Tunable Ag Nanocavity Enhanced Green Electroluminescence from SiNx:O Light-Emitting Diode

Abstract

:1. Introduction

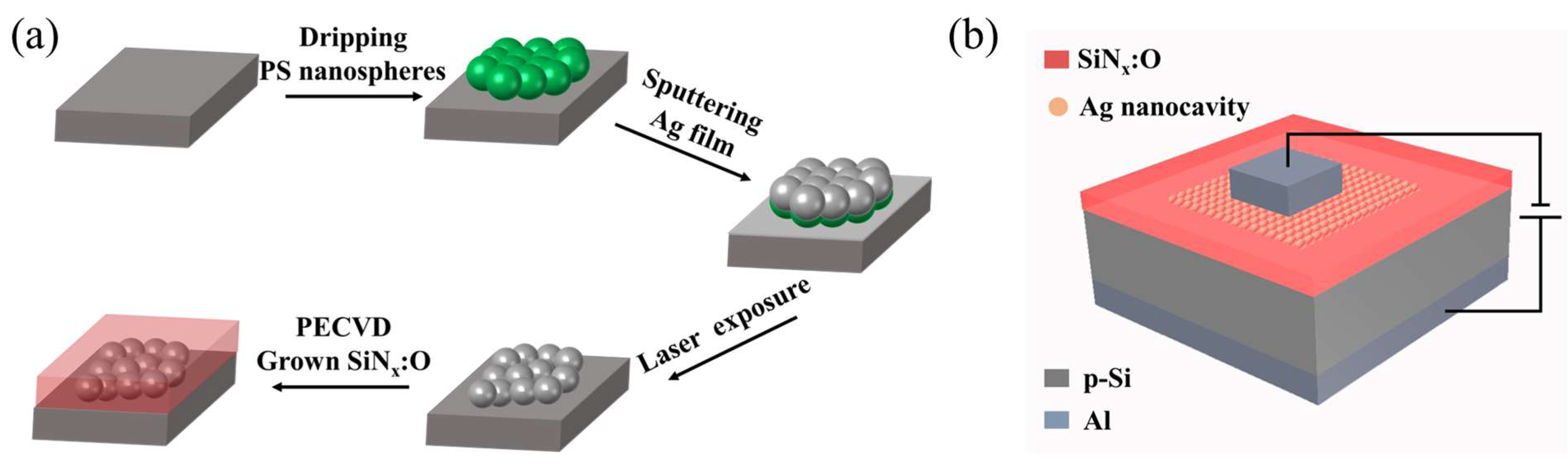

2. Materials and Methods

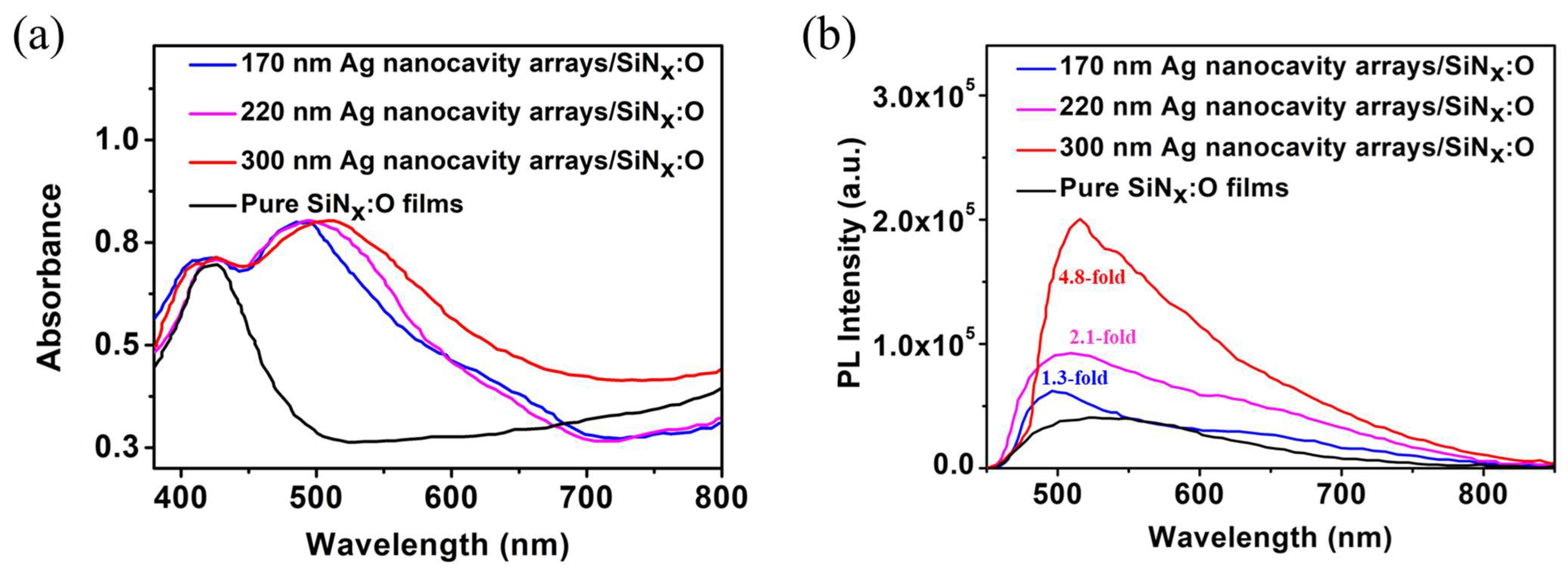

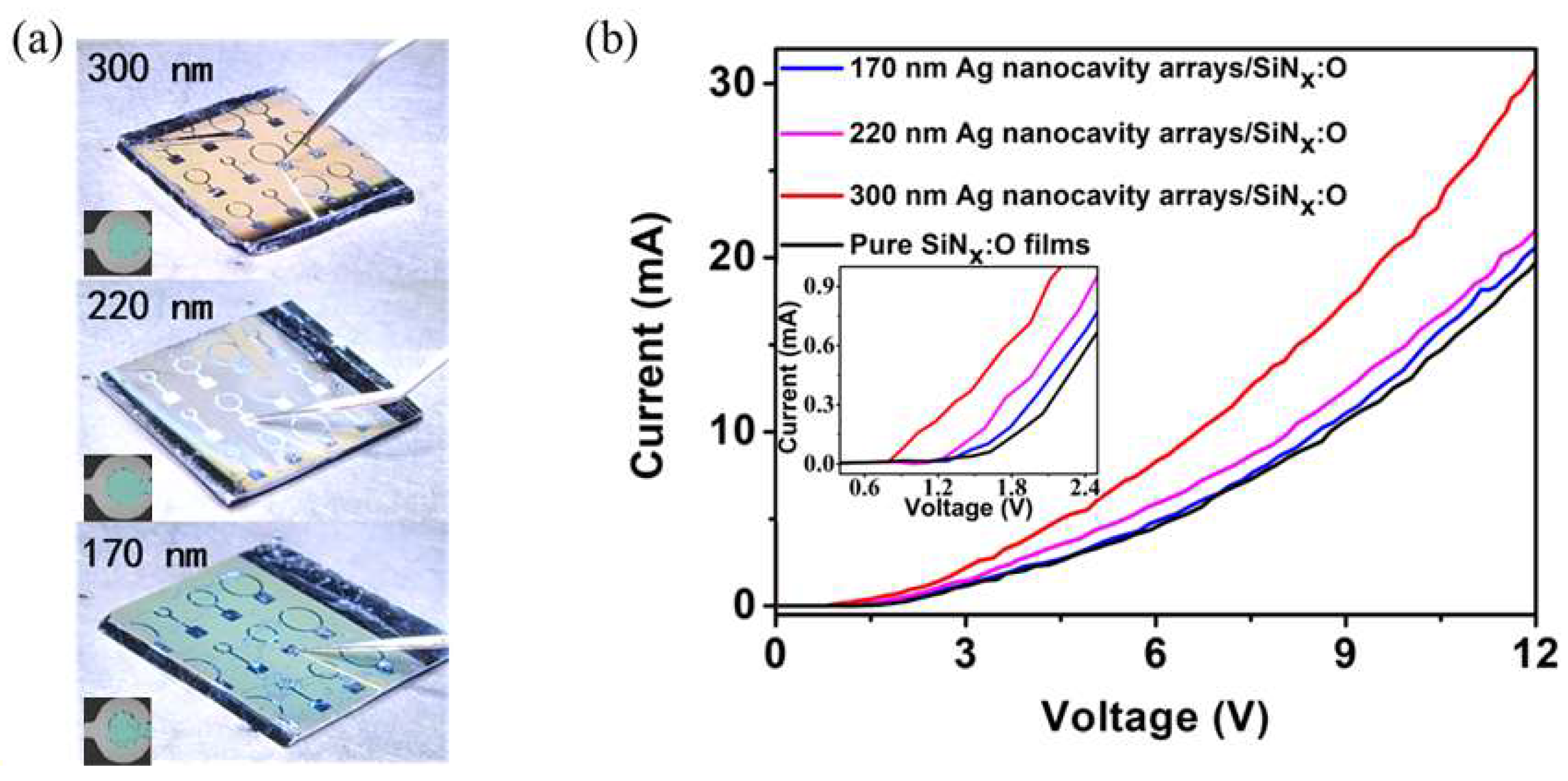

