Optimization of Thermoelectric Properties and Physical Mechanisms of Cu2Se-Based Thin Films via Heat Treatment

Abstract

:1. Introduction

2. Materials and Methods

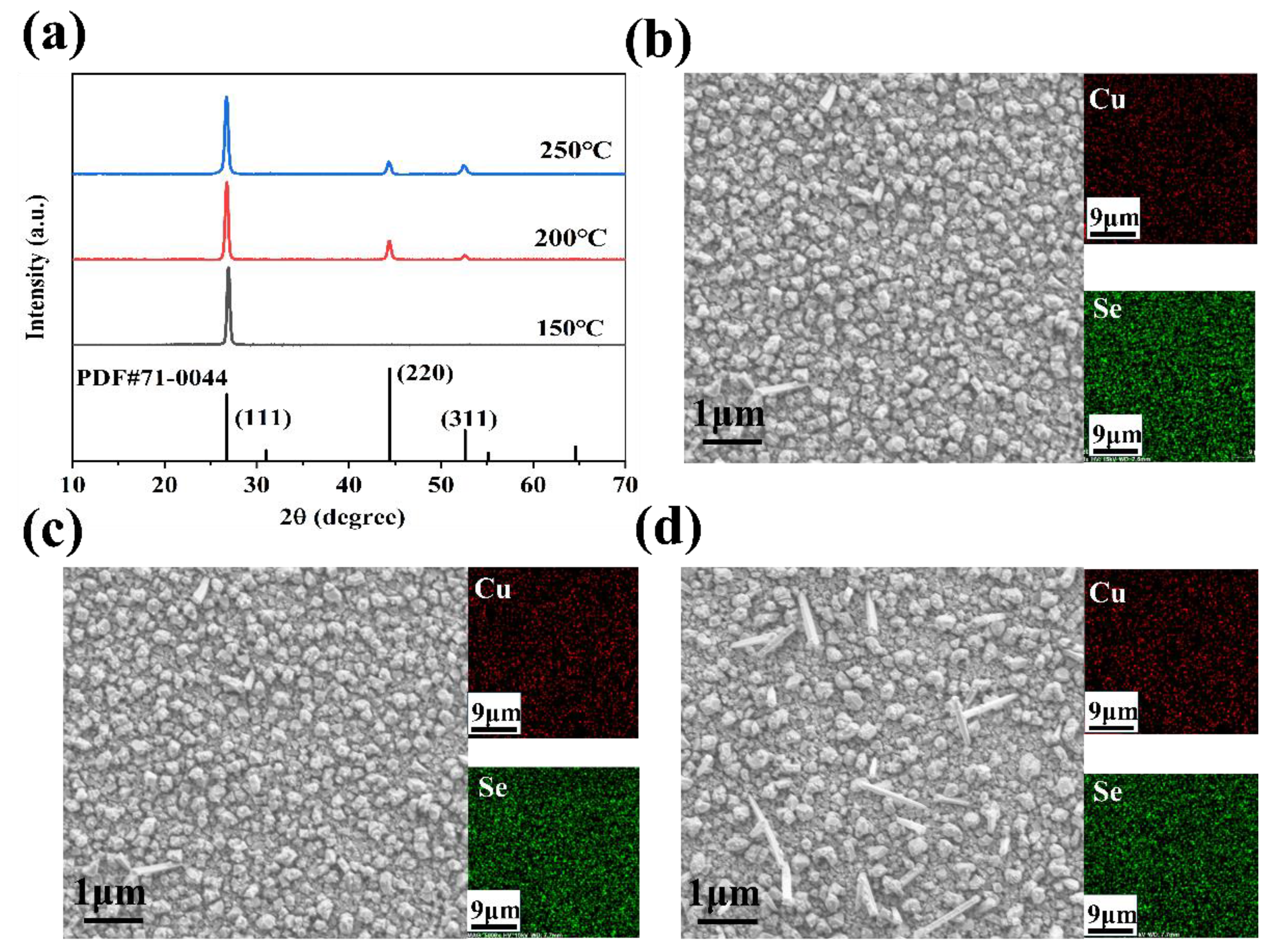

