Embrittlement Mechanisms of HR3C Pipe Steel at Room Temperature in Ultra-Supercritical Unit

Abstract

1. Introduction

2. Materials and Methods

3. Experimental Results

3.1. Metallographic Test

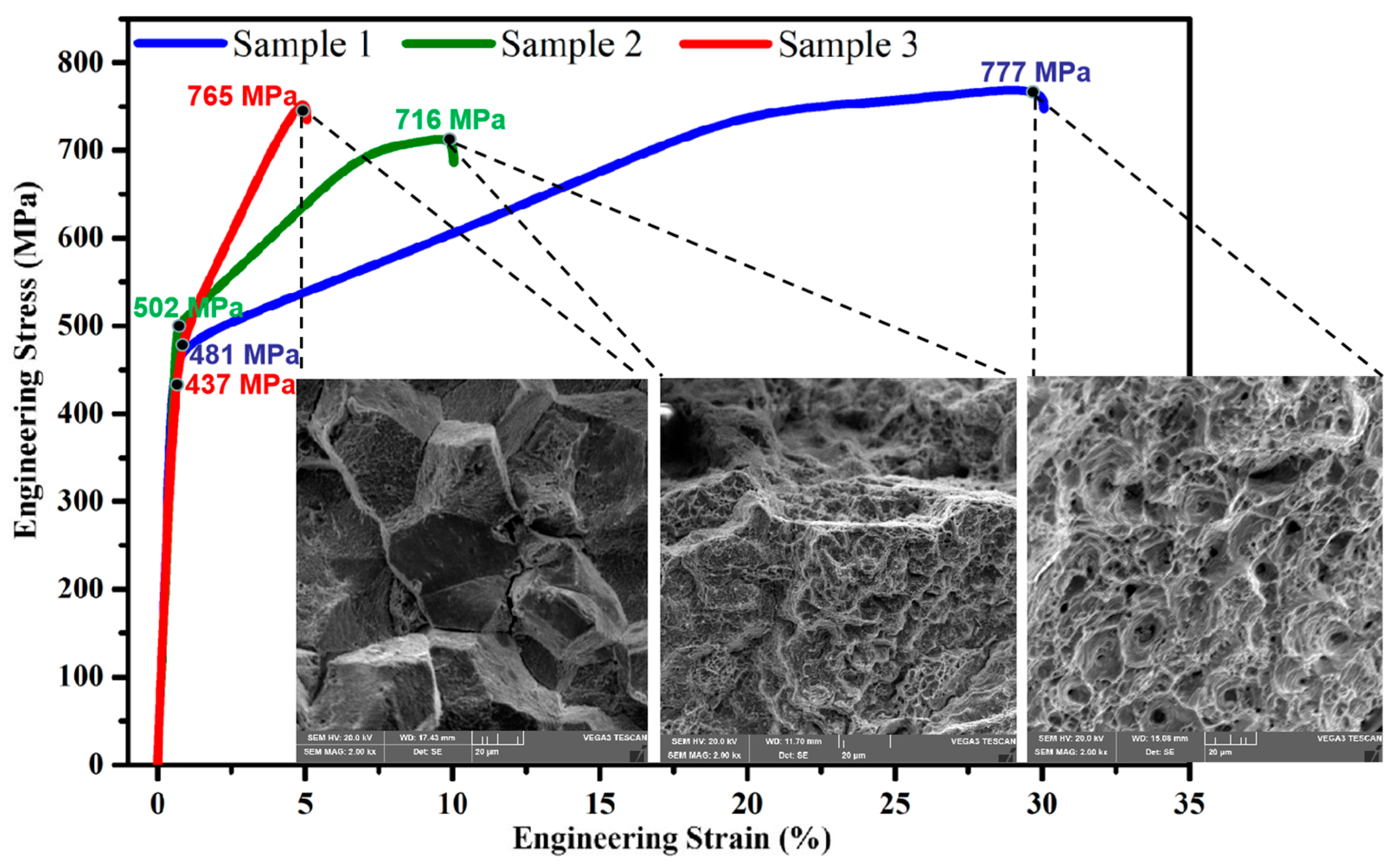

3.2. Tensile Test

3.3. Impact Test

3.4. Result

4. Discussion

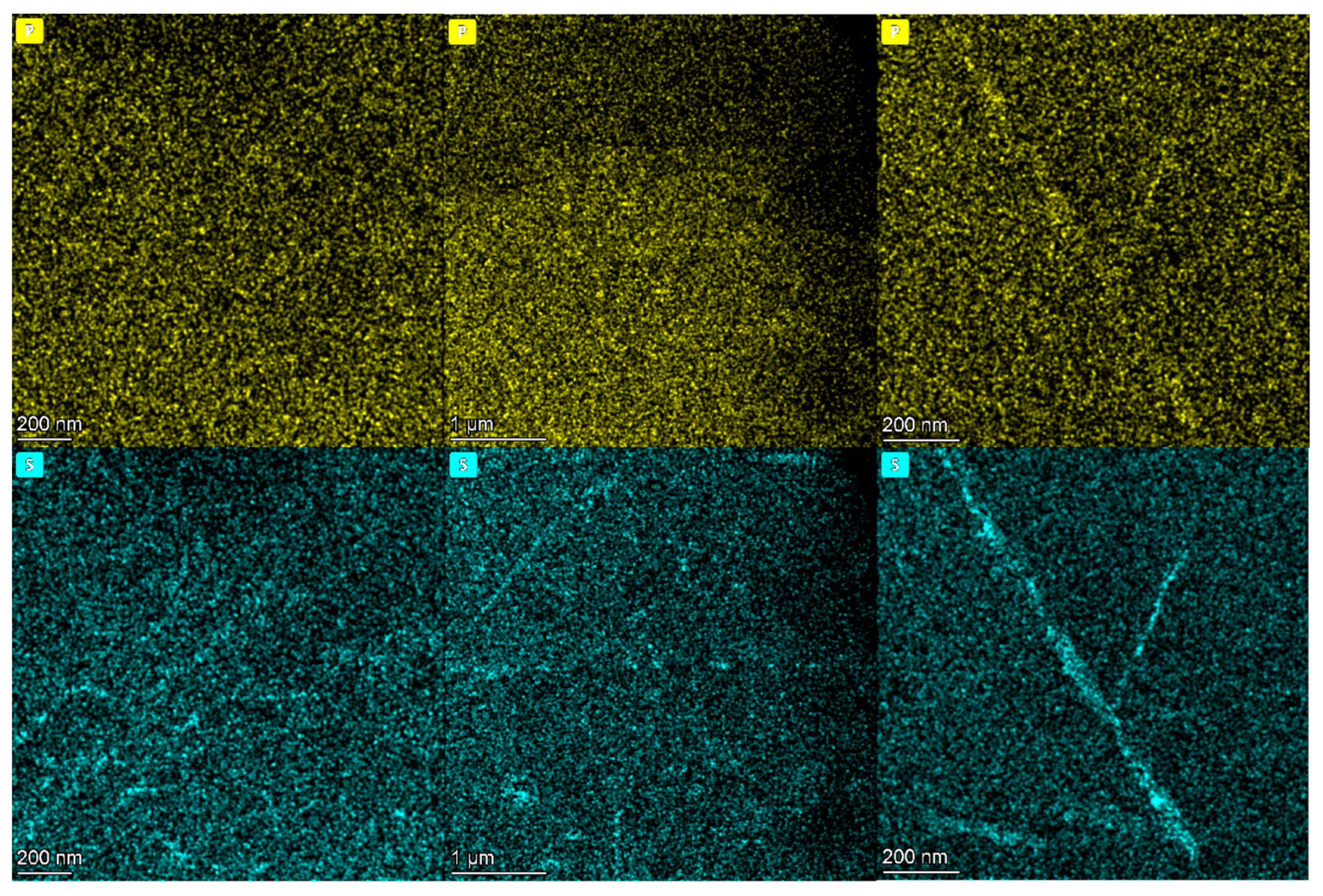

