Advancements and Strategies in CsPbI2Br Perovskite Solar Cells for Enhanced Efficiency and Stability

Abstract

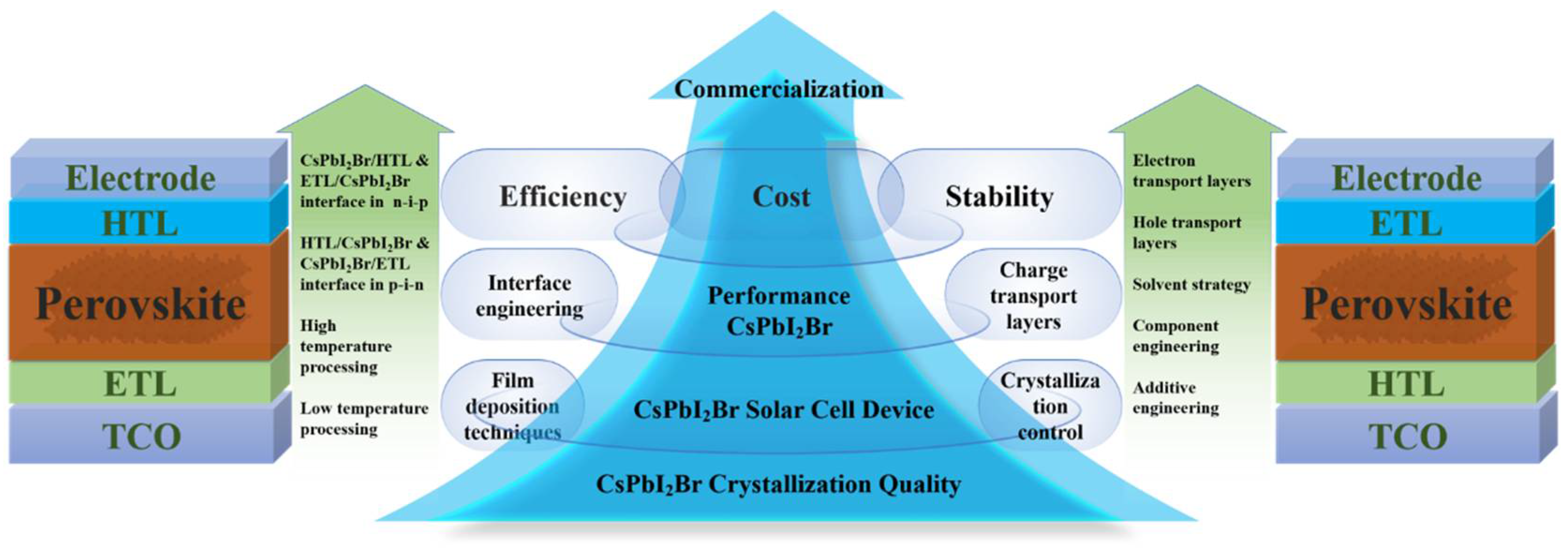

:1. Introduction

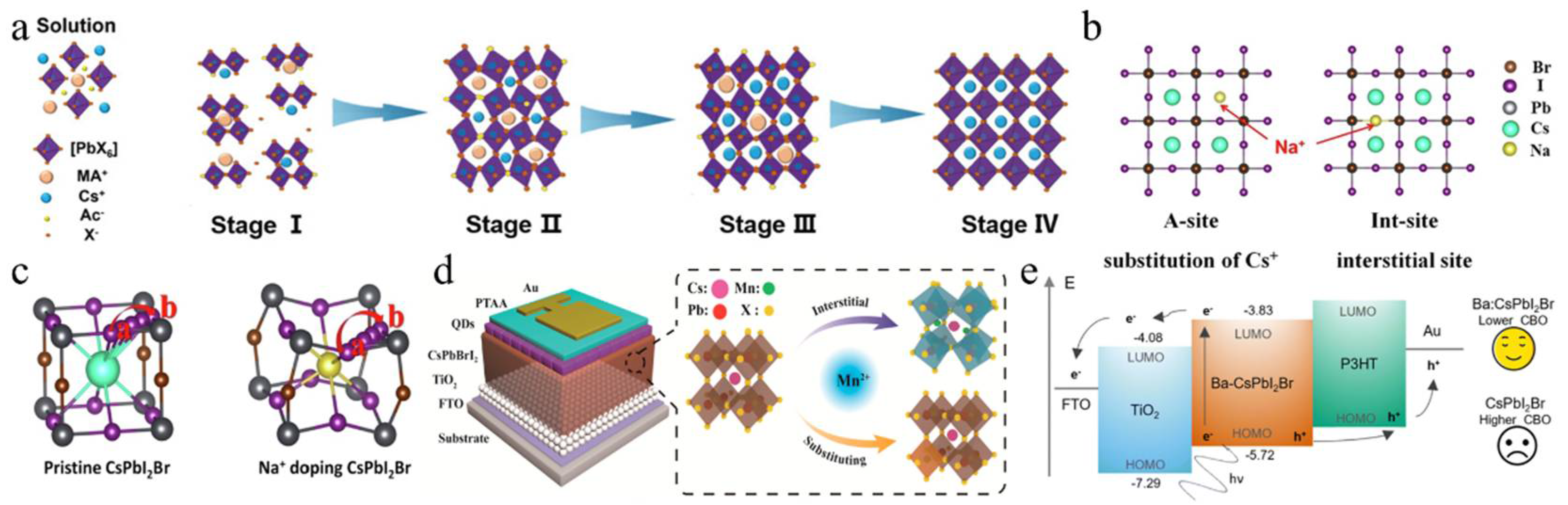

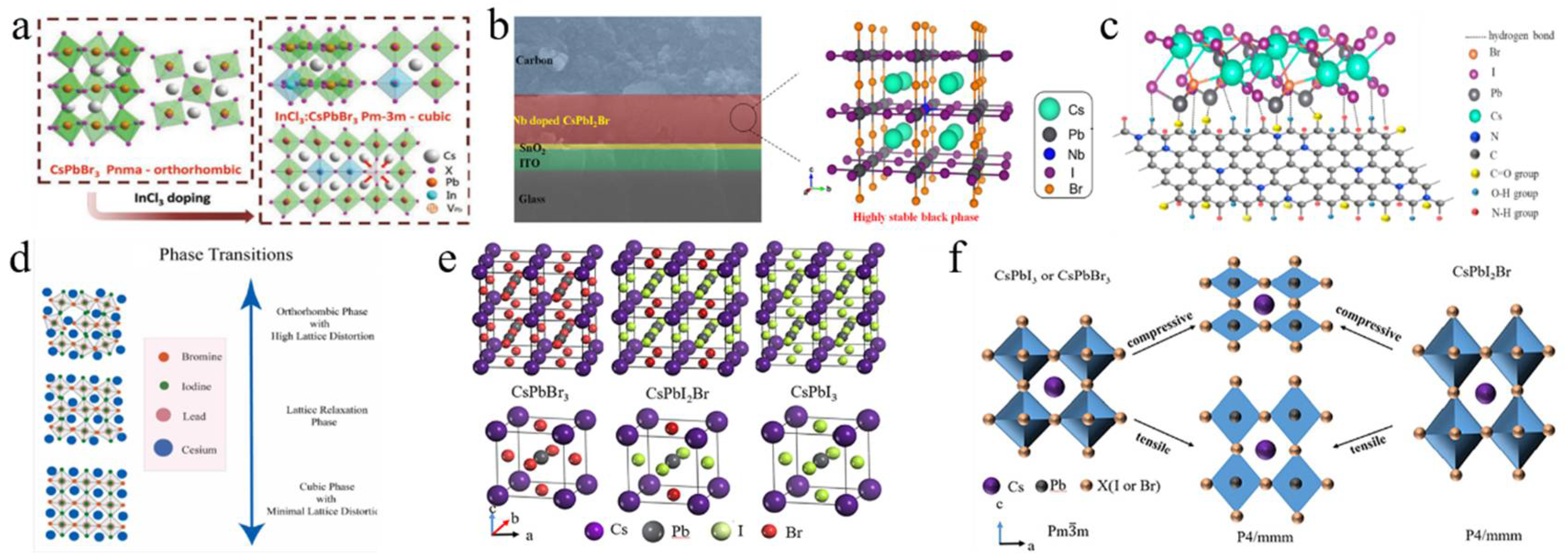

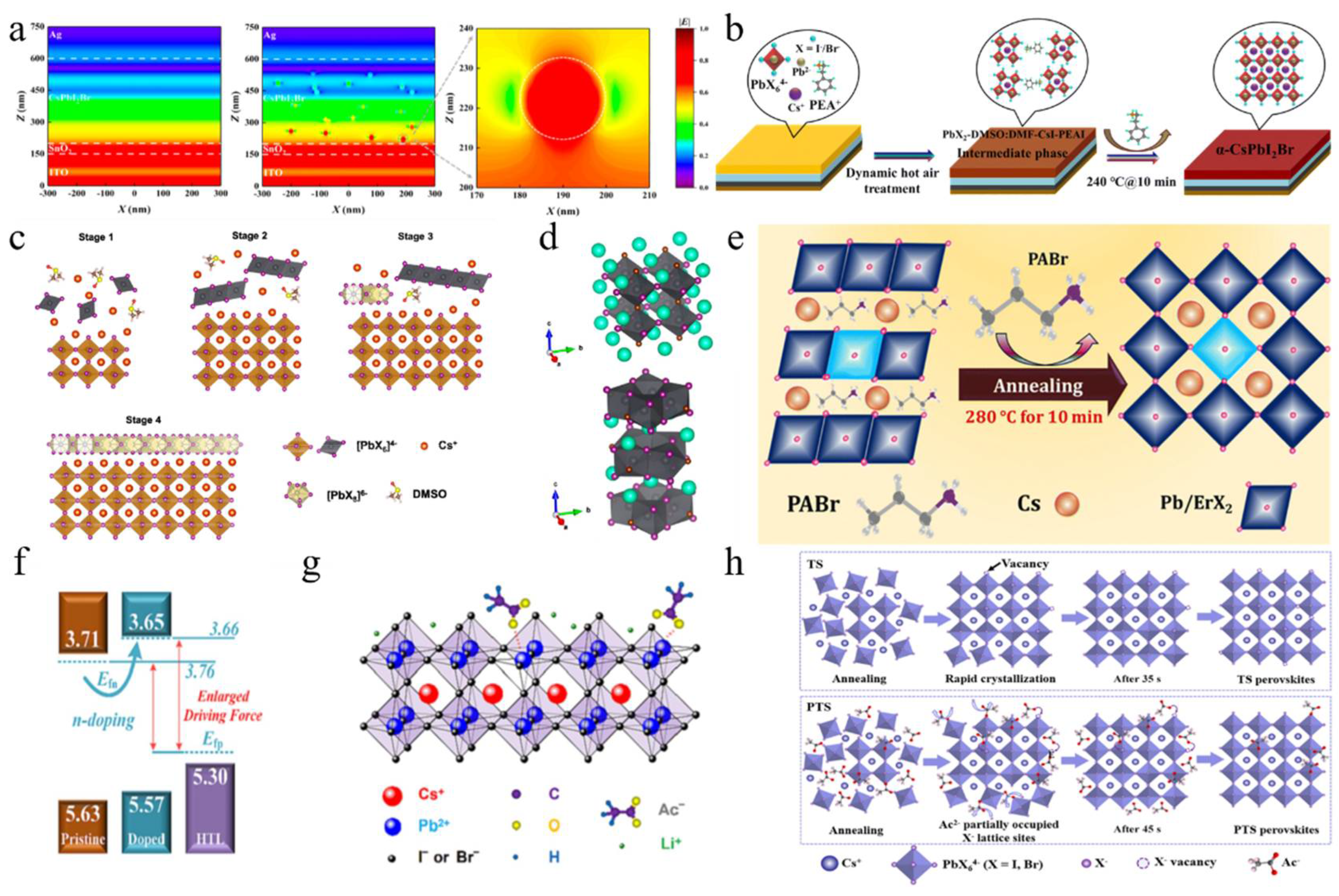

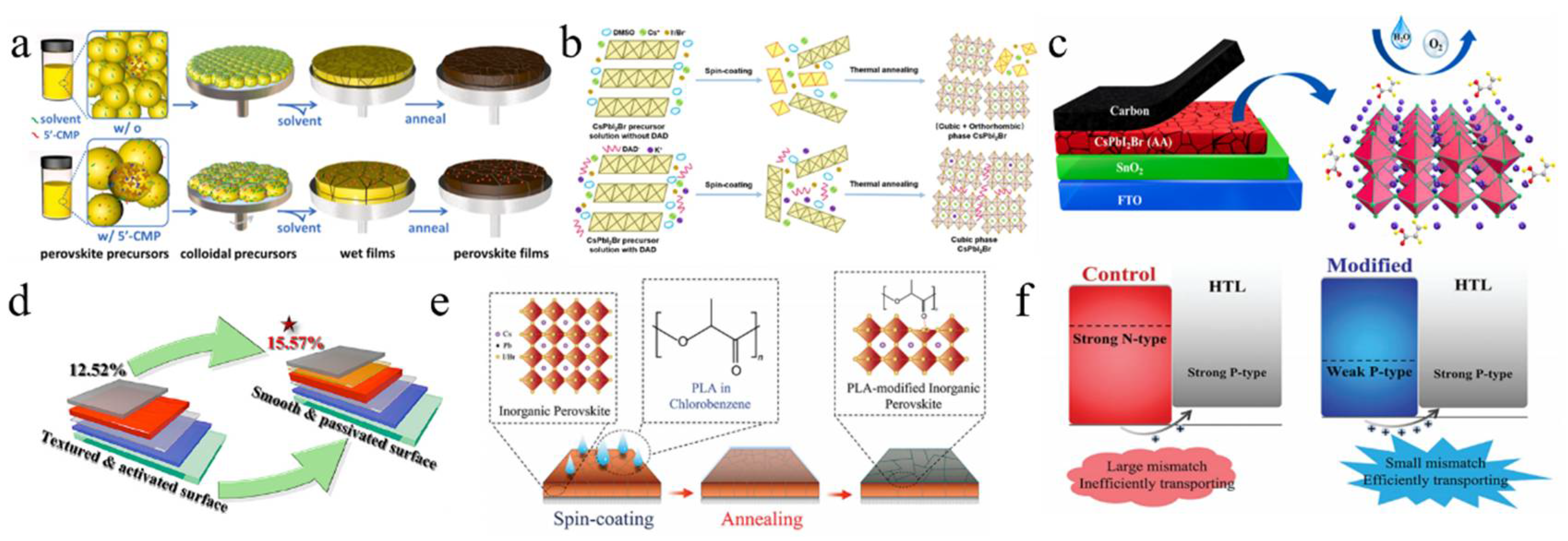

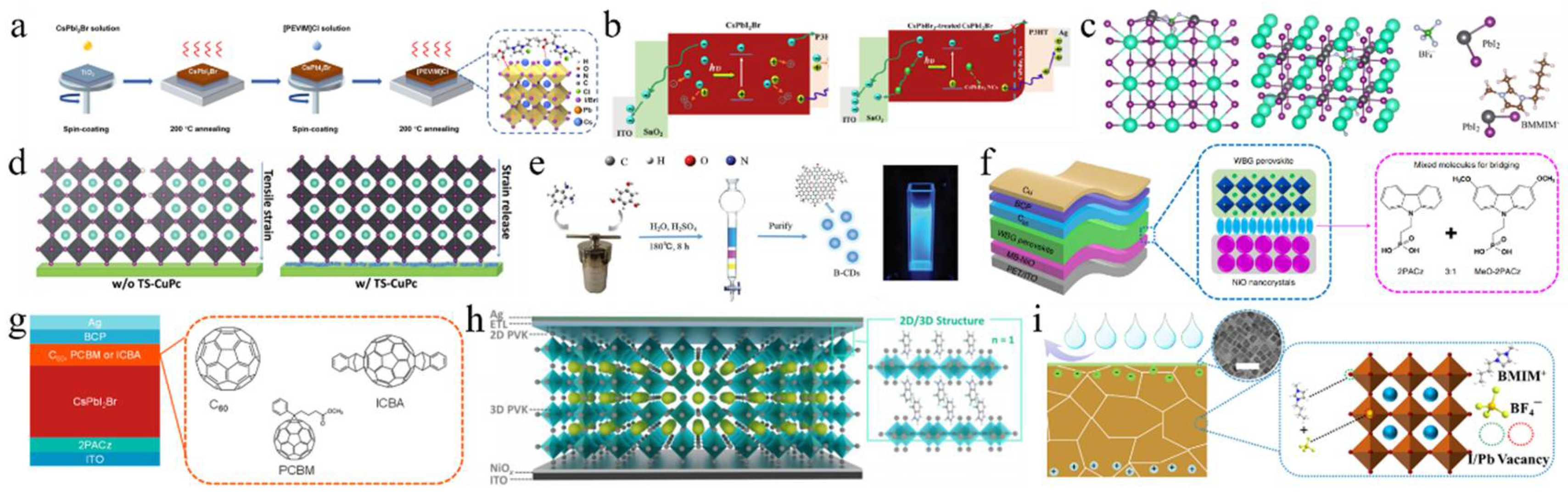

2. CsPbI2Br Film Deposition Techniques

2.1. High-Temperature Processing

2.2. Low-Temperature Processing

3. CsPbI2Br Crystallization Control

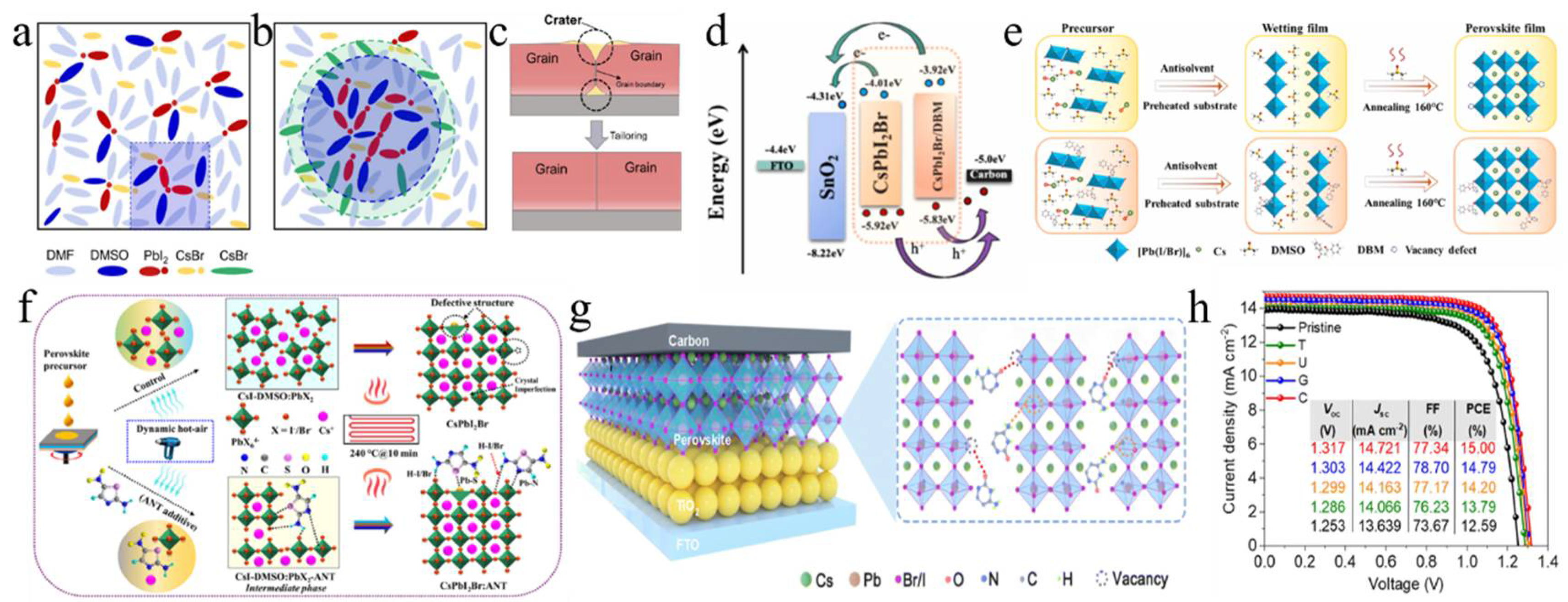

3.1. Solvent Strategy

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year | Refs. |

|---|---|---|---|---|---|---|---|---|

| FTO/c-TiO2/mp-TiO2/CPI2/Spiro-OMeTAD/Ag | 0.12 | 12.52 | 13.56 | 1.24 | 74.3 | No detectable degradation for more than 500 h | 2018 | [57] |

| PET/ITO/NiOx/CsPbI2Br/C60/BCP/Ag | 0.118 | 7.3 | 11.5 | 0.97 | 0.65 | / | 2018 | [58] |

| FTO/c-TiO2/CsPbI2Br/carbon | 0.12 | 10.0 | 13.54 | 1.15 | 64.2 | Retained 94% of its initial PCE after being exposed to air with 15–30% RH for 39 d | 2018 | [62] |

| FTO/SnO2/CsPbI2Br/Spiro-OMeTAD/MoO3/Ag | 0.05 | 15.83 | 16.52 | 1.32 | 72.40 | Maintained 85% of its initial efficiency after being exposed to a N2 atmosphere for 1500 h | 2020 | [60] |

| FTO/c-TiO2/CsPbI2Br/Spiro-OMeTAD/Au | 0.09 | 16.03 | 15.98 | 1.270 | 79.00 | Retained more than 90% of its initial efficiency after 500 h of thermal aging at 85 °C in a N2-filled glove box | 2020 | [61] |

| ITO/SnO2/TiO2/CsPbI2Br/Spiro-OMeTAD/MoO3/Ag | 0.075 | 15.86 | 15.67 | 1.23 | 82.29 | Kept ~95% of its initial PCE after 1 m storage in a N2-filled glove box without any encapsulation | 2020 | [63] |

| FTO/TiO2/CsPbI2Br/PCBM/carbon | 0.9 | 13.46 | 14.71 | 1.19 | 76.28 | Almost no decay after 33 d of storage at 25 °C with an RH of 25% | 2023 | [59] |

3.2. Component Engineering

3.2.1. A-Site

3.2.2. B-Site

3.2.3. X-Site

3.3. Additive Engineering

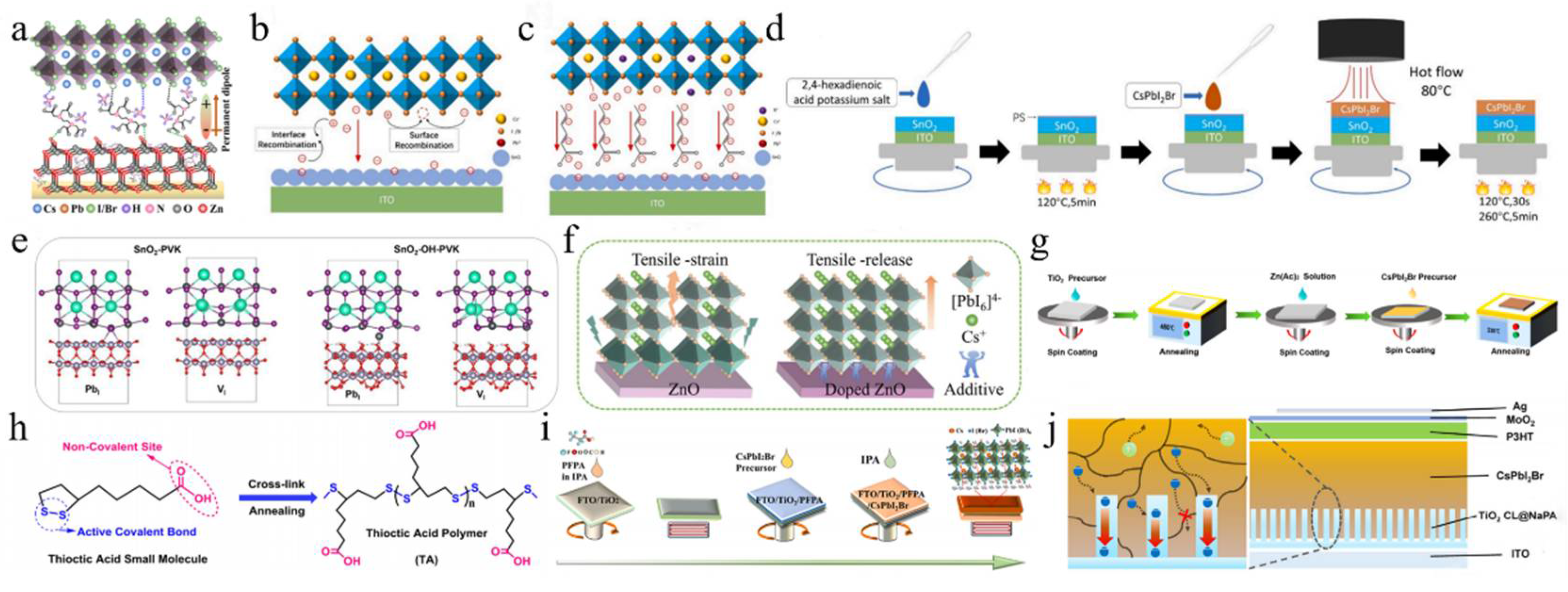

4. Interface Engineering

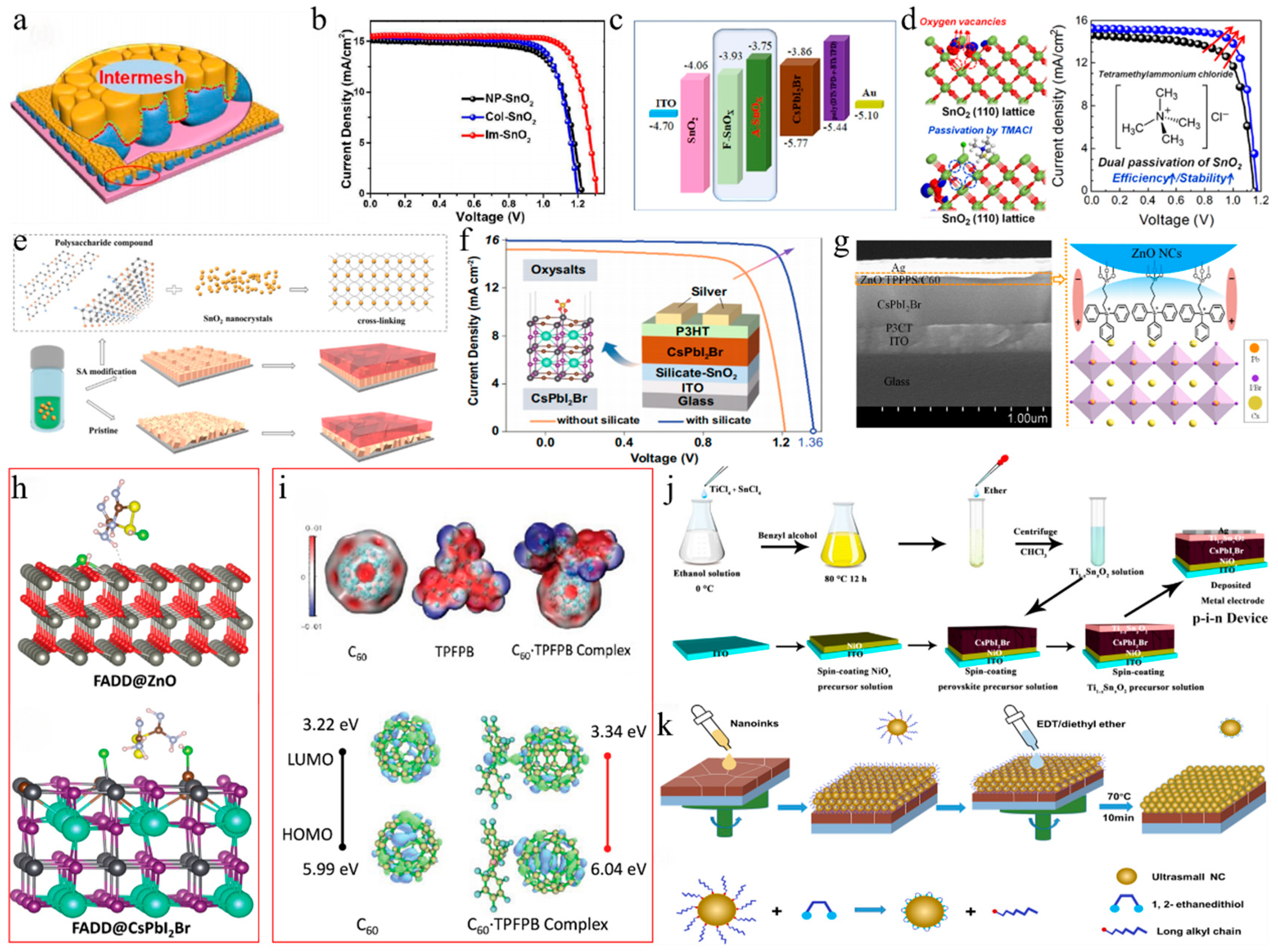

4.1. The ETL/CsPbI2Br Interface in a Conventional n-i-p Structure

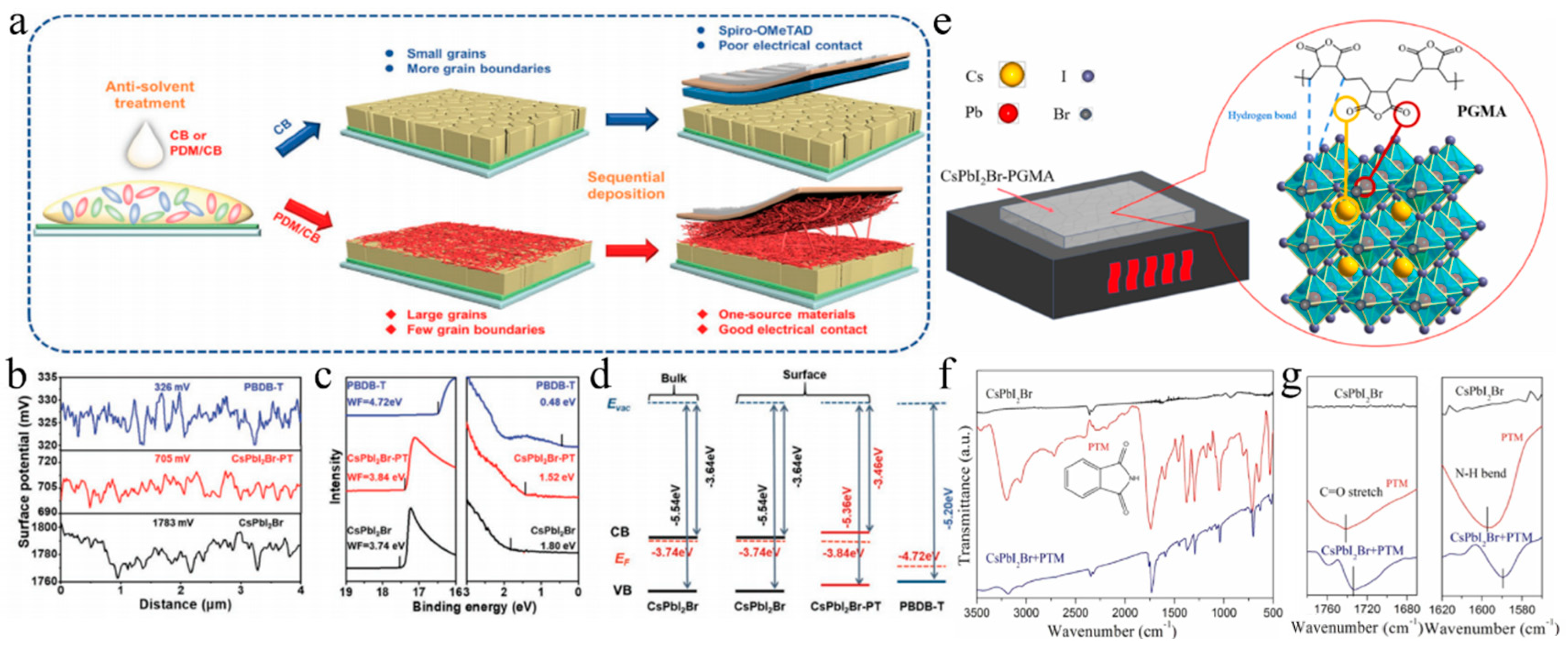

4.2. The CsPbI2Br/HTL Interface in a Conventional n-i-p Structure

