Ceramic Nanocomposites from Tailor-Made Preceramic Polymers

Abstract

:1. Introduction

2. Preceramic Polymers

2.1. Silicon-Containing Preceramic Polymers

2.2. Single-Source Precursors Based on Metallopolymers

3. Polymer-to-Ceramic Transformation

3.1. Cross-Linking

3.2. Ceramization

4. Ceramic Nanocomposites with Tailor-Made Phase Compositions and (Micro)Structures

4.1. Tailor-Made Compositions from Single-Source Precursors

4.2. Hard-Template-Assisted Techniques towards Ordered (Micro)structures

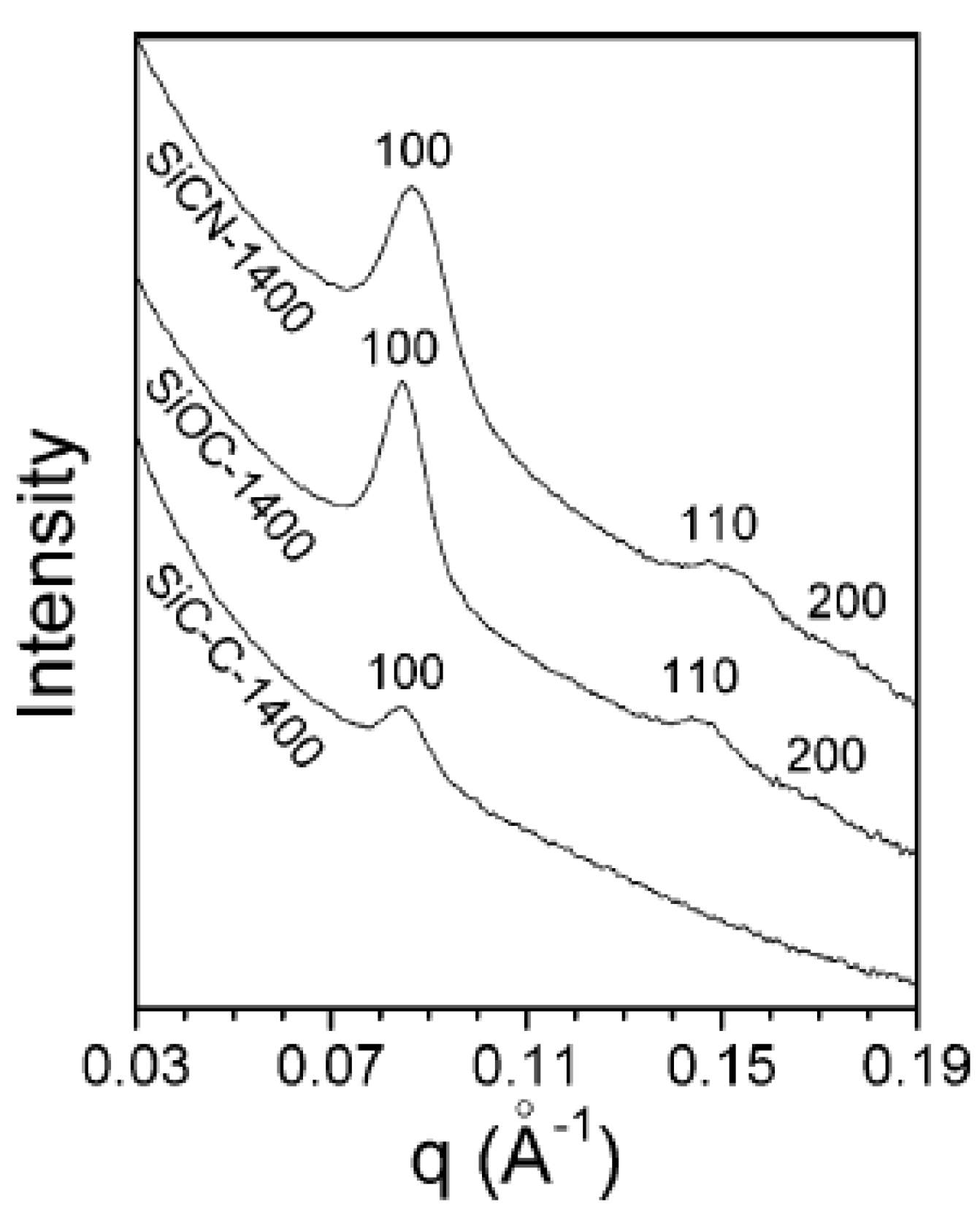

4.3. Self-Assembly Strategies Based on Preceramic Block Copolymers and Particles

5. Properties of Ceramic Nanocomposites

5.1. Structural Properties

5.1.1. High-Temperature Stability towards Crystallization and Decomposition

5.1.2. High Temperature Oxidation and Corrosion Behavior

5.1.3. High Temperature Creep Behavior

5.2. Functional Properties

5.2.1. Electrical Properties

5.2.2. Magnetic Properties

| Ceramic material | Si-containing precursor | Fe-containing precursor | Pyrolysis conditions | Fe-containing crystalline phase(s) | References |

|---|---|---|---|---|---|

| Si–Fe–C–(O) | Polycarbosilane | Fe(NO3)3 | 1000–1200 °C (Ar) | Fe3Si | [358] |

| Fe(acac)3 | 1300 °C (Ar) | Fe5Si3 (major), Fe3Si, FeC | [359] | ||

| Fe(CO)5 | 1000 °C (N2) | Fe | [360] | ||

| Si–Fe–C–N–(O) | Polysilazane | Fe3O4 | 1000 °C (N2) | Fe (major), Fe2SiO4 | [361] |

| FeCl3/THF | 1000 °C (N2) | Fe3Si | [362] | ||

| Fe(CO)5 | 1100 °C (Ar) | Fe3Si | [215] | ||

| Ferrocene | 1200 °C (Ar) | Fe3C | [363] | ||

| Fe (powder) | 1100 °C (Ar) | Fe3Si | [216] | ||

| Si–Fe–O–C | Polysiloxane | FeCl2 | 1250 °C (N2) | Fe3Si | [364] |

| 1250–1300 °C (Ar) | Fe3Si, Fe5Si3 | ||||

| Fe(acac)3 | 1100 °C (Ar) | Fe3Si | [219,221] |

5.2.3. Mechanical Properties

5.3. Applications of Ceramic Nanocomposites

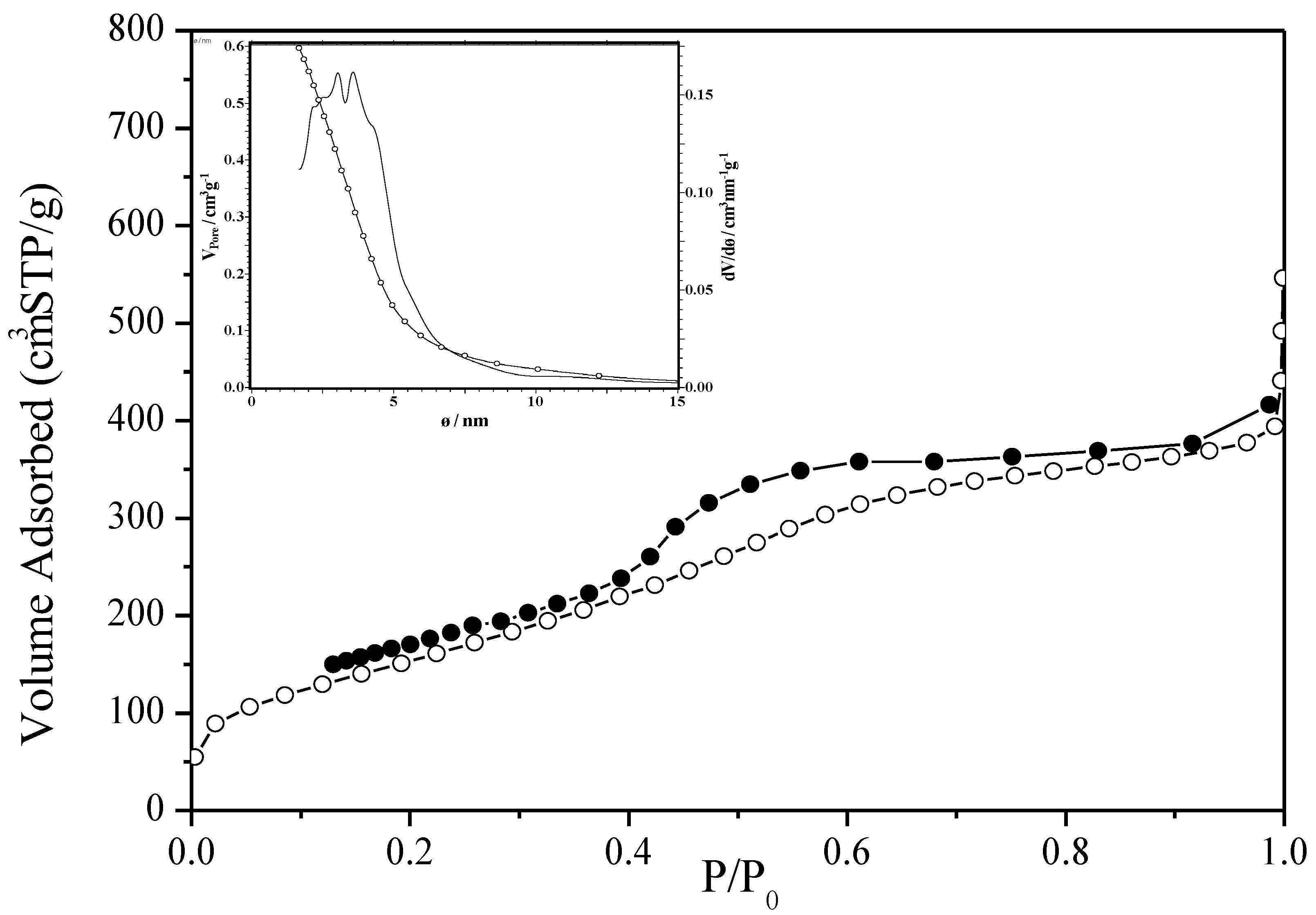

5.3.1. Ceramic Membranes

5.3.2. Porous Materials for Hydrogen Generation and Storage

5.3.3. Heterogeneous Catalysis

5.3.4 Anode Materials for Secondary Li Ion Batteries

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Matic, P. Overview of Multifunctional Materials. In Proceedings of the SPIE 5053, Smart Structures and Materials 2003: Active Materials: Behavior and Mechanics, San Diego, CA, USA, 2 March 2003.

- Momoda, L.A. The future of engineering materials: Multifunction for performance-tailored structures. Bridge. 2004, 34, 18–21. [Google Scholar]

- Christodoulou, L.; Venables, J. Multifunctional material systems: The first generation. JOM 2003, 55, 39–45. [Google Scholar] [CrossRef]

- Mera, G.; Ionescu, E. Silicon-Containing Preceramic Polymers. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar]

- Ionescu, E.; Riedel, R. Polymer Processing of Ceramics. In Ceramics and Composites Processing Methods; Bansal, N., Boccaccini, A., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 235–270. [Google Scholar]

- Riedel, R.; Mera, G.; Hauser, R.; Klonczynski, A. Silicon-based polymer-derived ceramics: Synthesis properties and applications—A review. J. Ceram. Soc. Jpn. 2006, 114, 425–444. [Google Scholar] [CrossRef]

- Mera, G.; Riedel, R. Organosilicon-Based Polymers as Precursors for Ceramics. In Polymer Derived Ceramics: From Nanostructure to Applications; Colombo, P., Riedel, R., Soraru, G.D., Kleebe, H.-J., Eds.; DEStech Publications Inc.: Lancaster, PA, USA, 2010; pp. 51–89. [Google Scholar]

- Ionescu, E.; Kleebe, H.-J.; Riedel, R. Silicon-containing polymer-derived ceramic nanocomposites (PDC-NCs): Preparative approaches and properties. Chem. Soc. Rev. 2012, 41, 5032–5052. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, E.; Gervais, C.; Babonneau, F. Polymer-to-Ceramic Transformation. In Polymer Derived Ceramics: From Nanostructure to Applications; Colombo, P., Riedel, R., Soraru, G.D., Kleebe, H.-J., Eds.; DEStech Publications Inc.: Lancaster, PA, USA, 2010; pp. 108–127. [Google Scholar]

- Miller, R.D.; Michl, J. Polysilane high polymers. Chem. Rev. 1989, 89, 1359–1410. [Google Scholar] [CrossRef]

- West, R. The polysilane high polymers. J. Organomet. Chem. 1986, 300, 327–346. [Google Scholar] [CrossRef]

- West, R.; Maxka, J.; Sinclair, R.; Cotts, P. Polysilane high polymers. Abstr. Pap. Am. Chem. S 1987, 193, 11–Inor. [Google Scholar]

- West, R.; Maxka, J. Polysilane high polymers—An overview. ACS Symp. Ser. 1988, 360, 6–20. [Google Scholar]

- Wynne, K.J. An introduction to inorganic and organometallic polymers. ACS Symp. Ser. 1988, 360, 1–4. [Google Scholar]

- Kipping, F.S.; Sands, J.E. XCIII.—Organic derivatives of silicon. Part XXV. Saturated and unsaturated silicohydrocarbons, Si4Ph8. J. Chem. Soc. Trans. 1921, 119, 830–847. [Google Scholar] [CrossRef]