4.1. Segregation of Elements P and S

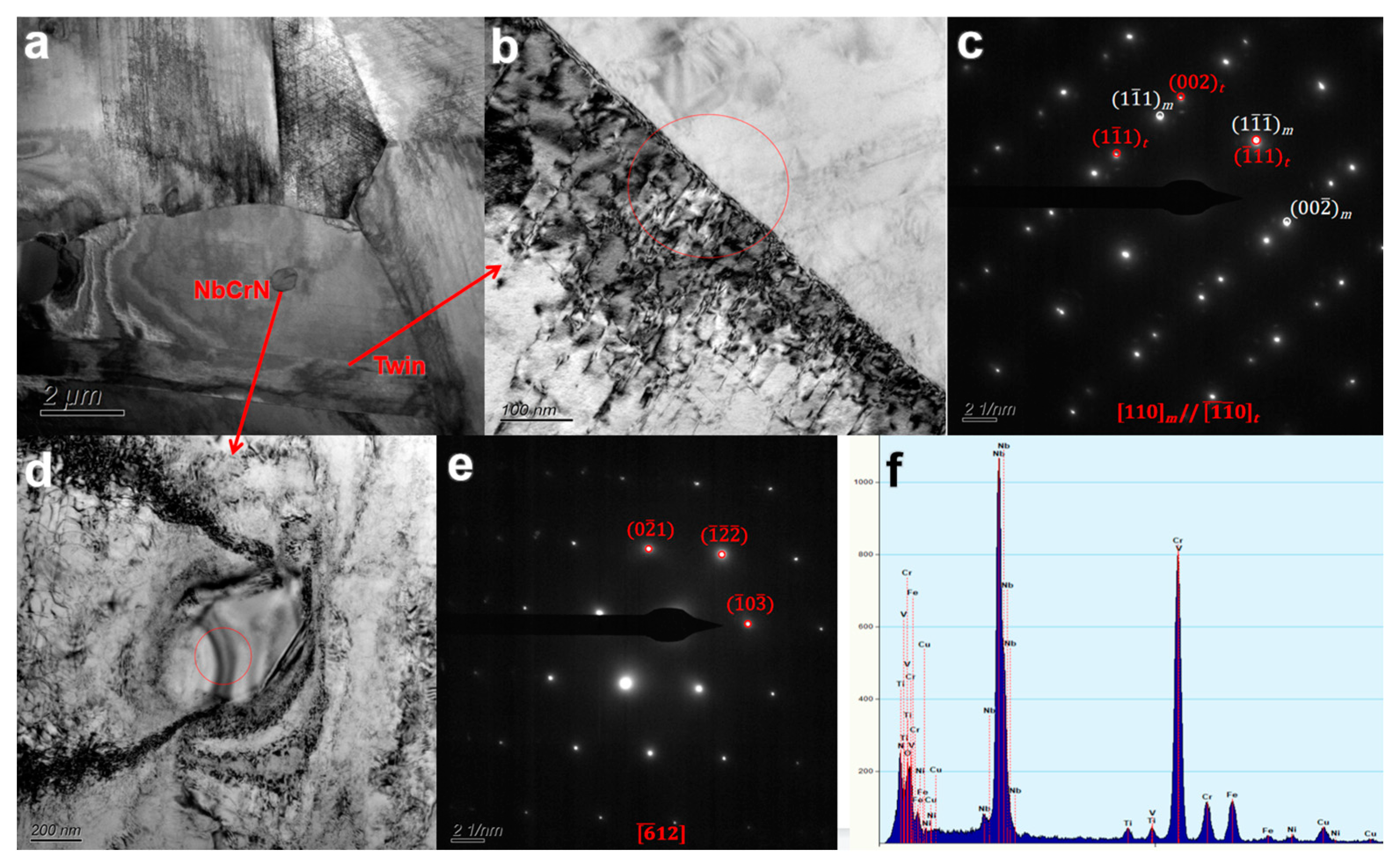

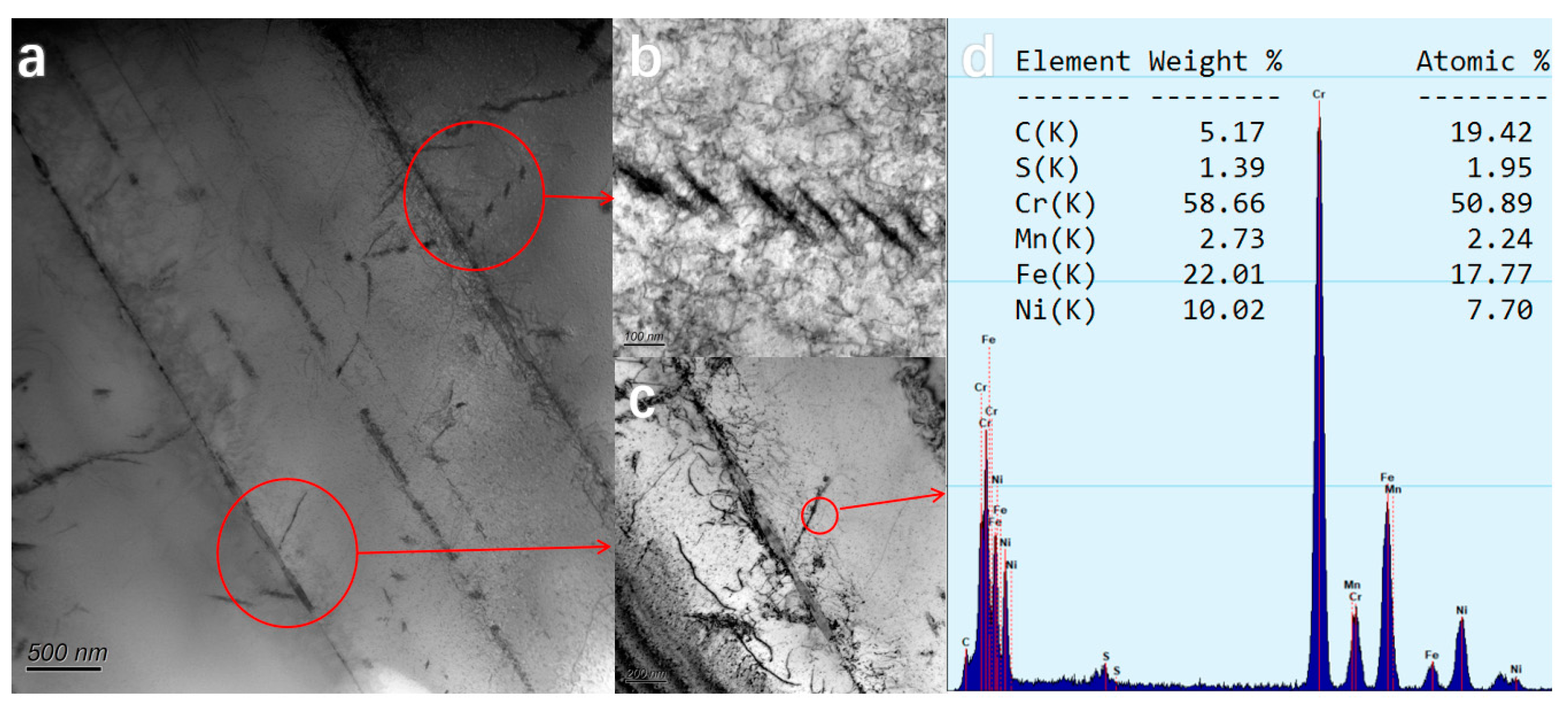

4.2. Evolution of Precipitated Phase of HR3C Steel

5. Conclusions

- After 500 h of high-temperature aging, the elongation of HR3C steel pipe after fracture is 10%, far lower than the ASME standard requirements of no less than 30%, and the average impact absorption work was 50 J, 70.4% lower than the supply steel pipe. These data prove that HR3C steel pipe demonstrates brittle changes in the early stage of high-temperature aging.

- The fracture position of the HR3C steel pipe sample was irregular in the tensile test, and the yield strength and ultimate tensile strength of the three groups of samples were higher than the requirements of ASME standards. Moreover, the tensile data of the steel pipe after high-temperature aging and service for 70,000 h were not lower than that of the steel pipe in the supply state, so HR3C steel pipe has excellent tensile properties.

