Ultrahigh Electrostrictive Effect in Lead-Free Sodium Bismuth Titanate-Based Relaxor Ferroelectric Thick Film

Abstract

:1. Introduction

2. Experimental

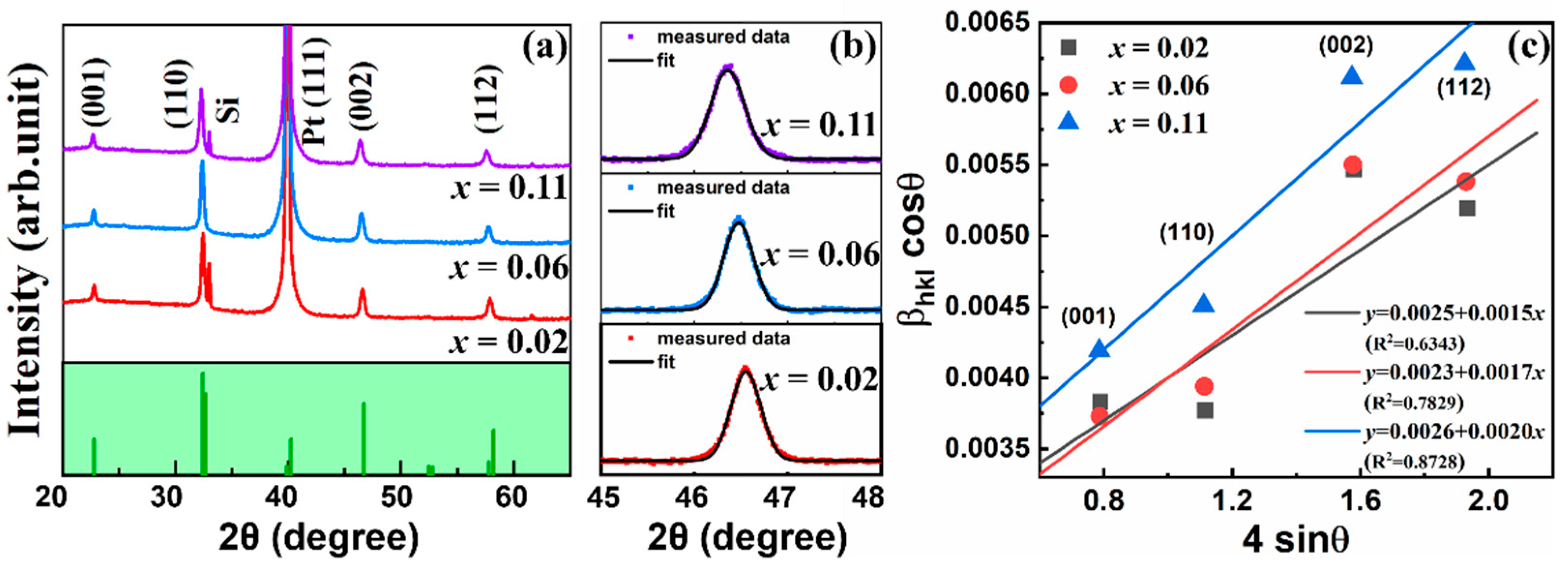

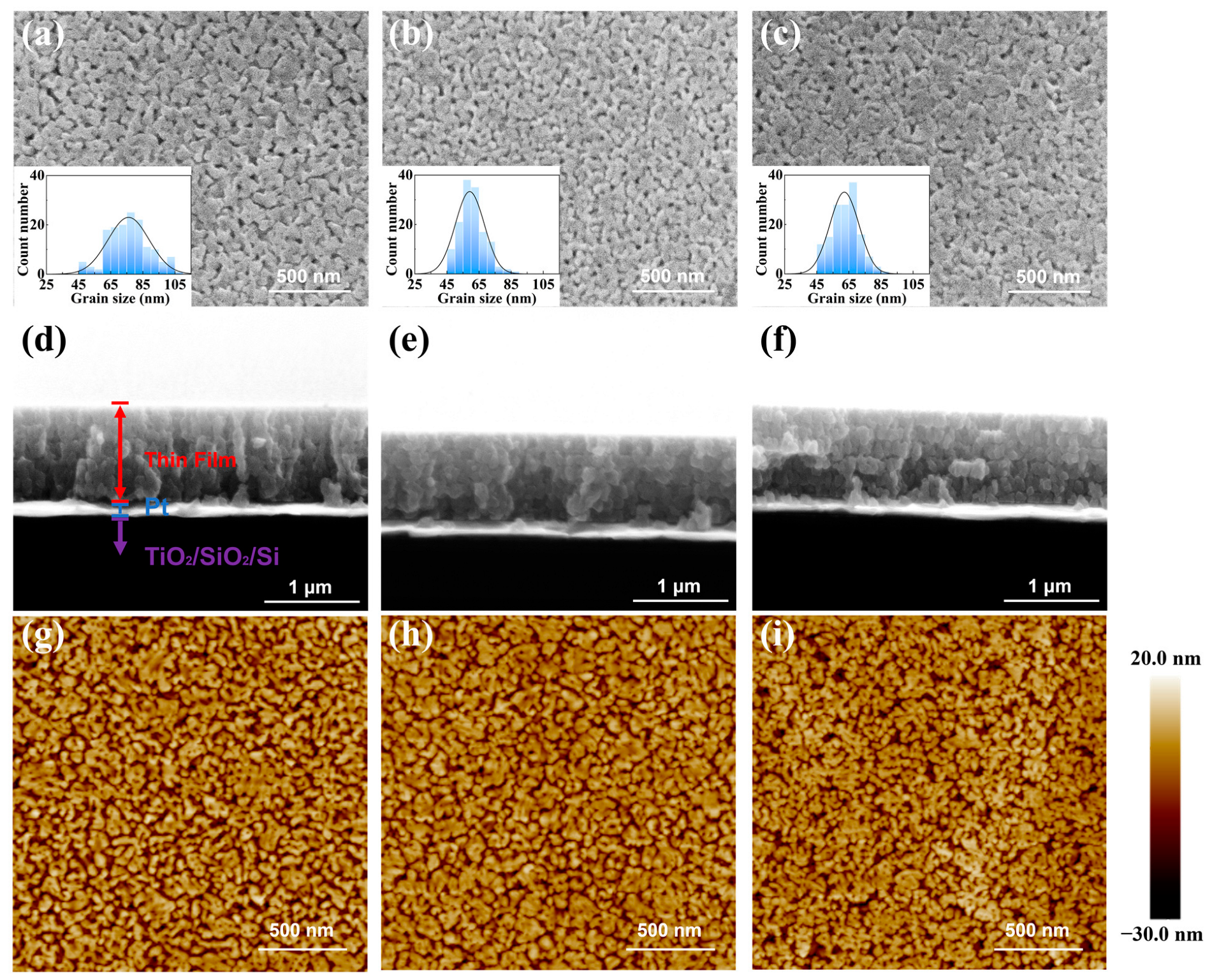

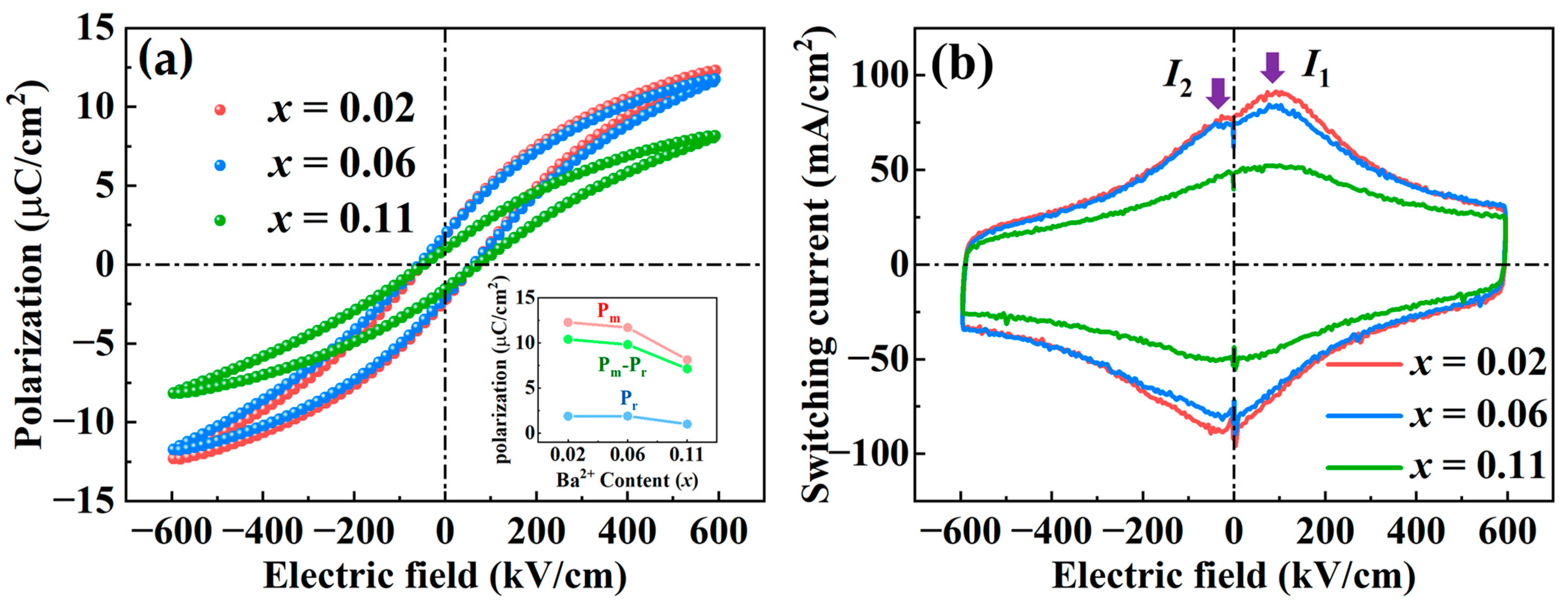

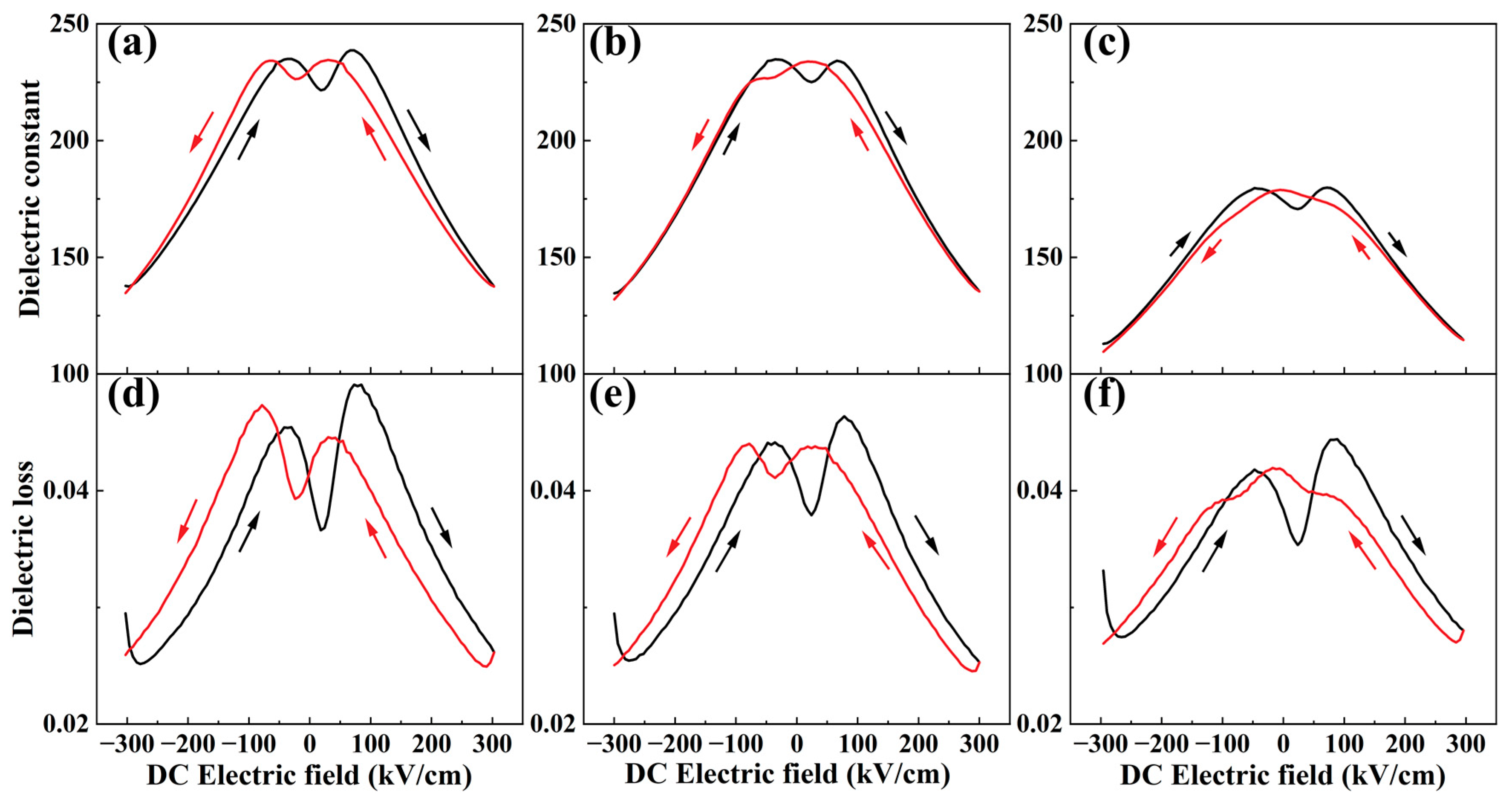

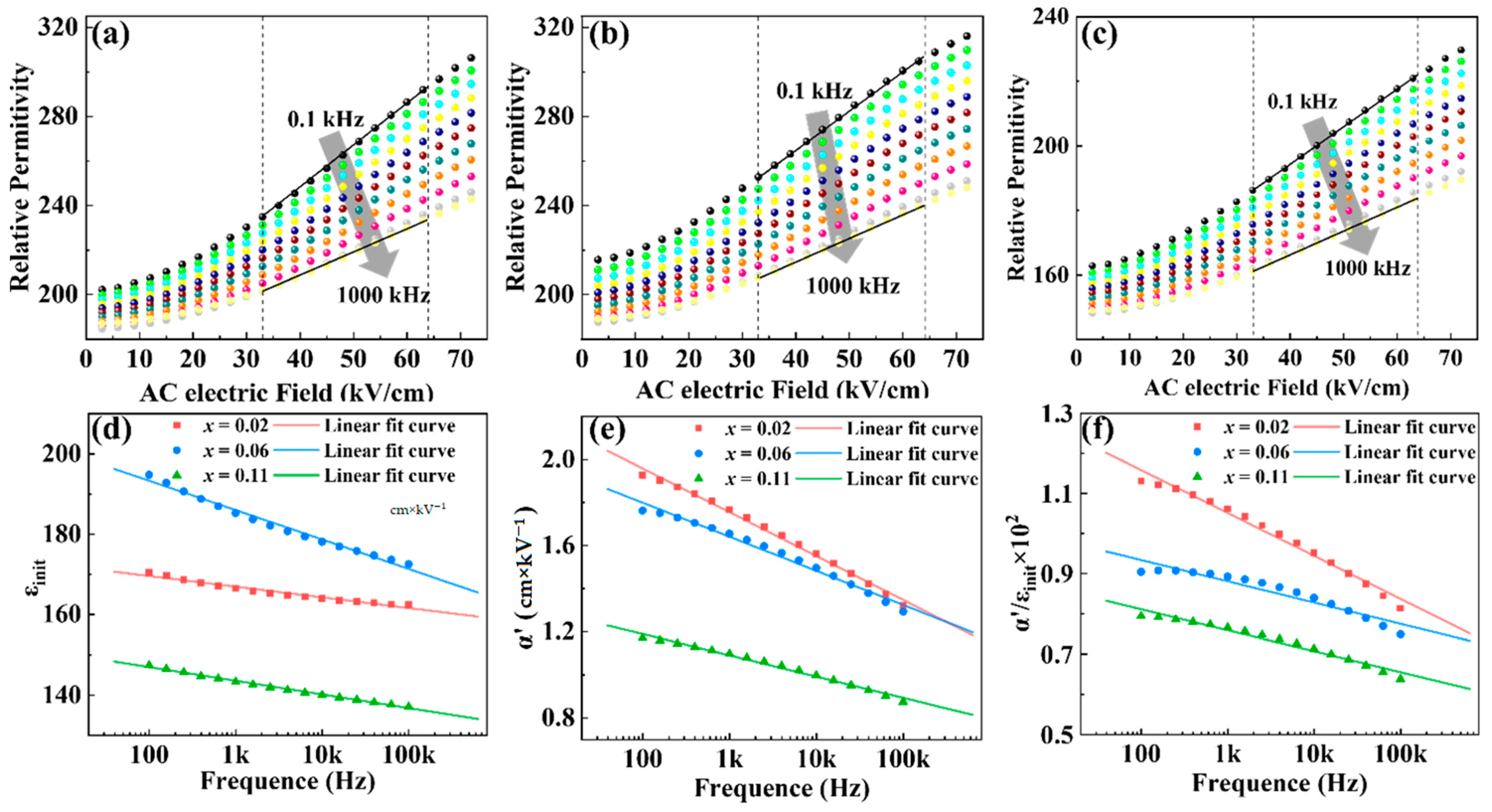

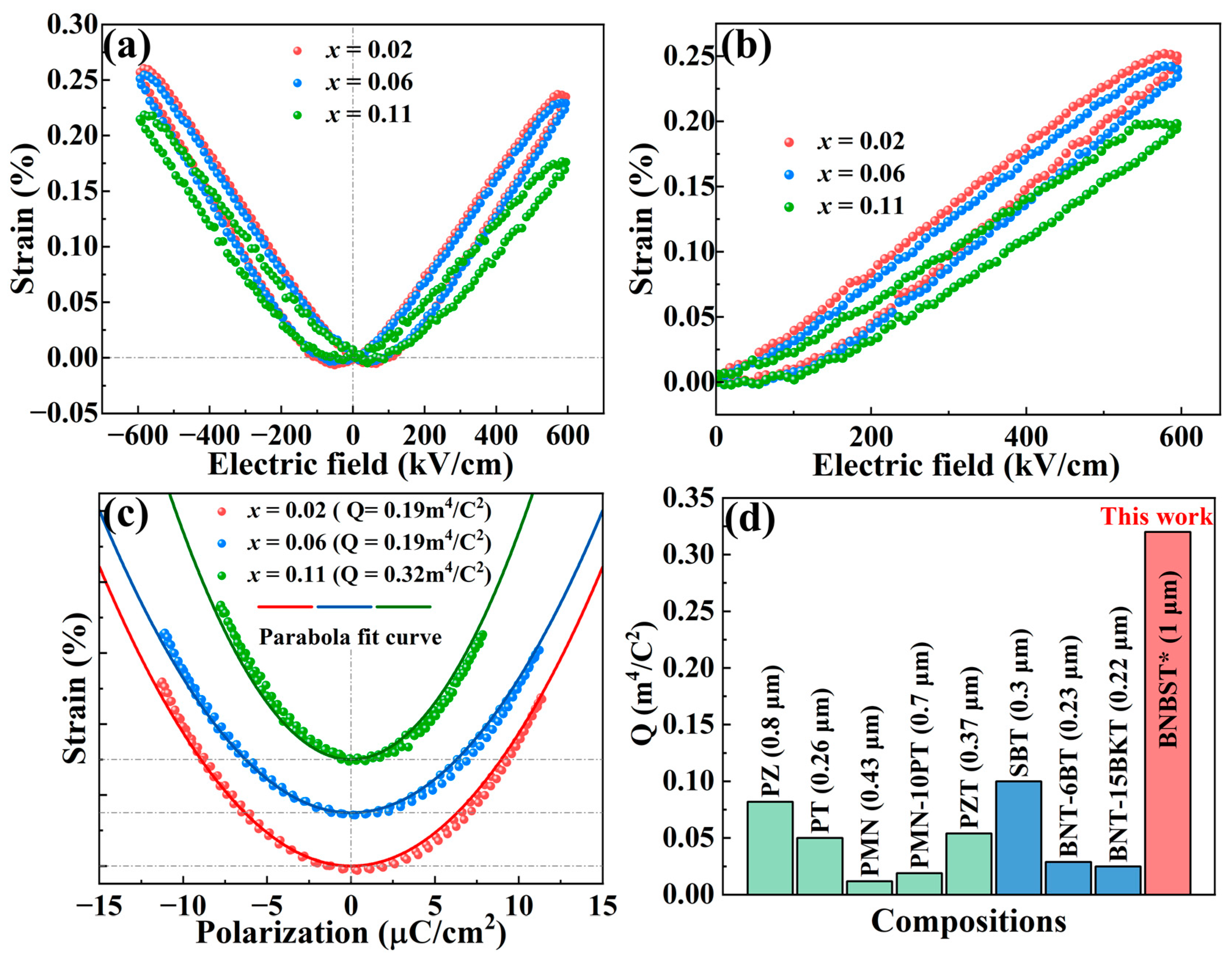

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, J.; Liu, G.; Zhao, C.; Huang, Y.; Li, Z.; Zhang, X.; Wang, K.; Wu, J. Perovskite Na0.5Bi0.5TiO3: A potential family of peculiar lead-free electrostrictors. J. Mater. Chem. A 2019, 7, 13658–13670. [Google Scholar] [CrossRef]

