Study on Electrical and Temperature Characteristics of β-Ga2O3-Based Diodes Controlled by Varying Anode Work Function

Abstract

1. Introduction

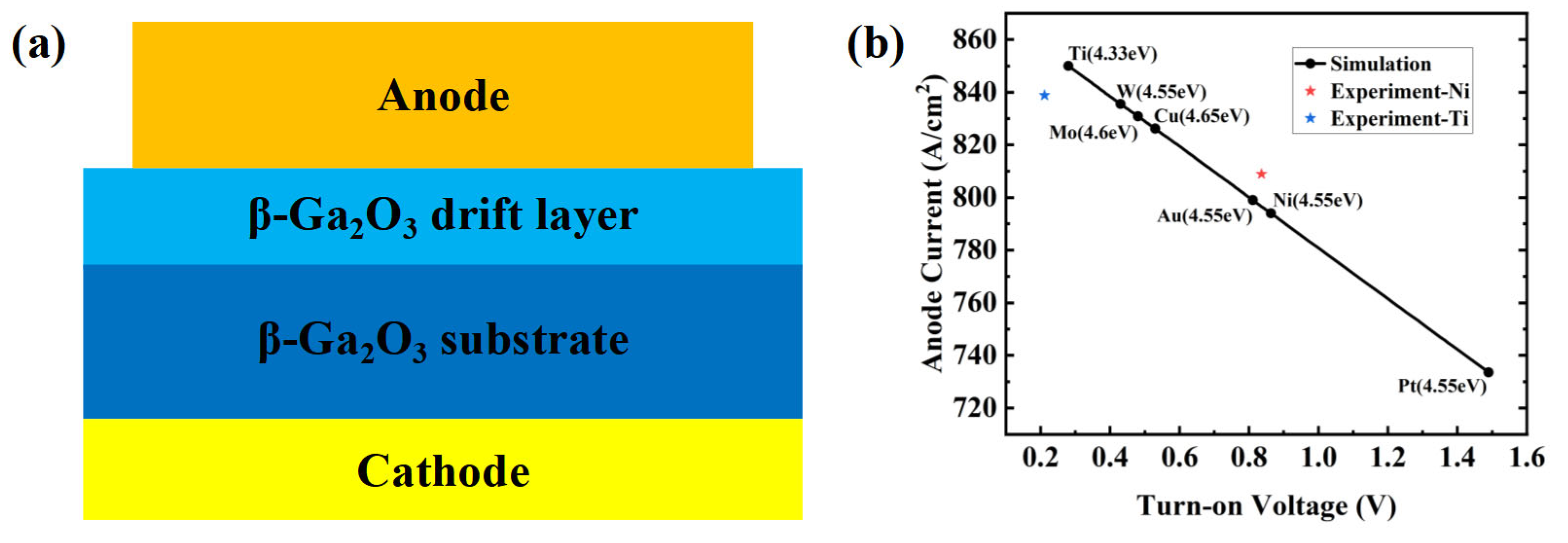

2. Simulation Settings

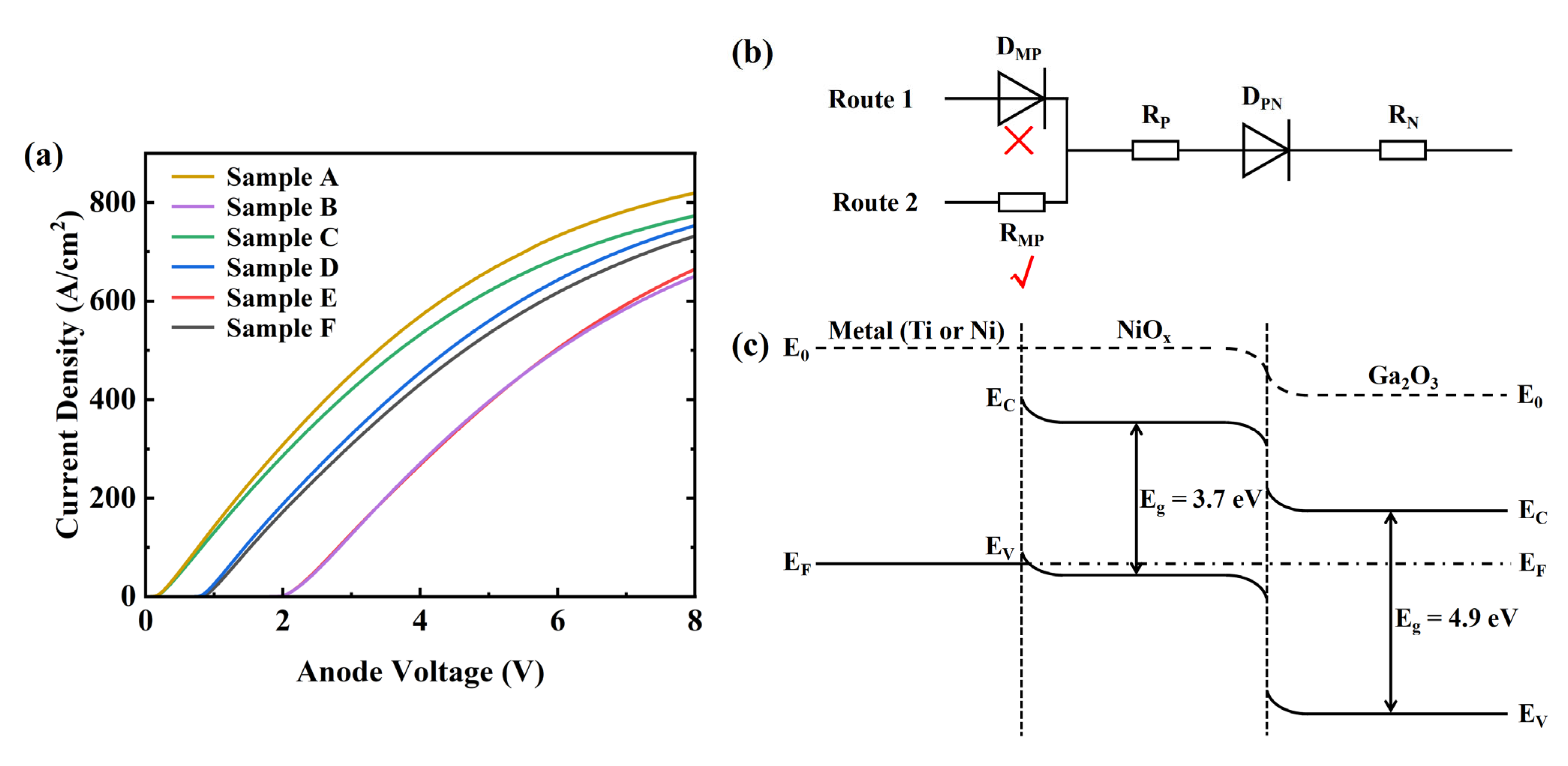

3. Experiment and Device Fabrication

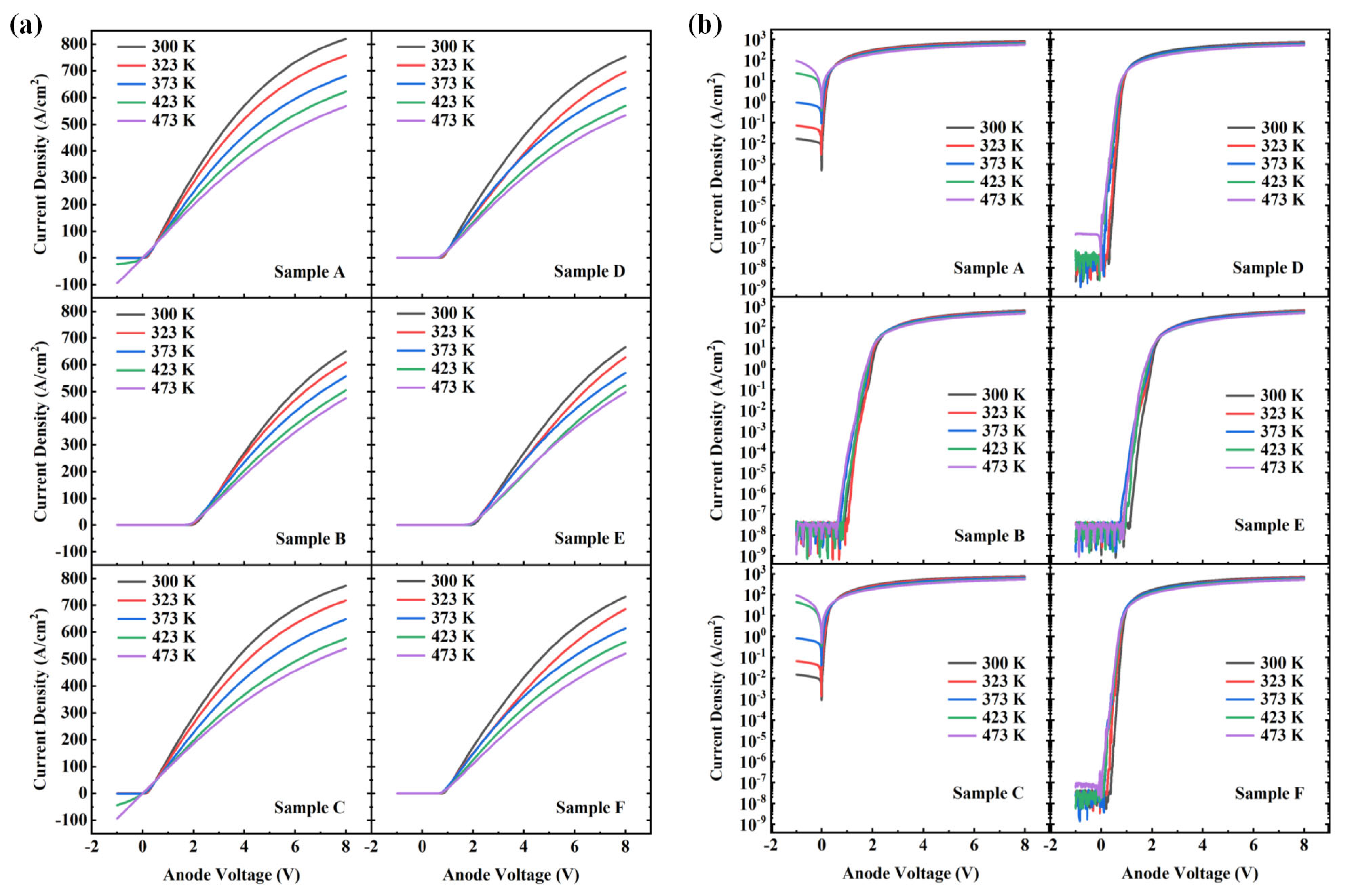

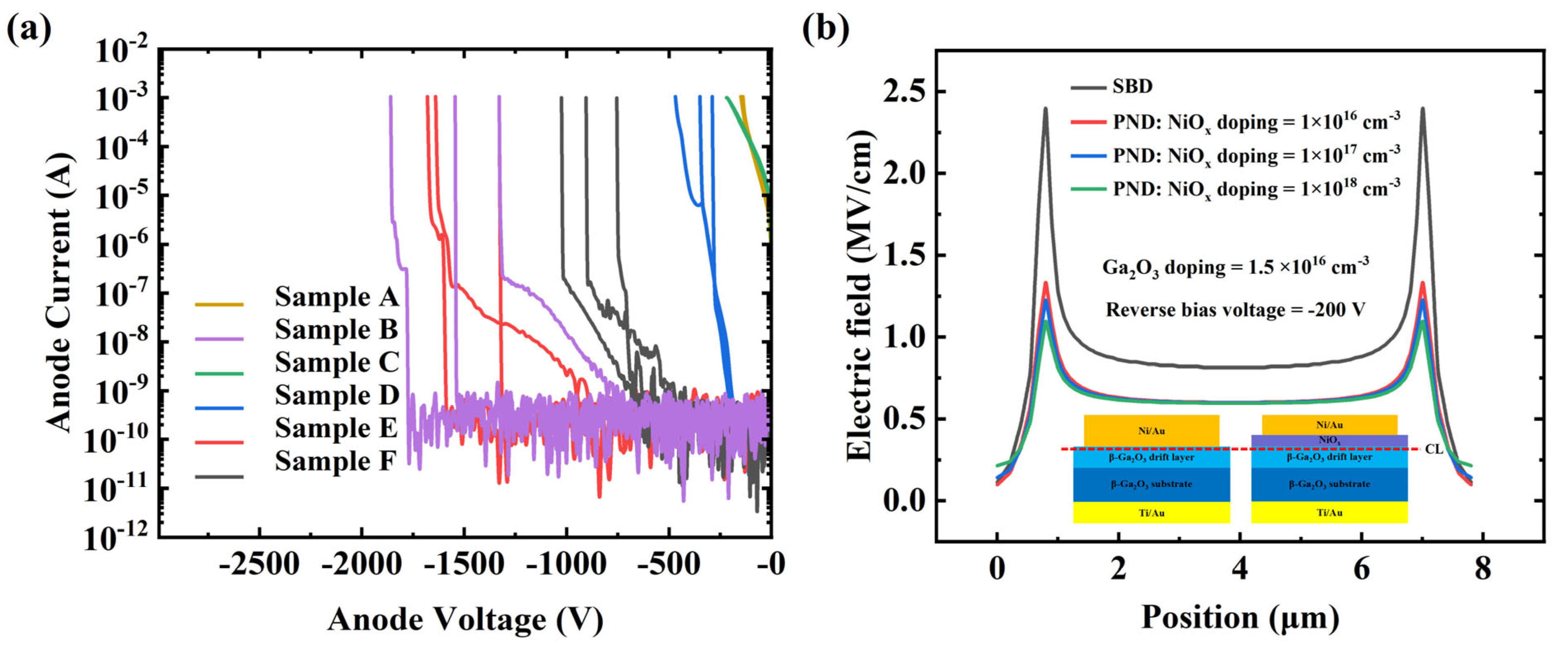