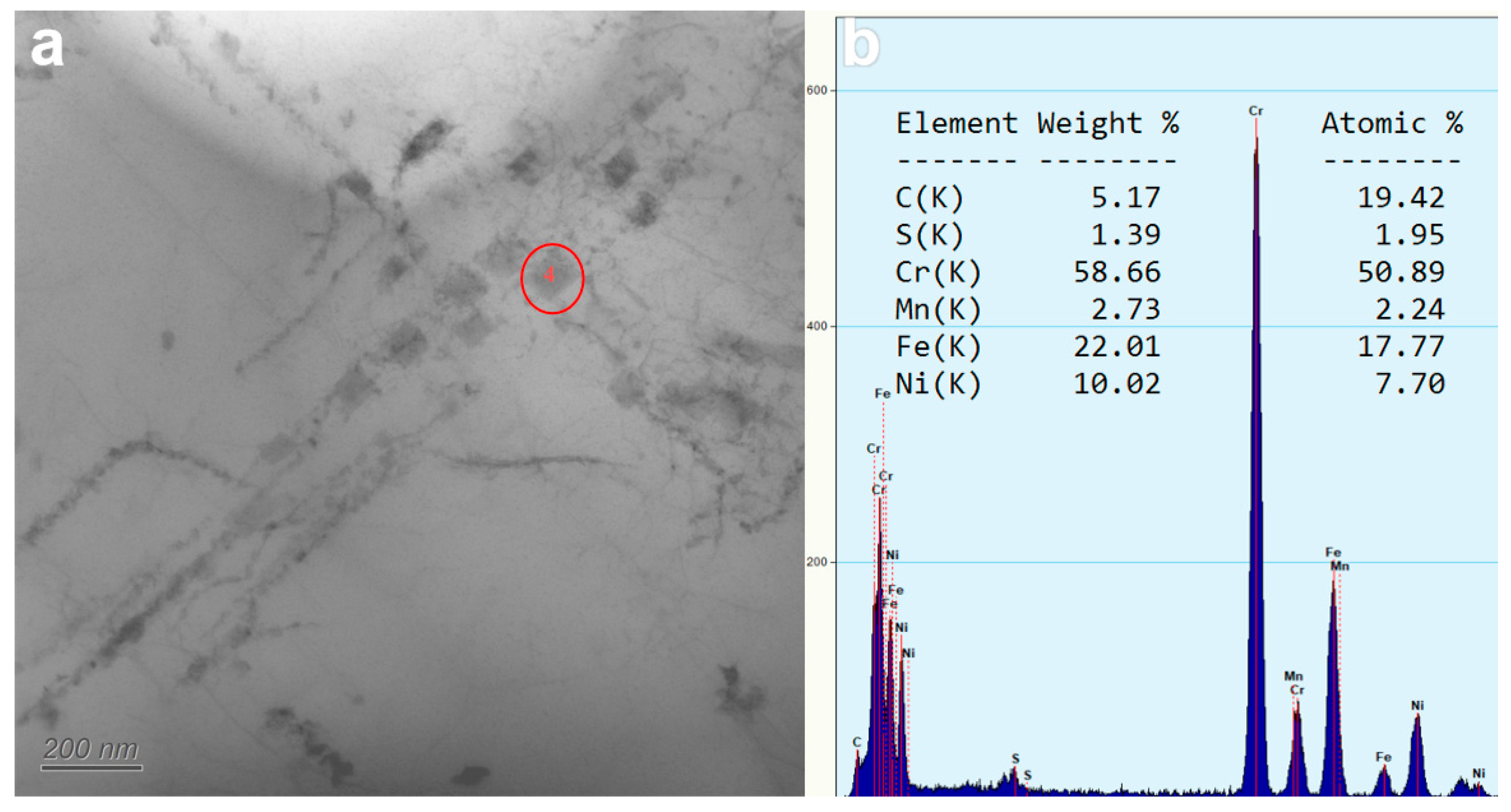

- In HR3C steel, continuous chain-cut M23C6 phases distributed along the grain boundaries were precipitated. P and S elements showed no obvious segregation in the early stage of high-temperature aging, and S elements showed a more obvious segregation phenomenon after service for 70,000 h. This is consistent with the results of Luo’s 40,000 h high-temperature aging study [25].

