossRef] [PubMed]

- Constantinoiu, I.; Miu, D.; Viespe, C. Surface Acoustic Wave Sensors for Ammonia Detection at Room Temperature Based on SnO2/Co3O4 Bilayers. J. Sens. 2019, 2019, 8203810. [Google Scholar] [CrossRef]

- Yang, L.; Yin, C.; Zhang, Z.; Zhou, J.; Xu, H. The investigation of hydrogen gas sensing properties of SAW gas sensor based on palladium surface modified SnO2 thin film. Mater. Sci. Semicond. Process. 2017, 60, 16–28. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, X.; Han, S.; Cai, C.; Du, H.; Zhu, H.; Zu, X.; Fu, Y. ZnO-Al2O3 nanocomposite as a sensitive layer for high performance surface acoustic wave H2S gas sensor with enhanced elastic loading effect. Sens. Actuators B Chem. 2020, 304, 127395. [Google Scholar] [CrossRef]

- Lim, J.-B.; Reddeppa, M.; Nam, D.; Pasupuleti, K.S.; Bak, N.-H.; Kim, S.-G.; Cho, H.D.; Kim, M.-D. Surface acoustic device for high response NO2 gas sensor using p-phenylenediamine-reduced graphene oxide nanocomposite coated on langasite. Smart Mater. Struct. 2021, 30, 095016. [Google Scholar] [CrossRef]

- Devkota, J.; Ohodnicki, P.; Greve, D. SAW Sensors for Chemical Vapors and Gases. Sensors 2017, 17, 801. [Google Scholar] [CrossRef] [PubMed]

- Khlebarov, Z.P.; Stoyanova, A.I.; Topalova, D.I. Surface acoustic wave gas sensors. Sens. Actuators B Chem. 1992, 8, 33–40. [Google Scholar] [CrossRef]

- Shen, C.-Y.; Huang, C.-P.; Huang, W.-T. Gas-detecting properties of surface acoustic wave ammonia sensors. Sens. Actuators B Chem. 2004, 101, 1–7. [Google Scholar] [CrossRef]

- Caliendo, C.; Verardi, P.; Verona, E.; D’Amico, A.; Natale, C.D.; Saggio, G.; Serafini, M.; Paolesse, R.; Huq, S.E. Advances in SAW-based gas sensors. Smart Mater. Struct. 1997, 6, 689–699. [Google Scholar] [CrossRef]

- Midhuna, A.S.; Shiju, B.S.; Sreenidhi, P.R. Optimizing Design of Surface Acoustic Wave Gas Sensor. In Proceedings of the 2021 5th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 3–5 June 2021; pp. 143–148. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.; Cai, H.; Mohammad Ali, M.; Tian, X.; Tao, L.; Yang, Y.; Ren, T. Surface acoustic wave devices for sensor applications. J. Semicond. 2016, 37, 021001. [Google Scholar] [CrossRef]

- Jakubik, W.P. Surface acoustic wave-based gas sensors. Thin Solid Films 2011, 520, 986–993. [Google Scholar] [CrossRef]

- Hamidon, M.N.; Yunusa, Z. Sensing Materials for Surface Acoustic Wave Chemical Sensors. In Progresses in Chemical Sensor; Wang, W., Ed.; InTech: Vienna, Austria, 2016. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Fu, Q.; Zhou, D.; Deng, J.; Liu, H.; Yan, G. A surface acoustic wave H2S gas sensor employing nanocrystalline SnO2 thin film. Sens. Actuators B Chem. 2013, 176, 746–752. [Google Scholar] [CrossRef]

- Dickert, F.L.; Forth, P.; Bulst, W.-E.; Fischerauer, G.; Knauer, U. SAW devices-sensitivity enhancement in going from 80 MHz to 1 GHz. Sens. Actuators B Chem. 1998, 46, 120–125. [Google Scholar] [CrossRef]

- Sayago, I.; Fernandez, M.J.; Fontecha, J.L.; Horrillo, M.C.; Terrado, E.; Seral-Ascaso, A.; Munoz, E. Carbon nanotube-based SAW sensors. In Proceedings of the 2013 Spanish Conference on Electron Devices, Valladolid, Spain, 12–14 February 2013; IEEE: Valladolid, Spain, 2013; pp. 127–130. [Google Scholar] [CrossRef]

- Sayago, I.; Fernández, M.J.; Fontecha, J.L.; Horrillo, M.C.; Vera, C.; Obieta, I.; Bustero, I. New sensitive layers for surface acoustic wave gas sensors based on polymer and carbon nanotube composites. Sens. Actuators B Chem. 2012, 175, 67–72. [Google Scholar] [CrossRef]