- Zhang, S.T.; Kounga, A.B.; Jo, W.; Jamin, C.; Seifert, K.; Granzow, T.; Rödel, J.; Damjanovic, D. High-Strain Lead-free Antiferroelectric Electrostrictors. Adv. Mater. 2009, 21, 4716–4720. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S.J. Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

- Ang, C.; Yu, Z. High, Purely Electrostrictive Strain in Lead-Free Dielectrics. Adv. Mater. 2005, 18, 103–106. [Google Scholar] [CrossRef]

- Qi, H.; Zuo, R. Giant electrostrictive strain in (Bi0.5Na0.5)TiO3–NaNbO3 lead-free relaxor antiferroelectrics featuring temperature and frequency stability. J. Mater. Chem. A 2020, 8, 2369–2375. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, C.; Wu, J. Electrostrictive Effect of Lead-free Perovskite Ceramics. J. Chin. Ceramic. Soc. 2022, 50, 575–586. [Google Scholar]

- Martin, L.W.; Rappe, A.M. Thin-film ferroelectric materials and their applications. Nat. Rev. Mater. 2017, 2, 16087. [Google Scholar] [CrossRef]

- Yu, J.C.; Janolin, P.E. Defining “giant” electrostriction. J. Appl. Phys. 2022, 131, 170701. [Google Scholar] [CrossRef]

- Zhou, X.F.; Xue, G.L.; Luo, H.; Bowen, C.R.; Zhang, D. Phase structure and properties of sodium bismuth titanate lead-free piezoelectric ceramics. Prog. Mater. Sci. 2021, 122, 100836. [Google Scholar]

- Li, J.; Wang, F.; Qin, X.; Xu, M.; Shi, W. Large electrostrictive strain in lead-free Bi0.5Na0.5TiO3–BaTiO3–KNbO3 ceramics. Appl. Phys. A 2011, 104, 117–122. [Google Scholar] [CrossRef]

