One-Step Synthesis of Heterostructured Mo@MoO2 Nanosheets for High-Performance Supercapacitors with Long Cycling Life and High Rate Capability

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation

2.2. Characterization

2.3. Electrochemical Measurements

3. Results and Discussion

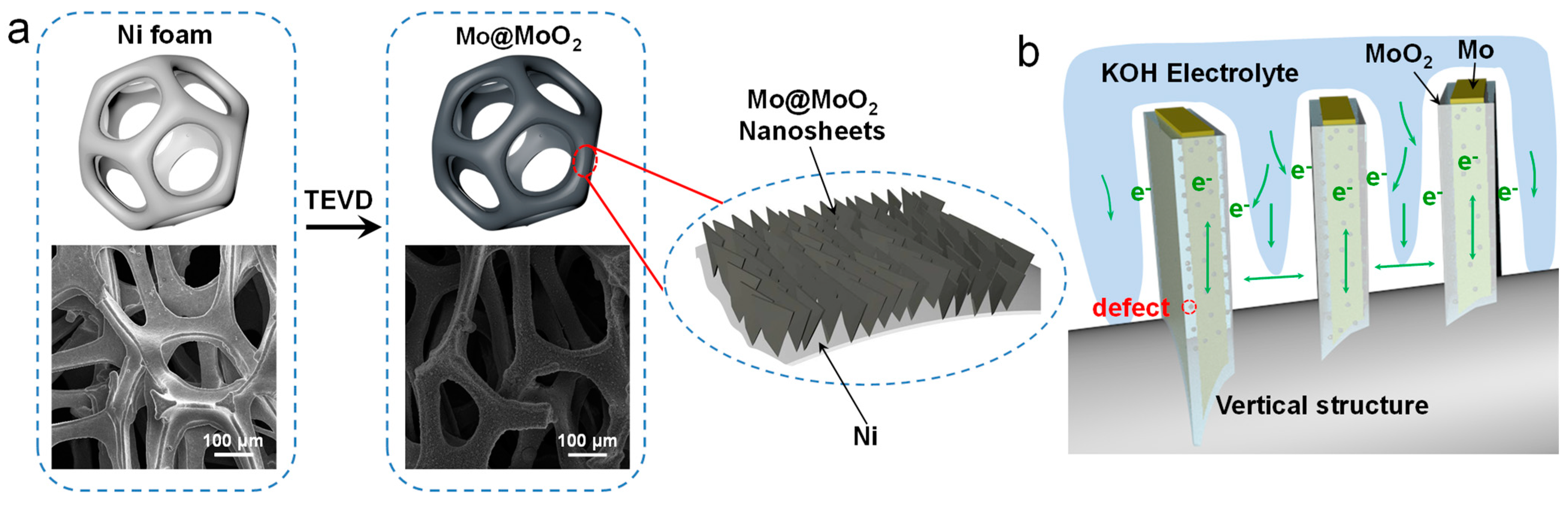

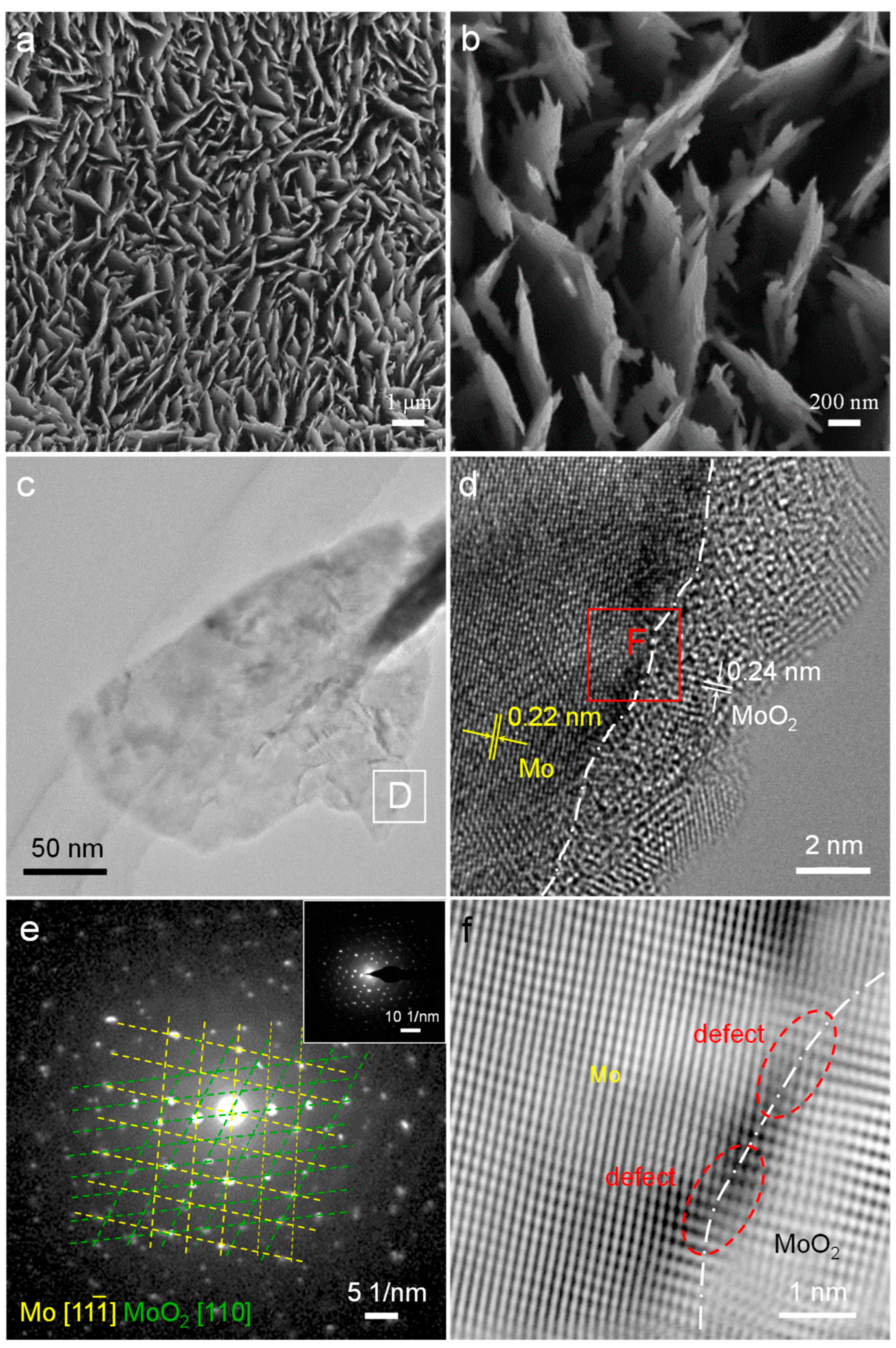

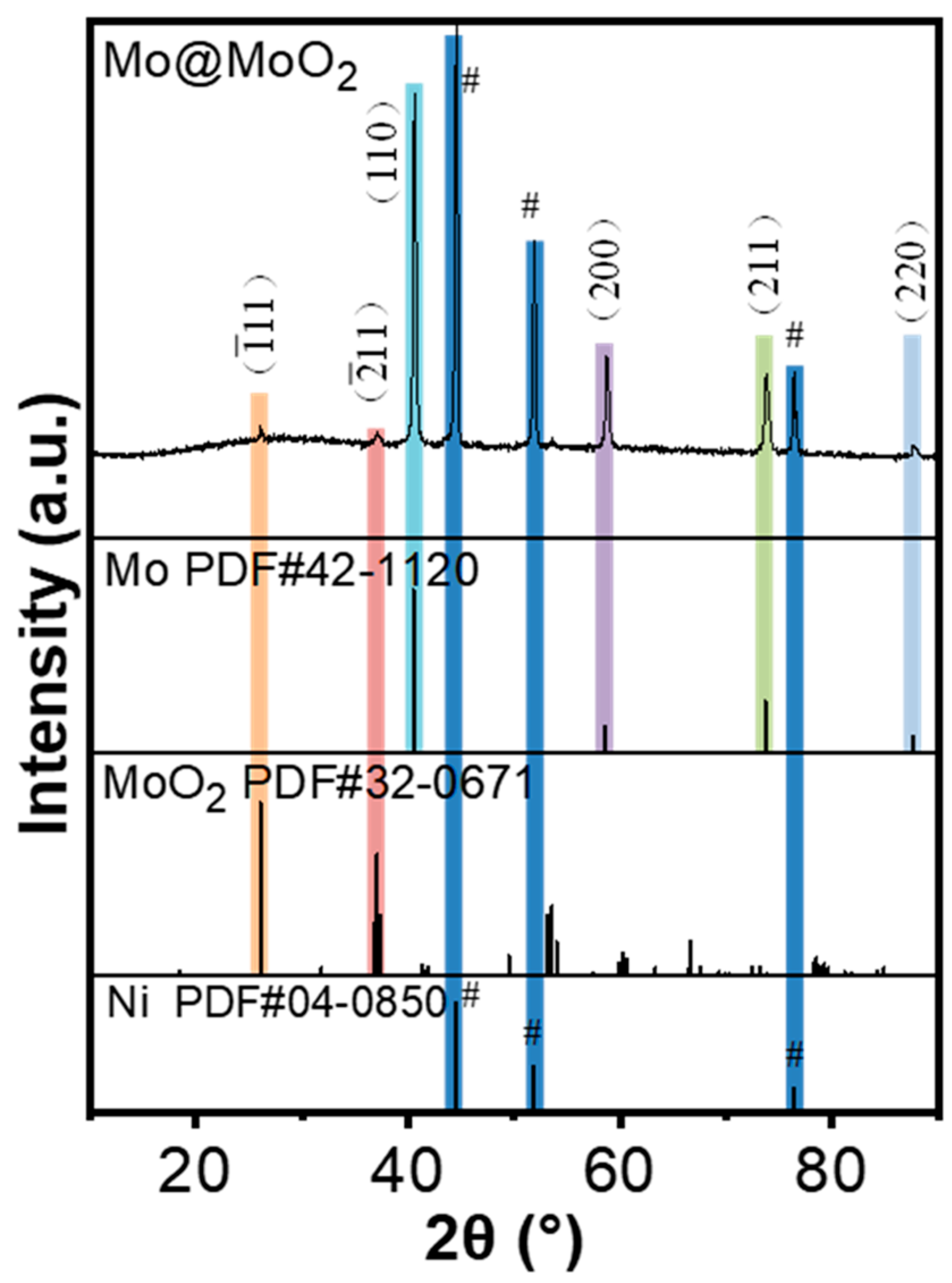

3.1. Synthesis Process and Structural Characterization

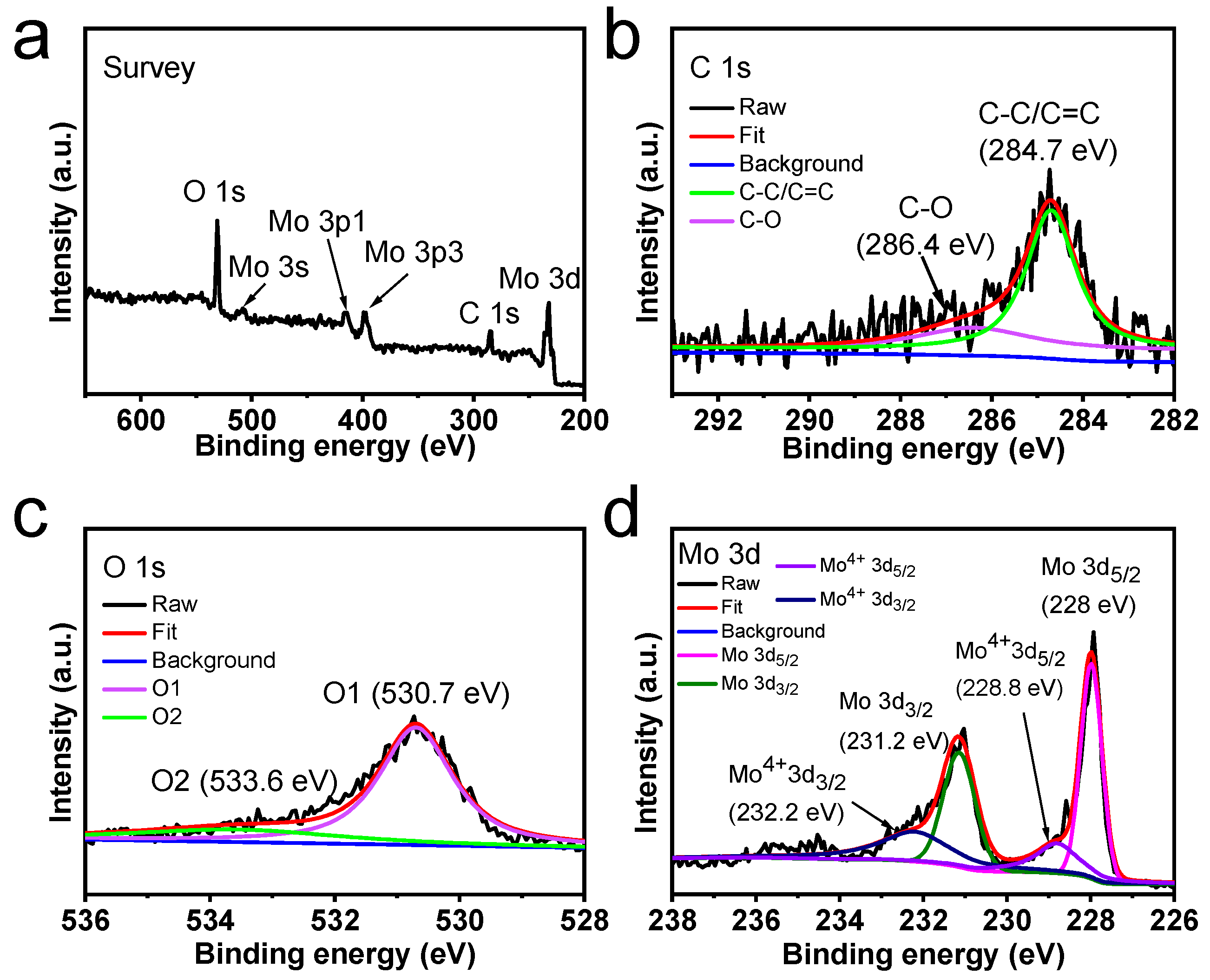

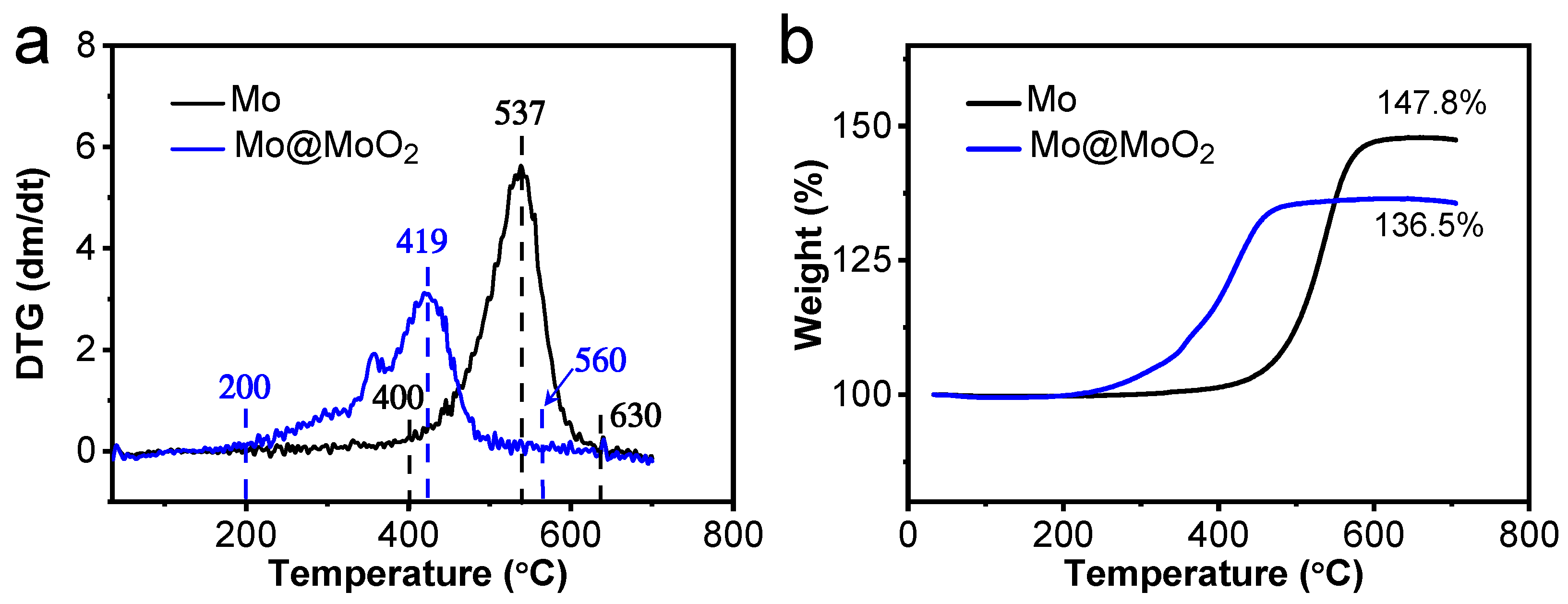

3.2. Component Analysis

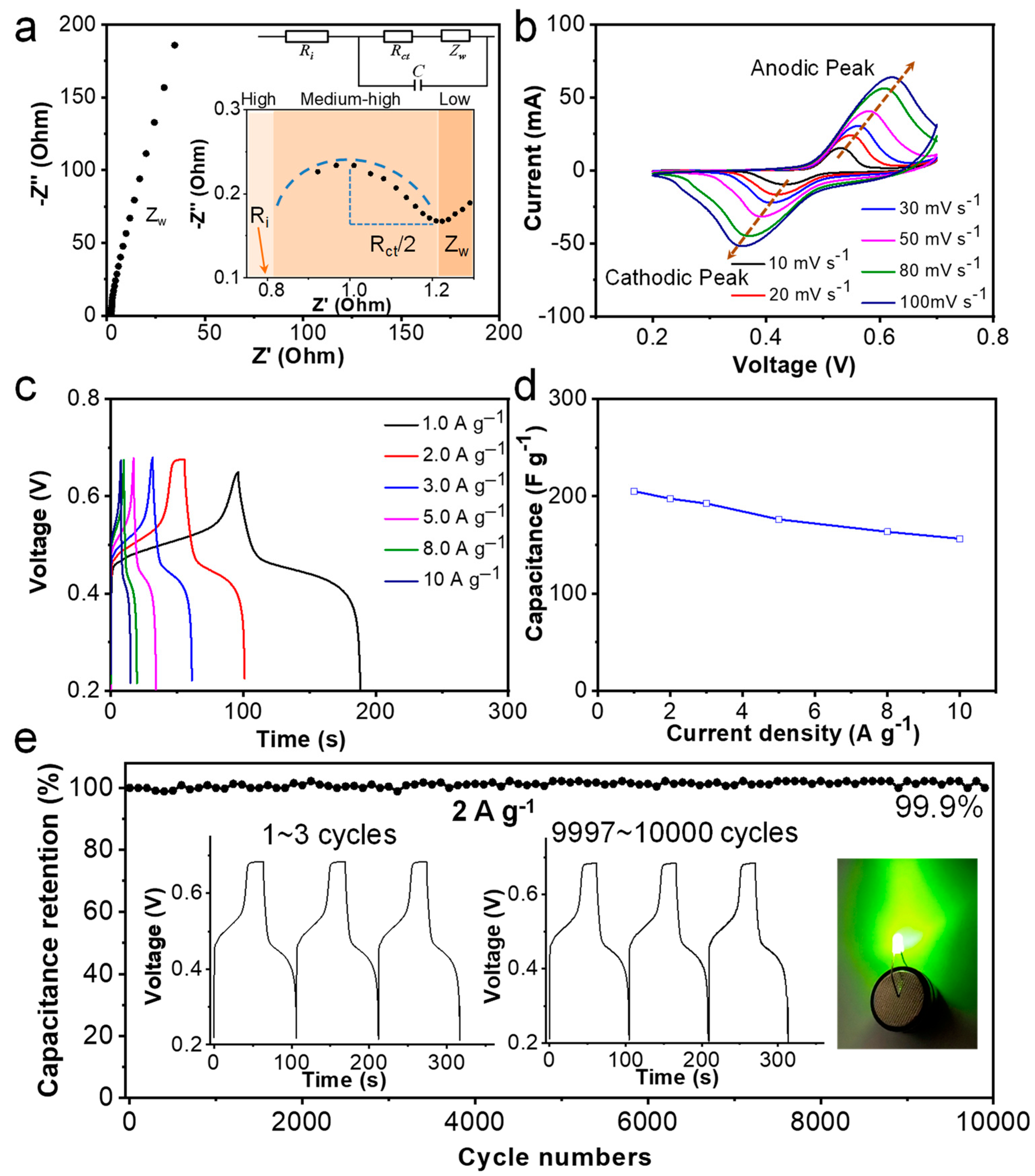