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stepanov, S.I.; Nikolaev, V.I.; Bougrov, V.E.; Romanov, A.E. Gallium oxide: Properties and applications—A review. Rev. Adv. Mater. Sci. 2016, 44, 63–86. [Google Scholar]

- Zhou, H.; Zhang, J.; Zhang, C.; Feng, Q.; Zhao, S.; Ma, P.; Hao, Y. A review of the most recent progresses of state-of-art gallium oxide power devices. J. Semicond. 2019, 40, 011803. [Google Scholar] [CrossRef]

- Li, W.; Nomoto, K.; Hu, Z.; Jena, D.; Xing, H.G. Guiding principles for trench Schottky barrier diodes based on ultrawide bandgap semiconductors: A case study in Ga2O3. IEEE Trans. Electron Devices 2020, 67, 3938–3947. [Google Scholar] [CrossRef]

- Kuramata, A.; Koshi, K.; Watanabe, S.; Yamaoka, Y.; Masui, T.; Yamakoshi, S. High-quality β-Ga2O3 single crystals grown by edge-defined film-fed growth. Jpn. J. Appl. Phys. 2016, 55, 1202A2. [Google Scholar] [CrossRef]

- Xue, H.; He, Q.; Jian, G.; Long, S.; Pang, T.; Liu, M. An overview of the ultrawide bandgap Ga2O3 semiconductor-based Schottky barrier diode for power electronics application. Nanoscale Res. Lett. 2018, 13, 290. [Google Scholar] [CrossRef] [PubMed]

- Konishi, K.; Goto, K.; Murakami, H.; Kumagai, Y.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M. 1-kV vertical Ga2O3 field-plated Schottky barrier diodes. Appl. Phys. Lett. 2017, 110, 103506. [Google Scholar] [CrossRef]

