Preparation of Thermochromic Vanadium Dioxide Films Assisted by Machine Learning

Abstract

:1. Introduction

2. Results and Discussion

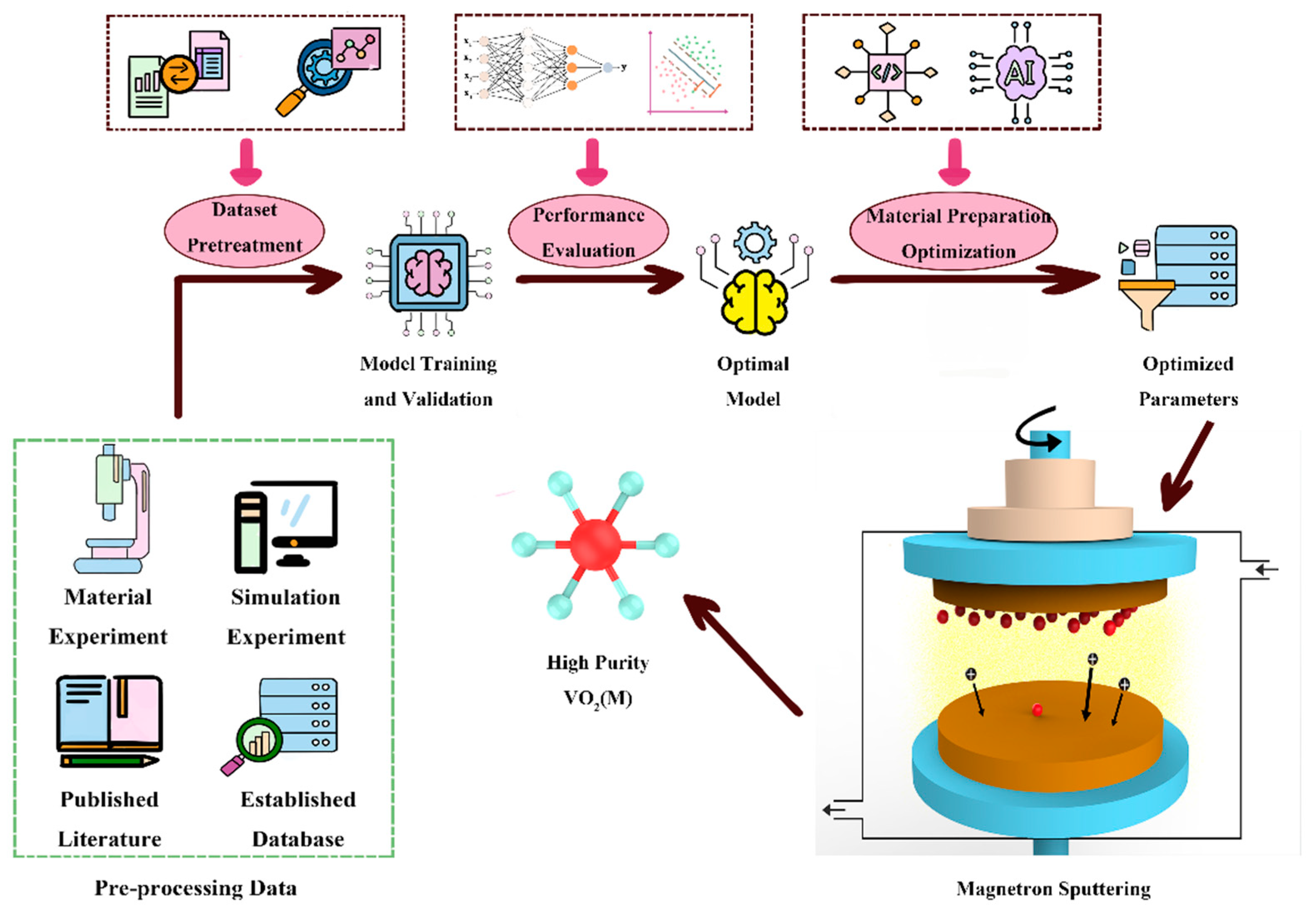

2.1. Optimized Synthesis Frame Design

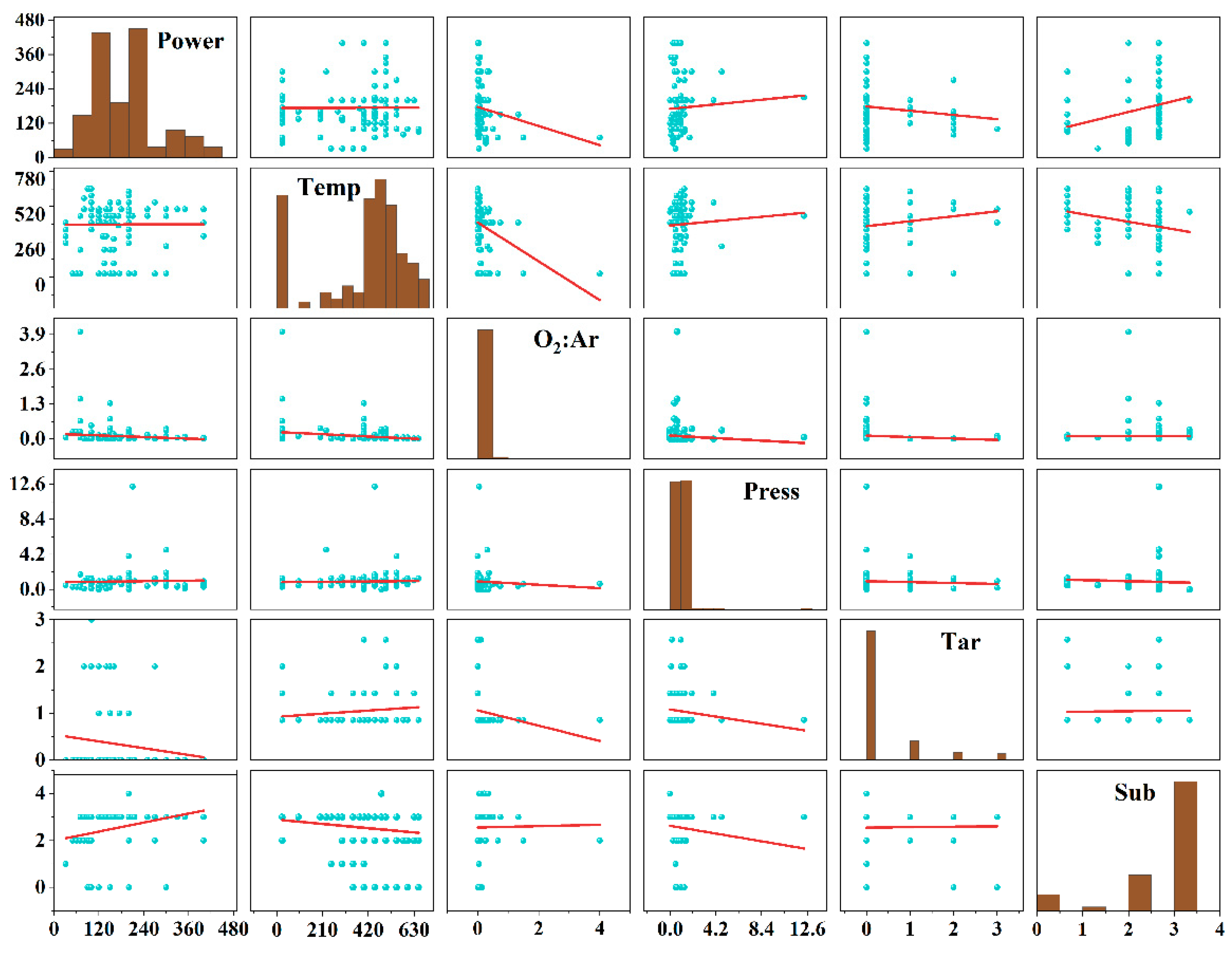

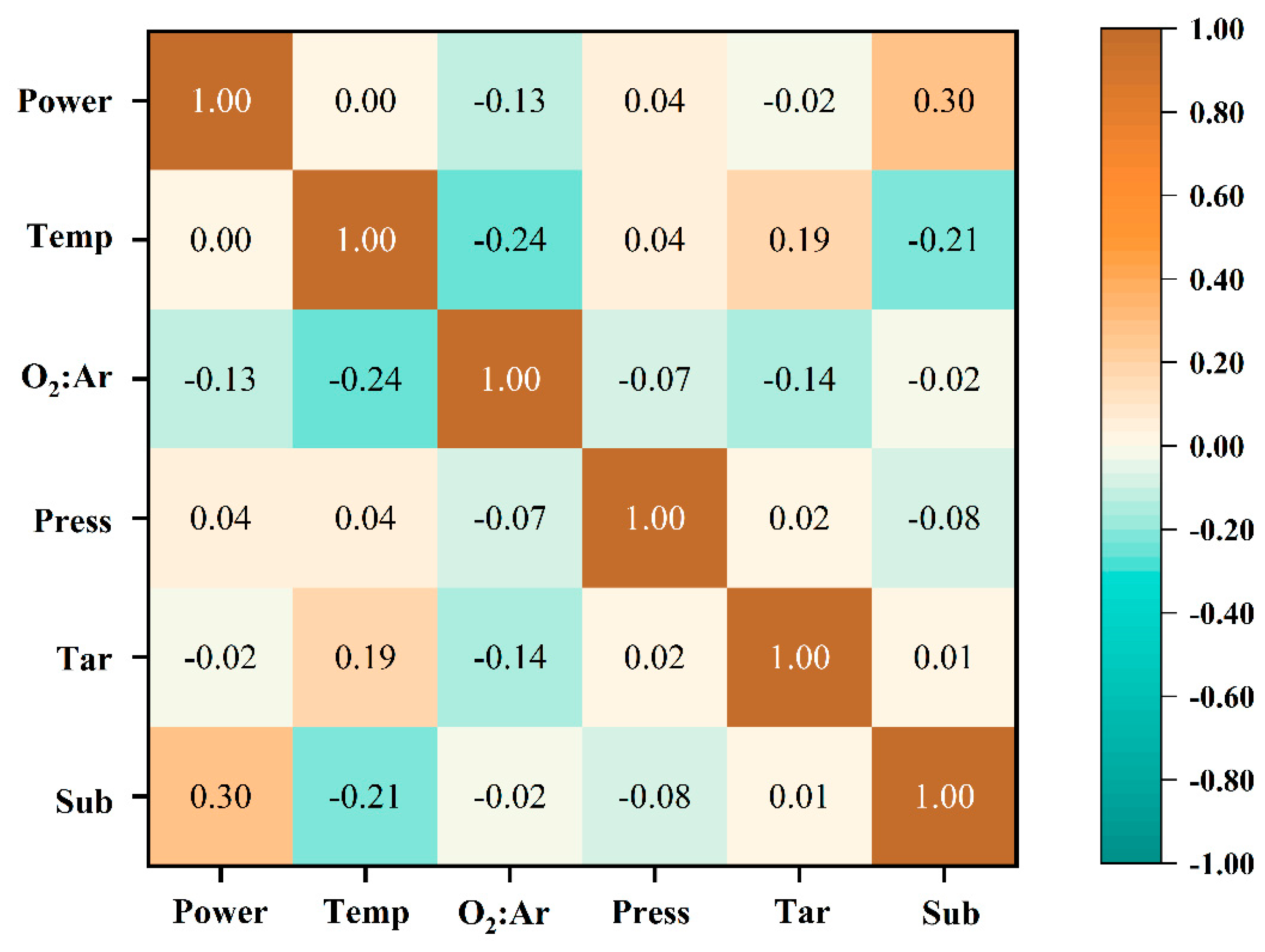