- Kipping, F.S. CCCVIII.—Organic derivatives of silicon. Part XXX. Complex silicohydrocarbons [SiPh2]n. J. Chem. Soc. Trans. 1924, 125, 2291–2297. [Google Scholar] [CrossRef]

- Wesson, J.P.; Williams, T.C. Organosilane polymers: I. Poly(dimethylsilylene). J. Polym. Sci. Polym. Chem. Ed. 1979, 17, 2833–2843. [Google Scholar] [CrossRef]

- West, R.; David, L.D.; Djurovich, P.I.; Stearley, K.L.; Srinivasan, K.S.V.; Yu, H. Phenylmethylpolysilanes: Formable silane copolymers with potential semiconducting properties. J. Am. Chem. Soc. 1981, 103, 7352–7354. [Google Scholar] [CrossRef]

- Trujillo, R.E. Preparation of long-chain poly(methylphenylsilane). J. Organomet. Chem. 1980, 198, C27–C28. [Google Scholar] [CrossRef]

- Kawabe, T.; Naito, M.; Fujiki, M. Multiblock polysilane copolymers: One-pot wurtz synthesis, fluoride anion-induced block-selective scission experiments, and spectroscopic characterization. Macromolecules 2008, 41, 1952–1960. [Google Scholar] [CrossRef]

- Jones, R.G.; Holder, S.J. High-yield controlled syntheses of polysilanes by the Wurtz-type reductive coupling reaction. Polym. Int. 2006, 55, 711–718. [Google Scholar] [CrossRef]

- Herzog, U.; West, R. Heterosubstituted polysilanes. Macromolecules 1999, 32, 2210–2214. [Google Scholar] [CrossRef]

- Lacave-Goffin, B.; Hevesi, L.; Devaux, J. Graphite? Potassium, a new reagent for the synthesis of polysilanes. J. Chem. Soc. Chem. Commun. 1995, 769–770. [Google Scholar] [CrossRef]

- Jones, R.G.; Benfield, R.E.; Evans, P.J.; Swain, A.C. Poly(methylphenylsilane) with an enhanced isotactic content prepared using the graphite intercalation compound, C8K. J. Chem. Soc. Chem. Commun. 1995, 1465–1466. [Google Scholar] [CrossRef]

- Chang, L.S.; Corey, J.Y. Dehydrogenative coupling of diarylsilanes. Organometallics 1989, 8, 1885–1893. [Google Scholar] [CrossRef]

- Woo, H.G.; Walzer, J.F.; Tilley, T.D. .sigma.-Bond metathesis mechanism for dehydropolymerization of silanes to polysilanes by d0 metal-catalysts. J. Am. Chem. Soc. 1992, 114, 7047–7055. [Google Scholar] [CrossRef]

- Sakamoto, K.; Obata, K.; Hirata, H.; Nakajima, M.; Sakurai, H. Novel anionic-polymerization of masked disilenes to polysilylene high polymers and block copolymers. J. Am. Chem. Soc. 1989, 111, 7641–7643. [Google Scholar] [CrossRef]

- Cypryk, M.; Gupta, Y.; Matyjaszewski, K. Anionic ring-opening polymerization of 1,2,3,4-tetramethyl-1,2,3,4-tetraphenylcyclotetrasilane. J. Am. Chem. Soc. 1991, 113, 1046–1047. [Google Scholar] [CrossRef]

- Kashimura, S.; Tane, Y.; Ishifune, M.; Murai, Y.; Hashimoto, S.; Nakai, T.; Hirose, R.; Murase, H. Practical method for the synthesis of polysilanes using Mg and Lewis acid system. Tetrahedron Lett. 2008, 49, 269–271. [Google Scholar] [CrossRef]

- Yajima, S.; Hayashi, J. Continuous silicon carbide fiber of high tensile strength. Chem. Lett. 1975, 4, 931–934. [Google Scholar] [CrossRef]

- Shiina, K.; Kumada, M. Thermal rearrangement of hexamethyldisilane to trimethyl(dimethylsilylmethyl)-silane. J. Org. Chem. 1958, 23, 139. [Google Scholar] [CrossRef]

- Whitmarsh, C.K.; Interrante, L.V. Synthesis and structure of a highly branched polycarbosilane derived from (chloromethyl)trichlorosilane. Organometallics 1991, 10, 1336–1344. [Google Scholar] [CrossRef]

- Smith, J.; Troy, L. Process for the Production of Silicon Carbide by the Pyrolysis of a Polycarbosilane Polymer. US Patent US4631179 A, 23 December 1986. [Google Scholar]

- Wu, H.J.; Interrante, L.V. Preparation of poly(dichlorosilaethylene) and poly(silaethylene) via ring-opening polymerization. Macromolecules 1992, 25, 1840–1841. [Google Scholar] [CrossRef]

- Nate, K.; Inoue, T.; Sugiyama, H.; Ishikawa, M. Organosilicon deep UV positive resist consisting of poly(P-disilanylenephenylene). J. Appl. Polym. Sci. 1987, 34, 2445–2455. [Google Scholar] [CrossRef]

- Iwahara, T.; Hayase, S.; West, R. Synthesis and properties of ethynylene disilanylene copolymers. Macromolecules 1990, 23, 1298–1301. [Google Scholar] [CrossRef]

- Corriu, R.J.P.; Guerin, C.; Henner, B.; Kuhlmann, T.; Jean, A.; Garnier, F.; Yassar, A. Organosilicon polymers—Synthesis of poly[(silanylene)diethynylene]s with conducting properties. Chem. Mater. 1990, 2, 351–352. [Google Scholar] [CrossRef]

- Ohshita, J.; Kanaya, D.; Ishikawa, M.; Yamanaka, T. Polymeric organo-silicon systems 6: Synthesis and properties of trans-poly[(disilanylene)ethenylene]. J. Organomet. Chem. 1989, 369, C18–C20. [Google Scholar] [CrossRef]

- Ohshita, J.; Kunai, A. Polymers with alternating organosilicon and Pi-conjugated units. Acta Polym. 1998, 49, 379–403. [Google Scholar] [CrossRef]

- Bacque, E.; Pillot, J.P.; Birot, M.; Dunogues, J.; Bourgeois, G. New model polycarbosilanes 3: Synthesis and characterization of functional linear carbosilanes. J. Organomet. Chem. 1988, 346, 147–160. [Google Scholar] [CrossRef]

- Kim, Y.H.; Gal, Y.S.; Kim, U.Y.; Choi, S.K. Cyclo-polymerization of dipropargylsilanes by transition-metal catalysts. Macromolecules 1988, 21, 1991–1995. [Google Scholar] [CrossRef]

- Shinar, J.; Ijadimaghsoodi, S.; Ni, Q.X.; Pang, Y.; Barton, T.J. Synthesis and study of a polysilole. Synth. Met. 1989, 28, C593–C598. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhou, Q.S.; Weber, W.P.; Horvath, R.F.; Chan, T.H.; Manuel, G. Anionic Ring-opening polymerization of sila-silacyclopent-3-enes and germacyclopent-3-enes. Macromolecules 1988, 21, 1563–1566. [Google Scholar] [CrossRef]

- Park, Y.T.; Zhou, Q.S.; Weber, W.P. Anionic ring-opening polymerization of 3,4-benzo-1,1-dimethyl-1-silacyclopentene—properties of poly(3,4-benzo-1,1-dimethyl-1-silapentene). Polym. Bull. 1989, 22, 349–353. [Google Scholar] [CrossRef]

- Park, Y.T.; Manuel, G.; Weber, W.P. Anionic ring-opening polymerization of 1,1,3-trimethyl-1-silacyclopent-3-ene—effect of temperature on poly(1,1,3-trimethyl-1-sila-cis-pent-3-ene) microstructure. Macromolecules 1990, 23, 1911–1915. [Google Scholar] [CrossRef]

- Zhou, S.Q.; Weber, W.P. Anionic-polymerization of 1-methyl-1-silacyclopent-3-ene—Characterization of poly(1-methyl-1-sila-cis-pent-3-ene) by H-1, C-13, and Si-29 NMR-spectroscopy and mechanism of polymerization. Macromolecules 1990, 23, 1915–1917. [Google Scholar] [CrossRef]

- Seyferth, D. Polycarbosilanes—An overview. ACS Symp. Ser. 1988, 360, 21–42. [Google Scholar]

- Mera, G. Contributions to The Synthesis of Silicon-Rich Oligocarbosilanes and Their Use as Precursors for Electrically Conductive Films. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2005. [Google Scholar]

- Jones, R.G.; Ando, W.; Chojnowski, J. Silicon-Containing Polymers: The Science and Technology of Their Synthesis and Applications; Kluwer: Dordrecht, The Netherland; Boston, MA, USA; London, UK, 2000. [Google Scholar]

- Babonneau, F.; Thorne, K.; Mackenzie, J.D. Dimethyldiethoxysilane/tetraethoxysilane copolymers: Precursors for the silicon-carbon-oxygen system. Chem. Mater. 1989, 1, 554–558. [Google Scholar] [CrossRef]

- Soraru, G.D. Silicon oxycarbide glasses from gels. J. Sol–Gel Sci. Technol. 1994, 2, 843–848. [Google Scholar] [CrossRef]

- Soraru, G.D.; D’Andrea, G.; Campostrini, R.; Babonneau, F.; Mariotto, G. Structural characterization and high-temperature behavior of silicon oxycarbide glasses prepared from sol–gel precursors containing Si–H bonds. J. Am. Ceram. Soc. 1995, 78, 379–387. [Google Scholar] [CrossRef]

- Dire, S.; Ceccato, R.; Babonneau, F. Structural and microstructural evolution during pyrolysis of hybrid polydimethylsiloxane-titania nanocomposites. J. Sol–Gel Sci. Technol. 2005, 34, 53–62. [Google Scholar] [CrossRef]

- Dire, S.; Campostrini, R.; Ceccato, R. Pyrolysis chemistry of sol–gel-derived poly(dimethylsiloxane)-zirconia nanocomposites. Influence of zirconium on polymer-to-ceramic conversion. Chem. Mater. 1998, 10, 268–278. [Google Scholar] [CrossRef]

- Alonso, B.; Sanchez, C. Structural investigation of polydimethylsiloxane-vanadate hybrid materials. J. Mater. Chem. 2000, 10, 377–386. [Google Scholar] [CrossRef]

- Huang, H.H.; Orler, B.; Wilkes, G.L. Structure property behavior of new hybrid materials incorporating oligomeric species into sol–gel glasses 3: Effect of acid content, tetraethoxysilane content, and molecular-weight of poly(dimethylsiloxane). Macromolecules 1987, 20, 1322–1330. [Google Scholar] [CrossRef]

- Dire, S.; Babonneau, F.; Sanchez, C.; Livage, J. Sol–gel synthesis of siloxane oxide hybrid coatings [Si(CH3)2O·Mox–M = Si, Ti, Zr, Al] with luminescent properties. J. Mater. Chem. 1992, 2, 239–244. [Google Scholar] [CrossRef]

- Yamada, N.; Yoshinaga, I.; Katayama, S. Synthesis and dynamic mechanical behaviour of inorganic-organic hybrids containing various inorganic components. J. Mater. Chem. 1997, 7, 1491–1495. [Google Scholar] [CrossRef]

- Fukushima, M.; Yasuda, E.; Nakamura, Y.; Tanabe, Y. Pyrolysis behavior of organic-inorganic hybrids with Si–O–Nb/Si–O–Ta oxygen bridged heterometallic bonds. J. Ceram. Soc. Jpn. 2003, 111, 857–859. [Google Scholar] [CrossRef]

- Saha, A.; Shah, S.R.; Raj, R. Amorphous silicon carbonitride fibers drawn from alkoxide modified Ceraset (TM). J. Am. Ceram. Soc. 2003, 86, 1443–1445. [Google Scholar] [CrossRef]

- Saha, A.; Shah, S.R.; Raj, R. Oxidation behavior of SiCN-ZrO2 fiber prepared from alkoxide-modified silazane. J. Am. Ceram. Soc. 2004, 87, 1556–1558. [Google Scholar] [CrossRef]

- Fukushima, M.; Yasuda, E.; Nakamura, Y.; Shimizu, M.; Teranishi, Y.; Manocha, L.M.; Tanabe, Y. Oxidation behavior of Si–Nb–C–O ceramics prepared by the pyrolysis of methyltriethoxysilane based organic-inorganic hybrid gel. J. Sol–Gel Sci. Technol. 2005, 34, 15–21. [Google Scholar] [CrossRef]

- Kroke, E.; Li, Y.L.; Konetschny, C.; Lecomte, E.; Fasel, C.; Riedel, R. Silazane derived ceramics and related materials. Mater. Sci. Eng. R 2000, 26, 97–199. [Google Scholar] [CrossRef]

- Narsavage, D.M.; Interrante, L.V.; Marchetti, P.S.; Maciel, G.E. Condensation polymerization of tetrakis(ethylamino)silane and its thermal-decomposition to Si3N4/SiC ceramics. Chem. Mater. 1991, 3, 721–730. [Google Scholar] [CrossRef]

- Schutzenberger, H.; Colson, C.R. Silicon. Rendus Hebd. Seances Acad. Sci. 1885, 92, 1508–1511. [Google Scholar]

- Glemser, O.; Naumann, P. Uber den thermischen abbau von siliciumdiimid Si(NH)2. Z. Anorg. Allg. Chem. 1959, 298, 134–141. [Google Scholar] [CrossRef]