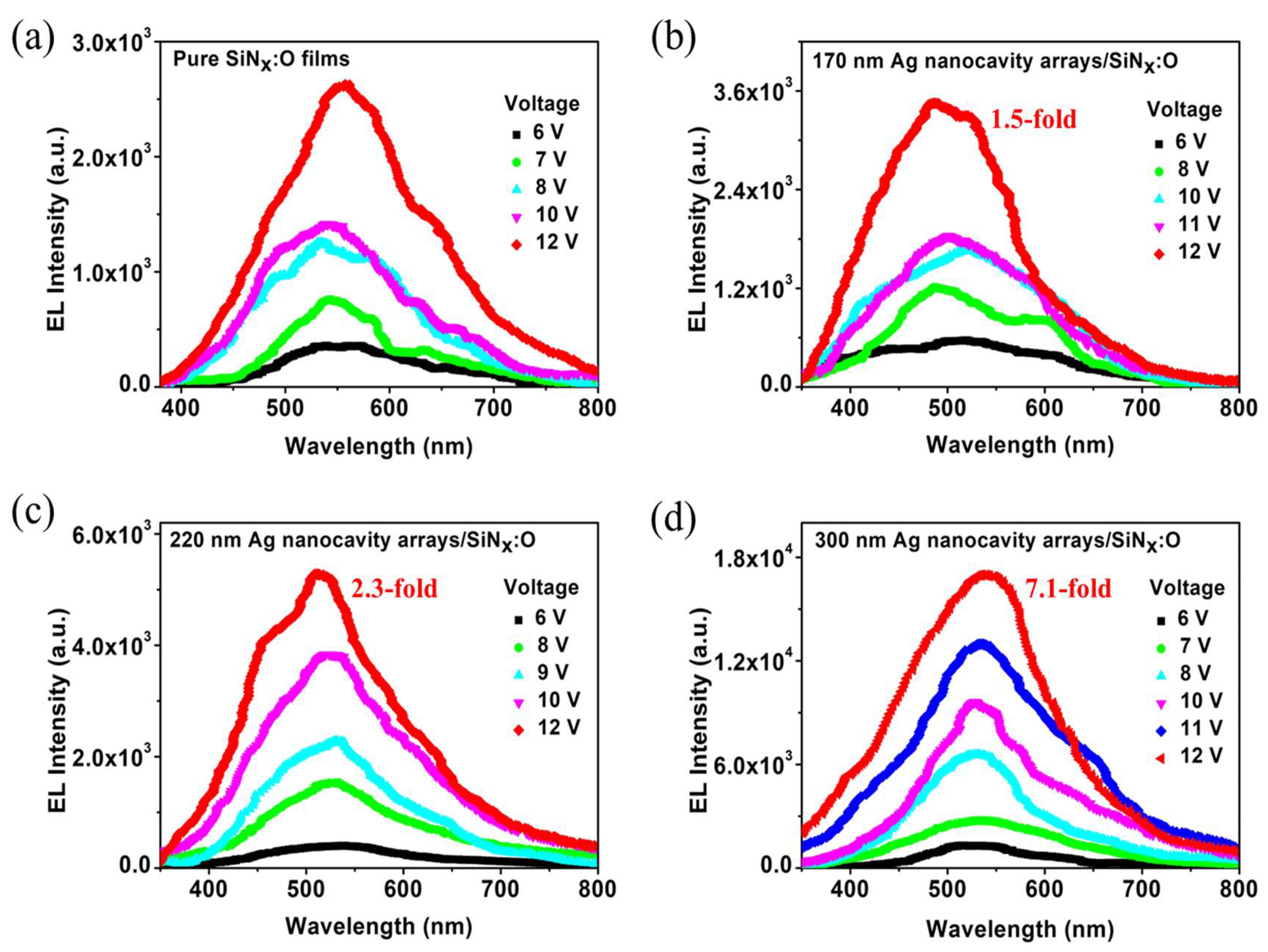

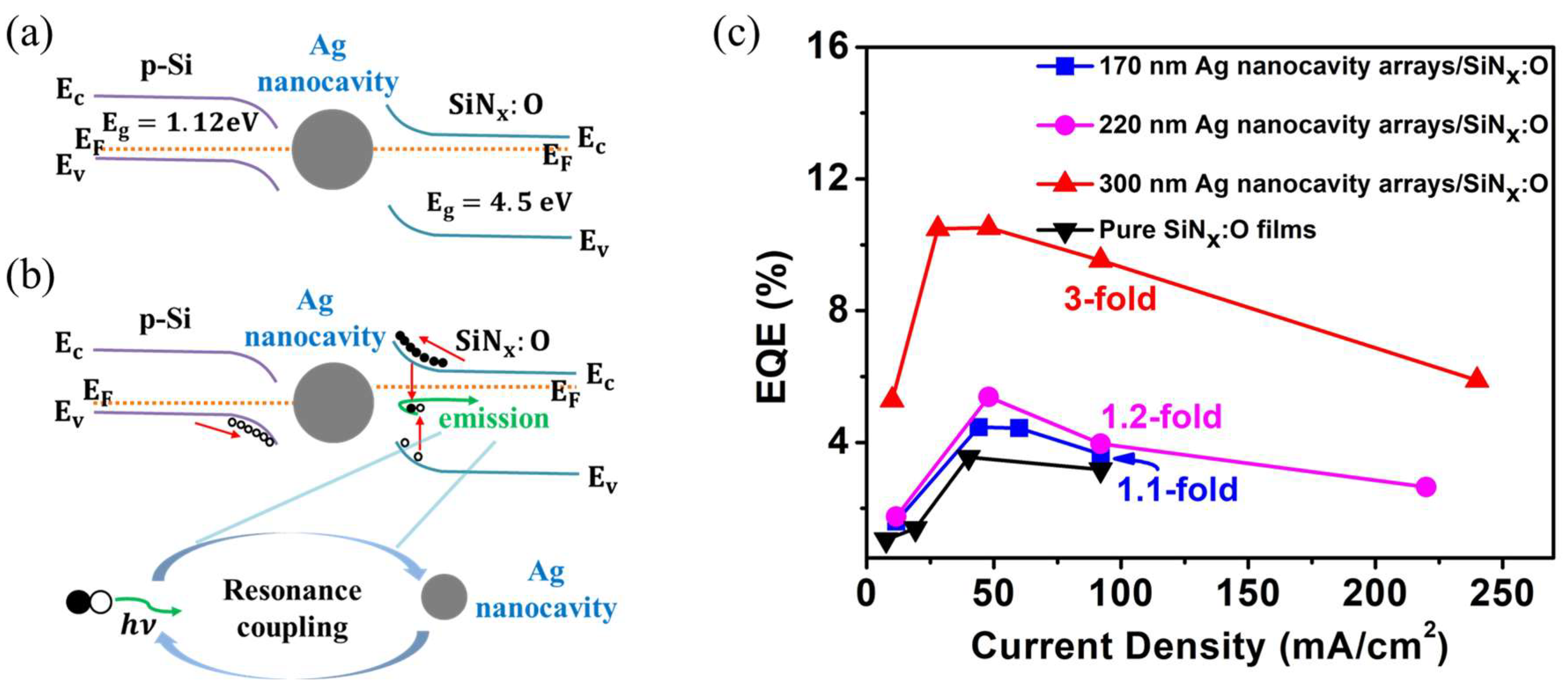

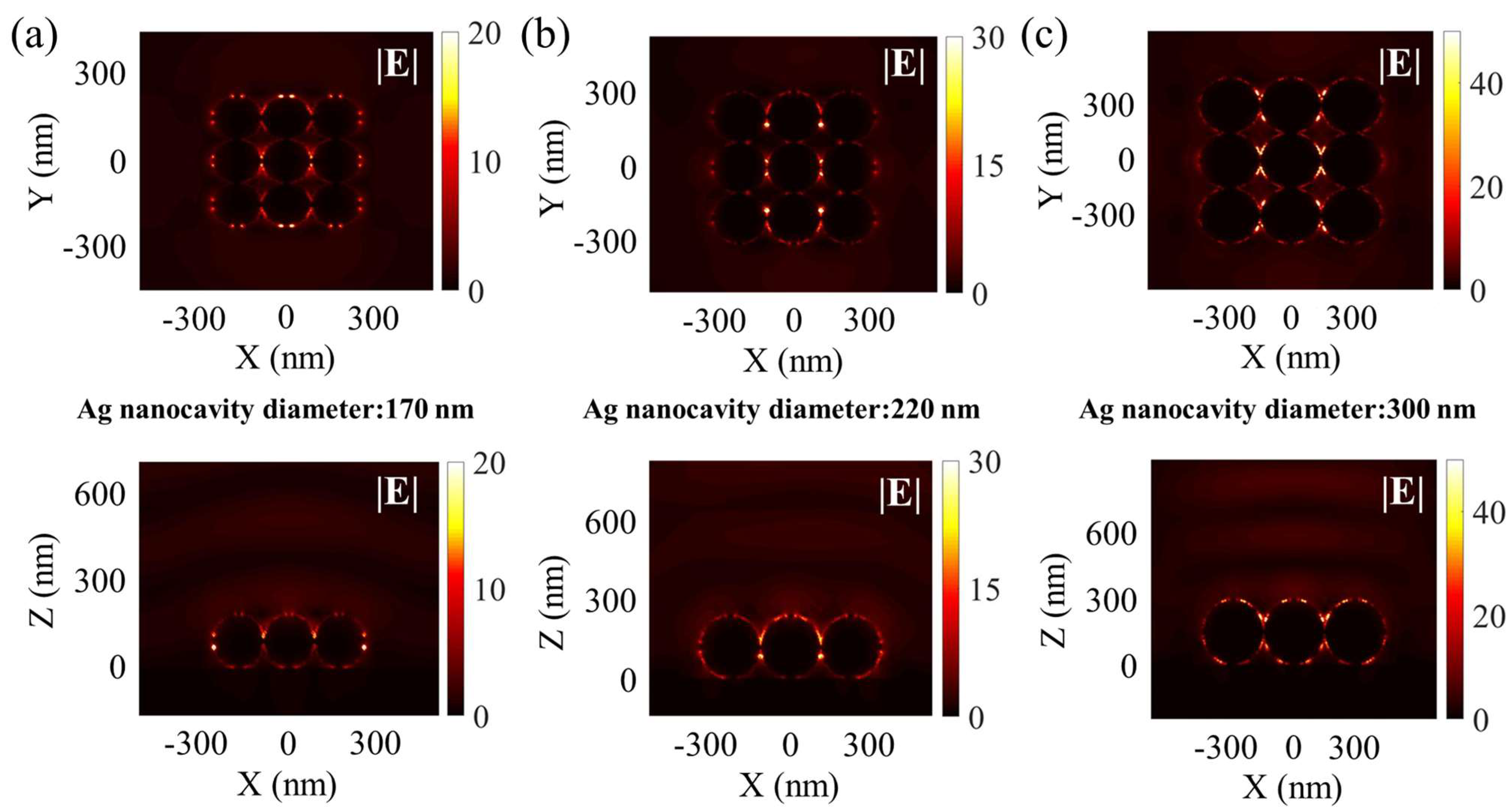

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.L.; Li, G.K.; Zhang, Z.; Liu, J.; Wu, N.J.; Wang, K.Y.; Qi, N.; Liu, L.Y. Silicon-based optoelectronic heterogeneous integration for optical interconnection. Chin. Phys. B 2024, 33, 024201. [Google Scholar] [CrossRef]

- Soref, R.; Shastri, B.J.; Tait, A.N. The silicon-based XOI wafer: The most general electronics-photonics platform for computing, sensing, and communications. IEEE J. Sel. Top. Quant. 2023, 29, 8200108. [Google Scholar] [CrossRef]

- Xu, Y.T.; Tian, Z.X.; Meng, X.Q.; Chai, Z. Methods and applications of on-chip beam splitting: A review. Front. Phys. 2022, 10, 985208. [Google Scholar] [CrossRef]

- He, T.; Ma, H.; Wang, Z.; Li, Q.; Liu, S.N.; Duan, S.K.; Xu, T.F.; Wang, J.C.; Wu, H.T.; Zhong, F.; et al. On-chip optoelectronic logic gates operating in the telecom band. Nat. Photonics 2024, 18, 60–67. [Google Scholar] [CrossRef]