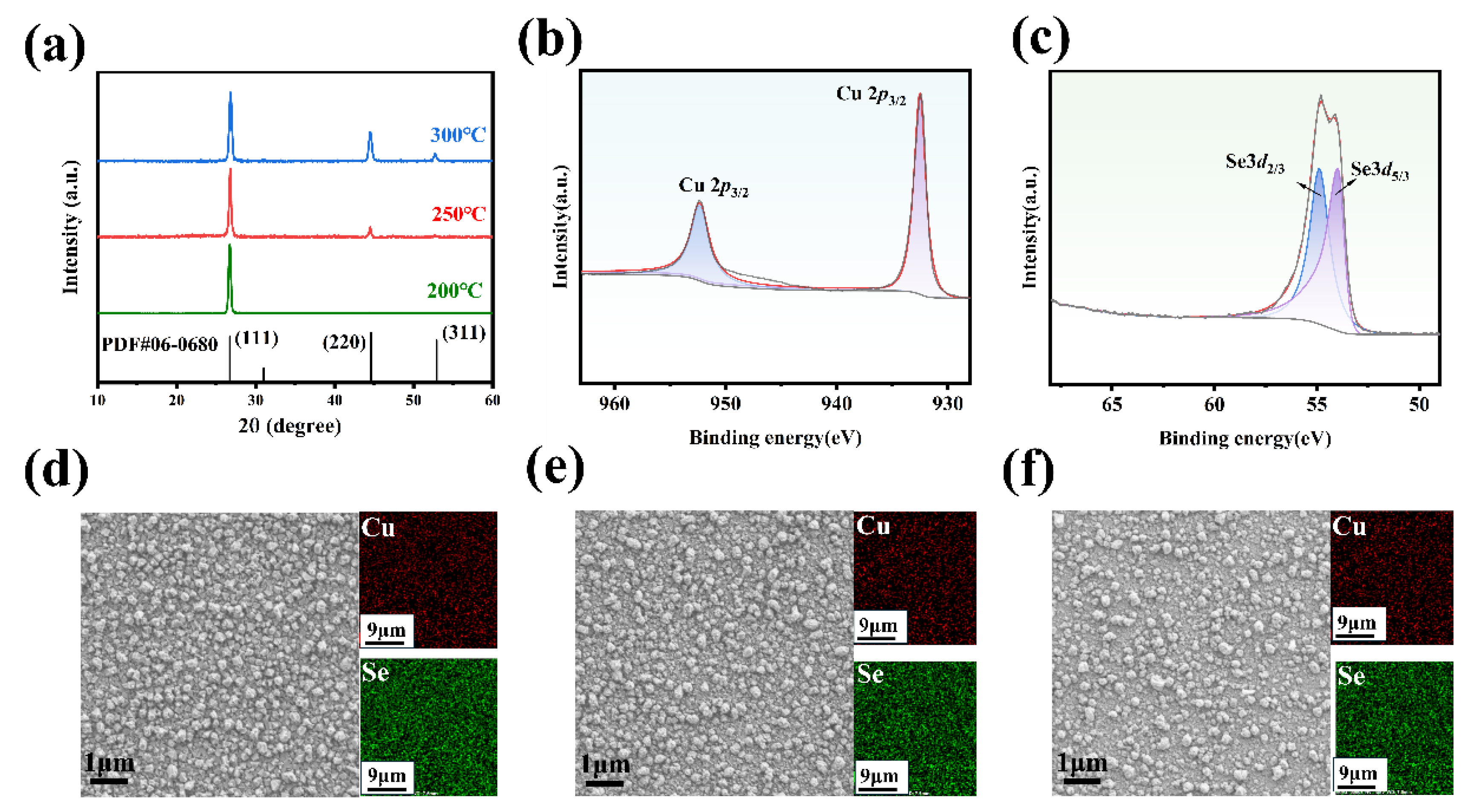

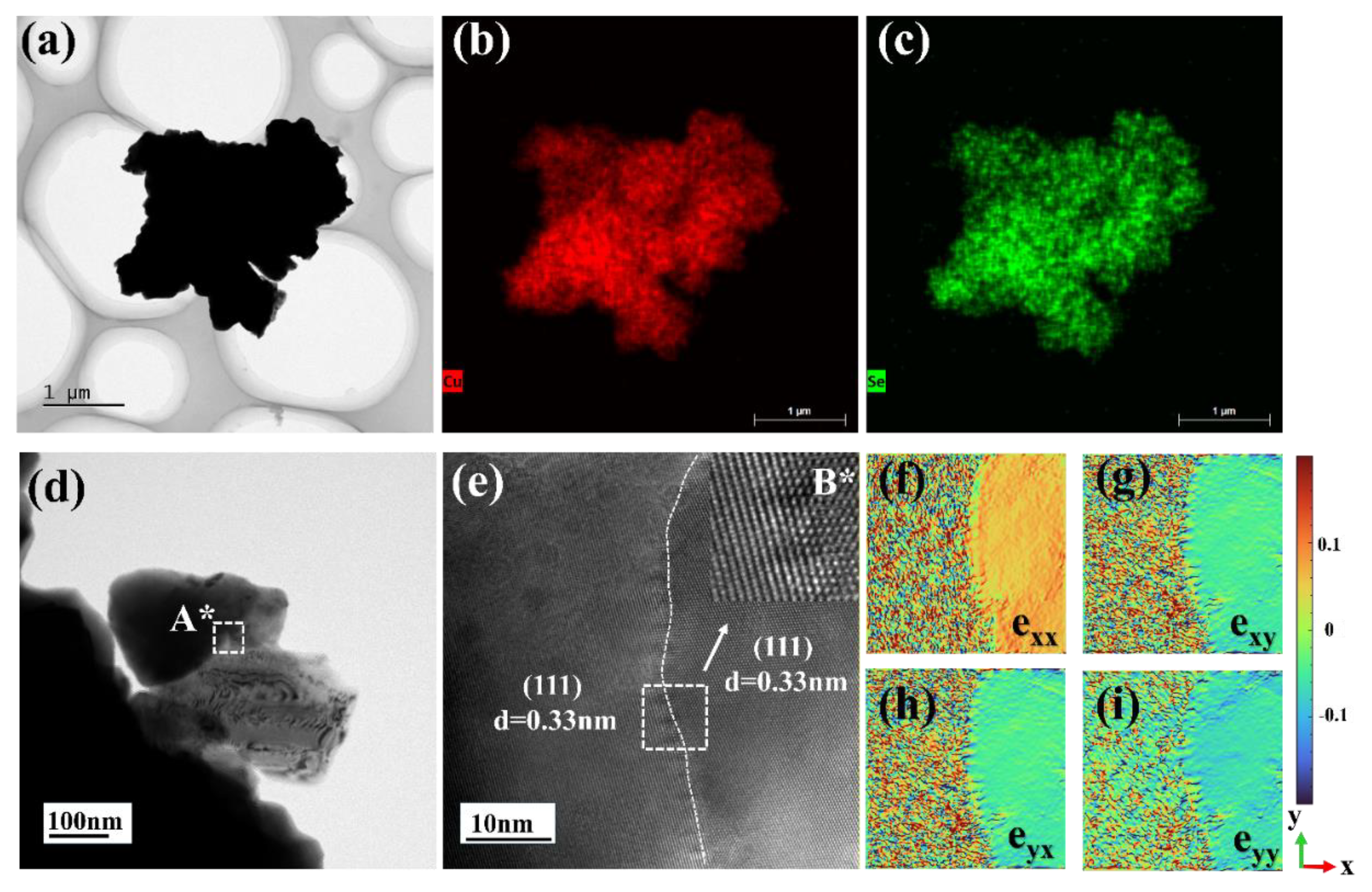

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prunet, G.; Pawula, F.; Fleury, G.; Cloutet, E.; Robinson, A.J.; Hadziioannou, G.; Pakdel, A. A review on conductive polymers and their hybrids for flexible and wearable thermoelectric applications. Mater. Today Phys. 2021, 18, 100402. [Google Scholar] [CrossRef]

