Employing Manganese Dioxide and Bamboo Carbon for Capacitive Water Desalination and Disinfection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of BC@MnO2-X

2.3. Characterization

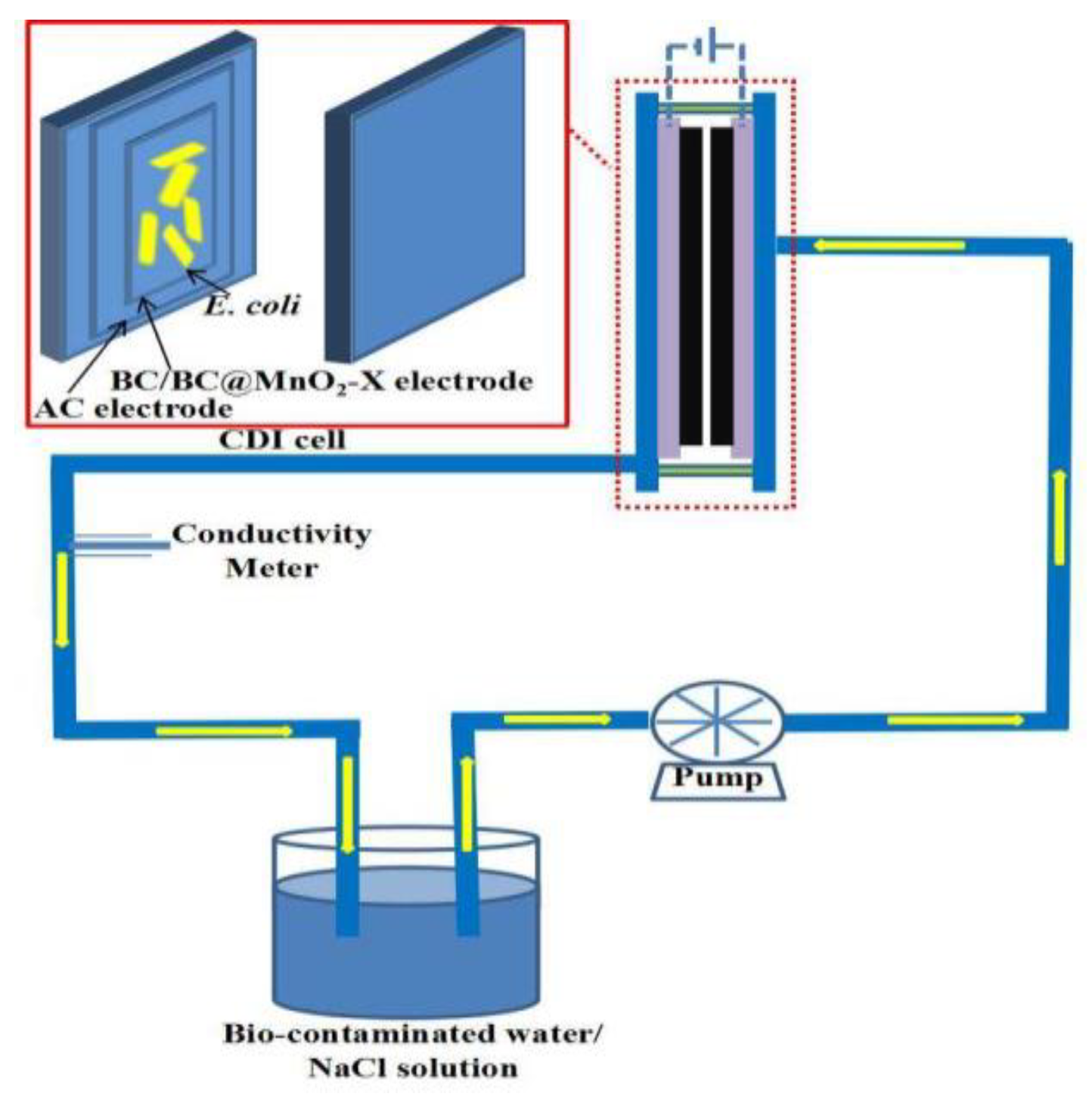

2.4. CDI Electrode Fabrication

2.5. CDI Experiments

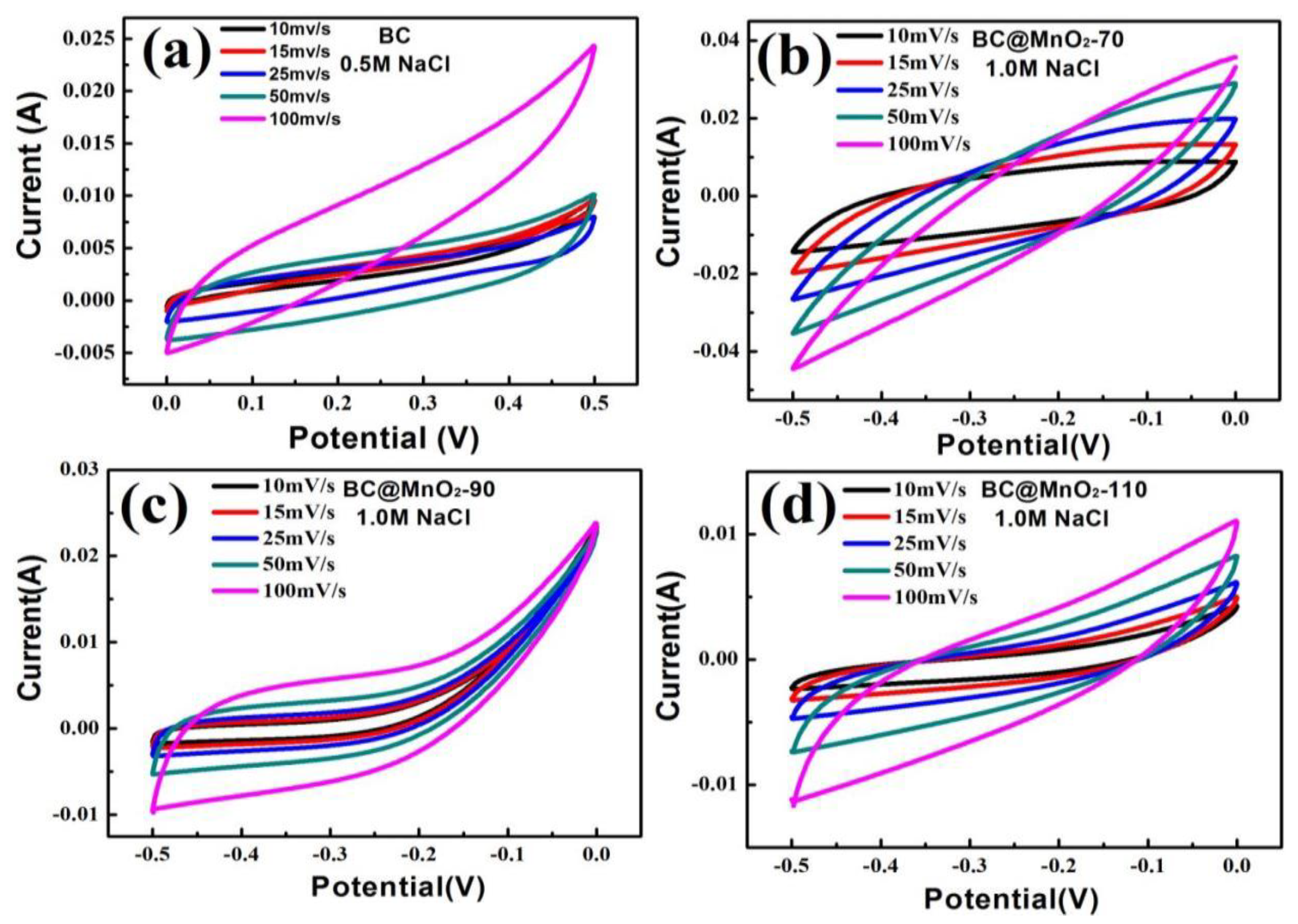

2.6. Electrochemical Measurements

2.7. Preparation of Microbial Cells

2.8. In Vitro Culture

2.9. CDI Percent Killing Calculation

3. Results and Discussion

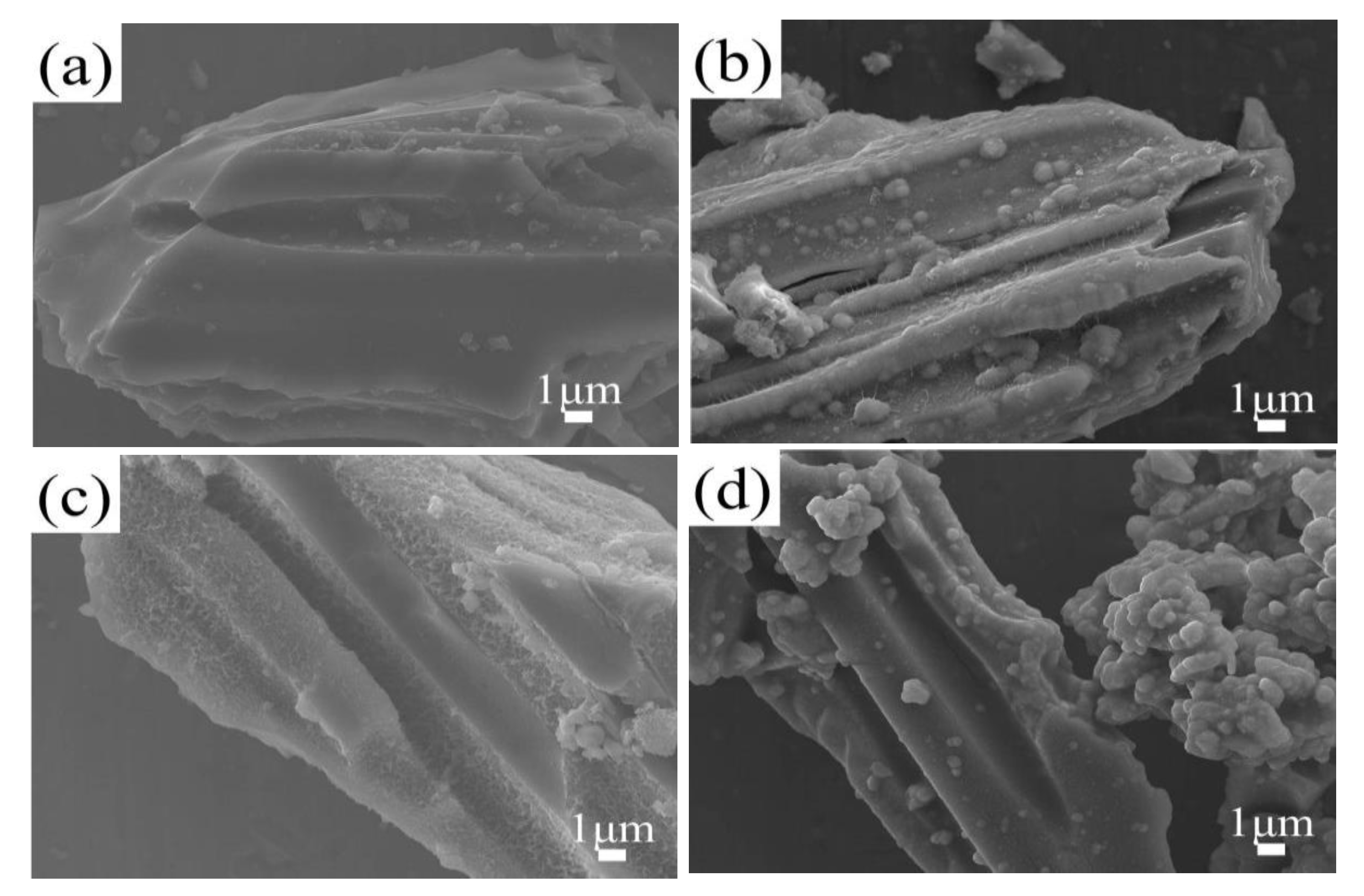

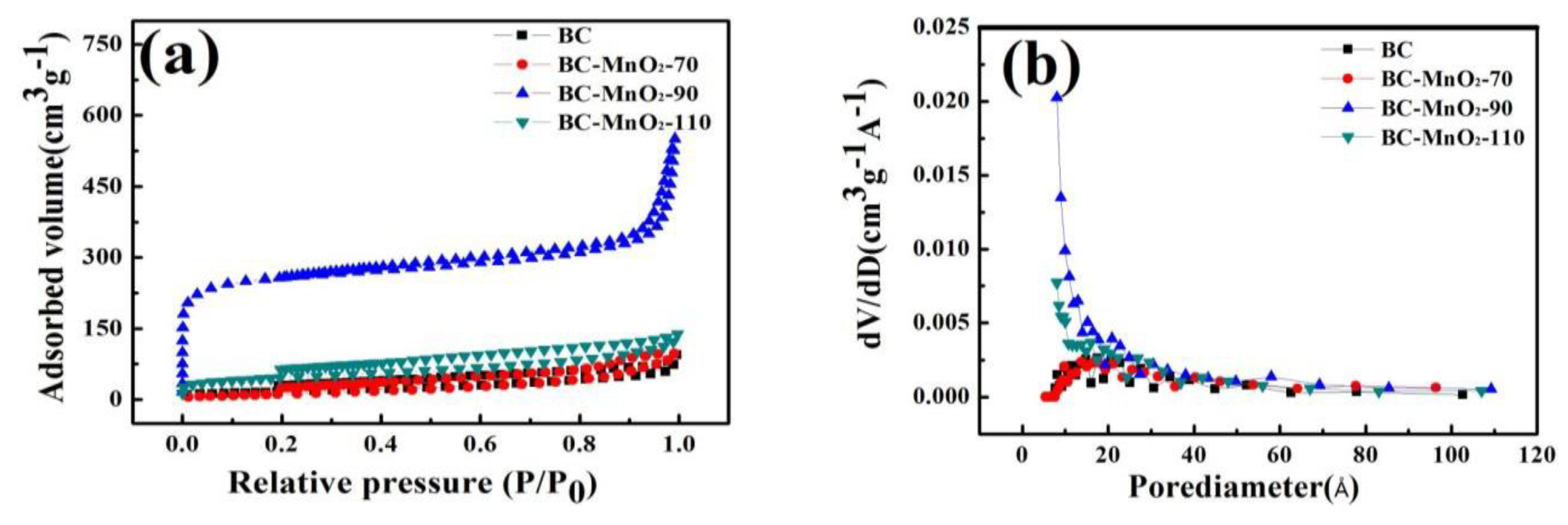

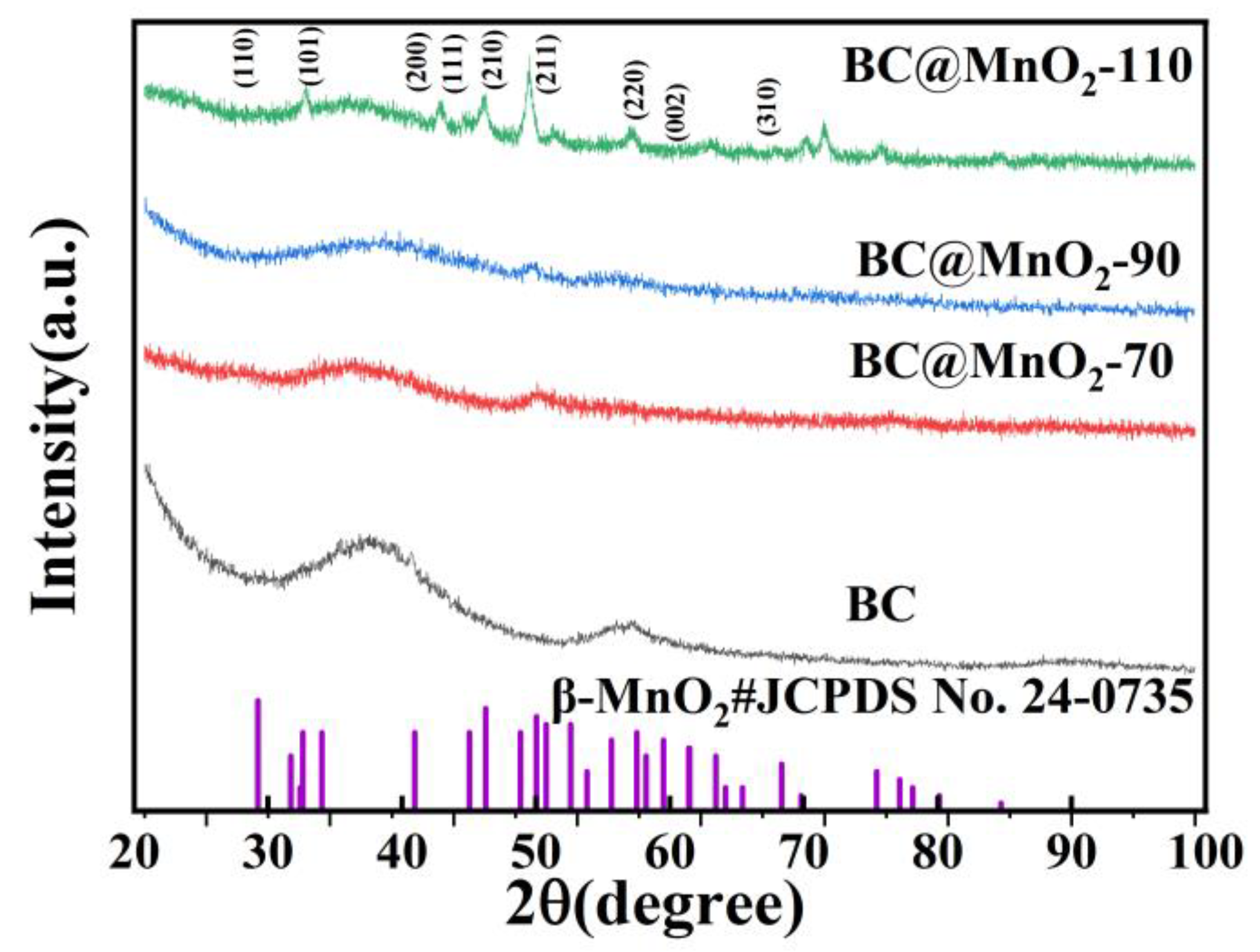

3.1. Characterization of BC and BC@MnO2-X

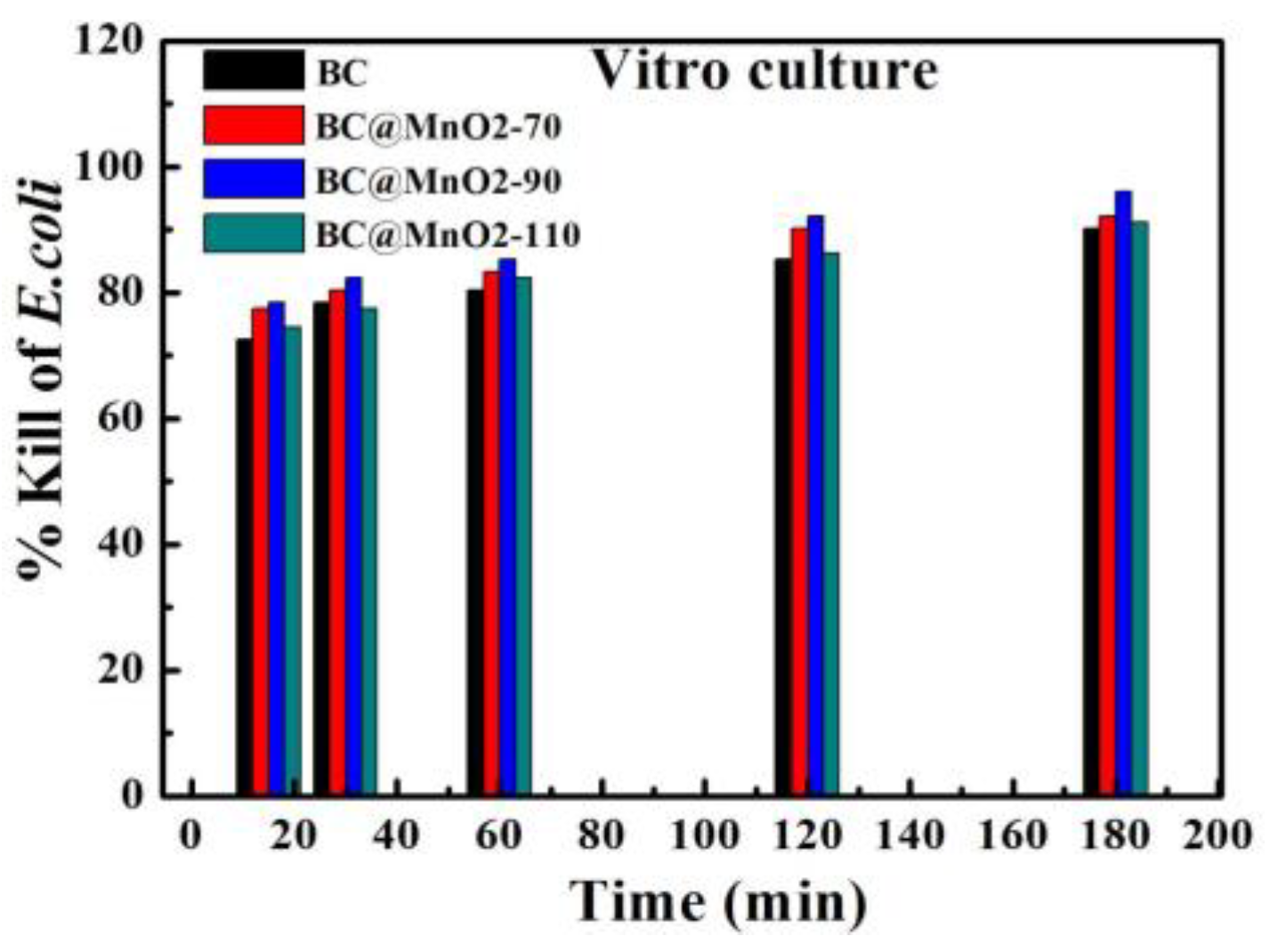

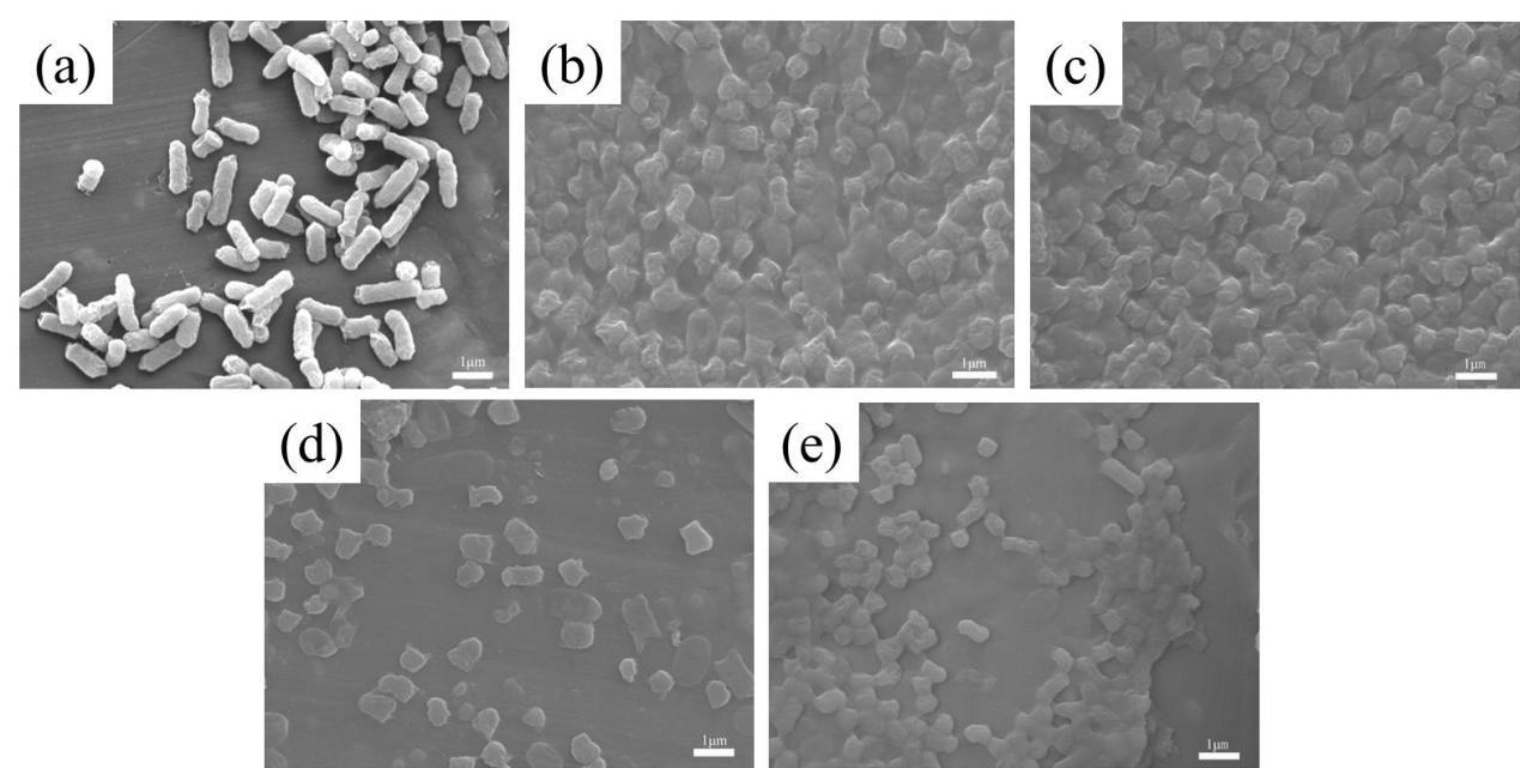