3.3. Electrochemical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, T.; Chen, C.; Chien, H.; Lu, S.; Hu, C. A cost-effective supercapacitor material of ultrahigh specific capacitances: Spinel nickel cobaltite aerogels from an epoxide-driven sol-gel process. Adv. Mater. 2010, 22, 347–351. [Google Scholar] [CrossRef]

- Salari, H.; Shayeh, J. A unique 3D structured NiMoO4/MoO3 heterojunction for enhanced supercapacitor performance. Energy Fuels 2021, 35, 16144–16151. [Google Scholar] [CrossRef]

- Jacobson, M.Z. Review of solutions to global warming, air pollution, and energy security. Energy Environ. Sci. 2009, 2, 148–173. [Google Scholar] [CrossRef]

- Jacobson, M.Z. Evaluation of nuclear power as a proposed solution to global warming, air pollution, and energy security. In 100% Clean, Renewable Energy and Storage for Everything; Cambridge University Press: New York, NY, USA, 2020; pp. 427–473. [Google Scholar]

- Lu, H.; Tian, K.; Bu, L.; Huang, X.; Li, X.; Zhao, Y.; Wang, F.; Bai, J.; Gao, L.; Zhao, J. Synergistic effect from coaxially integrated CNTs@MoS2/MoO2 composite enables fast and stable lithium storage. J. Energy Chem. 2021, 55, 449–458. [Google Scholar] [CrossRef]