- The main reason for the brittleness of HR3C steel at room temperature is the continuous precipitation and aggregation of M23C6 carbides at the grain boundary, because brittle changes have been shown after 500 h of high-temperature aging, but there is no σ phase and other precipitates in the crystal at that time, and P and S elements do not occur with segregation. Compared with the steel pipe that had been in service for 70,000 h, it was shown that a small amount of the σ phase was produced in the crystal after the HR3C steel pipe had been in service for a long time at high temperature. Because the σ phase is a brittle phase with high hardness and low plasticity, the embrittlement degree of HR3C steel pipe is further aggravated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuboň, Z. New Austenitic Creep Resistant Steels for Superheaters of USC Boilers. Key Eng. Mater. 2015, 635, 75–80. [Google Scholar] [CrossRef]

- Yin, X.S.; Shen, K.; Liu, C.F.; Du, S.M.; Dong, S.Q. Cause of Leakage on HR3C Stainless Steel Final Superheater Tube of Boiler. Phys. Test. Chem. Anal. Part A Phys. Test. 2021, 57, 50–53, 58. [Google Scholar]

- Jin, X.; Xia, X.; Zhu, B.; Zhao, Y.; Duan, P.; Liang, J.; Zhang, G. The microstructure and tensile property changes of S31042 steel after long time service. J. Phys. Conf. Ser. 2020, 2263, 012002. [Google Scholar] [CrossRef]

- Wang, J.; Meng, B.; Lu, J.; Zhou, Y.; Yang, D.; Wang, Q.; Wang, F. Studies on the Oxidation Behavior and Microstructural Evolution of Two Nb-Modified Hr3c Austenitic Steels under Pure Water Vapor at 650 C. Materials 2022, 13, 5447. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Qiao, Y.; Dong, N.; Fang, X.; Quan, X.; Cui, Y.; Han, P. The influence of temperature on the oxidation mechanism in air of HR3C and aluminum-containing 22Cr–25Ni austenitic stainless steels. Oxid. Met. 2018, 89, 713–730. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, J.; Li, H.; Le, M.; Yan, J.; Yuan, Y. Influence of dissolved oxygen concentration and exposure temperature on the steam oxidation behaviour of HR3C. Corros. Eng. Sci. Technol. 2019, 54, 422–430. [Google Scholar] [CrossRef]

- Li, Y.H.; Wang, S.Z.; Li, X.D.; Lu, J.M. Corrosion of an austenitic heat-resistant steel HR3C in high-temperature steam and supercritical water. Adv. Mater. Res. 2014, 908, 67–71. [Google Scholar] [CrossRef]

- Yan, J.B.; Gu, Y.F.; Sun, F.; Xu, Y.X.; Yuan, Y.; Lu, J.T.; Yang, Z.; Dang, Y.Y. Evolution of microstructure and mechanical properties of a 25Cr-20Ni heat resistant alloy after long-term service. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 675, 289–298. [Google Scholar] [CrossRef]

- Zielinski, A.; Sroka, M.; Hernas, A.; Kremzer, M. The Effect of Long-Term Impact of Elevated Temperature on Changes in Microstructure and Mechanical Properties of Hr3c Steel. Arch. Metall. Mater. 2016, 61, 761–765. [Google Scholar] [CrossRef]

- Wang, R.; Duan, M.; Zhang, J.; Chen, G.; Miao, C.; Chen, X.; Tang, W. Microstructure characteristics and their effects on the mechanical properties of as-served HR3C heat-resistant steel. J. Mater. Eng. Perform. 2021, 30, 4552–4561. [Google Scholar] [CrossRef]

- Bai, J.M.; Yuan, Y.; Zhang, P.; Yan, J.B. Effect of carbon on microstructure and mechanical properties of HR3C type heat resistant steels. Mater. Sci. Eng. A 2020, 784, 138943. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Evolution of the microstructure and mechanical properties of HR3C austenitic stainless steel after ageing for up to 30,000 h at 650–750 °C. Mater. Sci. Eng. A 2020, 796, 139944. [Google Scholar] [CrossRef]

- Zhu, C.Z.; Yuan, Y.; Bai, J.M.; Zhang, P.; Yan, J.B.; You, C.Y.; Gu, Y.F. Impact toughness of a modified HR3C austenitic steel after long-term thermal exposure at 650 °C. Mater. Sci. Eng. A 2019, 740, 71–81. [Google Scholar] [CrossRef]

- Cao, T.S.; Cheng, C.Q.; Zhao, J.; Wang, H. Precipitation behavior of σ phase in ultra-supercritical boiler applied HR3C heat-resistant steel. Acta Metall. Sin. (Engl. Lett.) 2019, 32, 1355–1361. [Google Scholar] [CrossRef]

- Wang, J.Z.; Liu, Z.D.; Bao, H.S.; Cheng, S.C.; Wang, B. Effect of Ageing at 700 °C on Microstructure and Mechanical Properties of S31042 Heat Resistant Steel. J. Iron Steel Res. Int. 2013, 20, 54–58. [Google Scholar] [CrossRef]

- ASTM A370-17; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2017.