- Yang, D.; Shi, X.L.; Li, M.; Nisar, M.; Mansoor, A.; Chen, S.; Chen, Y.X.; Li, F.; Ma, H.L.; Liang, G.X.; et al. Flexible power generators by Ag2Se thin films with record-high thermoelectric performance. Nat. Commun. 2024, 15, 923. [Google Scholar] [CrossRef] [PubMed]

- Tan, M.; Liu, W.D.; Shi, X.L.; Sun, Q.; Chen, Z.G. Minimization of the electrical contact resistance in thin-film thermoelectric device. Appl. Phys. Rev. 2023, 10, 021404. [Google Scholar]

- Zheng, Z.H.; Shi, X.L.; Ao, D.W.; Liu, W.D.; Li, M.; Kou, L.Z.; Chen, Y.X.; Li, F.; Wei, M.; Liang, G.X.; et al. Harvesting waste heat with flexible Bi2Te3 thermoelectric thin film. Nat. Sustain. 2023, 6, 180–191. [Google Scholar] [CrossRef]

- Ao, D.W.; Liu, W.D.; Chen, Y.X.; Wei, M.; Jabar, B.; Li, F.; Shi, X.L.; Zheng, Z.H.; Liang, G.X.; Zhang, X.H.; et al. Novel Thermal Diffusion Temperature Engineering Leading to High Thermoelectric Performance in Bi2Te3-Based Flexible Thin-Films. Adv. Sci. 2022, 9, 2103547. [Google Scholar] [CrossRef] [PubMed]

- Qin, D.D.; Shi, W.J.; Lu, Y.Z.; Cai, W.; Liu, Z.H.; Sui, J.H. Roles of interface engineering in performance optimization of skutterudite-based thermoelectric materials. Carbon Neutralization 2022, 1, 233–246. [Google Scholar] [CrossRef]

- Chen, Y.X.; Lu, C. Graphitic carbon nitride nanomaterials for high-performance supercapacitors. Carbon Neutralization 2023, 2, 585–602. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Li, J.H.; Tan, Y.J.; Zhu, C.L.; Chen, Y.J. Recent progress in device designs and dual-functional photoactive materials for direct solar to electrochemical energy storage. Carbon Neutralization 2023, 3, 32–63. [Google Scholar] [CrossRef]

- Peng, Y.; Miao, L.; Liu, C.Y.; Song, H.L.; Kurosawa, M.; Nakatsuka, O.; Back, S.Y.; Rhyee, J.S.; Murata, M.; Tanemura, S.; et al. Constructed Ge Quantum Dots and Sn Precipitate SiGeSn Hybrid Film with High Thermoelectric Performance at Low Temperature Region. Adv. Energy Mater. 2022, 12, 2103191. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.L.; Yang, Y.L.; Chen, Z.G. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108. [Google Scholar] [CrossRef]

- Jia, Y.H.; Jiang, Q.L.; Sun, H.D.; Liu, P.P.; Hu, D.H.; Pei, Y.Z.; Liu, W.S.; Crispin, X.; Fabiano, S.; Ma, Y.G.; et al. Wearable Thermoelectric Materials and Devices for Self-Powered Electronic Systems. Adv. Mater. 2021, 33, 2102990. [Google Scholar] [CrossRef]

- Lei, Y.; Qi, R.J.; Chen, M.Y.; Chen, H.; Xing, C.C.; Sui, F.R.; Gu, L.Y.; He, W.W.; Zhang, Y.G.; Baba, T.; et al. Microstructurally Tailored Thin β-Ag2Se Films toward Commercial Flexible Thermoelectrics. Adv. Mater. 2022, 34, 2104786. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; Su, X.L.; Yang, D.W.; Zhang, Q.J.; Tan, G.J.; Uher, C.; Tang, X.F.; Wu, J.S. An Instant Change of Elastic Lattice Strain during Cu2Se Phase Transition: Origin of Abnormal Thermoelectric Properties. Adv. Funct. Mater. 2021, 31, 2100431. [Google Scholar] [CrossRef]

