Systematic Study of Reaction Conditions for Size-Controlled Synthesis of Silica Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Silica Nanoparticle Synthesis

- -

- varied the ammonia concentration between 0.29 mol/dm3 and 0.097 mol/dm3, at a constant water concentration (5 mol/dm3) and a constant temperature (25 °C)

- -

- varied the water concentration between 2 mol/dm3 and 5 mol/dm3 at a constant ammonia concentration (0.29/0.194/0.097 mol/dm3) and a constant temperature (25 °C)

- -

- varied the temperature between 25 °C and 50 °C at a constant ammonia concentration (0.29/0.194/0.097 mol/dm3) and a constant water concentration (5 mol/dm3)

2.3. Characterization of Silica Nanoparticles

2.4. Statistical Analysis

3. Results

4. Discussion

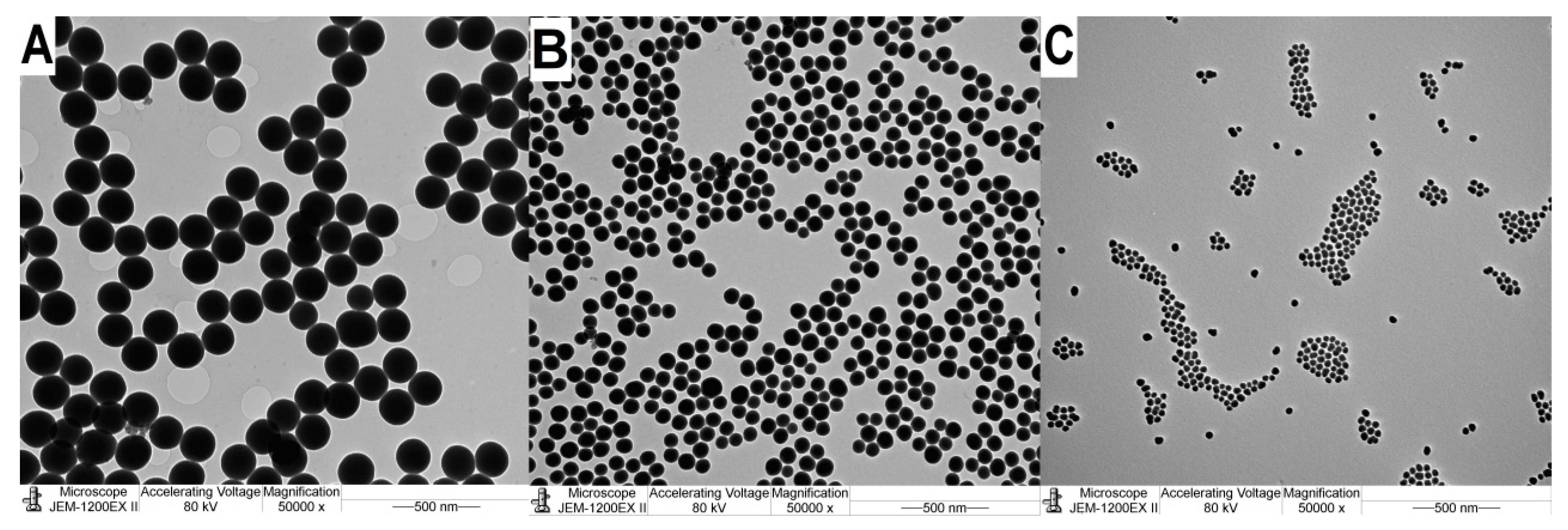

4.1. Influence of Ammonium Hydroxide Concentration

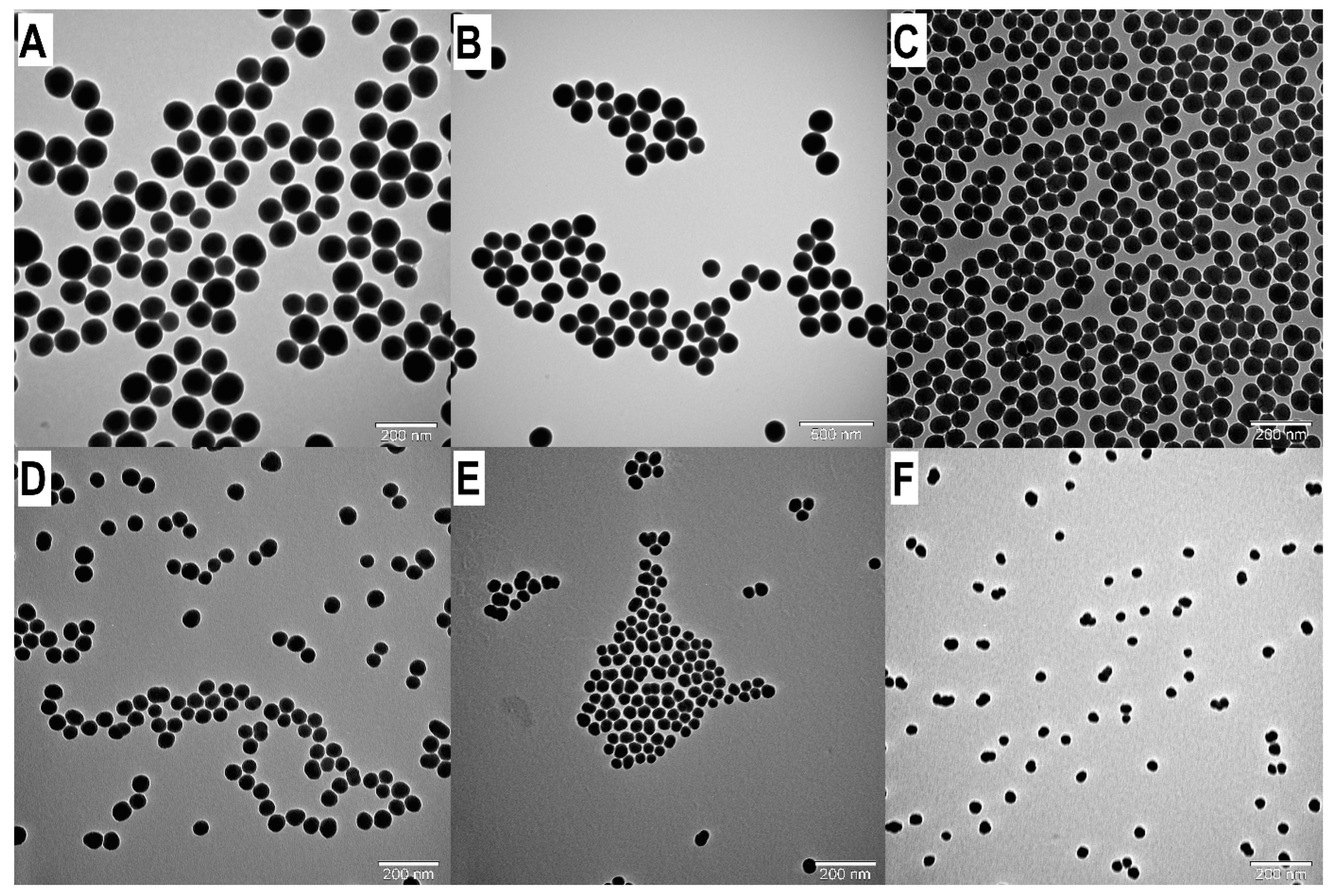

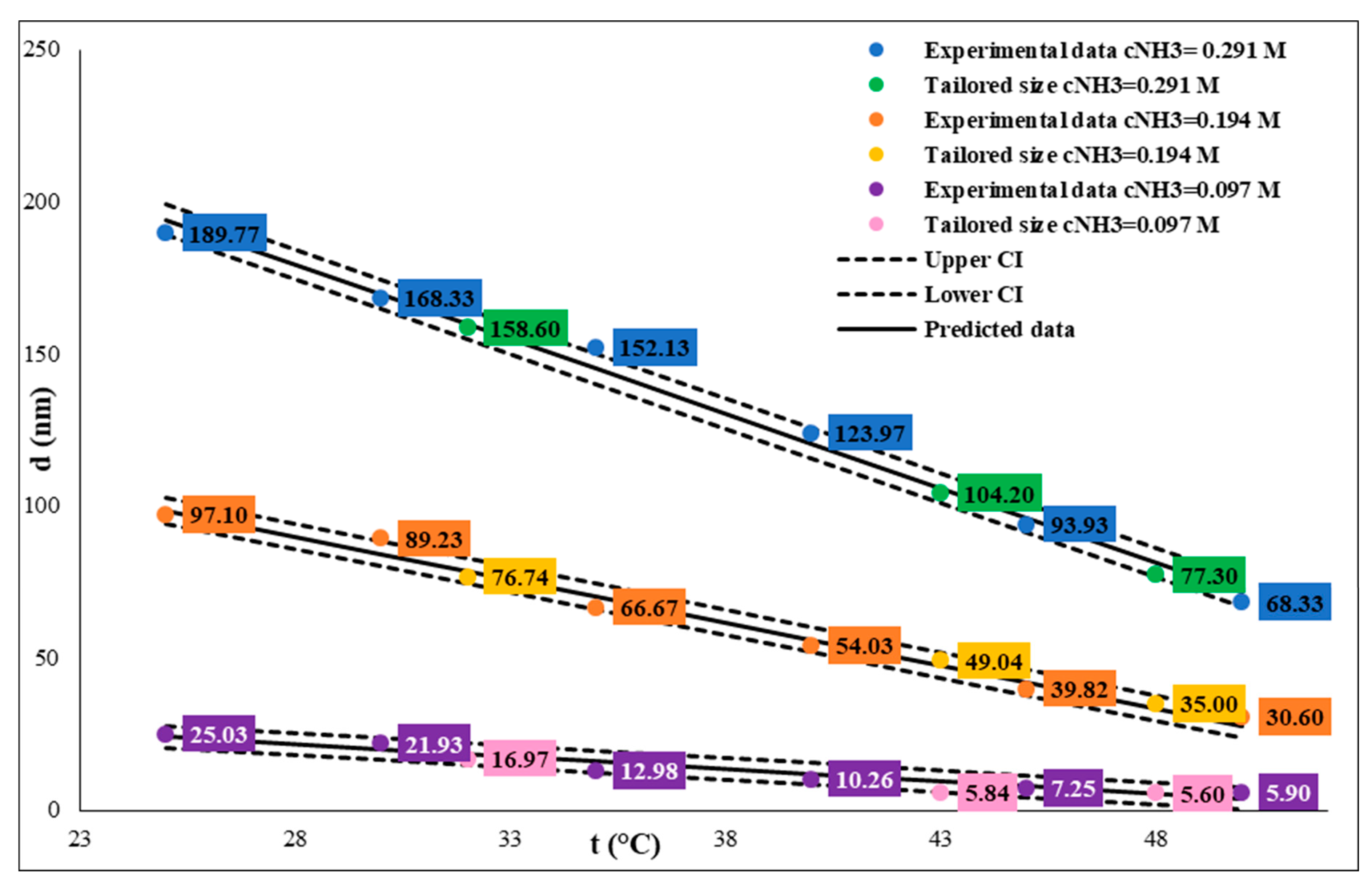

4.2. Influence of Temperature

4.3. Influence of Water Concentration

4.4. Practical Implications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, T.; Malugin, A.; Ghandehari, H. Impact of Silica Nanoparticle Design on Cellular Toxicity and Hemolytic Activity. ACS Nano 2011, 5, 5717–5728. [Google Scholar] [CrossRef] [PubMed]

- Sperling, R.A.; Parak, W.J. Surface modification, functionalization and bioconjugation of colloidal inorganic nanoparticles. Philos. Trans. R. Soc. 2010, 368, 1333–1383. [Google Scholar] [CrossRef] [PubMed]

- Bharti, C.; Nagaich, U.; Pal, A.K.; Gulati, N. Mesoporous silica nanoparticles in target drug delivery system: A review. Int. J. Pharm. Investig. 2015, 5, 124–133. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wu, M.; Zhao, J.X. Recent Development of Silica Nanoparticles as Delivery Vectors for Cancer Imaging and Therapy. Nanomedicine 2014, 10, 297–312. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Chen, D.; Song, H.; Li, Y.; Fuab, Z.; Su, Y. High-performance Pd–Au bi-metallic catalyst with mesoporous silica nanoparticles as support and its catalysis of cinnamaldehyde hydrogena-tion. J. Catal. 2012, 291, 36–43. [Google Scholar] [CrossRef]