- Yi, F.; Ren, H.; Dai, K.; Wang, X.; Han, Y.; Wang, K.; Li, K.; Guan, B.; Wang, J.; Tang, M.; et al. Solar thermal-driven capacitance enhancement of supercapacitors. Energy Environ. Sci. 2018, 11, 2016–2024. [Google Scholar] [CrossRef]

- Zhao, N.; Fan, H.; Zhang, M.; Ma, J.; Du, Z.; Yan, B.; Li, H.; Jiang, X. Simple electrodeposition of MoO3 film on carbon cloth for high-performance aqueous symmetric supercapacitors. Chem. Eng. J. 2020, 390, 124477. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, Q.; Huang, H.; Wei, L.; Guo, X. Silver-quantum-dot-modified MoO3 and MnO2 paper-like freestanding films for flexible solid-state asymmetric supercapacitors. Small 2019, 15, 1805235. [Google Scholar] [CrossRef]

- Lei, D.; Shang, W.; Zhang, X.; Li, Y.; Qiao, S.; Zhong, Y.; Deng, X.; Shi, X.; Zhang, Q.; Hao, C.; et al. Facile synthesis of heterostructured MoS2-MoO3 nanosheets with active electrocatalytic sites for high-performance lithium-sulfur batteries. ACS Nano 2021, 15, 20478–20488. [Google Scholar] [CrossRef]

- Xu, L.; Zhou, W.; Chao, S.; Liang, Y.; Zhao, X.; Liu, C.; Xu, J. Advanced oxygen-vacancy Ce-doped MoO3 ultrathin nanoflakes anode materials used as asymmetric supercapacitors with ultrahigh energy density. Adv. Energy Mater. 2022, 12, 2200101. [Google Scholar] [CrossRef]

