Synthesis of Highly Porous Lignin-Sulfonate Sulfur-Doped Carbon for Efficient Adsorption of Sodium Diclofenac and Synthetic Effluents

Abstract

1. Introduction

2. Materials and Methods

2.1. LS-Carbon Synthesis

2.2. Characterization of Activated Biochars

2.3. Adsorption Experiments

3. Results and Discussion

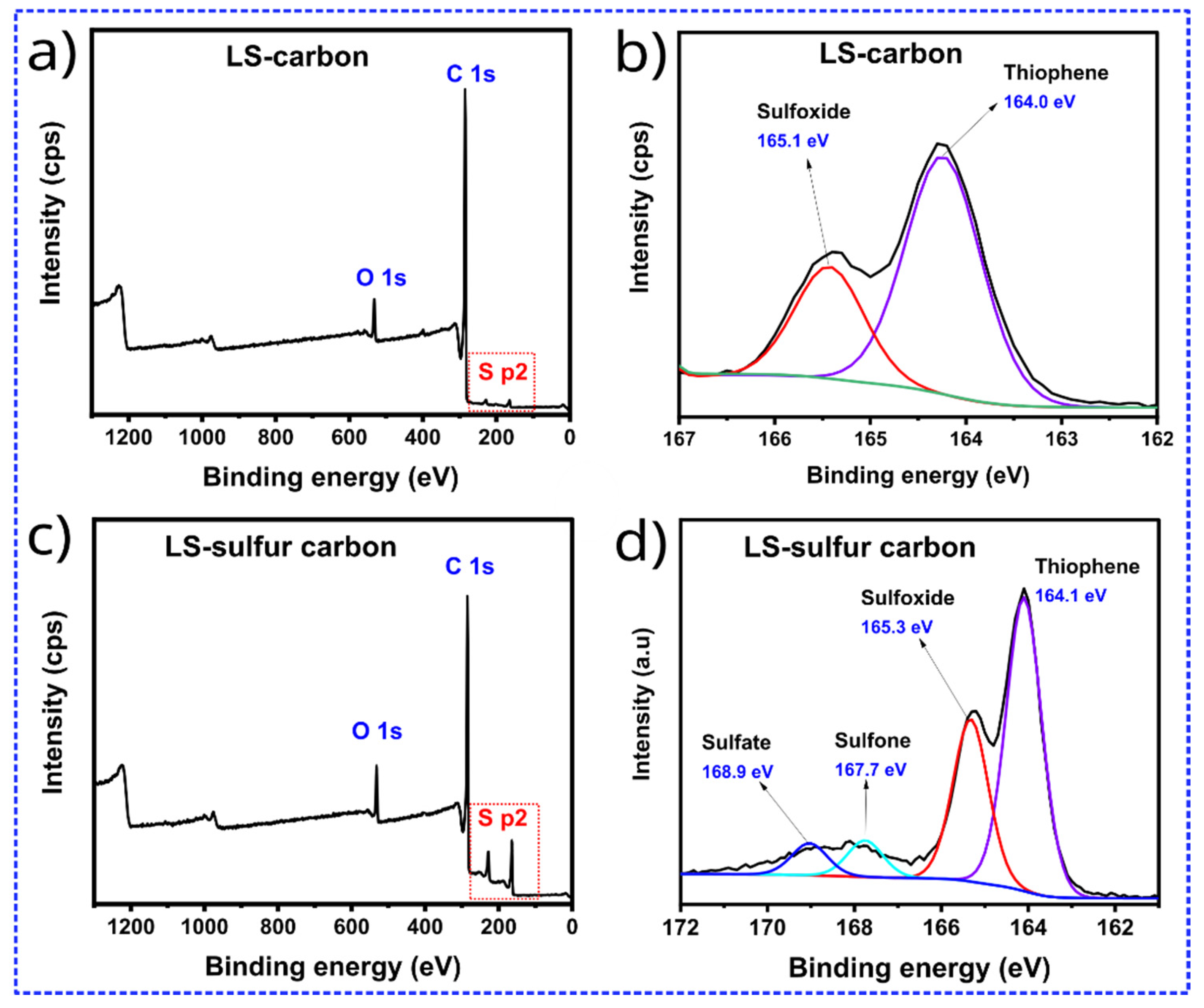

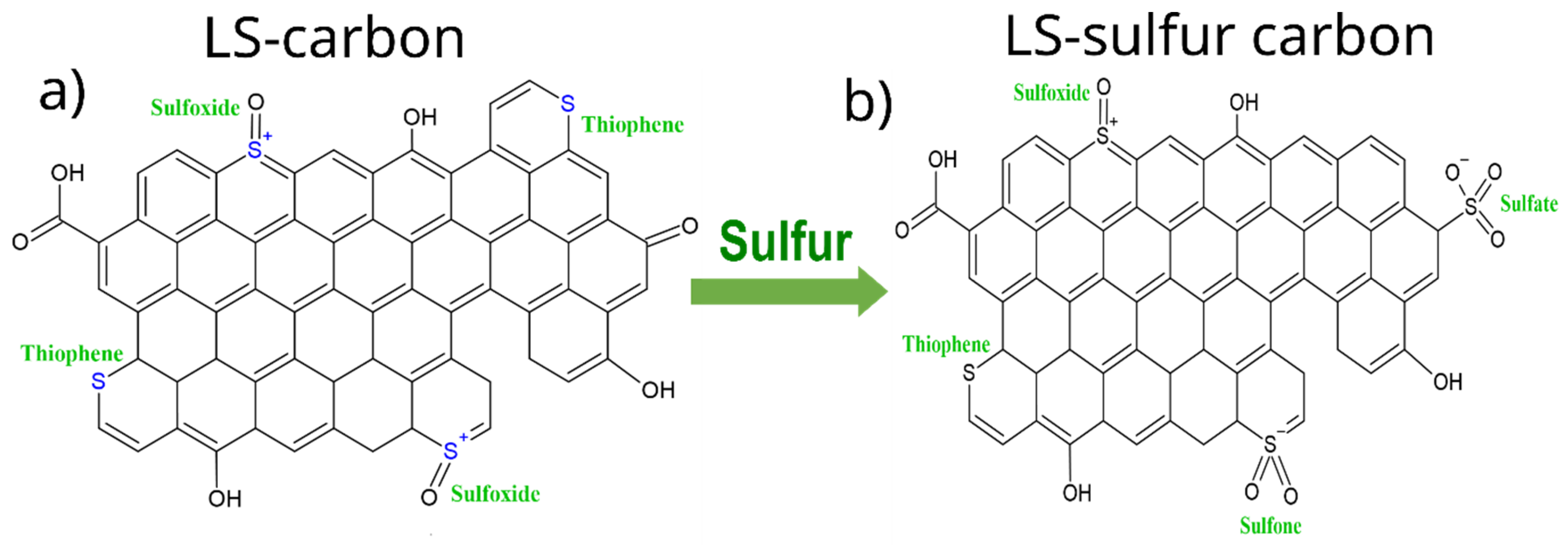

