Ultrathin Gold Nanowires

Abstract

:1. Introduction

2. Methodology

2.1. In Situ TEM Experiment

2.2. First-Principle Calculations

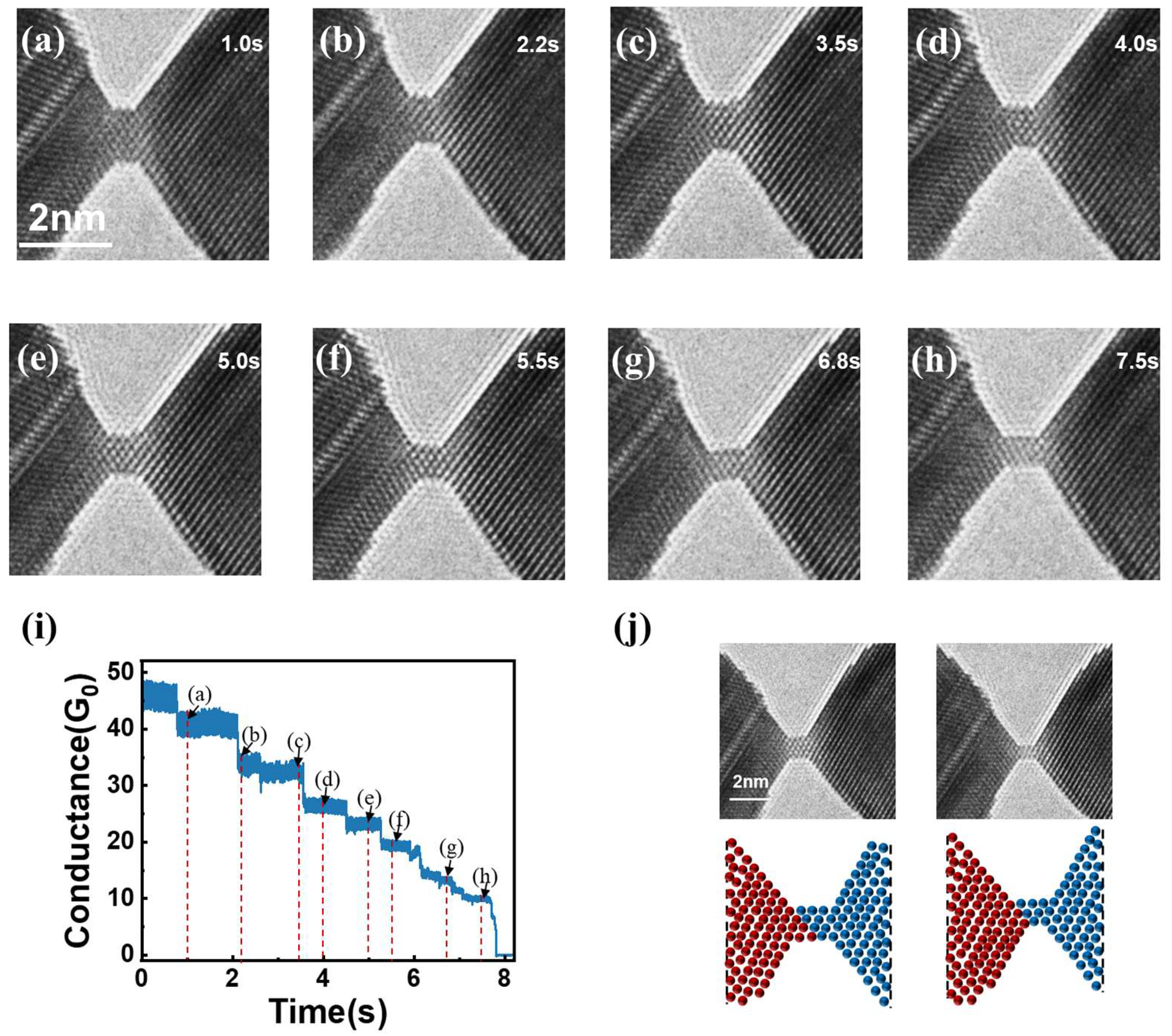