- ASME SA213/SA213M; Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes. ASTM: West Conshohocken, PA, USA, 2019.

- Hald, J. High-alloyed martensitic steel grades for boilers in ultra-supercritical power plants. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Woodhead Publishing: Sawston, UK, 2017; pp. 77–97. [Google Scholar]

- Mou, C.H.; Yang, Z.; Zhao, X.B. Research progress of HR3C heat resistant steel used in ultra supercritical boiler. Hot Work. Technol. 2018, 47, 23–27. [Google Scholar]

- Qi, W.; Rui, X.; Zhi, W.; Zhe, H.; Xiang, J.; Ju, K. Microstructure and its effect on high-temperature tensile properties of T92/HR3C dissimilar weld joints. J. Manuf. Process. 2022, 82, 792–799. [Google Scholar]

- Iseda, A.; Okada, H.; Semba, H.A.; Igarashi, M. Long term creep properties and microstructure of SUPER304H, TP347HFG and HR3C for A-USC boilers. Energy Mater. 2007, 2, 199–206. [Google Scholar] [CrossRef]

- Hu, Z.F.; Zhang, Z. Investigation the effect of precipitating characteristics on the creep behavior of HR3C austenitic steel at 650 °C. Mater. Sci. Eng. A 2019, 742, 451–463. [Google Scholar] [CrossRef]

- Wang, D. Segregation and Grain Boundary Embrittlement of Trace Elements in Steel; Metallurgical Industry Press: Beijing, China, 1985. [Google Scholar]

- Zhang, M.; Yang, K.; Chen, Z.; Wang, Y.; Zhang, J. Review of atomistic scale studies on solute segregation and its mechanism at grain boundary. J. Shanghai Jiaotong Univ. 2013, 42, 1531–1535. [Google Scholar]

- Luo, K.J.; Zhao, Y.F.; Zhang, L.; Liu, Y.; Zhang, G.D.; Xue, F. Embrittlement mechanism of austenitic heat-resistant steel HR3C for ultra-supercritical boiler. J. Heat Treat. Mater. 2017, 38, 79–86. [Google Scholar]

- Golański, G.; Kolan, C.; Zieliński, A.; Klimaszewska, K.; Kłosowicz, J. Microstructure and mechanical properties of HR3C austenitic steel after service. Arch. Mater. Sci. Eng. 2016, 81, 62–67. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Z.; Tu, H.; Schmauder, S.; Wu, G. Microstructure evolution in HR3C austenitic steel during long-term creep at 650 °C. Mater. Sci. Eng. A 2017, 681, 74–84. [Google Scholar] [CrossRef]

- Xu, L.M.; He, Y.S.; Kang, Y.; Yeonkwan, K.; Jinesung, J.; Keesam, S. Precipitation Evolution in the Austenitic Heat-Resistant Steel HR3C upon Creep at 700 °C and 750 °C. Materials 2022, 15, 4704. [Google Scholar] [CrossRef]

- Golański, G.; Zieliński, A.; Sroka, M.; Słania, J. The Effect of Service on Microstructure and Mechanical Properties of HR3C Heat-Resistant Austenitic Stainless Steel. Materials 2020, 13, 1297. [Google Scholar] [CrossRef]

- Ding, Z.; Liang, B.; Xu, Z.; Dong, L. Multiple interface structures of M23C6 carbides at grain boundary in an aged 100Mn13 high carbon high manganese steel. ACS Appl. Mater. Interfaces 2020, 12, 19235–19242. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Cheng, S.C.; Liu, C.M.; Wang, J.Z. Microstructure Evolution and Mechanical Properties of HR3C Steel during Long-term Aging at High Temperature. J. Iron Steel Res. Int. 2014, 21, 765–773. [Google Scholar] [CrossRef]