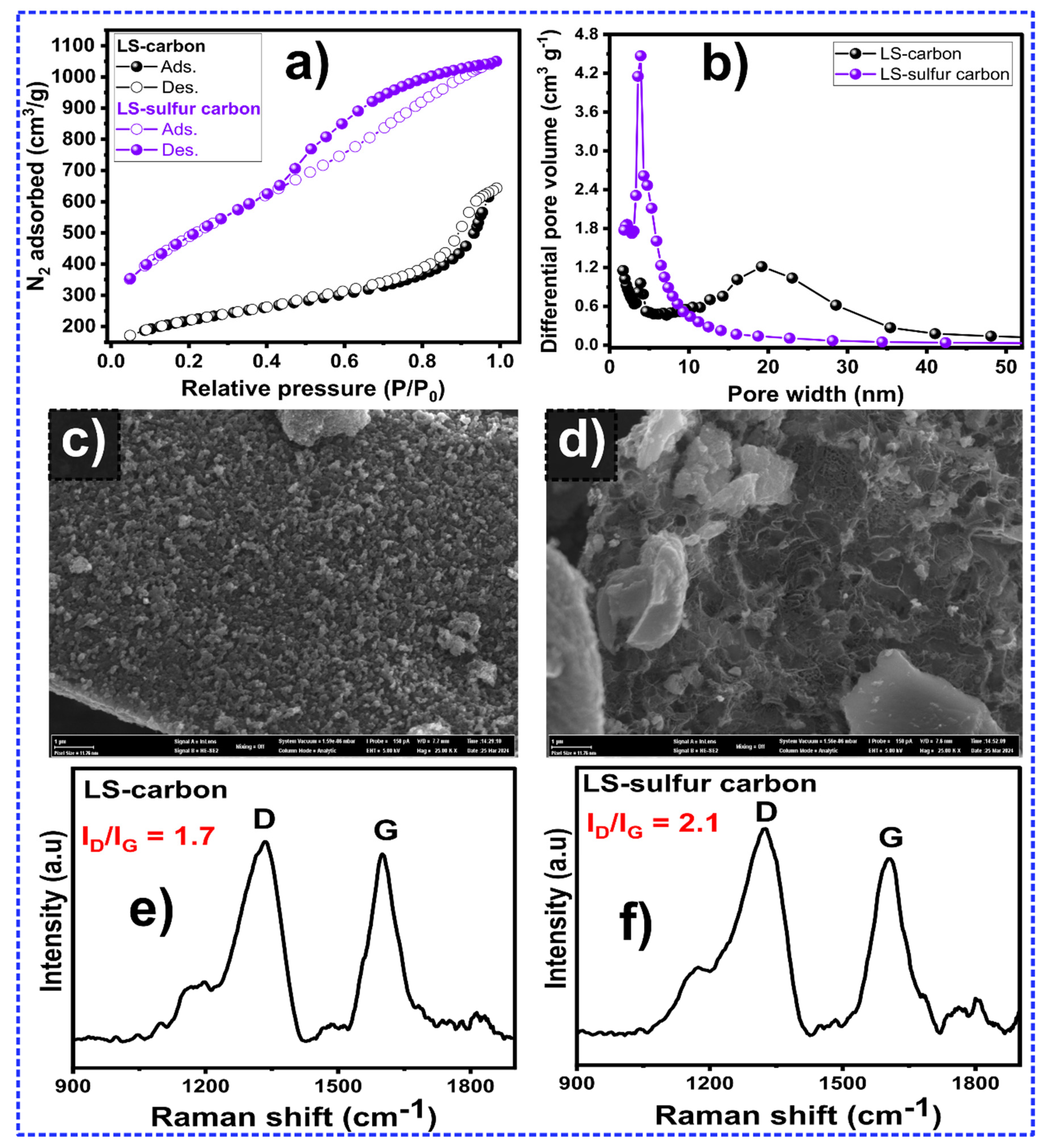

3.1. Physicochemical Characterization of the LS-Based Carbons

3.2. Adsorption Experiments

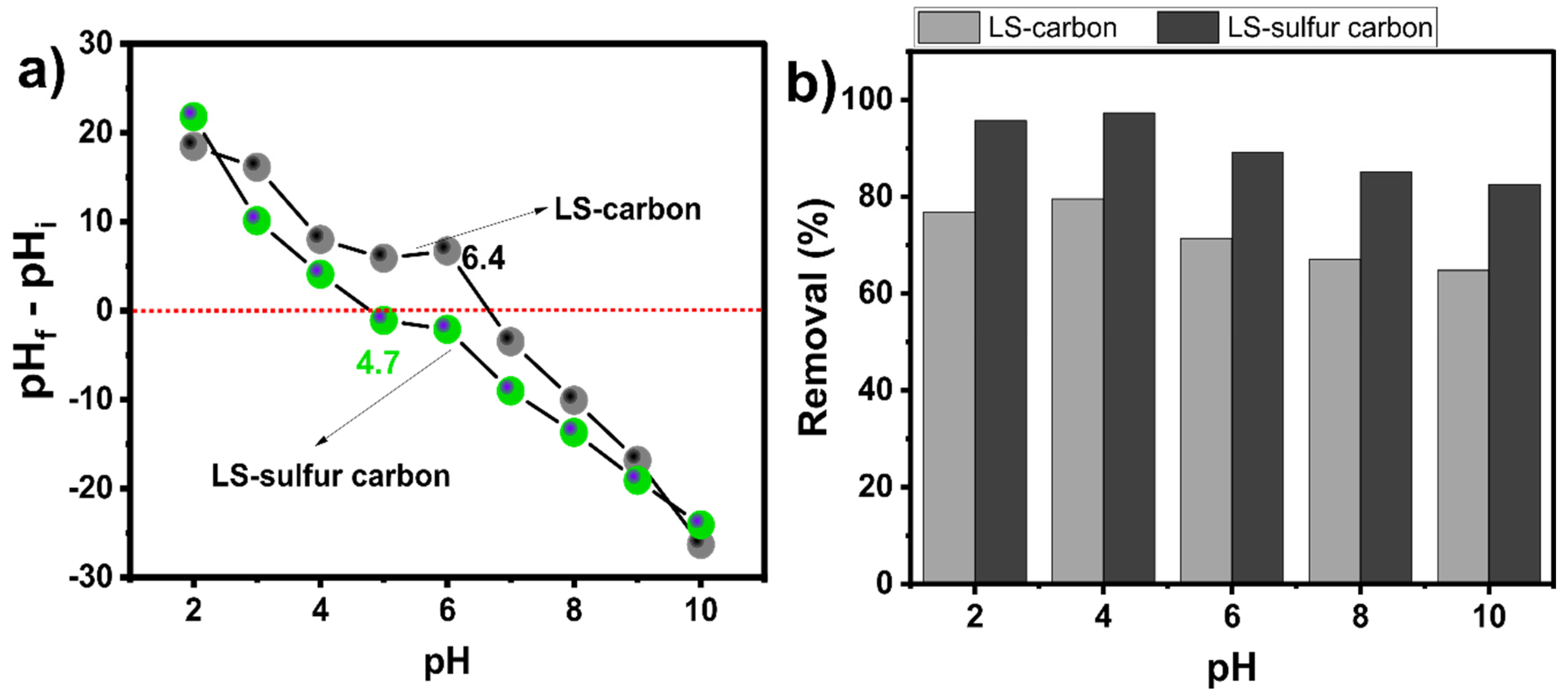

3.2.1. pHpzc and the Effect of the pH on DCF Removal

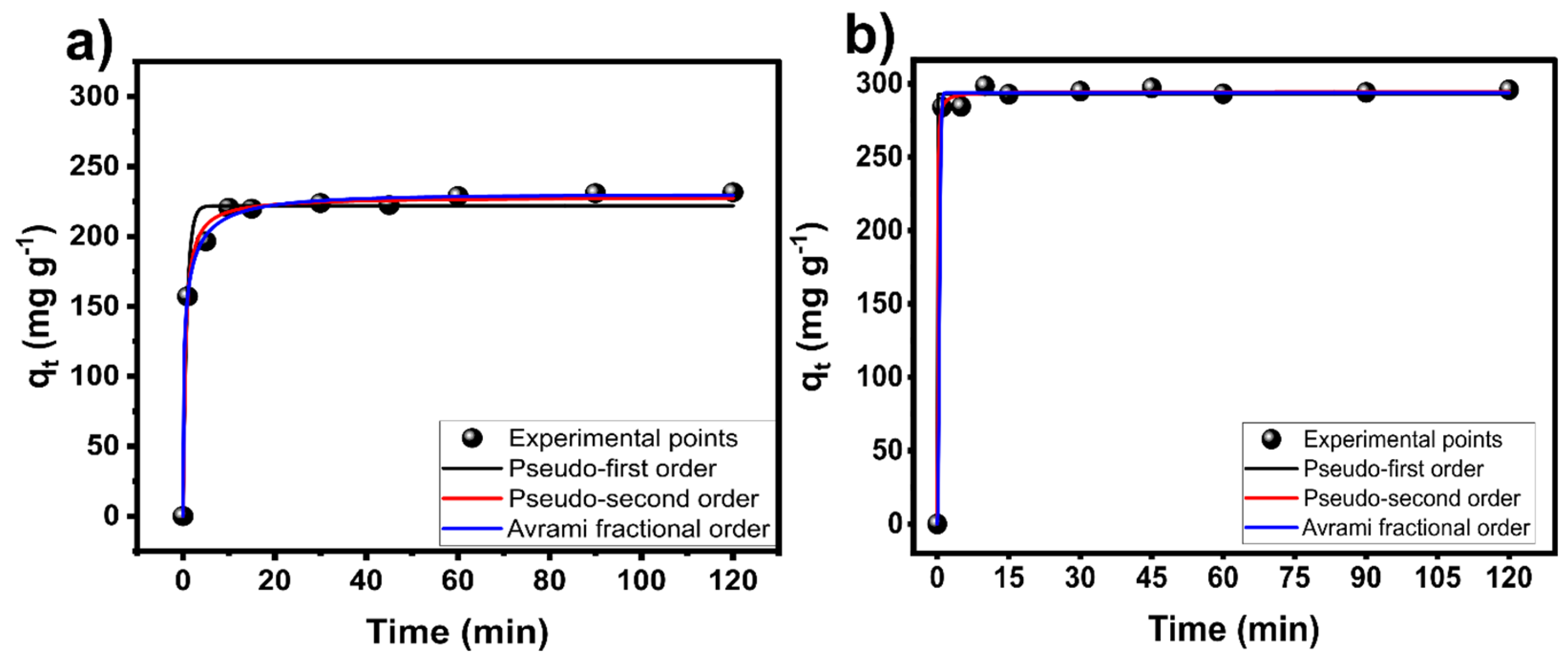

3.2.2. Kinetic Studies

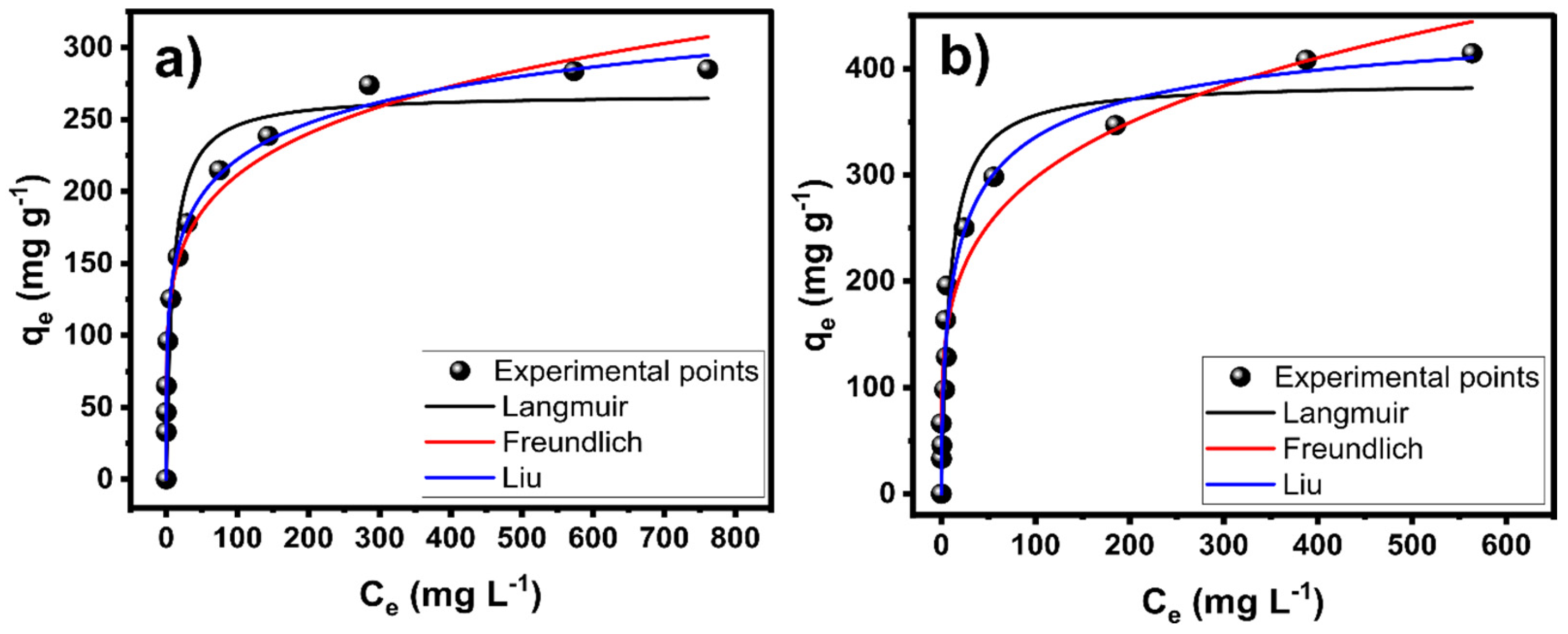

3.2.3. Isotherm Studies

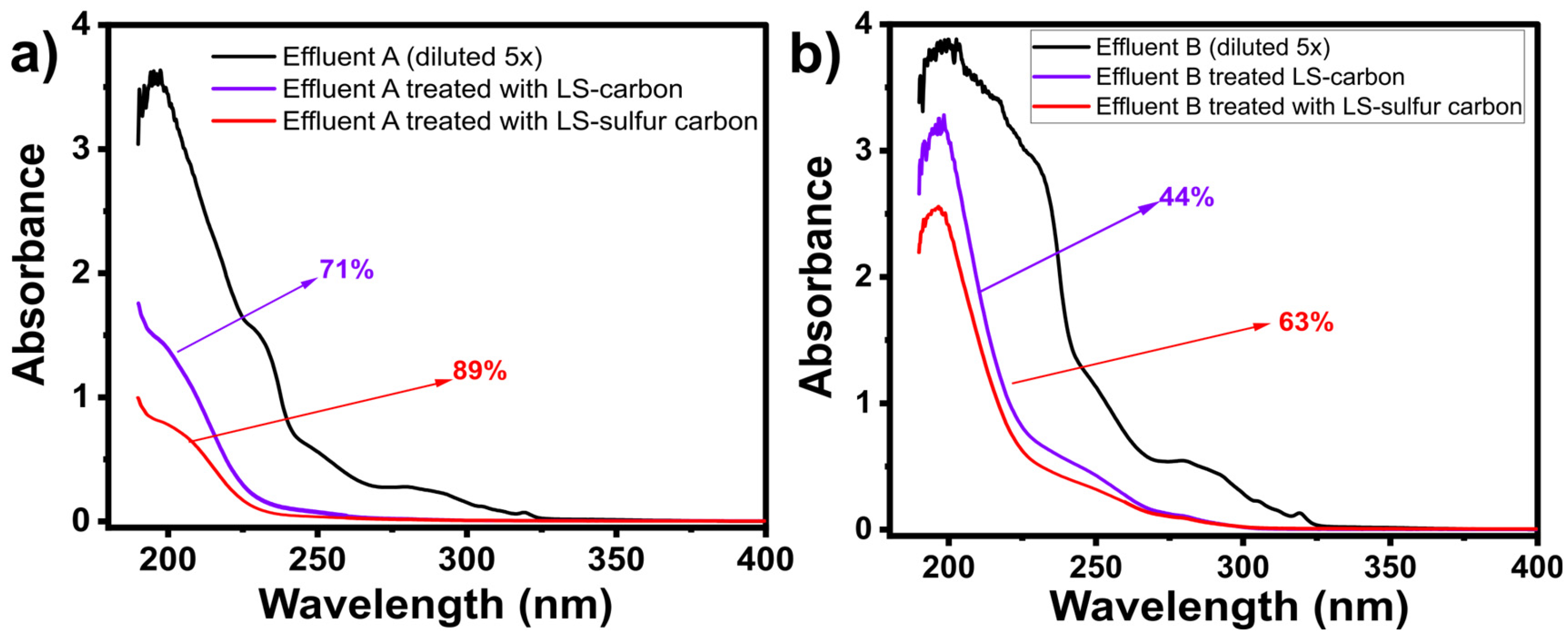