- Asad, M.; Sheikhi, M.H. Surface acoustic wave based H2S gas sensors incorporating sensitive layers of single wall carbon nanotubes decorated with Cu nanoparticles. Sens. Actuators B Chem. 2014, 198, 134–141. [Google Scholar] [CrossRef]

- Xu, S.; Li, C.; Li, H.; Li, M.; Qu, C.; Yang, B. Carbon dioxide sensors based on a surface acoustic wave device with a graphene–nickel– L -alanine multilayer film. J. Mater. Chem. C 2015, 3, 3882–3890. [Google Scholar] [CrossRef]

- Wang, S.-H.; Shen, C.-Y.; Su, J.-M.; Chang, S.-W. A Room Temperature Nitric Oxide Gas Sensor Based on a Copper-Ion-Doped Polyaniline/Tungsten Oxide Nanocomposite. Sensors 2015, 15, 7084–7095. [Google Scholar] [CrossRef] [PubMed]

- Sadek, A.Z.; Wlodarski, W.; Shin, K.; Kaner, R.B.; Kalantar-zadeh, K. A layered surface acoustic wave gas sensor based on a polyaniline/In2O3 nanofibre composite. Nanotechnology 2006, 17, 4488–4492. [Google Scholar] [CrossRef]

- Sil, D.; Hines, J.; Udeoyo, U.; Borguet, E. Palladium Nanoparticle-Based Surface Acoustic Wave Hydrogen Sensor. ACS Appl. Mater. Interfaces 2015, 7, 5709–5714. [Google Scholar] [CrossRef]

- Robinson, A.L.; Stavila, V.; Zeitler, T.R.; White, M.I.; Thornberg, S.M.; Greathouse, J.A.; Allendorf, M.D. Ultrasensitive Humidity Detection Using Metal–Organic Framework-Coated Microsensors. Anal. Chem. 2012, 84, 7043–7051. [Google Scholar] [CrossRef] [PubMed]

- Tasaltin, C.; Ebeoglu, M.A.; Ozturk, Z.Z. Acoustoelectric Effect on the Responses of SAW Sensors Coated with Electrospun ZnO Nanostructured Thin Film. Sensors 2012, 12, 12006–12015. [Google Scholar] [CrossRef]

- Kumar, A.; Prajesh, R. The potential of acoustic wave devices for gas sensing applications. Sens. Actuators Phys. 2022, 339, 113498. [Google Scholar] [CrossRef]

- Omori, T.; Hashimoto, K.; Yamaguchi, M. PZT Thin Films for SAW and BAW Devices, Engineering, Materials Science, Physics, Department of Electronics and Mechanical Engineering, Chiba University Inage-ku, Chiba-shi, 263-8522, Japan. Available online: https://www.te.chiba-u.jp/lab/ken/Symp/Symp2001/PAPER/OMORI.PDF (accessed on 27 October 2022).

- Hsiao, Y.-J.; Fang, T.-H.; Chang, Y.-H.; Chang, Y.-S.; Wu, S. Surface acoustic wave characteristics and electromechanical coupling coefficient of lead zirconate titanate thin films. Mater. Lett. 2006, 60, 1140–1143. [Google Scholar] [CrossRef]

- Shilpa, G.D.; Sreelakshmi, K.; Ananthaprasad, M.G. PZT thin film deposition techniques, properties and its application in ultrasonic MEMS sensors: A review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012190. [Google Scholar] [CrossRef]

- Takenaka, T. Lead-free piezo-ceramics. In Advanced Piezoelectric Materials; Elsevier: Amsterdam, The Netherlands, 2010; pp. 130–170. [Google Scholar] [CrossRef]

- Jaffe, W.R.C.B.; Jaffe, H. Piezoelectric Ceramics, 1st ed.; Academic Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Liu, W.; Ren, X. Large Piezoelectric Effect in Pb-Free Ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Xue, D.; Liu, W.; Zhou, C.; Ren, X. Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications. Actuators 2017, 6, 24. [Google Scholar] [CrossRef]

- Li, W.L.; Zhang, T.D.; Xu, D.; Hou, Y.F.; Cao, W.P.; Fei, W.D. LaNiO3 seed layer induced enhancement of piezoelectric properties in (100)-oriented (1−x)BZT–xBCT thin films. J. Eur. Ceram. Soc. 2015, 35, 2041–2049. [Google Scholar] [CrossRef]

- Li, W.L.; Zhang, T.D.; Hou, Y.F.; Zhao, Y.; Xu, D.; Cao, W.P.; Fei, W.D. Giant piezoelectric properties of BZT–0.5BCT thin films induced by nanodomain structure. RSC Adv. 2014, 4, 56933–56937. [Google Scholar] [CrossRef]