- Du, W.; Liu, R.; Jiang, Y.; Lu, Q.; Fan, Y.; Gao, F. Facile synthesis of hollow Co3O4 boxes for high capacity supercapacitor. J. Power Sources 2013, 227, 101–105. [Google Scholar] [CrossRef]

- Zan, G.; Li, S.; Chen, P.; Dong, K.; Wu, Q.; Wu, T. Mesoporous cubic nanocages assembled by coupled monolayers with 100% theoretical capacity and robust cycling. ACS Cent. Sci. 2024, 10, 1283–1294. [Google Scholar] [CrossRef]

- Kong, D.; Lv, W.; Liu, R.; He, Y.; Wu, D.; Li, F.; Fu, R.; Yang, Q.; Kang, F. Superstructured carbon materials: Design and energy applications. Energy Mater. Devices 2023, 1, 9370017. [Google Scholar] [CrossRef]

- Cheng, A.; Shen, Y.; Hong, T.; Zhan, R.; Chen, E.; Chen, Z.; Chen, G.; Liang, M.; Sun, X.; Wang, D.; et al. Self-assembly vertical graphene-based MoO3 nanosheets for high performance supercapacitors. Nanomaterials 2022, 12, 2057. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.; Wan, L.; Sun, S.; Chen, Q.; Sun, J.; Xia, Q.; Xia, H. Phosphate ion functionalized Co3O4 ultrathin nanosheets with greatly improved surface reactivity for high performance pseudocapacitors. Adv. Mater. 2017, 29, 1604167. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Gao, L.; Wang, J.; Shen, Y. MoO3 nanobelts for high-performance asymmetric supercapacitor. J. Mater. Sci. 2019, 54, 13685–13693. [Google Scholar] [CrossRef]

- Li, Z.; Yu, P.; Zhong, W.; Zhang, M.; Li, Z.; Cheng, A.; Liang, Y.; Miao, L.; Yang, X.; Zhang, H. Hydrothermal intercalation for the synthesis of novel three-dimensional hierarchically superstructured carbons composed of graphene-like ultrathin nanosheets. Carbon 2021, 176, 1–10. [Google Scholar] [CrossRef]

- Jiang, Q.; Kurra, N.; Alhabeb, M.; Gogotsi, Y.; Alshareef, H.N. All pseudocapacitive MXene-RuO2 asymmetric supercapacitors. Adv. Energy Mater. 2018, 8, 1703043. [Google Scholar] [CrossRef]

- Chang, L.; Chen, S.; Fei, Y.; Stacchiola, D.; Hu, Y. Superstructured NiMoO4@CoMoO4 core-shell nanofibers for supercapacitors with ultrahigh areal capacitance. Proc. Natl. Acad. Sci. USA 2023, 120, e2219950120. [Google Scholar] [CrossRef]

- Kumbhar, V.; Chodankar, N.; Lee, K.; Kim, D. Insights into the interfacial nanostructuring of NiCo2S4 and their electrochemical activity for ultra-high capacity all-solid-state flexible asymmetric supercapacitors. J. Colloid Interface Sci. 2019, 557, 423–437. [Google Scholar] [CrossRef]

- Xiao, J.; Wan, L.; Yang, S.; Xiao, F.; Wang, S. Design hierarchical electrodes with highly conductive NiCo2S4 nanotube arrays grown on carbon fiber paper for high-performance pseudocapacitors. Nano Lett. 2014, 14, 831–838. [Google Scholar] [CrossRef]

- Fu, L.; Qu, Q.; Holze, R.; Kondratiev, V.V.; Wu, Y. Composites of metal oxides and intrinsically conducting polymers as supercapacitor electrode materials: The best of both worlds? J. Mater. Chem. A 2019, 7, 14937–14970. [Google Scholar] [CrossRef]

- Kong, D.; Wang, Y.; Huang, S.; Hu, J.; Lim, Y.; Liu, B.; Fan, S.; Shi, Y.; Yang, H. 3D self-branched zinc-cobalt Oxide@N-doped carbon hollow nanowall arrays for high-performance asymmetric supercapacitors and oxygen electrocatalysis. Energy Storage Mater. 2019, 23, 653–663. [Google Scholar] [CrossRef]

- Qin, J.; Sari, H.M.; Wang, X.; Yang, H.; Zhang, J.; Li, X. Controlled design of metal oxide-based (Mn2+/Nb5+) anodes for superior sodium-ion hybrid supercapacitors: Synergistic mechanisms of hybrid ion storage. Nano Energy 2020, 71, 104594. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Gates, I.; Jia, B.; Huang, Z.; Ma, T. Integrated electrode-electrolyte optimization to manufacture a real-life applicable aqueous supercapacitor with record-breaking lifespan. Energy Environ. Mater. 2023, 6, e12520. [Google Scholar] [CrossRef]