- Seyferth, D.; Wiseman, G.H.; Prudhomme, C. A liquid silazane precursor to silicon-nitride. J. Am. Ceram. Soc. 1983, 66, C13–C14. [Google Scholar] [CrossRef]

- Arai, M.; Sakurada, S.; Isoda, T.; Tomizawa, H. Preceramic polysilazane to silicon-nitride. Abstr. Pap. Am. Chem. S 1987, 193, 41–Inor. [Google Scholar]

- Blanchard, C.R.; Schwab, S.T. X-ray-diffraction analysis of the pyrolytic conversion of perhydropolysilazane into silicon-nitride. J. Am. Ceram. Soc. 1994, 77, 1729–1739. [Google Scholar] [CrossRef]

- Seyferth, D.; Wiseman, G.H. High-yield synthesis of Si3N4/SiC ceramic materials by pyrolysis of a novel polyorganosilazane. J. Am. Ceram. Soc. 1984, 67, C132–C133. [Google Scholar]

- Iwamoto, Y.; Kikuta, K.; Hirano, S. Crystallization and microstructure development of Si2N4-Ti(C,N)-Y2O3 ceramics derived from chemically modified perhydropolysilazane. J. Ceram. Soc. Jpn. 2000, 108, 1072–1078. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Kikuta, K.; Hirano, S. Synthesis of poly-titanosilazanes and conversion into Si3N4–TiN ceramics. J. Ceram. Soc. Jpn. 2000, 108, 350–356. [Google Scholar] [CrossRef]

- Papendorf, B.; Nonnenmacher, K.; Ionescu, E.; Kleebe, H.-J.; Riedel, R. Strong influence of polymer architecture on the microstructural evolution of hafnium-alkoxide-modified silazanes upon ceramization. Small 2011, 7, 970–978. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, E.; Papendorf, B.; Kleebe, H.-J.; Breitzke, H.; Nonnenmacher, K.; Buntkowsky, G.; Riedel, R. Phase separation of a hafnium alkoxide-modified polysilazane upon polymer-to-ceramic transformation—A case study. J. Eur. Ceram. Soc. 2012, 32, 1873–1881. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Kikuta, K.; Hirano, S. Si3N4-TiN-Y2O3 ceramics derived from chemically modified perhydropolysilazane. J. Mater. Res. 1999, 14, 4294–4301. [Google Scholar] [CrossRef]

- Bechelany, M.C.; Proust, V.; Gervais, C.; Ghisleni, R.; Bernard, S.; Miele, P. In situ controlled growth of titanium nitride in amorphous silicon nitride: A general route toward bulk nitride nanocomposites with very high hardness. Adv. Mater. 2014, 26, 6548–6553. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Luan, X.; Riedel, R.; Ionescu, E. Preparation and hydrothermal corrosion behavior of Cf/SiCN and Cf/SiHfBCN ceramic matrix composites. J. Eur. Ceram. Soc. 2015, in press. [Google Scholar]

- Yuan, J.; Hapis, S.; Breitzke, H.; Xu, Y.P.; Fasel, C.; Kleebe, H.J.; Buntkowsky, G.; Riedel, R.; Ionescu, E. Single-source-precursor synthesis of hafnium-containing ultrahigh-temperature ceramic nanocomposites (UHTC-NCs). Inorg. Chem. 2014, 53, 10443–10455. [Google Scholar] [CrossRef] [PubMed]

- Mera, G.; Riedel, R.; Poli, F.; Muller, K. Carbon-rich SiCN ceramics derived from phenyl-containing poly(silylcarbodiimides). J. Eur. Ceram. Soc. 2009, 29, 2873–2883. [Google Scholar] [CrossRef]

- Ebsworth, E.A.; Mays, M.J. Zur Reaktion zwischen halogensilanen und silbercyanamid. Angew. Chem. Int. Ed. 1962, 74. [Google Scholar] [CrossRef]

- Ebsworth, E.A.; Mays, M.J. Preparation and properties of disilylcyanamide. J. Chem. Soc. 1961, 4879–4882. [Google Scholar] [CrossRef]

- Pump, J.; Wannagat, U. Bis-(trimethylsilyl)-carbodiimid. Angew. Chem. Int. Ed. 1962, 74, 117. [Google Scholar] [CrossRef]

- Birkofer, L.; Ritter, A.; Richter, P. Uber siliciumorganische verbindungen 13: N,N'-bis-trimethylsilyl-carbodiimid. Tetrahedron Lett. 1962, 195–198. (In German) [Google Scholar]

- Klebe, J.F.; Murray, J.G. Organosiliconcarbodiimide Polymers and Process for Their Preparation. US Patent 3,352,799, 14 November 1967. [Google Scholar]

- Razuvaev, G.A.; Gordetsov, A.S.; Kozina, A.P.; Brevnova, T.N.; Semenov, V.V.; Skobeleva, S.E.; Boxer, N.A.; Dergunov, Y.I. Synthesis of monomeric and oligomeric carbodiimides with polysilane and siloxane fragments. J. Organomet. Chem. 1987, 327, 303–309. [Google Scholar] [CrossRef]

- Gorbatenko, V.I.; Gertsyuk, M.N.; Samarai, L.I. Synthesis of 2,4-bis(trimethylsilyloxy)-6-chloro-1,3,5-triazine. Zh. Org. Khim. 1977, 13, 899. [Google Scholar]

- Riedel, R.; Kroke, E.; Greiner, A.; Gabriel, A.O.; Ruwisch, L.; Nicolich, J.; Kroll, P. Inorganic solid-state chemistry with main group element carbodiimides. Chem. Mater. 1998, 10, 2964–2979. [Google Scholar] [CrossRef]

- Morcos, R.M.; Mera, G.; Navrotsky, A.; Varga, T.; Riedel, R.; Poli, F.; Muller, K. Enthalpy of formation of carbon-rich polymer-derived amorphous SiCN ceramics. J. Am. Ceram. Soc. 2008, 91, 3349–3354. [Google Scholar] [CrossRef]

- Mera, G.; Tamayo, A.; Nguyen, H.; Sen, S.; Riedel, R. Nanodomain structure of carbon-rich silicon carbonitride polymer-derived ceramics. J. Am. Ceram. Soc. 2010, 93, 1169–1175. [Google Scholar] [CrossRef]

- Widgeon, S.; Mera, G.; Gao, Y.; Stoyanov, E.; Sen, S.; Navrotsky, A.; Riedel, R. Nanostructure and energetics of carbon-rich SiCN ceramics derived from polysilylcarbodiimides: Role of the nanodomain interfaces. Chem. Mater. 2012, 24, 1181–1191. [Google Scholar] [CrossRef]

- Prasad, R.M.; Mera, G.; Morita, K.; Muller, M.; Kleebe, H.J.; Gurlo, A.; Fasel, C.; Riedel, R. Thermal decomposition of carbon-rich polymer-derived silicon carbonitrides leading to ceramics with high specific surface area and tunable micro- and mesoporosity. J. Eur. Ceram. Soc. 2012, 32, 477–484. [Google Scholar] [CrossRef]

- Graczyk-Zajac, M.; Mera, G.; Kaspar, J.; Riedel, R. Electrochemical studies of carbon-rich polymer-derived SiCN ceramics as anode materials for lithium-ion batteries. J. Eur. Ceram. Soc. 2010, 30, 3235–3243. [Google Scholar] [CrossRef]

- Pump, J.; Rochow, E.G. Silycarbodiimide 4: Sila-polycarbodiimide. Z. Anorg. Allg. Chem. 1964, 330, 101–106. [Google Scholar] [CrossRef]

- Gabriel, A.O.; Riedel, R.; Storck, S.; Maier, W.F. Synthesis and thermally induced ceramization of a non-oxidic poly(methylsilsesquicarbodiimide) gel. Appl. Organomet. Chem. 1997, 11, 833–841. [Google Scholar] [CrossRef]

- Kim, D.S.; Kroke, E.; Riedel, R.; Gabriel, A.O.; Shim, S.C. An anhydrous sol–gel system derived from methyldichlorosilane. Appl. Organomet. Chem. 1999, 13, 495–499. [Google Scholar] [CrossRef]

- Nahar-Borchart, S.; Kroke, E.; Riedel, R.; Boury, B.; Corriu, R.J.P. Synthesis and characterization of alkylene-bridged silsesquicarbodiimide hybrid xerogels. J. Organomet. Chem. 2003, 686, 127–133. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Volger, W.; Kroke, E.; Riedel, R.; Saitou, T.; Matsunaga, K. Crystallization behavior of amorphous silicon carbonitride ceramics derived from organometallic precursors. J. Am. Ceram. Soc. 2001, 84, 2170–2178. [Google Scholar] [CrossRef]

- Kienzle, A.; Bill, J.; Aldinger, F.; Riedel, R. Nanosized Si–C–N-power by pyrolysis of highly crosslinked silylcarbodiimide. Nanostruct. Mater. 1995, 6, 349–352. [Google Scholar] [CrossRef]

- Riedel, R.; Greiner, A.; Miehe, G.; Dressier, W.; Fuess, H.; Bill, J.; Aldinger, F. The first crystalline solids in the ternary Si–C–N system. Angew. Chem. Int. Ed. Engl. 1997, 36, 603–606. [Google Scholar] [CrossRef]

- Dressler, W.; Riedel, R. Progress in silicon-based non-oxide structural ceramics. Int. J. Refract. Met. H 1997, 15, 13–47. [Google Scholar] [CrossRef]

- Schadler, H.D.; Jager, L.; Senf, I. Pseudoelement compounds 5: Pseudochalcogens—An attempt of an empirical and theoretical characterization. Z. Anorg. Allg. Chem. 1993, 619, 1115–1120. [Google Scholar] [CrossRef]

- Abd-El-Aziz, A.S.; Manners, I. Frontiers in Transition Metal-Containing Polymers; Wiley-Interscience: Hoboken, NJ, USA, 1997. [Google Scholar]

- Wöhrle, D.; Pomogailo, A.D. Metal Complexes and Metals in Macromolecules: Synthesis, Structure and Properties; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Carraher, C.E.; Abd-El-Aziz, A.S.; Pittman, C.; Sheats, J.; Zeldin, M. A Half Century of Metal and Metalloid Containing Polymers; Wiley: New York, NY, USA, 2003. [Google Scholar]

- Manners, I. Synthetic Metal-Containing Polymers; VCH: Weinheim, Germany, 2004. [Google Scholar]

- Whittell, G.R.; Manners, I. Metallopolymers: New multifunctional materials. Adv. Mater. 2007, 19, 3439–3468. [Google Scholar] [CrossRef]

- Whittell, G.R.; Hager, M.D.; Schubert, U.S.; Manners, I. Functional soft materials from metallopolymers and metallosupramolecular polymers. Nat. Mater. 2011, 10, 176–188. [Google Scholar] [CrossRef] [PubMed]

- Gallei, M. The renaissance of side-chain ferrocene-containing polymers: Scope and limitations of vinylferrocene and ferrocenyl methacrylates. Macromol. Chem. Phys. 2014, 215, 699–704. [Google Scholar] [CrossRef]

- Cai, T.; Qiu, W.F.; Liu, D.; Han, W.J.; Ye, L.; Zhao, A.J.; Zhao, T. Synthesis of soluble poly-yne polymers containing zirconium and silicon and corresponding conversion to nanosized ZrC/SiC composite ceramics. Dalton Trans. 2013, 42, 4285–4290. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.Y.; Qiu, W.F.; Li, H.; Zhao, T.; Wei, X.Y. New route to synthesize preceramic polymers for zirconium carbide. Chin. Chem. Lett. 2012, 23, 1075–1078. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, W.; Zhang, J. Pyrolysis synthesis and microstructure of zirconium carbide from new preceramic polymers. Certif. Int. 2014, 40, 5967–5972. [Google Scholar] [CrossRef]

- Wang, H.; Gao, B.; Chen, X.; Wang, J.; Chen, S.; Gou, Y. Synthesis and pyrolysis of a novel preceramic polymer PZMS from PMS to fabricate high-temperature-resistant ZrC/SiC ceramic composite. Appl. Organomet. Chem. 2013, 27, 166–173. [Google Scholar] [CrossRef]

- Demars, T.; Boltoeva, M.; Vigier, N.; Maynadié, J.; Ravaux, J.; Genre, C.; Meyer, D. From coordination polymers to doped rare-earth oxides. Eur. J. Inorg. Chem. 2012, 2012, 3875–3884. [Google Scholar] [CrossRef]

- Abd-El-Aziz, A.S.; Agatemor, C.; Etkin, N. Sandwich complex-containing macromolecules: Property tunability through versatile synthesis. Macromol. Rapid Commun. 2014, 35, 513–559. [Google Scholar] [CrossRef] [PubMed]

- Clendenning, S.B.; Han, S.; Coombs, N.; Paquet, C.; Rayat, M.S.; Grozea, D.; Brodersen, P.M.; Sodhi, R.N.S.; Yip, C.M.; Lu, Z.-H.; et al. Magnetic ceramic films from a metallopolymer resist using reactive ion etching in a secondary magnetic field. Adv. Mater. 2004, 16, 291–296. [Google Scholar] [CrossRef]

- Kulbaba, K.; Manners, I. Polyferrocenylsilanes: Metal-containing polymers for materials science, self-assembly and nanostructure applications. Macromol. Rapid Commun. 2001, 22, 711–724. [Google Scholar] [CrossRef]