2.2. Dataset Establishment

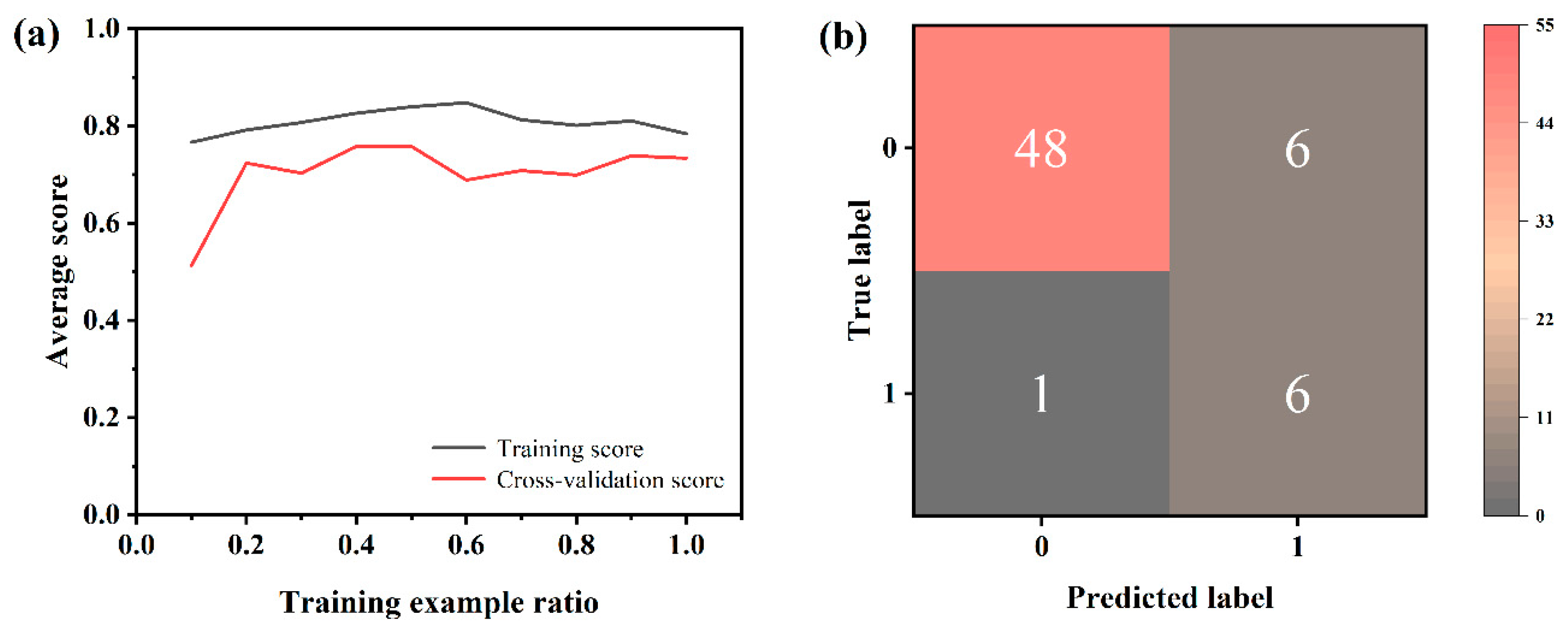

2.3. Classification Model

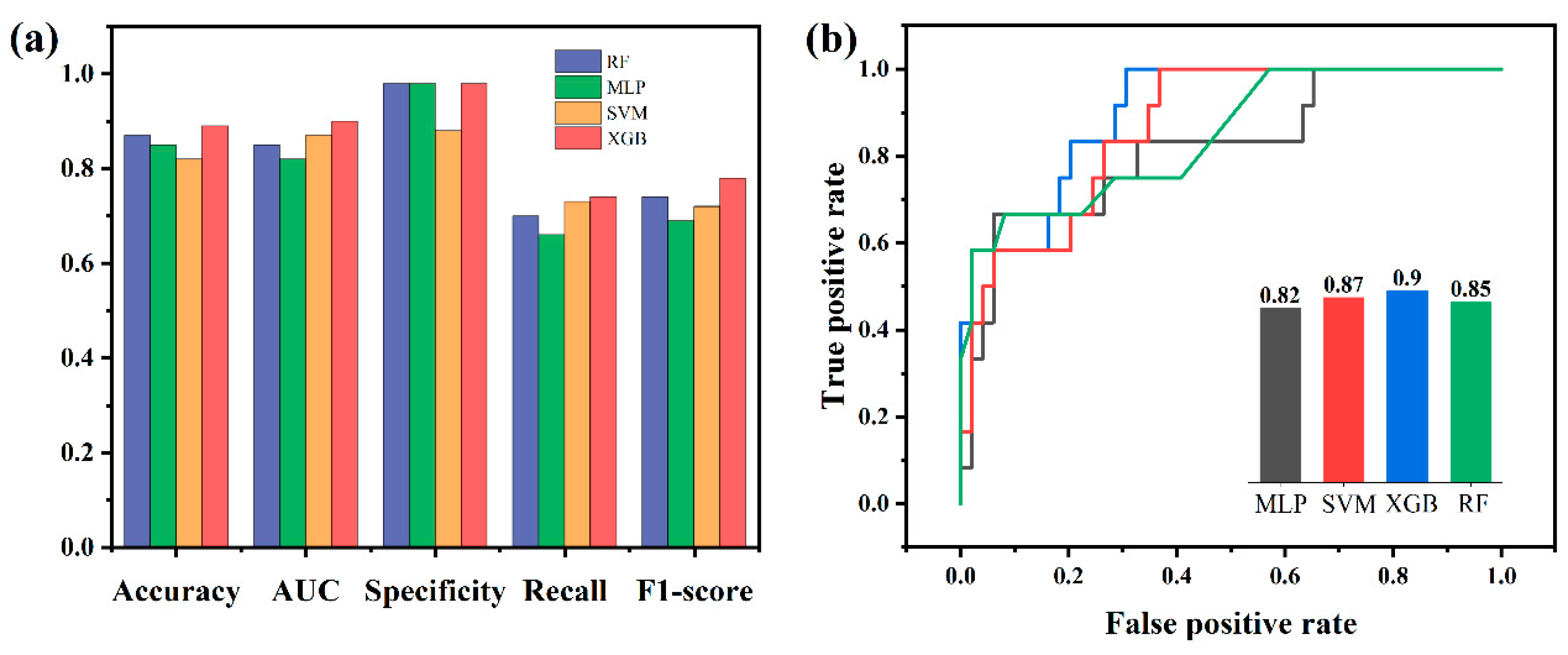