- Dai, J.; Yang, C.; Xu, Y.; Wang, X.; Yang, S.; Li, D.; Luo, L.; Xia, L.; Li, J.; Qi, X.; et al. MoS2@Polyaniline for aqueous ammonium-ion supercapacitors. Adv. Mater. 2023, 35, 2303732. [Google Scholar] [CrossRef]

- Ma, B.; Hao, W.; Ruan, W.; Yuan, C.; Wang, Q.; Teng, F. Unveiling capacitive behaviors of MoO2 in different electrolytes and flexible MoO2-based asymmetric micro-supercapacitor. J. Energy Storage 2022, 52, 104833. [Google Scholar] [CrossRef]

- Sharma, M.; Adalati, R.; Kumar, A.; Chawla, V.; Chandra, R. Single step fabrication of nanostructured Cr2O3-MoO2 composite flexible electrode for top-notch asymmetric supercapacitor. Appl. Surf. Sci. 2021, 555, 149721. [Google Scholar] [CrossRef]

- Li, X.; Shao, J.; Li, J.; Zhang, L.; Qu, Q.; Zheng, H. Ordered mesoporous MoO2 as a high-performance anode material for aqueous supercapacitors. J. Power Sources 2013, 237, 80–83. [Google Scholar] [CrossRef]

- Yang, L.; Sun, W.; Zhong, Z.; Liu, J.; Gao, Q.; Hu, R.; Zhu, M. Hierarchical MoO2/N-doped carbon heteronanowires with high rate and improved long-term performance for lithium-ion batteries. J. Power Sources 2016, 306, 78–84. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, H.; Zhai, L.; Nie, M.; Zhou, J.; Zhuo, S. Enhanced supercapacitor performance based on 3D porous graphene with MoO2 nanoparticles. J. Mater. Res. 2017, 32, 292–300. [Google Scholar] [CrossRef]

- Zhao, C.; Hu, Y.; Zhou, Y.; Li, N.; Ding, Y.; Guo, J.; Zhao, C.; Yang, Y. Aerobic recovered carbon fiber support-based MoO2//MnO2 asymmetric supercapacitor with a widened voltage window. Energy Fuels 2021, 35, 6909–6920. [Google Scholar] [CrossRef]

- Ferrari, A.G.-M.; Pimlott, J.; Down, M.; Rowley-Neale, S.; Banks, C. MoO2 nanowire electrochemically decorated graphene additively manufactured supercapacitor platforms. Adv. Energy Mater. 2021, 11, 2100433. [Google Scholar] [CrossRef]

- Vaddiraju, S.; Chandrasekaran, H.; Sunkara, M. Vapor phase synthesis of tungsten nanowires. J. Am. Chem. Soc. 2003, 125, 10792–10793. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Deng, S.; Gong, L.; Ding, Y.; Chen, J.; Huang, J.; Chen, J.; Xu, N.; Wang, Z. Growth of large-area aligned molybdenum nanowires by high temperature chemical vapor deposition: Synthesis, growth mechanism, and device application. J. Phys. Chem. B 2006, 110, 10296–10302. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Yan, P.; Xu, F.; Wu, W.; Hu, T.; Wei, C.; Xu, Q. Solid-phase synthesis of atomically thin two-dimensional non-layered MoO2 nanosheets for surface enhanced Raman spectroscopy. J. Mater. Chem. C 2019, 7, 7196–7200. [Google Scholar] [CrossRef]

- Smudde, G.; Stair, P. The oxidation of Mo (100) studied by XPS and surface Raman spectroscopy: The onset of MoO2 formation and the formation of surface polymolybdate. Surf. Sci. 1994, 317, 65–72. [Google Scholar] [CrossRef]

- Werfel, F.; Minni, E. Photoemission study of the electronic structure of Mo and Mo oxides. J. Phys. C Solid State Phys. 1983, 16, 6091–6100. [Google Scholar] [CrossRef]

- Haripriya, M.; Manimekala, T.; Dharmalingam, G.; Minakshi, M.; Sivasubramanian, R. Asymmetric supercapacitors based on ZnCo2O4 nanohexagons and orange peel derived activated carbon electrodes. Chem. Asian J. 2024, 19, e202400202. [Google Scholar] [CrossRef]

- Vasudevan, S.; Tharani, S.; Manickam, M.; Sivasubramanian, R. A sol–gel derived LaCoO3 perovskite as an electrocatalyst for Al–air batteries. Dalton Trans. 2024, 53, 3713–3721. [Google Scholar] [CrossRef]

- Shafi, P.; Dhanabal, R.; Chithambararaj, A.; Velmathi, S.; Bose, A. α-MnO2/h-MoO3 hybrid material for high performance supercapacitor electrode and photocatalyst. ACS Sustain. Chem. Eng. 2017, 5, 4757–4770. [Google Scholar] [CrossRef]

- Pham, D.; Patil, R.; Yang, C.; Yeh, W.; Liou, Y.; Ma, Y. Impact of the crystal phase and 3d-valence conversion on the capacitive performance of one-dimensional MoO2, MoO3, and Magnéli-phase Mo4O11 nanorod-based pseudocapacitors. Nano Energy 2018, 47, 105–114. [Google Scholar] [CrossRef]