- Ren, A.B.; Wang, H.; Dai, L.J.; Xia, J.F.; Bai, X.Y.; Butler-Caddle, E.; Smith, J.A.; Lai, H.G.; Ye, J.Z.; Li, X.; et al. High-bandwidth perovskite photonic sources on silicon. Nat. Photonics 2023, 17, 798–805. [Google Scholar] [CrossRef]

- Yang, C.J.; Liang, L.; Qin, L.; Tang, H.; Lei, Y.X.; Jia, P.; Chen, Y.Y.; Wang, Y.B.; Song, Y.; Qiu, C.; et al. Advances in silicon-based, integrated tunable semiconductor lasers. Nanophotonics 2023, 12, 197–217. [Google Scholar] [CrossRef]

- Huang, J.Z.; Wei, W.Q.; Chen, J.J.; Wang, Z.H.; Wang, T.; Zhang, J.J. P-doped 1300 nm InAs/GaAs quantum dot lasers directly grown on an SOI substrate. Opt. Lett. 2021, 46, 5525–5528. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Ge, W.Y.; Zhang, X.M.; Tian, Y.; Yin, Z. Silicon-based nanoparticles grafted lanthanide coordination polymer phosphor: Facile synthesis, formation process and white light-emitting diodes. J. Alloys Compd. 2023, 967, 171811. [Google Scholar] [CrossRef]

- Xu, P.F.; Zhou, Z.P. Silicon-based optoelectronics for general-purpose matrix computation: A review. Adv. Photonics 2022, 4, 044001. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhou, P.Q.; He, Y.D.; Zhou, Z.P. Erbium silicate compound optical waveguide amplifier and laser. Opt. Mater. Express 2018, 8, 2970–2990. [Google Scholar] [CrossRef]

- Wu, K.J.; Cheng, J.J.; Huang, G.H.; Yuan, J.; Xu, K.K. Poly-silicon light-emitting-device based electro-optical interfaces in standard silicon-CMOS integrated circuitry. Opt. Mater. 2020, 102, 109783. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, X.D.; Wang, C.Q.; Cao, Y.F.; Wang, B.H.; Ou, H.W.; Wu, Y.Z.; Mei, Q.X.; Zhang, J.L.; Cong, Z.; et al. Silicon-based metastructure optical scattering multiply-accumulate computation chip. Nanomaterials 2022, 12, 2136. [Google Scholar] [CrossRef]

- Zhang, P.Z.; Zhang, L.; Lyu, F.; Wang, D.B.; Zhang, L.; Wu, K.P.; Wang, S.K.; Tang, C.M. Luminescent amorphous silicon oxynitride systems: High quantum efficiencies in the visible range. Nanomaterials 2023, 13, 1269. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.M.; He, J.J.; Dan, Y.P. Near-infrared and mid-infrared light emission of boron-doped crystalline silicon. Opt. Express 2024, 32, 10941–10947. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.Z.; Liu, Y.; Yang, Y.; Sun, J.M. Exploration of the green electroluminescence from Al2O3/Ho2O3 nanolaminate films fabricated by atomic layer deposition on silicon. Opt. Mater. 2020, 107, 110125. [Google Scholar] [CrossRef]

- Wu, Y.P.; Xiao, Y.X.; Navid, I.; Sun, K.; Malhotra, Y.; Wang, P.; Wang, D.; Xu, Y.X.; Pandey, A.; Reddeppa, M.; et al. InGaN micro-light-emitting diodes monolithically grown on Si: Achieving ultra-stable operation through polarization and strain engineering. Light Sci. Appl. 2022, 11, 294. [Google Scholar] [CrossRef]

- Dutt, A.; Salinas, R.A.; Martínez-Tolibia, S.E.; Ramos-Serrano, J.R.; Jain, M.; Hamui, L.; Ramos, C.D.; Mostafavi, E.; Mishra, Y.K.; Matsumoto, Y. Silicon compound nanomaterials: Exploring emission mechanisms and photobiological applications. Adv. Photonics Res. 2023, 4, 2300054. [Google Scholar] [CrossRef]

- Li, Z.; Xue, J.; de Cea, M.; Kim, J.; Nong, H.; Chong, D.; Lim, K.Y.; Quek, E.; Ram, R.J. A sub-wavelength Si LED integrated in a CMOS platform. Nat. Commun. 2023, 14, 882. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Chen, K.J.; Qian, B.; Chen, S.; Li, W.; Xu, J.; Ma, Z.Y.; Huang, X.F. Oxygen induced strong green light emission from low-temperature grown amorphous silicon nitride films. Appl. Phys. Lett. 2006, 89, 221120. [Google Scholar] [CrossRef]