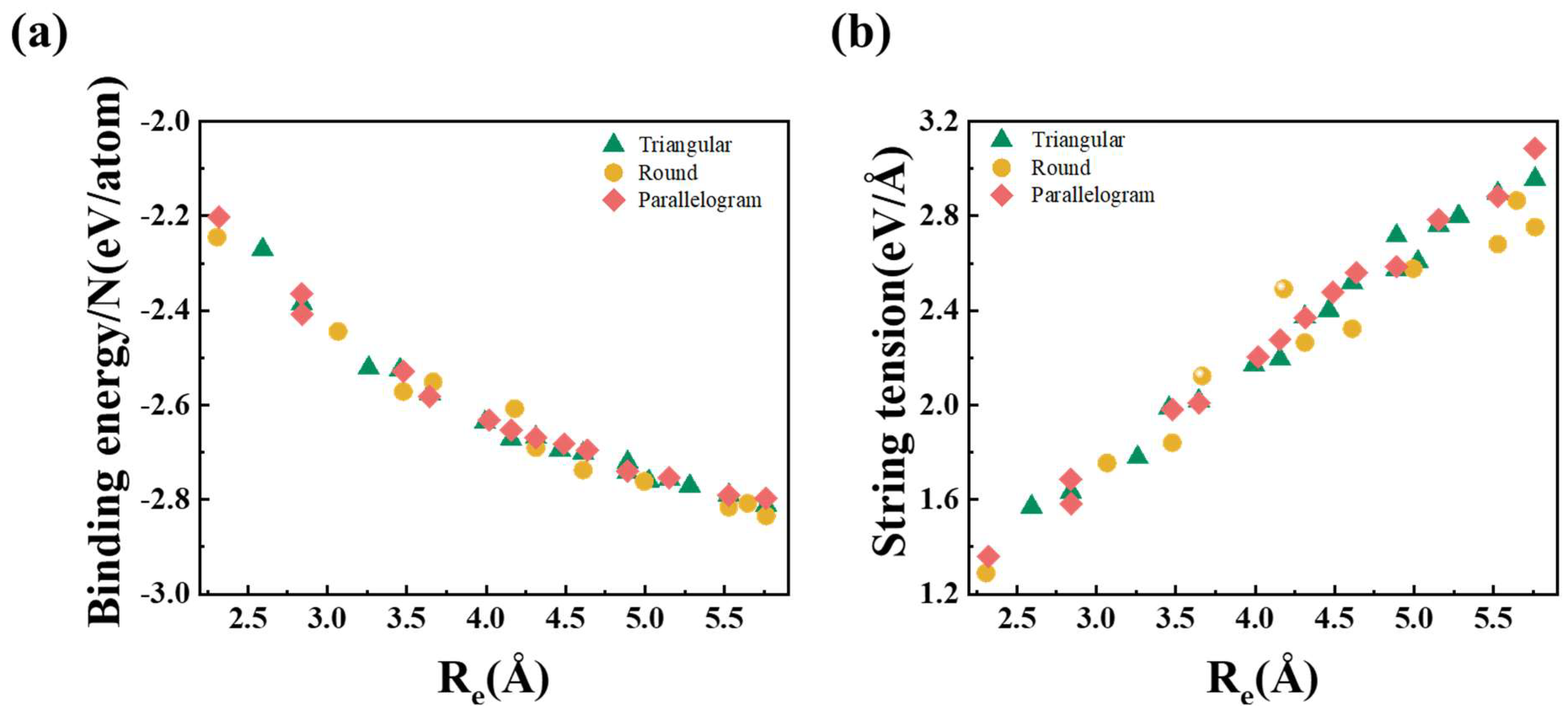

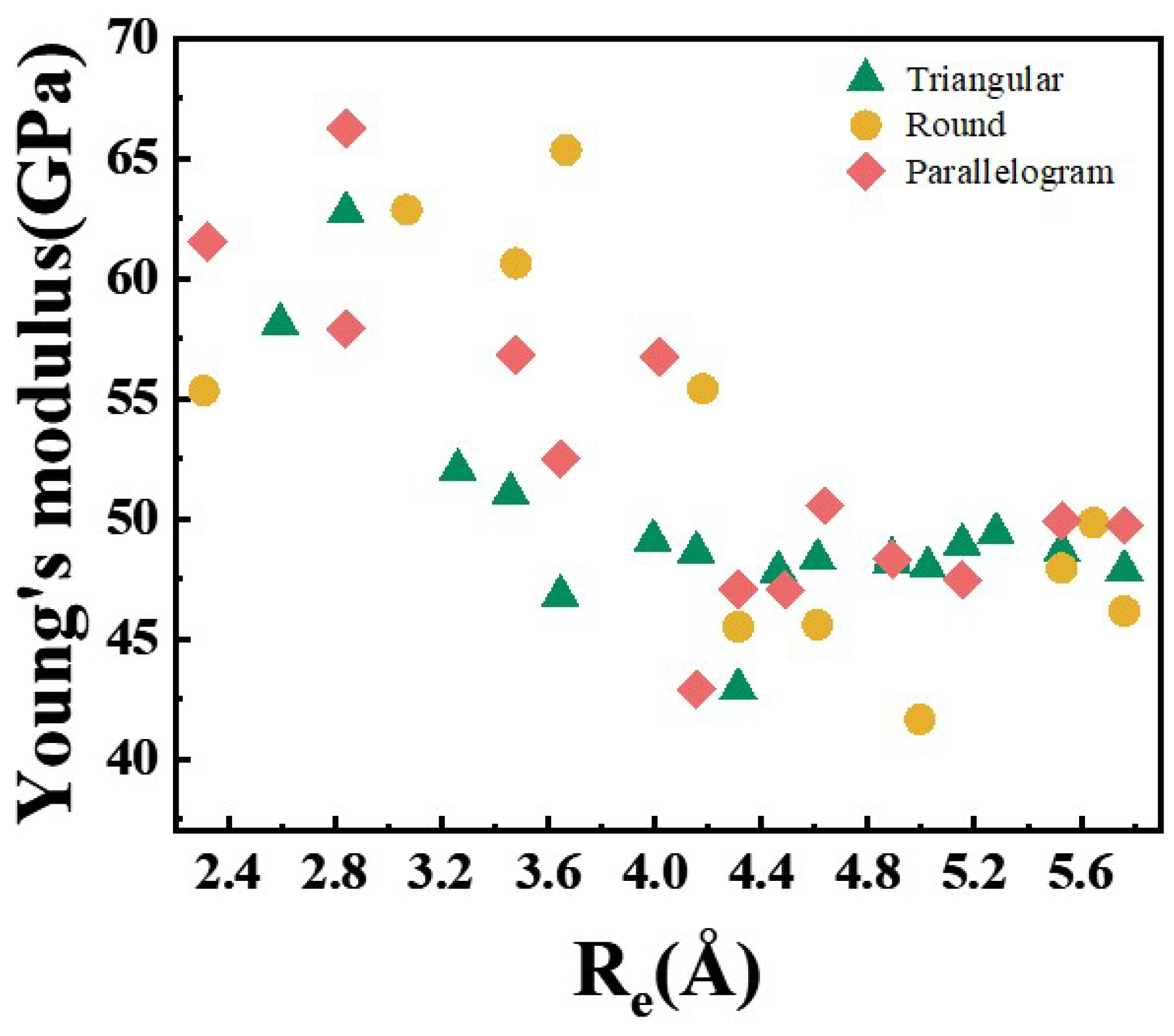

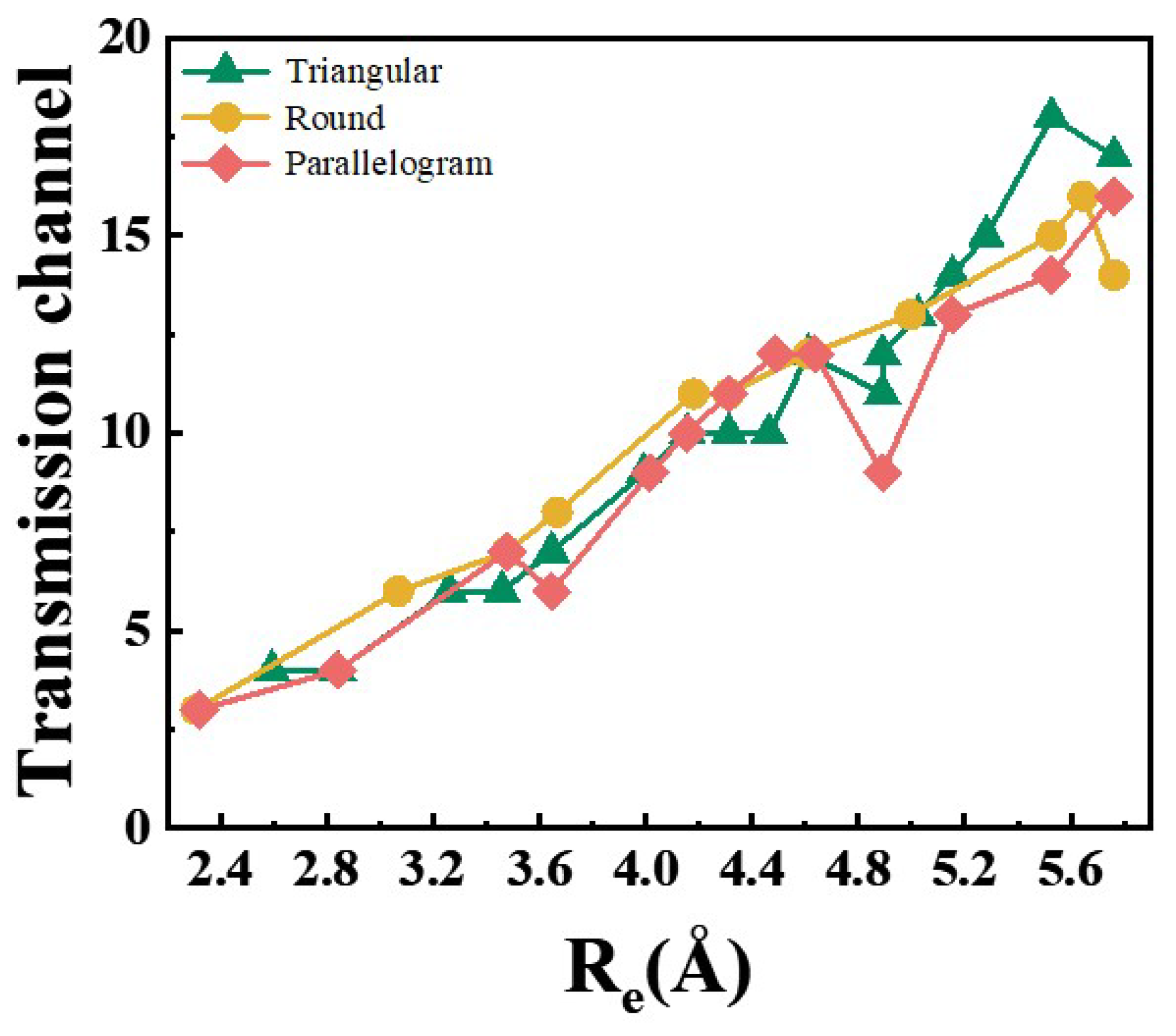

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sivkov, I.N.; Brovko, O.O.; Bazhanov, D.I.; Stepanyuk, V.S. Emergence of high spin polarization of conductance in atomic-size Co-Au contacts. Phys. Rev. B 2014, 89, 75436. [Google Scholar] [CrossRef]