- Noh, J.; Yoon, C.; Kim, Y.; Jang, J. High performance asymmetric supercapacitor twisted from carbon fiber/MnO2 and carbon fiber/MoO3. Carbon 2017, 116, 470–478. [Google Scholar] [CrossRef]

- Dai, J.; Qi, X.; Xia, L.; Xue, Q.; Luo, L.; Wang, X.; Yang, C.; Li, D.; Xie, H.; Cabot, A.; et al. Aqueous ammonium-ion supercapacitors with unprecedented energy density and stability enabled by Oxygen vacancy-enriched MoO3@C. Adv. Funct. Mater. 2023, 33, 2212440. [Google Scholar] [CrossRef]

- Worthing, A. Physical properties of well seasoned molybdenum and tantalum as a function of temperature. Phys. Rev. 1926, 28, 190–201. [Google Scholar] [CrossRef]

- Bardeen, J. Electrical conductivity of metals. J. Appl. Phys. 1940, 11, 88. [Google Scholar] [CrossRef]

- Shen, Y.; Deng, S.; Zhang, Y.; Liu, F.; Chen, J.; Xu, N. Highly conductive vertically aligned molybdenum nanowalls and their field emission property. Nanoscale Res. Lett. 2012, 7, 463. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Han, Y.; Zhan, R.; Zhao, P.; Zhang, Y.; Liu, F.; Chen, J.; She, J.; Xu, N.; Deng, S. Study on pyramidal molybdenum nanostructures cold cathode with large-current properties based on self-assembly growth method. ACS Appl. Mater. Interfaces 2020, 12, 35354–35364. [Google Scholar] [CrossRef]

- Cho, B.; Park, K.; Baek, J.; Oh, H.; Lee, Y.K.; Sung, M. Single-crystal Poly(3,4-ethylenedioxythiophene) nanowires with ultrahigh conductivity. Nano Lett. 2014, 14, 3321–3327. [Google Scholar] [CrossRef]

- Day, R.; Bediako, D.; Rezaee, M.; Parent, L.; Skorupskii, G.; Arguilla, M.; Hendon, C.; Stassen, I.; Gianneschi, N.; Kim, P.; et al. Single crystals of electrically conductive two-dimensional metal-organic frameworks: Structural and electrical transport properties. ACS Cent. Sci. 2019, 5, 1959–1964. [Google Scholar] [CrossRef]

- Shen, Y.; Han, Y.; Zhan, R.; Chen, X.; Wen, S.; Huang, W.; Sun, F.; Wei, Y.; Chen, H.; Wu, J.; et al. Pyramid-shaped single-crystalline nanostructure of molybdenum with excellent mechanical, electrical, and optical properties. ACS Appl. Mater. Interfaces 2020, 12, 24218–24230. [Google Scholar] [CrossRef]

- Cheng, A.; Shen, Y.; Cui, T.; Feng, W.; Zhan, R.; Pei, Y.; Tang, S.; Chen, H.; Deng, S. Needle-shaped single-crystalline molybdenum micro-nano structure with high conductivity and excellent field emission properties: Implications for large-current cold-cathodes. ACS Appl. Nano Mater. 2023, 6, 12486–12496. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, A.; Shen, Y.; Cui, T.; Liu, Z.; Lin, Y.; Zhan, R.; Tang, S.; Zhang, Y.; Chen, H.; Deng, S. One-Step Synthesis of Heterostructured Mo@MoO2 Nanosheets for High-Performance Supercapacitors with Long Cycling Life and High Rate Capability. Nanomaterials 2024, 14, 1404. https://doi.org/10.3390/nano14171404

Cheng A, Shen Y, Cui T, Liu Z, Lin Y, Zhan R, Tang S, Zhang Y, Chen H, Deng S. One-Step Synthesis of Heterostructured Mo@MoO2 Nanosheets for High-Performance Supercapacitors with Long Cycling Life and High Rate Capability. Nanomaterials. 2024; 14(17):1404. https://doi.org/10.3390/nano14171404

Chicago/Turabian StyleCheng, Ao, Yan Shen, Tao Cui, Zhe Liu, Yu Lin, Runze Zhan, Shuai Tang, Yu Zhang, Huanjun Chen, and Shaozhi Deng. 2024. "One-Step Synthesis of Heterostructured Mo@MoO2 Nanosheets for High-Performance Supercapacitors with Long Cycling Life and High Rate Capability" Nanomaterials 14, no. 17: 1404. https://doi.org/10.3390/nano14171404

APA StyleCheng, A., Shen, Y., Cui, T., Liu, Z., Lin, Y., Zhan, R., Tang, S., Zhang, Y., Chen, H., & Deng, S. (2024). One-Step Synthesis of Heterostructured Mo@MoO2 Nanosheets for High-Performance Supercapacitors with Long Cycling Life and High Rate Capability. Nanomaterials, 14(17), 1404. https://doi.org/10.3390/nano14171404