4.3. The HTL/CsPbI2Br Interface in an Inverted p-i-n Structure

4.4. The CsPbI2Br/ETL Interface in an Inverted p-i-n Structure

5. Charge Transport Layers

5.1. Electron Transport Layers

5.2. Hole Transport Layers

6. Challenges and Outlooks for CsPbI2Br PSCs

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S.I. Chemical Management for Colorful, Efficient, and Stable Inorganic-Organic Hybrid Nanostructured Solar Cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef] [PubMed]

- Stranks, S.D.; Eperon, G.E.; Grancini, G.; Menelaou, C.; Alcocer, M.J.P.; Leijtens, T.; Herz, L.M.; Petrozza, A.; Snaith, H.J. Electron-Hole Diffusion Lengths Exceeding 1 Micrometer in an Organometal Trihalide Perovskite Absorber. Science 2013, 342, 341–344. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Armin, A.; Nagiri, R.C.R.; Burn, P.L.; Meredith, P. Electro-Optics of Perovskite Solar Cells. Nat. Photonics 2015, 9, 106–112. [Google Scholar] [CrossRef]

- Dong, Q.; Fang, Y.; Shao, Y.; Mulligan, P.; Qiu, J.; Cao, L.; Huang, J. Electron-Hole Diffusion Lengths >175 Mm in Solution-Grown CH3NH3PbI3 Single Crystals. Science 2015, 347, 967–970. [Google Scholar]

- Li, B.; Gao, D.; Sheppard, S.A.; Tremlett, W.D.J.; Liu, Q.; Li, Z.; White, A.J.P.; Brown, R.K.; Sun, X.; Gong, J.; et al. Highly Efficient and Scalable P-i-n Perovskite Solar Cells Enabled by Poly-Metallocene Interfaces. J. Am. Chem. Soc. 2024, 146, 13391–13398. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, Q.; Yao, L.; Değer, C.; Shen, J.; Zhang, X.; Shi, P.; Tian, Y.; Luo, Y.; Xu, J.; et al. Peri-Fused Polyaromatic Molecular Contacts for Perovskite Solar Cells. Nature 2024, 632, 301–306. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Xiao, W.; Chen, R.; Sun, Z.; Zhang, Y.; Lei, X.; Hu, S.; Kober-Czerny, M.; Wang, J.; et al. Buried Interface Molecular Hybrid for Inverted Perovskite Solar Cells. Nature 2024, 632, 536–542. [Google Scholar] [CrossRef]

- Chen, H.; Liu, C.; Xu, J.; Maxwell, A.; Zhou, W.; Yang, Y.; Zhou, Q.; R Bati, A.S.; Wan, H.; Wang, Z.; et al. Improved Charge Extraction in Inverted Perovskite Solar Cells with Dual-Site-Binding Ligands. Science 2024, 384, 189–193. [Google Scholar]

- Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 10 February 2025).

