Optimized Ammonia-Sensing Electrode with CeO2/rGO Nano-Composite Coating Synthesized by Focused Laser Ablation in Liquid

Abstract

:1. Introduction

2. Experimental Methods

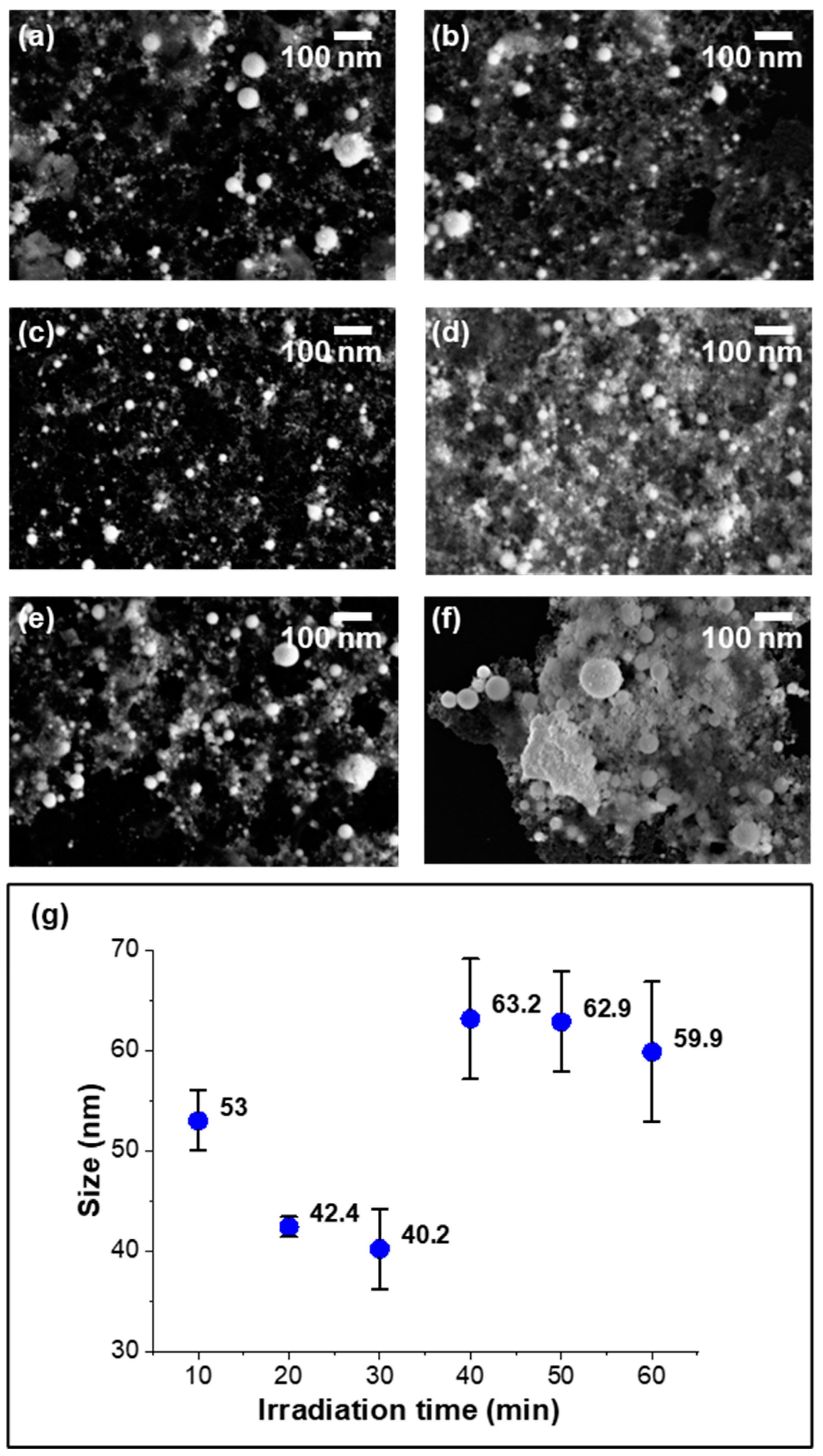