- Scarisoreanu, N.D.; Craciun, F.; Moldovan, A.; Ion, V.; Birjega, R.; Ghica, C.; Negrea, R.F.; Dinescu, M. High Permittivity (1 − x)Ba(Zr0.2Ti0.8)O3 − x (Ba0.7Ca0.3)TiO3 (x = 0.45) Epitaxial Thin Films with Nanoscale Phase Fluctuations. ACS Appl. Mater. Interfaces 2015, 7, 23984–23992. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Yang, G.; Xu, J.-L.; Zhang, M.; Kuo, C.-C.; Wang, S.-D. Conducting polymer-inorganic nanocomposite-based gas sensors: A review. Sci. Technol. Adv. Mater. 2020, 21, 768–786. [Google Scholar] [CrossRef] [PubMed]

- Fratoddi, I.; Venditti, I.; Cametti, C.; Russo, M.V. Chemiresistive polyaniline-based gas sensors: A mini review. Sens. Actuators B Chem. 2015, 220, 534–548. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Archer, P.B.M.; Ling-Chung, S.K. Conducting polymer gas sensors part I: Fabrication and characterization. Sens. Actuators 1989, 19, 125–140. [Google Scholar] [CrossRef]

- Dinca, V.; Viespe, C.; Brajnicov, S.; Constantinoiu, I.; Moldovan, A.; Bonciu, A.; Toader, C.; Ginghina, R.; Grigoriu, N.; Dinescu, M.; et al. MAPLE Assembled Acetylcholinesterase–Polyethylenimine Hybrid and Multilayered Interfaces for Toxic Gases Detection. Sensors 2018, 18, 4265. [Google Scholar] [CrossRef]

- Regensburger, S.; Mohammadi, M.; Khawaja, A.A.; Radetinac, A.; Komissinskiy, P.; Alff, L.; Preu, S. Optical Properties of Highly Conductive SrMoO3 Oxide Thin Films in the THz Band and Beyond. J. Infrared Millim. Terahertz Waves 2020, 41, 1170–1180. [Google Scholar] [CrossRef]

- Scarisoreanu, N.D.; Craciun, F.; Birjega, R.; Ion, V.; Teodorescu, V.S.; Ghica, C.; Negrea, R.; Dinescu, M. Joining Chemical Pressure and Epitaxial Strain to Yield Y-doped BiFeO3 Thin Films with High Dielectric Response. Sci. Rep. 2016, 6, 25535. [Google Scholar] [CrossRef] [PubMed]

- Metzger, T.; Höpler, R.; Born, E.; Ambacher, O.; Stutzmann, M.; Stömmer, R.; Schuster, M.; Göbel, H.; Christiansen, S.; Albrecht, M.; et al. Defect structure of epitaxial GaN films determined by transmission electron microscopy and triple-axis X-ray diffractometry. Philos. Mag. A 1998, 77, 1013–1025. [Google Scholar] [CrossRef]

- Schwarzkopf, J.; Braun, D.; Schmidbauer, M.; Duk, A.; Wördenweber, R. Ferroelectric domain structure of anisotropically strained NaNbO3 epitaxial thin films. J. Appl. Phys. 2014, 115, 204105. [Google Scholar] [CrossRef]

- Spectroscopic Ellipsometry: Principles and Applications|Wiley. Available online: https://www.wiley.com/en-us/Spectroscopic+Ellipsometry%3A+Principles+and+Applications-p-9780470016084 (accessed on 27 October 2022).

- Liu, D.; Shim, J.; Sun, Y.; Li, Q.; Yan, Q. Growth of Ca, Zr co-doped BaTiO3 lead-free ferroelectric single crystal and its room-temperature piezoelectricity. AIP Adv. 2017, 7, 095311. [Google Scholar] [CrossRef]

- Wemple, S.H.; Didomenico, M.; Camlibel, I. Dielectric and optical properties of melt-grown BaTiO3. J. Phys. Chem. Solids 1968, 29, 1797–1803. [Google Scholar] [CrossRef]

- Santhosh Kumar, T.; Bhuyan, R.K.; Pamu, D. Effect of post annealing on structural, optical and dielectric properties of MgTiO3 thin films deposited by RF magnetron sputtering. Appl. Surf. Sci. 2013, 264, 184–190. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Park, K.; Seo, D.J. Gas sensing characteristics of BaTiO3-based ceramics. Mater. Chem. Phys. 2004, 85, 47–51. [Google Scholar] [CrossRef]