2.4. Model Selection and Performance Evaluation

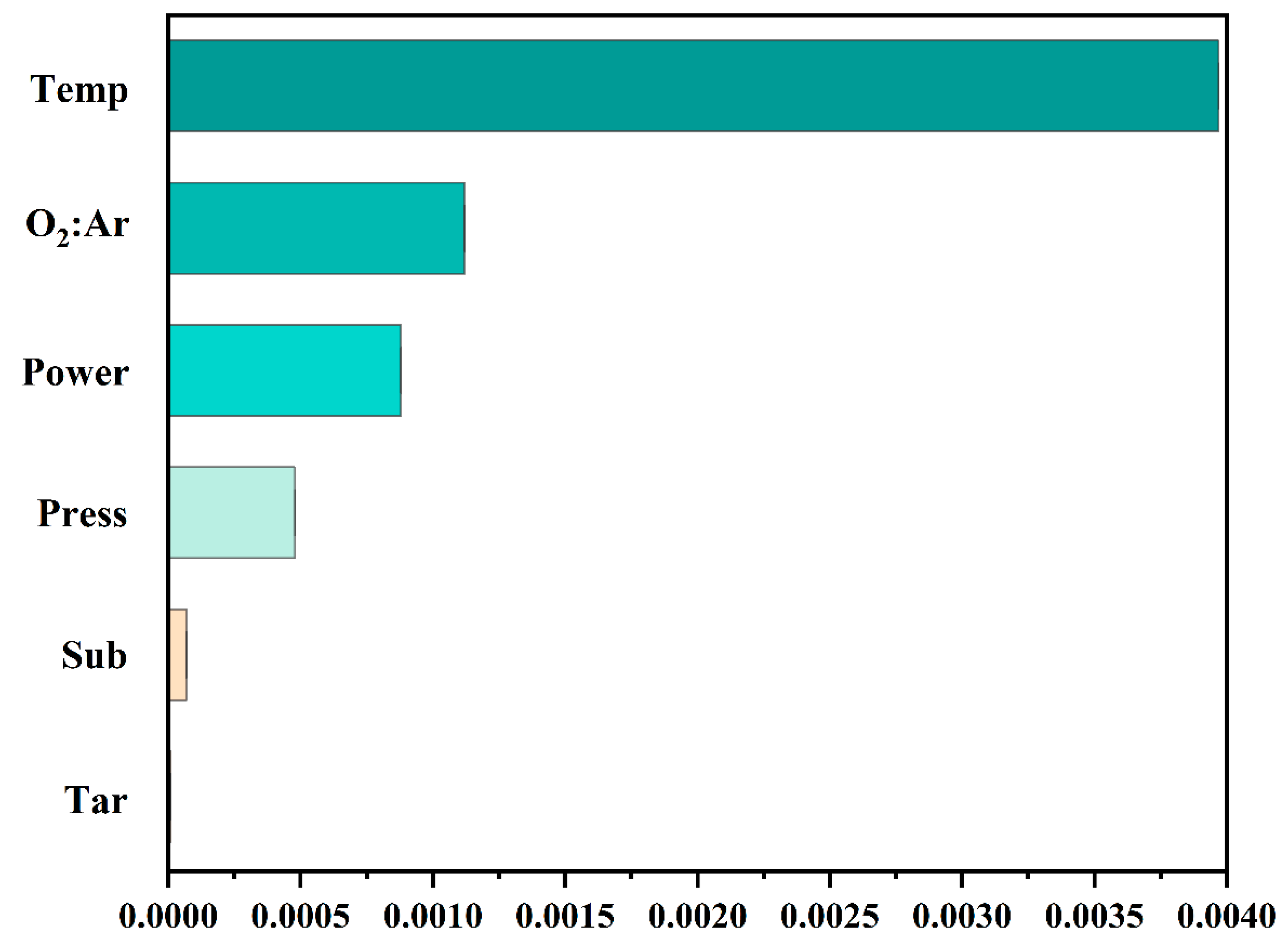

2.5. Material Synthesis Pathway Optimization