3.2.4. Lab-Made Effluent Treatment Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Evgenidou, E.N.; Konstantinou, I.K.; Lambropoulou, D.A. Occurrence and removal of transformation products of PPCPs and illicit drugs in wastewaters: A review. Sci. Total Environ. 2015, 505, 905–926. [Google Scholar] [CrossRef]

- Imwene, K.O.; Ngumba, E.; Kairigo, P.K. Emerging technologies for enhanced removal of residual antibiotics from source-separated urine and wastewaters: A review. J. Environ. Manag. 2022, 322, 116065. [Google Scholar] [CrossRef] [PubMed]

- Carmalin, S.A.; Lima, E. Removal of emerging contaminants from the environment by adsorption. Ecotoxicol. Environ. Saf. 2018, 150, 1–17. [Google Scholar]

- Li, X.; Wang, B.; Liu, F.; Yu, G. Occurrence and Removal of Pharmaceutical Contaminants in Urine: A Review. Water 2023, 15, 1517. [Google Scholar] [CrossRef]

- de Oliveira, J.F.; Fia, R.; Rodrigues, F.N.; Fia, F.R.L.; de Matos, M.P.; Siniscalchi, L.A.B.; Sanson, A.L. Quantification, removal and potential ecological risk of emerging contaminants in different organic loads of swine wastewater treated by integrated biological reactors. Chemosphere 2020, 260, 127516. [Google Scholar] [CrossRef]

