High-Entropy Alloy Activating Laves-Phase Network for Multi-Component Metallic Coatings with High Hardness

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Microstructure Characterization

2.3. Microhardness and Wear Behavior Tests

3. Results and Discussions

3.1. Phase Analysis

3.2. Microstructures and Evolutions

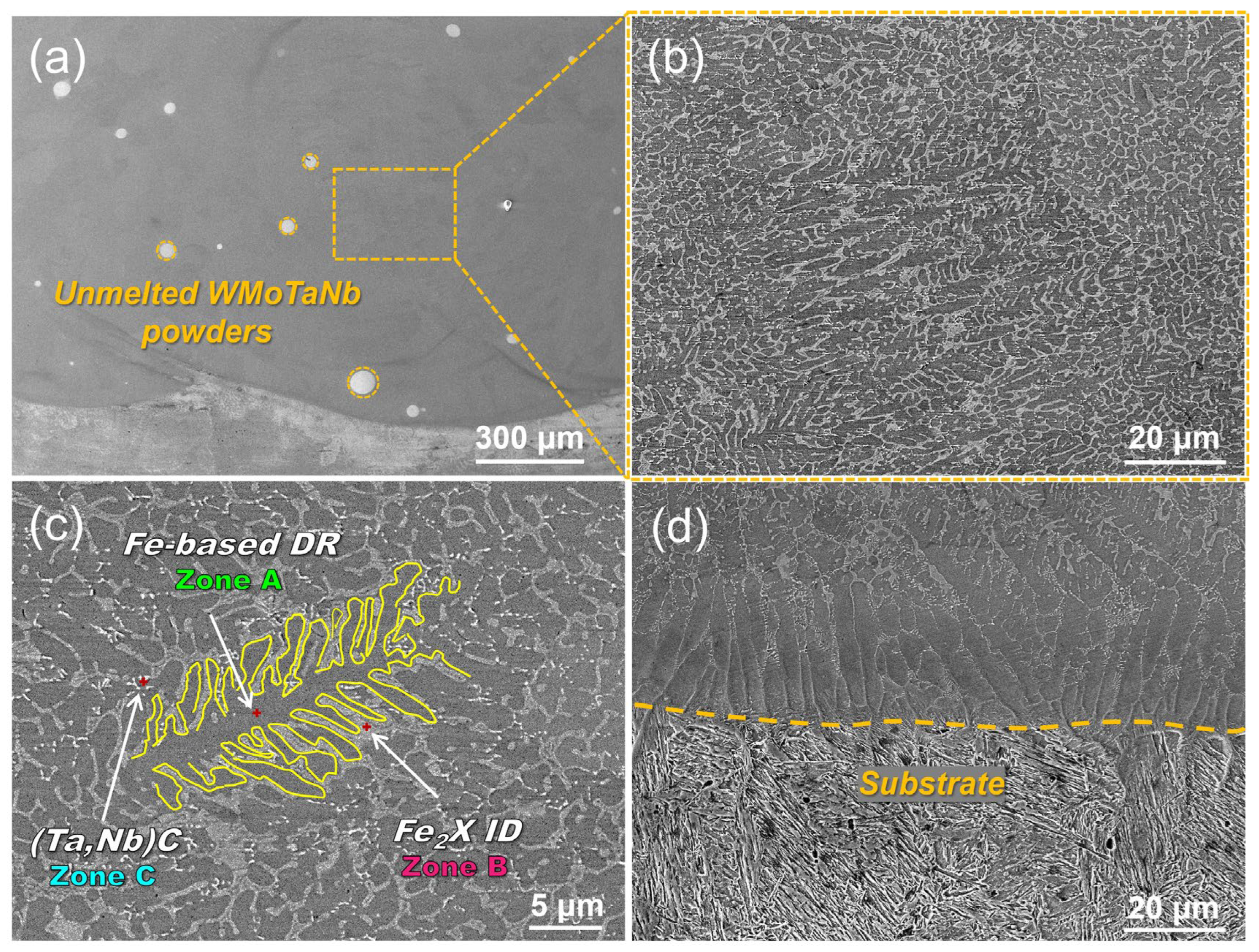