- Elbert, J.; Didzoleit, H.; Fasel, C.; Ionescu, E.; Riedel, R.; Stühn, B.; Gallei, M. Surface-initiated anionic polymerization of [1]silaferrocenophanes for the preparation of colloidal preceramic materials. Macromol. Rapid Commun. 2015. [CrossRef]

- Manners, I. Poly(ferrocenylsilanes): Novel organometallic plastics. Chem. Commun. 1999, 857–865. [Google Scholar] [CrossRef]

- MacLachlan, M.J.; Ginzburg, M.; Coombs, N.; Coyle, T.W.; Raju, N.P.; Greedan, J.E.; Ozin, G.A.; Manners, I. Shaped ceramics with tunable magnetic properties from metal-containing polymers. Science 2000, 287, 1460–1463. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, P.; Gomez-Elipe, P.; Manners, I. Organometallic polymers with transition metals in the main chain. Chem. Rev. 1999, 99, 1515–1548. [Google Scholar] [CrossRef]

- Kumar, M.; Metta-Magana, A.J.; Pannell, K.H. Ferrocenylene- and carbosiloxane-bridged bis(sila[1]ferrocenophanes) E[SiMe2-X-SiMeFC](2) {E = (eta(5)-C5H4)Fe(eta(5)-C5H4) or O; X = (CH2)(n) (n = 2, 3, 6); CH=CH; FC = (eta(5)-C5H4)(2)Fe}. Organometallics 2008, 27, 6457–6463. [Google Scholar] [CrossRef]

- Sun, Q.H.; Lam, J.W.Y.; Xu, K.T.; Xu, H.Y.; Cha, J.A.K.; Wong, P.C.L.; Wen, G.H.; Zhang, X.X.; Jing, X.B.; Wang, F.S.; et al. Nanocluster-containing mesoporous magnetoceramics from hyperbranched organometallic polymer precursors. Chem. Mater. 2000, 12, 2617–2624. [Google Scholar] [CrossRef]

- Sun, Q.H.; Xu, K.T.; Peng, H.; Zheng, R.H.; Haussler, M.; Tang, B.Z. Hyperbranched organometallic polymers: Synthesis and properties of poly(ferrocenylenesilyne)s. Macromolecules 2003, 36, 2309–2320. [Google Scholar] [CrossRef]

- Shi, J.B.; Tong, B.; Li, Z.; Shen, J.B.; Zhao, W.; Fu, H.H.; Zhi, J.; Dong, Y.P.; Haussler, M.; Lam, J.W.Y.; et al. Hyperbranched poly(ferrocenylphenylenes): Synthesis, characterization, redox activity, metal complexation, pyrolytic ceramization, and soft ferromagnetism. Macromolecules 2007, 40, 8195–8204. [Google Scholar] [CrossRef]

- Gadt, T.; Ieong, N.S.; Cambridge, G.; Winnik, M.A.; Manners, I. Complex and hierarchical micelle architectures from diblock copolymers using living, crystallization-driven polymerizations. Nat. Mater. 2009, 8, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Kulbaba, K.; Cheng, A.; Bartole, A.; Greenberg, S.; Resendes, R.; Coombs, N.; Safa-Sefat, A.; Greedan, J.E.; Stover, H.D.H.; Ozin, G.A.; et al. Polyferrocenylsilane microspheres: Synthesis, mechanism of formation, size and charge tunability, electrostatic self-assembly, and pyrolysis to spherical magnetic ceramic particles. J. Am. Chem. Soc. 2002, 124, 12522–12534. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.S.; Guerin, G.; Wang, H.; Wang, Y.S.; Manners, I.; Winnik, M.A. Cylindrical block copolymer micelles and co-micelles of controlled length and architecture. Science 2007, 317, 644–647. [Google Scholar] [CrossRef] [PubMed]

- Rider, D.A.; Liu, K.; Eloi, J.-C.; Vanderark, L.; Yang, L.; Wang, J.-Y.; Grozea, D.; Lu, Z.-H.; Russell, T.P.; Manners, I.; et al. Nanostructured magnetic thin films from organometallic block copolymers: pyrolysis of self-assembled polystyrene-block-poly(ferrocenylethylmethylsilane). ACS Nano 2008, 2, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Wurm, F.; Hilf, S.; Frey, H. Electroactive linear-hyperbranched block copolymers based on linear poly(ferrocenylsilane)s and hyperbranched poly(carbosilane)s. Chem. Eur. J. 2009, 15, 9068–9077. [Google Scholar] [CrossRef] [PubMed]

- Thomas, K.R.; Ionescu, A.; Gwyther, J.; Manners, I.; Barnes, C.H.W.; Steiner, U.; Sivaniah, E. Magnetic properties of ceramics from the pyrolysis of metallocene-based polymers doped with palladium. J. Appl. Phys. 2011, 109, 073904:1–073904:8. [Google Scholar] [CrossRef]

- Häußler, M.; Sun, Q.; Xu, K.; Lam, J.W.Y.; Dong, H.; Tang, B.Z. Hyperbranched poly(ferrocenylene)s containing groups 14 and 15 elements: Syntheses, optical and thermal properties, and pyrolytic transformations into nanostructured magnetoceramics. J. Inorg. Organomet. Polym. Mater. 2005, 15, 67–81. [Google Scholar] [CrossRef]

- Scheid, D.; Cherkashinin, G.; Ionescu, E.; Gallei, M. Single-source magnetic nanorattles by using convenient emulsion polymerization protocols. Langmuir 2014, 30, 1204–1209. [Google Scholar] [CrossRef] [PubMed]

- Scheid, D.; Lederle, C.; Vowinkel, S.; Schäfer, C.G.; Stühn, B.; Gallei, M. Redox- and mechano-chromic response of metallopolymer-based elastomeric colloidal crystal films. J. Mater. Chem. C 2014, 2, 2583–2590. [Google Scholar] [CrossRef]

- Hardy, C.G.; Ren, L.; Ma, S.; Tang, C. Self-assembly of well-defined ferrocene triblock copolymers and their template synthesis of ordered iron oxide nanoparticles. Chem. Commun. 2013, 49, 4373–4375. [Google Scholar] [CrossRef]

- Morsbach, J.; Natalello, A.; Elbert, J.; Winzen, S.; Kroeger, A.; Frey, H.; Gallei, M. Redox-responsive block copolymers: Poly(vinylferrocene)-b-poly(lactide) diblock and miktoarm star polymers and their behavior in solution. Organometallics 2013, 32, 6033–6039. [Google Scholar] [CrossRef]

- Mazurowski, M.; Gallei, M.; Li, J.; Didzoleit, H.; Stühn, B.; Rehahn, M. Redox-responsive polymer brushes grafted from polystyrene nanoparticles by means of surface initiated atom transfer radical polymerization. Macromolecules 2012, 45, 8970–8981. [Google Scholar] [CrossRef]

- Yu, Z.J.; Yang, L.; Min, H.; Zhang, P.; Zhou, C.; Riedel, R. Single-source-precursor synthesis of high temperature stable SiC/C/Fe nanocomposites from a processable hyperbranched polyferrocenylcarbosilane with high ceramic yield. J. Mater. Chem. C 2014, 2, 1057–1067. [Google Scholar] [CrossRef]

- Kenaree, A.R.; Berven, B.M.; Ragogna, P.J.; Gilroy, J.B. Highly-metallized phosphonium polyelectrolytes. Chem. Commun. 2014, 50, 10714–10717. [Google Scholar] [CrossRef]

- Puerta, A.R.; Remsen, E.E.; Bradley, M.G.; Sherwood, W.; Sneddon, L.G. Synthesis and ceramic conversion reactions of 9-BBN-modified allylhydridopolycarbosilane: A new single-source precursor to boron-modified silicon carbide. Chem. Mater. 2003, 15, 478–485. [Google Scholar] [CrossRef]

- Donaghy, K.J.; Carroll, P.J.; Sneddon, L.G. Reactions of 1,1'-bis(diphenylphosphino)ferrocene with boranes, thiaboranes, and carboranes. Inorg. Chem. 1997, 36, 547–553. [Google Scholar] [CrossRef]

- Boshra, R.; Venkatasubbaiah, K.; Doshi, A.; Jakle, F. Resolution of planar-chiral ferrocenylborane lewis acids: the impact of steric effects on the stereoselective binding of ephedrine derivatives. Organometallics 2009, 28, 4141–4149. [Google Scholar] [CrossRef]

- Eckensberger, U.D.; Kunz, K.; Bolte, M.; Lerner, H.W.; Wagner, M. Synthesis and structural characterization of the diborylated organometallics 1,3-bis(dibromoboryl)-1',2',3',4',5'-(pentamethyl)ferrocene and 1,3-bis(dibromoboryl)cymantrene. Organometallics 2008, 27, 764–768. [Google Scholar] [CrossRef]

- Bauer, F.; Braunschweig, H.; Schwab, K. 1,1-Diboration of isocyanides with [2]borametalloarenophanes. Organometallics 2010, 29, 934–938. [Google Scholar] [CrossRef]

- Scheibitz, M.; Li, H.Y.; Schnorr, J.; Perucha, A.S.; Bolte, M.; Lerner, H.W.; Jakle, F.; Wagner, M. Ferrocenylhydridoborates: Synthesis, structural characterization, and application to the preparation of ferrocenylborane polymers. J. Am. Chem. Soc. 2009, 131, 16319–16329. [Google Scholar] [CrossRef] [PubMed]

- Parab, K.; Jakle, F. Synthesis, characterization, and anion binding of redox-active triarylborane polymers. Macromolecules 2009, 42, 4002–4007. [Google Scholar] [CrossRef]

- Jakle, F.; Berenbaum, A.; Lough, A.J.; Manners, I. Selective ring-opening reactions of [1]ferrocenophanes with boron halides: A novel route to functionalized ferrocenylboranes and boron-containing oligo- and poly(ferrocene)s. Chem. Eur. J. 2000, 6, 2762–2771. [Google Scholar] [CrossRef] [PubMed]

- Heilmann, J.B.; Scheibitz, M.; Qin, Y.; Sundararaman, A.; Jakle, F.; Kretz, T.; Bolte, M.; Lerner, H.W.; Holthausen, M.C.; Wagner, M. A synthetic route to borylene-bridged poly(ferrocenylene)s. Angew. Chem. Int. Ed. 2006, 45, 920–925. [Google Scholar] [CrossRef]

- Heilmann, J.B.; Qin, Y.; Jakle, F.; Lerner, H.W.; Wagner, M. Boron-bridged poly(ferrocenylene)s as promising materials for nanoscale molecular wires. Inorg. Chim. Acta 2006, 359, 4802–4806. [Google Scholar] [CrossRef]

- Kong, J.; Schmalz, T.; Motz, G.; Muller, A.H.E. Novel hyperbranched ferrocene-containing poly(boro)carbosilanes synthesized via a convenient “A(2) + B-3” approach. Macromolecules 2011, 44, 1280–1291. [Google Scholar] [CrossRef]

- Kamperman, M.; Burns, A.; Weissgraeber, R.; van Vegten, N.; Warren, S.C.; Gruner, S.M.; Baiker, A.; Wiesner, U. Integrating structure control over multiple length scales in porous high temperature ceramics with functional platinum nanoparticles. Nano Lett. 2009, 9, 2756–2762. [Google Scholar] [CrossRef] [PubMed]

- Glatz, G.; Schmalz, T.; Kraus, T.; Haarmann, F.; Motz, G.; Kempe, R. Copper-containing SiCN precursor ceramics (Cu@SiCN) as selective hydrocarbon oxidation catalysts using air as an oxidant. Chem. Eur. J. 2010, 16, 4231–4238. [Google Scholar] [CrossRef] [PubMed]

- Zaheer, M.; Keenan, C.D.; Hermannsdorfer, J.; Roessler, E.; Motz, G.; Senker, J.; Kempe, R. Robust microporous monoliths with integrated catalytically active metal sites investigated by hyperpolarized Xe-129 NMR. Chem. Mater. 2012, 24, 3952–3963. [Google Scholar] [CrossRef]

- Zaheer, M.; Schmalz, T.; Motz, G.; Kempe, R. Polymer derived non-oxide ceramics modified with late transition metals. Chem. Soc. Rev. 2012, 41, 5102–5116. [Google Scholar] [CrossRef] [PubMed]

- Zaheer, M.; Hermannsdorfer, J.; Kretschmer, W.P.; Motz, G.; Kempe, R. Robust heterogeneous nickel catalysts with tailored porosity for the selective hydrogenolysis of aryl ethers. ChemCatChem 2014, 6, 91–95. [Google Scholar] [CrossRef]

- Bazarjani, M.S.; Kleebe, H.J.; Muller, M.M.; Fasel, C.; Baghaie Yazdi, M.; Gurlo, A.; Riedel, R. Nanoporous silicon oxycarbonitride ceramics derived from polysilazanes in situ modified with nickel nanoparticles. Chem. Mater. 2011, 23, 4112–4123. [Google Scholar] [CrossRef]

- Yajima, S.; Hasegawa, Y.; Hayashi, J.; Iimura, M. Synthesis of continuous silicon-carbide fiber with high-tensile strength and high youngs modulus 1: Synthesis of polycarbosilane as precursor. J. Mater. Sci. 1978, 13, 2569–2576. [Google Scholar] [CrossRef]

- Yajima, S.; Hasegawa, Y.; Okamura, K.; Matsuzawa, T. Development of high-tensile strength silicon-carbide fiber using an organosilicon polymer precursor. Nature 1978, 273, 525–527. [Google Scholar] [CrossRef]