- Allen, N.; Xiao, M.; Yan, X.; Sasaki, K.; Tadjer, M.J.; Ma, J.; Zhang, R.; Wang, H.; Zhang, Y. Vertical Ga2O3 Schottky barrier diodes with small-angle beveled field plates: A Baliga’s figure-of-merit of 0.6 GW/cm2. IEEE Electron Device Lett. 2019, 40, 1399–1402. [Google Scholar] [CrossRef]

- Sasaki, K.; Wakimoto, D.; Thieu, Q.T.; Koishikawa, Y.; Kuramata, A.; Higashiwaki, M.; Yamakoshi, S. First demonstration of Ga2O3 trench MOS-type Schottky barrier diodes. IEEE Electron Device Lett. 2017, 38, 783–785. [Google Scholar] [CrossRef]

- Lin, C.H.; Yuda, Y.; Wong, M.H.; Sato, M.; Takekawa, N.; Konishi, K.; Watahiki, T.; Yamamuka, M.; Murakami, H.; Kumagai, Y.; et al. Vertical Ga2O3 Schottky barrier diodes with guard ring formed by nitrogen-ion implantation. IEEE Electron Device Lett. 2019, 40, 1487–1490. [Google Scholar] [CrossRef]

- Wang, Y.; Lv, Y.; Long, S.; Zhou, X.; Song, X.; Liang, S.; Han, T.; Tan, X.; Feng, Z.; Cai, S.; et al. High-voltage (-201) β-Ga2O3 vertical Schottky barrier diode with thermally-oxidized termination. IEEE Electron Device Lett. 2019, 41, 131–134. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, W.; Wang, Q.; Gao, S.; Chen, W.Z.; Tang, X.S.; Zhang, H.S.; Liu, B. NiO/β-Ga2O3 heterojunction diodes with ultra-low leakage current below 10−10 A and high thermostability. Chin. Phys. B 2023, 32, 098502. [Google Scholar] [CrossRef]

- Li, W.; Nomoto, K.; Hu, Z.; Jena, D.; Xing, H.G. Field-plated Ga2O3 trench Schottky barrier diodes with a BV2/Ron,sp of up to 0.95 GW/cm2. IEEE Electron Device Lett. 2019, 41, 107–110. [Google Scholar] [CrossRef]

- Yan, Q.; Gong, H.; Zhou, H.; Zhang, J.; Ye, J.; Liu, Z.; Wang, C.; Zheng, X.; Zhang, R.; Hao, Y. Low density of interface trap states and temperature dependence study of Ga2O3 Schottky barrier diode with p-NiOx termination. Appl. Phys. Lett. 2022, 120, 092106. [Google Scholar] [CrossRef]

- Li, J.-S.; Wan, H.-H. Ultra-wide bandgap semiconductor Ga2O3 power diodes. ESC J. Solid State Sci. Technol. 2024, 13, 035003. [Google Scholar] [CrossRef]

- Wu, F.; Wang, Y.; Jian, G.; Xu, G.; Zhou, X.; Guo, W.; Du, J.; Liu, Q.; Dun, S.; Yu, Z.; et al. Superior performance β-Ga2O3 junction barrier Schottky diodes implementing p-NiO heterojunction and beveled field plate for Hybrid Cockcroft-Walton voltage multiplier. IEEE Trans. Electron Devices 2023, 70, 1199–1205. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Wang, X.; Li, W.; Zhi, Y.; Wang, X.; Li, P.; Tang, W. Energy-band alignments at ZnO/Ga2O3 and Ta2O5/Ga2O3 heterointerfaces by X-ray photoelectron spectroscopy and electron affinity rule. J. Appl. Phys. 2019, 126, 045707. [Google Scholar] [CrossRef]

- Chen, H.; Wang, H.Y.; Sheng, K. Vertical β-Ga2O3 Schottky barrier diodes with field plate assisted negative beveled termination and positive beveled termination. IEEE Electron Device Lett. 2022, 44, 21–24. [Google Scholar] [CrossRef]