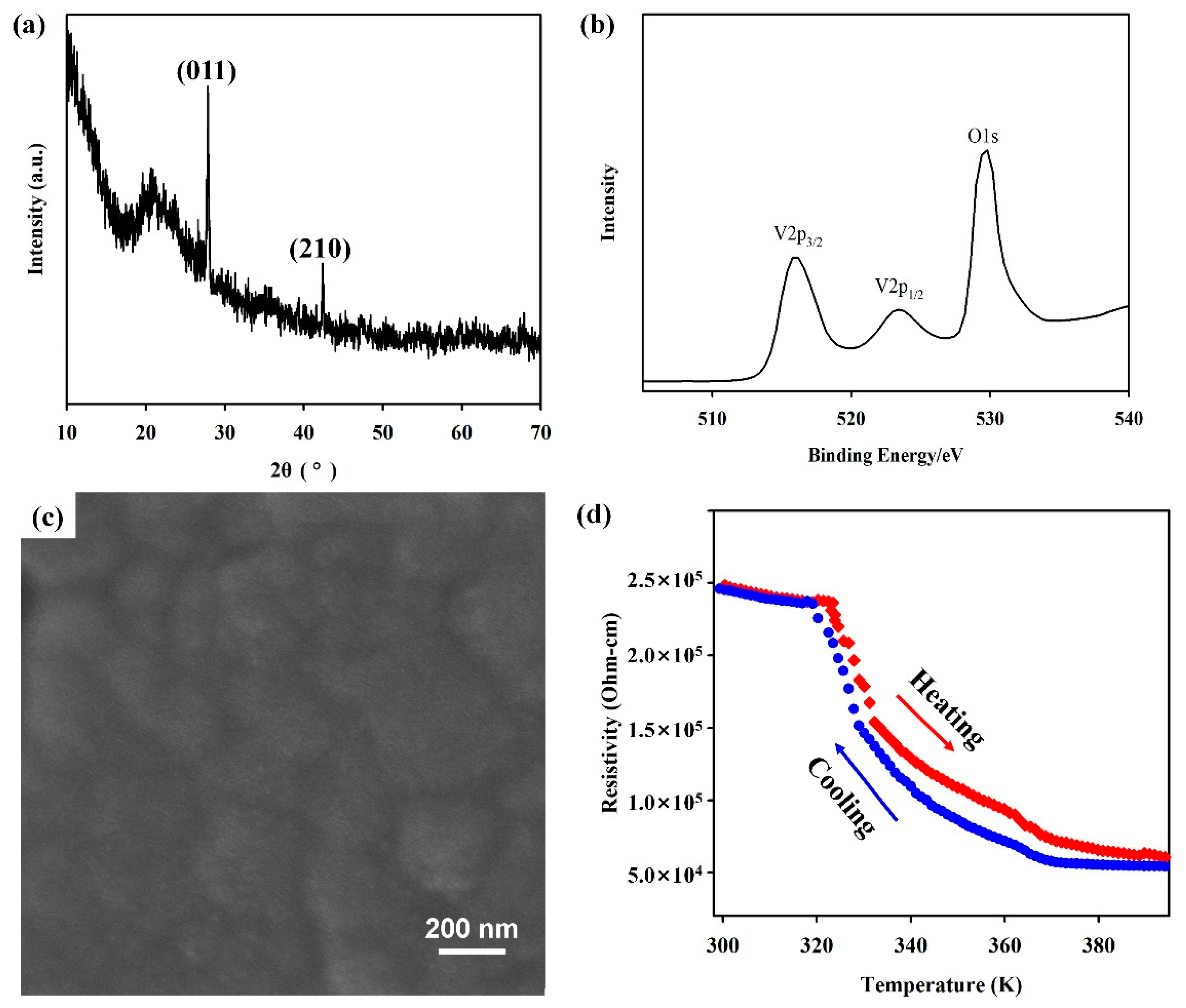

2.6. Model Verification

| Number | Power (W) | Temp (°C) | O2:Ar | Press (Pa) | Tar | Sub | Model Predict | Reference |