- Reiser, B.; Gerstner, D.; Gonzalez-Garcia, L.; Maurer, J.H.M.; Kanelidis, I.; Kraus, T. Spinning hierarchical gold nanowire microfibers by shear alignment and intermolecular self-assembly. ACS Nano 2017, 11, 4934–4942. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.C.; Lee, H.M.; Kim, W.Y.; Kwon, S.K.; Nautiyal, T.; Cheng, D.-Y.; Vishwanathan, K.; Kim, K.S. How can we make stable linear monoatomic chains? gold-cesium binary subnanowires as anexample of a charge-transfer-driven approach to alloying. Phys. Rev. Lett. 2007, 98, 76101. [Google Scholar] [CrossRef]

- Vargas, J.A.; Petkov, V.; Nouh, E.S.A.; Ramamoorthy, R.K.; Lacroix, L.-M.; Poteau, R.; Viau, G.; Lecante, P.; Arenal, R. Ultrathin Gold nanowires with the polytetrahedral structure of bulk manganese. ACS Nano 2018, 12, 9521–9531. [Google Scholar] [CrossRef] [PubMed]

- Comtet, J.; Lainé, A.; Niguès, A.; Bocquet, L.; Siria, A. Atomic rheology of gold nanojunctions. Nature 2019, 569, 393–397. [Google Scholar] [CrossRef]

- Yi, B.; Pang, R.; Ren, X.; Guo, H.; Shang, Y.; Duan, X.; Cho, J.-H.; Li, S. Phase transition of nanoscale Au atom chains on NiAl(110). Phys. Lett. A 2020, 384, 126183. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, K.; Zhao, X.; Xue, X.; Zhang, L.; Pang, R.; Ren, X.; Li, S. Negative-positive oscillation in interfacial friction of a In2Se3-graphene heterojunction. Phys. Rev. B 2022, 106, 195416. [Google Scholar] [CrossRef]

- Wang, Q. Negative differential friction predicted in two-dimensional electride commensurate contacts: Role of the electronic structure. Phys. Rev. B 2024, 109, 85420. [Google Scholar] [CrossRef]

- Hauser, J.; Rothhardt, D.; Pfender-Siedle, R.; Hoffmann-Vogel, R. Shell effects and free-electrons in electromigrated oxidized Cu-nanocontacts. Nanotechnology 2023, 34, 175703. [Google Scholar] [CrossRef]

- Zhang, J.; Tomitori, M.; Arai, T.; Oshima, Y. Surfaceeffect on young’s modulus of sub-two-nanometer gold [111] nanocontacts. Phys. Rev. Lett. 2022, 128, 146101. [Google Scholar] [CrossRef]

- De Heer, W.A. The physics of simple metal clusters: Experimental aspects and simple models. Rev. Mod. Phys. 1993, 65, 611–676. [Google Scholar] [CrossRef]

- Ohnishi, H.; Kondo, Y.; Takayanagi, K. Quantized conductance through individual rows of suspended gold atoms. Nature 1998, 395, 780–783. [Google Scholar] [CrossRef]

- Zhang, J.; Ishizuka, K.; Tomitori, M.; Arai, T.; Oshima, Y. Atomic scale mechanics explored by in situ transmission electron microscopy with a quartz length-extension resonator as a force sensor. Nanotechnology 2020, 31, 205706. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Lichtenstein, T.; Tegenkamp, C.; Braun, C.; Schmidt, W.G.; Sanna, S.; Pfnür, H. Plasmon spectroscopy: Robust metallicity of Au wires on Si(557) upon oxidation. Phys. Rev. Mater. 2018, 2, 66002. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Tegenkamp, C.; Pfnür, H. Plasmon localization by adatoms in gold atomic wires on Si(775). J. Phys. Condens. Matter 2021, 33, 205001. [Google Scholar] [CrossRef]

- Scheer, E.; Agraït, N.; Cuevas, J.C.; Yeyati, A.L.; Ludoph, B.; Martín-Rodero, A.; Bollinger, G.R.; Van Ruitenbeek, J.M.; Urbina, C. The signature of chemical valence in the electrical conduction through a single-atom contact. Nature 1998, 394, 154–157. [Google Scholar] [CrossRef]

- Medina, E.; Díaz, M.; León, N.; Guerrero, C.; Hasmy, A.; Serena, P.A.; Costa-Krämer, J.L. Ionic shell and subshell structures in aluminum and gold nanocontacts. Phys. Rev. Lett. 2003, 91, 26802. [Google Scholar] [CrossRef]

