Polymer Coating Enabled Carrier Modulation for Single-Walled Carbon Nanotube Network Inverters and Antiambipolar Transistors

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Instruments

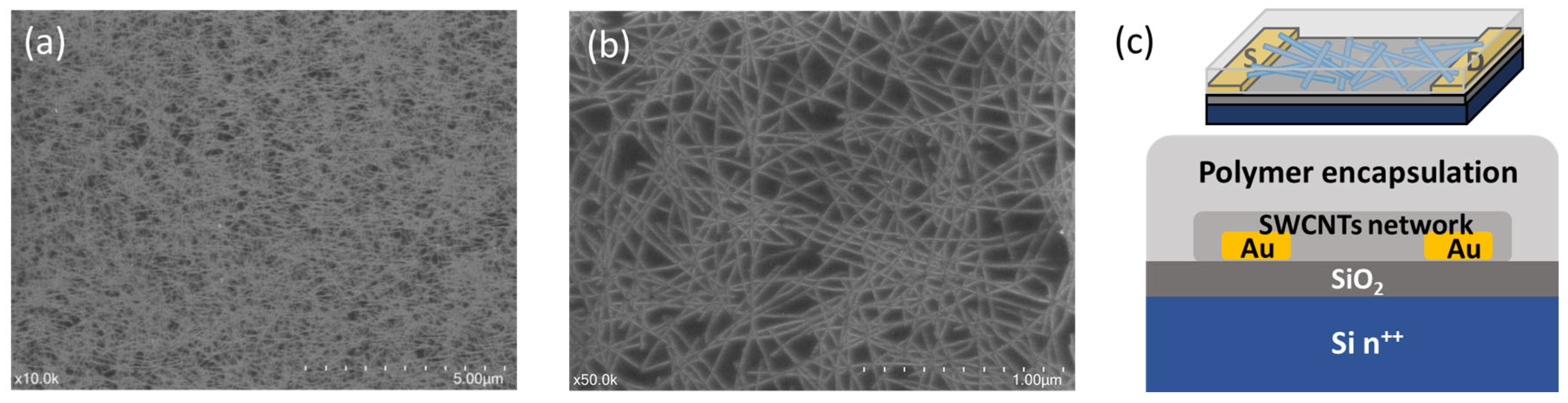

2.2. TFT Fabrication Process and Characterization

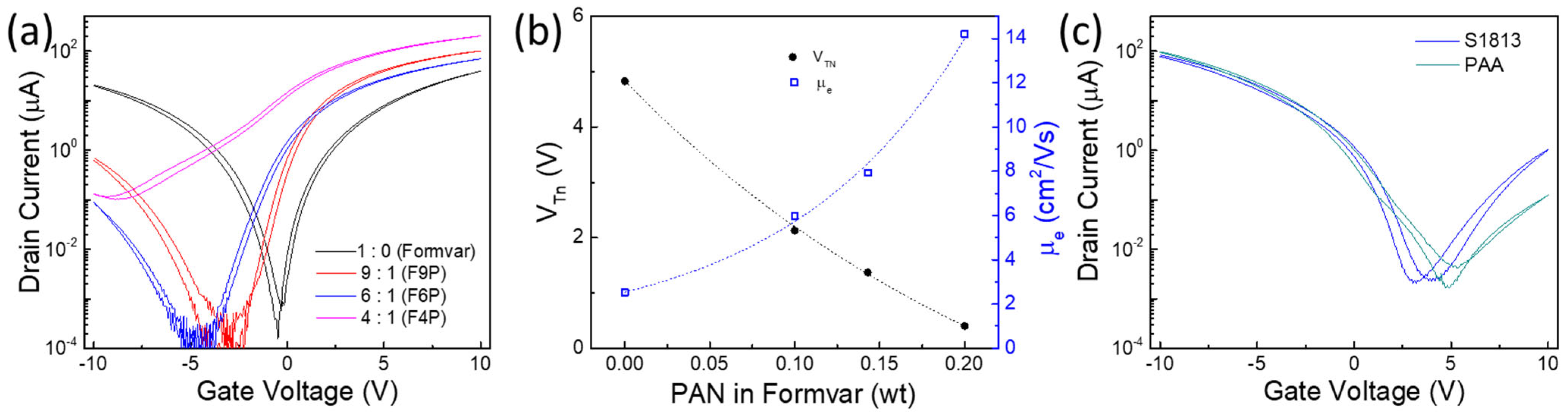

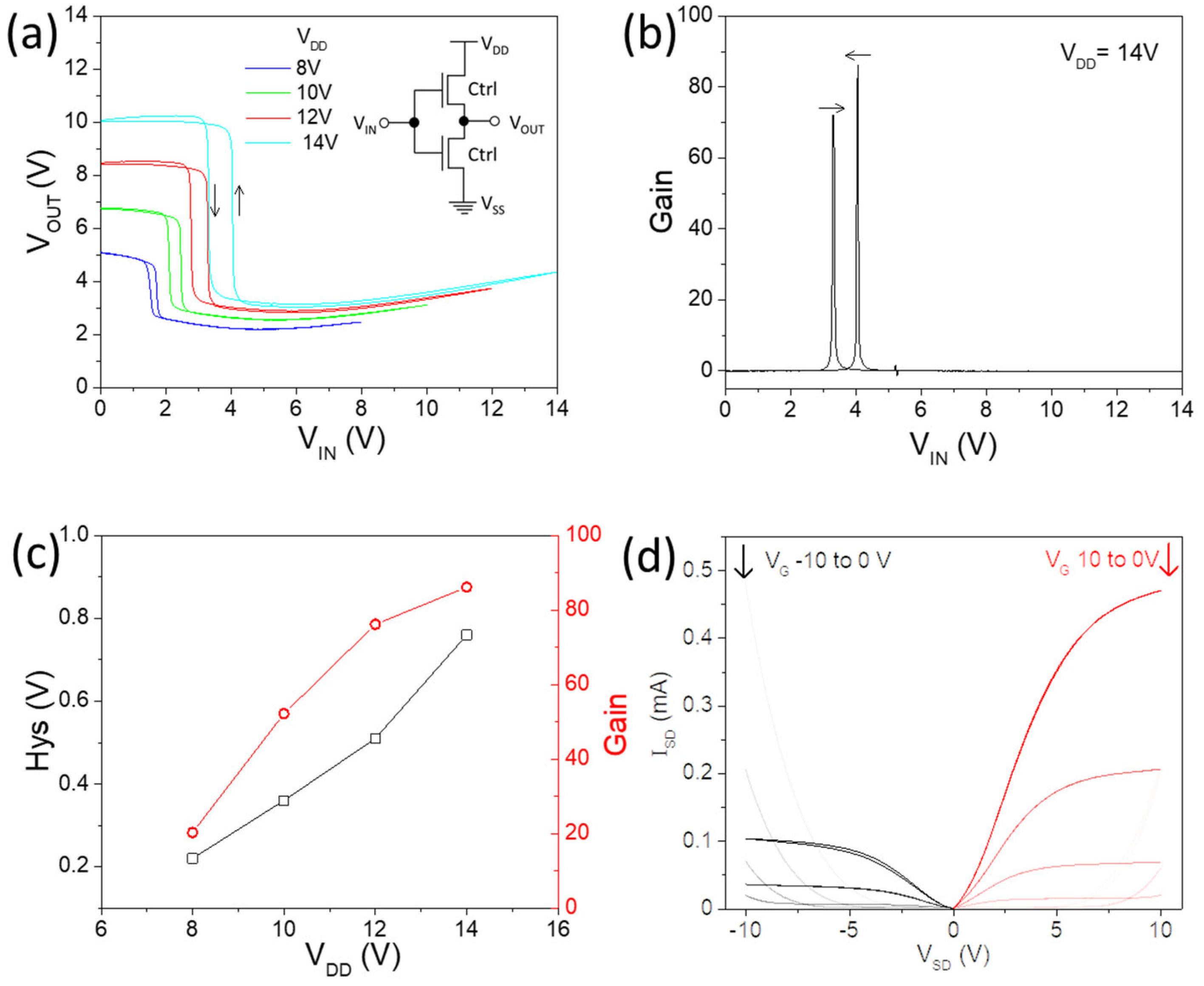

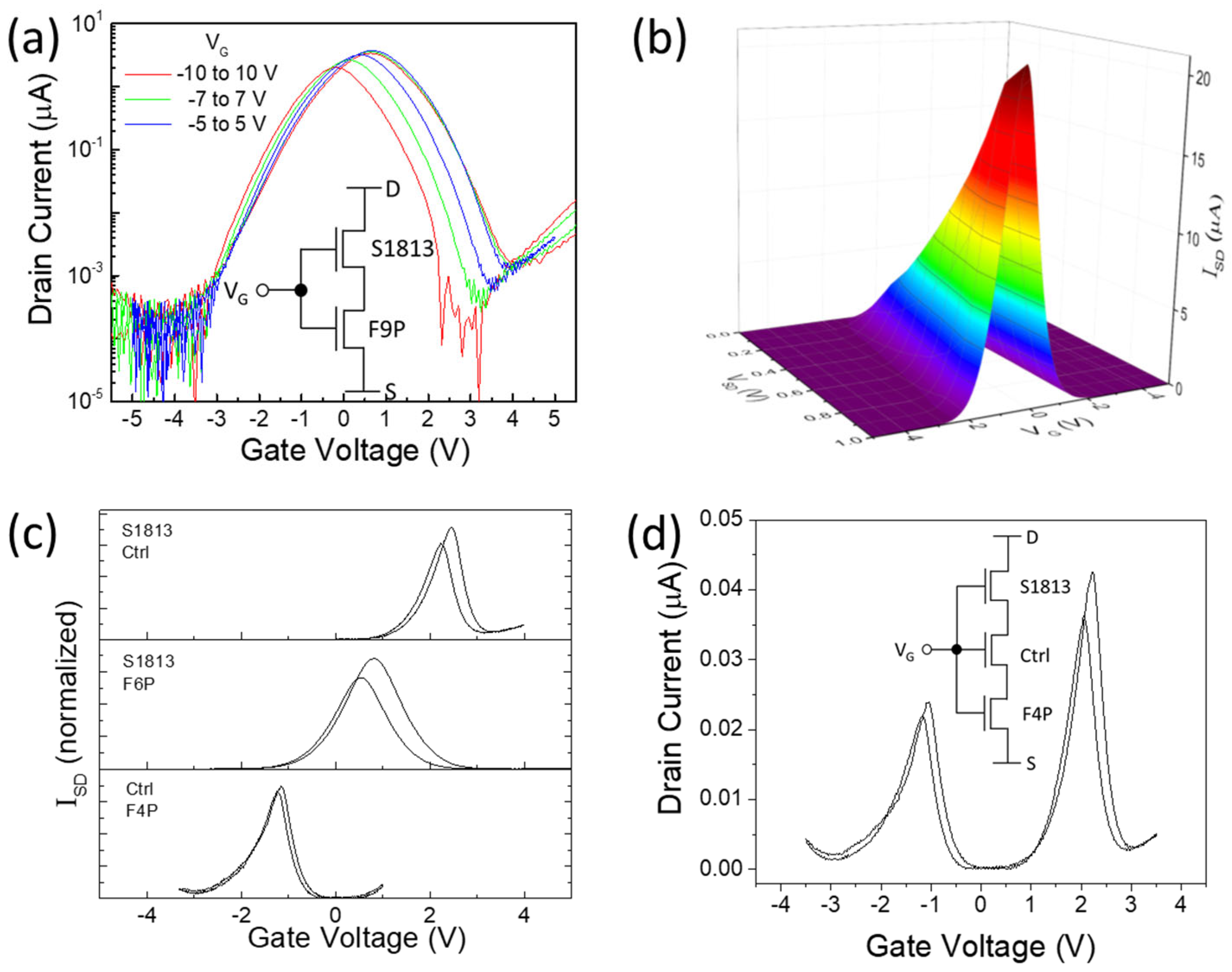

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Franklin, A.D.; Hersam, M.C.; Wong, H.-S.P. Carbon nanotube transistors: Making electronics from molecules. Science 2022, 378, 726–732. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Xu, Y.; Haider, M.; Sun, J.; Zhang, D.; Yang, J. Printing flexible thin-film transistors. Appl. Phys. Rev. 2023, 10, 031313. [Google Scholar] [CrossRef]