- Ferreiro, V.; Gómez-Motos, I.; Lombrana, J.I.; de Luis, A.; Villota, N.; Ros, O.; Etxebarria, N. Contaminants of emerging concern removal in the effluent of wastewater treatment plant under biological and continuous mode ultrafiltration treatment. Water 2020, 12, 725. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Q.; Campos, L.C. The application of GAC sandwich slow sand filtration to remove pharmaceuticals and personal care products. Sci. Total Environ. 2018, 635, 1182–1190. [Google Scholar] [CrossRef]

- Isac, L.; Cazan, C.; Andronic, L.; Enesca, A. CuS-Based Nanostructures as Catalysts for Organic Pollutants Photodegradation. Catalysts 2022, 12, 1135. [Google Scholar] [CrossRef]

- Ibanez, M.; Gracia-Lor, E.; Bijlsma, L.; Morales, E.; Pastor, L.; Hernández, F. Removal of emerging contaminants in sewage water subjected to advanced oxidation with ozone. J. Hazard. Mater. 2013, 260, 389–398. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Thivet, J.; Laisne, E.; Srivastava, V.; Grimm, A.; Lima, E.C.; Bergna, D.; Hu, T.; Naushad, M.; Lassi, U. Synthesis of novel mesoporous selenium-doped biochar with high-performance sodium diclofenac and reactive orange 16 dye removals. Chem. Eng. Sci. 2023, 281, 119129. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Larsson, S.H.; Mathieu, M.; Thyrel, M.; Pham, T.N. Application of design of experiments (DoE) for optimised production of micro- and mesoporous Norway spruce bark activated carbons. Biomass Convers. Biorefinery 2021, 13, 10113–10131. [Google Scholar]

- Grimm, A.; dos Reis, G.S.; Dinh, V.M.; Larsson, S.H.; Mikkola, J.P.; Lima, E.C.; Xiong, S.J. Hardwood spent mushroom substratebased activated biochar as a sustainable bioresource for removal of emerging pollutants from wastewater. Biomass. Convers. Biorefinery 2022, 14, 2293–2309. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Grimm, A.; Fungaro, D.A.; Hu, T.; de Brum, I.A.; Lima, E.C.; Naushad, M.; Dotto, G.L.; Lassi, U. Synthesis of sustainable mesoporous sulfur-doped biobased carbon with superior performance sodium diclofenac removal: Kinetic, equilibrium, thermodynamic and mechanism. Environ. Res. 2024, 251, 118595. [Google Scholar] [CrossRef]

- Thue, P.S.; Umpierres, C.S.; Lima, E.C.; Lima, D.R.; Machado, F.M.; dos Reis, G.S.; da Silva, R.S.; Pavan, F.A.; Tran, H.N. Single-step pyrolysis for producing magnetic activated carbon from tucumã (Astrocaryum aculeatum) seed and nickel(II) chloride and zinc(II) chloride. Application for removal of Nicotinamide and Propanolol. J. Hazard Mater. 2020, 398, 122903. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, Q.; Ji, G.; Li, A.; Niu, J. Doping strategy, properties and application of heteroatom-doped ordered mesoporous carbon. RSC Adv. 2021, 11, 5361–5383. [Google Scholar] [CrossRef]

- Du, W.; Zhang, Q.; Shang, Y.; Wang, W.; Li, Q.; Yue, Q.; Gao, B.; Xu, X. Sulfate saturated biosorbent-derived Co-S@NC nanoarchitecture as an efficient catalyst for peroxymonosulfate activation. Appl. Catal. B 2020, 262, 118302. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.; Sun, M.; Zheng, Y.; Fan, H.; Wang, S.; Jiang, C. Bifunctional sulfur-doped biochar for efficient removal of tetracycline and resistant bacteria via adsorption and peroxydisulfate activation. Sep. Purif. Technol. 2025, 354, 128728. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sirajudheen, P.; Nikitha, M.; Ramkumar, K.; Meenakshi, S. Facile synthesis of sulfur-doped chitosan/biochar derived from tapioca peel for the removal of organic dyes: Isotherm, kinetics and mechanisms. J. Mol. Liq. 2021, 326, 115303. [Google Scholar] [CrossRef]

- ASTM E2108-16; Standard Practice for Calibration of the Electron Binding-Energy Scale of an X-ray Photoelectron Spec-trometer. ASTM: Philadelphia, PA, USA, 2016.

- ISO 15472:2010; Surface Chemical Analysis—X-ray Photoelectron Spectrometers—Calibration of Energy Scales. ISO: Geneva, Switzerland, 2010.