|---|---|---|---|---|---|---|---|---|

| 1 | 90 | 650 | 0.013 | 1.33 | V | Al2O3 | 86.23% | Zhang C et al. [44] |

| 2 | 100 | 650 | 0.013 | 1.33 | V | Si | 85.50% | Zhang C et al. [45] |

| 3 | 80 | 580 | 0.06 | 1.00 | V | Si | 71.47% | Ma X et al. [46] |

| 4 | 100 | 500 | 0.025 | 1.00 | V2O3 | Al2O3 | 28.64% | Yang Z et al. [47] |

| 5 | 200 | 600 | 0.05 | 1.00 | V | Si | 30.41% | Xiong Y et al. [48] |

| Parameters | Min | Max |

|---|---|---|

| Power (W) | 110 | 210 |

| Temp (℃) | 500 | 700 |

| O2:Ar | 0.1 | 2.2 |

| Press (Pa) | 0.15 | 2.9 |

| Tar | 0 or 1, 2, 3 | |

| Sub | 0 or 1, 2, 3, 4 |

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Ren, Y.; Mo, L.; Liu, C.; Hsu, K.; Ding, Y.; Zhang, X.; Li, X.; Hu, L.; Ji, D.; et al. Impacts of oxygen vacancies on zinc ion intercalation in VO2. ACS Nano 2020, 14, 5581–5589. [Google Scholar] [CrossRef] [PubMed]

- Cui, F.; Zhao, J.; Zhang, D.; Fang, Y.; Hu, F.; Zhu, K. VO2(B) nanobelts and reduced graphene oxides composites as cathode materials for low-cost rechargeable aqueous zinc ion batteries. Chem. Eng. J. 2020, 390, 124118. [Google Scholar] [CrossRef]

- Vaseem, M.; Zhen, S.; Yang, S.; Li, W.; Shamim, A. Development of VO2-nanoparticle-based metal-insulator transition electronic ink. Adv. Electron. Mater. 2019, 5, 1800949. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Z.; Huang, Y. Monoclinic VO2(D) hollow nanospheres with super-long cycle life for aqueous zinc ion batteries. Nanoscale 2019, 11, 13032–13039. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yu, K.; Feng, Y.; Qi, R.; Ren, J.; Zhu, Z. VO2(P)-V2C (MXene) grid structure as a lithium polysulfide catalytic host for high-performance Li-S battery. ACS Appl. Mater. Interfaces 2019, 11, 44282–44292. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Gao, Y.; Luo, H. Pure single-crystal rutile vanadium dioxide powders: Synthesis, mechanism and phase-transformation property. J. Phys. Chem. C 2008, 112, 18810–18814. [Google Scholar] [CrossRef]

- Ji, H.; Liu, D.; Cheng, H.; Zhang, C.; Yang, L.; Ren, D. Infrared thermochromic properties of monoclinic VO2 nanopowders using a malic acid-assisted hydrothermal method for adaptive camouflage. RSC Adv. 2017, 7, 5189–5194. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, X.; Lu, X.; Chai, G.; Sun, Y.; Zhan, Y.; Xu, G. A cost-effective method to fabricate VO2(M) nanoparticles and films with excellent thermochromic properties. J. Alloys Compd. 2015, 636, 106–112. [Google Scholar] [CrossRef]

- Xiao, X.; Huan, C.; Cheng, H.; Lu, Y.; Qi, S.; Zhan, Y.; Liu, H.; Xu, G. A novel method to improve phase transition of VO2 thermochromic films by Cs0.32WO3 nanoparticles. Mater. Lett. 2019, 249, 95–98. [Google Scholar] [CrossRef]

- Li, G.; Xie, D.; Zhong, H.; Zhang, Z.; Fu, X.; Zhou, Q.; Li, Q.; Ni, H.; Wang, J.; Guo, E.J.; et al. Photo-induced non-volatile VO2 phase transition for neuromorphic ultraviolet sensors. Nat. Commun. 2022, 13, 1729. [Google Scholar] [CrossRef]

- Khan, Z.; Singh, P.; Ansari, S.A.; Manippady, S.R.; Jaiswal, A.; Saxena, M. VO2 nanostructures for batteries and supercapacitors: A review. Small 2021, 17, 2006651. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Ji, H.; Ou, Y.; Wang, Y.; Chen, Y.; Tao, J.; Liu, B.; Lu, M.; Huang, Y.; Wang, J. Novel sunlight-driven Cu7S4/VO2 composite films for smart windows. J. Mater. Chem. C 2024, 12, 2534–2543. [Google Scholar] [CrossRef]

- Ji, H.; Zhao, Y.; Lu, M.; Tao, J.; Chen, Y.; Ou, Y.; Wang, Y.; Mao, Y. Novel warm/cool-tone switchable VO2-based smart window composite films with excellent optical performance. Ceram. Int. 2023, 49, 22630–22635. [Google Scholar] [CrossRef]