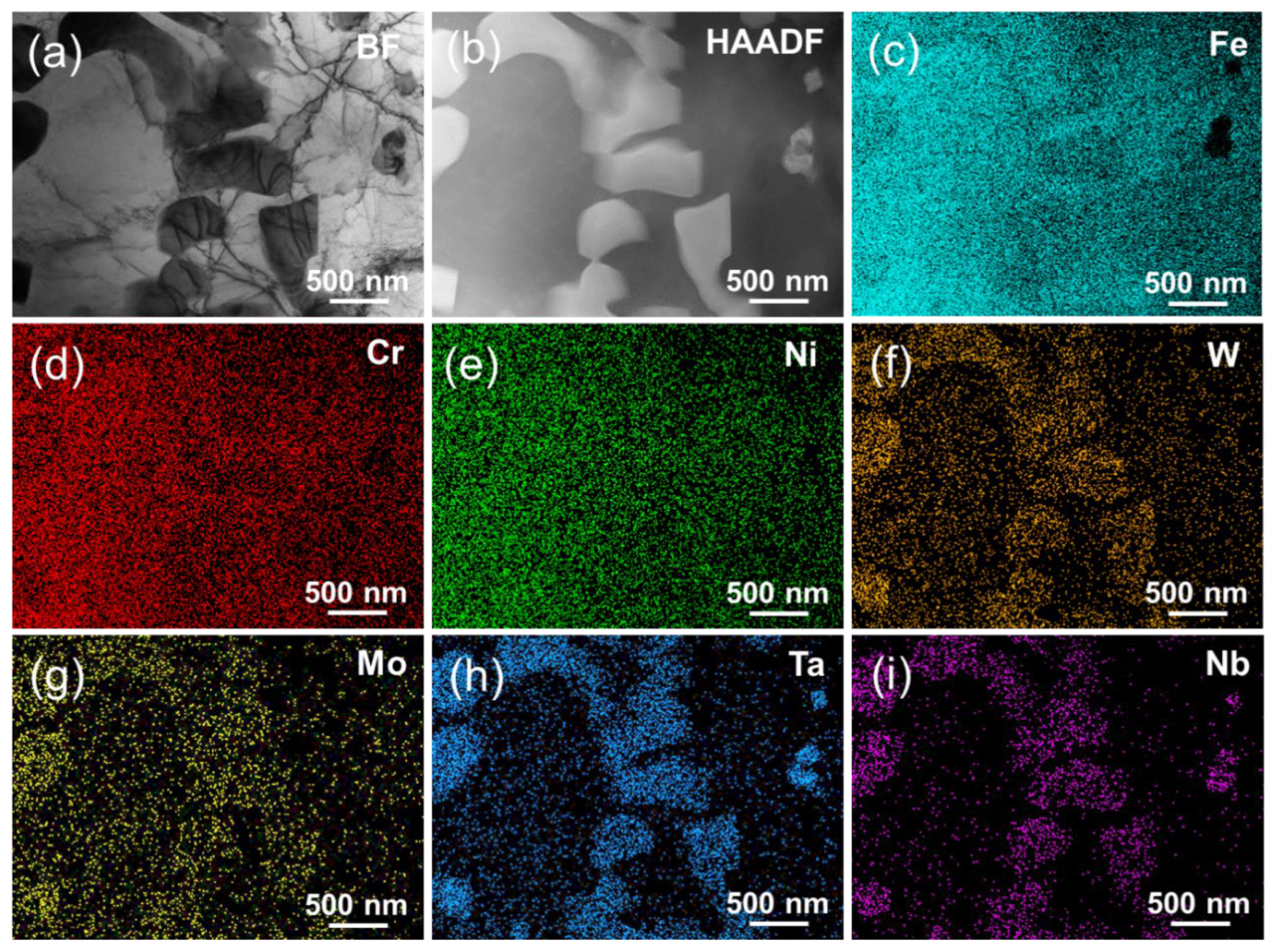

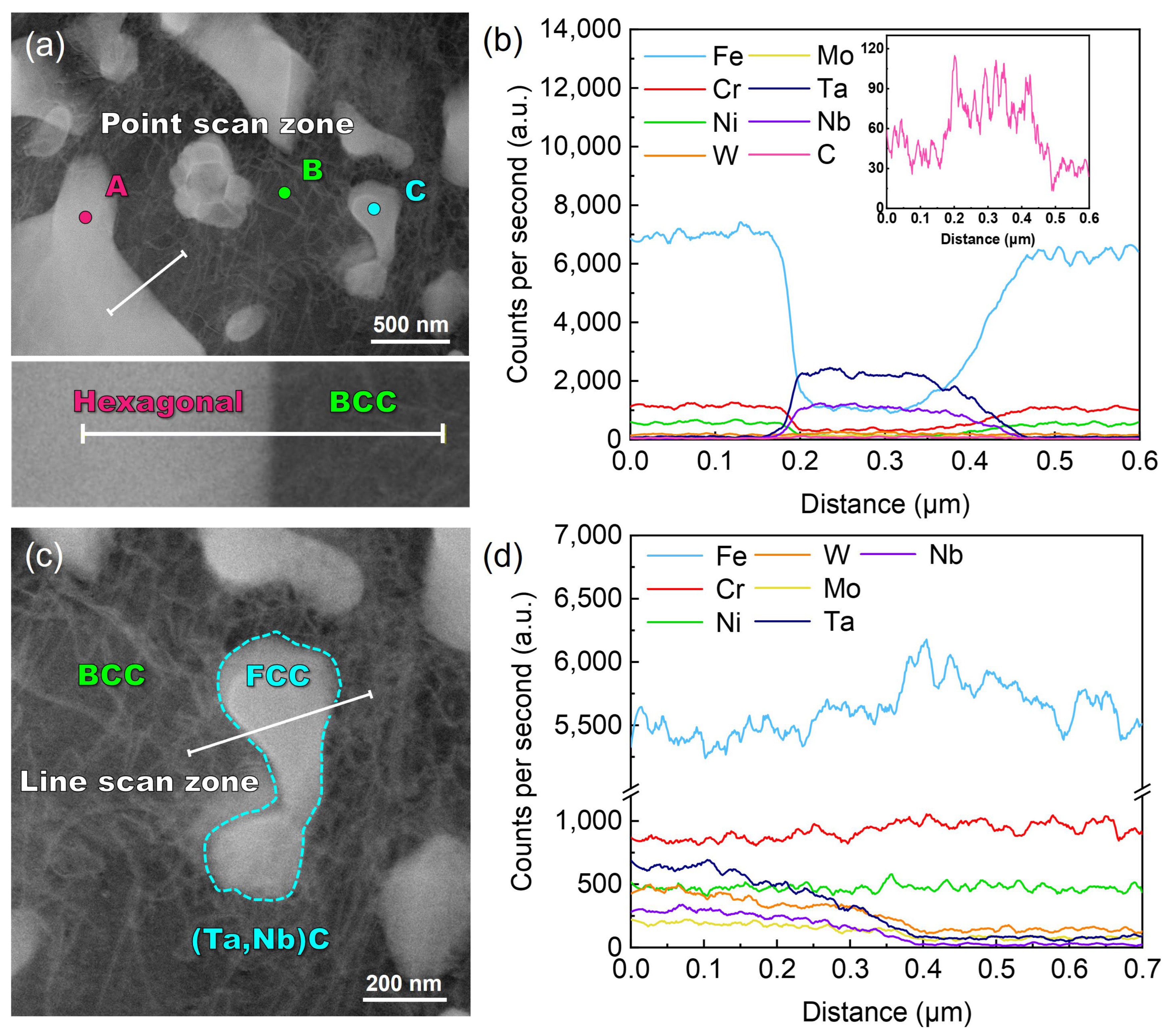

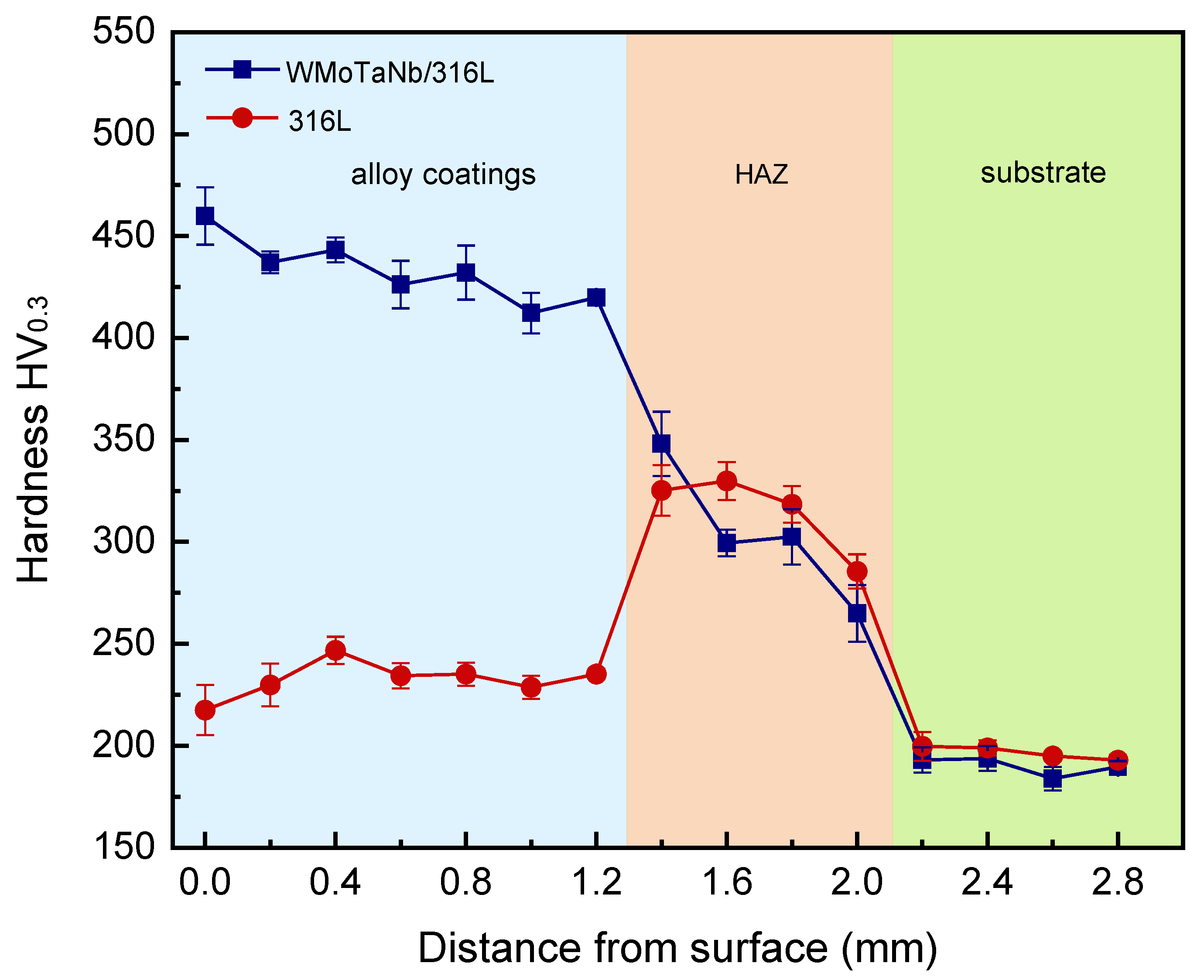

3.3. Microhardness

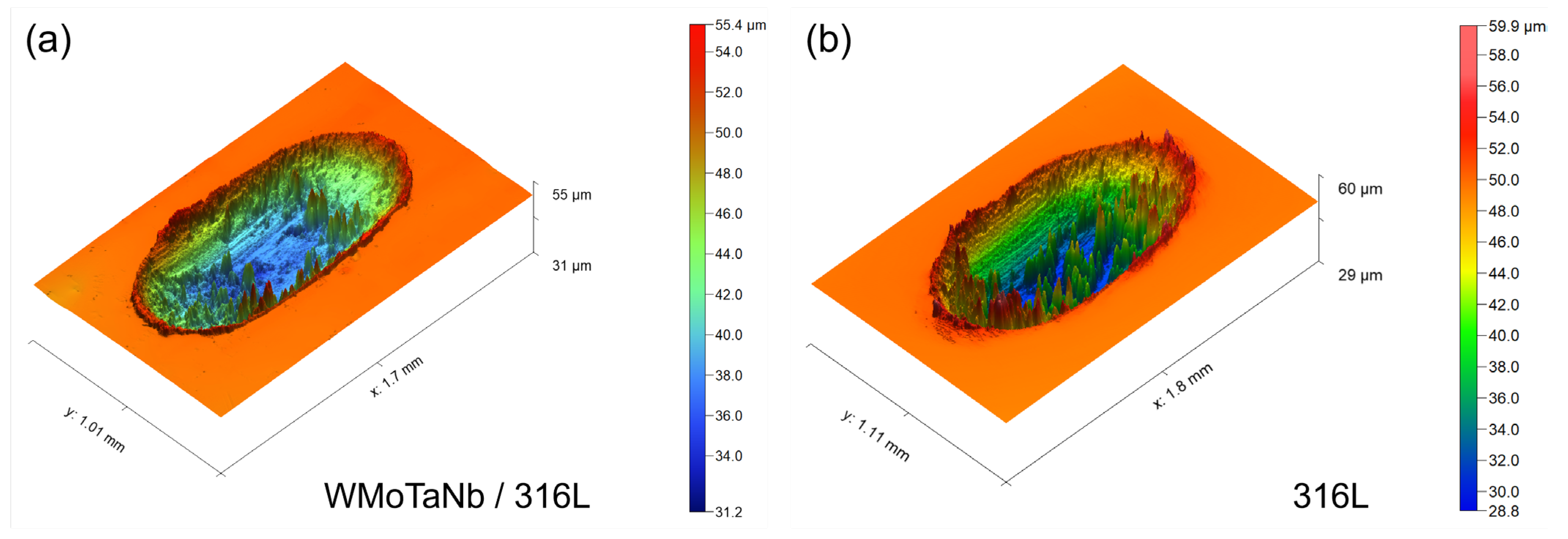

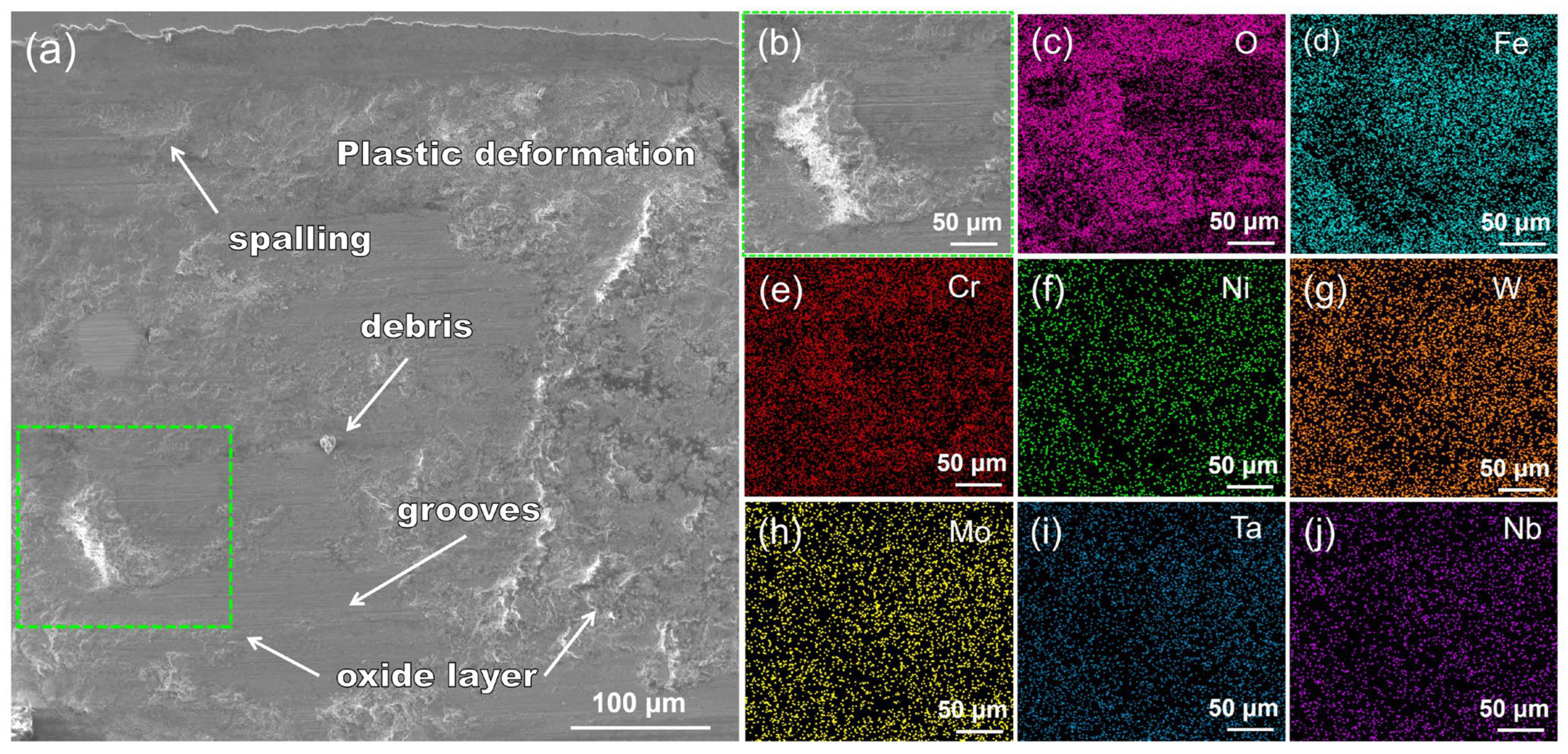