- Laine, R.M.; Babonneau, F. Preceramic polymer routes to silicon-carbide. Chem. Mater. 1993, 5, 260–279. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Iimura, M.; Yajima, S. Synthesis of continuous silicon-carbide fiber 2: Conversion of polycarbosilane fiber into silicon-carbide fibers. J. Mater. Sci. 1980, 15, 720–728. [Google Scholar] [CrossRef]

- Ichikawa, H.; Machino, F.; Mitsuno, S.; Ishikawa, T.; Okamura, K.; Hasegawa, Y. Synthesis of continuous silicon-carbide fiber 5: Factors affecting stability of polycarbosilane to oxidation. J. Mater. Sci. 1986, 21, 4352–4358. [Google Scholar] [CrossRef]

- Hasegawa, Y. Synthesis of continuous silicon-carbide fiber 6: Pyrolysis process of cured polycarbosilane fiber and structure of SiC fiber. J. Mater. Sci. 1989, 24, 1177–1190. [Google Scholar] [CrossRef]

- Taki, T.; Maeda, S.; Okamura, K.; Sato, M.; Matsuzawa, T. Oxidation curing mechanism of polycarbosilane fibers by solid-state Si-29 high-resolution NMR. J. Mater. Sci. Lett. 1987, 6, 826–828. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Okamura, K. Synthesis of continuous silicon-carbide fiber 3: Pyrolysis process of polycarbosilane and structure of the products. J. Mater. Sci. 1983, 18, 3633–3648. [Google Scholar] [CrossRef]

- Babonneau, F.; Soraru, G.D.; Mackenzie, J.D. Si-29 Mas-NMR investigation of the conversion process of a polytitanocarbosilane into SiC-TiC ceramics. J. Mater. Sci. 1990, 25, 3664–3670. [Google Scholar] [CrossRef]

- Dunham, M.L.; Bailey, D.L.; Mixer, R.Y. New curing system for silicone rubber. Ind. Eng. Chem. 1957, 49, 1373–1376. [Google Scholar] [CrossRef]

- Valles, E.M.; Macosko, C.W. Properties of networks formed by end linking of poly(dimethylsiloxane). Macromolecules 1979, 12, 673–679. [Google Scholar] [CrossRef]

- Heidingsfeldova, M.; Capka, M. Rhodium complexes as catalysts for hydrosilylation crosslinking of silicone-rubber. J. Appl. Polym. Sci. 1985, 30, 1837–1846. [Google Scholar] [CrossRef]

- Grzelka, A.; Chojnowski, J.; Cypryk, M.; Fortuniak, W.; Hupfield, P.C.; Taylor, R.G. Polysiloxanol condensation and disproportionation in the presence of a superacid. J. Organomet. Chem. 2004, 689, 705–713. [Google Scholar] [CrossRef]

- Scheffler, M.; Bordia, R.; Travitzky, N.; Greil, P. Development of a rapid crosslinking preceramic polymer system. J. Eur. Ceram. Soc. 2005, 25, 175–180. [Google Scholar] [CrossRef]

- Yive, N.S.C.K.; Corriu, R.J.P.; Leclercq, D.; Mutin, P.H.; Vioux, A. Silicon carbonitride from polymeric precursors—Thermal cross-linking and pyrolysis of oligosilazane model compounds. Chem. Mater. 1992, 4, 141–146. [Google Scholar] [CrossRef]

- Lavedrine, A.; Bahloul, D.; Goursat, P.; Choong Kwet Yive, N.; Corriu, R.; Leclerq, D.; Mutin, H.; Vioux, A. Pyrolysis of polyvinylsilazane precursors to silicon carbonitride. J. Eur. Ceram. Soc. 1991, 8, 221–227. [Google Scholar] [CrossRef]

- Martinez-Crespiera, S.; Ionescu, E.; Kleebe, H.J.; Riedel, R. Pressureless synthesis of fully dense and crack-free SiOC bulk ceramics via photo-crosslinking and pyrolysis of a polysiloxane. J. Eur. Ceram. Soc. 2011, 31, 913–919. [Google Scholar] [CrossRef]

- Bill, J.; Aldinger, F. Precursor-derived covalent ceramics. Adv. Mater. 1995, 7, 775–787. [Google Scholar] [CrossRef]

- Greil, P.; Seibold, M. Modeling of dimensional changes during polymer ceramic conversion for bulk component fabrication. J. Mater. Sci. 1992, 27, 1053–1060. [Google Scholar] [CrossRef]

- Schwartz, K.B.; Rowcliffe, D.J. Modeling density contributions in preceramic polymer ceramic powder systems. J. Am. Ceram. Soc. 1986, 69, C106–C108. [Google Scholar] [CrossRef]

- Greil, P. Active-filler-controlled pyrolysis of preceramic polymers. J. Am. Ceram. Soc. 1995, 78, 835–848. [Google Scholar] [CrossRef]

- Greil, P. Near net shape manufacturing of polymer derived ceramics. J. Eur. Ceram. Soc. 1998, 18, 1905–1914. [Google Scholar] [CrossRef]

- Harshe, R.; Balan, C.; Riedel, R. Amorphous Si(Al)OC ceramic from polysiloxanes: Bulk ceramic processing, crystallization behavior and applications. J. Eur. Ceram. Soc. 2004, 24, 3471–3482. [Google Scholar] [CrossRef]

- Kaur, S.; Riedel, R.; Ionescu, E. Pressureless fabrication of dense monolithic SiC ceramics from a polycarbosilane. J. Eur. Ceram. Soc. 2014, 34, 3571–3578. [Google Scholar] [CrossRef]

- Linck, C.; Ionescu, E.; Papendorf, B.; Galuskova, D.; Galusek, D.; Sajgalik, P.; Riedel, R. Corrosion behavior of silicon oxycarbide-based ceramic nanocomposites under hydrothermal conditions. Int. J. Mater. Res. 2012, 103, 31–39. [Google Scholar] [CrossRef]

- Wen, Q.B.; Xu, Y.P.; Xu, B.B.; Fasel, C.; Guillon, O.; Buntkowsky, G.; Yu, Z.J.; Riedel, R.; Ionescu, E. Single-source-precursor synthesis of dense SiC/HfCxN1−x-based ultrahigh-temperature ceramic nanocomposites. Nanoscale 2014, 6, 13678–13689. [Google Scholar] [CrossRef] [PubMed]

- Ishihara, S.; Gu, H.; Bill, J.; Aldinger, F.; Wakai, F. Densification of precursor-derived Si–C–N ceramics by high-pressure hot isostatic pressing. J. Am. Ceram. Soc. 2002, 85, 1706–1712. [Google Scholar] [CrossRef]

- Esfehanian, M.; Oberacker, R.; Fett, T.; Hoffmann, M.J. Development of dense filler-free polymer-derived SiOC ceramics by field-assisted sintering. J. Am. Ceram. Soc. 2008, 91, 3803–3805. [Google Scholar] [CrossRef]

- Bechelany, M.C.; Salameh, C.; Viard, A.; Guichaoua, L.; Rossignol, F.; Chartier, T.; Bernard, S.; Miele, P. Preparation of polymer-derived Si–B–C–N monoliths by spark plasma sintering technique. J. Eur. Ceram. Soc. 2015, 35, 1361–1374. [Google Scholar] [CrossRef]

- Soraru, G.D.; Babonneau, F.; Mackenzie, J.D. Structural concepts on new amorphous covalent solids. J. Non-Cryst. Solids 1988, 106, 256–261. [Google Scholar] [CrossRef]

- Monthioux, M.; Oberlin, A.; Bouillon, E. Relationship between microtexture and electrical-properties during heat-treatment of SiC fiber precursor. Compos. Sci. Technol. 1990, 37, 21–35. [Google Scholar] [CrossRef]

- Corriu, R.J.P.; Leclercq, D.; Mutin, P.H.; Vioux, A. Preparation and structure of silicon oxycarbide glasses derived from polysiloxane precursors. J. Sol–Gel Sci. Technol. 1997, 8, 327–330. [Google Scholar]

- Pantano, C.G.; Singh, A.K.; Zhang, H.X. Silicon oxycarbide glasses. J. Sol–Gel Sci. Technol. 1999, 14, 7–25. [Google Scholar] [CrossRef]

- Belot, V.; Corriu, R.J.P.; Leclercq, D.; Mutin, P.H.; Vioux, A. Silicon oxycarbide glasses with low O/Si ratio from organosilicon precursors. J. Non-Cryst. Solids 1994, 176, 33–44. [Google Scholar] [CrossRef]

- Brequel, H.; Enzo, S.; Walter, S.; Soraru, G.D.; Badheka, R.; Babonneau, F. Structure/property relationship in silicon oxycarbide glasses and ceramics obtained via the sol–gel method. Mater. Sci. Forum. 2002, 386–388, 359–364. [Google Scholar]

- Dibandjo, P.; Dire, S.; Babonneau, F.; Soraru, G.D. Influence of the polymer architecture on the high temperature behavior of SiCO glasses: A comparison between linear- and cyclic-derived precursors. J. Non-Cryst. Solids 2010, 356, 132–140. [Google Scholar] [CrossRef]

- Zhang, H.; Pantano, C.G. Synthesis and characterization of silicon oxycarbide glasses. J. Am. Ceram. Soc. 1990, 73, 958–963. [Google Scholar] [CrossRef]

- Renlund, G.M.; Prochazka, S.; Doremus, R.H. Silicon oxycarbide glasses 1: Preparation and chemistry. J. Mater. Res. 1991, 6, 2716–2722. [Google Scholar] [CrossRef]

- Soraru, G.D.; Campostrini, R.; Maurina, S.; Babonneau, F. Gel precursor to silicon oxycarbide glasses with ultrahigh ceramic yield. J. Am. Ceram. Soc. 1997, 80, 999–1004. [Google Scholar] [CrossRef]

- Soraru, G.D.; Liu, Q.; Interrante, L.V.; Apple, T. Role of precursor molecular structure on the microstructure and high temperature stability of silicon oxycarbide glasses derived from methylene-bridged polycarbosilanes. Chem. Mater. 1998, 10, 4047–4054. [Google Scholar] [CrossRef]

- Belot, V.; Corriu, R.J.P.; Leclercq, D.; Mutin, P.H.; Vioux, A. Thermal redistribution reactions in cross-linked polysiloxanes. J. Polym. Sci. Pol. Chem. 1992, 30, 613–623. [Google Scholar] [CrossRef]

- Bois, L.; Maquet, J.; Babonneau, F.; Mutin, H.; Bahloul, D. Structural characterization of sol–gel derived oxycarbide glasses 1: Study of the pyrolysis process. Chem. Mater. 1994, 6, 796–802. [Google Scholar] [CrossRef]

- Kalfat, R.; Babonneau, F.; Gharbi, N.; Zarrouk, H. Si-29 MAS NMR investigation of the pyrolysis process of cross-linked polysiloxanes prepared from polymethylhydrosiloxane. J. Mater. Chem. 1996, 6, 1673–1678. [Google Scholar] [CrossRef]

- Gualandris, V.; Hourlier-Bahloul, D.; Babonneau, F. Structural investigation of the first stages of pyrolysis of Si–C–O preceramic polymers containing Si–H bonds. J. Sol–Gel Sci. Technol. 1999, 14, 39–48. [Google Scholar] [CrossRef]

- Ionescu, E.; Papendorf, B.; Kleebe, H.-J.; Poli, F.; Muller, K.; Riedel, R. Polymer-derived silicon oxycarbide/hafnia ceramic nanocomposites. Part I: Phase and microstructure evolution during the ceramization process. J. Am. Ceram. Soc. 2010, 93, 1774–1782. [Google Scholar] [CrossRef]

- Chomel, A.D.; Dempsey, P.; Latournerie, J.; Hourlier-Bahloul, D.; Jayasooriya, U.A. Gel to glass transformation of methyltriethoxysilane: A silicon oxycarbide glass precursor investigated using vibrational spectroscopy. Chem. Mater. 2005, 17, 4468–4473. [Google Scholar] [CrossRef]

- Ionescu, E.; Linck, C.; Fasel, C.; Mueller, M.; Kleebe, H.-J.; Riedel, R. Polymer-derived SiOC/ZrO2 ceramic nanocomposites with excellent high-temperature stability. J. Am. Ceram. Soc. 2010, 93, 241–250. [Google Scholar] [CrossRef]

- Soraru, G.D.; Pederiva, L.; Latournerie, J.; Raj, R. Pyrolysis kinetics for the conversion of a polymer into an amorphous silicon oxycarbide ceramic. J. Am. Ceram. Soc. 2002, 85, 2181–2187. [Google Scholar] [CrossRef]

- Narisawa, M.; Watase, S.; Matsukawa, K.; Dohmaru, T.; Okamura, K. White Si–O–C(–H) particles with photoluminescence synthesized by decarbonization reaction on polymer precursor in a hydrogen atmosphere. Bull. Chem. Soc. Jpn. 2012, 85, 724–726. [Google Scholar] [CrossRef]

- Bill, J.; Seitz, J.; Thurn, G.; Durr, J.; Canel, J.; Janos, B.Z.; Jalowiecki, A.; Sauter, D.; Schempp, S.; Lamparter, H.P.; et al. Structure analysis and properties of Si–C–N ceramics derived from polysilazanes. Phys. Status Solidi A 1998, 166, 269–296. [Google Scholar] [CrossRef]