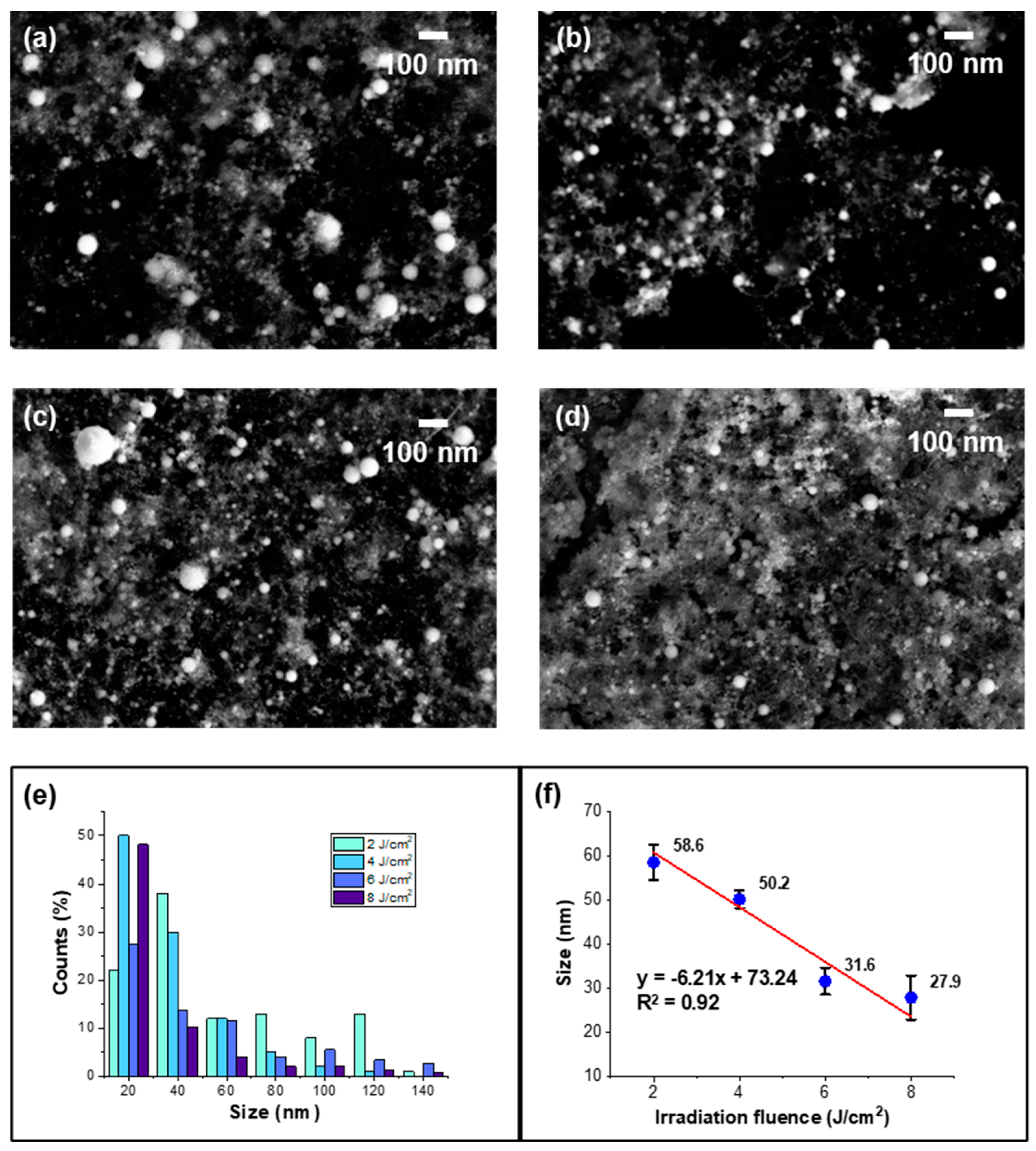

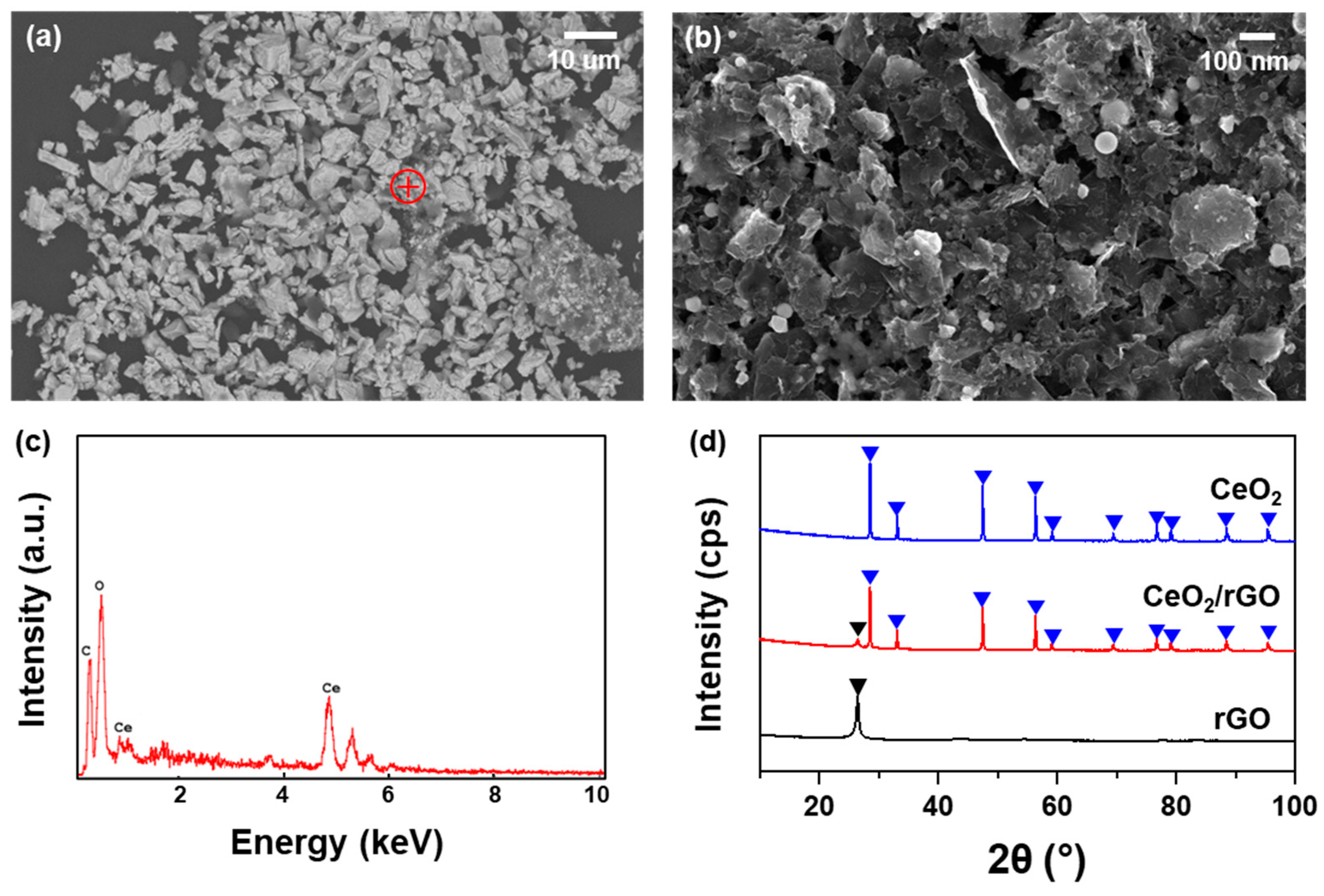

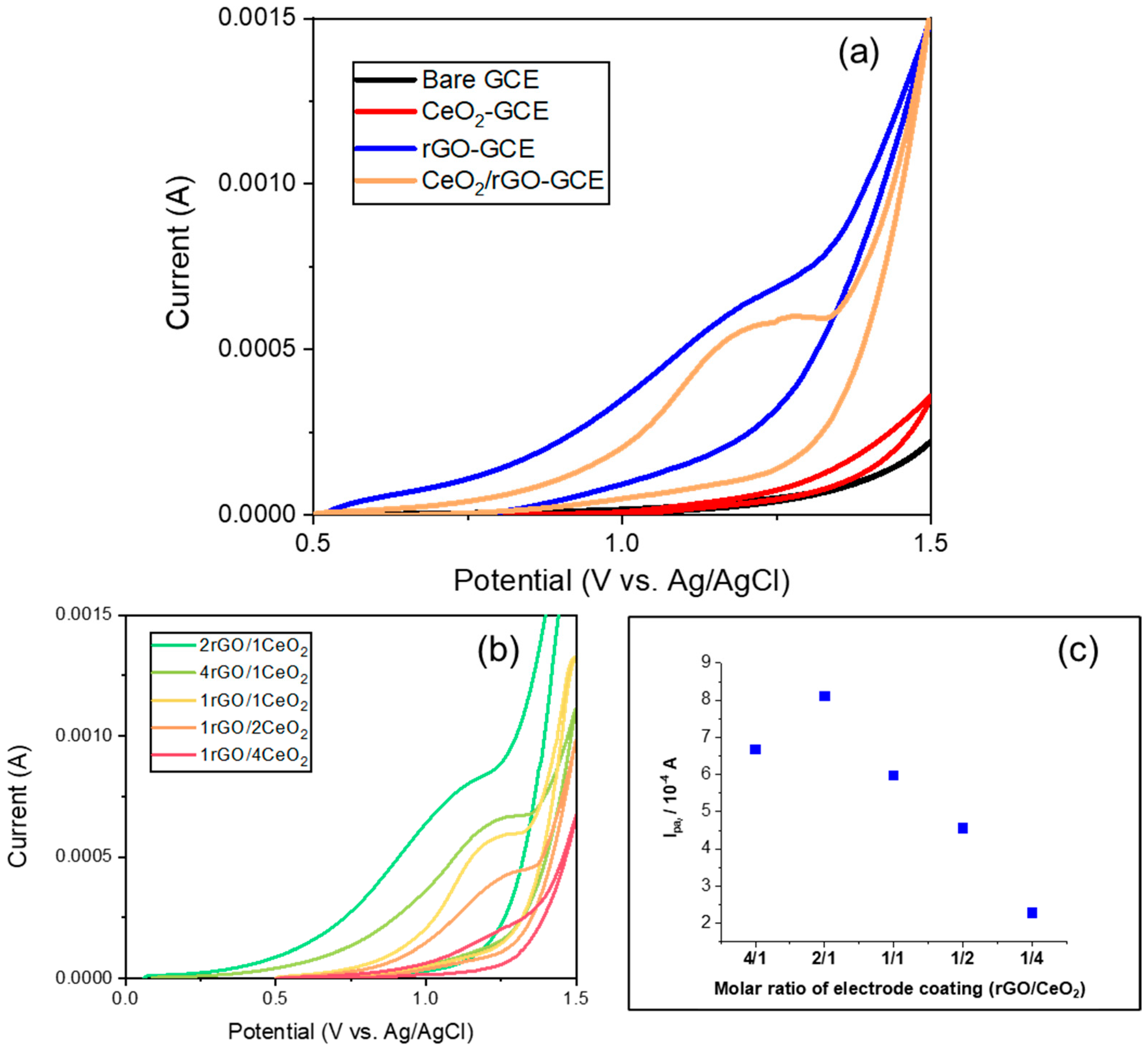

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wyer, K.E.; Kelleghan, D.B.; Blanes-Vidal, V.; Schauberger, G.; Curran, T.P. Ammonia emissions from agriculture and their contribution to fine particulate matter: A review of implications for human health. J. Environ. Manag. 2022, 323, 116285. [Google Scholar] [CrossRef]

- Brannelly, N.T.; Hamilton-Shield, J.P.; Killard, A.J. The Measurement of Ammonia in Human Breath and its Potential in Clinical Diagnostics Crit. Rev. Anal. Chem. 2016, 46, 490. [Google Scholar] [CrossRef] [PubMed]