- Zhang, P.Z.; Chen, K.J.; Lin, Z.W.; Dong, H.P.; Li, W.; Xu, J.; Huang, X.F. The role of N-Si-O bonding configurations in tunable photoluminescence of oxygenated amorphous silicon nitride films. Appl. Phys. Lett. 2015, 106, 231103. [Google Scholar] [CrossRef]

- Pathak, S.K.; Yang, C.L. Chapter 10-Aggregation-Induced Emission Luminogens for Organic Light-Emitting Diodes. Mater. Today 2022, 2022, 315–372. [Google Scholar]

- Yu, L.; Wu, Z.B.; Xie, G.H.; Zhong, C.; Zhu, Z.C.; Ma, D.G.; Yang, C.L. An efficient exciton harvest route for high-performance OLEDs based on aggregation-induced delayed fluorescence. Chem. Commun. 2018, 54, 1379–1382. [Google Scholar] [CrossRef] [PubMed]

- Rahman, I.K.M.R.; Uddin, S.Z.; Kim, H.; Higashitarumizu, N.; Javey, A. Low voltage AC electroluminescence in silicon MOS capacitors. Appl. Phys. Lett. 2022, 121, 193502. [Google Scholar] [CrossRef]

- Takahashi, H.; Suzuki, Y.; Yoshida, N.; Nakagawa, K.; Maki, H. High-speed electroluminescence from semiconducting carbon nanotube films. J. Appl. Phys. 2020, 127, 164301. [Google Scholar] [CrossRef]

- Wang, H.Y.; Guo, Y.Y.; Zang, J.Y.; Hao, H.X.; Wang, L.; Liu, T.H.; Bian, H.T.; Jiang, R.B.; Wen, R.J.; Li, H.X.; et al. Nanoantennas involved optical plasmonic cavity for improved luminescence of quantum dots light-emitting diodes. ACS Appl. Mater. 2021, 13, 44760–44767. [Google Scholar] [CrossRef] [PubMed]

- Glassner, S.; Keshmiri, H.; Hill, D.J.; Cahoon, J.F.; Fernandez, B.; den Hertog, M.I.; Lugstein, A. Tuning electroluminescence from a plasmonic cavity-coupled silicon light source. Nano Lett. 2018, 18, 7230–7237. [Google Scholar] [CrossRef]

- Wang, P.L.; Liang, Z.H.; Zhao, J.Y.; Nie, Y.X.; Xu, S.P.; Ma, Q. A polarization-resolved ECL strategy based on the surface plasmon coupling effect of orientational Au nanobipyramids patterned structures. Chem. Eng. J. 2022, 448, 137630. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Zhao, Y.; Chen, X.; Zhang, Z.Q.; Song, H. Integrated effects of near-field enhancement-induced excitation and surface plasmon-coupled emission of elongated gold nanocrystals on fluorescence enhancement and the applications in PLEDs. ACS Appl. Electron. 2019, 1, 2116–2123. [Google Scholar] [CrossRef]

- Zhang, S.Y.; He, R.; Duo, Y.; Chen, R.F.; Wang, L.G.; Wang, J.X.; Wei, T.B. Plasmon-enhanced deep ultraviolet Micro-LED arrays for solar-blind communications. Opt. Lett. 2023, 48, 3841–3844. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, M.M.; Tang, K.; Ma, K.J.; Wu, Y.T.; Ji, J.L.; Kan, C.X. Plasmon-enhanced high-performance Si-based light sources by incorporating alloyed Au and Ag nanorods. Crystengcomm 2020, 22, 6106–6115. [Google Scholar] [CrossRef]

- Huang, C.L.; Huang, H.J.; Chen, S.H.; Huang, Y.S.; Kao, P.C.; Chau, Y.F.C.; Chiang, H.P. Localized surface plasmon resonance enhanced by the light-scattering property of silver nanoparticles for improved luminescence of polymer light-emitting diodes. J. Ind. Eng. Chem. 2021, 103, 283–291. [Google Scholar] [CrossRef]

- Kim, S.K.; Lee, S.H.; Yoon, S.Y.; Jo, D.Y.; Kim, H.M.; Kim, Y.; Park, S.M.; Kim, Y.H.; Yang, H. Localized surface plasmon-enhanced blue electroluminescent device based on ZnSeTe quantum dots and AuAg nanoparticles. Inorg. Chem. Front. 2022, 9, 3138–3147. [Google Scholar] [CrossRef]