- Wu, M.; Cui, H.H.; Cai, S.T.; Hao, S.Q.; Liu, Y.K.; Bailey, T.P.; Zhang, Y.Y.; Chen, Z.X.; Luo, Y.B.; Uher, C.; et al. Weak Electron-Phonon Coupling and Enhanced Thermoelectric Performance in n-type PbTe-Cu2Se via Dynamic Phase Conversion. Adv. Energy Mater. 2023, 13, 2203325. [Google Scholar] [CrossRef]

- Ren, Y.Y.; Yang, J.Y.; Jiang, Q.H.; Zhang, D.; Zhou, Z.W.; Li, X.; Xin, J.W.; He, X. Synergistic effect by Na doping and S stitution for high thermoelectric performance of p-type MnTe. J. Mater. Chem. C. 2017, 5, 5076–5082. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, D.L.; Ao, D.W.; Nisar, M.; Mansoor, A.; Chen, Y.X.; Li, F.; Ma, H.L.; Liang, G.X.; Zhang, X.H.; et al. High thermoelectric performance of aluminum-doped cuprous selenide thin films with exceptional flexibility for wearable applications. Nano Energy 2023, 117, 108930. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Zhang, D.L.; Jabar, B.; Chen, T.B.; Nisar, M.; Chen, Y.F.; Li, F.; Chen, S.; Liang, G.X.; Zhang, X.H.; et al. Realizing high thermoelectric performance in highly (0l0)-textured flexible Cu2Se thin film for wearable energy harvesting. Mater. Today Phys. 2022, 24, 100659. [Google Scholar] [CrossRef]

- Yang, D.W.; Su, X.L.; Li, J.; Bai, H.; Wang, S.Y.; Li, Z.; Tang, H.; Tang, K.C.; Luo, T.T.; Yan, Y.G.; et al. Blocking Ion Migration Stabilizes the High Thermoelectric Performance in Cu2Se Composites. Adv. Mater. 2020, 32, 2003730. [Google Scholar] [CrossRef]

- Lei, J.D.; Ma, Z.; Zhang, D.; Chen, Y.Q.; Wang, C.; Yang, X.Y.; Cheng, Z.X.; Wang, Y.X. High thermoelectric performance in Cu2Se superionic conductor with enhanced liquid-like behaviour by dispersing SiC. J. Mater. Chem. A. 2019, 7, 7006–7014. [Google Scholar] [CrossRef]

- Zhao, X.D.; Ning, S.T.; Qi, N.; Li, Y.H.; Dong, Y.; Zhang, H.J.; Liu, J.D.; Ye, B.J.; Chen, Z.Q. Synergetic Optimization of Electrical and Thermal Transport Properties by Cu Vacancies and Nanopores in Cu2Se. ACS Appl. Mater. Interfaces 2021, 13, 58936–58948. [Google Scholar] [CrossRef]

- Wang, A.A.; Xue, Y.L.; Wang, J.X.; Yang, X.Q.; Wang, J.L.; Li, Z.L.; Wang, S.F. High thermoelectric performance of Cu2Se-based thin films with adjustable element ratios by pulsed laser deposition. Mater. Today Energy 2022, 24, 100929. [Google Scholar] [CrossRef]

- Scimeca, M.R.; Yang, F.; Zaia, E.; Chen, N.; Zhao, P.; Gordon, M.P.; Forster, J.D.; Liu, Y.S.; Guo, J.H.; Urban, J.J.; et al. Rapid Stoichiometry Control in Cu2Se Thin Films for Room-Temperature Power Factor Improvement. ACS Appl. Energ. Mater. 2019, 2, 1517–1525. [Google Scholar] [CrossRef]

- Jin, Y.; Hwang, J.; Kim, S.; Kim, J.; Kim, S.J. Synergetic enhancement of thermoelectric performances by localized carrier and phonon scattering in Cu2Se with incorporated fullerene nanoparticles. Nanoscale Adv. 2021, 3, 3107–3113. [Google Scholar] [CrossRef]