- Korzeniowska, B.; Nooney, R.; Wencel, D.; McDonagh, C. Silica nanoparticles for cell imaging and intracellular sensing. Nanotechnology 2013, 24, 442002. [Google Scholar] [CrossRef]

- Tan, W.; Wang, K.; He, X.; Zhao, X.J.; Drake, T.; Wang, L.; Bagwe, R.P. Bionan-otechnology based on silica nanoparticles. Med. Res. Rev. 2004, 24, 621–638. [Google Scholar] [CrossRef]

- Matsoukas, T.; Gulari, E. Monomer-addition growth with a slow initiation step: A growth model for silica particles from alkoxides. J. Colloid. Interface Sci. 1989, 132, 13–21. [Google Scholar] [CrossRef]

- Matsoukas, T.; Gulari, E. Dynamics of growth of silica particles from ammonia-catalyzed hydrolysis of tetra-ethyl-orthosilicate. J. Colloid. Interface Sci. 1988, 124, 252–261. [Google Scholar] [CrossRef]

- Bogush, G.; Zukoski, C. Studies of the Kinetics of the Precipitation of Uniform Silica Particles through the Hydrolysis and Condensation of Silicon Alkoxides. J. Colloid. Interface Sci. 2005, 289, 125–131. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron sized range. J. Colloid. Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Wang, X.-D.; Shen, Z.-X.; Sang, T.; Cheng, X.-B.; Li, M.-F.; Chen, L.-Y.; Wang, Z.-S. Preparation of spherical silica particles by Stöber process with high concentration of tetra-ethyl-orthosilicate. J. Colloid. Interface Sci. 2010, 341, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Park, S.K.; Kim, K.D.; Kim, H.T. Preparation of silica nanoparticles: Determination of the optimal synthesis conditions for small and uniform particles. Colloids Surf. A Physicochem. Eng. Asp. 2002, 197, 7–17. [Google Scholar] [CrossRef]

- Meier, M.; Ungerer, J.; Klinge, M.; Nirschl, H. Synthesis of nanometric silica particles via a modified Stöber synthesis route. Colloids Surf. A 2018, 538, 559–564. [Google Scholar] [CrossRef]

- Singh, L.P.; Bhattacharyya, S.K.; Kumar, R.; Mishra, G.; Sharma, U.; Singh, G.; Ahalawat, S. Sol-Gel processing of silica nanoparticles and their applications. Adv. Colloid. Interface Sci. 2014, 214, 17–37. [Google Scholar] [CrossRef]

- Nozawa, K.; Gailhanou, H.; Raison, L.; Panizza, P.; Ushiki, H.; Sellier, E.; Delville, J.P.; Delville, M.H. Smart Control of Monodisperse Stöber Silica Particles: Effect of Reactant Addition Rate on Growth Process. Langmuir 2005, 21, 1516–1523. [Google Scholar] [CrossRef]

- Green, D.L.; Lin, J.S.; Lam, Y.F.; Hu, M.C.; Schaefer, D.W.; Harris, M.T. Size, volume fraction, and nucleation of Stöber silica nanoparticles. J. Colloid. Interface Sci. 2003, 266, 346–358. [Google Scholar] [CrossRef]

- Plumeré, N.; Ruff, A.; Speiser, B.; Feldmann, V.; Mayer, H.A. Stöber silica particles as basis for redox modifica-tions: Particle shape, size, polydispersity, and porosity. J. Colloid. Interface Sci. 2012, 368, 208–219. [Google Scholar] [CrossRef]

- Chen, S.; Dong, P.; Yang, G.; Yang, J. Kinetics of formation of monodisperse colloidal silica particles through the hydrolysis and condensation of tetraethylorthosilicate. Ind. Eng. Chem. Res. 1996, 35, 208–219. [Google Scholar] [CrossRef]