- Ott, P.; Vilstrup, H. Cerebral effects of ammonia in liver disease: Current hypotheses. Metab. Brain Dis. 2014, 29, 901–911. [Google Scholar] [CrossRef]

- Moore, J.H.; Boczko, E.M.; Summar, M.L. Connecting the dots between genes, biochemistry, and disease susceptibility: Systems biology modeling in human genetics. Mol. Genet. Metab. 2005, 84, 104–111. [Google Scholar] [CrossRef]

- Holecek, M. Ammonia and amino acid profiles in liver cirrhosis: Effects of variables leading to hepatic encephalopathy. Nutrition 2015, 31, 14. [Google Scholar] [CrossRef] [PubMed]

- Butterworth, R.F. Pathophysiology of Hepatic Encephalopathy: A New Look at Ammonia. Metab. Brain Dis. 2002, 17, 221–227. [Google Scholar] [CrossRef]

- Watanabe, A. Cerebral changes in hepatic encephalopathy. J. Gastroenterol. Hepatol. 1998, 13, 752–760. [Google Scholar] [CrossRef]

- Zieve, L. Pathogenesis of hepatic encephalopathy. Metab. Brain Dis. 1987, 2, 147. [Google Scholar] [CrossRef] [PubMed]

- Mazelis, M. 15—Amino Acid Catabolism. Amino Acid Catabolism; Miflin, B.J., Ed.; Academic Press: Cambridge, MA, USA, 1980; p. 541. [Google Scholar]

- Duan, Y.; Liu, Q.; Wang, Y.; Zhang, J.; Xiong, D. Impairment of the intestine barrier function in Litopenaeus vannamei exposed to ammonia and nitrite stress. Fish Shellfish Immunol. 2018, 78, 279–288. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, Y.; Hu, A.; Xiong, G.; Wu, W.; Shi, L.; Chen, L.; Guo, X.; Qiao, Y.; Liu, C.; et al. Difference in muscle metabolism caused by metabolism disorder of rainbow trout liver exposed to ammonia stress. Sci. Total. Environ. 2024, 924, 171576. [Google Scholar] [CrossRef]

- He, K.; Luo, X.; Wen, M.; Wang, C.; Qin, C.; Shao, J.; Gan, L.; Dong, R.; Jiang, H. Effect of acute ammonia toxicity on inflammation, oxidative stress and apoptosis in head kidney macrophage of Pelteobagrus fulvidraco and the alleviation of curcumin. Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 2021, 248, 109098. [Google Scholar] [CrossRef] [PubMed]

- Deepak, K.; Balapure, A.; Priya, P.; Kumar, P.; Dubey, S.K.; Javed, A.; Chattopadhyay, S.; Goel, S. Development of a microfluidic device for the dual detection and quantification of ammonia and urea from the blood serum. Sens. Actuators A Phys. 2024, 369, 115174. [Google Scholar] [CrossRef]

- Shooshtari, M.; Salehi, A. An electronic nose based on carbon nanotube -titanium dioxide hybrid nanostructures for detection and discrimination of volatile organic compounds. Sens. Actuators B Chem. 2022, 357, 131418. [Google Scholar] [CrossRef]

- Privett, B.J.; Shin, J.H.; Schoenfisch, M.H. Electrochemical Sensors. Anal. Chem. 2010, 82, 4723. [Google Scholar] [CrossRef] [PubMed]

- Saputra, H.A. Electrochemical sensors: Basic principles, engineering, and state of the art. Monatsh. Chem. 2023, 154, 1083–1100. [Google Scholar] [CrossRef]

- Bakker, E.; Telting-Diaz, M. Electrochemical Sensors. Anal. Chem. 2002, 74, 2781. [Google Scholar] [CrossRef] [PubMed]

- Gorbova, E.; Tzorbatzoglou, F.; Molochas, C.; Chloros, D.; Demin, A.; Tsiakaras, P. Fundamentals and Principles of Solid-State Electrochemical Sensors for High Temperature Gas Detection. Catalysts 2022, 12, 1. [Google Scholar] [CrossRef]