- Lee, H.W.; Yoon, Y.; Park, S.; Oh, J.H.; Hong, S.; Liyanage, L.S.; Wang, H.; Morishita, S.; Patil, N.; Park, Y.J.; et al. Selective dispersion of high purity semiconducting single-walled carbon nanotubes with regioregular poly(3-alkylthiophene)s. Nat. Commun. 2011, 2, 541. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Javey, A.; Vermesh, O.; Wang, Q.; Li, Y.; Dai, H. Hysteresis Caused by Water Molecules in Carbon Nanotube Field-Effect Transistors. Nano Lett. 2003, 3, 193–198. [Google Scholar] [CrossRef]

- Qian, L.; Xie, Y.; Zhang, S.; Zhang, J. Band engineering of carbon nanotube for device applications. Matter 2020, 3, 664–695. [Google Scholar] [CrossRef]

- Wang, H.; Wei, P.; Li, Y.; Han, J.; Lee, H.R.; Naab, B.D.; Liu, N.; Wang, C.; Adijanto, E.; Tee, B.C.-K.; et al. Tuning the threshold voltage of carbon nanotube transistors by n-type molecular doping for robust and flexible complementary circuits. Proc. Natl. Acad. Sci. USA 2014, 111, 4776–4781. [Google Scholar] [CrossRef]