- Tan, C.G.; Bowen, B.D.; Epstein, N. Production of monodisperse colloidal silica spheres: Effect of temperature. J. Colloid. Interface Sci. 1987, 118, 290. [Google Scholar] [CrossRef]

- Rahman, I.A.; Vejayakumaran, P.; Sipaut, C.S.; Ismail, J.; Bakar, M.A.; Adnan, R.; Chee, C.K. An optimized sol–gel synthesis of stable primary equivalent silica particles. Colloids Surf. A 2007, 294, 102–110. [Google Scholar] [CrossRef]

- Kim, K.D.; Kim, H.T. Formation of silica nanoparticles by hydrolysis of TEOS using a mixed semi-batch/batch method. J. Sol–Gel Sci. Technol. 2002, 25, 183–189. [Google Scholar] [CrossRef]

- Lindberg, R.; Sjöblom, J.; Sundholm, G. Preparation of silica particles utilizing the sol-gel and the emulsion-gel processes. Colloids Surf. A Physicochem. Eng. Asp. 1995, 99, 79–88. [Google Scholar] [CrossRef]

- Bogush, G.H.; Traycy, M.A.; Zukoski, C.F. Preparation of monodisperse silica particles: Control of size and mass fraction. J. Non-Cryst. Solids 1988, 104, 95–106. [Google Scholar] [CrossRef]

| Sample | cNH3 (mol/dm3) | cH2O (mol/dm3) | t (°C) | dDLS (nm) | PDIDLS | dTEM (nm) | PDITEM |