- Seitz, J.; Bill, J.; Egger, N.; Aldinger, F. Structural investigations of Si/C/N-ceramics from polysilazane precursors by nuclear magnetic resonance. J. Eur. Ceram. Soc. 1996, 16, 885–891. [Google Scholar] [CrossRef]

- Li, Y.L.; Kroke, E.; Riedel, R.; Fasel, C.; Gervais, C.; Babonneau, F. Thermal cross-linking and pyrolytic conversion of poly(ureamethylvinyl)silazanes to silicon-based ceramics. Appl. Organomet. Chem. 2001, 15, 820–832. [Google Scholar] [CrossRef]

- Laine, R.M.; Babonneau, F.; Blowhowiak, K.Y.; Kennish, R.A.; Rahn, J.A.; Exarhos, G.J.; Waldner, K. The evolutionary process during pyrolytic transformation of poly(N-methylsilazane) from a preceramic polymer into an amorphous-silicon nitride carbon composite. J. Am. Ceram. Soc. 1995, 78, 137–145. [Google Scholar] [CrossRef]

- Schuhmacher, J.; Weinmann, M.; Bill, J.; Aldinger, F.; Muller, K. Solid-state NMR studies of the preparation of Si–C–N ceramics from polysilylcarbodiimide polymers. Chem. Mater. 1998, 10, 3913–3922. [Google Scholar] [CrossRef]

- Riedel, R.; Toma, L.; Fasel, C.; Miehe, G. Polymer-derived mullite-SiC-based nanocomposites. J. Eur. Ceram. Soc. 2009, 29, 3079–3090. [Google Scholar] [CrossRef]

- Dire, S.; Ceccato, R.; Gialanella, S.; Babonneau, F. Thermal evolution and crystallisation of polydimethylsiloxane-zirconia nanocomposites prepared by the sol–gel method. J. Eur. Ceram. Soc. 1999, 19, 2849–2858. [Google Scholar] [CrossRef]

- Ionescu, E.; Papendorf, B.; Kleebe, H.J.; Riedel, R. Polymer-derived silicon oxycarbide/hafnia ceramic nanocomposites. Part II: Stability toward decomposition and microstructure evolution at T1000 degrees C. J. Am. Ceram. Soc. 2010, 93, 1783–1789. [Google Scholar] [CrossRef]

- Bazarjani, M.S.; Kleebe, H.J.; Muller, M.M.; Fasel, C.; Yazdi, M.B.; Gurlo, A.; Riedel, R. Nanoporous silicon oxycarbonitride ceramics derived from polysilazanes in situ modified with nickel nanoparticles. Chem. Mater. 2011, 23, 4112–4123. [Google Scholar] [CrossRef]

- Hauser, R.; Francis, A.; Theismann, R.; Riedel, R. Processing and magnetic properties of metal-containing SiCN ceramic micro- and nano-composites. J. Mater. Sci. 2008, 43, 4042–4049. [Google Scholar] [CrossRef]

- Francis, A.; Ionescu, E.; Fasel, C.; Riedel, R. Crystallization behavior and controlling mechanism of iron-containing Si–C–N ceramics. Inorg. Chem. 2009, 48, 10078–10083. [Google Scholar] [CrossRef] [PubMed]

- Zaheer, M.; Motz, G.; Kempe, R. The generation of palladium silicide nanoalloy particles in a SiCN matrix and their catalytic applications. J. Mater. Chem. 2011, 21, 18825–18831. [Google Scholar] [CrossRef]

- Kaspar, J.; Terzioglu, C.; Ionescu, E.; Graczyk-Zajac, M.; Hapis, S.; Kleebe, H.J.; Riedel, R. Stable SiOC/Sn nanocomposite anodes for lithium-ion batteries with outstanding cycling stability. Adv. Funct. Mater. 2014, 24, 4097–4104. [Google Scholar] [CrossRef]

- Hojamberdiev, M.; Prasad, R.M.; Fasel, C.; Riedel, R.; Ionescu, E. Single-source-precursor synthesis of soft magnetic Fe3Si- and Fe5Si3-containing SiOC ceramic nanocomposites. J. Eur. Ceram. Soc. 2013, 33, 2465–2472. [Google Scholar] [CrossRef]

- Umicevic, A.B.; Cekic, B.D.; Belosevic-Cavor, J.N.; Koteski, V.J.; Papendorf, B.; Riedel, R.; Ionescu, E. Evolution of the local structure at Hf sites in SiHfOC upon ceramization of a hafnium-alkoxide-modified polysilsesquioxane: A perturbed angular correlation study. J. Eur. Ceram. Soc. 2015, 35, 29–35. [Google Scholar] [CrossRef]

- Ionescu, E.; Terzioglu, C.; Linck, C.; Kaspar, J.; Navrotsky, A.; Riedel, R. Thermodynamic control of phase composition and crystallization of metal-modified silicon oxycarbides. J. Am. Ceram. Soc. 2013, 96, 1899–1903. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas solid systems with special reference to the determination of surface-area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Kresge, C.T.; Leonowicz, M.E.; Roth, W.J.; Vartuli, J.C.; Beck, J.S. Ordered mesoporous molecular-sieves synthesized by a liquid-crystal template mechanism. Nature 1992, 359, 710–712. [Google Scholar] [CrossRef]

- Beck, J.S.; Vartuli, J.C.; Roth, W.J.; Leonowicz, M.E.; Kresge, C.T.; Schmitt, K.D.; Chu, C.T.W.; Olson, D.H.; Sheppard, E.W.; Mccullen, S.B.; et al. A New family of mesoporous molecular-sieves prepared with liquid-crystal templates. J. Am. Chem. Soc. 1992, 114, 10834–10843. [Google Scholar] [CrossRef]

- Kresge, C.T.; Vartuli, J.C.; Roth, W.J.; Leonowicz, M.E.; Beck, J.S.; Schmitt, K.D.; Chu, C.T.W.; Olson, D.H.; Sheppard, E.W.; McCullen, S.B.; et al. M41S: A new family of mesoporous molecular sieves prepared with liquid crystal templates. Stud. Surf. Sci. Catal. 1995, 92, 11–19. [Google Scholar]

- Yanagisawa, T.; Shimizu, T.; Kuroda, K.; Kato, C. The preparation of alkyltrimethylammonium-kanemite complexes and their conversion to microporous materials. Bull. Chem. Soc. Jpn. 1990, 63, 988–992. [Google Scholar] [CrossRef]

- Shi, Y.F.; Wan, Y.; Zhao, D.Y. Ordered mesoporous non-oxide materials. Chem. Soc. Rev. 2011, 40, 3854–3878. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Zhao, D.Y. On the controllable soft-templating approach to mesoporous silicates. Chem. Rev. 2007, 107, 2821–2860. [Google Scholar] [CrossRef] [PubMed]

- Kamperman, M.; Garcia, C.B.W.; Du, P.; Ow, H.S.; Wiesner, U. Ordered mesoporous ceramics stable up to 1500 degrees C from diblock copolymer mesophases. J. Am. Chem. Soc. 2004, 126, 14708–14709. [Google Scholar] [CrossRef] [PubMed]

- Malenfant, P.R.L.; Wan, J.L.; Taylor, S.T.; Manoharan, M. Self-assembly of an organic-inorganic block copolymer for nano-ordered ceramics. Nat. Nanotechnol. 2007, 2, 43–46. [Google Scholar] [CrossRef] [PubMed]

- Nghiem, Q.D.; Kim, D.; Kim, D.P. Synthesis of inorganic-organic diblock copolymers as a precursor of ordered mesoporous SiCN ceramic. Adv. Mater. 2007, 19, 2351–2354. [Google Scholar] [CrossRef]

- Ryoo, R.; Joo, S.H.; Jun, S. Synthesis of highly ordered carbon molecular sieves via template-mediated structural transformation. J. Phys. Chem. B 1999, 103, 7743–7746. [Google Scholar] [CrossRef]

- Shi, Y.F.; Meng, Y.; Chen, D.H.; Cheng, S.J.; Chen, P.; Yang, T.F.; Wan, Y.; Zhao, D.Y. Highly ordered mesoporous silicon carbide ceramics with large surface areas and high stability. Adv. Funct. Mater. 2006, 16, 561–567. [Google Scholar] [CrossRef]

- Shi, Y.; Wan, Y.; Tu, B.; Zhao, D. Nanocasting synthesis of ordered mesoporous silicon nitrides with a high nitrogen content. J. Phys. Chem. C 2008, 112, 112–116. [Google Scholar] [CrossRef]

- Yan, J.; Wang, A.; Kim, D.-P. Preparation of ordered mesoporous SiC from preceramic polymer templated by nanoporous silica. J. Phys. Chem. B 2006, 110, 5429–5433. [Google Scholar] [CrossRef] [PubMed]

- Monthioux, M.; Delverdier, O. Thermal behavior of (organosilicon) polymer-derived ceramics 5: Main facts and trends. J. Eur. Ceram. Soc. 1996, 16, 721–737. [Google Scholar] [CrossRef]

- Yan, J.; Wang, A.J.; Kim, D.P. Preparation of ordered mesoporous SiCN ceramics with large surface area and high thermal stability. Microporous Mesoporous Mater. 2007, 100, 128–133. [Google Scholar] [CrossRef]

- Shi, Y.F.; Wan, Y.; Zhai, Y.P.; Liu, R.L.; Meng, Y.; Tu, B.; Zhao, D.Y. Ordered mesoporous SiOC and SiCN ceramics from atmosphere-assisted in situ transformation. Chem. Mater. 2007, 19, 1761–1771. [Google Scholar] [CrossRef]

- Bill, J.; Kamphowe, T.W.; Muller, A.; Wichmann, T.; Zern, A.; Jalowieki, A.; Mayer, J.; Weinmann, M.; Schuhmacher, J.; Muller, K.; et al. Precursor-derived Si–(B–)C–N ceramics: Thermolysis, amorphous state and crystallization. Appl. Organomet. Chem. 2001, 15, 777–793. [Google Scholar] [CrossRef]

- Yan, X.B.; Gottardo, L.; Bernard, S.; Dibandjo, P.; Brioude, A.; Moutaabbid, H.; Miele, P. Ordered mesoporous silicoboron carbonitride materials via preceramic polymer nanocasting. Chem. Mater. 2008, 20, 6325–6334. [Google Scholar] [CrossRef]

- Majoulet, O.; Alauzun, J.G.; Gottardo, L.; Gervais, C.; Schuster, M.E.; Bernard, S.; Miele, P. Ordered mesoporous silicoboron carbonitride ceramics from boron-modified polysilazanes: Polymer synthesis, processing and properties. Microporous Microporous Mater. 2011, 140, 40–50. [Google Scholar] [CrossRef]

- Bernard, S.; Majoulet, O.; Sandra, F.; Malchere, A.; Miele, P. Direct synthesis of periodic mesoporous silicoboron carbonitride frameworks via the nanocasting from ordered mesoporous silica with boron-modified polycarbosilazane. Adv. Eng. Mater. 2013, 15, 134–140. [Google Scholar] [CrossRef]

- Lewis, M.H.; Barnard, P. Oxidation mechanisms in Si–Al–O–N ceramics. J. Mater. Sci. 1980, 15, 443–448. [Google Scholar] [CrossRef]

- MacKenzie, K.J.D.; Shimada, S.; Aoki, T. Thermal oxidation of carbothermal β'-sialon powder: Reaction sequence and kinetics. J. Mater. Chem. 1997, 7, 527–530. [Google Scholar] [CrossRef]

- Nordberg, L.O.; Nygren, M.; Kall, P.O.; Shen, Z.J. Stability and oxidation properties of RE-alpha-sialon ceramics (RE = Y, Nd, Sm, Yb). J. Am. Ceram. Soc. 1998, 81, 1461–1470. [Google Scholar] [CrossRef]

- An, L.N.; Wang, Y.G.; Bharadwaj, L.; Zhang, L.G.; Fan, Y.; Jiang, D.P.; Sohn, Y.H.; Desai, V.H.; Kapat, J.; Chow, L.C.; et al. Silicoaluminum carbonitride with anomalously high resistance to oxidation and hot corrosion. Adv. Eng. Mater. 2004, 6, 337–340. [Google Scholar] [CrossRef]

- Majoulet, O.; Salameh, C.; Schuster, M.E.; Demirci, U.B.; Sugahara, Y.; Bernard, S.; Miele, P. Preparation, characterization, and surface modification of periodic mesoporous silicon-aluminum-carbon-nitrogen frameworks. Chem. Mater. 2013, 25, 3957–3970. [Google Scholar] [CrossRef]

- Alauzun, J.G.; Ungureanu, S.; Brun, N.; Bernard, S.; Miele, P.; Backov, R.; Sanchez, C. Novel monolith-type boron nitride hierarchical foams obtained through integrative chemistry. J. Mater. Chem. 2011, 21, 14025–14030. [Google Scholar] [CrossRef]

- Majoulet, O.; Sandra, F.; Bechelany, M.C.; Bonnefont, G.; Fantozzi, G.; Joly-Pottuz, L.; Malchere, A.; Bernard, S.; Miele, P. Silicon-boron-carbon-nitrogen monoliths with high, interconnected and hierarchical porosity. J. Mater. Chem. A 2013, 1, 10991–11000. [Google Scholar] [CrossRef]

- Bernard, S.; Miele, P. Ordered mesoporous polymer-derived ceramics and their processing into hierarchically porous boron nitride and silicoboron carbonitride monoliths. New J. Chem. 2014, 38, 1923–1931. [Google Scholar] [CrossRef]