3.4. Wear Resistance

4. Conclusions

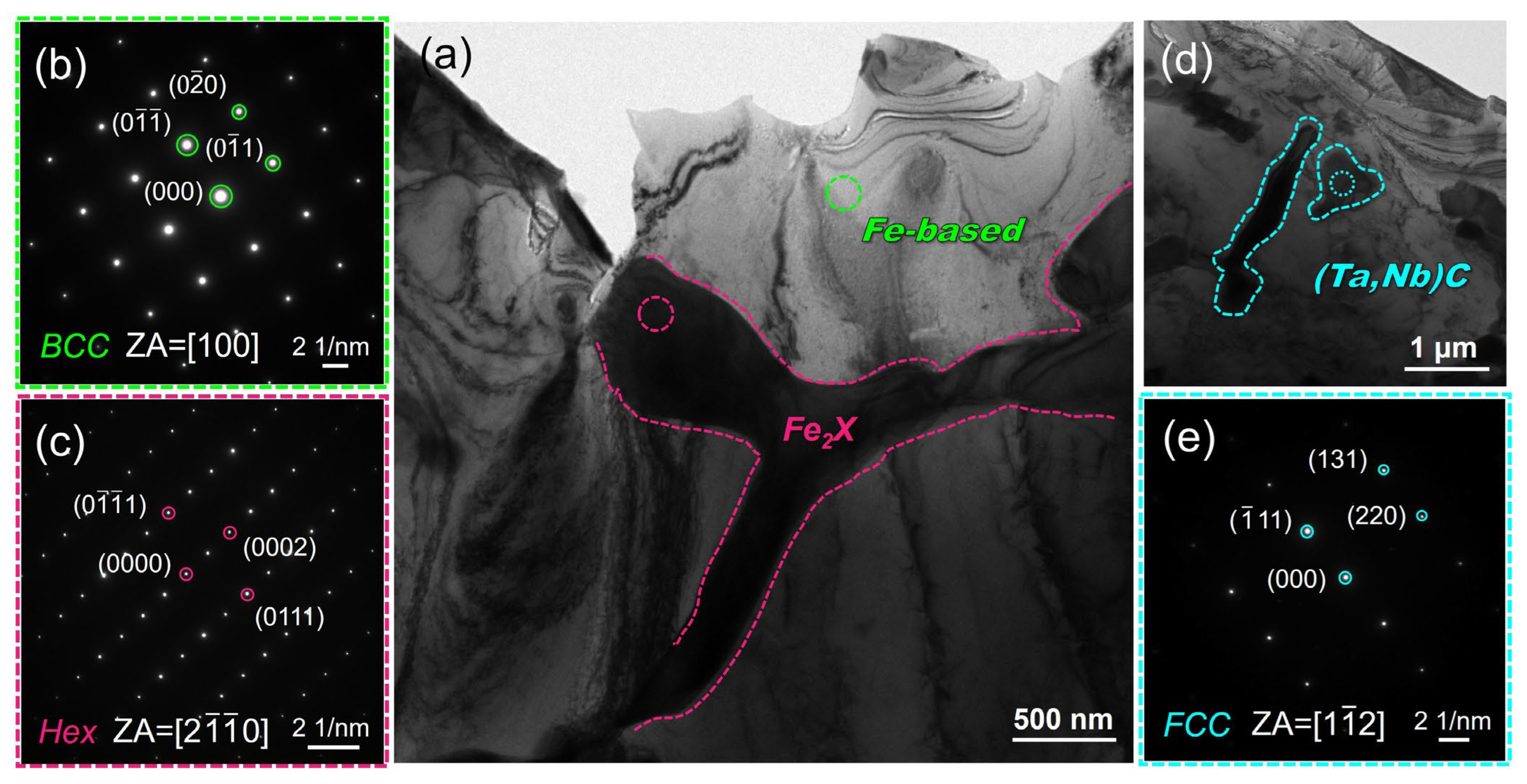

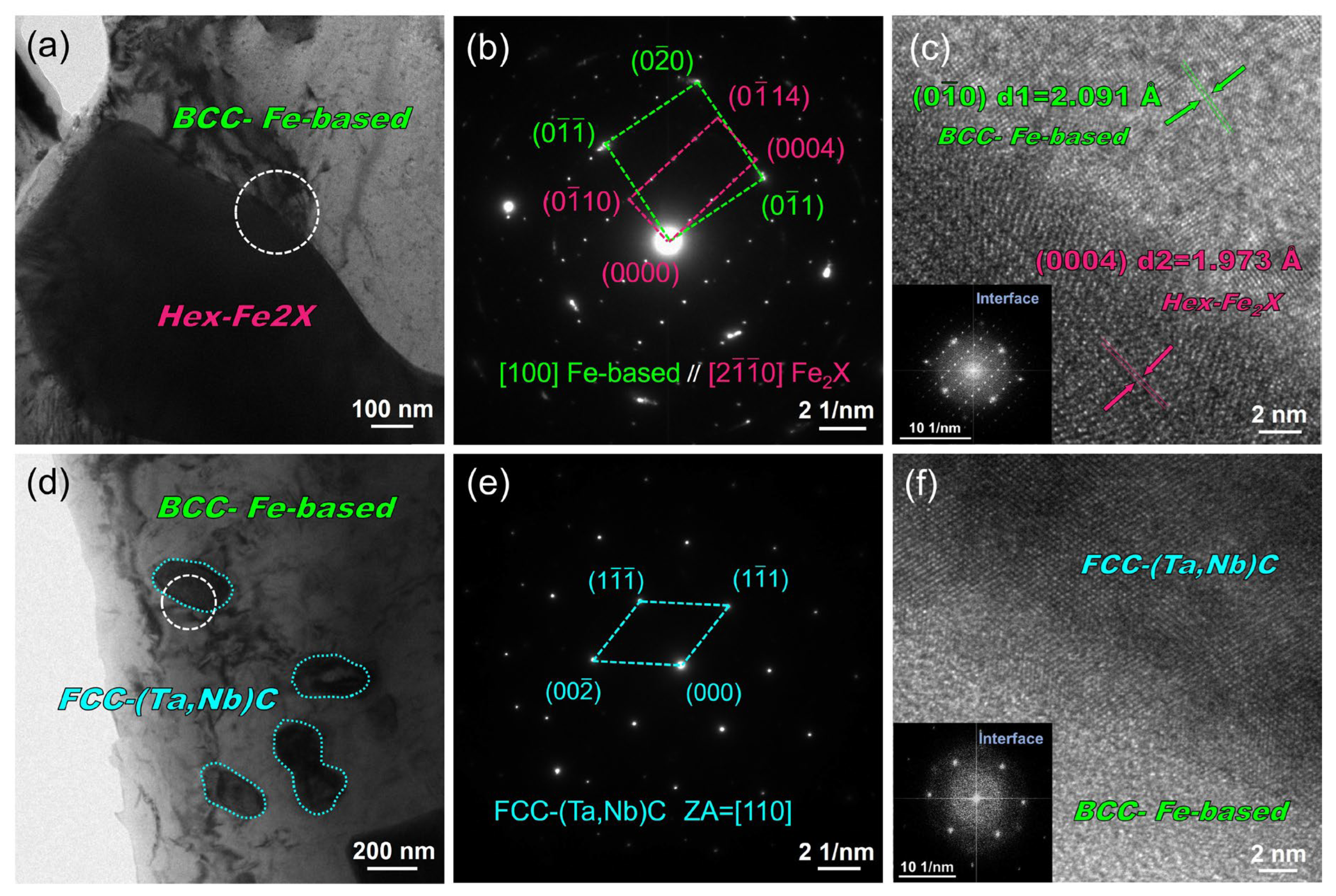

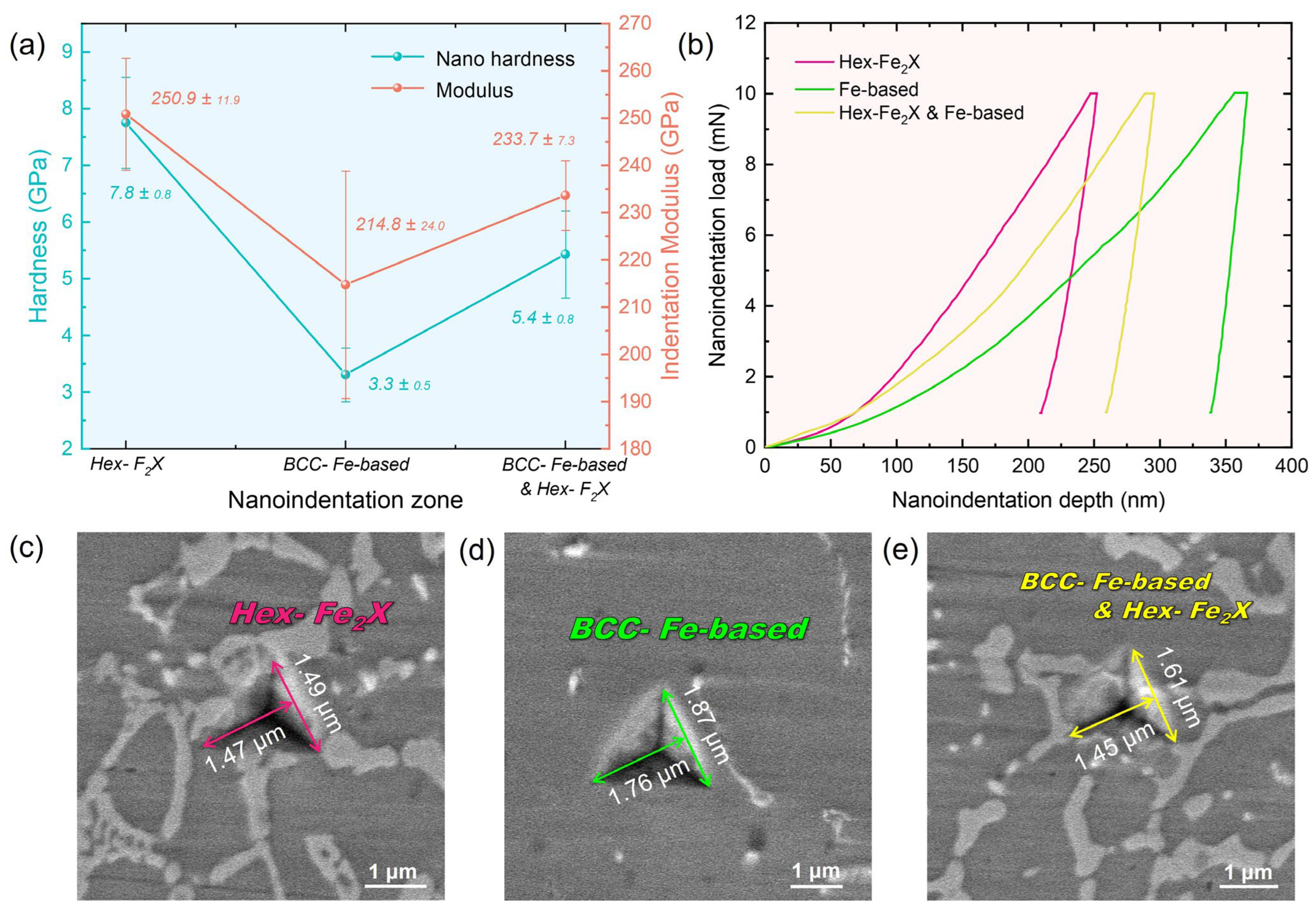

- The microstructure of the coating consists of a BCC Fe-based dendritic solid solution, a hexagonal Fe2X (W, Mo, Ta, and Nb) Laves interdendritic phase, and an FCC (Ta, Nb)C interdendritic granular phase.