- Zaidi, S.A.; Shin, J.H. Molecularly Imprinted Polymer Electrochemical Sensors Based on Synergistic Effect of Composites Synthesized from Graphene and Other Nanosystems. Int. J. Electrochem. Sci. 2014, 9, 4598–4616. [Google Scholar] [CrossRef]

- Lin, B.; Liu, Y.; Heng, L.; Wang, X.; Ni, J.; Lin, J.; Jiang, L. Morphology Effect of Ceria on the Catalytic Performances of Ru/CeO2 Catalysts for Ammonia Synthesis. Ind. Eng. Chem. Res. 2018, 57, 9127–9135. [Google Scholar] [CrossRef]

- Ly, T.N.; Park, S. Highly sensitive ammonia sensor for diagnostic purpose using reduced graphene oxide and conductive polymer. Sci. Rep. 2018, 8, 18030. [Google Scholar] [CrossRef]

- Huang, T.-Y.; Kung, C.-W.; Wei, H.-Y.; Boopathi, K.M.; Chu, C.-W.; Ho, K.-C. A high performance electrochemical sensor for acetaminophen based on a rGO–PEDOT nanotube composite modified electrode. J. Mater. Chem. A 2014, 2, 7229–7237. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Guo, Z.; Xu, J.; Wang, H.; Zhai, K.; Zhuo, X. A novel hydrazine electrochemical sensor based on the high specific surface area graphene. Microchim. Acta 2010, 169, 1–6. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P.; Ouyang, Z.; Zhang, M.; Lin, Z.; Li, J.; Su, Z.; Wei, G. Nanoscale Graphene Doped with Highly Dispersed Silver Nanoparticles: Quick Synthesis, Facile Fabrication of 3D Membrane-Modified Electrode, and Super Performance for Electrochemical Sensing. Adv. Funct. Mater. 2016, 26, 2122–2134. [Google Scholar] [CrossRef]

- Yang, G.W. Laser ablation in liquids: Applications in the synthesis of nanocrystals. Mater. Sci. 2007, 52, 648. [Google Scholar]

- Shi, M.; Kitamoto, Y.; Hara, M.; Wada, H. Preparation of CeO2 nanoparticles by laser ablation in liquid method and its UV-absorption properties. Appl. Phys. A 2022, 128, 968. [Google Scholar] [CrossRef]

- Monsa, Y.; Gal, G.; Lerner, N.; Bar, I. A simple strategy for enhanced production of nanoparticles by laser ablation in liquids. Nanotechnology 2020, 31, 235601. [Google Scholar] [CrossRef]

- Tilaki, R.M.; Zad, A.I.; Mahdavi, S.M. The effect of liquid environment on size and aggregation of gold nanoparticles prepared by pulsed laser ablation. J. Nanopart. Res. 2007, 9, 853–860. [Google Scholar] [CrossRef]

- Elsayed, K.A.; Imam, H.; Ahmed, M.; Ramadan, R. Effect of focusing conditions and laser parameters on the fabrication of gold nanoparticles via laser ablation in liquid. Opt. Laser Technol. 2013, 45, 495–502. [Google Scholar] [CrossRef]

- Dittrich, S.; Spellauge, M.; Barcikowski, S.; Huber, H.P.; Gökce, B. Time resolved studies reveal the origin of the unparalleled high efficiency of one nanosecond laser ablation in liquids. Opto-Electron. Adv. 2022, 5, 210053. [Google Scholar] [CrossRef]

- Devaux, D.; Fabbro, R.; Tollier, L.; Bartnicki, E. Generation of shock waves by laser-induced plasma in confined geometry. J. Appl. Phys. 1993, 74, 2268–2273. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Bartnicki, E. Wavelength dependent of laser shock-wave generation in the water-confinement regime. J. Appl. Phys. 1999, 85, 7552–7555. [Google Scholar] [CrossRef]

- Waag, F.; Gökce, B.; Barcikowski, S. Ablation target cooling by maximizing the nanoparticle productivity in laser synthesis of colloids. Appl. Surf. Sci. 2019, 466, 647–656. [Google Scholar] [CrossRef]