- Baikie, T.; Fang, Y.; Kadro, J.M.; Schreyer, M.; Wei, F.; Mhaisalkar, S.G.; Graetzel, M.; White, T.J. Synthesis and Crystal Chemistry of the Hybrid Perovskite (CH 3NH3)PbI3 for Solid-State Sensitised Solar Cell Applications. J. Mater. Chem. A Mater. 2013, 1, 5628–5641. [Google Scholar] [CrossRef]

- Eperon, G.E.; Stranks, S.D.; Menelaou, C.; Johnston, M.B.; Herz, L.M.; Snaith, H.J. Formamidinium Lead Trihalide: A Broadly Tunable Perovskite for Efficient Planar Heterojunction Solar Cells. Energy Environ. Environ. Sci. 2014, 7, 982–988. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, C.; Jha, S.K.; Li, Z.; Zhu, K.; Priya, S. Improved Phase Stability of Formamidinium Lead Triiodide Perovskite by Strain Relaxation. ACS Energy Lett. 2016, 1, 1014–1020. [Google Scholar] [CrossRef]

- Li, R.; Zhang, S.; Zhang, H.; Wang, Z.; Feng, X.; Du, Y.; Zhou, T.; Chen, X.; Liu, P.; Liu, L.; et al. Customizing Aniline-Derived Molecular Structures to Attain beyond 22% Efficient Inorganic Perovskite Solar Cells. Angew. Chem. Int. Ed. 2024, 63, e202410600. [Google Scholar] [CrossRef]

- Sutton, R.J.; Eperon, G.E.; Miranda, L.; Parrott, E.S.; Kamino, B.A.; Patel, J.B.; Hörantner, M.T.; Johnston, M.B.; Haghighirad, A.A.; Moore, D.T.; et al. Bandgap-Tunable Cesium Lead Halide Perovskites with High Thermal Stability for Efficient Solar Cells. Adv. Energy Mater. 2016, 6, 1502458. [Google Scholar] [CrossRef]

- Eperon, G.E.; Sutton, R.J.; Haghighirad, A.A.; Snaith, H.J.; Paternò, G.M.; Zampetti, A.; Cacialli, F. Inorganic Caesium Lead Iodide Perovskite Solar Cells. J. Mater. Chem. A Mater. 2015, 3, 19688–19695. [Google Scholar] [CrossRef]

- Kulbak, M.; Cahen, D.; Hodes, G. How Important Is the Organic Part of Lead Halide Perovskite Photovoltaic Cells? Efficient CsPbBr3 Cells. J. Phys. Chem. Lett. 2015, 6, 2452–2456. [Google Scholar] [CrossRef]

- Gao, B.; Meng, J. Highly Stable All-Inorganic CsPbIBr2Perovskite Solar Cells with 11.30% Efficiency Using Crystal Interface Passivation. ACS Appl. Energy Mater. 2020, 3, 8249–8256. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhang, X.; Feng, X.; Lu, S.; Chen, Z.; Yong, X.; Redfern, S.A.T.; Wei, H.; Wang, H.; Shen, H.; et al. Polymer-Passivated Inorganic Cesium Lead Mixed-Halide Perovskites for Stable and Efficient Solar Cells with High Open-Circuit Voltage over 1.3 V. Adv. Mater. 2018, 30, 1705393. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, J.; Gan, X.; Sun, H.; Shang, M.; Hou, D.; Lu, C.; Chen, R.; Zhu, Y.; Han, L. In Situ Grain Boundary Functionalization for Stable and Efficient Inorganic CsPbI2Br Perovskite Solar Cells. Adv. Energy Mater. 2018, 8, 1801050. [Google Scholar] [CrossRef]

- Xu, W.; He, F.; Zhang, M.; Nie, P.; Zhang, S.; Zhao, C.; Luo, R.; Li, J.; Zhang, X.; Zhao, S.; et al. Minimizing Voltage Loss in Efficient All-Inorganic CsPbI2Br Perovskite Solar Cells through Energy Level Alignment. ACS Energy Lett. 2019, 4, 2491–2499. [Google Scholar] [CrossRef]

- Li, H.; Zhang, W. Perovskite Tandem Solar Cells: From Fundamentals to Commercial Deployment. Chem. Rev. 2020, 120, 9835–9950. [Google Scholar] [CrossRef]

- Cretì, A.; Prete, P.; Lovergine, N.; Lomascolo, M. Enhanced Optical Absorption of GaAs Near-Band-Edge Transitions in GaAs/AlGaAs Core-Shell Nanowires: Implications for Nanowire Solar Cells. ACS Appl. Nano Mater. 2022, 5, 18149–18158. [Google Scholar] [CrossRef]

- Chen, G.; Sun, G.; Ding, Y.J.; Prete, P.; Miccoli, I.; Lovergine, N.; Shtrikman, H.; Kung, P.; Livneh, T.; Spanier, J.E. Direct Measurement of Band Edge Discontinuity in Individual Core-Shell Nanowires by Photocurrent Spectroscopy. Nano Lett. 2013, 13, 4152–4157. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.Y.; Lin, H.Y.; Chiang, K.M.; Tsai, W.L.; Huang, Y.C.; Tsao, C.S.; Lin, H.W. All-Vacuum-Deposited Stoichiometrically Balanced Inorganic Cesium Lead Halide Perovskite Solar Cells with Stabilized Efficiency Exceeding 11%. Adv. Mater. 2017, 29, 1605290. [Google Scholar] [CrossRef]

- Lin, Z.; Qiao, H.; Zhou, Z.; Hou, Y.; Li, X.; Yang, H.; Yang, S. Water Assisted Formation of Highly Oriented CsPbI2Br Perovskite Films with Solar Cell Efficiency Exceeding 16% J. Mater. Chem. A 2020, 8, 17670–17674. [Google Scholar] [CrossRef]

- Li, H.; Yin, L. Efficient Bidentate Molecules Passivation Strategy for High-Performance and Stable Inorganic CsPbI2Br Perovskite Solar Cells. Sol. RRL 2020, 4, 2000268. [Google Scholar] [CrossRef]

- Yue, Y.; Zhou, J.; Cheng, Q.; Zhang, X.; Wang, B.; Li, Y.; Li, S.; Cao, R.; Wang, K.; Wang, H.; et al. Peculiar Steric Hindrance Assists Monoclinic Phase Formation toward High-Quality All-Inorganic Perovskites. J. Phys. Chem. Lett. 2021, 12, 11228–11237. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Tang, W.; Wu, Y.; Yuan, R.; Yang, J.; Shan, W.; Zhang, S.; Zhang, W. Multilayer Cascade Charge Transport Layer for High Performance Inverted Mesoscopic All-Inorganic and Hybrid Wide-Bandgap Perovskite Solar Cells. Sol. RRL 2020, 2000344. [Google Scholar] [CrossRef]

- Öz, S.; Jena, A.K.; Kulkarni, A.; Mouri, K.; Yokoyama, T.; Takei, I.; Ünlu, F.; Mathur, S.; Miyasaka, T. Lead(II) Propionate Additive and a Dopant- Free Polymer Hole Transport Material for CsPbI2Br Perovskite Solar Cells. ACS Energy Lett. 2020, 5, 1292–1299. [Google Scholar]

- Jiang, K.; Wang, J.; Wu, F.; Xue, Q.; Yao, Q.; Zhang, J.; Chen, Y.; Zhang, G.; Zhu, Z.; Yan, H.; et al. Dopant-Free Organic Hole-Transporting Material for Efficient and Stable Inverted All-Inorganic and Hybrid Perovskite Solar Cells. Adv. Mater. 2020, 32, 1908011. [Google Scholar] [CrossRef]

- Mali, S.S.; Patil, J.V.; Hong, C.K. Simultaneous Improved Performance and Thermal Stability of Planar Metal Ion Incorporated CsPbI2Br All-Inorganic Perovskite Solar Cells Based on MgZnO Nanocrystalline Electron Transporting Layer. Adv. Energy Mater. 2020, 10, 1902708. [Google Scholar] [CrossRef]

- Shen, E.C.; Chen, J.D.; Tian, Y.; Luo, Y.X.; Shen, Y.; Sun, Q.; Jin, T.Y.; Shi, G.Z.; Li, Y.Q.; Tang, J.X. Interfacial Energy Level Tuning for Efficient and Thermostable CsPbI2Br Perovskite Solar Cells. Adv. Sci. 2020, 7, 1901952. [Google Scholar] [CrossRef]

- Song, J.; Xie, H.; Lim, E.L.; Hagfeldt, A.; Bi, D. Progress and Perspective on Inorganic CsPbI2Br Perovskite Solar Cells. Adv. Energy Mater. 2022, 12, 2201854. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Cui, X.; Wang, X.; Yang, D. The Progress and Efficiency of CsPbI2Br Perovskite Solar Cells. J. Mater. Chem. C Mater. 2023, 11, 426–455. [Google Scholar] [CrossRef]

- Lim, E.L.; Yang, J.; Wei, Z. Inorganic CsPbI2Br Halide Perovskites: From Fundamentals to Solar Cell Optimizations. Energy Environ. Environ. Sci. 2023, 16, 862–888. [Google Scholar] [CrossRef]

- Nam, J.K.; Jung, M.S.; Chai, S.U.; Choi, Y.J.; Kim, D.; Park, J.H. Unveiling the Crystal Formation of Cesium Lead Mixed-Halide Perovskites for Efficient and Stable Solar Cells. J. Phys. Chem. Lett. 2017, 8, 2936–2940. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Chai, W.; Chen, D.; Ma, J.; Chen, D.; Xi, H.; Zhang, J.; Zhang, C.; Hao, Y. High-Efficiency (>14%) and Air-Stable Carbon-Based, All-Inorganic CsPbI2Br Perovskite Solar Cells through a Top-Seeded Growth Strategy. ACS Energy Lett. 2021, 6, 1500–1510. [Google Scholar] [CrossRef]

- Zhang, M.; Li, W.; Zhao, W.; Han, X. Enhancing Charge Carrier Transport in the Carbon-Electrode-Based CsPbI2Br Perovskite Solar Cells via I/Br Homogenization Process Modulation and Oleic Acid Surface Passivation. ACS Appl. Energy Mater. 2023, 6, 2973–2980. [Google Scholar] [CrossRef]

- Papadopoulou, A.; Saha, R.A.; Pintor-Monroy, M.I.; Song, W.; Lieberman, I.; Solano, E.; Roeffaers, M.B.J.; Gehlhaar, R.; Genoe, J. In Situ Annealing Effect on Thermally Co-Evaporated CsPbI2Br Thin Films Studied via Spectroscopic Ellipsometry. ACS Appl. Mater. Interfaces 2024, 16, 47889–47901. [Google Scholar] [CrossRef]

- Rao, H.; Ye, S.; Gu, F.; Zhao, Z.; Liu, Z.; Bian, Z.; Huang, C. Morphology Controlling of All-Inorganic Perovskite at Low Temperature for Efficient Rigid and Flexible Solar Cells. Adv. Energy Mater. 2018, 8, 1800758. [Google Scholar] [CrossRef]

- Jiang, H.; Feng, J.; Zhao, H.; Li, G.; Yin, G.; Han, Y.; Yan, F.; Liu, Z.; Liu, S. Low Temperature Fabrication for High Performance Flexible CsPbI2Br Perovskite Solar Cells. Adv. Sci. 2018, 5, 1801117. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.; Liu, S.; Wang, X.; Gong, X.; Sun, Q.; Shen, Y.; Wang, M. Lowerature Stable α-Phase Inorganic Perovskite Compounds via Crystal Cross-Linking. J. Phys. Chem. Lett. 2019, 10, 200–205. [Google Scholar] [CrossRef]

- Fan, Y.; Fang, J.; Chang, X.; Tang, M.C.; Barrit, D.; Xu, Z.; Jiang, Z.; Wen, J.; Zhao, H.; Niu, T.; et al. Scalable Ambient Fabrication of High-Performance CsPbI2Br Solar Cells. Joule 2019, 3, 2485–2502. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, X.; Bi, Z.; Wang, J.; Liu, Y.; Zhu, Y.; Xu, X.; Xu, G. A Facile Method to Improve the Stability and Efficiency of CsPbI2Br Perovskite Solar Cells Prepared at Low Temperature. Sol. Energy 2020, 195, 544–551. [Google Scholar] [CrossRef]

- Byranvand, M.M.; Kodalle, T.; Zuo, W.; Magorian Friedlmeier, T.; Abdelsamie, M.; Hong, K.; Zia, W.; Perween, S.; Clemens, O.; Sutter-Fella, C.M.; et al. One-Step Thermal Gradient- and Antisolvent-Free Crystallization of All-Inorganic Perovskites for Highly Efficient and Thermally Stable Solar Cells. Adv. Sci. 2022, 9, 2202441. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.; Chen, Q.; Hu, Y.; Chen, S.; Cao, J.; Lu, Y.; Liu, Y.; Tang, Y.; Hu, Y. Hot-Casting Process Assisted Air-Compatible Low-Temperature CsPbI2Br Perovskite Solar Cells. Mater. Res. Bull. 2024, 174, 112707. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, T.; Xu, F.; Li, Y.; Zhao, Y. A Facile Low Temperature Fabrication of High Performance CsPbI2Br All-Inorganic Perovskite Solar Cells. Sol. RRL 2017, 2, 1700180. [Google Scholar] [CrossRef]

- Liu, D.; Yang, C.; Bates, M.; Lunt, R.R. Room Temperature Processing of Inorganic Perovskite Films to Enable Flexible Solar Cells. iScience 2018, 6, 272–279. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, X.; Lin, Y.; Liao, Y.; Wei, Q.; Chen, H.; Qiu, J.; Chen, Y.; Zheng, Y. Hot-Substrate Deposition of All-Inorganic Perovskite Films for Low-Temperature Processed High-Efficiency Solar Cells. J. Mater. Chem. A Mater. 2019, 7, 2773–2779. [Google Scholar] [CrossRef]

- Ye, Z.; Zhou, J.; Hou, J.; Deng, F.; Zheng, Y.Z.; Tao, X. Low Temperature-Processed Stable and Efficient Carbon-Based CsPbI2Br Planar Perovskite Solar Cells by In Situ Passivating Grain Boundary and Trap Density. Sol. RRL 2019, 3, 1900109. [Google Scholar] [CrossRef]

- Chen, W.; Chen, H.; Xu, G.; Xue, R.; Wang, S.; Li, Y.; Li, Y. Precise Control of Crystal Growth for Highly Efficient CsPbI 2 Br Perovskite Solar Cells. Joule 2019, 3, 191–204. [Google Scholar] [CrossRef]