- Song, L.R.; Zhang, J.W.; Iversen, B.B. Enhanced thermoelectric properties of SnSe thin films grown by single-target magnetron sputtering. J. Mater. Chem. A. 2019, 7, 17981–17986. [Google Scholar] [CrossRef]

- Perez-Taborda, J.A.; Vera, L.; Caballero-Calero, O.; Lopez, E.O.; Romero, J.J.; Stroppa, D.G.; Briones, F.; Martin-Gonzalez, M. Pulsed Hybrid Reactive Magnetron Sputtering for High zT Cu2Se Thermoelectric Films. Adv. Mater. Technol. 2017, 2, 1700012. [Google Scholar] [CrossRef]

- Sun, Y.; Christensen, M.; Johnsen, S.; Nong, N.V.; Ma, Y.; Sillassen, M.; Zhang, E.; Palmqvist, A.E.C.; Bottiger, J.; Iversen, B.B. Low-Cost High-Performance Zinc Antimonide Thin Films for Thermoelectric Applications. Adv. Mater. 2012, 24, 1693–1696. [Google Scholar] [CrossRef]

- Jabar, B.; Mansoor, A.; Chen, Y.X.; Jamil, S.; Chen, S.; Liang, G.X.; Li, F.; Fan, P.; Zheng, Z.H. High thermoelectric performance of BixSb2-xTe3 alloy achieved via structural manipulation under optimized heat treatment. Chem. Eng. J. 2022, 435, 135062. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Niu, J.Y.; Ao, D.W.; Jabar, B.; Shi, X.L.; Li, X.R.; Li, F.; Liang, G.X.; Chen, Y.X.; Chen, Z.G.; et al. In-situ growth of high-performance (Ag, Sn) co-doped CoSb3 thermoelectric thin films. J. Mater. Sci. Technol. 2021, 92, 178–185. [Google Scholar] [CrossRef]

| Deposition Temperature (°C) | Thickness (nm) | Cu (at.%) | Se (at.%) | Cu:Se |

|---|---|---|---|---|

| 150 | 322 | 67.47 | 32.53 | 2.07 |

| 200 | 318 | 68.52 | 31.48 | 2.18 |

| 250 | 276 | 74.9 | 25.1 | 2.98 |

| Deposition Temperature (°C) | Thickness (nm) | Cu (at.%) | Se (at.%) | Cu:Se |

|---|---|---|---|---|

| 200 | 282 | 68.73 | 31.27 | 2.2 |

| 250 | 245 | 70.01 | 29.99 | 2.33 |

| 300 | 267 | 70.56 | 29.44 | 2.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, F.; Chen, Y.; Liang, G.; Luo, J.; Wei, M.; Zheng, Z.; Zheng, Z. Optimization of Thermoelectric Properties and Physical Mechanisms of Cu2Se-Based Thin Films via Heat Treatment. Nanomaterials 2024, 14, 1421. https://doi.org/10.3390/nano14171421

Li H, Li F, Chen Y, Liang G, Luo J, Wei M, Zheng Z, Zheng Z. Optimization of Thermoelectric Properties and Physical Mechanisms of Cu2Se-Based Thin Films via Heat Treatment. Nanomaterials. 2024; 14(17):1421. https://doi.org/10.3390/nano14171421

Chicago/Turabian StyleLi, Haobin, Fu Li, Yuexing Chen, Guangxing Liang, Jingting Luo, Meng Wei, Zhi Zheng, and Zhuanghao Zheng. 2024. "Optimization of Thermoelectric Properties and Physical Mechanisms of Cu2Se-Based Thin Films via Heat Treatment" Nanomaterials 14, no. 17: 1421. https://doi.org/10.3390/nano14171421

APA StyleLi, H., Li, F., Chen, Y., Liang, G., Luo, J., Wei, M., Zheng, Z., & Zheng, Z. (2024). Optimization of Thermoelectric Properties and Physical Mechanisms of Cu2Se-Based Thin Films via Heat Treatment. Nanomaterials, 14(17), 1421. https://doi.org/10.3390/nano14171421