Candle Soot as a Novel Support for Nickel Nanoparticles in the Electrocatalytic Ethanol Oxidation

Abstract

:1. Introduction

2. Methodology

2.1. Collection of Candle Soot Nanoparticles

2.2. Synthesis of Ni–CS Electrocatalyst

2.3. Structural Characterization of Electrocatalyst

2.4. Working Electrode Preparation

2.5. Electrocatalytic Performance Measurements

3. Results and Discussion

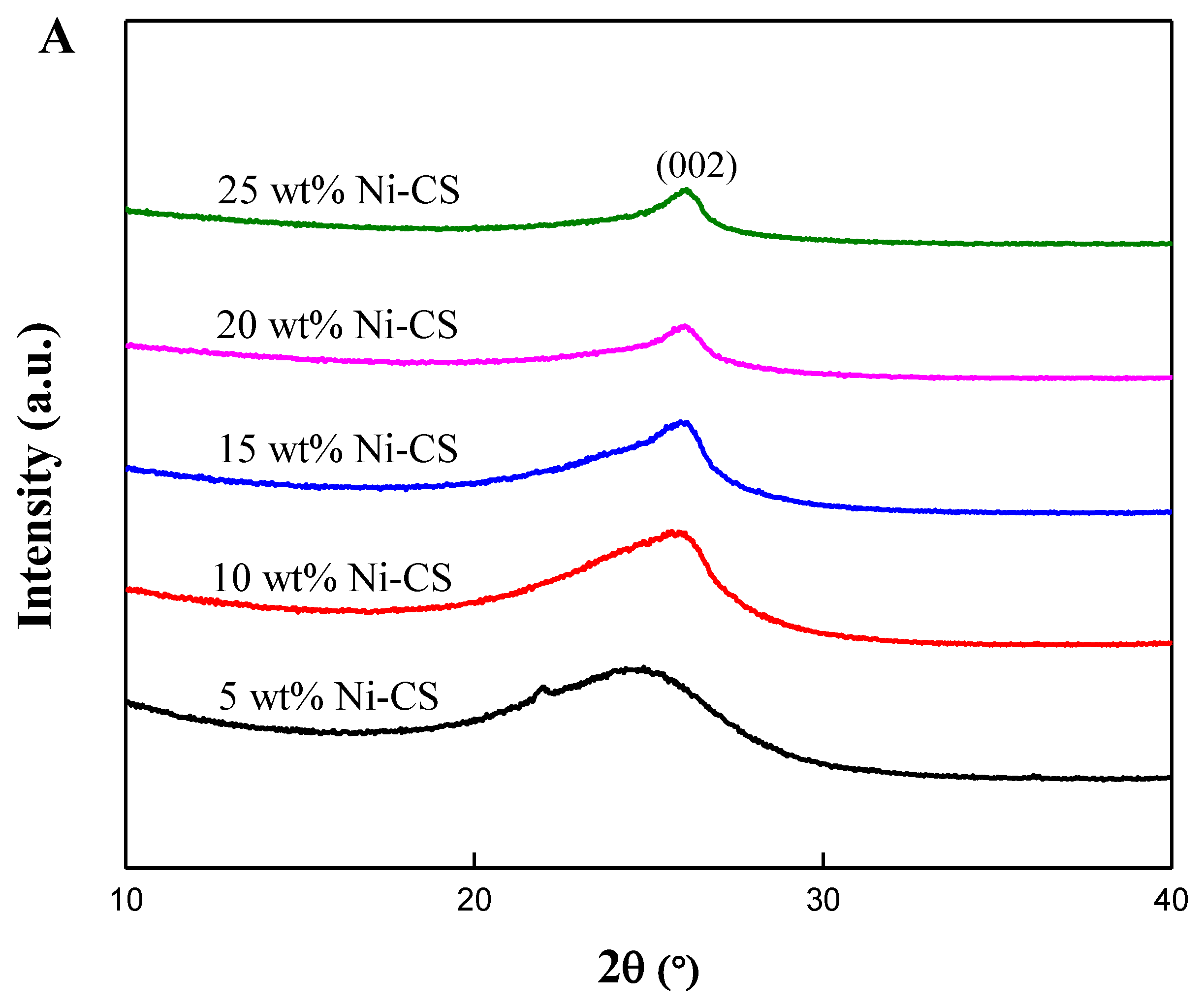

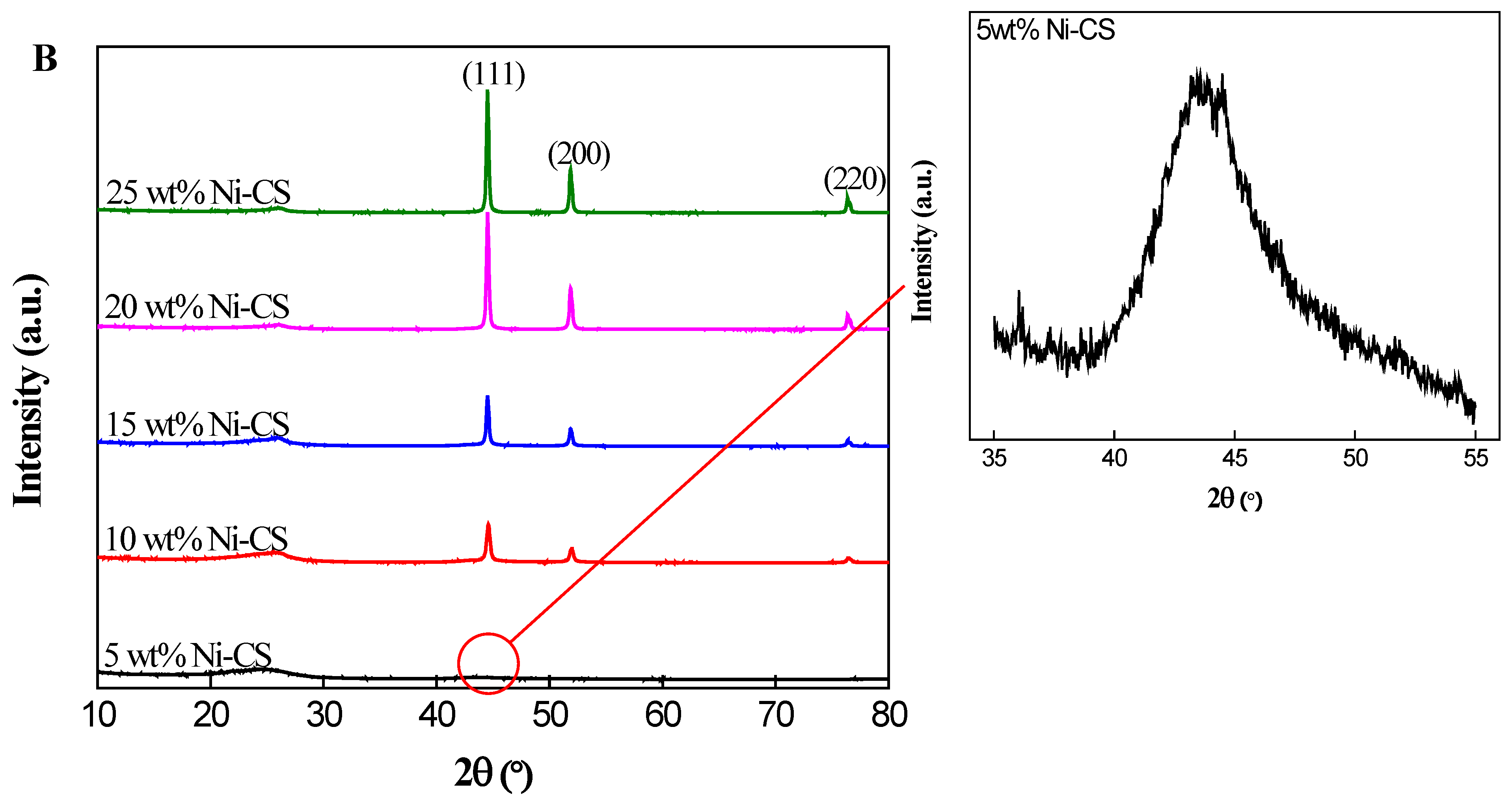