- Bates, F.S.; Fredrickson, G.H. Block copolymers—designer soft materials. Phys. Today 1999, 52, 32–38. [Google Scholar] [CrossRef]

- Hamley, I.W. The Physics of Block Copolymers; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Hillmyer, M.A. Nanoporous materials fromblock copolymer precursors. Adv. Polym. Sci. 2005, 190, 137–181. [Google Scholar]

- Darling, S.B. Directing the self-assembly of block copolymers. Prog. Polym. Sci. 2007, 32, 1152–1204. [Google Scholar] [CrossRef]

- Aissou, K.; Shaver, J.; Fleury, G.; Pecastaings, G.; Brochon, C.; Navarro, C.; Grauby, S.; Rampnoux, J.M.; Dilhaire, S.; Hadziioannou, G.; et al. Nanoscale block copolymer ordering induced by visible interferometric micropatterning: A route towards large scale block copolymer 2D crystals. Adv. Mater. 2013, 25, 213–217. [Google Scholar] [CrossRef] [PubMed]

- Koo, K.; Ahn, H.; Kim, S.-W.; Ryu, D.Y.; Russell, T.P. Directed self-assembly of block copolymers in the extreme: Guiding microdomains from the small to the large. Soft Matter 2013, 9, 9059–9071. [Google Scholar] [CrossRef]

- Orilall, M.C.; Wiesner, U. Block copolymer based composition and morphology control in nanostructured hybrid materials for energy conversion and storage: Solar cells, batteries, and fuel cells. Chem. Soc. Rev. 2011, 40, 520–535. [Google Scholar] [CrossRef] [PubMed]

- She, M.-S.; Lo, T.-Y.; Hsueh, H.-Y.; Ho, R.-M. Nanostructured thin films of degradable block copolymers and their applications. NPG Asia Mater. 2013, 5, e42:1–e42:9. [Google Scholar] [CrossRef]

- Ren, Y.; Ma, Z.; Bruce, P.G. Ordered mesoporous metal oxides: Synthesis and applications. Chem. Soc. Rev. 2012, 41, 4909–4927. [Google Scholar] [CrossRef] [PubMed]

- Innocenzi, P.; Malfatti, L. Mesoporous thin films: Properties and applications. Chem. Soc. Rev. 2013, 42, 4198–4216. [Google Scholar] [CrossRef] [PubMed]

- Petkovich, N.D.; Stein, A. Controlling macro- and mesostructures with hierarchical porosity through combined hard and soft templating. Chem. Soc. Rev. 2013, 42, 3721–3739. [Google Scholar] [CrossRef] [PubMed]

- Rawolle, M.; Niedermeier, M.A.; Kaune, G.; Perlich, J.; Lellig, P.; Memesa, M.; Cheng, Y.J.; Gutmann, J.S.; Muller-Buschbaum, P. Fabrication and characterization of nanostructured titania films with integrated function from inorganic-organic hybrid materials. Chem. Soc. Rev. 2012, 41, 5131–5142. [Google Scholar] [CrossRef] [PubMed]

- Hsueh, H.Y.; Ho, R.M. Bicontinuous ceramics with high surface area from block copolymer templates. Langmuir 2012, 28, 8518–8529. [Google Scholar] [CrossRef] [PubMed]

- Hsueh, H.Y.; Chen, H.Y.; She, M.S.; Chen, C.K.; Ho, R.M.; Gwo, S.; Hasegawa, H.; Thomas, E.L. Inorganic gyroid with exceptionally low refractive index from block copolymer templating. Nano Lett. 2010, 10, 4994–5000. [Google Scholar] [CrossRef] [PubMed]

- Jones, B.H.; Lodge, T.P. High-temperature nanoporous ceramic monolith prepared from a polymeric bicontinuous microemulsion template. J. Am. Chem. Soc. 2009, 131, 1676–1677. [Google Scholar] [CrossRef] [PubMed]

- Reitz, C.; Haetge, J.; Suchomski, C.; Brezesinski, T. Facile and general synthesis of thermally stable ordered mesoporous rare-earth oxide ceramic thin films with uniform mid-size to large-size pores and strong crystalline texture. Chem. Mater. 2013, 25, 4633–4642. [Google Scholar]

- Rauda, I.E.; Buonsanti, R.; Saldarriaga-Lopez, L.C.; Benjauthrit, K.; Schelhas, L.T.; Stefik, M.; Augustyn, V.; Ko, J.; Dunn, B.; Wiesner, U.; et al. General method for the synthesis of hierarchical nanocrystal-based mesoporous materials. ACS Nano 2012, 6, 6386–6399. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, J.; Tu, M. Synthesis of porous methylphenylsiloxane/poly(dimethylsiloxane) composite using poly(dimethylsiloxane)-poly(ethylene oxide) (PDMS-PEO) as template. J. Mater. Sci. 2012, 47, 3350–3353. [Google Scholar] [CrossRef]

- Kamperman, M.; Du, P.; Scarlat, R.O.; Herz, E.; Werner-Zwanziger, U.; Graf, R.; Zwanziger, J.W.; Spiess, H.W.; Wiesner, U. Composition and morphology control in ordered mesostructured high-temperature ceramics from block copolymer mesophases. Macromol. Chem. Phys. 2007, 208, 2096–2108. [Google Scholar] [CrossRef]

- Wan, J.; Malenfant, P.R.L.; Taylor, S.T.; Loureiro, S.M.; Manoharan, M. Microstructure of block copolymer/precursor assembly for Si–C–N based nano-ordered ceramics. Mater. Sci. Eng. A 2007, 463, 78–88. [Google Scholar] [CrossRef]

- Nghiem, Q.D.; Kim, D.-P. Direct preparation of high surface area mesoporous SiC-based ceramic by pyrolysis of a self-assembled polycarbosilane-block-polystyrene diblock copolymer. Chem. Mater. 2008, 20, 3735–3739. [Google Scholar] [CrossRef]

- Matsumoto, K.; Matsuoka, H. Synthesis of core-crosslinked carbosilane block copolymer micelles and their thermal transformation to silicon-based ceramics nanoparticles. J. Polym. Sci. A 2005, 43, 3778–3787. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Hoang, P.H.; Perumal, J.; Kim, D.P. An inorganic-organic diblock copolymer photoresist for direct mesoporous SiCN ceramic patterns via photolithography. Chem. Commun. 2011, 47, 3484–3486. [Google Scholar] [CrossRef]

- Chan, V.Z.-H.; Hoffman, J.; Lee, V.Y.; Iatrou, H.; Avgeropoulos, A.; Hadjichristidis, N.; Miller, R.D.; Thomas, E.L. Ordered bicontinuous nanoporous and nanorelief ceramic films from self assembling polymer precursors. Science 1999, 286, 1716–1719. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Sai, H.; Tan, K.W.; Hoheisel, T.N.; Gruner, S.M.; Wiesner, U. Ordered nanostructured ceramic-metal composites through multifunctional block copolymer-metal nanoparticle self-assembly. J. Sol–Gel Sci. Technol. 2014, 70, 286–291. [Google Scholar] [CrossRef]

- Chao, C.-C.; Ho, R.-M.; Georgopanos, P.; Avgeropoulos, A.; Thomas, E.L. Silicon oxy carbide nanorings from polystyrene-b-polydimethylsiloxane diblock copolymer thin films. Soft Matter 2010, 6, 3582–3587. [Google Scholar] [CrossRef]

- Pillai, S.K.; Kretschmer, W.P.; Denner, C.; Motz, G.; Hund, M.; Fery, A.; Trebbin, M.; Forster, S.; Kempe, R. SiCN nanofibers with a diameter below 100 nm synthesized via concerted block copolymer formation, microphase separation, and crosslinking. Small 2013, 9, 984–989. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, R.; Priimagi, A.; Faul, C.F.; Manners, I. Redox-active, organometallic surface-relief gratings from azobenzene-containing polyferrocenylsilane block copolymers. Adv. Mater. 2012, 24, 926–931. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Massey, J.A.; Winnik, M.A.; Manners, I.; Riethmüller, S.; Banhart, F.; Spatz, J.P.; Möller, M. Reactive ion etching of cylindrical polyferrocenylsilane block copolymer micelles: Fabrication of ceramic nanolines on semiconducting substrates. Adv. Funct. Mater. 2003, 13, 271–276. [Google Scholar] [CrossRef]

- Temple, K.; Kulbaba, K.; Power-Billard, K.N.; Manners, I.; Leach, K.A.; Xu, T.; Russell, T.P.; Hawker, C.J. Spontaneous vertical ordering and pyrolytic formation of nanoscopic ceramic patterns from poly(styrene-b-ferrocenylsilane). Adv. Mater. 2003, 15, 297–300. [Google Scholar] [CrossRef]

- Wang, X.-S.; Arsenault, A.; Ozin, G.A.; Winnik, M.A.; Manners, I. Shell cross-linked cylinders of polyisoprene-b-ferrocenyldimethylsilane: Formation of magnetic ceramic replicas and microfluidic channel alignment and patterning. J. Am. Chem. Soc. 2003, 125, 12686–12687. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.Y.; Ross, C.A.; Chan, V.Z.-H.; Thomas, E.L.; Lammertink, R.G.H.; Vancso, G.J. Formation of a cobalt magnetic dot array via block copolymer lithography. Adv. Mater. 2001, 13, 1174–1178. [Google Scholar] [CrossRef]

- Gallei, M.; Tockner, S.; Klein, R.; Rehahn, M. Silacyclobutane-based diblock copolymers with vinylferrocene, ferrocenylmethyl methacrylate, and [1]dimethylsilaferrocenophane. Macromol. Rapid Commun. 2010, 31, 889–896. [Google Scholar] [CrossRef] [PubMed]

- Gallei, M.; Schmidt, B.V.K.J.; Klein, R.; Rehahn, M. Defined poly[styrene-block-(ferrocenylmethyl methacrylate)] diblock copolymers via living anionic polymerization. Macromol. Rapid Commun. 2009, 30, 1463–1469. [Google Scholar] [CrossRef] [PubMed]

- Rittscher, V.; Gallei, M. A convenient synthesis strategy for microphase-separating functional copolymers: The cyclohydrocarbosilane tool box. Polym. Chem. 2015. [CrossRef]

- Ge, J.; Yin, Y. Responsive photonic crystals. Angew. Chem. Int. Ed. Engl. 2011, 50, 1492–1522. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, C.G.; Lederle, C.; Zentel, K.; Stühn, B.; Gallei, M. Utilising stretch-tunable thermochromic elastomeric opal films as novel reversible switchable photonic materials. Macromol. Rapid Commun. 2014, 35, 1852–1860. [Google Scholar] [PubMed]

- Schäfer, C.G.; Viel, B.; Hellmann, G.P.; Rehahn, M.; Gallei, M. Thermo-cross-linked elastomeric opal films. ACS Appl. Mater. Interfaces 2013, 5, 10623–10632. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, C.G.; Smolin, D.A.; Hellmann, G.P.; Gallei, M. Fully reversible shape transition of soft spheres in elastomeric polymer opal films. Langmuir 2013, 29, 11275–11283. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, C.G.; Gallei, M.; Zahn, J.T.; Engelhardt, J.; Hellmann, G.P.; Rehahn, M. Reversible light-, thermo-, and mechano-responsive elastomeric polymer opal films. Chem. Mater. 2013, 25, 2309–2318. [Google Scholar] [CrossRef]

- Galisteo-López, J.F.; Ibisate, M.; Sapienza, R.; Froufe-Pérez, L.S.; Blanco, Á.; López, C. Self-assembled photonic structures. Adv. Mater. 2011, 23, 30–69. [Google Scholar] [CrossRef] [PubMed]

- Von Freymann, G.; Kitaev, V.; Lotsch, B.V.; Ozin, G.A. Bottom-up assembly of photonic crystals. Chem. Soc. Rev. 2013, 42, 2528–2554. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, C.G.; Vowinkel, S.; Hellmann, G.P.; Herdt, T.; Contiu, C.; Schneider, J.J.; Gallei, M. A polymer based and template-directed approach towards functional multidimensional microstructured organic/inorganic hybrid materials. J. Mater. Chem. C 2014, 2, 7960–7975. [Google Scholar] [CrossRef]

- Galloro, J.; Ginzburg, M.; Miguez, H.; Yang, S.M.; Coombs, N.; Safa-Sefat, A.; Greedan, J.E.; Manners, I.; Ozin, G.A. Replicating the structure of a crosslinked polyferrocenylsilane inverse opal in the form of a magnetic ceramic. Adv. Funct. Mater. 2002, 12, 382–388. [Google Scholar] [CrossRef]

- Zhou, J.; Li, H.; Ye, L.; Liu, J.; Wang, J.; Zhao, T.; Jiang, L.; Song, Y. Facile fabrication of tough SiC inverse opal photonic crystals. J. Phys. Chem. C 2010, 114, 22303–22308. [Google Scholar] [CrossRef]

- Brequel, H.; Soraru, G.D.; Schiffini, L.; Enzo, S. Radial distribution function of amorphous silicon oxycarbide compounds. Metastable Mech. Alloy. Nanocryst. Mater. 2000, 8, 677–682. [Google Scholar] [CrossRef]

