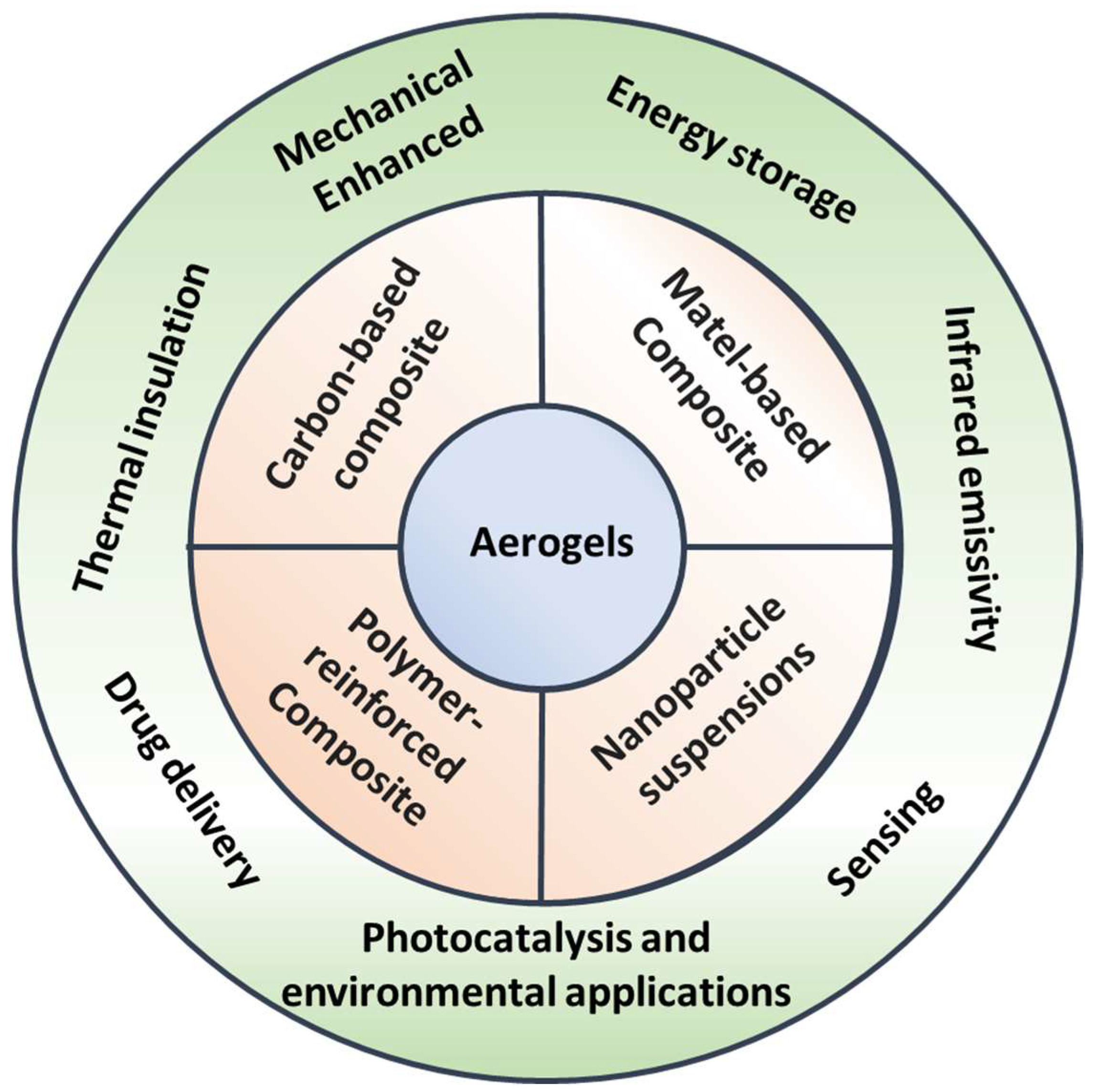

Advances in Nanoporous Composited Aerogels: Enhancing Durability and Expanding Applications