- Requist, R.; Baruselli, P.P.; Smogunov, A.; Fabrizio, M.; Modesti, S.; Tosatti, E. Metallic, magnetic and molecular nanocontacts. Nat. Nanotechnol. 2016, 11, 499–508. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, D.; Huang, Z.; Liu, X.; Chen, J.; Sekiguchi, T.; Qu, W.; Chen, J.; Xu, D.; Bando, Y.; et al. Stable single atomic silver wires assembling into a circuitry-connectable nanoarray. Nat. Commun. 2021, 12, 1191. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Sanna, S.; Lichtenstein, T.; Tegenkamp, C.; Pfnür, H. Extrinsic doping on the atomic scale: Tuning metallicity in atomic Au chains. Phys. Rev. B 2018, 98, 245414. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Fink, C.; Holtgrewe, K.; Pfnür, H.; Sanna, S. Enforced long-range order in 1D wires by coupling to higher dimensions. Phys. Rev. Lett. 2021, 126, 106101. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Pfnür, H. View on Si (111) − (5×2) − Au with plasmon spectroscopy. Phys. Rev. B 2020, 102, 75438. [Google Scholar] [CrossRef]

- Mamiyev, Z.; Tzschoppe, M.; Huck, C.; Pucci, A.; Pfnür, H. Plasmon standing waves by oxidation of Si(553)–Au. J. Phys. Chem. C 2019, 123, 9400–9406. [Google Scholar] [CrossRef]

- Sanna, S.; Lichtenstein, T.; Mamiyev, Z.; Tegenkamp, C.; Pfnür, H. How one-dimensional are atomic gold chains on asubstrate? J. Phys. Chem. C 2018, 122, 25580–25588. [Google Scholar] [CrossRef]

- Liang, M.; Xia, T.; Gao, H.; Zhao, K.; Cao, T.; Deng, M.; Ren, X.; Li, S.; Guo, H.; Wang, R. Modulating reaction pathways of formic acid oxidation for optimized electrocatalytic performance of PtAu/CoNC. Nano Res. 2022, 15, 1221–1229. [Google Scholar] [CrossRef]

- Chen, C.; Song, K.; Wang, X.; Du, K. Phase Transition to heptagonal-cluster-packed structure of gold nanoribbons. J. Am. Chem. Soc. 2022, 144, 1158–1163. [Google Scholar] [CrossRef]

- Kurui, Y.; Oshima, Y.; Okamoto, M.; Takayanagi, K. Conductance quantization and dequantization in gold nanowires due to multiple reflection at the interface. Phys. Rev. B 2009, 79, 165414. [Google Scholar] [CrossRef]

- Jia, B.; Shangguan, L.; Li, Q.; Ma, L.; Li, M.; Zhong, Y.; Duan, Z. Improve anisotropy shrinkage and conductivity of Ag interconnected wires by non-contact ultrasonic field. J. Phys. Appl. Phys. 2019, 52, 375103. [Google Scholar] [CrossRef]

- Zhao, K.; Qian, T.; Bai, X.; Feng, M.; Gao, H.; Xia, T.; Wang, Z.; Guo, H. PtNi multi-branched nanostructures as efficient bifunctional electrocatalysts for fuel cell. J. Phys. Appl. Phys. 2022, 55, 344001. [Google Scholar] [CrossRef]

- Filho, M.A.M.; Farmer, W.; Hsiao, C.-L.; Dos Santos, R.B.; Hultman, L.; Birch, J.; Ankit, K.; Gueorguiev, G.K. Density functional theory-fed phase field model for semiconductor nanostructures: The case of self-induced core–shell InAlN nanorods. Cryst. Growth Des. 2024, 24, 4717–4727. [Google Scholar] [CrossRef]

- Gueorguiev, G.K.; Stafström, S.; Hultman, L. Nano-wire formation by self-assembly of silicon–metal cage-like molecules. Chem. Phys. Lett. 2008, 458, 170–174. [Google Scholar] [CrossRef]

- Alves Machado Filho, M.; Hsiao, C.-L.; Dos Santos, R.B.; Hultman, L.; Birch, J.; Gueorguiev, G.K. Self-induced core–shell InAlN nanorods:formation andstability unraveled by Abinitio simulations. ACS Nanosci. Au 2023, 3, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Zhang, F.; Wang, Y.; Xue, X.; Shi, J.; Zhao, X.; Zhang, L.; Pang, R.; Ren, X.; Li, S.; et al. Dynamically confined single-atom catalytic sites within a porous heterobilayer for CO oxidation via electronic antenna effects. Phys. Rev. B 2023, 107, 205421. [Google Scholar] [CrossRef]

- Liu, C.; Hongo, K.; Maezono, R.; Zhang, J.; Oshima, Y. Stiffer bonding of armchair edge in single-layer molybdenum disulfide nanoribbons. Adv. Sci. 2023, 10, 2303477. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Zhang, L.; Pang, R.; Zhao, X.; Cheng, J.; Zhang, Y.; Xue, X.; Ren, X.; Zhu, W.; Li, S.; et al. Negative differential friction predicted in 2D ferroelectric In2 Se3 commensurate contacts. Adv. Sci. 2022, 9, 2103443. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Li, Y.; Fu, R.; Feng, Y.; Chang, D.; Yuan, Y.; Gao, H.; Jiang, S.; Wang, F.; et al. Pressure-induced metallization of lead-free halide double perovskite (NH4)2 PtI6. Adv. Sci. 2022, 9, 2203442. [Google Scholar] [CrossRef]