- Ji, H.; Liu, D.; Cheng, H. Infrared optical modulation characteristics of W-doped VO2(M) nanoparticles in the MWIR and LWIR regions. Mater. Sci. Semicond. Process. 2020, 119, 105141. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, H.; Chen, Y.; Liu, B.; Huang, J.; Lu, M.; Ou, Y.; Zhao, Y.; Tao, J.; Huang, Y.; et al. Artificially adjustable radiative cooling device with environmental adaptability. Ceram. Int. 2023, 49, 40297–40304. [Google Scholar] [CrossRef]

- Liu, D.; Cheng, H.; Xing, X.; Zhang, C.; Zheng, W. Thermochromic properties of W-doped VO2 thin films deposited by aqueous sol-gel method for adaptive infrared stealth application. Infrared Phys. Technol. 2016, 77, 339–343. [Google Scholar] [CrossRef]

- Liu, D.; Ji, H.; Peng, R.; Cheng, H.; Zhang, C. Infrared chameleon-like behavior from VO2(M) thin films prepared by transformation of metastable VO2(B) for adaptive camouflage in both thermal atmospheric windows. Sol. Energy Mater. Sol. Cells 2018, 185, 210–217. [Google Scholar] [CrossRef]

- Kim, H.; Cheung, K.; Auyeung, R.C.; Wilson, D.E.; Charipar, K.M.; Piqué, A.; Charipar, N.A. VO2-based switchable radiator for spacecraft thermal control. Sci. Rep. 2019, 9, 11329. [Google Scholar] [CrossRef] [PubMed]

- Long, L.; Taylor, S.; Wang, L. Enhanced infrared emission by thermally switching the excitation of magnetic polariton with scalable microstructured VO2 metasurfaces. ACS Photonics 2020, 7, 2219–2227. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Yang, L.; Li, X.; Chen, J.; Huang, C. A convenient way to reduce the hysteresis width of VO2(M) nanomaterials. New J. Chem. 2017, 41, 15260–15267. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Ho, H.; Lai, Y.; Chen, K.; Dao, T.D.; Hsueh, C.H.; Nagao, T. High quality thermochromic VO2 films prepared by magnetron sputtering using V2O5 target with in situ annealing. Appl. Surf. Sci. 2019, 495, 143436. [Google Scholar] [CrossRef]

- Ahmad, T.; Madonski, R.; Zhang, D.; Huang, C.; Mujeeb, A. Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: Key developments, challenges, and future research opportunities in the context of smart grid paradigm. Renew. Sustain. Energy Rev. 2022, 160, 112128. [Google Scholar] [CrossRef]

- Pugliese, R.; Regondi, S.; Marini, R. Machine learning-based approach: Global trends, research directions, and regulatory standpoints. Data Sci. Manag. 2021, 4, 19–29. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ji, H.; Lu, M.; Liu, B.; Zhao, Y.; Ou, Y.; Wang, Y.; Tao, J.; Zou, T.; Huang, Y.; et al. Machine learning guided hydrothermal synthesis of thermochromic VO2 nanoparticles. Ceram. Int. 2023, 49, 30794–30800. [Google Scholar] [CrossRef]

- Lu, M.; Ji, H.; Zhao, Y.; Chen, Y.; Tao, J.; Ou, Y.; Wang, Y.; Huang, Y.; Wang, J.; Hao, G. Machine learning-assisted synthesis of two-dimensional materials. ACS Appl. Mater. Interfaces 2022, 15, 1871–1878. [Google Scholar] [CrossRef]

- Wang, J.; Lu, M.; Chen, Y.; Hao, G.; Liu, B.; Tang, P.; Yu, L.; Wen, L.; Ji, H. Machine Learning-Assisted Large-Area Preparation of MoS2 Materials. Nanomaterials 2023, 13, 2283. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Gu, G.X. Machine learning for composite materials. MRs Commun. 2019, 9, 556–566. [Google Scholar] [CrossRef]

- MDieb, T.; Hou, Z.; Tsuda, K. Structure prediction of boron-doped graphene by machine learning. J. Chem. Phys. 2018, 148, 241716. [Google Scholar] [CrossRef]

- Botu, V.; Ramprasad, R. Adaptive machine learning framework to accelerate ab initio molecular dynamics. Int. J. Quantum Chem. 2015, 115, 1074–1083. [Google Scholar] [CrossRef]

- De Jong, M.; Chen, W.; Notestine, R.; Persson, K.; Ceder, G.; Jain, A.; Asta, M.; Gamst, A. A statistical learning framework for materials science: Application to elastic moduli of k-nary inorganic polycrystalline compounds. Sci. Rep. 2016, 6, 34256. [Google Scholar] [CrossRef] [PubMed]

- Pilania, G.; Wang, C.; Jiang, X.; Rajasekaran, S.; Ramprasad, R. Accelerating materials property predictions using machine learning. Sci. Rep. 2013, 3, 2810. [Google Scholar] [CrossRef] [PubMed]

- Sai, N.J.; Rathore, P.; Chauhan, A. Machine learning-based predictions of fatigue life for multi-principal element alloys. Scr. Mater. 2023, 226, 115214. [Google Scholar] [CrossRef]

- Wang, X.J.; Li, H.D.; Fei, Y.J.; Wang, X.; Xiong, Y.Y.; Nie, Y.X.; Feng, K.A. XRD and Raman study of vanadium oxide thin films deposited on fused silica substrates by RF magnetron sputtering. Appl. Surf. Sci. 2001, 177, 8–14. [Google Scholar] [CrossRef]