1. Introduction

2. An Overview of Published Articles

3. Conclusions

Conflicts of Interest

References

- Cai, B.; Eychmüller, A. Promoting electrocatalysis upon aerogels. Adv. Mater. 2019, 31, 1804881. [Google Scholar] [CrossRef] [PubMed]

- Meti, P.; Mahadik, D.; Lee, K.-Y.; Wang, Q.; Kanamori, K.; Gong, Y.-D.; Park, H.-H. Overview of organic–inorganic hybrid silica aerogels: Progress and perspectives. Mater. Des. 2022, 222, 111091. [Google Scholar] [CrossRef]

- Jiang, X.; Du, R.; Hübner, R.; Hu, Y.; Eychmüller, A. A roadmap for 3D metal aerogels: Materials design and application attempts. Matter 2021, 4, 54–94. [Google Scholar] [CrossRef]

- Zhao, S.; Malfait, W.J.; Guerrero-Alburquerque, N.; Koebel, M.M.; Nyström, G. Biopolymer aerogels and foams: Chemistry, properties, and applications. Angew. Chem. Int. Ed. 2018, 57, 7580–7608. [Google Scholar] [CrossRef]

- Lin, D.; Yuen, P.Y.; Liu, Y.; Liu, W.; Liu, N.; Dauskardt, R.H.; Cui, Y. A silica-aerogel-reinforced composite polymer electrolyte with high ionic conductivity and high modulus. Adv. Mater. 2018, 30, 1802661. [Google Scholar] [CrossRef]

- Jin, M.; Wu, Z.; Guan, F.; Zhang, D.; Wang, B.; Sheng, N.; Qu, X.; Deng, L.; Chen, S.; Chen, Y. Hierarchically designed three-dimensional composite structure on a cellulose-based solar steam generator. ACS Appl. Mater. Interfaces 2022, 14, 12284–12294. [Google Scholar] [CrossRef]

- Rahmanian, V.; Pirzada, T.; Wang, S.; Khan, S.A. Cellulose-based hybrid aerogels: Strategies toward design and functionality. Adv. Mater. 2021, 33, 2102892. [Google Scholar] [CrossRef]

- Benad, A.; Jürries, F.; Vetter, B.; Klemmed, B.; Hübner, R.; Leyens, C.; Eychmüller, A. Mechanical properties of metal oxide aerogels. Chem. Mater. 2018, 30, 145–152. [Google Scholar] [CrossRef]

- Tao, J.; Yang, F.; Wu, T.; Shi, J.; Zhao, H.-B.; Rao, W. Thermal insulation, flame retardancy, smoke suppression, and reinforcement of rigid polyurethane foam enabled by incorporating a P/Cu-hybrid silica aerogel. Chem. Eng. J. 2023, 461, 142061. [Google Scholar] [CrossRef]

- Fu, C.; Sheng, Z.; Zhang, X. Laminated structural engineering strategy toward carbon nanotube-based aerogel films. ACS Nano 2022, 16, 9378–9388. [Google Scholar] [CrossRef]

- Zhao, S.; Siqueira, G.; Drdova, S.; Norris, D.; Ubert, C.; Bonnin, A.; Galmarini, S.; Ganobjak, M.; Pan, Z.; Brunner, S. Additive manufacturing of silica aerogels. Nature 2020, 584, 387–392. [Google Scholar] [CrossRef]

- Peng, F.; Jiang, Y.; Feng, J.; Cai, H.; Feng, J.; Li, L. Thermally insulating, fiber-reinforced alumina–silica aerogel composites with ultra-low shrinkage up to 1500 C. Chem. Eng. J. 2021, 411, 128402. [Google Scholar] [CrossRef]

- Huang, R.; Jiang, Y.; Feng, J.; Li, L.; Hu, Y.; Wang, X.; Feng, J. Robust and exceptional thermal insulating alumina-silica aerogel composites reinforced by ultra IR-opacified ZrO2 nanofibers. Chem. Eng. J. 2024, 498, 155283. [Google Scholar] [CrossRef]