- Hao, W.; Wu, F.; Li, W.; Xu, G.; Xie, X.; Zhou, K.; Guo, W.; Zhou, X.; He, Q.; Zhao, X.; et al. Improved vertical β-Ga2O3 Schottky barrier diodes with conductivity-modulated p-NiO junction termination extension. IEEE Trans. Electron Devices 2023, 70, 2129–2134. [Google Scholar] [CrossRef]

- Hendricks, N.S.; Farzana, E.; Islam, A.E.; Leedy, K.D.; Liddy, K.J.; Williams, J.; Dryden, D.M.; Adams, A.M.; Speck, J.S.; Chabak, K.D.; et al. Vertical metal-dielectric-semiconductor diode on (001) β-Ga2O3 with high-κ TiO2 interlayer exhibiting reduced turn-on voltage and leakage current and improved breakdown. Appl. Phys. Express 2023, 16, 071002. [Google Scholar] [CrossRef]

- Yue, S.; Zheng, X.; Hong, Y.; Zhang, X.; Zhang, F.; Wang, Y.; Lv, L.; Cao, Y.; Ma, X.; Hao, Y. Effect of hydrogen on electrical performance of Pt/Au β-Ga2O3 (001) Schottky barrier diodes. IEEE Trans. Electron Devices 2023, 70, 2403–2407. [Google Scholar] [CrossRef]

- He, Y.L.; Sheng, B.S.; Hong, Y.H.; Liu, P.; Lu, X.L.; Zhang, F.; Wang, X.C.; Li, Y.; Zheng, X.F.; Ma, X.H.; et al. Research on the β-Ga2O3 Schottky barrier diodes with oxygen-containing plasma treatment. Appl. Phys. Lett. 2023, 122, 163503. [Google Scholar] [CrossRef]

- Su, C.; Zhou, H.; Zhang, K.; Wang, C.; Sun, S.; Gong, H.; Ye, J.; Liu, Z.; Dang, K.; Hu, Z.; et al. Low turn-on voltage and 2.3 kV β-Ga2O3 heterojunction barrier Schottky diodes with Mo anode. Appl. Phys. Lett. 2024, 124, 173506. [Google Scholar] [CrossRef]

- Michaelson, H.B. The work function of the elements and its periodicity. J. Appl. Phys. 1997, 48, 4729–4733. [Google Scholar] [CrossRef]

- Lim, W.T.; Stafford, L.; Sadik, P.W.; Norton, D.P.; Pearton, S.J.; Wang, Y.L.; Ren, F. Ni/Au ohmic contacts to p-type Mg-doped CuCrO2 epitaxial layers. Appl. Phys. Lett. 2007, 90, 142101. [Google Scholar] [CrossRef]

- Li, Y.L.; Schubert, E.F.; Graff, J.W.; Osinsky, A.; Schaff, W.F. Low-resistance ohmic contacts to p-type GaN. Appl. Phys. Lett. 2000, 76, 2728–2730. [Google Scholar] [CrossRef]

- Abdy, H.; Aletayeb, A.; Kolahdouz, M.; Soleimani, E.A. Investigation of metal-nickel oxide contacts used for perovskite solar cell. AIP Adv. 2019, 9, 015216. [Google Scholar] [CrossRef]

- Wang, L.; Nathan, M.I.; Lim, T.H.; Khan, M.A.; Chen, Q. High barrier height GaN Schottky diodes: Pt/GaN and Pd/GaN. Appl. Phys. Lett. 1996, 68, 1267–1269. [Google Scholar] [CrossRef]

- Li, A.; Feng, Q.; Zhang, J.; Hu, Z.; Feng, Z.; Zhang, K.; Zhang, C.; Zhou, H. Investigation of temperature dependent electrical characteristics on Au/Ni/β-Ga2O3 Schottky diodes. Superlattices Microstuct. 2018, 119, 212–217. [Google Scholar] [CrossRef]

- Camuso, G.; Napoli, E.; Pathirana, V.; Udugampola, N.; Hsieh, A.P.S.; Trajkovic, T.; Udrea, F. Effect of bandgap narrowing on performance of modern power devices. IEEE Trans. Electron Devices 2013, 60, 4185–4190. [Google Scholar] [CrossRef]