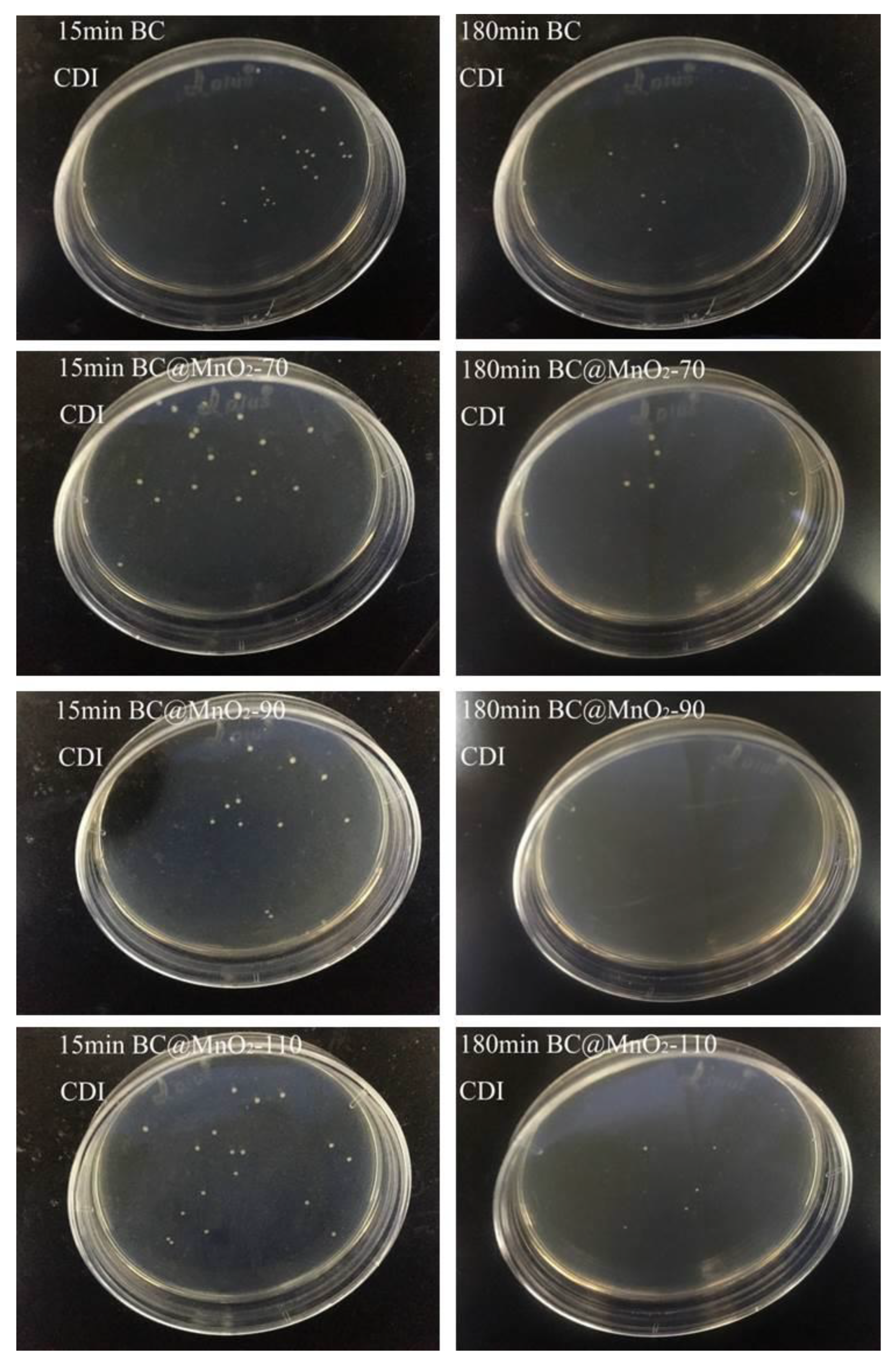

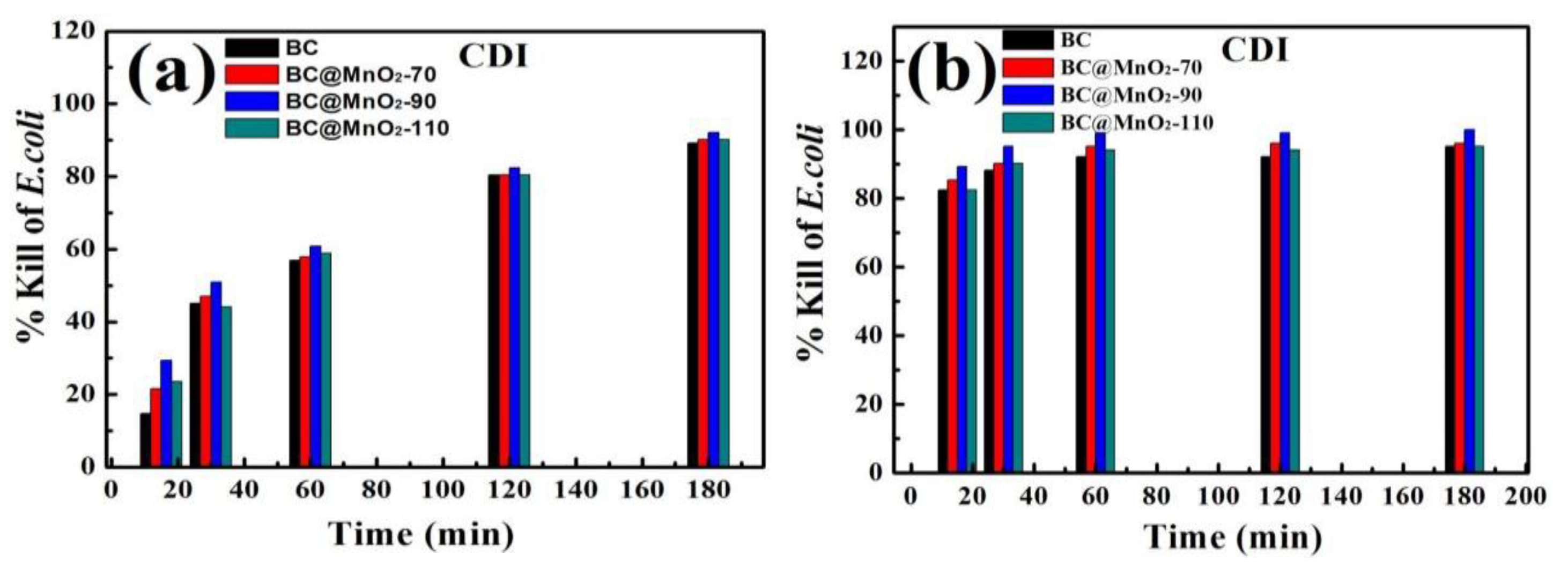

3.2. Antimicrobial Activity

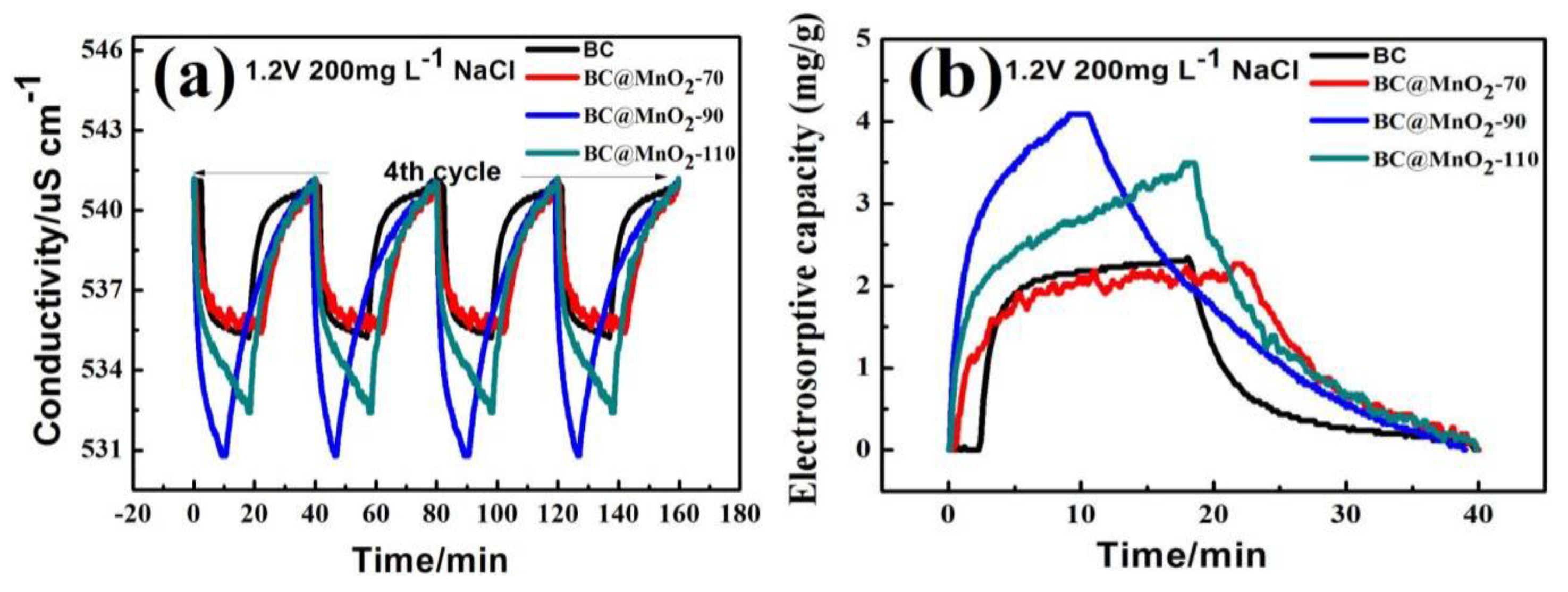

3.3. CDI Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, J.; Shi, J.; Chen, L.; Zhang, Z.; Kuang, E. Exploring the spatial spillover effects of Yangtze River Delta ports on urban economic growth. PLoS ONE 2024, 19, e0307770. [Google Scholar] [CrossRef]

- Sinha, S.; Ahmad, R.; Chowdhury, K.; Ferdaus, F.; Banik, S.; Mehta, M.; Kumar, S.; Haq, A.; Haque, M. The Impact of Saline Water on Women’s Health in the Coastal Region of Bangladesh: Special Attention on Menstrual Hygiene Practices. Cureus 2024, 16, e67032. [Google Scholar] [CrossRef]