- Guerrero, S.E.; Nava, R.; Reyes-Esqueda, J.A. Plasmonic-enhanced photoluminescence in porous silicon with pore-embedded gold nanoparticles fabricated by direct reduction of chloroauric acid. J. Lumin. 2024, 269, 120465. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Yan, M.Y.; Jiang, X.F.; Yang, H.F.; Xia, G.Y.; Ni, X.D.; Ling, T.; Li, W.; Xu, L.; Chen, K.J.; et al. Strong blue light emission from a-SiNx:O films via localized surface plasma enhancement. Appl. Phys. Lett. 2012, 101, 013106. [Google Scholar] [CrossRef]

- Yin, J.M.; Wu, S.B.; Rong, X.M.; Han, S.; Cao, P.J.; Zeng, Y.X.; Fang, M.; Liu, W.J.; Zhu, D.L.; Lu, Y.M. Electroluminescence enhancement of ZnO nanorods array determined by Au-nanoparticles position under external electric field. Opt. Mater. 2023, 143, 114181. [Google Scholar] [CrossRef]

- Diallo, A.T.; Chakaroun, M.; Khadir, S.; Hamdad, S.; Esparza-Villa, J.U.; Maître, A.; Boudrioua, A. Plasmonic effects of thermally evaporated aluminum nanoparticles on the electroluminescence of organic light-emitting diode subject to exciplex. J. Nanophotonics 2019, 13, 016004. [Google Scholar] [CrossRef]

- Kim, T.; Uthirakumar, P.; Cho, Y.H.; Nam, K.H.; Lee, I.H. Enhanced quantum efficiency of horizontally aligned individual InGaN/GaN nanorod LEDs by self-assembled Ag nanoparticles. Appl. Surf. Sci. 2024, 656, 159706. [Google Scholar] [CrossRef]

- Chen, S.H.; Hong, Y.W.; Chau, Y.F.C.; Huang, H.J.; Chiang, H.P. Enhancement of luminous efficacy of polymer light-emitting diodes with silver-nanoparticles by oxygen-plasma treatment. Microsc. Res. Tech. 2023, 86, 725–730. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Uthirakumar, P.; Cho, Y.H.; Lee, I.H. Enabling localized surface plasmon emission from InGaN/GaN nano-LEDs integrated with Ag/SiO2 nanoparticles. ACS Photonics 2024, 11, 570–579. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Ni, X.D.; Zhang, W.P.; Jiang, X.F.; Yang, H.F.; Yu, J.; Wang, W.; Xu, L.; Xu, J.; Chen, K.J.; et al. Hexagonal Ag nanoarrays induced enhancement of blue light emission from amorphous oxidized silicon nitride via localized surface plasmon coupling. Opt. Express 2014, 22, 28180–28189. [Google Scholar] [CrossRef]

- Gou, F.W.; Hsiang, E.L.; Tan, G.J.; Chou, P.T.; Li, Y.L.; Lan, Y.F.; Wu, S.O. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746–A757. [Google Scholar] [CrossRef] [PubMed]

- Mafun’e, F.; Kohno, J.Y.; Takeda, Y.; Kondow, T.; Sawabe, H. Formation and size control of silver nanoparticles by laser ablation in aqueous solution. J. Phys. Chem. B 2000, 104, 9111–9117. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, Z.; Ma, Z.; Chen, T.; Zhang, W.; Li, W.; Xu, J.; Xu, L.; Chen, K. Tunable Ag Nanocavity Enhanced Green Electroluminescence from SiNx:O Light-Emitting Diode. Nanomaterials 2024, 14, 1306. https://doi.org/10.3390/nano14151306

Zuo Z, Ma Z, Chen T, Zhang W, Li W, Xu J, Xu L, Chen K. Tunable Ag Nanocavity Enhanced Green Electroluminescence from SiNx:O Light-Emitting Diode. Nanomaterials. 2024; 14(15):1306. https://doi.org/10.3390/nano14151306

Chicago/Turabian StyleZuo, Zongyan, Zhongyuan Ma, Tong Chen, Wenping Zhang, Wei Li, Jun Xu, Ling Xu, and Kunji Chen. 2024. "Tunable Ag Nanocavity Enhanced Green Electroluminescence from SiNx:O Light-Emitting Diode" Nanomaterials 14, no. 15: 1306. https://doi.org/10.3390/nano14151306