- The Fe-based solid solution and the Fe2X Laves phase show a semi-coherent interface with a lattice mismatch of 5.81%. There is no orientation relationship between the Fe-based solid solution and the (Ta, Nb)C phase, which is a non-coherent interface.

- The microhardness of the laser-cladding WMoTaNb/316L composite coating surface was about 460 HV0.3, which was 2.1 times higher than that of the 316L coating. The primary strengthening mechanism involves the incorporation of a WMoTaNb refractory high entropy alloy, which facilitates the formation of a robust network Fe2X Laves phase with enhanced strength, as well as solid solution strengthening within the iron-based solid solution.

- The wear resistance of laser-cladding WMoTaNb/316L composite coatings is superior to that of 316L coatings. The main wear mechanisms at room temperature were adhesive, oxidative, and abrasive wear.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Voisin, T.; Forien, J.-B.; Perron, A.; Aubry, S.; Bertin, N.; Samanta, A.; Baker, A.; Wang, Y.M. New insights on cellular structures strengthening mechanisms and thermal stability of an austenitic stainless steel fabricated by laser powder-bed-fusion. Acta Mater. 2021, 203, 116476. [Google Scholar] [CrossRef]

- Fang, T.H.; Tao, N.R. Martensitic transformation dominated tensile plastic deformation of nanograins in a gradient nanostructured 316L stainless steel. Acta Mater. 2023, 248, 118780. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, J.; Luo, Z.; Yi, J.; He, M.; Zhao, Y.; Wang, S. Enhancing corrosion resistance of additively manufactured 316L stainless steel by fabricating pillar arrays. Mater. Des. 2023, 230, 111940. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, P.; Wang, F.; Lu, Y.H.; Shoji, T. Anisotropy of microstructure and corrosion resistance of 316L stainless steel fabricated by wire and arc additive manufacturing. Corros. Sci. 2022, 206, 110549. [Google Scholar] [CrossRef]

- Liu, X.; Wang, H.; Liu, Y.; Wang, C.; Song, Q.; Cui, H.; Zhang, C.; Huang, K. The effect of Nb content on microstructure and properties of laser cladding 316L SS coating. Surf. Coat. Technol. 2021, 425, 127684. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, R.; Zhao, C.; Wei, R.; Li, H.; Deng, R.; Bai, Q.; Liu, Y. Study on ductile iron surface laser cladding austenitic stainless steel coating heat treatment to enhance wear resistance. Tribol. Int. 2024, 191, 109202. [Google Scholar] [CrossRef]

- Ouyang, W.; Xu, Z.; Chao, Y.; Liu, Y.; Luo, W.; Jiao, J.; Sheng, L.; Zhang, W. Effect of electrostatic field on microstructure and mechanical properties of the 316L stainless steel modified layer fabricated by laser cladding. Mater. Charact. 2022, 191, 112123. [Google Scholar] [CrossRef]

- Yu, J.; Wang, Y.; Zhou, F.; Wang, L.; Pan, Z. Laser remelting of plasma-sprayed nanostructured Al2O3—20 wt.% ZrO2 coatings onto 316L stainless steel. Appl. Surf. Sci. 2018, 431, 112–121. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, S.; Shen, M.; Jia, Y.; Wang, W.; Wang, F. Microstructure and cavitation erosion behavior of sputtered NiCrAlTi coatings with and without N incorporations. J. Mater. Sci. Technol. 2020, 54, 211–222. [Google Scholar] [CrossRef]

- Zhuang, D.D.; Du, B.; Zhang, S.H.; Tao, W.W.; Wang, Q.; Shen, H.B. Effect and action mechanism of ultrasonic assistance on microstructure and mechanical performance of laser cladding 316L stainless steel coating. Surf. Coat. Technol. 2022, 433, 128122. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; ur Rehman, E.; Ullah, S.; Atif, M.; Tariq, A. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar] [CrossRef]

- Sun, P.; Yan, N.; Wei, S.; Wang, D.; Song, W.; Tang, C.; Yang, J.; Xu, Z.; Hu, Q.; Zeng, X. Microstructural evolution and strengthening mechanisms of Inconel 718 alloy with different W addition fabricated by laser cladding. Mater. Sci. Eng. A 2023, 868, 144535. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Xu, X.; Hopper, C.; Dong, H.; Wang, X.; Zhu, H.; Jiang, J. The study of hot deformation on laser cladding remanufactured 316L stainless steel. Mater. Des. 2021, 212, 110255. [Google Scholar] [CrossRef]

- Kim, R.E.; Moon, J.; Kim, E.S.; Lee, J.; Kim, H.S. Surface heterostructuring of laser-clad 316L stainless steel through texture-driven deformation twinning. Scr. Mater. 2022, 221, 114989. [Google Scholar] [CrossRef]

- He, B.; Zhang, L.; Zhu, Q.; Wang, J.; Yun, X.; Luo, J.; Chen, Z. Effect of solution treated 316L layer fabricated by laser cladding on wear and corrosive wear resistance. Opt. Laser Technol. 2020, 121, 105788. [Google Scholar] [CrossRef]

- Ding, H.; Yang, T.; Wang, W.; Zhu, Y.; Lin, Q.; Guo, J.; Xiao, Q.; Gan, L.; Liu, Q. Optimization and wear behaviors of 316L stainless steel laser cladding on rail material. Wear 2023, 523, 204830. [Google Scholar] [CrossRef]

- Koube, K.D.; Kennedy, G.; Bertsch, K.; Kacher, J.; Thoma, D.J.; Thadhani, N.N. Spall damage mechanisms in laser powder bed fabricated stainless steel 316L. Mater. Sci. Eng. A 2022, 851, 143622. [Google Scholar] [CrossRef]

- Maurizi Enrici, T.; Dedry, O.; Boschini, F.; Tchuindjang, J.T.; Mertens, A. Microstructural and Thermal Characterization of 316L + WC Composite Coatings Obtained by Laser Cladding. Adv. Eng. Mater. 2020, 22, 2000291. [Google Scholar] [CrossRef]