- Wang, T.; Yang, Y.; Zhang, Y.; Nian, L.; Wang, P.; Qian, Y.; Rong, Q.; Zhou, G.; Li, N. Vacuum-Controlled Growth of CsPbI2Br for Highly Efficient and Stable All-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 21539–21547. [Google Scholar] [CrossRef]

- Li, M.H.; Liu, S.C.; Qiu, F.Z.; Zhang, Z.Y.; Xue, D.J.; Hu, J.S. High-Efficiency CsPbI2Br Perovskite Solar Cells with Dopant-Free Poly(3-Hexylthiophene) Hole Transporting Layers. Adv. Energy Mater. 2020, 10, 2000501. [Google Scholar] [CrossRef]

- Ullah, S.; Yang, P.; Wang, J.; Liu, L.; Yang, S.; Xia, T.; Chen, Y. Journal of Solid State Chemistry Low-Temperature Processing of Polyvinylpyrrolidone Modi Fi Ed CsPbI 2 Br Perovskite Fi Lms for High-Performance Solar Cells. J. Solid. State Chem. 2022, 305, 122656. [Google Scholar] [CrossRef]

- Mali, S.S.; Patil, J.V.; Hong, C.K. Hot-Air-Assisted Fully Air-Processed Barium Incorporated CsPbI2Br Perovskite Thin Films for Highly Efficient and Stable All-Inorganic Perovskite Solar Cells. Nano Lett. 2019, 19, 6213–6220. [Google Scholar] [CrossRef]

- Mali, S.S.; Patil, J.V.; Shinde, P.S.; de Miguel, G.; Hong, C.K. Fully Air-Processed Dynamic Hot-Air-Assisted M:CsPbI2Br (M: Eu2+, In3+) for Stable Inorganic Perovskite Solar Cells. Matter 2021, 4, 635–653. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Yuan, J.; Wang, M.; Shen, T.; Huang, F.; Wen, W.; Cao, G.; Tian, J. High-Voltage-Efficiency Inorganic Perovskite Solar Cells in a Wide Solution-Processing Window. J. Phys. Chem. Lett. 2018, 9, 3646–3653. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, S.; Chen, W.; Zhu, H.; Xiong, Z.; Yang, Z.; Chen, C.; Chen, R.; Han, L.; Chen, W. Solvent engineering for efficient inverted perovskite solar cells based on inorganic CsPbI2Br light absorber. Materials Today Energy 2018, 8, 125e133. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, J.; Xu, C.; Ji, P.; Xu, Z.; Ma, L.; Cai, H.; Zhang, F.; Wu, X. Effect of Passivation on Buried Interface of CsPbI2Br Perovskite Films. Appl. Phys. Lett. 2023, 123, 061601. [Google Scholar] [CrossRef]

- Wang, X.; Ran, X.; Liu, X.; Gu, H.; Zuo, S.; Hui, W.; Lu, H.; Sun, B.; Gao, X.; Zhang, J.; et al. Tailoring Component Interaction for Air-Processed Efficient and Stable All-Inorganic Perovskite Photovoltaic. Angew. Chem.-Int. Ed. 2020, 59, 13354–13361. [Google Scholar] [CrossRef]

- Tang, W.; Chen, Y.; Yang, J.; Yuan, R.; Lv, Y.; Ma, Q.; Wu, Y.; Zhang, P.; Zhang, W.H. Acetone-Assisted Precursor Engineering Enables Low-Temperature Fabrication of CsPbI2Br Perovskite for Efficient Solar Cells. J. Power Sources 2021, 482, 228965. [Google Scholar] [CrossRef]

- Dong, C.; Han, X.; Zhao, Y.; Li, J.; Chang, L.; Zhao, W. A Green Anti-Solvent Process for High Performance Carbon-Based CsPbI2Br All-Inorganic Perovskite Solar Cell. Sol. RRL 2018, 2, 1800139. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, C.; Zhang, X.; Rujisamphan, N.; Liu, Y.; Li, Y.; Yuan, J.; Ma, W. Dual Interfacial Engineering Enables Efficient and Reproducible CsPbI2Br All-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 31659–31666. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhang, G.; Zhang, J.; Pan, Z.; Yang, S.; Liu, B.; Rao, H.; Zhong, X. Synergistic Passivation by Alkali Metal and Halogenoid Ions for High Efficiency HTM-Free Carbon-Based CsPbI2Br Solar Cells. Chem. Eng. J. 2022, 430, 133083. [Google Scholar] [CrossRef]

- Bai, D.; Zhang, J.; Jin, Z.; Bian, H.; Wang, K.; Wang, H.; Liang, L.; Wang, Q.; Liu, S.F. Interstitial Mn2+-Driven High-Aspect-Ratio Grain Growth for Low-Trap-Density Microcrystalline Films for Record Efficiency CsPbI2Br Solar Cells. ACS Energy Lett. 2018, 3, 970–978. [Google Scholar] [CrossRef]

- Rondiya, S.R.; Mali, S.S.; Roy, A.; Inwati, G.K.; Rahane, G.K.; Jadhav, Y.A.; Suresh, S.; Debnath, T.; Hong, C.K.; Dzade, N.Y. Interfacial Band Offset Engineering with Barium-Doping towards Enhanced Performance of All Inorganic CsPbI2Br Perovskite Solar Cells. Phys. Chem. Chem. Phys. 2023, 25, 29050–29060. [Google Scholar] [CrossRef]

- Nam, J.K.; Chai, S.U.; Cha, W.; Choi, Y.J.; Kim, W.; Jung, M.S.; Kwon, J.; Kim, D.; Park, J.H. Potassium Incorporation for Enhanced Performance and Stability of Fully Inorganic Cesium Lead Halide Perovskite Solar Cells. Nano Lett. 2017, 17, 2028–2033. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Hong, C.K. A-Site Rubidium Cation-Incorporated CsPbI2Br All-Inorganic Perovskite Solar Cells Exceeding 17% Efficiency. Sol. RRL 2020, 4, 2000164. [Google Scholar] [CrossRef]

- Zhang, W.; Xiong, J.; Li, J.; Daoud, W.A. Guanidinium Passivation for Air-Stable Rubidium-Incorporated Cs(1 − x)RbxPbI2Br Inorganic Perovskite Solar Cells. Sol. RRL 2020, 4, 2000112. [Google Scholar] [CrossRef]

- Duan, S.; Tian, N.; Zhang, J.; Huang, Z.; Yao, D.; Zheng, G.; Wang, J.; Yang, Y.; Zhou, B.; Long, F. Synthesis of Stable Cs-Rich FA-Cs Perovskite Solar Cells by Assistance of a Lewis Base Additive. ACS Appl. Energy Mater. 2024, 7, 4826–4833. [Google Scholar] [CrossRef]

- Lau, C.F.J.; Zhang, M.; Deng, X.; Zheng, J.; Bing, J.; Ma, Q.; Kim, J.; Hu, L.; Green, M.A.; Huang, S.; et al. Strontium-Doped Low-Temperature-Processed CsPbI2Br Perovskite Solar Cells. ACS Energy Lett. 2017, 2, 2319–2325. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, J.; Gan, X.; Yu, L.; Yuan, H.; Shang, M.; Lu, C.; Hou, D.; Hu, Z.; Zhu, Y.; et al. Pb-Reduced CsPb0.9Zn0.1I2Br Thin Films for Efficient Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1900896. [Google Scholar] [CrossRef]

- Xiang, W.; Wang, Z.; Kubicki, D.J.; Wang, X.; Tress, W.; Luo, J.; Zhang, J.; Hofstetter, A.; Zhang, L.; Emsley, L.; et al. Ba-Induced Phase Segregation and Band Gap Reduction in Mixed-Halide Inorganic Perovskite Solar Cells. Nat. Commun. 2019, 10, 4685. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, H.; Han, Y.; Duan, C.; Liu, Z.; Liu, S. Europium and Acetate Co-Doping Strategy for Developing Stable and Efficient CsPbI2Br Perovskite Solar Cells. Small 2019, 15, 1904387. [Google Scholar] [CrossRef]

- Xiang, W.; Wang, Z.; Kubicki, D.J.; Tress, W.; Luo, J.; Prochowicz, D.; Akin, S.; Emsley, L.; Zhou, J.; Dietler, G.; et al. Europium-Doped CsPbI 2 Br for Stable and Highly Efficient Inorganic Perovskite Solar Cells. Joule 2019, 3, 205–214. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, S.; Liu, A.; Kamata, Y.; Teo, S.; Yang, S.; Xu, Z.; Hayase, S.; Ma, T. Niobium Incorporation into CsPbI2Br for Stable and Efficient All-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 19994–20003. [Google Scholar] [CrossRef] [PubMed]

- Patil, J.V.; Mali, S.S.; Hong, C.K. Efficient and Stable All-Inorganic Niobium-Incorporated CsPbI2Br-Based Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 27176–27183. [Google Scholar] [CrossRef]

- Ozturk, T.; Akman, E.; Shalan, A.E.; Akin, S. Composition Engineering of Operationally Stable CsPbI2Br Perovskite Solar Cells with a Record Efficiency over 17%. Nano Energy 2021, 87, 106157. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Hong, C.K. Fully-Inorganic Strontium Incorporated CsPbI2Br Perovskite Solar Cells with Promoted Efficiency and Stability. J. Energy Chem. 2021, 62, 451–458. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, L.; Wang, Y.; Gao, Z.; Fu, Y.; Liu, Q.; Li, J.; He, D. Enhancement of Photoelectric Performance for CsPbI2Br Solar Cells by the Synergistic Effect of Binary Additives. J. Mater. 2023, 9, 27–34. [Google Scholar] [CrossRef]

- Chen, C.; Liu, K.; Tao, L.; Hu, Q. High-Performance CsPbI2Br Perovskite Solar Cells Based on Excess CsBr and Ultra Thin MgF2 Layer. J. Alloys Compd. 2023, 960, 170856. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Yan, Q.; Yuan, X.; Lu, Y.; Cao, H.; He, D.; Jiang, Z.; Xu, R.; Chen, T.; et al. Dual-Doping Strategy of Metal Chlorides in Ambient Air with High Humidity for Achieving Highly Air-Stable All-Inorganic Perovskite Solar Cells. Sol. RRL 2024, 8, 2400216. [Google Scholar] [CrossRef]

- Ma, P.; Bie, T.; Liu, Y.; Yang, L.; Bi, S.; Wang, Z.; Shao, M. Zirconium Doping to Enable High-Efficiency and Stable CsPbI2Br All-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2024, 16, 1217–1224. [Google Scholar] [CrossRef] [PubMed]

- Mali, S.S.; Patil, J.V.; Steele, J.A.; Rondiya, S.R.; Dzade, N.Y.; Hong, C.K. Implementing Dopant-Free Hole-Transporting Layers and Metal-Incorporated CsPbI2Br for Stable All-Inorganic Perovskite Solar Cells. ACS Energy Lett. 2021, 6, 778–788. [Google Scholar] [CrossRef] [PubMed]

- Mali, S.S.; Patil, J.V.; Rondiya, S.R.; Dzade, N.Y.; Steele, J.A.; Nazeeruddin, M.K.; Patil, P.S.; Hong, C.K. Terbium-Doped and Dual-Passivated γ-CsPb(I1−xBrx)3 Inorganic Perovskite Solar Cells with Improved Air Thermal Stability and High Efficiency. Adv. Mater. 2022, 34, 2203204. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Hong, C.K. Boosting the Stability of Fully-Inorganic Perovskite Solar Cells through Samarium Doped CsPbI2Br Perovskite. ACS Sustain. Chem. Eng. 2020, 8, 16364–16371. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Park, D.W.; Hong, C.K. Novel Ytterbium-Doped CsPbI2Br Thin-Films–Based Inorganic Perovskite Solar Cells toward Improved Phase Stability. Mater. Today Chem. 2021, 22, 100557. [Google Scholar] [CrossRef]

- Yang, F.; Hirotani, D.; Kapil, G.; Kamarudin, M.A.; Ng, C.H.; Zhang, Y.; Shen, Q.; Hayase, S. All-Inorganic CsPb 1− x Ge x I 2 Br Perovskite with Enhanced Phase Stability and Photovoltaic Performance. Angew. Chem. 2018, 130, 12927–12931. [Google Scholar] [CrossRef]

- Liu, C.; Li, W.; Li, H.; Wang, H.; Zhang, C.; Yang, Y.; Gao, X.; Xue, Q.; Yip, H.L.; Fan, J.; et al. Structurally Reconstructed CsPbI 2 Br Perovskite for Highly Stable and Square-Centimeter All-Inorganic Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1803572. [Google Scholar] [CrossRef]

- Haider, Z.; Farooq, A.; Tayyab, M.; Musharaf, M.; Ahmed, N.; Majid, A.; Javed, K. Improvement in Stability and Exploring the Photovoltaic Properties of CsPbI2Br Thin Films for Perovskite Solar Cells. J. Alloys Compd. 2024, 989, 174170. [Google Scholar] [CrossRef]

- Ju, J.; Chen, J.; Zhao, W.; He, J.; Peng, Z.; Chen, J. Stress-Induced Phase Stability and Optoelectronic Property Changes in Cesium Lead Halide Perovskites. J. Appl. Phys. 2024, 135, 173101. [Google Scholar] [CrossRef]

- Nicholson, S.; Bruckbauer, J.; Edwards, P.R.; Trager-Cowan, C.; Martin, R.W.; Ivaturi, A. Unravelling the Chloride Dopant Induced Film Improvement in All-Inorganic Perovskite Absorbers. J. Mater. Chem. A Mater. 2024, 12, 25131–25139. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Hong, C.K. Reducing Defects of All-Inorganic γ-CsPbI2Br Thin Films by Ethylammonium Bromide Additives for Efficient Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 25576–25583. [Google Scholar] [CrossRef] [PubMed]

- Patil, J.V.; Mali, S.S.; Hong, C.K. Grain Size Enlargement and Controlled Crystal Growth by Formamidinium Chloride Additive-Added γ-CsPbI2Br Thin Films for Stable Inorganic Perovskite Solar Cells. Mater. Today Chem. 2022, 26, 101118. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Wang, S.; Xu, G.; Liu, S.; Li, Y.; Li, Y. One-Source Strategy Boosting Dopant-Free Hole Transporting Layers for Highly Efficient and Stable CsPbI2Br Perovskite Solar Cells. Adv. Funct. Mater. 2021, 31, 2010696. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Tang, X.; Liu, L.; Zhang, H.; Yao, X.; Wang, F.; Wu, S.; Liu, X. Understanding the Doping Effect in CsPbI2Br Solar Cells: Crystallization Kinetics, Defect Passivation and Energy Level Alignment. Chem. Eng. J. 2023, 453, 139952. [Google Scholar] [CrossRef]

- Yu, F.; Liu, J.; Xu, P.; Huang, J.; Li, C.H.; Zheng, Y.X. High-Quality All-Inorganic CsPbI2Br Thin Films Derived from Phase-Pure Intermediate for Efficient Wide-Bandgap Perovskite Solar Cells. J. Solid. State Chem. 2023, 317, 123728. [Google Scholar] [CrossRef]

- Bahadur, J.; Ryu, J.; Lee, D.G.; Hong, J.; Hayase, S.; Sang Cho, J.; Mun Jeong, S.; Kang, D.W. In-Situ Surface Defects Passivation with Small Carbon Chain Molecules for Highly Efficient, Air-Processed Inorganic CsPbI2Br Perovskite Photovoltaics. Appl. Surf. Sci. 2023, 614, 156229. [Google Scholar] [CrossRef]

- Bai, S.; Da, P.; Li, C.; Wang, Z.; Yuan, Z.; Fu, F.; Kawecki, M.; Liu, X.; Nobuya, S.; Wang, J.; et al. Planar perovskite solar cells with long-term stability using ionic liquid additives. Nature 2019, 571, 245–250. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Gao, Z.; Chen, Q.; Liu, W.; Fu, Y.; Liu, Q.; He, D.; Li, J. Notable Performance Enhancement of CsPbI2Br Solar Cells by a Dual-Function Strategy with CsPbBr3 Nanocrystals. ACS Appl. Mater. Interfaces 2023, 15, 53558–53567. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Chen, Q.; Liu, W.; Gao, Z.; Fu, Y.; Liu, Q.; He, D.; Li, Y. Enhancing the Photovoltaic Performance of CsPbI2Br Solar Cells by Adding SiO2 Nanoparticles into the Photoactive Layer. ACS Appl. Energy Mater. 2023, 6, 4584–4592. [Google Scholar] [CrossRef]

- Bahadur, J.; Ryu, J.; Pandey, P.; Cho, S.W.; Cho, J.S.; Kang, D.W. In Situ Crystal Reconstruction Strategy-Based Highly Efficient Air-Processed Inorganic CsPbI2Br Perovskite Photovoltaics for Indoor, Outdoor, and Switching Applications. Nanoscale 2023, 15, 3850–3863. [Google Scholar] [CrossRef] [PubMed]