|---|---|---|---|---|---|---|---|

| A1 | 0.291 | 5 | 25 | 190.80 ± 0.93 | 0.008 | 191.38 | 0.003 |

| A2 | 0.194 | 99.09 ± 1.15 | 0.021 | 91.72 | 0.006 | ||

| A3 | 0.097 | 27.05 ± 0.80 | 0.082 | 28.33 | 0.005 | ||

| T30A | 0.291 | 5 | 30 | 170.50 ± 1.17 | 0.002 | 169.75 | 0.001 |

| T30B | 0.194 | 88.60 ± 1.05 | 0.018 | 81.85 | 0.004 | ||

| T30C | 0.097 | 22.51 ± 0.25 | 0.095 | 23.19 | 0.002 | ||

| T35A | 0.291 | 5 | 35 | 153.60 ± 0.91 | 0.014 | 155.12 | 0.007 |

| T35B | 0.194 | 67.81 ± 0.77 | 0.005 | 64.53 | 0.015 | ||

| T35C | 0.097 | 12.08 ± 0.06 | 0.146 | 14.06 | 0.026 | ||

| T40A | 0.291 | 5 | 40 | 142.70 ± 1.02 | 0.023 | 145.17 | 0.008 |

| T40B | 0.194 | 56.11 ± 0.85 | 0.041 | 55.42 | 0.003 | ||

| T40C | 0.097 | 10.43 ± 0.12 | 0.226 | 10.99 | 0.018 | ||

| T45A | 0.291 | 5 | 45 | 96.35 ± 0.99 | 0.041 | 95.91 | 0.008 |

| T45B | 0.194 | 41.87 ± 0.75 | 0.048 | 42.14 | 0.007 | ||

| T45C | 0.097 | 7.49 ± 1.04 | 0.467 | 6.53 | 0.019 | ||

| T50A | 0.291 | 5 | 50 | 69.32 ± 0.88 | 0.016 | 67.80 | 0.012 |

| T50B | 0.194 | 30.15 ± 0.69 | 0.455 | 31.96 | 0.031 | ||

| T50C | 0.097 | 6.11 ± 0.20 | 0.455 | 8.91 | 0.074 | ||

| W4A | 0.291 | 4 | 25 | 142.70 ± 3.34 | 0.041 | 146.62 | 0.004 |

| W4B | 0.194 | 58.97 ± 1.58 | 0.043 | 60.29 | 0.002 | ||

| W4C | 0.097 | 9.54 ± 1.15 | 0.263 | 20.27 | 0.008 | ||

| W3A | 0.291 | 3 | 25 | 58.50 ± 2.17 | 0.061 | 54.74 | 0.010 |

| W3B | 0.194 | 34.50 ± 2.08 | 0.095 | 33.60 | 0.011 | ||

| W3C | 0.097 | 7.58 ± 1.64 | 0.190 | 15.71 | 0.006 | ||

| W2A | 0.291 | 2 | 25 | 52.18 ± 3.72 | 0.059 | 50.74 | 0.013 |

| W2B | 0.194 | 27.81 ± 8.16 | 0.073 | 28.2 | 0.013 | ||

| W2C | 0.097 | 6.92 ± 2.23 | 0.250 | 6.55 | 0.019 |

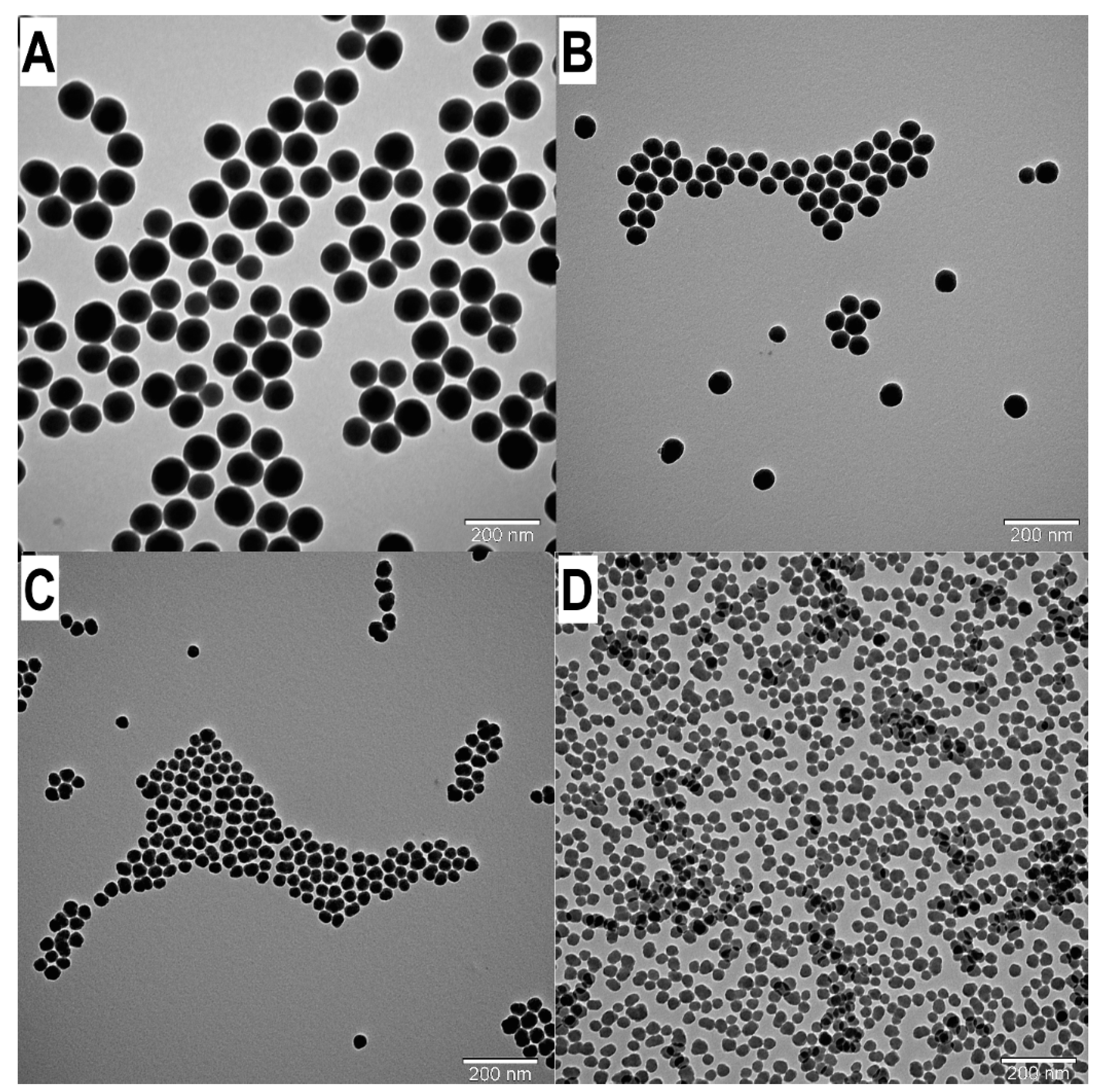

| Sample | cNH3 (mol/dm3) | cH2O (mol/dm3) | t (°C) | dcal (nm) | dDLS (nm) | PDIDLS |