- Lian, G.; Zhao, C.; Zhang, Y.; Feng, M.; Jiang, J. Investigation into Micro-Hardness and Wear Resistance of 316L/SiC Composite Coating in Laser Cladding. Appl. Sci. 2020, 10, 3167. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Han, R.; Peng, Y.; Wang, K.; Li, X. Investigating the microstructure and mechanical properties of 316L/TiB2 composites fabricated by laser cladding additive manufacturing. J. Mater. Res. Technol. 2024, 29, 28–39. [Google Scholar] [CrossRef]

- Yu, J.; Ho, H. Microstructure and Mechanical Properties of (Ti, Nb)C Ceramic-Reinforced 316L Stainless Steel Coating by Laser Cladding. Appl. Sci. 2022, 12, 6684. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Wang, L.; Yang, X.; Zeng, T.; Sun, L.; Wang, R. Microstructure evolution and wear resistance of laser cladded 316L stainless steel reinforced with in-situ VC-Cr7C3. Surf. Coat. Technol. 2022, 435, 128264. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Ying, H.; Yang, X.; He, H.; Tao, K.; Guo, Z.; Wang, L.; Ge, J.; Liu, S.; Fu, S.; Lou, Y.; et al. Formation of strong and ductile FeNiCoCrB network-structured high-entropy alloys by fluxing. Microstructures 2023, 3, 2023018. [Google Scholar] [CrossRef]

- Chang, X.; Zeng, M.; Liu, K.; Fu, L. Phase Engineering of High-Entropy Alloys. Adv. Mater. 2020, 32, 1907226. [Google Scholar] [CrossRef] [PubMed]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Wang, S.; Wu, M.; Shu, D.; Zhu, G.; Wang, D.; Sun, B. Mechanical instability and tensile properties of TiZrHfNbTa high entropy alloy at cryogenic temperatures. Acta Mater. 2020, 201, 517–527. [Google Scholar] [CrossRef]

- Edalati, P.; Floriano, R.; Tang, Y.; Mohammadi, A.; Pereira, K.D.; Luchessi, A.D.; Edalati, K. Ultrahigh hardness and biocompatibility of high-entropy alloy TiAlFeCoNi processed by high-pressure torsion. Mater. Sci. Eng. C 2020, 112, 110908. [Google Scholar] [CrossRef]

- Edalati, P.; Mohammadi, A.; Ketabchi, M.; Edalati, K. Ultrahigh hardness in nanostructured dual-phase high-entropy alloy AlCrFeCoNiNb developed by high-pressure torsion. J. Alloys Compd. 2021, 884, 161101. [Google Scholar] [CrossRef]

- Edalati, P.; Mohammadi, A.; Ketabchi, M.; Edalati, K. Microstructure and microhardness of dual-phase high-entropy alloy by high-pressure torsion: Twins and stacking faults in FCC and dislocations in BCC. J. Alloys Compd. 2022, 894, 162413. [Google Scholar] [CrossRef]

- Edalati, P.; Mohammadi, A.; Tang, Y.; Floriano, R.; Fuji, M.; Edalati, K. Phase transformation and microstructure evolution in ultrahard carbon-doped AlTiFeCoNi high-entropy alloy by high-pressure torsion. Mater. Lett. 2021, 302, 130368. [Google Scholar] [CrossRef]

- Ying, H.; Yang, X.; He, H.; Yan, A.; An, K.; Ke, Y.; Wu, Z.; Tang, S.; Zhang, Z.; Dong, H.; et al. Anomalous dislocation response to deformation strain in CrFeCoNiPd high-entropy alloys with nanoscale chemical fluctuations. Scr. Mater. 2024, 250, 116181. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, M.; Hou, J.; Chen, Y.; Zhang, C.; Cheng, J.; Li, R. Microstructure and high temperature properties of laser cladded WTaNbMo refractory high entropy alloy coating assisted with ultrasound vibration. J. Alloys Compd. 2022, 920, 165888. [Google Scholar] [CrossRef]

- Chen, Z.B.; Zhang, G.G.; Chen, J.J.; Guo, C.H.; Sun, W.Y.; Yang, Z.L.; Li, H.X.; Jiang, F.C.; Han, B. Microstructure and wear property of WMoTaNb refractory high entropy alloy coating by laser cladding. J. Mater. Res. Technol. 2024, 28, 1557–1569. [Google Scholar] [CrossRef]

- Chen, H.; Ye, L.; Han, Y.; Chen, C.; Fan, J. Additive manufacturing of W–Fe composites using laser metal deposition: Microstructure, phase transformation, and mechanical properties. Mater. Sci. Eng. A 2021, 811, 141036. [Google Scholar] [CrossRef]

- Xiao, B.; Dong, H.; Yang, T.; Liu, S.; Jin, S.; Cao, B.; Han, Y.; Zhao, L.; Yang, X.; Sha, G.; et al. Creep-induced heterogeneous precipitation of Laves phase with two morphologies in tempered martensite ferritic steels. Mater. Res. Lett. 2023, 11, 630–637. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Li, K.; Li, D.; Liu, D.; Pei, G.; Sun, L. Microstructure evolution and mechanical properties of multiple-layer laser cladding coating of 308L stainless steel. Appl. Surf. Sci. 2015, 340, 143–150. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Shi, Y.; Su, G.; Gu, Y.; Volodymyr, K. Intergranular corrosion characteristics of high-efficiency wire laser additive manufactured Inconel 625 alloys. Corros. Sci. 2022, 205, 110422. [Google Scholar] [CrossRef]

- Kim, H.-K.; Ha, H.-Y.; Bae, J.-H.; Cho, M.K.; Kim, J.; Han, J.; Suh, J.-Y.; Kim, G.-H.; Lee, T.-H.; Jang, J.H.; et al. Nanoscale light element identification using machine learning aided STEM-EDS. Sci. Rep. 2020, 10, 13699. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zou, J.; Zeng, X.; Ding, W. Hydrogen storage properties of a Mg-La-Fe-H nano-composite prepared through reactive ball milling. J. Alloys Compd. 2017, 701, 208–214. [Google Scholar] [CrossRef]

- Kim, D.W.; Kwon, D.Y.; Kang, J.-H. Strengthening of high nitrogen austenitic stainless steel by Nb addition. Mater. Charact. 2024, 209, 113776. [Google Scholar] [CrossRef]

- Wan, W.; Wang, J.; Liang, M.; Fan, K.; Wang, Z.; Li, Y. Fracture behaviors of Ti(C, N)-based cermets with different contents of metal binder. Ceram. Int. 2022, 48, 32399–32408. [Google Scholar] [CrossRef]