- Kim, S.M.; Jang, J.H.; Kim, K.K.; Park, H.K.; Bae, J.J.; Yu, W.J.; Lee, I.H.; Kim, G.; Loc, D.D.; Kim, U.J.; et al. Reduction-Controlled Viologen in Bisolvent as an Environmentally Stable n-Type Dopant for Carbon Nanotubes. J. Am. Chem. Soc. 2008, 131, 327–331. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Nakano, M.; Murayama, T.; Hagino, H.; Hama, S.; Miyazaki, K.; Matsubara, R.; Nakamura, M.; Kawai, T. Simple Salt-Coordinated n-Type Nanocarbon Materials Stable in Air. Adv. Funct. Mater. 2016, 26, 3021–3028. [Google Scholar] [CrossRef]

- Kim, S.M.; Jo, Y.W.; Kim, K.K.; Duong, D.L.; Shin, H.-J.; Han, J.H.; Choi, J.-Y.; Kong, J.; Lee, Y.H. Transparent Organic P-Dopant in Carbon Nanotubes: Bis(trifluoromethanesulfonyl)imide. ACS Nano 2010, 4, 6998–7004. [Google Scholar] [CrossRef]

- Tan, F.W.; Hirotani, J.; Kishimoto, S.; Ohno, Y. PMMA/Al2O3 bilayer passivation for suppression of hysteresis in chemically doped carbon nanotube thin-film transistors. Jpn. J. Appl. Phys. 2022, 61, 034002. [Google Scholar] [CrossRef]

- Lapointe, F.; Sapkota, A.; Ding, J.; Lefebvre, J. Polymer Encapsulants for Threshold Voltage Control in Carbon Nanotube Transistors. ACS Appl. Mater. Interfaces 2019, 11, 36027–36034. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ding, J.; Lapointe, F.; Malenfant, P.R.L. Efficient charge carrier control on single walled carbon nanotube thin film transistors using water soluble polymer coatings, cited for water soluble polymer coating. J. Mater. Sci. Mater. Electron. 2021, 32, 23923–23934. [Google Scholar] [CrossRef]