- Mali, S.S.; Patil, J.V.; Steele, J.A.; Jung, Y.H.; Nazeeruddin, M.K.; Hong, C.K. Controlled Crystallization and Surface Engineering of Mixed-Halide γ-CsPbI2Br Inorganic Perovskites via Guanidinium Iodide Additive in Air-Processed Perovskite Solar Cells. Mater. Today 2023, 67, 33–45. [Google Scholar] [CrossRef]

- Kang, C.; Xu, S.; Rao, H.; Pan, Z.; Zhong, X. All-Inorganic CsPb2I4Br/CsPbI2Br 2D/3D Bulk Heterojunction Boosting Carbon-Based CsPbI2Br Perovskite Solar Cells with an Efficiency of Over 15%. ACS Energy Lett. 2023, 8, 909–916. [Google Scholar] [CrossRef]

- Patil, J.V.; Mali, S.S.; Sadale, S.B.; Hong, C.K. Understanding the Synergistic Influence of the Propylammonium Bromide Additive and Erbium-Doped CsPbI2Br for Highly Stable Inorganic Perovskite Solar Cells. Inorg. Chem. Front. 2023, 10, 3213–3223. [Google Scholar] [CrossRef]

- Sun, J.; Jin, Y.; Liu, Q.; Qiu, F. Surface-Modification-Induced Synergies of Crystal Growth and Defect Passivation toward CsPbI2Br Solar Cells with Efficiency Exceeding 17%. Chem. Eng. J. 2023, 457, 141300. [Google Scholar] [CrossRef]

- Yao, X.; Tang, X.; Wu, M.; Wang, Z.; Zhang, H.; Wang, H.; Wang, H.; Zhang, H.; Wang, F.; Zheng, Y.; et al. Interfacial and Doping Synergistic Effect of Versatile Potassium Acetate toward Efficient CsPbI2Br Perovskite Solar Cells. ACS Appl. Energy Mater. 2023, 6, 5997–6005. [Google Scholar] [CrossRef]

- Jeong, M.J.; Jeon, S.W.; Kim, S.Y.; Noh, J.H. High Fill Factor CsPbI2Br Perovskite Solar Cells Via Crystallization Management. Adv. Energy Mater. 2023, 13, 2300698. [Google Scholar] [CrossRef]

- Xu, W.; Xiong, J.; Yuan, Q.; Xu, W.; Shu, Q.; Lou, Y.; Feng, L. Cytidylic Acid Improves Crystal Growth, Defect Passivation and Flexibility of Inorganic CsPbI2Br Film for Inverted Photovoltaics towards Versatile Applications. Chem. Eng. J. 2024, 480, 147946. [Google Scholar] [CrossRef]

- Hu, Y.; Cai, L.; Xu, Z.; Wang, Z.; Zhou, Y.; Sun, G.; Sun, T.; Qi, Y.; Zhang, S.; Tang, Y. High-Efficiency CsPbI2Br Perovskite Solar Cells with over 83% Fill Factor by Synergistic Effects of a Multifunctional Additive. Inorg. Chem. 2023, 62, 5408–5414. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, H.; Li, J.; Wei, P.; Qi, Y.; Xie, Y. Effective Improvement of the Carbon-Based CsPbI2Br Perovskite Solar Cells through Additive and Interface Strategies. Opt. Mater. 2023, 136, 113427. [Google Scholar] [CrossRef]

- Xiao, H.; Zuo, C.; Yan, K.; Jin, Z.; Cheng, Y.; Tian, H.; Xiao, Z.; Liu, F.; Ding, Y.; Ding, L. Highly Efficient and Air-Stable Inorganic Perovskite Solar Cells Enabled by Polylactic Acid Modification. Adv. Energy Mater. 2023, 13, 2300738. [Google Scholar] [CrossRef]

- Bi, J.; Wang, D.; Chang, J.; Li, J.; Meng, F.; Wang, G. Phthalimide Additive-Promoted Ambient Fabrication of Inorganic CsPbI2Br Perovskite for Highly Efficient and Stable Solar Cells. J. Alloys Compd. 2023, 965, 171441. [Google Scholar] [CrossRef]

- Su, Z.; Sun, Y.; Yu, B.; Yu, H. In Situ PL Probes the Effect of 2D SnSe Nanosheets on the Crystallization Process of CsPbI2Br Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2024, 16, 43489–43497. [Google Scholar] [CrossRef]

- Yue, Y.; Yang, R.; Zhang, W.; Cheng, Q.; Zhou, H.; Zhang, Y. Cesium Cyclopropane Acid-Aided Crystal Growth Enables Efficient Inorganic Perovskite Solar Cells with a High Moisture Tolerance. Angew. Chem. 2024, 136, e202315717. [Google Scholar] [CrossRef]

- Li, M.H.; Gong, X.; Wang, S.; Li, L.; Fu, J.; Wu, J.; Tan, Z.; Hu, J.S. Facile Hydrogen-Bonding Assisted Crystallization Modulation for Large-Area High-Quality CsPbI2Br Films and Efficient Solar Cells. Angew. Chem.-Int. Ed. 2024, 63, e202318591. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, Y.; Wang, Z.; Chen, Q.; Xu, H.; Sun, T.; Tang, Y. Crystallization Regulation and Lead Leakage Prevention Simultaneously for High-Performance CsPbI2Br Perovskite Solar Cells. J. Phys. Chem. Lett. 2024, 15, 4158–4166. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, L.; Xing, C.; Yang, J.; Huang, S.; Bao, Q.; Wang, D.; Zhang, T. Microregion Characterization of Grain Boundary Defects and Electron Capture of CsPbI2Br Perovskite. Energy Technol. 2024, 12, 2300907. [Google Scholar] [CrossRef]

- He, L.; Zhong, M. Optimization of the Performance of CsPbI2Br Perovskite Solar Cells in Air by Adding Polyethylene-Graft-Maleic Anhydride and Its Mechanism. Micro Nanostructures 2024, 191, 207862. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Gao, Z.; Wan, G.; Liu, X.; Fu, Y.; Liu, Q.; He, D.; Li, J. Enhanced Comprehensive Performance of Carbon-Based Hole-Transport-Layer-Free CsPbI2Br Solar Cells by a Low-Cost and Stable Long Chain Polymer. J. Mater. Chem. C Mater. 2023, 12, 1421–1429. [Google Scholar] [CrossRef]

- Duan, X.; Duan, J.; Liu, N.; Li, J.; Dou, J.; Zhang, X.; Guo, Q.; Wang, Y.; Wang, Z.; Zhao, Y.; et al. Inhibited Superoxide-induced Halide Oxidation with a Bioactive Factor for Stabilized Inorganic Perovskite Solar Cells. SusMat 2024, 4, e233. [Google Scholar] [CrossRef]

- Geng, S.; Duan, J.; Liu, N.; Li, H.; Zhu, X.; Duan, X.; Guo, Q.; Dou, J.; He, B.; Zhao, Y.; et al. Influence of Donor Skeleton on Intramolecular Electron Transfer Amount for Efficient Perovskite Solar Cells. Angew. Chem. 2024, 136, e202407383. [Google Scholar] [CrossRef]

- Hu, J.; Xie, D.; Tang, Z.; Lan, D.; Zhang, R.; Ng, C.H.; Teo, S.H.; Xu, Z.; Yi, B. Flattening of the Cratered Inorganic Perovskite Film via Precursor Engineering for CsPbI2Br Solar Cells with 16.86% Efficiency. ACS Sustain. Chem. Eng. 2024, 12, 13392–13400. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Chen, J.; Peng, L.; Liu, X.; Lin, J. Crystallization Management and Defect Passivation via Additive Engineering for Efficient and Stable Carbon-Based CsPbI2Br Perovskite Solar Cells. J. Power Sources 2024, 609, 234702. [Google Scholar] [CrossRef]

- Li, H.; Duan, J.; Liu, N.; Ma, L.; Dou, J.; Zhang, X.; Guo, Q.; Zhao, Y.; He, B.; Tang, Q. Effective N-Type de-Doping of Perovskite Surface via Defect Passivation and Improved Film Crystallization for High-Efficiency Inorganic Solar Cells. J. Mater. Chem. A Mater. 2024, 12, 23067–23075. [Google Scholar] [CrossRef]

- Bahadur, J.; Cho, S.W.; Pandey, P.; Yoon, S.; Lee, D.G.; Ryu, J.; Song, J.T.; Lim, J.; Kang, D.W. Mitigating Defect States of All-Inorganic CsPbI2Br Perovskite via Multifunctional 2-Amino-5-Nitrothiazole Additive for an Efficient Air-Processed Outdoor/Indoor Photovoltaics. Solar RRL 2024, 8, 2300912. [Google Scholar] [CrossRef]

- Liu, Y.; Lang, K.; Han, H.; Liu, H.; Fu, Y.; Zou, P.; Lyu, Y.; Xu, J.; Yao, J. Crystallization Management of CsPbI2Br Perovskites by PbAc2-Incorporated Twice Spin-Coating Process for Efficient and Stable CsPbI2Br Perovskite Solar Cells. J. Energy Chem. 2024, 97, 419–428. [Google Scholar] [CrossRef]

- Wang, W.; Lin, Y.; Zhang, G.; Kang, C.; Pan, Z.; Zhong, X.; Rao, H. Modification of Compact TiO2 Layer by TiCl4-TiCl3 Mixture Treatment and Construction of High-Efficiency Carbon-Based CsPbI2Br Perovskite Solar Cells. J. Energy Chem. 2021, 63, 442–451. [Google Scholar] [CrossRef]

- Pan, B.; Gu, J.; Xu, X.; Xiao, L.; Zhao, J.; Zou, G. Interface Engineering of High Performance All-Inorganic Perovskite Solar Cells via Low-Temperature Processed TiO2 Nanopillar Arrays. Nano Res. 2021, 14, 3431–3438. [Google Scholar] [CrossRef]

- Zhao, A.; Han, Y.; Che, Y.; Liu, Q.; Wang, X.; Li, Q.; Sun, J.; Lei, Z.; He, X.; Liu, Z.H. High-Quality Borophene Quantum Dot Realization and Their Application in a Photovoltaic Device. J. Mater. Chem. A Mater. 2021, 9, 24036–24043. [Google Scholar] [CrossRef]

- Ma, J.; Lin, Z.; Guo, X.; Zhou, L.; He, J.; Yang, Z.; Zhang, J.; Hao, Y.; Liu, S.; Chang, J. Secondary Crystallization Strategy for Highly Efficient Inorganic CsPbI2Br Perovskite Solar Cells with Efficiency Approaching 17%. J. Energy Chem. 2021, 63, 558–565. [Google Scholar] [CrossRef]

- Pu, X.; Han, J.; Wang, S.; Zhou, H.; Cao, Q.; Yang, J.; He, Z.; Li, X. Surface Modification with Ionic Liquid for Efficient CsPbI2Br Perovskite Solar Cells. J. Mater. 2021, 7, 1039–1048. [Google Scholar] [CrossRef]

- Guo, X.; Zhao, B.; Xu, K.; Yang, S.; Liu, Z.; Han, Y.; Xu, J.; Xu, D.; Tan, Z.; Liu, S. P-Type Carbon Dots for Effective Surface Optimization for Near-Record-Efficiency CsPbI2Br Solar Cells. Small 2021, 17, 2102272. [Google Scholar] [CrossRef]

- Han, D.; Yi, S.; Yuan, Q.; Tang, X.; Shu, Q.; Li, Q.; Wang, F.; Zhou, D.Y.; Feng, L. Managing Defects Density and Interfacial Strain via Underlayer Engineering for Inverted CsPbI2Br Perovskite Solar Cells with All-Layer Dopant-Free. Small 2021, 17, 2101902. [Google Scholar] [CrossRef]

- Li, Q.; Shu, Q.; Wang, Y.; Zhou, D.Y.; Wang, F.; Yuan, Q.; Yi, S.; Wang, H.; Feng, L. Interfacial Engineering by in Situ Building of a 3D/2D Heterojunction for Inverted CsPbI2Br Solar Cells: Beyond Moisture Proof. ACS Appl. Energy Mater. 2021, 4, 10081–10090. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, F.; Zhang, L.; Ren, W.; Sunli, Z.; Ma, Y.; Hao, Y. Improving the Performance of Inorganic Perovskite Solar Cells via the Perovskite Quantum Dot Dynamically Mediated Film Growth Method. Phys. Chem. Chem. Phys. 2022, 24, 7451–7457. [Google Scholar] [CrossRef]

- Xu, J.; Cui, J.; Yang, S.; Han, Y.; Guo, X.; Che, Y.; Xu, D.; Duan, C.; Zhao, W.; Guo, K.; et al. Unraveling Passivation Mechanism of Imidazolium-Based Ionic Liquids on Inorganic Perovskite to Achieve Near-Record-Efficiency CsPbI2Br Solar Cells. Nanomicro Lett. 2022, 14, 7. [Google Scholar] [CrossRef]

- Yuan, Q.; Tang, X.; Shu, Q.; Zhu, B.; Cai, J.; He, Y.; Zhou, D.Y.; Feng, L. Double-Side Healing at CsPbI2Br/ZnO Interface by Bipyrimidine Hydroiodide Enables Inverted Solar Cells with Enhanced Efficiency and Stability. Chem. Eng. J. 2022, 435, 134760. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; Guo, T.; Jin, J.; Zou, J.; Zhu, Z.; Zhou, Y.; Cao, Q.; Zhang, J.; Ren, Z.; et al. Regulating the Interplay at the Buried Interface for Efficient and Stable Carbon-Based CsPbI2Br Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2023, 15, 10897–10906. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, Y.; Li, R.; Jing, Y.; Yan, Z.; Liu, F.; Wu, L.; Tu, Y.; Shi, J.; Du, Z.; et al. High-Efficiency Carbon-Based CsPbI2Br Perovskite Solar Cells from Dual Direction Thermal Diffusion Treatment with Cadmium Halides. Small 2023, 19, 2206245. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, D.; Guo, T.; Zou, J.; Jin, J.; Zheng, C.; Zhou, Y.; Zhu, Z.; Hu, Z.; Cao, Q.; et al. Targeting the Imperfections at the ZnO/CsPbI2Br Interface for Low-Temperature Carbon-Based Perovskite Solar Cells. J. Mater. Chem. A Mater. 2023, 11, 9616–9625. [Google Scholar] [CrossRef]

- Liu, X.; Liu, N.; Liu, Z.; Wang, J.; Huang, L.; Hu, Z.; Zhang, J.; Zhu, Y. Crosslinked Thioctic Acid as a Multifunctional Buried Interface Modifier for High-Performance Inorganic Perovskite Solar Cells. J. Mater. Chem. C Mater. 2023, 11, 15682–15689. [Google Scholar] [CrossRef]

- Pu, X.; Cao, Q.; Su, J.; Yang, J.; Wang, T.; Zhang, Y.; Chen, H.; He, X.; Chen, X.; Li, X. One-Step Construction of a Perovskite/TiO2 Heterojunction toward Highly Stable Inverted All-Layer-Inorganic CsPbI2Br Perovskite Solar Cells with 17.1% Efficiency. Adv. Energy Mater. 2023, 13, 2301607. [Google Scholar] [CrossRef]

- Jiang, J.; Li, R.; Liu, D.; Xie, H.; Zeng, Q.; Li, Y. Efficient and Stable CsPbI2Br Inorganic Perovskite Solar Cell Co-Modified with Ionic Liquids and Quantum Dots. ACS Appl. Energy Mater. 2023, 6, 5378–5387. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, L.; Hu, S.; Wang, X.; Han, J.; Huang, J.; Chen, J.; Zhang, Y.; Zhang, X.; He, J.; et al. Bridging the Buried Interface with Conjugated Molecule for Highly Efficient Carbon-Based Inorganic CsPbI2Br Perovskite Solar Cells Fabricated in Air. Chem. Eng. J. 2024, 492, 152210. [Google Scholar] [CrossRef]

- Qiu, F.; Li, M.H.; Wu, J.; Hu, J.S. Buried Interface Management via Bifunctional NH4BF4 towards Efficient CsPbI2Br Solar Cells with a Voc over 1.4 V. J. Energy Chem. 2024, 89, 364–370. [Google Scholar] [CrossRef]

- Niu, Z.; Liu, W.; Wang, K.; Sun, W.; Huo, X.; Miao, Y.; You, T.; Yin, P. Acetate-Assisted Buried Interface Engineering for Highly Efficient Carbon-Based CsPbI2Br Perovskite Solar Cells. ACS Appl. Energy Mater. 2024, 7, 3635–3644. [Google Scholar] [CrossRef]