- Hepditch, S.; Gutierrez-Villagomez, J.; To, T.; Larocque, E.; Xin, Q.; Heshka, N.; Meulen, I.V.; Headley, J.; Dettman, H.; Triffault-Bouchet, G.; et al. Aquatic toxicity and chemical fate of diluted bitumen spills in freshwater under natural weathering. Environ. Int. 2024, 190, 108944. [Google Scholar] [CrossRef]

- Shen, Z.; Cui, J.; Li, J.; Peng, Y.; Li, J.; Liang, Y.; Zhou, Y.; Zhang, Z.; Sun, L.; Yao, D. Typical alien invasive aquatic-plant species changed the stability rather than the diversity of plankton community in fresh water. Sci. Total Environ. 2024, 951, 175490. [Google Scholar] [CrossRef]

- Hu, P.; Qian, Y.; Xu, Y.; Radian, A.; Yang, Y.; Gu, J.D. A positive contribution to nitrogen removal by a novel NOB in a full-scale duck wastewater treatment system. Water Res. X 2024, 24, 100237. [Google Scholar] [CrossRef]

- Liu, H.; Yu, J. Ozonation degradation of wastewater using rotational hydrodynamic cavitation reactor with a conical rotor. Environ. Technol. 2024, 19, 1–16. [Google Scholar] [CrossRef]

- Xiao, J.; Dong, H.; Li, Y.; Li, L.; Chu, D.; Xiang, S.; Hou, X.; Dong, Q.; Xiao, S.; Jin, Z.; et al. Graphene shell-encapsulated copper-based nanoparticles (G@Cu-NPs) effectively activate peracetic acid for elimination of sulfamethazine in water under neutral condition. J. Hazard. Mater. 2023, 441, 129895. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, M.; Jia, R.; Zhao, Q.; Liu, L.; Sun, S. Comparison of UV-based advanced oxidation