- dos Reis, G.S.; Bergna, D.; Tuomikoski, S.; Grimm, A.; Lima, E.C.; Thyrel, M.; Skoglund, N.; Lassi, U.; Larsson, S.H. Preparation and characterization of pulp and paper mill sludge-activated biochars using alkaline activation: A box–Behnken design approach. ACS Omega 2022, 7, 32620–32630. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Larsson, S.H.; Thyrel, M.; Pham, T.N.; Claudio Lima, E.; de Oliveira, H.P.; Dotto, G.L. Preparation and Application of Efficient Biobased Carbon Adsorbents Prepared from Spruce Bark Residues for Efficient Removal of Reactive Dyes and Colors from Synthetic Effluents. Coatings 2021, 11, 772. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J. Physisorption of gases, with special reference to the evaluation of the surface area and pore size distribution (IUPAC technical report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Larkin, P. Infrared and Raman Spectroscopy: Principles and Spectral Interpretation; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Smith, E.; Dent, G. Modern Raman Spectroscopy—A Practical Approach; Wiley: Chichester, UK, 2005; pp. 1–210. [Google Scholar]

- Song, X.; Ma, X.; Li, Y.; Ding, L.; Jiang, R. Tea waste-derived microporous active carbon with enhanced double-layer su-percapacitor behaviors. Appl. Surf. Sci. 2019, 487, 189–197. [Google Scholar] [CrossRef]

- Huang, G.G.; Liu, Y.F.; Wu, X.-X.; Cai, J.-J. Activated carbons prepared by the KOH activation of a hydrochar from garlic peel and their CO2 adsorption performance. New Carbon Mater. 2019, 34, 247–257. [Google Scholar] [CrossRef]

- Oladoja, N.A. A critical review of the applicability of Avrami fractional kinetic equation in adsorption-based water treatment studies. Desalin. Water Treat. 2016, 57, 15813–15825. [Google Scholar] [CrossRef]

- Lopes, E.C.; dos Anjos, F.S.; Vieira, E.F.; Cestari, A.R. An alternative Avrami equation to evaluate kinetic parameters of the interaction of Hg (II) with thin chitosan membranes. J. Colloid Interface Sci. 2003, 263, 542–547. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.J. Biosorption isotherms, kinetics and thermodynamics. Separ. Purif. Technol. 2008, 61, 229–242. [Google Scholar] [CrossRef]

- Hu, Q.; Lan, R.; He, L.; Liu, H.; Pei, X. A critical review of adsorption isotherm models for aqueous contaminants: Curve characteristics, site energy distribution and common controversies. J. Environ. Manag. 2023, 329, 117104. [Google Scholar] [CrossRef]

- Reis, G.S.; Bergna, D.; Grimm, A.; Lima, E.C.; Hu, T.; naushad, M.; Lassi, U. Preparation of highly porous nitrogen-doped biochar derived from birch tree wastes with superior dye removal performance. Colloids Surf. A Physicochem. Eng. Asp. 2023, 669, 131493. [Google Scholar] [CrossRef]

- Chatir, E.M.; Hadrami, A.E.; Ojala, S.; Brahmi, R. Thermal treatment of H3PO4-impregnated hydrochar under controlled oxygen flows for producing materials with tunable properties and enhanced diclofenac adsorption. Sustain. Chem. Pharm. 2023, 34, 101164. [Google Scholar] [CrossRef]

- Zhang, B.; Mei, M.; Li, K.; Liu, J.; Wang, T.; Chen, S.; Li, J. One-pot synthesis of MnFe2O4 functionalized magnetic biochar by the sol-gel pyrolysis method for diclofenac sodium removal. J. Clean. Prod. 2022, 381, 135210. [Google Scholar] [CrossRef]

- Xu, D.; Li, Z.; Wang, P.; Bai, W.; Wang, H. Aquatic plant-derived biochars produced in different pyrolytic conditions: Spectroscopic studies and adsorption behavior of diclofenac sodium in water media. Sustain. Chem. Pharm. 2020, 17, 100275. [Google Scholar] [CrossRef]

- Obeso, J.L.; Viltres, H.; Flores, C.V.; Lopez-Olvera, A.; Rajabzadeh, A.R.; Srinivasan, S.; Ibarra, I.A.; Leyva, C. Al(III)-based MOFs adsorbent for pollution remediation: Insights into selective adsorption of sodium diclofenac. J. Environ. Chem. Eng. 2023, 11, 109872. [Google Scholar] [CrossRef]

- Rigueto, C.V.T.; Rosseto, M.; Nazari, M.T.; Ostwald, B.E.P.; Alessandretti, I.; Manera, C.; Piccin, J.S.; Dettmer, A. Adsorption of diclofenac sodium by composite beads prepared from tannery wastes-derived gelatin and carbon nanotubes. J. Environ. Chem. Eng. 2021, 9, 105030. [Google Scholar] [CrossRef]

- de Souza dos Santos, G.E.; Ide, A.H.; Duarte, J.L.S.; McKay, G.; Silva, A.O.S.; Meili, L. Adsorption of anti-inflammatory drug diclofenac by MgAl/layered double hydroxide supported on Syagrus coronata biochar. Powder Technol. 2020, 364, 229–240. [Google Scholar] [CrossRef]