- Stanescu, D.; Magnan, H.; Sarpi, B.; Rioult, M.; Aghavnian, T.; Moussy, J.-B.; Rountree, C.L.; Barbier, A. Electrostriction, Electroresistance, and Electromigration in Epitaxial BaTiO3-Based Heterostructures: Role of Interfaces and Electric Poling. ACS Appl. Nano Mater. 2019, 2, 3556–3569. [Google Scholar] [CrossRef]

- Cross, L.E.; Jang, S.J.; Newnham, R.E.; Nomura, S.; Uchino, K. Large Electrostrictive Effects in Relaxor Ferroelectrics. Ferroelectrics 1980, 23, 187–191. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S.; Cross, L.E.; Newnham, R.E.; Jang, S.J. Electrostrictive Effect in Perovskites and Its Transducer Applications. J. Mater. Sci. 1981, 16, 569–578. [Google Scholar] [CrossRef]

- Kighelman, Z.; Damjanovic, D.; Setter, N. Dielectric and electromechanical properties of ferroelectric-relaxor 0.9Pb(Mg1/3Nb2/3)O3–0.1PbTiO3 thin films. J. Appl. Phys. 2001, 90, 4682–4689. [Google Scholar] [CrossRef]

- Kighelman, Z.; Damjanovic, D.; Setter, N. Electromechanical properties and self-polarization in relaxor Pb(Mg1/3Nb2/3)O3 thin films. J. Appl. Phys. 2001, 89, 1393–1401. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, L.; Shi, W.; Hu, Q.; Shur, V.; Wei, X.; Jin, L. Ferroelectric-to-relaxor transition and ultrahigh electrostrictive effect in Sm3+-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 ferroelectrics ceramics. J. Mater. Sci. Technol. 2023, 165, 75–84. [Google Scholar] [CrossRef]