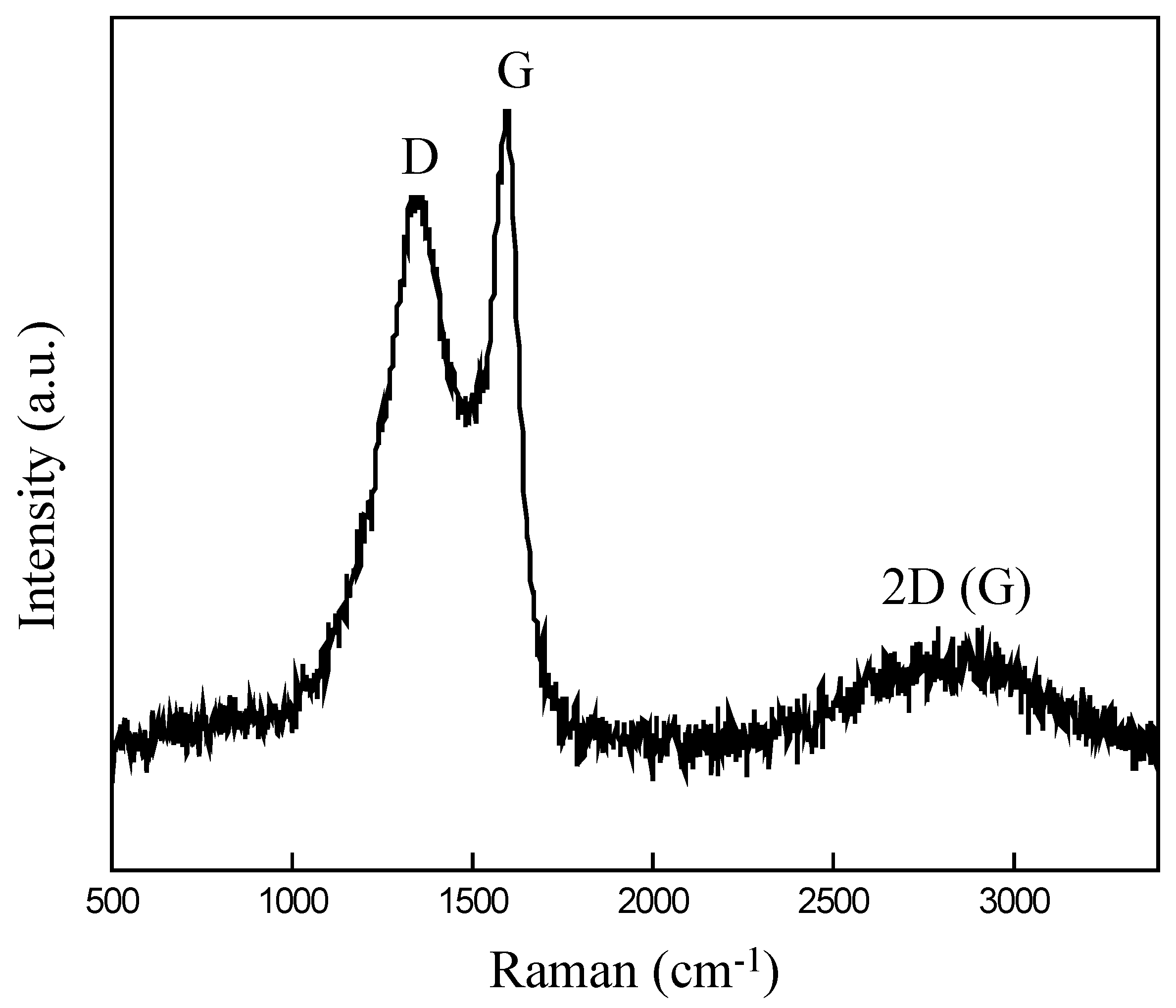

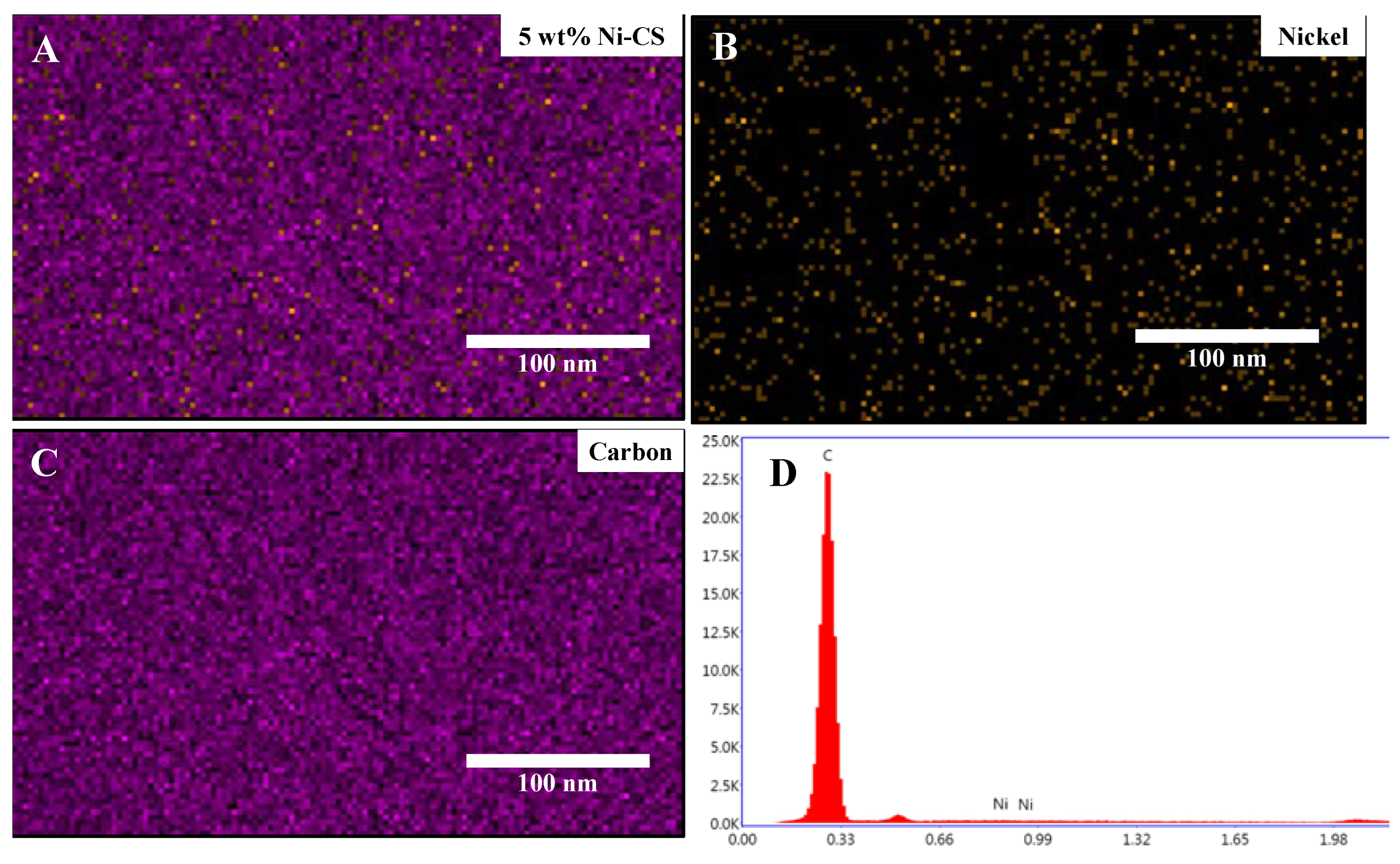

3.1. Structural Characterization

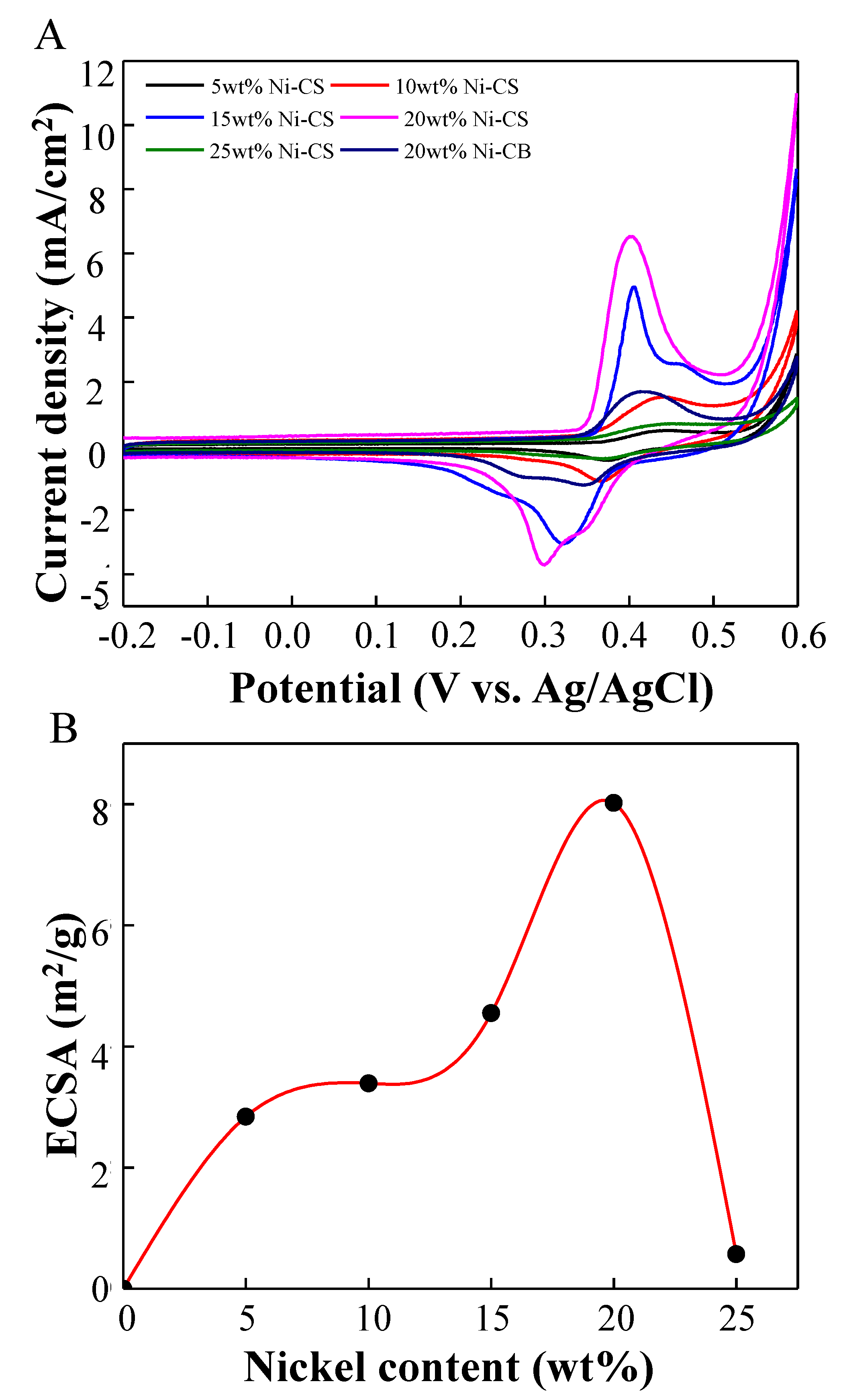

3.2. Electrochemical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yaqoob, L.; Noor, T.; Iqbal, N. A Comprehensive and Critical Review of the Recent Progress in Electrocatalysts for the Ethanol Oxidation Reaction. RSC Adv. 2021, 11, 16768–16804. [Google Scholar] [CrossRef] [PubMed]