- Jiang, C.; Yang, Z.; Xiong, W.; Wang, F. Effect of strain engineering on magnetism-induced valley splitting in WSe2 based on the WSe2/CrSe2 heterojunction. Appl. Phys. Lett. 2021, 119, 162101. [Google Scholar] [CrossRef]

- Rodrigues, V.; Fuhrer, T.; Ugarte, D. Signature of atomic structure in the quantum conductance of gold nanowires. Phys. Rev. Lett. 2000, 85, 4124–4127. [Google Scholar] [CrossRef]

- Kondo, Y.; Takayanagi, K. Synthesis and characterization of helical multi-shell gold nanowires. Science 2000, 289, 606–608. [Google Scholar] [CrossRef]

- Hu, H.; Choi, J.-H. Adsorption of atomic hydrogen on monolayer MoS2. Nanotechnology 2021, 32, 235701. [Google Scholar] [CrossRef]

- Tavazza, F.; Levine, L.E.; Chaka, A.M. Structural changes during the formation of gold single-atom chains: Stability criteria and electronic structure. Phys. Rev. B 2010, 81, 235424. [Google Scholar] [CrossRef]

- Cai, X.; Niu, C.; Wang, J.; Yu, W.; Ren, X.; Zhu, Z. Magnetic engineering in 3d transition metals on phosphorene by strain. Phys. Lett. A 2017, 381, 1236–1240. [Google Scholar] [CrossRef]

- Li, S.F.; Li, H.; Xue, X.; Jia, Y.; Guo, Z.X.; Zhang, Z.; Gong, X.G. hcp metal nanoclusters with hexagonal A − A bilayer stacking stabilized by enhanced covalent bonding. Phys. Rev. B 2010, 82, 35443. [Google Scholar] [CrossRef]

- Yang, Y.-Q.; Zhao, C.-X.; Bai, S.-Y.; Wang, C.-P.; Niu, C.-Y. Activating MoS2 basal planes for hydrogen evolution through the as doping and strain. Phys. Lett. A 2019, 383, 2997–3000. [Google Scholar] [CrossRef]

- Oenen, K.; Dinu, D.F.; Liedl, K.R. Determining internal coordinate sets for optimal representation of molecular vibration. J. Chem. Phys. 2024, 160, 14104. [Google Scholar] [CrossRef]

- Hermes, E.D.; Sargsyan, K.; Najm, H.N.; Zádor, J. Geometry optimization speedup through a geodesic approach to internal coordinates. J. Chem. Phys. 2021, 155, 94105. [Google Scholar] [CrossRef]

- Cheng, D.; Kim, W.Y.; Min, S.K.; Nautiyal, T.; Kim, K.S. Magic structures and quantum conductance of [110] silver nanowires. Phys. Rev. Lett. 2006, 96, 96104. [Google Scholar] [CrossRef]

- Jia, J.; Shi, D.; Zhao, J.; Wang, B. Structural properties of silver nanowires from atomistic descriptions. Phys. Rev. B 2007, 76, 165420. [Google Scholar] [CrossRef]

- Jariwala, P.H.; Gupta, S.K.; Sonvane, Y.A.; Thakor, P.B. Structural, electronic, mechanical and quantum transport of ultrathin gold nanowire: A density functional approach. Superlattices Microstruct. 2017, 106, 206–215. [Google Scholar] [CrossRef]

- Tosatti, E. Nanowire formation at metal–metal contacts. Solid State Commun. 2005, 135, 610–617. [Google Scholar] [CrossRef]

- Tosatti, E.; Prestipino, S.; Kostlmeier, S.; Corso, A.D.; Di Tolla, F.D. String tension and stability of magic tip-suspended nanowires. Science 2001, 291, 288–290. [Google Scholar] [CrossRef] [PubMed]

- Oshima, Y.; Kurui, Y.; Takayanagi, K. One-by-one introduction of single lattice planes in a bottlenecked gold contact during stretching. J. Phys. Soc. Jpn. 2010, 79, 54702. [Google Scholar] [CrossRef]

- Calvo, M.R.; Sabater, C.; Dednam, W.; Lombardi, E.B.; Caturla, M.J.; Untiedt, C. Influence of relativistic effects on the contact formation of transition metals. Phys. Rev. Lett. 2018, 120, 76802. [Google Scholar] [CrossRef] [PubMed]

- Rose, J.H.; Ferrante, J.; Smith, J.R. Universal binding energy curves for metals and bimetallic interfaces. Phys. Rev. Lett. 1981, 47, 675–678. [Google Scholar] [CrossRef]

- Sun, S.; Kong, D.; Li, D.; Liao, X.; Liu, D.; Mao, S.; Zhang, Z.; Wang, L.; Han, X. Atomistic mechanism of stress-induced combined slip and diffusion in Sub-5 nanometer-sized Ag nanowires. ACS Nano 2019, 13, 8708–8716. [Google Scholar] [CrossRef]