- Huo, X.; Jiang, Y.; Lv, J.; Sun, W.; Liu, W.; Yin, R.; Gao, Y.; Wang, K.; You, T.; Yin, P. Bottom-up Multi-Interface Modification Boosts the Performance of Carbon-Based HTL-Free All-Inorganic CsPbI2Br Perovskite Solar Cells. Chem. Eng. J. 2024, 484, 149626. [Google Scholar] [CrossRef]

- Liu, X.; She, X.; Wang, L.; Li, W.; Zhang, W.; Wang, S.; Wangyang, P.; Wang, Z.; Li, J.; Cui, X.; et al. Fluorinated Organic Ammonium Salt Passivation for High-Efficiency and Stable Inverted CsPbI2Br Perovskite Solar Cells. J. Chem. Phys. 2024, 160, 094705. [Google Scholar] [CrossRef]

- Wang, L.; She, X.; Li, W.; Cao, S.; Gong, Q.; Zhong, Z.; Wang, Z.; Li, J.; Liu, H.; Wang, X.; et al. Effective Surface Passivation for Stable and High-Performance Inverted CsPbI2Br Perovskite Solar Cells with Efficiency over 15%. Mater. Today Chem. 2024, 36, 101980. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Wang, X.; Lin, R.; Luo, X.; Liu, Z.; Zhou, K.; Xiong, S.; Bao, Q.; Chen, G.; et al. Flexible All-Perovskite Tandem Solar Cells Approaching 25% Efficiency with Molecule-Bridged Hole-Selective Contact. Nat. Energy 2022, 7, 708–717. [Google Scholar] [CrossRef]

- Peng, Z.; Tian, J.; Zhang, K.; These, A.; Xie, Z.; Zhao, Y.; Osvet, A.; Guo, F.; Lüer, L.; Li, N.; et al. Reducing Open-Circuit Voltage Losses in All-Inorganic Perovskite Cells by Dedoping. ACS Energy Lett. 2023, 8, 2077–2085. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, Q.; Li, H.; Niu, Y.; Han, D.; Yang, Q.; Yang, Y.; Yi, S.; Zhou, D.Y.; Feng, L. Dopant Free Mixture of Spiro-OMeTAD and PTAA with Tunable Wettability as Hole Transport Layer Enhancing Performance of Inverted CsPbI2Br Perovskite Solar Cells. Org. Electron. 2020, 86, 105873. [Google Scholar] [CrossRef]

- Lovergine, N.; Liaci, L.; Ganière, J.D.; Leo, G.; Drigo, A.V.; Romanato, F.; Mancini, A.M.; Vasanelli, L. Inhomogeneous Strain Relaxation and Defect Distribution of ZnTe Layers Deposited on (100)GaAs by Metalorganic Vapor Phase Epitaxy. J. Appl. Phys. 1995, 78, 229–235. [Google Scholar] [CrossRef]

- Liu, X.; Li, W.; She, X.; Wang, L.; Li, Z.; Zhang, W.; He, X.; Wangyang, P.; Wang, Z.; Sun, H.; et al. Effects of Passivated Molecular Side Group on Inverted Inorganic CsPbI2Br Perovskite Solar Cells. Ceram. Int. 2024, 50, 15303–15311. [Google Scholar] [CrossRef]

- Cao, S.; Wang, L.; She, X.; Li, W.; Wei, L.; Xiong, X.; Wang, Z.; Li, J.; Tian, H.; Cui, X.; et al. Enhanced Efficiency and Stability of Inverted CsPbI2Br Perovskite Solar Cells via Fluorinated Organic Ammonium Salt Surface Passivation. Langmuir 2024, 40, 3715–3724. [Google Scholar] [CrossRef]

- Gong, Q.; Huang, S.; Wang, H.; Wang, L.; Cao, S.; She, X.; Zhang, J.; Wang, Z.; Li, J.; Liu, H.; et al. Effective Surface Treatment for Efficient and Stable Inverted Inorganic CsPbI2Br Perovskite Solar Cells. Org. Electron. 2024, 132, 107097. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, S.; Chen, W.; Wu, S.; Chen, R.; Huang, Y.; Yang, Z.; Li, J.; Han, L. A General Strategy to Prepare High-Quality Inorganic Charge-Transporting Layers for Efficient and Stable All-Layer-Inorganic Perovskite Solar Cells. J. Mater. Chem. A Mater. 2019, 7, 18603–18611. [Google Scholar] [CrossRef]

- Tian, J.; Xue, Q.; Tang, X.; Chen, Y.; Li, N.; Hu, Z.; Shi, T.; Wang, X.; Huang, F.; Brabec, C.J.; et al. Dual Interfacial Design for Efficient CsPbI2Br Perovskite Solar Cells with Improved Photostability. Adv. Mater. 2019, 31, 1901152. [Google Scholar] [CrossRef]

- Liu, C.; Yang, Y.; Zhang, C.; Wu, S.; Wei, L.; Guo, F.; Arumugam, G.M.; Hu, J.; Liu, X.; Lin, J.; et al. Tailoring C60 for Efficient Inorganic CsPbI2Br Perovskite Solar Cells and Modules. Adv. Mater. 2020, 32, 1907361. [Google Scholar] [CrossRef]

- Guo, Z.; Jena, A.K.; Takei, I.; Kim, G.M.; Kamarudin, M.A.; Sanehira, Y.; Ishii, A.; Numata, Y.; Hayase, S.; Miyasaka, T. VOCOver 1.4 V for Amorphous Tin-Oxide-Based Dopant-Free CsPbI2Br Perovskite Solar Cells. J. Am. Chem. Soc. 2020, 142, 9725–9734. [Google Scholar] [CrossRef]

- Liu, S.; Chen, W.; Shen, Y.; Wang, S.; Zhang, M.; Li, Y.; Li, Y. An Intermeshing Electron Transporting Layer for Efficient and Stable CsPbI2Br Perovskite Solar Cells with Open Circuit Voltage over 1.3 v. J. Mater. Chem. A Mater. 2020, 8, 14555–14565. [Google Scholar] [CrossRef]

- Yang, X.; Yang, H.; Hu, X.; Li, W.; Fang, Z.; Zhang, K.; Huang, R.; Li, J.; Yang, Z.; Song, Y. Low-Temperature Interfacial Engineering for Flexible CsPbI2Br Perovskite Solar Cells with High Performance beyond 15%. J. Mater. Chem. A Mater. 2020, 8, 5308–5314. [Google Scholar] [CrossRef]

- Ou, Y.; Sun, A.; Li, H.; Wu, T.; Zhang, D.; Xu, P.; Zhao, R.; Zhu, L.; Wang, R.; Xu, B.; et al. Developing D-π-D Hole-Transport Materials for Perovskite Solar Cells: The Effect of the π-Bridge on Device Performance. Mater. Chem. Front. 2021, 5, 876–884. [Google Scholar] [CrossRef]

- Chen, L.; Yin, Z.; Mei, S.; Xiao, X.; Wang, H.Q. Enhanced Photoelectric Performance of Inverted CsPbI2Br Perovskite Solar Cells with Zwitterion Modified ZnO Cathode Interlayer. J. Power Sources 2021, 499, 229909. [Google Scholar] [CrossRef]

- Parida, B.; Jin, I.S.; Jung, J.W. Dual Passivation of SnO2 by Tetramethylammonium Chloride for High-Performance CsPbI2 Br-Based Inorganic Perovskite Solar Cells. Chem. Mater. 2021, 33, 5850–5858. [Google Scholar] [CrossRef]

- Lin, Z.Q.; Lian, H.J.; Ge, B.; Zhou, Z.; Yuan, H.; Hou, Y.; Yang, S.; Yang, H.G. Mediating the Local Oxygen-Bridge Interactions of Oxysalt/Perovskite Interface for Defect Passivation of Perovskite Photovoltaics. Nanomicro Lett. 2021, 13, 177. [Google Scholar] [CrossRef]

- Zhang, S.; Gu, H.; Chen, S.C.; Zheng, Q. KF-Doped SnO2as an Electron Transport Layer for Efficient Inorganic CsPbI2Br Perovskite Solar Cells with Enhanced Open-Circuit Voltages. J. Mater. Chem. C Mater. 2021, 9, 4240–4247. [Google Scholar] [CrossRef]

- Li, M.H.; Shao, J.Y.; Jiang, Y.; Qiu, F.Z.; Wang, S.; Zhang, J.; Han, G.; Tang, J.; Wang, F.; Wei, Z.; et al. Electrical Loss Management by Molecularly Manipulating Dopant-Free Poly(3-Hexylthiophene) towards 16.93% CsPbI2Br Solar Cells. Angew. Chem.-Int. Ed. 2021, 60, 16388–16393. [Google Scholar] [CrossRef]

- Guo, Z.; Jena, A.K.; Takei, I.; Ikegami, M.; Ishii, A.; Numata, Y.; Shibayama, N.; Miyasaka, T. Dopant-Free Polymer HTM-Based CsPbI2Br Solar Cells with Efficiency Over 17% in Sunlight and 34% in Indoor Light. Adv. Funct. Mater. 2021, 31, 2103614. [Google Scholar] [CrossRef]

- Liu, X.; Fu, S.; Zhang, W.; Xu, Z.; Li, X.; Fang, J.; Zhu, Y. A Universal Dopant-Free Polymeric Hole-Transporting Material for Efficient and Stable All-Inorganic and Organic-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2021, 13, 52549–52559. [Google Scholar] [CrossRef]

- Duan, C.; Wen, Q.; Fan, Y.; Li, J.; Liu, Z.; Yan, K. Improving the Stability and Scalability of All-Inorganic Inverted CsPbI2Br Perovskite Solar Cell. J. Energy Chem. 2022, 68, 176–183. [Google Scholar] [CrossRef]

- Chen, W.; Sun, Z.; Guan, X.; Tian, X.; Wang, B.; Zhou, J.; Chen, R.; Ren, F.; Wang, J.; Liu, S.; et al. A General Low-Temperature Strategy to Prepare High-Quality Metal Sulfides Charge-Transporting Layers for All-Inorganic CsPbI2Br Perovskite Solar Cells. Sol. RRL 2022, 6, 2200098. [Google Scholar] [CrossRef]

- Jeong, W.; Ha, S.R.; Jang, J.W.; Jeong, M.; Ahn, H.; Choi, H.; Jung, I.H. Simple-Structured Low-Cost Dopant-Free Hole-Transporting Polymers for High-Stability CsPbI 2 Br Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 13400–13409. [Google Scholar]

- Wang, Z.; Gan, J.; Liu, X.; Shao, M.; Bie, T.; Qiao, L.; Zheng, Y. Dimethylamine Exchanging of a New Hole Transport Material for Highly Efficient CsPbI2Br Solar Cells. J. Phys. Conf. Ser. 2022, 2174, 012027. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, Q.; Geng, Y.; Dai, Z.; Wang, Z.; Chen, Z.; Guo, Q.; Zheng, Z.; Li, Y.; Zhou, E. A Low-Cost Hole Transport Layer Enables CsPbI2Br Single-Junction and Tandem Perovskite Solar Cells with Record Efficiencies of 17.8% and 21.4%. Nano Today 2022, 46, 101586. [Google Scholar] [CrossRef]

- Li, Y.; Liu, N.; Xu, Z.; Xu, Z.; Pan, Y.; Zhang, J.; Huang, L.; Hu, Z.; Zhu, Y.; Liu, X. Doping Engineering of ZnO Electron Transporting Layer for High Performance CsPbI2Br Inorganic Perovskite Solar Cells. Appl. Phys. Lett. 2023, 123, 163901. [Google Scholar] [CrossRef]

- Jing, Y.; Liu, X.; Xu, Y.; Zhang, M.; Li, R.; Wang, S.; Yan, Z.; Sun, W.; Wu, J.; Lan, Z. Amorphous Antimony Sulfide Nanoparticles Construct Multi-Contact Electron Transport Layers for Efficient Carbon-Based All-Inorganic CsPbI2Br Perovskite Solar Cells. Chem. Eng. J. 2023, 455, 140871. [Google Scholar] [CrossRef]

- Tian, H.; He, J.; Liu, X.; Li, Q.; Liu, D.; Shen, B.; Yang, S.; Niu, Q.; Hou, Y. Low-Temperature Synthesis of SnO2 Nanocrystals as Electron Transport Layers for High-Efficiency CsPbI2Br Perovskite Solar Cells. Small Sci. 2023, 3, 2200112. [Google Scholar] [CrossRef]

- Ding, Y.; Duan, C.; Guo, Q.; Meng, Y.; Wang, Z.; Dai, Z.; Zhou, E. Side-Chain Engineering of Benzotriazole-Based Polymers as Hole Transport Material Enables High-Efficiency CsPbI2Br Single-Junction and Tandem Perovskite Solar Cells. Nano Today 2023, 53, 102046. [Google Scholar] [CrossRef]

- Dai, Z.; Guo, Q.; Ding, Y.; Wang, Z.; Jiang, N.; Zhou, E. Constructing D-A Type Polymers as Dopant-Free Hole Transport Materials for High-Performance CsPbI2Br Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 15, 9784–9791. [Google Scholar] [CrossRef]

- Zheng, K.; Liu, C.; Yu, K.; Meng, Y.; Yin, X.; Bu, S.; Lin, S.; Liu, C.; Ge, Z. Approaching the Fill Factor Limit in Dopant-Free Hole Transporting Layer-Based All-Inorganic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2023, 15, 14748–14759. [Google Scholar] [CrossRef]

- He, J.; Xu, X.; Dai, Y.; Xue, D.; Zhang, P.; Niu, Q. Polysaccharide-Modified SnO2 for Highly Efficient Perovskite Solar Cells. Sol. RRL 2024, 8, 2400080. [Google Scholar] [CrossRef]

- Xu, W.; Tang, X.; Xiong, J.; Xu, W.; Zhou, H.; Yu, C.; Lou, Y.; Feng, L. Organic-Hydrochloride-Modified ZnO Electron Transport Layer for Efficient Defect Passivation and Stress Release in Rigid and Flexible All Inorganic Perovskite Solar Cells. Small 2024, 20, 2312230. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, X.; Fu, S.; Wang, J.; Zhang, J.; Huang, L.; Hu, Z.; Zhu, Y. Mitigating Voltage Loss in Efficient Cspbi2br All-Inorganic Perovskite Solar Cells via Metal Ion-Doped Zno Electron Transport Layer. Appl. Phys. Lett. 2021, 119, 212101. [Google Scholar] [CrossRef]

- Farva, U.; Lee, H.W.; Kim, R.; Lee, D.G.; Kang, D.W.; Kim, J. Growth Temperature Influence on Atomic-Layer-Deposited In2o3 Thin Films and Their Application in Inorganic Perovskite Solar Cells. Nanomaterials 2021, 11, 2047. [Google Scholar] [CrossRef]

- Liu, H.; Tu, Q.; Wang, D.; Zheng, Q. Ladder-Type Heteroacene-Based Dopant-Free Hole-Transporting Materials for Efficient and Stable CsPbI2Br Perovskite Solar Cells. Dye. Pigment. 2021, 191, 109368. [Google Scholar] [CrossRef]

- Zhai, M.; Wang, A.; Chen, C.; Hao, F.; Wang, H.; Ding, L.; Yang, X.; Cheng, M. Construct Efficient CsPbI2Br Solar Cells by Minimizing the Open-Circuit Voltage Loss through Controlling the Peripheral Substituents of Hole-Transport Materials. Chem. Eng. J. 2021, 425, 131675. [Google Scholar] [CrossRef]

- Duan, C.; Zou, F.; Li, S.; Zhu, Q.; Li, J.; Chen, H.; Zhang, Z.; Chen, C.; Guo, H.; Qiu, J.; et al. Dopant-Free Starlike Molecular Hole Conductor with Ordered Packing for Durable All-Inorganic Perovskite Solar Cells. Adv. Energy Mater. 2024, 14, 2303997. [Google Scholar] [CrossRef]

- Dai, Z.; Duan, C.; Guo, Q.; Wang, Z.; Jiang, N.; Ding, Y.; Gao, L.; Zhou, E. Fluorine Substitutions Engineering of Benzotriazole-Based Hole Transport Polymers toward High-Performance CsPbI2Br Perovskite Solar Cells. Battery Energy 2024, 3, 20230065. [Google Scholar] [CrossRef]

- Kojima, M.; Xue, L.; Oyaizu, K.; Nishide, H.; Suga, T. Combination of Poly(3-Butylthiophene) Hole-Transporting Layer and Butylammonium Interface Passivation to Improve an Inorganic Perovskite Solar Cell. ACS Appl. Polym. Mater. 2023, 5, 4100–4105. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Fang, Z.; Xie, H.; Yuan, Y.; Zuo, C.; Ding, L.; Yang, B. Adjusting Energy Level Alignment between HTL and CsPbI2Br to Improve Solar Cell Efficiency. J. Semicond. 2021, 42, 030501. [Google Scholar] [CrossRef]