- Ding, J.; Li, Z.; Lefebvre, J.; Cheng, F.; Dubey, G.; Zou, S.; Finnie, P.; Hrdina, A.; Scoles, L.; Lopinski, G.P.; et al. Enrichment of large-diameter semiconducting SWCNTs by polyfluorene extraction for high network density thin film transistors. Nanoscale 2014, 6, 2328–2339. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.-X.; Lin, C.-T.; Tsai, M.-H.; Lin, K.-C. Review-Hysteresis in Carbon Nano-Structure Field Effect Transistor. Micromachines 2022, 13, 509. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ouyang, J.; Ding, J. Diameter-Dependent Semiconducting Carbon Nanotube Network Transistor Performance. ACS Appl. Electron. Mater. 2022, 4, 6335–6344. [Google Scholar] [CrossRef]

- Star, A.; Han, T.-R.; Gabriel, J.-C.P.; Bradley, G.K.; Grüner, G. Interaction of Aromatic Compounds with Carbon Nanotubes: Correlation to the Hammett Parameter of the Substituent and Measured Carbon Nanotube FET Response. Nano Lett. 2003, 3, 1421–1423. [Google Scholar] [CrossRef]

- Hansch, C.; Leo, A.; Taft, R.W. A Survey of Hammett Substituent Constants and Resonance and Field Parameters. Chem. Rev. 1991, 91, 165–195. [Google Scholar] [CrossRef]

- Li, Z.; Ding, J.; Ouyang, J.; Malenfant, P.R.L. Fluorene Copolymer and Carbon Nanotube Interaction Modulates Network Transistor Performance. ACS Appl. Electron. Mater. 2021, 3, 4424–4432. [Google Scholar] [CrossRef]

- Brownile, L.; Shapter, J. Advances in carbon nanotube n-type doping: Methods, analysis and applications. Carbon 2018, 126, 257–270. [Google Scholar] [CrossRef]

- Yang, D.; Hwang, K.; Kim, Y.-J.; Kim, Y.; Moon, Y.; Han, N.; Lee, M.; Lee, S.-H.; Kim, D.-Y. High-performance carbon nanotube field-effect transistors with electron mobility of 39.4 cm2V−1s−1 using anion–π interaction doping. Carbon 2023, 203, 761–769. [Google Scholar] [CrossRef]

- Xu, Q.; Zhao, J.; Pecunia, V.; Xu, W.; Zhou, C.; Dou, J.; Gu, W.; Lin, J.; Mo, L.; Zhao, Y.; et al. Selective Conversion from p-Type to n-Type of Printed Bottom-Gate Carbon Nanotube Thin-Film Transistors and Application in Complementary Metal–Oxide–Semiconductor Inverters. ACS Appl. Mater. Interfaces 2017, 9, 12750–12758. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, Z.; Xu, Z.; Wu, K.; Yu, X.; Chen, X.; Meng, Y.; Li, H.; Qiu, S.; Jin, H.; et al. Low Hysteresis Carbon Nanotube Transistors Constructed via a General Dry-Laminating Encapsulation Method on Diverse Surfaces. ACS Appl. Mater. Interfaces 2017, 9, 14292–14300. [Google Scholar] [CrossRef] [PubMed]

- Wei, M.; Robin, M.; Portilla, L.; Ren, Y.; Shao, S.; Bai, L.; Cao, Y.; Pecunia, V.; Cui, Z.; Zhao, J. Air-stable N-type printed carbon nanotube thin film transistors for CMOS logic circuits. Carbon 2020, 163, 145–153. [Google Scholar] [CrossRef]