- Bischl, B.; Binder, M.; Lang, M.; Pielok, T.; Richter, J.; Coors, S.; Thomas, J.; Ullmann, T.; Becker, M.; Boulesteix, A.L.; et al. Hyperparameter optimization: Foundations, algorithms, best practices and open challenges. arXiv 2021, arXiv:2107.05847. [Google Scholar] [CrossRef]

- Tang, B.; Lu, Y.; Zhou, J.; Chouhan, T.; Wang, H.; Golani, P.; Xu, M.; Xu, Q.; Guan, C.; Liu, Z. Machine learning-guided synthesis of advanced inorganic materials. Mater. Today 2020, 41, 72–80. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, C. A strategy to apply machine learning to small datasets in materials science. Npj Comput. Mater. 2018, 4, 25. [Google Scholar] [CrossRef]

- Song, Y.; Lindsay, J.; Zhao, Y.; Nasiri, A.; Louis, S.Y.; Ling, J.; Hu, M.; Hu, J. Machine learning based prediction of noncentrosymmetric crystal materials. Comput. Mater. Sci. 2020, 183, 109792. [Google Scholar] [CrossRef]

- Cruz, J.A.; Wishart, D.S. Applications of machine learning in cancer prediction and prognosis. Cancer Inform. 2006, 2, 743338146. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, W.; Wang, H.; Zhang, X.; Yang, C.; Liu, H. Identification of soil texture classes under vegetation cover based on Sentinel-2 data with SVM and SHAP techniques. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2022, 15, 3758–3770. [Google Scholar] [CrossRef]

- Sirvent, P.; Pérez, G.; Guerrero, A. Efficient VO2(M) synthesis to develop thermochromic cement-based materials for smart building envelopes. Mater. Chem. Phys. 2021, 269, 124765. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, H.; Chai, G.; Sun, Y.; Yang, T.; Cheng, H.; Chen, L.; Miao, L.; Xu, G. A cost-effective process to prepare VO2(M) powder and films with superior thermochromic properties. Mater. Res. Bull. 2014, 51, 6–12. [Google Scholar] [CrossRef]

- Zhang, C.; Koughia, C.; Güneş, O.; Luo, J.; Hossain, N.; Li, Y.; Cui, X.; Wen, S.J.; Wong, R.; Yang, Q.; et al. Synthesis, structure and optical properties of high-quality VO2 thin films grown on silicon, quartz and sapphire substrates by high temperature magnetron sputtering: Properties through the transition temperature. J. Alloys Compd. 2020, 848, 156323. [Google Scholar] [CrossRef]

- Zhang, C.; Koughia, C.; Li, Y.; Cui, X.; Ye, F.; Shiri, S.; Sanayei, M.; Wen, S.J.; Yang, Q.; Kasap, S. Near-zero IR transmission of VO2 thin films deposited on Si substrate. Appl. Surf. Sci. 2018, 440, 415–420. [Google Scholar] [CrossRef]

- Ma, X.; Liu, X.; Li, H.; Zhang, A.; Huang, M. Influence of oxygen flow rate on metal–insulator transition of vanadium oxide thin films grown by RF magnetron sputtering. Appl. Phys. A 2017, 123, 1–6. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Q.; Yang, L.; Dai, B.; Xia, F.; Wang, P.; Guo, S.; Gao, G.; Xu, L.; Zhang, Y.; et al. Effect of thickness on infrared optical property of VO2 film deposited by magnetron sputtering. Sci. China Technol. Sci. 2020, 63, 1591–1598. [Google Scholar] [CrossRef]

- Xiong, Y.; Wen, Q.; Chen, Z.; Tian, W.; Wen, T.L.; Jing, Y.L.; Yang, Q.H.; Zhang, H.W. Tuning the phase transitions of VO2 thin films on silicon substrates using ultrathin Al2O3 as buffer layers. J. Phys. D Appl. Phys. 2014, 47, 455304. [Google Scholar] [CrossRef]

| Mark | Reaction Conditions |

|---|---|

| Power | The sputtering power of magnetron sputtering |

| Temp | The temperature of the substrate |

| O2:Ar | The ratio of oxygen to argon flow rate |

| Press | Magnetron sputtering reaction pressure |

| Tar | Sputtering target material |

| Sub | Sputtering reaction substrate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, G.; Ji, H.; Chen, Y.; Liu, B.; Wang, Y.; Long, P.; Zeng, J.; Tao, J.; Deng, C. Preparation of Thermochromic Vanadium Dioxide Films Assisted by Machine Learning. Nanomaterials 2024, 14, 1153. https://doi.org/10.3390/nano14131153

Xiong G, Ji H, Chen Y, Liu B, Wang Y, Long P, Zeng J, Tao J, Deng C. Preparation of Thermochromic Vanadium Dioxide Films Assisted by Machine Learning. Nanomaterials. 2024; 14(13):1153. https://doi.org/10.3390/nano14131153

Chicago/Turabian StyleXiong, Gaoyang, Haining Ji, Yongxing Chen, Bin Liu, Yi Wang, Peng Long, Jinfang Zeng, Jundong Tao, and Cong Deng. 2024. "Preparation of Thermochromic Vanadium Dioxide Films Assisted by Machine Learning" Nanomaterials 14, no. 13: 1153. https://doi.org/10.3390/nano14131153