- He, C.; Zhang, W.X.; Shi, Z.Q.; Wang, J.P.; Pan, H. Effect of bending stress on structures and quantum conduction of Cu nanowires. Appl. Phys. Lett. 2012, 100, 123107. [Google Scholar] [CrossRef]

- Kundu, P.; Turner, S.; Van Aert, S.; Ravishankar, N.; Van Tendeloo, G. Atomic structure of quantum gold nanowires: Quantification of the lattice strain. ACS Nano 2014, 8, 599–606. [Google Scholar] [CrossRef]

- Da Silva, E.Z.; Novaes, F.D.; Da Silva, A.J.R.; Fazzio, A. Theoretical study of the formation, evolution, and breaking of gold nanowires. Phys. Rev. B 2004, 69, 115411. [Google Scholar] [CrossRef]

- Ma, L.-C.; Zhang, J.-M.; Xu, K.-W. Structural and electronic properties of ultrathin copper nanowires: A density-functional theory study. Phys. B Condens. Matter 2013, 410, 105–111. [Google Scholar] [CrossRef]

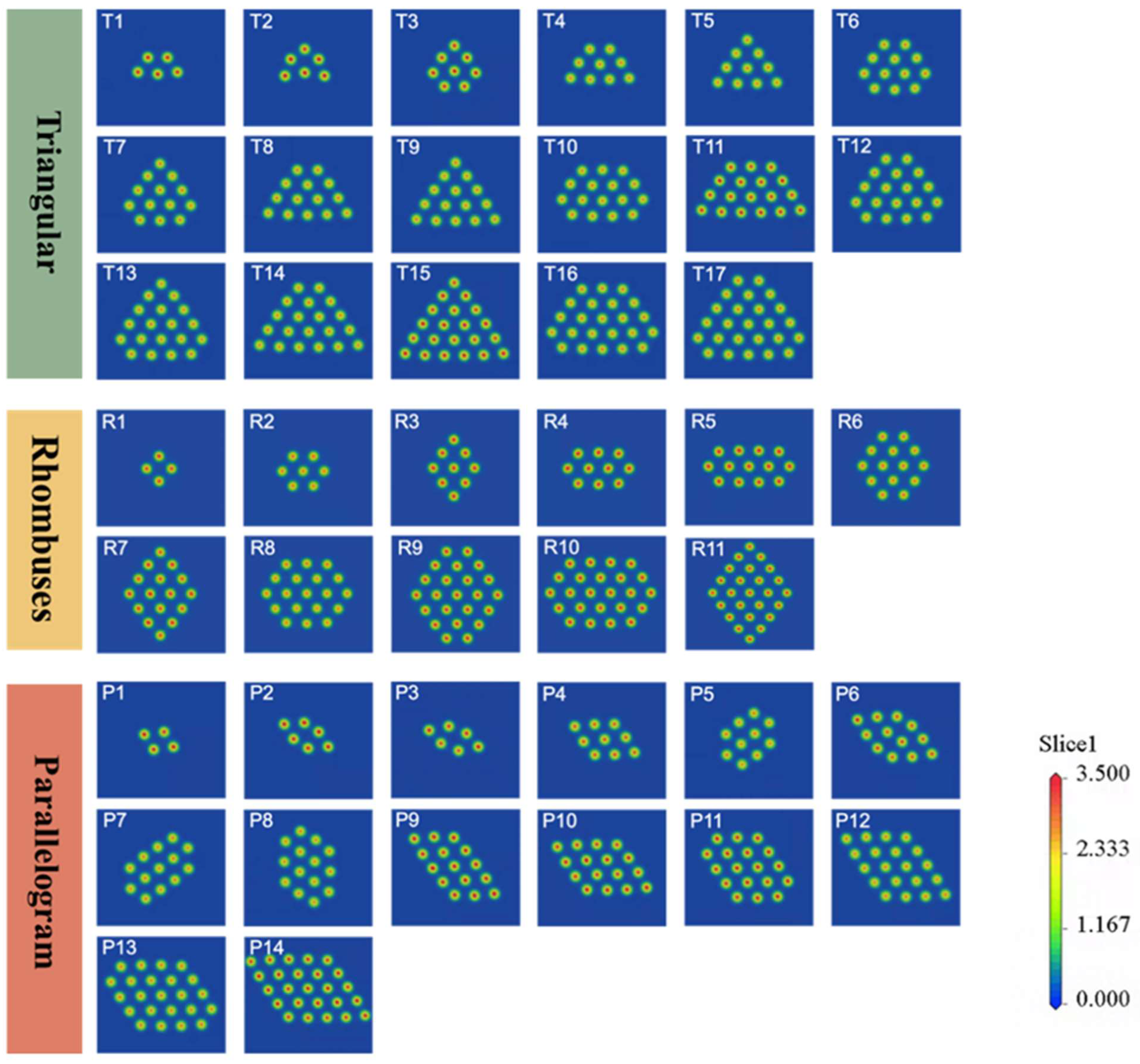

| Configurations | Natoms | NG0 | E (eV/atom) | f (ev/Å) | Proportion of (111) Facet | Y(Gpa) | |