- Dabirifar, Z.; Khadempir, S.; Kardan, A.; Karaman, C. Boosting the Electrocatalytic Activity of ZrO2/MWCNT Supported PdPt Bi-Metallic Electrocatalyst towards Ethanol Oxidation Reaction by Electrochemical Activation Process and Modeling by Artificial Neural Network Approach. Chem. Eng. Res. Des. 2022, 180, 38–49. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Wang, C.; He, W.; Zhao, Y.; Wang, X. Droplet Flow Characteristics on Experimentally Measured Gas Diffusion Layer Surfaces of Polymer Electrolyte Membrane Fuel Cells. J. Power Sources 2024, 590, 233801. [Google Scholar] [CrossRef]

- Wang, K.; Wang, F.; Zhao, Y.; Zhang, W. Surface-Tailored PtPdCu Ultrathin Nanowires as Advanced Electrocatalysts for Ethanol Oxidation and Oxygen Reduction Reaction in Direct Ethanol Fuel Cell. J. Energy Chem. 2020, 52, 251–261. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, S.; Liao, X.; Jia, Y.; Xu, H.; Wang, C.; He, W.; Zhao, Y. Lattice Boltzmann Study of the Effect of Catalyst Layer Structure on Oxygen Reduction Reaction within a PEMFC. Int. J. Hydrogen Energy 2024, 52, 1105–1114. [Google Scholar] [CrossRef]

- Maya-Cornejo, J.; Carrera-Cerritos, R.; Sebastián, D.; Ledesma-García, J.; Arriaga, L.G.; Aricò, A.S.; Baglio, V. PtCu Catalyst for the Electro-Oxidation of Ethanol in an Alkaline Direct Alcohol Fuel Cell. Int. J. Hydrogen Energy 2017, 42, 27919–27928. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, W.; Pang, D.; Xu, Q. Methanol Electrooxidation Reaction in Alkaline Medium on Glassy Carbon Electrode Modified with Ordered Mesoporous Ni/Al2O3. Int. J. Electrochem. Sci. 2017, 12, 2194–2206. [Google Scholar] [CrossRef]

- Askari, M.B.; Salarizadeh, P.; Seifi, M.; Rozati, S.M. Ni/NiO Coated on Multi-Walled Carbon Nanotubes as a Promising Electrode for Methanol Electro-Oxidation Reaction in Direct Methanol Fuel Cell. Solid State Sci. 2019, 97, 106012. [Google Scholar] [CrossRef]

- Chemchoub, S.; Oularbi, L.; El Attar, A.; Younssi, S.A.; Bentiss, F.; Jama, C.; El Rhazi, M. Cost-Effective Non-Noble Metal Supported on Conducting Polymer Composite Such as Nickel Nanoparticles/Polypyrrole as Efficient Anode Electrocatalyst for Ethanol Oxidation. Mater. Chem. Phys. 2020, 250, 123009. [Google Scholar] [CrossRef]

- Sayed, E.T.; Olabi, A.G.; Wilberforce, T.; Al-Murisi, M.; Chae, K.J.; Abdelkareem, M.A. Ni Sulfide Nano-Sheets as an Efficient Standalone Electrode in Direct Ethanol Fuel Cells. J. Taiwan Inst. Chem. Eng. 2023, 146, 104906. [Google Scholar] [CrossRef]

- Castegnaro, M.V.; Paschoalino, W.J.; Fernandes, M.R.; Balke, B.; Alves, M.C.; Ticianelli, E.A.; Morais, J. Pd-M/C (M = Pd, Cu, Pt) Electrocatalysts for Oxygen Reduction Reaction in Alkaline Medium: Correlating the Electronic Structure with Activity. Langmuir 2017, 33, 2734–2743. [Google Scholar] [CrossRef] [PubMed]

- Kakaei, K.; Rahnavardi, M. Synthesis of Nitrogen-Doped Reduced Graphene Oxide and Its Decoration with High Efficiency Palladium Nanoparticles for Direct Ethanol Fuel Cell. Renew. Energy 2021, 163, 1277–1286. [Google Scholar] [CrossRef]

- Samimi, G.; Ashrafi, H.; Tashkhourian, J.; Haghighi, B. RGO@Ni/NiO Composite an Effective Electrocatalyst for Methanol Oxidation Reaction in Alkaline Media. J. Phys. Chem. Solids 2024, 184, 111724. [Google Scholar] [CrossRef]

- Sikeyi, L.L.; Adekunle, A.S.; Maxakato, N.W. Electro-Catalytic Activity of Carbon Nanofibers Supported Palladium Nanoparticles for Direct Alcohol Fuel Cells in Alkaline Medium. Electrocatalysis 2019, 10, 420–428. [Google Scholar] [CrossRef]