- Kighelman, Z.; Damjanovic, D.; Cantoni, M.; Setter, N. Properties of ferroelectric PbTiO3 thin films. J. Appl. Phys. 2002, 91, 1495–1501. [Google Scholar] [CrossRef]

- Nadaud, K.; Borderon, C.; Renoud, R.; Bah, M.; Ginestar, S.; Gundel, H.W. Dielectric, piezoelectric and electrostrictive properties of antiferroelectric lead-zirconate thin films. J. Alloys Compd. 2022, 914, 165340. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Guo, R. High electrostrictive coefficient Q33 in lead-free Ba(Zr0.2Ti0.8)O3-x(Ba0.7Ca0.3)TiO3 piezoelectric ceramics. Appl. Phys. Lett. 2014, 105, 232903. [Google Scholar] [CrossRef]

- Quan, Q.; Fan, H.; Shen, Q.; Jia, Y.; Wang, H.; Zhang, A.; Hou, D.; Wang, W.; Li, Q. Large electrostrictive effect and dielectric properties of (K0.5Na0.5)NbO3-BaZrO3 ceramics. J. Eur. Ceram. Soc. 2022, 42, 2195–2203. [Google Scholar] [CrossRef]

- Ullah, A.; Gul, H.B.; Ullah, A.; Sheeraz, M.; Bae, J.S.; Jo, W.; Ahn, C.W.; Kim, I.W.; Kim, T.H. Giant room-temperature electrostrictive coefficients in lead-free relaxor ferroelectric ceramics by compositional tuning. APL Mater. 2018, 6, 016104. [Google Scholar] [CrossRef]

- Zhang, S.T.; Yan, F.; Yang, B.; Cao, W.W. Phase diagram and electrostrictive properties of Bi0.5Na0.5TiO3–BaTiO3–K0.5Na0.5NbO3 ceramics. Appl. Phys. Lett. 2010, 97, 122901. [Google Scholar] [CrossRef]

- Wang, F.F.; Jin, C.C.; Yao, Q.R.; Shi, W.Z. Large electrostrictive effect in ternary Bi0.5Na0.5TiO3-based solid solutions. J. Appl. Phys. 2013, 114, 027004. [Google Scholar] [CrossRef]

- Hao, J.; Xu, Z.; Chu, R.; Li, W.; Fu, P.; Du, J.; Li, G. Structure evolution and electrostrictive properties in (Bi0.5Na0.5)0.94Ba0.06TiO3–M2O5 (M = Nb, Ta, Sb) lead-free piezoceramics. J. Eur. Ceram. Soc. 2016, 36, 4003–4014. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, J.; Jia, X.; Xing, H.; He, J.; Wang, J.; Wen, F. Large electrostrictive effect and high optical temperature sensing in Bi0.5Na0.5TiO3-BaTiO3-(Sr0.7Bi0.18Er0.02)TiO3 luminescent ferroelectrics. Ceram. Int. 2018, 44, 5785–5789. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, X.J.; Liu, J.Y.; Zhou, K.S.; Huang, D.H. Effect of annealing temperature on the electrostrictive properties of 0.94(Na0.5Bi0.5)TiO3-0.06BaTiO3 thin films. J. Electroceram. 2012, 29, 270–276. [Google Scholar] [CrossRef]

- Zheng, X.J.; Liu, J.Y.; Peng, J.F.; Liu, X.; Gong, Y.Q.; Zhou, K.S.; Huang, D.H. Effect of potassium content on electrostrictive properties of Na0.5Bi0.5TiO3-based relaxor ferroelectric thin films with morphotropic phase boundary. Thin Solid Film. 2013, 548, 118–124. [Google Scholar] [CrossRef]

- Kholkin, A.L.; Akdogan, E.K.; Safari, A.; Chauvy, P.F.; Setter, N. Characterization of the effective electrostriction coefficients in ferroelectric thin films. J. Appl. Phys. 2001, 89, 8066–8073. [Google Scholar] [CrossRef]

- Zhan, K.; Su, M.; Han, H.; Xie, S.F.; Zhu, Y.K.; Wang, D.; Cheng, H.B.; Wang, X.Y. Effect of annealing temperature on piezoelectric and mechanical properties of (Bi0.5Na0.5)TiO3–(Bi0.5K0.5)TiO3–BaTiO3 thin films. Ceram. Int. 2016, 42, 1627–1632. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, J.; Ren, W. Effect of the Annealing Conditions on the Strain Responses of Lead-Free (Bi0.5Na0.5)TiO3–BaZrO3 Ferroelectric Thin Films. Crystals 2023, 13, 606. [Google Scholar] [CrossRef]

- Li, L.; Zhou, C.; Yu, D.; Zheng, Y.; Du, Y.; Ma, L.; Zhao, J.; Rao, G. Effect of Film Thickness on the Microstructure and Dielectric and Ferroelectric Properties of (Bi0.5Na0.5)0.94Ba0.06TiO3 Films by Pulsed Laser Deposition. J. Electron. Mater. 2023, 52, 3488–3498. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Liu, L.; Luo, J.; Zhen, Z.; Li, J.-F. Thickness-dependent switching behavior of 0.8(Bi0.5Na0.5)TiO3-0.2SrTiO3 lead-free piezoelectric thin films. Ceram. Int. 2019, 45, 16022–16027. [Google Scholar] [CrossRef]