- Ruan, T.; Shen, J.; Li, B.; Zhao, Z.; Zhang, D. High-temperature strengthening mechanism and thermal stability of Laves phase in ferritic matrix. Mater. Sci. Eng. A 2022, 859, 144183. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, H.; Lv, Y.; Song, C.; Guo, N.; Xiao, G.; Zhao, W. Microstructure and properties of W0.5Ta0.3MoNbVAlTi1−xZrx high entropy alloy coatings by laser cladding on the surface of 45# steel. Ceram. Int. 2023, 49, 36416–36428. [Google Scholar] [CrossRef]

- Cao, Y.-B.; Zhi, S.-X.; Gao, Q.; Tian, X.-T.; Geng, T.; Guan, X.; Qin, C. Formation behavior of in-situ NbC in Fe-based laser cladding coatings. Mater. Charact. 2016, 119, 159–165. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, T.; Xiao, M.; Shen, Y. Effect of Nb content on microstructure and properties of laser cladding FeNiCoCrTi0.5Nbx high-entropy alloy coating. Optik 2019, 198, 163316. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A.J.M.T. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Dangwal, S.; Edalati, K. High-entropy alloy TiV2ZrCrMnFeNi for hydrogen storage at room temperature with full reversibility and good activation. Scr. Mater. 2024, 238, 115774. [Google Scholar] [CrossRef]

- Dangwal, S.; Li, Y.; Edalati, K. AB-type dual-phase high-entropy alloys as negative electrode of Ni-MH batteries: Impact of interphases on electrochemical performance. Mater. Chem. Phys. 2024, 319, 129397. [Google Scholar] [CrossRef]

- Edalati, P.; Floriano, R.; Mohammadi, A.; Li, Y.; Zepon, G.; Li, H.-W.; Edalati, K. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Scr. Mater. 2020, 178, 387–390. [Google Scholar] [CrossRef]

- Edalati, P.; Mohammadi, A.; Li, Y.; Li, H.-W.; Floriano, R.; Fuji, M.; Edalati, K. High-entropy alloys as anode materials of nickel—Metal hydride batteries. Scr. Mater. 2022, 209, 114387. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ikeda, Y.; Edalati, P.; Mito, M.; Grabowski, B.; Li, H.-W.; Edalati, K. High-entropy hydrides for fast and reversible hydrogen storage at room temperature: Binding-energy engineering via first-principles calculations and experiments. Acta Mater. 2022, 236, 118117. [Google Scholar] [CrossRef]

- Barkia, B.; Aubry, P.; Haghi-Ashtiani, P.; Auger, T.; Gosmain, L.; Schuster, F.; Maskrot, H. On the origin of the high tensile strength and ductility of additively manufactured 316L stainless steel: Multiscale investigation. J. Mater. Sci. Technol. 2020, 41, 209–218. [Google Scholar] [CrossRef]

- Bertsch, K.M.; Meric de Bellefon, G.; Kuehl, B.; Thoma, D.J. Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L. Acta Mater. 2020, 199, 19–33. [Google Scholar] [CrossRef]

- Ren, Z.Y.; Hu, Y.L.; Tong, Y.; Cai, Z.H.; Liu, J.; Wang, H.D.; Liao, J.Z.; Xu, S.; Li, L.K. Wear-resistant NbMoTaWTi high entropy alloy coating prepared by laser cladding on TC4 titanium alloy. Tribol. Int. 2023, 182, 108366. [Google Scholar] [CrossRef]

- Archard, J.F. Single Contacts and Multiple Encounters. J. Appl. Phys. 1961, 32, 1420–1425. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, K.; Ma, Q.; Song, C.; Xiao, G.; Zhang, H.; Lv, Y.; Guo, N.; Li, Z. Synergistic effects of Mo and in-situ TiC on the microstructure and wear resistance of AlCoCrFeNi high entropy alloy fabricated by laser cladding. Tribol. Int. 2023, 188, 108827. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, B.; Ge, Y.; Hu, X.; Zhang, L.; Liang, X.; Zhang, X. Nb doping in laser-cladded Fe25Co25Ni25(B0.7Si0.3)25 high entropy alloy coatings: Microstructure evolution and wear behavior. Surf. Coat. Technol. 2020, 402, 126321. [Google Scholar] [CrossRef]

| Elements | W | Mo | Ta | Nb | Fe | Cr | Ni | Si | Mn | C | S | P | O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WMoTaNb | 21.00 | 26.00 | 24.00 | 29.00 | - | - | - | - | - | - | - | - | - |

| 316L | - | 2.59 | - | - | Bal. | 16.56 | 10.75 | 0.31 | 0.68 | 0.015 | 0.005 | 0.012 | 0.07 |

| Substrate | - | - | - | - | Bal. | 0.02 | 0.01 | 0.20 | 0.53 | 0.45 | 0.009 | 0.021 | - |

| Elements | W | Mo | Ta | Nb | Fe | Cr | Ni |

|---|---|---|---|---|---|---|---|

| Zone A | 1.7 | 2.3 | 0.4 | 0.2 | 76.0 | 11.8 | 7.6 |

| Zone B | 5.3 | 5.6 | 7.2 | 6.4 | 60.6 | 9.9 | 5.0 |

| Zone C | 4.9 | 5.2 | 22.0 | 24.5 | 31.8 | 7.7 | 3.8 |

| Elements | W | Mo | Ta | Nb | Fe | Cr | Ni | C |

|---|---|---|---|---|---|---|---|---|

| Point A | 4.4 | 5.3 | 6.2 | 6.2 | 63.1 | 10.0 | 4.8 | - |

| Point B | 1.5 | 2.3 | 0.3 | 0.4 | 76.4 | 13.2 | 5.9 | - |

| Point C | 1.5 | 2.7 | 32.1 | 33.2 | 13.3 | 3.6 | 0.8 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, A.; Chen, G.; Ying, H.; Yang, X.; Kou, Z.; Tang, S.; Fan, L.; Chen, X.; Zhu, H.; Zhu, Z.; et al. High-Entropy Alloy Activating Laves-Phase Network for Multi-Component Metallic Coatings with High Hardness. Nanomaterials 2024, 14, 1016. https://doi.org/10.3390/nano14121016

Yan A, Chen G, Ying H, Yang X, Kou Z, Tang S, Fan L, Chen X, Zhu H, Zhu Z, et al. High-Entropy Alloy Activating Laves-Phase Network for Multi-Component Metallic Coatings with High Hardness. Nanomaterials. 2024; 14(12):1016. https://doi.org/10.3390/nano14121016

Chicago/Turabian StyleYan, Ao, Guoxing Chen, Huiqiang Ying, Xiao Yang, Zongde Kou, Song Tang, Longlong Fan, Xiang Chen, He Zhu, Zhiguang Zhu, and et al. 2024. "High-Entropy Alloy Activating Laves-Phase Network for Multi-Component Metallic Coatings with High Hardness" Nanomaterials 14, no. 12: 1016. https://doi.org/10.3390/nano14121016