- Mamidi, S.; Yoon, B.; Na, D.; Kampara, R.K.; Lee, D.Y.; Lee, C.R.; Seo, I. Candle Soot-Metal-Organic Framework-Based Hierarchical Electrode as High-Performance Anode for Li-Ion Batteries. J. Electroanal. Chem. 2023, 949, 117853. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, D.; Fang, Z.; Xu, S.; Liu, Q.; Hou, H.; Wang, L.; Zhou, Z.; Shao, G.; Yang, W.; et al. N and S Co-Doped Carbon Nanofibers with Embedded Candle Soot and Designed Surface Decoration for Efficient Bifunctional Electrocatalysts. Electrochim. Acta 2021, 380, 138261. [Google Scholar] [CrossRef]

- Surib, N.A.; Khairunnisa, M.P.; Lenggoro, I.W.; Liza, S.; Yew, H.W. Conductive Particulate Films Fabricated by Electrospray Deposition of Candle Soot Suspensions with Acid Treatment. Adv. Powder Technol. 2023, 34, 104107. [Google Scholar] [CrossRef]

- Uttaravalli, A.N.; Dinda, S.; Kakara, V.R.; Rao, A.V.R.; Daida, T.; Gidla, B.R. Sustainable Use of Recycled Soot (Carbon Black) for the Cleaner Production of Value-Added Products: A Compendium. Chem. Eng. J. Adv. 2022, 11, 100324. [Google Scholar] [CrossRef]

- Kanakaraj, R.; Sudakar, C. Candle Soot Carbon Nanoparticles as High-Performance Universal Anode for M-Ion (M = Li+, Na+ and K+) Batteries. J. Power Sources 2020, 458, 228064. [Google Scholar] [CrossRef]

- Zhang, Z.; Hao, J.; Yang, W.; Lu, B.; Tang, J. Modifying Candle Soot with FeP Nanoparticles into High-Performance and Cost-Effective Catalysts for the Electrocatalytic Hydrogen Evolution Reaction. Nanoscale 2015, 7, 4400–4405. [Google Scholar] [CrossRef]

- Surib, N.A.; Mohd Paad, K. Electrospray Flow Rate Influenced the Sized of Functionalized Soot Nanoparticles. Asia-Pacific J. Chem. Eng. 2020, 15, e2417. [Google Scholar] [CrossRef]

- Mansor, M.; Timmiati, S.N.; Zainoodin, A.M.; Pa’ad, K.M.; Lim, K.L. Investigation of Palladium-Mesostructured Silica Nanoparticles (Pd-MSN) as Anode Electrocatalyst for Alkaline Direct Methanol Fuel Cell. Chem. Phys. Lett. 2021, 785, 139125. [Google Scholar] [CrossRef]

- Eswaran, M.; Dhanusuraman, R.; Tsai, P.C.; Ponnusamy, V.K. One-Step Preparation of Graphitic Carbon Nitride/Polyaniline/Palladium Nanoparticles Based Nanohybrid Composite Modified Electrode for Efficient Methanol Electro-Oxidation. Fuel 2019, 251, 91–97. [Google Scholar] [CrossRef]

- Shi, Q.; Liu, Q.; Ma, Y.; Fang, Z.; Liang, Z.; Shao, G.; Tang, B.; Yang, W. High-Performance Trifunctional Electrocatalysts Based on FeCo/Co2P Hybrid Nanoparticles for Zinc—Air Battery and Self-Powered Overall Water Splitting. Adv. Energy Mater. 2020, 10, 1903854. [Google Scholar] [CrossRef]

- Khairudin, N.F.; Mohammadi, M.; Mohamed, A.R. An Investigation on the Relationship between Physicochemical Characteristics of Alumina-Supported Cobalt Catalyst and Its Performance in Dry Reforming of Methane. Environ. Sci. Pollut. Res. 2021, 28, 29157–29176. [Google Scholar] [CrossRef]

- Hassanzadeh-Tabrizi, S.A. Precise Calculation of Crystallite Size of Nanomaterials: A Review. J. Alloys Compd. 2023, 968, 171914. [Google Scholar] [CrossRef]

- Khan, H.; Yerramilli, A.S.; D’Oliveira, A.; Alford, T.L.; Boffito, D.C.; Patience, G.S. Experimental Methods in Chemical Engineering: X-ray Diffraction Spectroscopy—XRD. Can. J. Chem. Eng. 2020, 98, 1255–1266. [Google Scholar] [CrossRef]

- Hao, Z.; Shen, J.; Lin, S.; Han, X.; Chang, X.; Liu, J.; Li, M.; Ma, X. Decoupling the Effect of Ni Particle Size and Surface Oxygen Deficiencies in CO2 Methanation over Ceria Supported Ni. Appl. Catal. B Environ. 2021, 286, 119922. [Google Scholar] [CrossRef]