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year. | Refs. |

|---|---|---|---|---|---|---|---|---|

| FTO/c-TiO2/CsPbI2Br/Spiro-OMeTAD/Au | 0.07 | 10.7 | 12.0 | 1.23 | 73 | Remained stable for a long period in a humid atmosphere | 2017 | [36] |

| FTO/c-TiO2/CsPbI2Br/Spiro-OMeTAD/Au | / | 10.56 | 13.61 | 1.13 | 68.64 | Exhibited thermal stability under 100 °C annealing for more than a week | 2018 | [47] |

| PET/ITO/Nb2O5/CsPbI2Br/ Spiro-OMeTAD/Au | / | 11.7 | 14.6 | 1.19 | 67.3 | Maintained 70% of their original PCE without any encapsulation after being stored in ambient air for 700 h | 2018 | [41] |

| ITO/PEDOT/CsPbI2Br/C60/BCP/Ag | 0.0485 | 8.67 | 12.4 | 1.16 | 60.1 | Showed improved humidity stability | 2018 | [48] |

| ITO/NiOx/CsPbI2Br/C60/BCP/Ag | 0.1 | 10.4 | 12.6 | 1.05 | 78.7 | Maintained 70% of their initial values | 2018 | [40] |

| FTO/TiO2/Al2O3/CsPbI2Br/NiOx/carbon | / | 8.44 | 14.33 | 0.945 | 62.5 | Retained its color all the time, even after storage in ambient air (25 °C, 30% RH) for 36 h | 2019 | [42] |

| ITO/SnO2/CsPbI2Br/PTAA/MoO3/Al | 0.16 | 13.8 | 15.58 | 1.19 | 74.1 | / | 2019 | [49] |

| ITO/SnO2/CsPbI2Br/carbon | 0.04 | 10.44 | 14.25 | 1.14 | 64.12 | Displayed only ~10% PCE loss after both 1000 h of storage in N2 and continuous heating at 85 °C after 300 h in a N2-filled glove box | 2019 | [50] |

| FTO/SnO2/CsPbI2Br/Spiro-OMeTAD/Au | / | 11.68 | 16.01 | 1.11 | 65.7 | Maintained its efficiency of 50% after 10 d | 2019 | [44] |

| ITO/c-TiO2/CsPbI2Br/Spiro-OMeTAD/Au | 0.1 | 16.07 | 16.79 | 1.23 | 77.81 | Retained 95% of its initial PCE after 1000 h in an air atmosphere with an RH of 30% | 2019 | [51] |

| ITO/NiOx/CsPbI2Br/PCBM/Ag | 0.04 | 12.32 | 15.79 | 1.02 | 76.68 | Retained over 95% of its initial PCE after being stored in a N2 glove box for over 1000 h | 2020 | [52] |

| ITO/SnO2/CsPbI2Br/P3HT/Au | 0.1 | 15.50 | 14.75 | 1.231 | 85.37 | Maintained a PCE of more than 95% of the initial value after being stored in an environment with humidity below 25% for 1300 h | 2020 | [53] |

| FTO/MoO3/CsPbI2Br/carbon | 0.09 | 14.84 | 16.62 | 1.207 | 73.83 | Retained its initial original color after being kept in ambient air with a specified RH of 20–25% and at room temperature for 9 h | 2021 | [37] |

| FTO/TiO2/PVP-CsPbI2Br/Spiro-OMeTAD/carbon | 0.06 | 10.47 | 18.47 | 1.01 | 56.35 | Maintained a stable cubic phase at ambient temperatures for 4 d | 2022 | [54] |

| ITO/bi-SnO2/CsPbI2Br/P3HT/Au | 0.16 | 17 | 16.6 | 1.27 | 80.5 | Had excellent thermal stability at 300 °C | 2022 | [45] |

| FTO/c-TiO2/CsPbI2Br/carbon | 0.045 | 15.57 | 16.74 | 1.161 | 80.2 | Retained 91.7% of the initial PCE | 2023 | [38] |

| FTO/SnO2/CsPbI2Br/Spiro-OMeTAD/Au | / | 16.44 | 15.76 | 1.31 | 79.63 | Maintained more than 88% of the initial PCE after 1000 h | 2024 | [46] |

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year | Refs. |

|---|---|---|---|---|---|---|---|---|

| FTO/TiO2/Cs0.925K0.075PbI2Br/Spiro-OMeTAD/Au | 0.15 | 10.0 | 11.6 | 1.18 | 73 | Maintained 80% of its initial value for 120 h at 20 °C and with RH = 20% | 2017 | [27] |

| FTO/c-TiO2/mp-TiO2/CsPb0.98Sr0.02I2Br/P3HT/Au | 0.159 | 11.3 | 14.9 | 1.067 | 70.9 | Remained stable for 3 weeks, with its PCE rising during the first week, under storage conditions of 25 °C and RH < 50% in the dark | 2017 | [71] |

| FTO/NiOx/InCl3:CsPbI2Br/ZnO@C60/Ag | 0.09 | 13.57 | 15.1 | 1.15 | 78 | Maintained its initial PCE for over 80 h in a sealed container with an RH of ~30% | 2018 | [26] |

| FTO/c-TiO2/CsPb0.9Zn0.1I2Br/Spiro-OMeTAD/Ag | 0.07 | 13.6 | 15.8 | 1.18 | 72.7 | Maintained 85% of its initial performance after 400 h in air (25 °C and RH of 20%) | 2019 | [72] |

| FTO/c-TiO2/m-TiO2/CsPb0.8Ba0.2I2Br/N,N-di-p-methoxyphenyl-amine/Spiro-OMeTAD/Au | 0.16 | 14.0 | 14.0 | 1.28 | 78.2 | Maintained ~80% of the initial efficiency after 450 h | 2019 | [73] |

| FTO/TiO2/Eu(Ac)3:CsPbI2Br/Spiro-OMeTAD/Au | 0.09 | 15.25 | 15.44 | 1.25 | 79.00 | Retained 82% of its initial value after 30 d of aging at 25 °C and 35–40% RH | 2019 | [74] |

| FTO/TiO2/CsPb0.95Eu0.05I2Br/Spiro-OMeTAD/Au | 0.16 | 13.71 | 14.63 | 1.223 | 76.6 | Retained 93% of the initial efficiency after 370 h | 2019 | [75] |

| ITO/SnO2/CsPb0.995Nb0.005I2Br/Carbon | 0.08 | 10.42 | 12.06 | 1.20 | 72 | Film has no changes even after 96 h | 2019 | [76] |

| FTO/c-TiO2/m-TiO2/CsPb0.995Nb0.005I2Br/P3HT/Au | 0.09 | 16.45 | 16.23 | 1.317 | 77 | Maintained 90% of its initial PCE after 96 h of storage in ambient conditions at 30% RH | 2020 | [77] |

| FTO/TiO2/Cs0.99Rb0.01PbI2Br/P3HT/Au | 0.09 | 17.16 | 16.25 | 1.320 | 80.03 | Maintained >90% initial efficiency in ambient conditions without encapsulation for 120 h with RH < 40% | 2020 | [68] |

| FTO/SnO2/Cs0.9Rb0.1PbI2Br/GABr/Spiro-OMeTAD/Au | 0.06 | 15.6 | 15.9 | 1.25 | 78.5 | Retained 88% of its initial PCE after 60 d of storage in an ambient atmosphere at 25 °C with 25% RH | 2020 | [69] |

| FTO/TiO2/Cs0.995Na0.005PbI2Br/Carbon | 0.125 | 14.63 | 14.13 | 1.267 | 80.66 | Maintained 90% of its initial value under an ambient environment with an RH of 40–60% after 330 h | 2021 | [64] |

| FTO/SnO2/CsPb0.995Fe0.005I2Br/PCBM/Au | 0.16 | 17.1 | 15.90 | 1.31 | 81.8 | A retention of over 95% of the initial PCE after 330 h of MPP tracking | 2021 | [78] |

| FTO/c-TiO2/m-TiO2/CsPb0.98Sr0.02I2Br/P3HT/Au | 0.09 | 14.57 | 15.19 | 1.309 | 73.30 | Maintained >85% of its initial PCE in ambient conditions for 100 h at 35% RH | 2021 | [79] |

| ITO/SnO2/NaCl + N-GQDs:CsPbI2Br/P3HT/Ag | / | 15.37 | 15.89 | 1.24 | 78 | Maintained about 96% of the initial PCE after being stored in air for 270 h under 20–30% RH | 2022 | [80] |

| FTO/c-TiO2/m-TiO2/CsPb0.95Ba0.05I2Br/P3HT/Au | 0.09 | 14.07 | 15.53 | 1.202 | 75.38 | / | 2023 | [66] |

| FTO/NiOx/CsBr:CsPbI2Br/PCBM/MgF/Ag | / | 15.6 | 15.5 | 1.27 | 79 | Retained more than 80% of its initial efficiency after 240 h of continuous illumination | 2023 | [81] |

| FTO/c-TiO2/Cs0.7FA0.3PbI2Br/Spiro-OMeTAD/Au | 0.058 | 14.55 | 16.3 | 1.2 | 74.1 | Maintained 98% of the initial PCE after 1000 s irradiation at AM 1.5G | 2024 | [70] |

| ITO/SnO2/CaInCsPbI2Br/Spiro-OMeTAD/Au | 0.1 | 16.60 | 16.09 | 1.29 | 80.02 | Maintained 90% PCE after aging for 2400 h in ambient air with an RH of 50 ± 5% | 2024 | [82] |

| ITO/ZnO/CsPb0.996Zr0.004I2Br/Spiro-OMeTAD/Ag | / | 16.60 | 15.84 | 1.29 | 81.14 | Retained over 91% of the initial PCE after 1000 h of aging in ambient air conditions | 2024 | [83] |

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year | Refs. |

|---|---|---|---|---|---|---|---|---|

| ITO/c-TiO2/CsPbI2Br + PTFE/PBDB-T/MoO3/Ag | 0.10 | 16.40 | 16.16 | 1.24 | 82.05 | Retained 91% of its initial PCE value after 500 h in an ambient atmosphere with an RH of ~30% | 2021 | [95] |

| ITO/SnO2/LiAc:CsPbI2Br/PCBM/Ag | 0.04 | 16.05 | 16.21 | 1.30 | 76.2 | Almost no PCE degradation after over 300 h of thermal aging at 85 °C | 2022 | [96] |

| FTO/SnO2/CsPbI2Br@FAAc/Spiro-OMeTAD/Ag | 0.09 | 15.86 | 16.41 | 1.22 | 77 | / | 2022 | [97] |

| ITO/SnO2/ZnO/CsPbI2Br:DIM/P3HT/Au | 0.04 | 16.42 | 16.11 | 1.236 | 82.47 | Maintained about 85% of the initial PCE after aging at 85 °C for 360 h | 2022 | [98] |

| FTO/NiO/Perovskite + ILs/PCBM/BCP/Au | / | 19.8 | 23.8 | 1.08 | 81.0 | / | 2019 | [99] |

| ITO/SnO2/CsPbI2Br + CsPbBr3 NCs/CsPbBr3 NCs/P3HT/Ag | / | 17.03 | 15.84 | 1.37 | 78 | / | 2023 | [100] |

| ITO/SnO2/CsPbI2Br + SiO2/P3HT/Ag | / | 15.32 | 16.21 | 1.23 | 77 | Maintained ~83% of the initial PCE in air with an RH of 20–30% after 160 h of storage | 2023 | [101] |

| ITO/SnO2/ZnO/CsPbI2Br + PEAI/P3HT/Au | 0.04 | 17.40 | 16.47 | 1.264 | 83.56 | Retained ~87.25% of its initial PCE at 85 °C in a dry box for 720 h without encapsulation | 2023 | [102] |

| FTO/c-TiO2/m-TiO2/PTACl-CsPbI2Br + GAI/P3HT/Au | 0.09 | 16.88 | 16.25 | 1.34 | 77.75 | Maintained over 95% of its initial efficiency under continuous illumination with a 100 mW/cm2 LED white light for more than 1000 h | 2023 | [103] |

| FTO/c-TiO2/m-TiO2/(2D/3D CsPb2I4Br/CsPbI2Br BHJ) + CsPbI2Br/Carbon | 0.125 | 15.25 | 14.60 | 1.32 | 79.11 | Maintained 97% of its initial efficiency after being stored for 1250 h at room temperature | 2023 | [104] |

| FTO/m-TiO2/ErCl3:CsPbI2Br/PCBM/Ag | 0.09 | 16.74 | 16.16 | 1.304 | 79.44 | Maintained 90% of the initial PCE after 400 h at 65 °C and ~30% RH | 2023 | [105] |

| ITO/SnO2/K-TFA:CsPbI2Br/P3HT/Au | 0.24 | 17.1 | 15.11 | 1.382 | 82.0 | Retained over 92% of its initial efficiency after aging for 1500 h under ambient air | 2023 | [106] |

| ITO/SnO2/KAc:CsPbI2Br/PCBM/Ag | 0.04 | 15.10 | 15.84 | 1.23 | 77.5 | Maintained 88% of its initial value after aging for over 400 h under conditions of 85 °C in a N2-filled glove box | 2023 | [107] |

| FTO/SnO2/NaFo:CsPbI2Br/P3HT/Au | 0.096 | 17.66 | 15.25 | 1.337 | 84.52 | Retained almost 97% of its initial PCE for 1000 h under 10% RH at room temperature without any encapsulation | 2023 | [108] |

| ITO/Spiro-OMeTAD@PTAA/5′-CMP:CsPbI2Br/PC61BM/BCP/Ag | 0.04 | 15.94 | 16.58 | 1.17 | 82.20 | Retained 95% of the PCE after 600 h in air with an RH of 25 ± 5% | 2023 | [109] |

| FTO/SnO2/DAD:CsPbI2Br/Spiro-OMeTAD/Au | 0.09 | 17.38 | 15.87 | 1.31 | 83.60 | Retained 90% of its initial efficiency after aging for 1000 h in air with an RH ranging from 20% to 30% | 2023 | [110] |

| FTO/SnO2/CsPbI2Br + AA + HBC/Carbon | 0.08 | 12.71 | 14.50 | 1.22 | 72 | Maintained 93% of the initial efficiency after 20 d in air with an RH ranging from 20% to 30% | 2023 | [111] |

| FTO/c-TiO2/CsPbI2Br + OA/Carbon | 0.045 | 15.57 | 16.74 | 1.161 | 80.2 | Retained 91.7% of the initial PCE in dry conditions | 2023 | [38] |

| ITO/SnO2/ZnO2/CsPbI2Br + PLA/PTAA/MoO3/Ag | 0.04 | 18.06 | 15.89 | 1.393 | 81.55 | Retained 92% of its initial PCE after being stored in air with an RH of 15–20% for 62 d | 2023 | [112] |

| FTO/c-TiO2/m-TiO2/CsPbI2Br + PTM/Carbon | 0.09 | 13.95 | 15.78 | 1.30 | 68 | Maintained 91% of its initial efficiency after being stored in ambient air for 14 d | 2023 | [113] |

| ITO/SnO2/CsPbI2Br + (2D)SnSe nanosheets/P3HT/Ag | 0.15 | 14.24 | 16.02 | 1.22 | 72.46 | / | 2024 | [114] |

| ITO/ZnO/PbAc2:CsPbI2Br/P3HT/Au | 0.09 | 16.19 | 16.16 | 1.26 | 79.38 | Maintained 96.7% of its initial PCE for 1500 h at room temperature and ~25% RH | 2024 | [115] |

| ITO/SnO2/MAAc:CsPbI2Br/P3HT/Au | 0.1/1 | 18.14/16.2 | 15.54/15.5 | 1.40/1.34 | 83.4/79.0 | Maintained 95% of its initial efficiency after heating at 85 °C for 1000 h | 2024 | [116] |

| FTO/SnO2/BP-9:CsPbI2Br/Spiro-OMeTAD/Au | / | 17.11 | 15.82 | 1.34 | 80.71 | Maintained more than 95% of its initial PCE after 1000 h under the conditions of 25 °C and ~50% RH | 2024 | [117] |

| FTO/SnO2/CsPbI2Br + 2,5-TDCA/Carbon | 0.1 | 13.42 | 14.95 | 1.31 | 68.4 | Maintained more than 80% of the initial PCE after 240 h under 85 °C and an RH of 20–30% | 2024 | [118] |

| FTO/SnO2/SnCl2/CsPbI2Br-PGMA/Spiro-OMeTAD/Au | 0.09 | 10.29 | 18.64 | 1.22 | 45 | Retained ~80% of its initial PCE after being stored in air at 25 °C with an RH of 50% for 600 h | 2024 | [119] |

| ITO/SnO2/CsPbI2Br + ABS/Carbon | / | 14.27 | 14.69 | 1.300 | 74.7 | Retained ~86% of the PCE after being exposed to air with an RH of ~40% for 150 h | 2024 | [120] |

| FTO/c-TiO2/CsPbI2Br + IIA/Carbon | 0.09 | 14.85 | 14.713 | 1.306 | 77.32 | Reached 70% after 300 h in air with an RH of 10% | 2024 | [121] |

| FTO/c-TiO2/CsPbI2Br + phenyl-amide/Carbon | 0.09 | 15.51 | 14.758 | 1.300 | 80.85 | Retained 91.5% of the initial efficiency after being stored in the dark for 1000 h at 25 °C and an RH of 10% | 2024 | [122] |

| ITO/SnO2/CsPbI2Br + DHBP/P3HT/Ag | 0.104 | 16.86 | 15.28 | 1.38 | 80.05 | Retained 95% of the initial PCE during 110 min of aging under continuous heating at 85 °C | 2024 | [123] |

| FTO/SnO2/CsPbI2Br + DBM/Carbon | 0.09 | 13.46 | 15.26 | 1.189 | 74.2 | Retained 90% of its initial value with an RH of 15–25% for 500 h | 2024 | [124] |

| FTO/c-TiO2/CsPbI2Br + cytosine/Carbon | 0.04 | 15.00 | 14.721 | 1.317 | 77.34 | Retained 94.74% of its initial efficiency after being stored for 65 d under the condition of 10% RH in the air and a temperature of 25 °C | 2024 | [125] |

| ITO/SnO2/ZnO/CsPbI2Br + ANT/P3HT/Au | 0.04 | 17.13 | 16.07 | 1.278 | 83.41 | Retained ~90% of its initial PCE after 720 h at 85 °C | 2024 | [126] |