|---|---|---|---|---|---|---|

| T32A | 0.291 | 5 | 32 | 160.92 | 158.60 | 0.024 |

| T32B | 0.194 | 79.61 | 76.70 | 0.043 | ||

| T32C | 0.097 | 19.04 | 17.00 | 0.143 | ||

| T43A * | 0.291 | 5 | 43 | 106.82 | 104.20 | 0.059 |

| T43B * | 0.194 | 48.35 | 49.00 | 0.065 | ||

| T43C * | 0.097 | 9.52 | 5.80 | 0.070 | ||

| T48A | 0.291 | 5 | 48 | 77.3 | 57.33 | 0.004 |

| T48B | 0.194 | 35.0 | 35.00 | 0.093 | ||

| T48C | 0.097 | 5.19 | 5.60 | 0.245 | ||

| W4.5A | 0.291 | 4.5 | 25 | 158.44 | 159.40 | 0.028 |

| W4.5B | 0.194 | 78.88 | 73.64 | 0.068 | ||

| W4.5C | 0.097 | 18.01 | 20.54 | 0.090 | ||

| W3.5A | 0.291 | 3.5 | 25 | 97.99 | 89.07 | 0.026 |

| W3.5B | 0.194 | 46.24 | 40.24 | 0.051 | ||

| W3.5C | 0.097 | 7.51 | 7.80 | 0.176 | ||

| W2.5A | 0.291 | 2.5 | 25 | 58.44 | 55.78 | 0.057 |

| W2.5B | 0.194 | 30.30 | 32.09 | 0.081 | ||

| W2.5C | 0.097 | 5.30 | 5.82 | 0.227 |

| cNH3 (mol/dm3) | Linear Regression | CI | R2 |

|---|---|---|---|

| 0.291 M | y = −4.906x + 316.720 | 93% | 0.9909 |

| 0.194 M | y = −2.819x + 168.630 | 95% | 0.9846 |

| 0.0197 M | y = −0.814x + 44.412 | 92% | 0.9326 |

| cNH3 (mol/dm3) | Linear Regression | CI | R2 |

|---|---|---|---|

| 0.291 M | y = 63.998x + 127.057 | 99% | 0.9566 |

| 0.194 M | y = 37.222x + 96.647 | 95% | 0.9906 |

| 0.097 M | y = 12.514x + 34.427 | 95% | 0.9350 |

| cNH3 (mol/dm3) | Linear Regression | CI | R2 |

|---|---|---|---|

| 0.291 M | y = 7.623x + 35.940 | 99% | 0.9679 |

| 0.194 M | y = 8.931x + 8.730 | 95% | 0.9793 |

| 0.097 M | y = 1.726x + 1.840 | 95% | 0.9385 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vörös-Horváth, B.; Salem, A.; Kovács, B.; Széchenyi, A.; Pál, S. Systematic Study of Reaction Conditions for Size-Controlled Synthesis of Silica Nanoparticles. Nanomaterials 2024, 14, 1561. https://doi.org/10.3390/nano14191561

Vörös-Horváth B, Salem A, Kovács B, Széchenyi A, Pál S. Systematic Study of Reaction Conditions for Size-Controlled Synthesis of Silica Nanoparticles. Nanomaterials. 2024; 14(19):1561. https://doi.org/10.3390/nano14191561

Chicago/Turabian StyleVörös-Horváth, Barbara, Ala’ Salem, Barna Kovács, Aleksandar Széchenyi, and Szilárd Pál. 2024. "Systematic Study of Reaction Conditions for Size-Controlled Synthesis of Silica Nanoparticles" Nanomaterials 14, no. 19: 1561. https://doi.org/10.3390/nano14191561