processes for the removal of different fractions of NOM from drinking water. J. Environ. Sci. 2023, 126, 387–395. [Google Scholar] [CrossRef]

- Hu, Z.; Jia, Y.; Wu, Y.; Zhang, Y. Occurrence and removal technologies of perchlorate in water: A systematic review and bibliometric analysis. Chemosphere 2024, 16, 143119. [Google Scholar] [CrossRef]

- Yu, Y.; Hossain, M.M.; Sikder, R.; Qi, Z.; Huo, L.; Chen, R.; Dou, W.; Shi, B.; Ye, T. Exploring the potential of machine learning to understand the occurrence and health risks of haloacetic acids in a drinking water distribution system. Sci. Total Environ. 2024, 951, 175573. [Google Scholar] [CrossRef]

- Anderson, B.N.; Black, G.P.; Young, T.M. Disinfection Byproducts in Drinking Water from the Tap: Variability in Household Calculated Additive Toxicity (CAT). ACS EST Water 2024, 4, 3532–3539. [Google Scholar] [CrossRef]

- Tang, Y.; Shi, Y.; Su, Y.; Cao, S.; Hu, J.; Zhou, H.; Sun, Y.; Liu, Z.; Zhang, S.; Xue, H.; et al. Enhanced Capacitive Deionization of Hollow Mesoporous Carbon Spheres/MOFs Derived Nanocomposites by Interface-Coating and Space-Encapsulating Design. Adv. Sci. 2024, 11, e2403802. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, Y.J.; Cai, N.; Xue, J.Q. A novel composite electrode with multiple pore structures for efficient treatment of heavy metal ions in capacitive deionization. J. Environ. Manag. 2024, 367, 121974–121988. [Google Scholar] [CrossRef]

- Cheng, F.L.; Wang, Y.Q.; Cai, C.Y.; Fu, Y. Multiscale MXene Engineering for Enhanced Capacitive Deionization via Adaptive Surface Charge Tailoring. Nano Lett. 2024, 24, 9477–9486. [Google Scholar] [CrossRef]

- Li, H.L.; Zhang, S.H.; Liu, B.H.; Li, X.H.; Shang, N.Z.; Zhao, X.X.; Eguchi, M.; Yamauchi, Y.; Xu, X.T. Nanoarchitectonics of ultrafine molybdenum carbide nanocrystals into three-dimensional nitrogen-doped carbon framework for capacitive deionization. Chem. Sci. 2024, 15, 11540–11550. [Google Scholar] [CrossRef]

- Lim, Y.J.; Goh, K.; Goto, A.; Zhao, Y.; Wang, R. Uranium and lithium extraction from seawater: Challenges and opportunities for a sustainable energy future. J. Mater. Chem. A 2023, 11, 22551. [Google Scholar] [CrossRef]