- Brequel, H.; Parmentier, J.; Walter, S.; Badheka, R.; Trimmel, G.; Masse, S.; Latournerie, J.; Dempsey, P.; Turquat, C.; Desmartin-Chomel, A.; et al. Systematic structural characterization of the high-temperature behavior of nearly stoichiometric silicon oxycarbide glasses. Chem. Mater. 2004, 16, 2585–2598. [Google Scholar] [CrossRef]

- Belot, V.; Corriu, R.; Leclercq, D.; Mutin, P.H.; Vioux, A. Thermal reactivity of hydrogenosilsesquioxane gels. Chem. Mater. 1991, 3, 127–131. [Google Scholar] [CrossRef]

- Kleebe, H.J.; Turquat, C.; Soraru, G.D. Phase separation in an SiCO glass studied by transmission electron microscopy and electron energy-loss spectroscopy. J. Am. Ceram. Soc. 2001, 84, 1073–1080. [Google Scholar] [CrossRef]

- Burns, G.T.; Taylor, R.B.; Xu, Y.R.; Zangvil, A.; Zank, G.A. High-temperature chemistry of the conversion of siloxanes to silicon carbide. Chem. Mater. 1992, 4, 1313–1323. [Google Scholar] [CrossRef]

- Saha, A.; Raj, R. Crystallization maps for SiCO amorphous ceramics. J. Am. Ceram. Soc. 2007, 90, 578–583. [Google Scholar] [CrossRef]

- Nonnenmacher, K.; Kleebe, H.J.; Rohrer, J.; Ionescu, E.; Riedel, R. Carbon mobility in SiOC/HfO2 ceramic nanocomposites. J. Am. Ceram. Soc. 2013, 96, 2058–2060. [Google Scholar] [CrossRef]

- Schiavon, M.A.; Gervais, C.; Babonneau, F.; Soraru, G.D. Crystallization behavior of novel silicon boron oxycarbide glasses. J. Am. Ceram. Soc. 2004, 87, 203–208. [Google Scholar] [CrossRef]

- Klonczynski, A.; Schneider, G.; Riedel, R.; Theissmann, R. Influence of boron on the microstructure of polymer derived SiCO ceramics. Adv. Eng. Mater. 2004, 6, 64–68. [Google Scholar] [CrossRef]

- Ngoumeni-Yappi, R.; Fasel, C.; Riedel, R.; Ischenko, V.; Pippel, E.; Woltersdorf, J.; Clade, J. Tuning of the rheological properties and thermal behavior of boron-containing polysiloxanes. Chem. Mater. 2008, 20, 3601–3608. [Google Scholar] [CrossRef]

- Soraru, G.D.; Pena-Alonso, R.; Kleebe, H.J. The effect of annealing at 1400 °C on the structural evolution of porous C-rich silicon (boron)oxycarbide glass. J. Eur. Ceram. Soc. 2012, 32, 1751–1757. [Google Scholar] [CrossRef]

- Chavez, R.; Ionescu, E.; Fasel, C.; Riedel, R. Silicon-containing polyimide-based polymers with high temperature stability. Chem. Mater. 2010, 22, 3823–3825. [Google Scholar] [CrossRef]

- Riedel, R.; Seher, M. Crystallization behaviour of amorphous silicon nitride. J. Eur. Ceram. Soc. 1991, 7, 21–25. [Google Scholar] [CrossRef]

- Weinmann, M.; Zern, A.; Aldinger, F. Stoichiometric silicon nitride/silicon carbide composites from polymeric precursors. Adv. Mater. 2001, 13, 1704–1708. [Google Scholar] [CrossRef]

- Riedel, R.; Kienzle, A.; Dressler, W.; Ruwisch, L.; Bill, J.; Aldinger, F. A silicoboron carbonitride ceramic stable to 2000 °C. Nature 1996, 382, 796–798. [Google Scholar] [CrossRef]

- Wang, Z.C.; Aldinger, F.; Riedel, R. Novel silicon-boron-carbon-nitrogen materials thermally stable up to 2200 °C. J. Am. Ceram. Soc. 2001, 84, 2179–2183. [Google Scholar] [CrossRef]

- Matsunaga, K.; Iwamoto, Y.; Fisher, C.A.J.; Matsubara, H. Molecular dynamics study of atomic structures in amorphous Si–C–N ceramics. J. Ceram. Soc. Jpn. 1999, 107, 1025–1031. [Google Scholar] [CrossRef]

- Matsunaga, K.; Iwamoto, Y. Molecular dynamics study of atomic structure and diffusion behavior in amorphous silicon nitride containing boron. J. Am. Ceram. Soc. 2001, 84, 2213–2219. [Google Scholar] [CrossRef]

- Tavakoli, A.H.; Gerstel, P.; Golczewski, J.A.; Bill, J. Crystallization kinetics of Si3N4 in Si–B–C–N polymer-derived ceramics. J. Mater. Res. 2010, 25, 2150–2158. [Google Scholar] [CrossRef]

- Tavakoli, A.H.; Gerstel, P.; Golczewski, J.A.; Bill, J. Kinetic effect of boron on the crystallization of Si3N4 in Si–B–C–N polymer-derived ceramics. J. Mater. Res. 2011, 26, 600–608. [Google Scholar] [CrossRef]

- Tavakoli, A.H.; Golczewski, J.A.; Bill, J.; Navrotsky, A. Effect of boron on the thermodynamic stability of amorphous polymer-derived Si(B)CN ceramics. Acta Mater. 2012, 60, 4514–4522. [Google Scholar] [CrossRef]

- Wang, Y.G.; Fei, W.F.; An, L.N. Oxidation/corrosion of polymer-derived SiAlCN ceramics in water vapor. J. Am. Ceram. Soc. 2006, 89, 1079–1082. [Google Scholar] [CrossRef]

- Sujith, R.; Kousaalya, A.B.; Kumar, R. Coarsening induced phase transformation of hafnia in polymer-derived Si–Hf–C–N–O ceramics. J. Am. Ceram. Soc. 2011, 94, 2788–2791. [Google Scholar] [CrossRef]

- Gurlo, A. Electrical Properties of Polymer-Derived Ceramics. In Polymer Derived Ceramics: From Nanostructure to Applications; Colombo, P., Riedel, R., Kleebe, H.-J., Soraru, G.D., Eds.; DesTech Publications, Inc.: Lancaster, PA, USA, 2010; pp. 261–274. [Google Scholar]

- Chollon, G. Oxidation behaviour of ceramic fibres from the Si–C–N–O system and related sub-systems. J. Eur. Ceram. Soc. 2000, 20, 1959–1974. [Google Scholar] [CrossRef]

- Naslain, R.; Guette, A.; Rebillat, F.; le Gallet, S.; Lamouroux, F.; Filipuzzi, L.; Louchet, C. Oxidation mechanisms and kinetics of SiC-matrix composites and their constituents. J. Mater. Sci. 2004, 39, 7303–7316. [Google Scholar] [CrossRef]

- Rodriguezviejo, J.; Sibieude, F.; Clavagueramora, M.T.; Monty, C. O-18 diffusion through amorphous SiO2 and cristobalite. Appl. Phys. Lett. 1993, 63, 1906–1908. [Google Scholar] [CrossRef]

- Modena, S.; Soraru, G.D.; Blum, Y.; Raj, R. Passive oxidation of an effluent system: The case of polymer-derived SiCO. J. Am. Ceram. Soc. 2005, 88, 339–345. [Google Scholar] [CrossRef]

- Butchereit, E.; Nickel, K.G. Oxidation behaviour of precursor derived Si–(B)–C–N ceramics. J. Mater. Process. Manuf. 1998, 7, 15–21. [Google Scholar] [CrossRef]

- Butchereit, E.; Nickel, K.G. Oxidation behaviour of precursor derived ceramics in the system Si–(B)–C–N. Key Eng. Mater. 2000, 175–176, 69–77. [Google Scholar]

- Muller, A.; Gerstel, P.; Butchereit, E.; Nickel, K.G.; Aldinger, F. Si/B/C/N/Al precursor-derived ceramics: Synthesis, high temperature behaviour and oxidation resistance. J. Eur. Ceram. Soc. 2004, 24, 3409–3417. [Google Scholar] [CrossRef]

- Nguyen, V.L. Molecular Approaches to Novel SiHfBCN Ceramic Nanocomposites: Synthesis and High-Temperature Behavior. Master Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2011. [Google Scholar]

- Wang, Y.G.; An, L.N.; Fan, Y.; Zhang, L.G.; Burton, S.; Gan, Z.H. Oxidation of polymer-derived SiAlCN ceramics. J. Am. Ceram. Soc. 2005, 88, 3075–3080. [Google Scholar] [CrossRef]

- Wang, Y.G.; Fan, Y.; Zhang, L.G.; Zhang, W.G.; An, L.A. Polymer-derived SiAlCN ceramics resist oxidation at 1400 °C. Scr. Mater. 2006, 55, 295–297. [Google Scholar] [CrossRef]

- Wang, Y.G.; Sohn, Y.H.; Fan, Y.; Zhang, L.G.; An, L.N. Oxygen diffusion through Al-doped amorphous SiO2. J. Phase Equilib. Diffus. 2006, 27, 671–675. [Google Scholar] [CrossRef]

- Renlund, G.M.; Prochazka, S.; Doremus, R.H. Silicon oxycarbide glasses 2: Structure and properties. J. Mater. Res. 1991, 6, 2723–2734. [Google Scholar] [CrossRef]

- Soraru, G.D.; Dallapiccola, E.; DAndrea, G. Mechanical characterization of sol–gel-derived silicon oxycarbide glasses. J. Am. Ceram. Soc. 1996, 79, 2074–2080. [Google Scholar] [CrossRef]

- Rouxel, T.; Massouras, G.; Soraru, G.D. High temperature behavior of a gel-derived SiOC glass: Elasticity and viscosity. J. Sol–Gel Sci. Technol. 1999, 14, 87–94. [Google Scholar] [CrossRef]

- Rouxel, T.; Soraru, G.D.; Vicens, J. Creep viscosity and stress relaxation of gel-derived silicon oxycarbide glasses. J. Am. Ceram. Soc. 2001, 84, 1052–1058. [Google Scholar] [CrossRef]

- Papendorf, B.; Ionescu, E.; Kleebe, H.J.; Guillon, O.; Nonnenmacher, K.; Riedel, R. High-temperature creep behavior of dense SiOC-based ceramic nanocomposites: Microstructural and phase composition effects. J. Am. Ceram. Soc. 2013, 96, 272–280. [Google Scholar] [CrossRef]

- Hampshire, S.; Drew, R.A.L.; Jack, K.H. Viscosities, glass-transition temperatures, and microhardness of Y–Si–Al–O–N glasses. J. Am. Ceram. Soc. 1984, 67, C46–C47. [Google Scholar]

- Rouxel, T.; Huger, M.; Besson, J.L. Rheological properties of Y–Si–Al–O–N glasses—Elastic moduli, viscosity and creep. J. Mater. Sci. 1992, 27, 279–284. [Google Scholar] [CrossRef]

- Ionescu, E.; Balan, C.; Kleebe, H.J.; Muller, M.M.; Guillon, O.; Schliephake, D.; Heilmaier, M.; Riedel, R. High-temperature creep behavior of SiOC glass-ceramics: Influence of network carbon versus segregated carbon. J. Am. Ceram. Soc. 2014, 97, 3935–3942. [Google Scholar] [CrossRef]

- An, L.A.; Riedel, R.; Konetschny, C.; Kleebe, H.J.; Raj, R. Newtonian viscosity of amorphous silicon carbonitride at high temperature. J. Am. Ceram. Soc. 1998, 81, 1349–1352. [Google Scholar] [CrossRef]

- Shah, S.R.; Raj, R. Nanoscale densification creep in polymer-derived silicon carbonitrides at 1350 °C. J. Am. Ceram. Soc. 2001, 84, 2208–2212. [Google Scholar] [CrossRef]

- Zimmermann, A.; Bauer, A.; Christ, M.; Cai, Y.; Aldinger, F. High-temperature deformation of amorphous Si–C–N and Si–B–C–N ceramics derived from polymers. Acta Mater. 2002, 50, 1187–1196. [Google Scholar] [CrossRef]

- Riedel, R.; Ruwisch, L.M.; An, L.N.; Raj, R. Amorphous silicoboron carbonitride ceramic with very high viscosity at temperatures above 1500 °C. J. Am. Ceram. Soc. 1998, 81, 3341–3344. [Google Scholar] [CrossRef]

- Kumar, N.V.R.; Prinz, S.; Cai, Y.; Zimmermann, A.; Aldinger, F.; Berger, F.; Muller, K. Crystallization and creep behavior of Si–B–C–N ceramics. Acta Mater. 2005, 53, 4567–4578. [Google Scholar] [CrossRef]

- Kim, K.J.; Eom, J.-H.; Kim, Y.-W.; Seo, W.-S. Electrical conductivity of dense, bulk silicon-oxycarbide ceramics. J. Eur. Ceram. Soc. 2015, 35, 1355–1360. [Google Scholar] [CrossRef]

- Cordelair, J.; Greil, P. Electrical conductivity measurements as a microprobe for structure transitions in polysiloxane derived Si–O–C ceramics. J. Eur. Ceram. Soc. 2000, 20, 1947–1957. [Google Scholar] [CrossRef]

- Trassl, S.; Motz, G.; Rossler, E.; Ziegler, G. Characterisation of the free-carbon phase in precursor-derived SiCN ceramics. J. Non-Cryst. Solids 2001, 293, 261–267. [Google Scholar] [CrossRef]