- Li, F.; Xu, J.; Yu, X.; Chen, L.; Zhu, J.; Yang, Z.; Xin, X. One-step solid-state reaction synthesis and gas sensing property of tin oxide nanoparticles. Sens. Actuators B Chem. 2002, 81, 165–169. [Google Scholar] [CrossRef]

- Yamazoe, N. New approaches for improving semiconductor gas sensors. Sens. Actuators B Chem. 1991, 5, 7–19. [Google Scholar] [CrossRef]

- Van Toan, N.; Viet Chien, N.; Van Duy, N.; Si Hong, H.; Nguyen, H.; Duc Hoa, N.; Van Hieu, N. Fabrication of highly sensitive and selective H2 gas sensor based on SnO2 thin film sensitized with microsized Pd islands. J. Hazard. Mater. 2016, 301, 433–442. [Google Scholar] [CrossRef]

- Sun, B.; Xie, G.; Jiang, Y.; Li, X. Comparative CO2-Sensing Characteristic Studies of PEI and PEI/Starch Thin Film Sensors. Energy Procedia 2011, 12, 726–732. [Google Scholar] [CrossRef]

| Probe | Laser Pulses | aout-of-plane (Å) | ain-plane (Å) | In-Plane Strain-ε in-plane (%) | FWHM-ω(002)(deg) | LII (nm) | αtilt (deg) |

|---|---|---|---|---|---|---|---|

| BCZT50/STO | 8000 | 4.0193 | 4.0173 | 2.88 | 0.068 | 72 | 0.227 |

| BCZT50/GSO | 8000 | 4.1022 | 3.9799 | 0.33 | 0.056 | 270 | 0.096 |

| BCZT50/STO | 36,000 | 4.0152 | 3.9857 | 2.07 | 0.078 | 376 | 0.051 |

| BCZT50/GSO | 36,000 | 4.0162 | 4.0147 | 1.20 | 0.031 | 471 | 0.054 |

| Probe | Laser Pulses | Thickness (nm) | Roughness (nm) | Amp Gauss | En (eV) | Br (eV) | MSE |

|---|---|---|---|---|---|---|---|

| BCTZ 50/STO | 8000 | 93.3 | 2.1 | 9.31 | 4.70 | 1.02 | 2.777 |

| BCTZ 50/STO | 36,000 | 314.9 | 1.3 | 12.29 | 4.93 | 1.12 | 1.374 |

| BCTZ 50/GSO | 8000 | 67.2 | 2.8 | 11.39 | 4.92 | 1.17 | 2.803 |

| BCTZ 50/GSO | 36,000 | 340.1 | 9.1 | 11.94 | 4.89 | 1.08 | 8.395 |

| Probe | Laser Pulses | Refractive Index (λ = 600 nm) | Packing Density | Porosity (%) |

|---|---|---|---|---|

| BCTZ50/GSO | 8000 | 2.33 | 0.961 | 8.8 |

| BCTZ 50/STO | 8000 | 2.335 | 0.966 | 8.34 |

| BCTZ 50/STO | 36,000 | 2.332 | 0.963 | 8.62 |

| BCTZ 50/GSO | 36,000 | 2.311 | 0.956 | 10.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enea, N.; Ion, V.; Viespe, C.; Constantinoiu, I.; Bonciu, A.; Stîngescu, M.L.; Bîrjega, R.; Scarisoreanu, N.D. Lead-Free Perovskite Thin Films for Gas Sensing through Surface Acoustic Wave Device Detection. Nanomaterials 2024, 14, 39. https://doi.org/10.3390/nano14010039

Enea N, Ion V, Viespe C, Constantinoiu I, Bonciu A, Stîngescu ML, Bîrjega R, Scarisoreanu ND. Lead-Free Perovskite Thin Films for Gas Sensing through Surface Acoustic Wave Device Detection. Nanomaterials. 2024; 14(1):39. https://doi.org/10.3390/nano14010039

Chicago/Turabian StyleEnea, Nicoleta, Valentin Ion, Cristian Viespe, Izabela Constantinoiu, Anca Bonciu, Maria Luiza Stîngescu, Ruxandra Bîrjega, and Nicu Doinel Scarisoreanu. 2024. "Lead-Free Perovskite Thin Films for Gas Sensing through Surface Acoustic Wave Device Detection" Nanomaterials 14, no. 1: 39. https://doi.org/10.3390/nano14010039

APA StyleEnea, N., Ion, V., Viespe, C., Constantinoiu, I., Bonciu, A., Stîngescu, M. L., Bîrjega, R., & Scarisoreanu, N. D. (2024). Lead-Free Perovskite Thin Films for Gas Sensing through Surface Acoustic Wave Device Detection. Nanomaterials, 14(1), 39. https://doi.org/10.3390/nano14010039