- Ghosh, S.; Polaki, S.R.; Macrelli, A.; Casari, C.S.; Barg, S.; Jeong, S.M.; Ostrikov, K. Nanoparticle-Enhanced Multifunctional Nanocarbons—Recent Advances on Electrochemical Energy Storage Applications. J. Phys. D Appl. Phys. 2022, 55, 413001. [Google Scholar] [CrossRef]

- Guerrero Peña, G.D.J.; Reddy, K.S.K.; Varghese, A.M.; Prabhu, A.; Dabbawala, A.A.; Polychronopoulou, K.; Baker, M.A.; Anjum, D.; Das, G.; Aubry, C.; et al. Carbon Dioxide Adsorbents from Flame-Made Diesel Soot Nanoparticles. Sci. Total Environ. 2023, 859, 160140. [Google Scholar] [CrossRef]

- Sivakumar, A.; Dai, L.; Dhas, S.S.J.; Dhas, S.A.M.B.; Mowlika, V.; Kumar, R.S.; Almansour, A.I. Reduction of Amorphous Carbon Clusters from the Highly Disordered and Reduced Graphene Oxide NPs by Acoustical Shock Waves—Towards the Formation of Highly Ordered Graphene. Diam. Relat. Mater. 2023, 137, 110139. [Google Scholar] [CrossRef]

- Chen, D.P.; Liu, X.C.; Liu, X.D.; Yuan, L.; Zhong, M.L.; Wang, C.Y. Pd Nanoparticles on Self-Doping-Defects Mesoporous Carbon Supports for Highly Active Ethanol Oxidation and Ethylene Glycol Oxidation. Int. J. Hydrogen Energy 2021, 46, 30455–30466. [Google Scholar] [CrossRef]

- Singh, S.; Singh, D.; Singh, S.P.; Pandey, A.K. Candle Soot Derived Carbon Nanoparticles: Assessment of Physico-Chemical Properties, Cytotoxicity and Genotoxicity. Chemosphere 2019, 214, 130–135. [Google Scholar] [CrossRef] [PubMed]

- Gopalakrishnan, A.; Sharma, C.S. High-Performance Dual Carbon Li-Ion Hybrid Capacitor Constructed from N, S-Co-Doped Candle Soot Derived Carbon Nanoparticles Anode and Porous Carbon Cathode. J. Energy Storage 2022, 55, 105788. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, X.; Meng, X.; Cai, L.; Chen, J.; Guo, P. Synthesis of Bimetallic PdSn Nanoparticle Assembly as Highly Efficient Electrocatalyst for Ethanol Oxidation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 621, 126577. [Google Scholar] [CrossRef]

- Ren, L.; Hui, K.S.; Hui, K.N. Self-Assembled Free-Standing Three-Dimensional Nickel Nanoparticle/Graphene Aerogel for Direct Ethanol Fuel Cells. J. Mater. Chem. A 2013, 1, 5689–5694. [Google Scholar] [CrossRef]

- Eisa, T.; Mohamed, H.O.; Choi, Y.J.; Park, S.G.; Ali, R.; Abdelkareem, M.A.; Oh, S.E.; Chae, K.J. Nickel Nanorods over Nickel Foam as Standalone Anode for Direct Alkaline Methanol and Ethanol Fuel Cell. Int. J. Hydrogen Energy 2020, 45, 5948–5959. [Google Scholar] [CrossRef]

- Aladeemy, S.A.; Al-Mayouf, A.M.; Amer, M.S.; Alotaibi, N.H.; Weller, M.T.; Ghanem, M.A. Structure and Electrochemical Activity of Nickel Aluminium Fluoride Nanosheets during Urea Electro-Oxidation in an Alkaline Solution. RSC Adv. 2021, 11, 3190–3201. [Google Scholar] [CrossRef] [PubMed]

- Bamuqaddam, A.M.; Aladeemy, S.A.; Ghanem, M.A.; Al-Mayouf, A.M.; Alotaibi, N.H.; Marken, F. Foam Synthesis of Nickel/Nickel (II) Hydroxide Nanoflakes Using Double Templates of Surfactant Liquid Crystal and Hydrogen Bubbles: A High-Performance Catalyst for Methanol Electrooxidation in Alkaline Solution. Nanomaterials 2022, 12, 879. [Google Scholar] [CrossRef]

- Yan, W.; Wang, D.; Diaz, L.A.; Botte, G.G. Nickel Nanowires as Effective Catalysts for Urea Electro-Oxidation. Electrochim. Acta 2014, 134, 266–271. [Google Scholar] [CrossRef]

- Barakat, N.A.M.; Ali, M.A. Molybdenum Carbide/Ni Nanoparticles-Incorporated Carbon Nanofibers as Effective Non-Precious Catalyst for Urea Electrooxidation Reaction. Sci. Rep. 2022, 12, 22574. [Google Scholar] [CrossRef] [PubMed]

- Karimi, F.; Ghorbani, M.; Soleimani, M.; Masoomeh, L. Polyaniline-Manganese Ferrite Supported Platinum—Ruthenium Nanohybrid Electrocatalyst: Synergizing Tailoring toward Boosted Ethanol Oxidation Reaction. Top. Catal. 2021, 65, 716–725. [Google Scholar] [CrossRef]