|---|---|---|---|---|---|---|---|

| T series | T1 | 5 | 4 | −2.27 | 1.57 | 0.36 | 58.14 |

| T2 | 6 | 4 | −2.39 | 1.63 | 0.63 | 62.77 | |

| T3 | 8 | 6 | −2.52 | 1.78 | 0.84 | 52.07 | |

| T4 | 9 | 6 | −2.53 | 1.99 | 0.46 | 51.09 | |

| T5 | 10 | 7 | −2.58 | 2.02 | 0.63 | 46.83 | |

| T6 | 12 | 9 | −2.64 | 2.17 | 0.63 | 49.13 | |

| T7 | 13 | 10 | −2.67 | 2.20 | 0.77 | 48.64 | |

| T8 | 14 | 10 | −2.67 | 2.37 | 0.51 | 42.95 | |

| T9 | 15 | 10 | −2.70 | 2.40 | 0.63 | 47.82 | |

| T10 | 16 | 12 | −2.70 | 2.52 | 0.51 | 48.32 | |

| T11 | 18 | 11 | −2.72 | 2.72 | 0.42 | 48.40 | |

| T12 | 18 | 12 | −2.74 | 2.57 | 0.63 | 48.20 | |

| T13 | 19 | 13 | −2.76 | 2.61 | 0.74 | 48.00 | |

| T14 | 20 | 14 | −2.76 | 2.76 | 0.53 | 48.96 | |

| T15 | 21 | 15 | −2.77 | 2.80 | 0.63 | 49.43 | |

| T16 | 23 | 18 | −2.79 | 2.89 | 0.53 | 48.66 | |

| T17 | 25 | 17 | −2.81 | 2.96 | 0.63 | 47.88 | |

| R series | R1 | 4 | 3 | −2.25 | 1.29 | 1 | 55.34 |

| R2 | 7 | 6 | −2.44 | 1.75 | 0.63 | 62.86 | |

| R3 | 9 | 7 | −2.57 | 1.84 | 1 | 60.63 | |

| R4 | 10 | 8 | −2.55 | 2.12 | 0.46 | 65.35 | |

| R5 | 13 | 11 | −2.61 | 2.49 | 0.36 | 55.41 | |

| R6 | 14 | 11 | −2.69 | 2.26 | 0.77 | 45.51 | |

| R7 | 16 | 12 | −2.74 | 2.32 | 1 | 45.60 | |

| R8 | 19 | 13 | −2.76 | 2.58 | 0.63 | 41.65 | |

| R9 | 23 | 15 | −2.82 | 2.68 | 0.84 | 47.95 | |

| R10 | 24 | 16 | −2.81 | 2.86 | 0.53 | 49.84 | |

| R11 | 25 | 14 | −2.84 | 2.75 | 1 | 46.16 | |

| P series | P1 | 4 | 3 | −2.20 | 1.36 | 0.46 | 61.52 |

| P2 | 6 | 4 | −2.41 | 1.58 | 0.63 | 57.91 | |

| P3 | 6 | 4 | −2.36 | 1.69 | 0.3 | 66.26 | |

| P4 | 9 | 7 | −2.53 | 1.98 | 0.46 | 56.82 | |

| P5 | 10 | 6 | −2.58 | 2.01 | 0.72 | 52.49 | |

| P6 | 12 | 9 | −2.63 | 2.20 | 0.56 | 56.74 | |

| P7 | 13 | 10 | −2.65 | 2.28 | 0.77 | 42.91 | |

| P8 | 14 | 11 | −2.67 | 2.37 | 0.63 | 47.05 | |

| P9 | 15 | 12 | −2.68 | 2.48 | 0.56 | 47.05 | |

| P10 | 16 | 12 | −2.70 | 2.56 | 0.46 | 50.55 | |

| P11 | 18 | 9 | −2.74 | 2.58 | 0.63 | 48.33 | |

| P12 | 20 | 13 | −2.75 | 2.79 | 0.53 | 47.48 | |

| P13 | 23 | 14 | −2.79 | 2.88 | 0.53 | 49.91 | |

| P14 | 25 | 16 | −2.80 | 3.09 | 0.46 | 49.73 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Liu, C.; Wang, Y.; Zhang, J.; Cheng, S.; Shan, C. Ultrathin Gold Nanowires. Nanomaterials 2025, 15, 428. https://doi.org/10.3390/nano15060428

Liu S, Liu C, Wang Y, Zhang J, Cheng S, Shan C. Ultrathin Gold Nanowires. Nanomaterials. 2025; 15(6):428. https://doi.org/10.3390/nano15060428

Chicago/Turabian StyleLiu, Shuo, Chunmeng Liu, Ye Wang, Jiaqi Zhang, Shaobo Cheng, and Chongxin Shan. 2025. "Ultrathin Gold Nanowires" Nanomaterials 15, no. 6: 428. https://doi.org/10.3390/nano15060428

APA StyleLiu, S., Liu, C., Wang, Y., Zhang, J., Cheng, S., & Shan, C. (2025). Ultrathin Gold Nanowires. Nanomaterials, 15(6), 428. https://doi.org/10.3390/nano15060428