- Feitoza, U.d.S.; Thue, P.S.; Lima, E.C.; dos Reis, G.S.; Rabiee, N.; de Alencar, W.S.; Mello, B.L.; Dehmani, Y.; Rinklebe, J.; Dias, S.L.P. Use of Biochar Prepared from the Açaí Seed as Adsorbent for the Uptake of Catechol from Synthetic Effluents. Molecules 2022, 27, 7570. [Google Scholar] [CrossRef]

| LS-Carbon | LS-Sulfur Carbon | |

|---|---|---|

| Pseudo-first order | ||

| q1 (mg g−1) | 221.9 | 292.7 |

| k1 (min−1) | 1.215 | 55.32 |

| R2adj | 0.9791 | 0.9969 |

| SD (mg g−1) | 10.32 | 5.146 |

| Pseudo-second order | ||

| q2 (mg g−1) | 228.24 | 294.3 |

| k2 (g mg−1 min−1) | 0.008960 | 0.08191 |

| R2adj | 0.9950 | 0.9878 |

| SD (mg g−1) | 5.060 | 3.534 |

| Avrami | ||

| qAV (mg g−1) | 229.8 | 293.8 |

| kAV (min−1) | 1.438 | 1.19 |

| nAV | 0.3681 | 6.916 |

| R2adj | 0.9972 | 0.9979 |

| SD (mg g−1) | 3.753 | 2.212 |

| LS-Carbon | LS-Sulfur Carbon | |

|---|---|---|

| Langmuir | ||

| qe (mg g−1) | 267.8 | 387.8 |

| k1 (L mg−1) | 0.1125 | 0.1124 |

| R2adj | 0.8977 | 0.9417 |

| SD (mg g−1) | 32.21 | 34.70 |

| Freundlich | ||

| kF ((mg g−1) (mg L−1)−1/nF) | 90.31 | 102.1 |

| nF (dimensionless) | 5.414 | 4.307 |

| R2adj | 0.9814 | 0.9329 |

| SD (mg g−1) | 13.74 | 37.23 |

| Liu | ||

| Qmax (mg g−1) | 301.6 | 473.8 |

| Kg (L mg−1) | 0.00703 | 0.04805 |

| nL (dimensionless) | 0.3091 | 0.5647 |

| R2adj | 0.9921 | 0.9602 |

| SD (mg g−1) | 8.910 | 28.67 |

| Adsorbents | qmax (mg g−1) | Adsorbent Dosage (g L−1) | T (°C) | pH | Ref. |

|---|---|---|---|---|---|

| Tree waste carbon | 355 | 1.0 | 25 °C | 6.0 | [10] |

| Tree waste selenium-doped carbon | 434 | 1.0 | 25 °C | 6.0 | [10] |

| H3PO4 activated hydrochar | 377.99 | 1.5 | 15 °C | 2.0 | [33] |

| MnFe2O4/biochar composite | 344.26 | 0.15 | 25 °C | 4.0 | [34] |

| Aquatic plant-based carbon | 23.25 | 1.5 | 20 °C | 6.0 | [35] |

| Al(III)-based MOF (MOF-303) | 334.89 | 1.0 | 25 °C | 7.0 | [36] |

| Al(III)-based MOF (DUT-5) | 103.36 | 1.0 | 25 °C | 7.0 | [36] |

| Commercial gelatin/CNT beads | 26.97 | 2.0 | 25 °C | 8.1 | [37] |

| RCTLW gelatin/CNT beads | 20.57 | 2.0 | 25 °C | 8.1 | [37] |

| MgAl-biocarbon composite | 168.04 | 4.0 | 60 °C | 5.0 | [38] |

| LS-carbon | 301.6 | 1.5 | 25 °C | 5.0 | This work |

| LS-sulfur carbon | 473.8 | 1.5 | 25 °C | 5.0 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Reis, G.S.; Conrad, S.; Lima, E.C.; Naushad, M.; Manavalan, G.; Gentili, F.G.; Dotto, G.L.; Grimm, A. Synthesis of Highly Porous Lignin-Sulfonate Sulfur-Doped Carbon for Efficient Adsorption of Sodium Diclofenac and Synthetic Effluents. Nanomaterials 2024, 14, 1374. https://doi.org/10.3390/nano14161374

dos Reis GS, Conrad S, Lima EC, Naushad M, Manavalan G, Gentili FG, Dotto GL, Grimm A. Synthesis of Highly Porous Lignin-Sulfonate Sulfur-Doped Carbon for Efficient Adsorption of Sodium Diclofenac and Synthetic Effluents. Nanomaterials. 2024; 14(16):1374. https://doi.org/10.3390/nano14161374

Chicago/Turabian Styledos Reis, Glaydson S., Sarah Conrad, Eder C. Lima, Mu. Naushad, Gopinathan Manavalan, Francesco G. Gentili, Guilherme Luiz Dotto, and Alejandro Grimm. 2024. "Synthesis of Highly Porous Lignin-Sulfonate Sulfur-Doped Carbon for Efficient Adsorption of Sodium Diclofenac and Synthetic Effluents" Nanomaterials 14, no. 16: 1374. https://doi.org/10.3390/nano14161374

APA Styledos Reis, G. S., Conrad, S., Lima, E. C., Naushad, M., Manavalan, G., Gentili, F. G., Dotto, G. L., & Grimm, A. (2024). Synthesis of Highly Porous Lignin-Sulfonate Sulfur-Doped Carbon for Efficient Adsorption of Sodium Diclofenac and Synthetic Effluents. Nanomaterials, 14(16), 1374. https://doi.org/10.3390/nano14161374