- Yoon, H.; Min, T.; Kim, S.H.; Lee, G.; Oh, D.; Choi, D.C.; Kim, S. Effect of activated carbon electrode material characteristics on hardness control performance of membrane capacitive deionization. RSC Adv. 2023, 13, 31480–31486. [Google Scholar] [CrossRef]

- Mashhadi, M.E.; Mozaffarian, M.; Mohseni, M.; Jafarikojour, M.; Dabir, B. Evaluation of synergistic effects of coupling capacitive deionization (CDI) and UV oxidation processes for saline water treatment. J. Environ. Chem. Eng. 2022, 10, 106909. [Google Scholar] [CrossRef]

- Huang, T.F.; Qiu, Z.H.; Wh, D.W.; Hu, Z.B. Bamboo-based activated carbon@MnO2 nanocomposites for flexible high-performance supercapacitor electrode materials. Int. J. Electrochem. Sci. 2015, 10, 6312–6323. [Google Scholar] [CrossRef]

- Zhang, Y.; Yao, Q.Q.; Gao, H.L.; Zhang, L.S.; Wang, L.Z.; Zhang, A.Q.; Song, Y.H.; Wang, L.X. Synthesis and electrochemical performance of MnO2/BC composite as active materials for supercapacitors. J. Anal. Appl. Pyrol. 2015, 111, 233–237. [Google Scholar] [CrossRef]

- Wen, Y.X.; Qin, T.F.; Wang, Z.L.; Jiang, X.Y.; Peng, S.L.; Zhang, J.C.; Hou, J.; Huang, F.; He, D.Y.; Cao, G.Z. Self-supported binder-free carbon fibers/MnO2 electrodes derived from disposable bamboo chopsticks for high-performance supercapacitors. J. Alloys Compd. 2017, 699, 126–135. [Google Scholar] [CrossRef]

- Diaz-Teran, J.; Nevskaia, D.M.; Fierro, J.L.G.; Lopez-Peinado, A.J.; Jerez, A. Study of chemical activation process of a lignocellulosic material with KOH by XPS and XRD. Microporous Mesoporous Mater. 2003, 60, 173–181. [Google Scholar] [CrossRef]

- Zhou, X.; Li, L.; Dong, S.; Chen, X.; Han, P.; Xu, H.; Yao, J.; Shang, C.; Liu, Z.; Cui, G. A renewable bamboo carbon/polyaniline composite for a high-performance supercapacitor electrode material. J. Solid State Electr. 2012, 16, 877–882. [Google Scholar] [CrossRef]

- Hao, P.; Zhao, Z.H.; Tian, J.; Li, H.D.; Sang, Y.H.; Yu, G.W.; Cai, H.Q.; Liu, H.; Wong, C.P.; Umar, A. Hierarchical porous carbon aerogel derived from bagasse for high-performance supercapacitor electrode. Nanoscale 2014, 6, 12120–12129. [Google Scholar] [CrossRef] [PubMed]

- Dawei, S.; Hyo-Jun, A.; Guoxiu, W. β-MnO2 nanorods with exposed tunnel structures as high-performance cathode materials for sodium-ion batteries. NPG Asia Mater. 2013, 5, e70. [Google Scholar]

- Agartan, L.; Hayes-Oberst, B.; Byles, B.W.; Akuzum, B.; Pomerantseva, E.; Kumbur, E.C. Influence of operating conditions and cathode parameters on desalination performance of hybrid CDI systems. Desalination 2018, 452, 1–8. [Google Scholar] [CrossRef]

- Ricardo, M.H.; Jan, W.; Muhammad, U.A.; Ali, R.K.; Steffen, F.; Stefan, K.; Viktor, Č. The determination of the electrochemically active surface area and its effects on the electrocatalytic properties of structured nickel electrodes produced by additive manufacturing. Electrochim. Acta 2024, 476, 143663. [Google Scholar]

- Zheng, X.; Zhong, T.; Zhao, H.; Huang, F.; Huang, W.; Hu, L.; Xia, D.; Tian, S.; Shu, D.; He, C. MnO2-based capacitive system enhances ozone inactivation of bacteria by disrupting cell membrane. Water Res. 2024, 256, 121608. [Google Scholar] [CrossRef]

- Wang, L.; He, H.; Zhang, C.; Sun, L.; Liu, S.; Wang, S. Antimicrobial activity of silver loaded MnO2 nanomaterials with different crystal phases against Escherichia coli. J. Environ. Sci. 2016, 41, 112–120. [Google Scholar] [CrossRef]

| Sample | SBET (m2/g) | Vtot (cm3/g) | Dpore (Å) |

|---|---|---|---|

| BC | 122.50 | 0.06 | 56.70 |

| BC@MnO2-70 | 101.82 | 0.15 | 29.70 |

| BC@MnO2-90 | 192.83 | 0.49 | 51.80 |

| BC@MnO2-110 | 118.13 | 0.15 | 25.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, C.; Wu, X.; Zheng, Y.; Zhang, L.; Chen, Y. Employing Manganese Dioxide and Bamboo Carbon for Capacitive Water Desalination and Disinfection. Nanomaterials 2024, 14, 1565. https://doi.org/10.3390/nano14191565

Cao C, Wu X, Zheng Y, Zhang L, Chen Y. Employing Manganese Dioxide and Bamboo Carbon for Capacitive Water Desalination and Disinfection. Nanomaterials. 2024; 14(19):1565. https://doi.org/10.3390/nano14191565

Chicago/Turabian StyleCao, Cuihui, Xiaofeng Wu, Yuming Zheng, Lizhen Zhang, and Yunfa Chen. 2024. "Employing Manganese Dioxide and Bamboo Carbon for Capacitive Water Desalination and Disinfection" Nanomaterials 14, no. 19: 1565. https://doi.org/10.3390/nano14191565