- Yaldagard, M.; Shahbaz, M.; Kim, H.W.; Kim, S.S. Ethanol Electro-Oxidation on Catalysts with S-ZrO2-Decorated Graphene as Support in Fuel Cell Applications. Nanomaterials 2022, 12, 3327. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.; Kamarudin, S.K.; Shyuan, L.K. TiO2 Nanotube-Carbon (TNT-C) as Support for Pt-Based Catalyst for High Methanol Oxidation Reaction in Direct Methanol Fuel Cell. Nanoscale Res. Lett. 2016, 11, 553. [Google Scholar] [CrossRef] [PubMed]

- Chi, X.; Gao, L.; Zhou, W.; Zhang, Y.; Hu, T. Enhanced Electrocatalytic Performance of 2D Ni-MOF for Ethanol Oxidation Reaction by Loading Carbon Dots. J. Solid State Chem. 2022, 311, 123094. [Google Scholar] [CrossRef]

- Tayal, J.; Rawat, B.; Basu, S. Effect of Addition of Rhenium to Pt-Based Anode Catalysts in Electro-Oxidation of Ethanol in Direct Ethanol PEM Fuel Cell. Int. J. Hydrogen Energy 2012, 37, 4597–4605. [Google Scholar] [CrossRef]

- Raveendran, A.; Chandran, M.; Mohammad Wabaidur, S.; Ataul Islam, M.; Dhanusuraman, R.; Ponnusamy, V.K. Facile Electrochemical Fabrication of Nickel-Coated Polydiphenylamine (Ni/PDPA) Nanocomposite Material as Efficient Anode Catalyst for Direct Alcohol Fuel Cell Application. Fuel 2022, 324, 124424. [Google Scholar] [CrossRef]

- Khodabakhshi, S.; Fulvio, P.F.; Andreoli, E. Carbon Black Reborn: Structure and Chemistry for Renewable Energy Harnessing. Carbon N. Y. 2020, 162, 604–649. [Google Scholar] [CrossRef]

| Electrocatalyst | 2θ (111) (°) | FWHM (°) | Ni0 Crystallite Sizes (nm) |

|---|---|---|---|

| 5 wt% Ni–CS | - | - | - |

| 10 wt% Ni–CS | 44.59 | 0.6652 | 13.5 |

| 15 wt% Ni–CS | 44.50 | 0.4606 | 19.5 |

| 20 wt% Ni–CS | 44.50 | 0.3582 | 25.0 |

| 25 wt% Ni–CS | 44.49 | 0.3582 | 25.0 |

| Electrocatalyst | Conditions | ECSA (m2/g) | Onset Potential (V) | IF (mA/cm2) | Ref. |

|---|---|---|---|---|---|

| Ni/Al2O3–5/GC | 0.1 M NaOH + 0.1 M CH3OH | NA | 0.72 vs. Ag/AgCl | 11.1 | [7] |

| MOF1-CDs@CC | 1 M KOH + 1 M CH3CH2OH | NA | 1.3 vs. RHE | 119 | [45] |

| Ni/NiO/MWCNT | 0.1 M NaOH + 0.7 M CH3OH | 4.52 | 0.43 vs. Ag/AgCl | 15.94 | [8] |

| NiNPs-R/PPy/CPE | 0.1 M NaOH + 0.2 M CH3CH2OH | NA | 0.80 vs. Ag/AgCl | 21.1 | [9] |

| 20 wt% Ni-CB | 1 M NaOH + 1 M CH3CH2OH | 6.80 | 0.36 vs. Ag/AgCl | 4.60 | This study |

| 20 wt% Ni-CS | 1 M NaOH + 1 M CH3CH2OH | 8.02 | 0.37 vs. Ag/AgCl | 18.43 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansor, M.; Budiman, S.N.; Zainoodin, A.M.; Khairunnisa, M.P.; Yamanaka, S.; Jusoh, N.W.C.; Liza, S. Candle Soot as a Novel Support for Nickel Nanoparticles in the Electrocatalytic Ethanol Oxidation. Nanomaterials 2024, 14, 1042. https://doi.org/10.3390/nano14121042

Mansor M, Budiman SN, Zainoodin AM, Khairunnisa MP, Yamanaka S, Jusoh NWC, Liza S. Candle Soot as a Novel Support for Nickel Nanoparticles in the Electrocatalytic Ethanol Oxidation. Nanomaterials. 2024; 14(12):1042. https://doi.org/10.3390/nano14121042

Chicago/Turabian StyleMansor, Muliani, Siti Noorleila Budiman, Azran Mohd Zainoodin, Mohd Paad Khairunnisa, Shinya Yamanaka, Nurfatehah Wahyuny Che Jusoh, and Shahira Liza. 2024. "Candle Soot as a Novel Support for Nickel Nanoparticles in the Electrocatalytic Ethanol Oxidation" Nanomaterials 14, no. 12: 1042. https://doi.org/10.3390/nano14121042