- Salazar-Rios, J.M.; Sengrian, A.A.; Talsma, W.; Duim, H.; Abdu-Aguye, M.; Jung, S.; Fröhlich, N.; Allard, S.; Scherf, U.; Loi, M.A. Customizing the Polarity of Single-Walled Carbon-Nanotube Field-Effect Transistors Using Solution-Based Additives. Adv. Electron. Mater. 2020, 6, 1900789. [Google Scholar] [CrossRef]

- Schneider, S.; Brohmann, M.; Lorenz, R.; Hofstetter, Y.J.; Rother, M.; Sauter, E.; Zharnikov, M.; Vaynzof, Y.; Himmel, H.-J.; Zaumseil, J. Efficient n-Doping and Hole Blocking in Single-Walled Carbon Nanotube Transistors with 1,2,4,5-Tetrakis(tetramethylguanidino)benzene. ACS Nano 2018, 12, 5895–5902. [Google Scholar] [CrossRef]

- Geier, M.L.; Prabhumirashi, P.L.; McMorrow, J.J.; Xu, W.; Seo, J.-W.T.; Everaerts, K.; Kim, C.H.; Marks, T.J.; Hersam, M.C. Subnanowatt Carbon Nanotube Complementary Logic Enabled by Threshold Voltage Control. Nano Lett. 2013, 13, 4810–4814. [Google Scholar] [CrossRef]

- Tousignant, M.N.; Ronnasi, B.; Tischler, V.; Lessard, B.H. N-Type Single Walled Carbon Nanotube Thin Film Transistors Using Green Tri-Layer Polymer Dielectric. Adv. Mater. Interfaces 2023, 10, 2300079. [Google Scholar] [CrossRef]

- Geier, M.L.; McMorrow, J.J.; Xu, W.; Zhu, J.; Kim, C.H.; Marks, T.J.; Hersam, M.C. Solution-processed carbon nanotube thin-film complementary static random access memory. Nature Nanotechnol. 2015, 10, 944–948. [Google Scholar] [CrossRef]

- Park, J.; Choi, H.W.; Kim, B. Facile Route to Inkjet Printed Carbon Nanotube-Based Inverters with High Gain for Biosignal Monitoring. ACS Appl. Electron. Mater. 2023, 5, 552–558. [Google Scholar] [CrossRef]

- Sun, P.; Wei, N.; Zhang, P.; Yang, Y.; Zhu, M.; Shi, H.; Peng, L.-M.; Zhang, Z. How to build good inverters from nanomaterial-based transistors. Nano Res. 2023, 16, 12594–12600. [Google Scholar] [CrossRef]

- Wakayama, Y.; Hayakawa, R. Antiambipolar Transistor: A Newcomer for Future Flexible Electronics. Adv. Funct. Mater. 2020, 30, 1903724. [Google Scholar] [CrossRef]

- Zhou, Y.; Gaur, A.; Hur, S.-H.; Kocabas, C.; Meitl, M.A.; Shim, M.; Rogers, J.A. p-Channel, n-Channel Thin Film Transistors and p-n Diodes Based on Single Wall Carbon Nanotube Networks. Nano Lett. 2004, 4, 2031–2035. [Google Scholar] [CrossRef]

- Jariwala, D.; Sangwan, V.K.; Wu, C.-C.; Prabhumirashi, P.L.; Geier, M.L.; Marks, T.J.; Lauhon, L.J.; Hersam, M.C. Gate-tunable carbon nanotube-MoS2 heterojunction p-n diode. Proc. Natl. Acad. Sci. USA 2013, 110, 18076–18080. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Seo, J.-W.T.; Xu, W.; Smith, J.; Kim, C.H.; Lauhon, L.J.; Marks, T.J.; Hersam, M.C. Large-Area, Low-Voltage, Antiambipolar Heterojunctions from Solution-Processed Semiconductors. Nano Lett. 2015, 15, 416–421. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.; Kim, J.-H.; Qian, C.; Kang, J.; Hersam, M.C.; Park, J.-H.; Cho, J.H. Gate-Tunable Synaptic Dynamics of Ferroelectric-Coupled Carbon-Nanotube Transistors. ACS Appl. Mater. Interfaces 2020, 12, 4707–4714. [Google Scholar] [CrossRef]