- Praharaj, S.; Rout, D.; Subramanian, V.; Kang, S.J.L. Study of relaxor behavior in a lead-free (Na0.5Bi0.5)TiO3-SrTiO3-BaTiO3 ternary solid solution system. Ceram. Int. 2016, 42, 12663–12671. [Google Scholar] [CrossRef]

- Praharaj, S.; Rout, D.; Kang, S.J.L.; Kim, I.W. Large electric field induced strain in a new lead-free ternary Na0.5Bi0.5TiO3-SrTiO3-BaTiO3 solid solution. Mater. Lett. 2016, 184, 197–199. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, J.; Niu, G.; Ren, W.; Zhang, N.; Zheng, K.; Quan, Y.; Wang, L.; Zhuang, J.; Cai, H.; et al. Giant strain responses and relaxor characteristics in lead-free (Bi0.5Na0.5)TiO3–BaZrO3 ferroelectric thin films. J. Mater. Chem. C 2022, 10, 7449–7459. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, J.; Niu, G.; Zhang, N.; Zheng, K.; Quan, Y.; Wang, L.; Zhuang, J.; Wang, G.; Li, X.; et al. Ultra-high strain responses in lead-free (Bi0.5Na0.5)TiO3-BaTiO3-NaNbO3 ferroelectric thin films. J. Eur. Ceram. Soc. 2023, 43, 5511–5520. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Nath, D.; Singh, F.; Das, R. X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles—A comparative study. Mater. Chem. Phys. 2020, 239, 122021. [Google Scholar] [CrossRef]

- Sarkar, S.; Das, R. Shape effect on the elastic properties of Ag nanocrystals. Micro Nano Lett. 2018, 13, 312–315. [Google Scholar] [CrossRef]

- Praharaj, S.; Rout, D.; Anwar, S.; Subramanian, V. Polar nano regions in lead free (Na0.5Bi0.5)TiO3-SrTiO3-BaTiO3 relaxors: An impedance spectroscopic study. J. Alloys Compd. 2017, 706, 502–510. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Zhao, M.; Yang, Y.L.; Li, Y.; Tang, M.Y.; Wang, D.; Wei, X.Y.; Liu, G.; Yan, Y.; Jin, L. Achieving ultrahigh energy density and ultrahigh efficiency simultaneously via characteristic regulation of polar nanoregions. Chem. Eng. J. 2023, 465, 142862. [Google Scholar] [CrossRef]

- Wu, S.; Song, B.; Li, P.; Chen, P.; Shen, B.; Zhai, J. Reduced leakage current and enhanced piezoelectricity of BNT–BT–BMO thin films. J. Am. Ceram. Soc. 2019, 103, 1219–1229. [Google Scholar] [CrossRef]

- Sun, N.; Li, Y.; Zhang, Q.; Hao, X. Giant energy-storage density and high efficiency achieved in (Bi0.5Na0.5)TiO3–Bi(Ni0.5Zr0.5)O3 thick films with polar nanoregions. J. Mater. Chem. C 2018, 6, 10693–10703. [Google Scholar] [CrossRef]

- Yao, K.; Zhou, C.R.; Li, Q.N.; Xiao, Z.J.; Yuan, C.L.; Xu, J.W.; Chen, G.H.; Rao, G.H. Large electrostrictive coefficient with optimized Electro-Strain in BNT-based ceramics with ergodic state. Mater. Sci. Eng. B-Adv. Funct. Solid-State Mater. 2022, 283, 115828. [Google Scholar] [CrossRef]

- Liu, X.; Xue, S.; Wang, F.; Zhai, J.; Shen, B. Grain size dependent physical properties in lead-free multifunctional piezoceramics: A case study of NBT-xST system. Acta Mater. 2019, 164, 12–24. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Xue, H.; Yin, J.; Wu, J. Temperature-independent large strain with small hysteresis in Sb-modified BNT-based lead-free ceramics. J. Am. Ceram. Soc. 2022, 105, 2116–2127. [Google Scholar] [CrossRef]

- Zeb, A.; Milne, S.J. Low variation in relative permittivity over the temperature range 25–450°C for ceramics in the system (1−x)[Ba0.8Ca0.2TiO3]–x[Bi(Zn0.5Ti0.5)O3]. J. Eur. Ceram. Soc. 2014, 34, 1727–1732. [Google Scholar] [CrossRef]

- Shi, J.; Fan, H.; Liu, X.; Bell, A.J.; Roedel, J. Large Electrostrictive Strain in (Bi0.5Na0.5)TiO3–BaTiO3–(Sr0.7Bi0.2)TiO3 Solid Solutions. J. Am. Ceram. Soc. 2013, 97, 848–853. [Google Scholar] [CrossRef]

- Li, T.Y.; Liu, C.; Ke, X.Q.; Liu, X.; He, L.Q.; Shi, P.; Ren, X.B.; Wang, Y.Z.; Lou, X.J. High electrostrictive strain in lead-free relaxors near the morphotropic phase boundary. Acta Mater. 2020, 182, 39–46. [Google Scholar] [CrossRef]