- Taccogna, F. Nucleation and growth of nanoparticles in a plasma by laser ablation in liquid. J. Plasma Phys. 2015, 81, 495810509. [Google Scholar] [CrossRef]

- Luo, F.; Guan, Y.; Ong, W.; Du, Z.; Ho, G.; Li, F.; Sun, S.; Lim, G.; Hong, M. Enhancement of pulsed laser ablation in environmentally friendly liquid. Opt. Express 2014, 22, 23875–23882. [Google Scholar] [CrossRef]

- Nayral, C.; Viala, E.; Fau, P.; Senocq, F.; Jumas, J.-C.; Maisonnat, A.; Chaudret, B. Synthesis of Tin and Tin Oxide Nanoparticles of Low Size Dispersity for Application in Gas Sensing. Chem. A Eur. J. 2000, 6, 4082–4090. [Google Scholar] [CrossRef]

- Sajti, C.L.; Sattari, R.; Chichkov, B.N.; Barcikowski, S. Gram Scale Synthesis of Pure Ceramic Nanoparticles by Laser Ablation in Liquid. J. Phys. Chem. C 2010, 114, 2421–2427. [Google Scholar] [CrossRef]

- Shi, M.; Kitamoto, Y.; Wada, H. Synthesis of CeO2/rGO Nanocomposites by Laser Ablation in Liquid Method and the Characterization for Advanced Materials Development. J. Laser Micro Nanoeng. 2023, 18, 170–176. [Google Scholar]

- Soliman, W.; El-Ansary, S.; Badr, Y. Impact of Liquid Medium on Laser Ablation Mechanism: Surface Heating and Cooling. Lasers Manuf. Mater. Process. 2018, 5, 430–438. [Google Scholar] [CrossRef]

- Tabayashi, Y.; Sakaki, S.; Koshizaki, N.; Yamauchi, Y.; Ishikawa, Y. Behavior of Thermally Induced Nanobubbles during Instantaneous Particle Heating by Pulsed Laser Melting in Liquid. Langmuir 2021, 37, 7167–7175. [Google Scholar] [CrossRef]

- Zolotko, A.N.; Poletaev, N.I.; Vovchuk, J.I.; Florko, A.V. Nanoparticles formation by combustion techniques. In Gas Phase Nanoparticle Synthesis, Chapter 5; Granqvist, C.G., Kish, L.B., Marlow, W.H., Eds.; Kluwer Academic: Dordrecht, The Netherlands, 2004; pp. 123–156. [Google Scholar]

- Koehler, J.M.; Visaveliya, N.; Knauer, A. Controlling formation and assembling of nanoparticles by control of electrical charging, polarization, and electrochemical potential. Nanotechnol. Rev. 2014, 3, 553–568. [Google Scholar] [CrossRef]

- Bourrous, S.; Ribeyre, Q.; Lintis, L.; Yon, J.; Bau, S.; Thomas, D.; Vallières, C.; Ouf, F.-X. A semi-automatic analysis tool for the determination of primary particle size, overlap coefficient and specific surface area of nanoparticles aggregates. J. Aerosol Sci. 2018, 126, 122–132. [Google Scholar] [CrossRef]

- Kocsis, L.; Herman, P.; Eke, A. The modified Beer–Lambert law revisited. Phys. Med. Biol. 2006, 51, N91. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Wada, H. Optimized Ammonia-Sensing Electrode with CeO2/rGO Nano-Composite Coating Synthesized by Focused Laser Ablation in Liquid. Nanomaterials 2024, 14, 1238. https://doi.org/10.3390/nano14151238

Shi M, Wada H. Optimized Ammonia-Sensing Electrode with CeO2/rGO Nano-Composite Coating Synthesized by Focused Laser Ablation in Liquid. Nanomaterials. 2024; 14(15):1238. https://doi.org/10.3390/nano14151238

Chicago/Turabian StyleShi, Mengqi, and Hiroyuki Wada. 2024. "Optimized Ammonia-Sensing Electrode with CeO2/rGO Nano-Composite Coating Synthesized by Focused Laser Ablation in Liquid" Nanomaterials 14, no. 15: 1238. https://doi.org/10.3390/nano14151238