- Kobashi, K.; Hayakawa, R.; Chikyow, T.; Wakayama, Y. Negative Differential Resistance Transistor with Organic p-n Heterojunction. Adv. Electron. Mater. 2017, 3, 1700106. [Google Scholar] [CrossRef]

- Kim, B. Inkjet-Printed Ternary Inverter Circuits with Tunable Middle Logic Voltages. Adv. Electron. Mater. 2020, 6, 2000426. [Google Scholar] [CrossRef]

| Coating Polymers | p-Branch (Hole Transport) | n-Branch (Electron Transport) | ||||||

|---|---|---|---|---|---|---|---|---|

| µh a) [cm2/Vs] | VTh [V] | On/Off b) | Hysteresis c) [V] | µe a) [cm2/Vs] | VTe [V] | On/Off b) | Hysteresis c) [V] | |

| Ctrl | 4.22 ± 0.28 | −4.85 ± 0.07 | 105.6 ± 0.1 | 0.62 ± 0.05 | 2.47 ± 0.10 | 5.24 ± 0.11 | 105.4 ± 0.1 | 0.26 ± 0.05 |

| PS | 4.67 ± 0.22 | −4.56 ± 0.06 | 104.7 ± 0.1 | 0.16 ± 0.02 | 0.99 ± 0.12 | 5.15 ± 0.08 | 104.0 ± 0.1 | 0.05 ± 0.02 |

| PVC | 7.63 ± 0.24 | −4.89 ± 0.06 | 104.6 ± 0.1 | 0.21 ± 0.03 | 0.58 ± 0.08 | 5.78 ± 0.12 | 103.4 ± 0.1 | 0.08 ± 0.03 |

| PMMA | 1.34 ± 0.29 | −6.07 ± 0.10 | 105.0 ± 0.1 | 0.46 ± 0.06 | 3.59 ± 0.12 | 3.31 ± 0.22 | 105.7 ± 0.1 | 0.20 ± 0.06 |

| Formvar | 1.42 ± 0.22 | −5.15 ± 0.05 | 105.1 ± 0.1 | 0.32 ± 0.04 | 2.53 ± 0.07 | 4.82 ± 0.12 | 105.4 ± 0.1 | 0.11 ± 0.04 |

| PVdF | 0.96 ± 0.23 | −5.82 ± 0.08 | 100.9 ± 0.1 | 0.24 ± 0.05 | 61.1 ± 0.22 | 1.26 ± 0.12 | 103.0 ± 0.1 | 0.05 ± 0.02 |

| PAN | - | - | - | - | 96.7 ± 1.54 | −17.24 ± 1.35 | - | 0.36 ± 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Ngai, J.H.L.; Ding, J. Polymer Coating Enabled Carrier Modulation for Single-Walled Carbon Nanotube Network Inverters and Antiambipolar Transistors. Nanomaterials 2024, 14, 1477. https://doi.org/10.3390/nano14181477

Li Z, Ngai JHL, Ding J. Polymer Coating Enabled Carrier Modulation for Single-Walled Carbon Nanotube Network Inverters and Antiambipolar Transistors. Nanomaterials. 2024; 14(18):1477. https://doi.org/10.3390/nano14181477

Chicago/Turabian StyleLi, Zhao, Jenner H. L. Ngai, and Jianfu Ding. 2024. "Polymer Coating Enabled Carrier Modulation for Single-Walled Carbon Nanotube Network Inverters and Antiambipolar Transistors" Nanomaterials 14, no. 18: 1477. https://doi.org/10.3390/nano14181477

APA StyleLi, Z., Ngai, J. H. L., & Ding, J. (2024). Polymer Coating Enabled Carrier Modulation for Single-Walled Carbon Nanotube Network Inverters and Antiambipolar Transistors. Nanomaterials, 14(18), 1477. https://doi.org/10.3390/nano14181477