- Ji, Y.S.; Park, J.; Lee, S.Y.; Kim, J.W.; Lee, S.M.; Nam, J.; Hwang, B.; Suh, J.Y.; Shim, J.H. Long-term evolution of σ phase in 304H austenitic stainless steel: Experimental and computational investigation. Mater. Charact. 2017, 128, 23–29. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, C.; Zhao, J. Study on σ phase precipitation of hr3c steel used in ultra-supercritical boiler. Acta Metall. Sin. 2015, 51, 920–924. [Google Scholar]

- Hong, H.U.; Rho, B.S.; Nam, S.W. Correlation of the M23C6 precipitation morphology with grain boundary characteristics in austenitic stainless steel. Mater. Sci. Eng. A 2001, 318, 285–292. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, L.; Wang, Q.; Zhu, C. Microstructural evolution and the effect on hardness and plasticity of S31042 heat-resistant steel during creep. Mater. Sci. Eng. A 2014, 608, 164–173. [Google Scholar] [CrossRef]

- Terada, M.; Saiki, M.; Costa, I.; Padilha, A.F. Microstructure and intergranular corrosion of the austenitic stainless steel 1.4970. J. Nucl. Mater. 2006, 358, 40–46. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Z.; Zhai, G.; Zhang, Z.; Gao, Z. Creep damage characteristics and evolution of HR3C austenitic steel during long term creep. Mater. Sci. Eng. A 2022, 832, 142432. [Google Scholar] [CrossRef]

- Peng, B.; Zhang, H.; Hong, J.; Gao, J.; Zhang, H.; Li, J.; Wang, Q. The evolution of precipitates of 22Cr–25Ni–Mo–Nb–N heat-resistant austenitic steel in long-term creep. Mater. Sci. Eng. A 2010, 527, 4424–4430. [Google Scholar] [CrossRef]

- Kaneko, K.; Fukunaga, T.; Yamada, K.; Nakada, N.; Kikuchi, M.; Saghi, Z.; Barnard, J.S.; Midgley, P.A. Formation of M23C6-type precipitates and chromium-depleted zones in austenite stainless steel. Scr. Mater. 2011, 65, 509–512. [Google Scholar] [CrossRef]

- Guan, K.S.; Xu, X.D.; Zhang, Y.Y. Cracks and precipitate phases in 321 stainless steel weld of flue gas pipe. Eng. Fail. Anal. 2005, 12, 623–633. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Ni | Nb | N | P | S | |

|---|---|---|---|---|---|---|---|---|---|

| Supply steel pipe | 0.05 | 1.16 | 0.42 | 25.37 | 20.97 | 0.36 | 0.25 | 0.021 | 0.002 |

| Service steel pipe | 0.05 | 1.11 | 0.43 | 25.52 | 20.73 | 0.42 | 0.21 | 0.023 | 0.002 |

| ASTM | 0.04~0.10 | ≤2.00 | ≤1.00 | 24.0~26.0 | 19.0~22.0 | 0.20~0.60 | 0.15~0.35 | <0.04 | <0.03 |

| Element | Cr | Nb | N | Fe | O | Ti | V | Cu | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Weight % | 34.26 | 28.44 | 18.07 | 5.37 | 7.08 | 1.36 | 2.03 | 2.46 | 0.89 |

| Atomic % | 22.59 | 10.49 | 44.23 | 3.29 | 15.18 | 0.97 | 1.37 | 1.33 | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Cao, X.; Zhang, Z. Embrittlement Mechanisms of HR3C Pipe Steel at Room Temperature in Ultra-Supercritical Unit. Nanomaterials 2024, 14, 306. https://doi.org/10.3390/nano14030306

Liu X, Cao X, Zhang Z. Embrittlement Mechanisms of HR3C Pipe Steel at Room Temperature in Ultra-Supercritical Unit. Nanomaterials. 2024; 14(3):306. https://doi.org/10.3390/nano14030306

Chicago/Turabian StyleLiu, Xinying, Xue Cao, and Zhongwu Zhang. 2024. "Embrittlement Mechanisms of HR3C Pipe Steel at Room Temperature in Ultra-Supercritical Unit" Nanomaterials 14, no. 3: 306. https://doi.org/10.3390/nano14030306

APA StyleLiu, X., Cao, X., & Zhang, Z. (2024). Embrittlement Mechanisms of HR3C Pipe Steel at Room Temperature in Ultra-Supercritical Unit. Nanomaterials, 14(3), 306. https://doi.org/10.3390/nano14030306