- Mao, J.; Iocozzia, J.; Huang, J.; Meng, K.; Lai, Y.; Lin, Z. Graphene aerogels for efficient energy storage and conversion. Energy Environ. Sci. 2018, 11, 772–799. [Google Scholar] [CrossRef]

- Li, J.; Xu, Z.; Li, T.; Zhi, D.; Chen, Y.; Lu, Q.; Wang, J.; Liu, Q.; Meng, F. Multifunctional antimony tin oxide/reduced graphene oxide aerogels with wideband microwave absorption and low infrared emissivity. Compos. Part B Eng. 2022, 231, 109565. [Google Scholar] [CrossRef]

- Wei, H.; Li, A.; Kong, D.; Li, Z.; Cui, D.; Li, T.; Dong, B.; Guo, Z. Polypyrrole/reduced graphene aerogel film for wearable piezoresisitic sensors with high sensing performances. Adv. Compos. Hybrid Mater. 2021, 4, 86–95. [Google Scholar] [CrossRef]

- Wei, S.; Ching, Y.C.; Chuah, C.H. Synthesis of chitosan aerogels as promising carriers for drug delivery: A review. Carbohydr. Polym. 2020, 231, 115744. [Google Scholar] [CrossRef]

- Ma, B.; Cheng, Y.; Hu, P.; Fang, D.; Wang, J. Passive daytime radiative cooling of silica aerogels. Nanomaterials 2023, 13, 467. [Google Scholar] [CrossRef]

- Shan, J.; Shan, Y.; Zou, C.; Hong, Y.; Liu, J.; Guo, X. Cost-Effective Preparation of Hydrophobic and Thermal-Insulating Silica Aerogels. Nanomaterials 2024, 14, 119. [Google Scholar] [CrossRef]

- Benamara, M.; Iben Nassar, K.; Rivero-Antúnez, P.; Essid, M.; Soreto Teixeira, S.; Zhao, S.; Serrà, A.; Esquivias, L. Study of Electrical and Dielectric Behaviors of Copper-Doped Zinc Oxide Ceramic Prepared by Spark Plasma Sintering for Electronic Device Applications. Nanomaterials 2024, 14, 402. [Google Scholar] [CrossRef]

- Wu, J.; Shao, G.; Wu, X.; Cui, S.; Shen, X. Ag-Incorporated Cr-Doped BaTiO3 Aerogel toward Enhanced Photocatalytic Degradation of Methyl Orange. Nanomaterials 2024, 14, 848. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Lu, J.; Duan, C.; Wu, C.; Lin, J.; Qiu, R.; Zhang, Z.; Yang, J.; Zhou, B.; Du, A. Effect of Titanium Dioxide Particles on the Thermal Stability of Silica Aerogels. Nanomaterials 2024, 14, 1304. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Siller, L.; Zhou, B.; Du, A. Advances in Nanoporous Composited Aerogels: Enhancing Durability and Expanding Applications. Nanomaterials 2025, 15, 185. https://doi.org/10.3390/nano15030185

Lu J, Siller L, Zhou B, Du A. Advances in Nanoporous Composited Aerogels: Enhancing Durability and Expanding Applications. Nanomaterials. 2025; 15(3):185. https://doi.org/10.3390/nano15030185

Chicago/Turabian StyleLu, Jialu, Lidija Siller, Bin Zhou, and Ai Du. 2025. "Advances in Nanoporous Composited Aerogels: Enhancing Durability and Expanding Applications" Nanomaterials 15, no. 3: 185. https://doi.org/10.3390/nano15030185

APA StyleLu, J., Siller, L., Zhou, B., & Du, A. (2025). Advances in Nanoporous Composited Aerogels: Enhancing Durability and Expanding Applications. Nanomaterials, 15(3), 185. https://doi.org/10.3390/nano15030185