- Gong, H.; Zhou, F.; Xu, W.; Yu, X.; Xu, Y.; Yang, Y.; Ren, F.F.; Gu, S.; Zheng, Y.; Zhang, R.; et al. 1.37 kV/12 A NiO/β-Ga2O3 heterojunction diode with nanosecond reverse recovery and rugged surge-current capability. IEEE Trans. Power Electron. 2021, 36, 12213–12217. [Google Scholar] [CrossRef]

- Zhou, H.; Zeng, S.; Zhang, J.; Liu, Z.; Feng, Q.; Xu, S.; Zhang, J.; Hao, Y. Comprehensive study and optimization of implementing p-NiO in β-Ga2O3 based diodes via TCAD simulation. Crystals 2021, 11, 1186. [Google Scholar] [CrossRef]

- Roccaforte, F.; La Via, F.; Di Franco, S.; Raineri, V. Dual metal SiC Schottky rectifiers with low power dissipation. Microelectron. Eng. 2003, 70, 524–528. [Google Scholar] [CrossRef]

| Samples | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Structure | SBD | PND | JBSD | SBD | PND | JBSD |

| Anode metal | Ti/Au | Ti/Au | Ti/Au | Ni/Au | Ni/Au | Ni/Au |

| Samples | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Von at 300 K (V) | 0.209 | 2.072 | 0.242 | 0.809 | 2.072 | 0.895 |

| Von at 473 K (V) | 0.003 | 1.901 | 0.005 | 0.708 | 1.902 | 0.793 |

| Variation value of Von (V) | 0.206 | 0.171 | 0.237 | 0.101 | 0.170 | 0.102 |

| Variation rate of Von | 98.56% | 8.25% | 97.93% | 12.48% | 8.20% | 11.40% |

| Current density at 300 K (A/cm2) | 819.4 | 651.0 | 770.9 | 753.4 | 664.9 | 732.1 |

| Current density at 473 K (A/cm2) | 567.6 | 475.2 | 541.6 | 533.3 | 496.6 | 520.5 |

| Variation value of current density (A/cm2) | 251.8 | 175.8 | 229.3 | 220.1 | 168.3 | 211.6 |

| Variation rate of current density | 30.73% | 27.00% | 30.29% | 29.21% | 25.31% | 28.90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Sheng, B.; Lu, X.; Chen, G.; Liu, P.; Zhou, Y.; Wang, X.; Chen, W.; Wang, L.; Yang, J.; et al. Study on Electrical and Temperature Characteristics of β-Ga2O3-Based Diodes Controlled by Varying Anode Work Function. Nanomaterials 2024, 14, 2035. https://doi.org/10.3390/nano14242035

He Y, Sheng B, Lu X, Chen G, Liu P, Zhou Y, Wang X, Chen W, Wang L, Yang J, et al. Study on Electrical and Temperature Characteristics of β-Ga2O3-Based Diodes Controlled by Varying Anode Work Function. Nanomaterials. 2024; 14(24):2035. https://doi.org/10.3390/nano14242035

Chicago/Turabian StyleHe, Yunlong, Baisong Sheng, Xiaoli Lu, Guran Chen, Peng Liu, Ying Zhou, Xichen Wang, Weiwei Chen, Lei Wang, Jun Yang, and et al. 2024. "Study on Electrical and Temperature Characteristics of β-Ga2O3-Based Diodes Controlled by Varying Anode Work Function" Nanomaterials 14, no. 24: 2035. https://doi.org/10.3390/nano14242035

APA StyleHe, Y., Sheng, B., Lu, X., Chen, G., Liu, P., Zhou, Y., Wang, X., Chen, W., Wang, L., Yang, J., Zheng, X., Ma, X., & Hao, Y. (2024). Study on Electrical and Temperature Characteristics of β-Ga2O3-Based Diodes Controlled by Varying Anode Work Function. Nanomaterials, 14(24), 2035. https://doi.org/10.3390/nano14242035