- Bai, W.F.; Li, L.Y.; Li, W.; Shen, B.; Zhai, J.W.; Chen, H. Phase Diagrams and Electromechanical Strains in Lead-Free BNT-Based Ternary Perovskite Compounds. J. Am. Ceram. Soc. 2014, 97, 3510–3518. [Google Scholar] [CrossRef]

- Yang, H.; Zhao, J.; Ren, W.; Ye, Z.-G.; Vinayakumar, K.B.; Dias, R.A.; Pinto, R.M.R.; Zhuang, J.; Zhang, N. Lead free 0.9Na1/2Bi1/2TiO3–0.1BaZr0.2Ti0.8O3 thin film with large piezoelectric electrostrain. Appl. Phys. Lett. 2022, 121, 132903. [Google Scholar] [CrossRef]

- Liu, G.; Dong, J.; Zhang, L.; Yan, Y.; Jing, R.; Jin, L. Phase evolution in (1−x)(Na0.5Bi0.5)TiO3-xSrTiO3 solid solutions: A study focusing on dielectric and ferroelectric characteristics. J. Mater. 2020, 6, 677–691. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, H.; Xue, G.; Luo, H.; Zhang, D. Optimized strain performance in <001>-textured Bi0.5Na0.5TiO3-based ceramics with ergodic relaxor state and core—Shell microstructure. J. Adv. Ceram. 2022, 11, 1542–1558. [Google Scholar]

- Sapper, E.; Novak, N.; Jo, W.; Granzow, T.; Rödel, J. Electric-field–temperature phase diagram of the ferroelectric relaxor system (1 − x)Bi1/2Na1/2TiO3 − xBaTiO3 doped with manganese. J. Appl. Phys. 2014, 115, 194104. [Google Scholar] [CrossRef]

- Dittmer, R.; Gobeljic, D.; Jo, W.; Shvartsman, V.V.; Lupascu, D.C.; Jones, J.L.; Rödel, J. Ergodicity reflected in macroscopic and microscopic field-dependent behavior of BNT-based relaxors. J. Appl. Phys. 2014, 115, 084111. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Niu, G.; Zhang, H.; Wang, C.; Jia, M.; Zhang, N.; Zheng, K.; Quan, Y.; Wang, L.; et al. Enhanced domain switching contributing to large strain response in (Bi0.5Na0.5)TiO3–SrTiO3 lead-free thin films. Ceram. Int. 2024, in press. [Google Scholar] [CrossRef]

- Zheng, H.; Sun, E.; Luo, H.; Zhang, X.; Yang, Y.; Yang, B.; Zhang, R.; Zhang, S.; Cao, W. Comprehensive optimization of piezoelectric coefficient and depolarization temperature in Mn-doped Bi0.5Na0.5TiO3-Bi0.5K0.5TiO3-BaTiO3 lead-free piezoceramics. J. Mater. Sci. Technol. 2024, 172, 255–263. [Google Scholar] [CrossRef]

- Bai, C.; Wang, J.; Lin, W.; Wu, F.; Jiang, J. Electrical Properties of Sandwich-like Multilevel Phase Structure BNT-BT Lead-Free Piezoelectric Ceramics. Integr. Ferroelectr. 2021, 218, 66–74. [Google Scholar] [CrossRef]

- Sorge, G.; Hauke, T.; Klee, M. Electromechanical properties of thin ferroelectric Pb(Zr0.53Ti0.47)o3-layers. Ferroelectrics 1995, 163, 77–88. [Google Scholar] [CrossRef]

- Zhang, L.; Jing, R.; Huang, Y.; Hu, Q.; Alikin, D.O.; Shur, V.Y.; Wang, D.; Wei, X.; Zhang, L.; Liu, G.; et al. Ultrahigh electrostrictive effect in potassium sodium niobate-based lead-free ceramics. J. Eur. Ceram. Soc. 2022, 42, 944–953. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhao, J.; Wang, Z.; Zheng, K.; Zhang, J.; Chen, C.; Wang, L.; Wang, G.; Li, X.; Zhao, Y.; et al. Ultrahigh Electrostrictive Effect in Lead-Free Sodium Bismuth Titanate-Based Relaxor Ferroelectric Thick Film. Nanomaterials 2024, 14, 1411. https://doi.org/10.3390/nano14171411

Li Y, Zhao J, Wang Z, Zheng K, Zhang J, Chen C, Wang L, Wang G, Li X, Zhao Y, et al. Ultrahigh Electrostrictive Effect in Lead-Free Sodium Bismuth Titanate-Based Relaxor Ferroelectric Thick Film. Nanomaterials. 2024; 14(17):1411. https://doi.org/10.3390/nano14171411

Chicago/Turabian StyleLi, Yizhuo, Jinyan Zhao, Zhe Wang, Kun Zheng, Jie Zhang, Chuying Chen, Lingyan Wang, Genshui Wang, Xin Li, Yulong Zhao, and et al. 2024. "Ultrahigh Electrostrictive Effect in Lead-Free Sodium Bismuth Titanate-Based Relaxor Ferroelectric Thick Film" Nanomaterials 14, no. 17: 1411. https://doi.org/10.3390/nano14171411