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year | Refs. |

|---|---|---|---|---|---|---|---|---|

| FTO/TiO2/TiCl4: TiCl3/CsPbI2Br/Carbon | 0.125 | 14.46 | 14.21 | 1.28 | 79.4 | / | 2021 | [128] |

| ITO/c-TiO2/TiO2 NaPAs/CsPbI2Br/P3HT/MoO3/Ag | / | 11.35 | 15.18 | 1.10 | 68.8 | Retained 60% of the initial PCE after 10 d of aging | 2021 | [129] |

| ITO/TiO2/BQD/CsPbI2Br/PTAA/Au | 0.09 | 15.31 | 15.18 | 1.28 | 78.5 | Retained 94% of the initial PCE in ambient air at 20% RH for 40 d | 2021 | [130] |

| ITO/ZnO/SnO2/CsPbI2Br/GABr/Spiro-OMeTAD/Ag | / | 16.97 | 15.90 | 1.31 | 81.5 | Retained ~85% of its initial PCE in dry air with <20% RH for 960 h | 2021 | [131] |

| FTO/c-TiO2/CsPbI2Br/[PEVIM]Cl/Spiro-OMeTAD/Au | 0.1 | 14.19 | 15.70 | 1.16 | 77.9 | Retained 89% of its initial PCE in ambient air with 50% RH for 960 h | 2021 | [132] |

| ITO/TiO2/CsPbI2Br/B-CDs/Spiro-OMeTAD/Au | 0.09 | 16.76 | 16.01 | 1.31 | 80.0 | Retained 95.33% of its initial PCE in ambient air with ~25% RH at 30 °C for 1000 h | 2021 | [133] |

| ITO/Spiro-OMeTAD/TS-CuPc/CsPbI2Br/Nano-Eu2O3/PC61BM/Bphen/Ag | / | 14.85 | 15.53 | 1.19 | 80.7 | Retained >60% of its initial PCE in ambient air with 60–70% RH for 1200 h | 2021 | [134] |

| ITO/NiOx/CsPbI2Br/BIZI/PCBM/BPhen/Ag | / | 14.32 | 15.59 | 1.15 | 79.79 | Retained 95% of its initial PCE in ambient air with 15 ± 5% RH at 25 °C for 14 d | 2021 | [135] |

| FTO/c-TiO2/Ce-doped CsPbI3 QD/CsPbI2Br/P3HT/Ag | / | 16.38 | 20.55 | 1.062 | 74.9 | Retained 64% of its initial PCE in a N2 glove box for 30 d | 2022 | [136] |

| FTO/TiO2/CsPbI2Br/BMMIMBF4/Spiro-OMeTAD/Au | 0.09 | 17.02 | 15.96 | 1.33 | 80.1 | Retained 94.4% of its initial PCE in ambient air at ~25% RH for 1440 h | 2022 | [137] |

| ITO/NiOx/CsPbI2Br/BP-HI/ZnO/C60/Ag | / | 15.36 | 16.31 | 1.21 | 78.2 | Retained 85% of its initial PCE in ambient air with ~30% RH at 25 °C for 330 h | 2022 | [138] |

| ITO/SnO2/ZnO-EAD/CsPbI2Br/Carbon | 0.09 | 14.58 | 14.98 | 1.27 | 76.5 | Retained 81% of its initial PCE under continuous 80 °C heating in a N2 glove box after 24 d | 2023 | [139] |

| FTO/SnO2/CdCl2/CsPbI2Br/Carbon | 0.0625 | 14.47 | 14.30 | 1.30 | 77.85 | Retained 94% of its initial PCE in ambient air at 15–20% RH for 30 d | 2023 | [140] |

| ITO/ZnO-CsTFA/CsPbI2Br/Carbon | 0.09 | 14.25 | 14.95 | 1.269 | 75.1 | / | 2023 | [141] |

| ITO/ZnO/TA/CsPbI2Br/PM6/MoO3/Ag | 0.09 | 16.56 | 15.61 | 1.306 | 81.22 | Retained 90.4% of its initial PCE after 1080 h | 2023 | [142] |

| ITO/SnO2/CsPbI2Br/CsPbBr3 NCs/P3HT/Au | / | 17.03 | 15.84 | 1.37 | 78.0 | / | 2023 | [100] |

| FTO/NiOx/CsPbI2Br/TiO2/Al | 0.1 | 17.1 | 16.4 | 1.26 | 83.1 | Retained 92% of its initial PCE in ambient air with 80% RH for 1000 h | 2023 | [143] |

| ITO/Cu:NiO/IL:CsPbI2Br/CsPbBr3-QDs/W:Nb2O3/Ti/Ag | / | 15.37 | 15.31 | 1.24 | 81.0 | Retained 80% of its nitial PCE in ambient air for 60 h | 2023 | [144] |

| ITO/SnO2/PS/CsPbI2Br/Carbon | / | 13.11 | 14.12 | 1.25 | 74.5 | Retained 76.6% of its initial PCE after 1000 h in a glove box | 2024 | [145] |

| ITO/SnO2/NH4BF4/CsPbI2Br/P3HT/Au | / | 17.09 | 14.57 | 1.43 | 81.1 | Retained 94.5% of its initial PCE after 1000 h of aging at 15 ± 5% RH | 2024 | [146] |

| FTO/TiO2/Zn(Ac)2/CsPbI2Br/PCBM/Ag | 0.0706 | 14.20 | 14.49 | 1.226 | 79.95 | Retained 86% of its initial PCE after 500 h in dry air | 2024 | [147] |

| FTO/TiO2/PFPA/CsPbI2Br/Carbon | 0.1256 | 14.15 | 14.41 | 1.21 | 79.07 | Retained 84.59% of its initial PCE in a N2 atmosphere for 30 d | 2024 | [148] |

| ITO/NiOx/CsPbI2Br/CFPMAI/PCBM/BCP/Ag | 0.048 | 14.43 | 16.31 | 1.12 | 79.02 | Retained 98.1% of its initial PCE in a N2 atmosphere for 984 h | 2024 | [149] |

| ITO/NiOx/CsPbI2Br/TM/PCBM/BCP/Ag | 0.048 | 15.07 | 16.42 | 1.16 | 79.11 | Retained 97.07% of its initial PCE in a N2 glove box after 1752 h | 2024 | [150] |

| Device Architecture | Active Area (cm2) | PCE (%) | Jsc (mA/cm2) | Voc (V) | FF (%) | Stability | Year | Refs. |

|---|---|---|---|---|---|---|---|---|

| ITO/TiO2/CsPbI2Br/P3HT/Au | 0.05 | 12.02 | 13.13 | 1.30 | 70.4 | Retained around 90% of their initial PCE after 960 h of storage in a dry glove box | 2018 | [18] |

| FTO/NiMgLiOx/CsPbI2Br/c- TiO2/Bi/Ag | / | 14.0 | 14.72 | 1.26 | 76.0 | Maintained >90% of their initial PCE at 85 °C in the dark and >92% under continuous illumination at 45 °C for 1000 h | 2019 | [158] |

| ITO/SnO2/PN4N/CsPbI2Br/PDCBT/MoO3/Ag | 0.04 | 16.2 | 15.3 | 1.30 | 81.5 | High photostability with an efficiency drop of less than 10% under continuous 1-sun-equivalent illumination for 400 h | 2019 | [159] |

| FTO/NiOx/CsPbI2Br/ZnO@C60/Ag | 0.09 | 15.19 | 15.87 | 1.23 | 78 | Retained ≈86.5% of its initial PCE after being stored for 75 d in a N2 atmosphere | 2020 | [160] |

| ITO/A-SnOx/CsPbI2Br/poly (DTSTPD-r-BThTPD)/Au | 0.09 | 15.53 | 14.25 | 1.41 | 77.0 | Retained 71.9% of the initial PCE for 900 h | 2020 | [161] |

| ITO/Im-SnO2/CsPbI2Br/Spiro-OMeTAD/Au | 0.1 | 16.10 | 15.49 | 1.31 | 79.13 | Retained ~96% of its initial PCE after being kept in an ambient atmosphere with an RH of 30% and 25 °C for 1000 h | 2020 | [162] |

| ITO/PEDOT:PSS/AZO/CsPbI2Br/t-BCA/PTAA/MoO3/Ag | 0.1 | 15.08 | 15.87 | 1.26 | 75.41 | Retained 93% of the original PCE after being stored for 60 d | 2020 | [163] |

| ITO/SnO2/ZnO2/CsPbI2Br/SY1 or SY2 or SY3/MoO3/Ag | 0.09 | 13.41 | 14.93 | 1.19 | 75.5 | Dropped to 82% under the same stored conditions | 2020 | [164] |

| ITO/P3CT/CsPbI2Br/ZnO:TPPPS@C60/Ag | / | 14.62 | 15.51 | 1.228 | 76.83 | Retained ~80% of its initial efficiency for 32 d under illumination | 2021 | [165] |

| ITO/TMACl-SnO2/CsPbI2Br/TFB/P3HT/Au | 0.1 | 13.84 | 15.29 | 1.16 | 77.53 | Retained 68% of its initial PCE for 96 h without any encapsulation | 2021 | [166] |

| ITO/SnO2/CsPbI2Br/P3HT/Au | 0.0625 | 17.26 | 15.86 | 1.36 | 80.0 | Retained 92% of the initial PCE after 500 h | 2021 | [167] |

| ITO/SnO2-KF/CsPbI2Br/Spiro-OMeTAD/MoO3/Ag | 0.0625 | 15.39 | 14.79 | 1.31 | 79.15 | Maintained 40% of its initial PCE after 22 d of storage | 2021 | [168] |

| ITO/SnO2/CsPbI2Br/P3HT or SMe-TATPyr/Au | 0.1 | 16.93 | 14.71 | 1.38 | 81.0 | Maintained 96% of its initial PCE after aging at 10–25% RH for 1500 h | 2021 | [169] |

| ITO/SnO2/A-SnOx/CsPbI2Br/PDTDT/P3HT/Au | 0.09 | 17.36 | 15.02 | 1.42 | 81.3 | Kept 88% of the maximum value after 45 d | 2021 | [170] |

| ITO/SnO2/ZnO/CsPbI2Br/PM6/MoO3/Ag | 0.09 | 16.06 | 15.68 | 1.241 | 82.54 | Maintained ~76% of the initial PCE | 2021 | [171] |

| ITO/NiOx/CsPbI2Br/Ti0.9Sn0.1O2/Ag | 0.08 | 14.0 | 15.90 | 1.15 | 76.6 | Retained 98% of the initial efficiency under 85 °C treatment after 65 d | 2022 | [172] |

| FTO/NiMgLiOx/CsPbI2Br/ETLs/Au | 0.04 | 15.04 | 15.68 | 1.214 | 79.0 | Maintained 95.2% of its initial PCE after 480 h under continuous light in a N2 atmosphere at 45 °C | 2022 | [173] |

| ITO/SnO2/CsPbI2Br/PCDA1/PCDA2/Au | 0.055 | 11.01 | 14.55 | 1.07 | 69.0 | Retained 86% of the initial PCE | 2022 | [174] |

| ITO/SnO2/CsPbI2Br/BDTB/BDMA/MoO3/Au | 0.04 | 12.32 | 15.44 | 1.12 | 71.5 | Sustained 80% of its PCE after 50 d in ambient air | 2022 | [175] |

| ITO/SnO2/CsPbI2Br/PTQ10/P3HT/MoO3/Ag | 0.048 | 17.8 | 15.24 | 1.40 | 83.2 | Retained 98.3% of its initial value after aging in a glove box for 1112 h | 2022 | [176] |

| ITO/ZnO:Ca/CsPbI2Br/PM6/MoO3/Ag | 0.075 | 16.39 | 15.36 | 1.292 | 80.61 | Maintained 87% efficiency after 275 h under continuous 100 mW/cm2 illumination in a N2 atmosphere | 2023 | [177] |

| FTO/TiO2@Sb2S3-MPA/CsPbI2Br/Carbon | 0.08 | 14.59 | 14.60 | 1.29 | 77.49 | Maintained the initial efficiency of ~96.4% after continuous heating at 85 °C for 28 d under N2 | 2023 | [178] |

| ITO/SnO2/CsPbI2Br/P3HT/Au | 0.0625 | 16.22 | 15.68 | 1.30 | 80 | Retained over 90% of its initial efficiency after 500 h at 85 °C in a N2-filled glove box | 2023 | [179] |

| ITO/SnO2/CsPbI2Br/PE51/PE52/PE53/MoO3/Ag | 0.04 | 17.65 | 15.07 | 1.42 | 82.48 | Maintained about 94% of its initial PCE after being exposed to an air environment with less than 10% RH for 840 h | 2023 | [180] |

| ITO/SnO2/CsPbI2Br/PE61/MoO3/Ag | 0.04 | 16.72 | 14.52 | 1.40 | 82.23 | Maintained 93% of its initial PCE after aging for 1000 h | 2023 | [181] |

| ITO/ZnO/CsPbI2Br/D18-Cl/MoO3/Ag | 0.04 | 16.73 | 15.57 | 1.259 | 85.34 | Maintained 81% of its initial PCE after aging for 1500 h at 85 °C in a N2 atmosphere | 2023 | [182] |

| ITO/SnO2-SA/CsPbI2Br/P3HT/Ag | 0.0625 | 16.90 | 15.90 | 1.24 | 0.837 | Retained 85% of its initial performance after 700 h of continuous operation under simulated one-sun illumination | 2024 | [183] |

| ITO/Spiro-OMeTAD:PTAA/CsPbI2Br/FADD:ZnO/C60/Ag | 0.04 | 16.05 | 16.19 | 1.222 | 81.14 | Maintained 80% of its original PCE after continuous heating for 1200 h | 2024 | [184] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, F.; Hou, T.; Xie, K.; Zhu, X.; Yang, D.; Liu, X. Advancements and Strategies in CsPbI2Br Perovskite Solar Cells for Enhanced Efficiency and Stability. Nanomaterials 2025, 15, 483. https://doi.org/10.3390/nano15070483

Sun F, Hou T, Xie K, Zhu X, Yang D, Liu X. Advancements and Strategies in CsPbI2Br Perovskite Solar Cells for Enhanced Efficiency and Stability. Nanomaterials. 2025; 15(7):483. https://doi.org/10.3390/nano15070483

Chicago/Turabian StyleSun, Fanbei, Tingting Hou, Kexuan Xie, Xinghua Zhu, Dingyu Yang, and Xin Liu. 2025. "Advancements and Strategies in CsPbI2Br Perovskite Solar Cells for Enhanced Efficiency and Stability" Nanomaterials 15, no. 7: 483. https://doi.org/10.3390/nano15070483

APA StyleSun, F., Hou, T., Xie, K., Zhu, X., Yang, D., & Liu, X. (2025). Advancements and Strategies in CsPbI2Br Perovskite Solar Cells for Enhanced Efficiency and Stability. Nanomaterials, 15(7), 483. https://doi.org/10.3390/nano15070483