Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release

Abstract

:1. Introduction

2. Results and Discussion

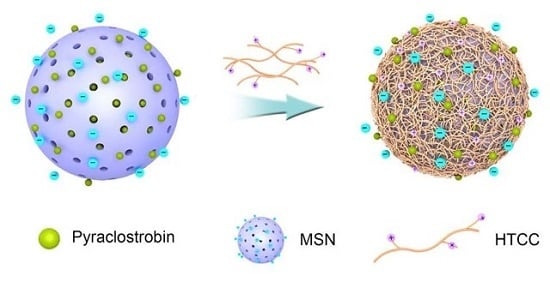

2.1. Preparation and Characterization of Pyraclostrobin-Loaded HTCC-Capped MSNs

2.1.1. Optimization of Pesticide Loading

2.1.2. Characterization

2.2. In Vitro Release of Pyraclostrobin

2.3. Fungicidal Activity of Pyraclostrobin-Loaded HTCC-Capped MSNs

3. Experimental Section

3.1. Materials

3.2. Characterization

3.3. Synthesis of Mesoporous Silica Nanoparticles

3.4. Loading of Pyraclostrobin into HTCC-Capped MSNs

3.5. Pyraclostrobin Loading Efficiency

3.6. Pyraclostrobin Release

3.7. Bioactivity Studies of Pyraclostrobin-Loaded HTCC-Capped MSNs

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| HPLC | High-performance liquid chromatography |

| LC | Loading content |

| MSN | Mesoporous silica nanoparticle |

| HTCC | N-(2-Hydroxyl)propyl-3-trimethylammonium chitosan chloride |

| TEOS | Tetraethylorthosilicate |

| CTAB | Cetyltrimethylammonium bromide |

| BET | Brunauer–Emmett–Teller |

| BJH | Barrett–Joyner–Halenda |

| FTIR | Fourier transform infrared |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| TGA | Thermogravimetric analysis |

| Py@MSNs-HTCC | Pyraclostrobin-loaded HTCC-capped MSNs |

| Py@MSN | Pyraclostrobin-loaded MSNs |

References

- Enserink, M.; Hines, P.J.; Vignieri, S.N.; Wigginton, N.S.; Yeston, J.S. The pesticide paradox. Science 2013, 341, 728–729. [Google Scholar] [CrossRef] [PubMed]

- Ghormade, V.; Deshpande, M.V.; Paknikar, K.M. Perspectives for nano-biotechnology enabled protection and nutrition of plants. Biotechnol. Adv. 2011, 29, 792–803. [Google Scholar] [CrossRef] [PubMed]

- Mogul, M.G.; Akin, H.; Hasirci, N.; Trantolo, D.J.; Gresser, J.D.; Wise, D.L. Controlled release of biologically active agents for purposes of agricultural crop management. Resour. Conserv. Recycl. 1996, 16, 289–320. [Google Scholar] [CrossRef]

- Campos, E.V.R.; de Oliveira, J.L.; Fraceto, L.F. Applications of controlled release systems for fungicides, herbicides, acaricides, nutrients, and plant growth hormones: A review. Adv. Sci. Eng. Med. 2014, 6, 373–387. [Google Scholar] [CrossRef]

- Campos, E.V.R.; de Oliveira, J.L.; Fraceto, L.F.; Singh, B. Polysaccharides as safer release systems for agrochemicals. Agron. Sustain. Dev. 2015, 35, 47–66. [Google Scholar] [CrossRef]

- Nair, R.; Varghese, S.H.; Nair, B.G.; Maekawa, T.; Yoshida, Y.; Kumar, D.S. Nanoparticulate material delivery to plants. Plant Sci. 2010, 179, 154–163. [Google Scholar] [CrossRef]

- Gogos, A.; Knauer, K.; Bucheli, T.D. Nanomaterials in plant protection and fertilization: Current state, foreseen applications, and research priorities. J. Agric. Food Chem. 2012, 60, 9781–9792. [Google Scholar] [CrossRef] [PubMed]

- Khot, L.R.; Sankaran, S.; Maja, J.M.; Ehsani, R.; Schuster, E.W. Applications of nanomaterials in agricultural production and crop protection: A review. Crop Prot. 2012, 35, 64–70. [Google Scholar] [CrossRef]

- Kah, M.; Beulke, S.; Tiede, K.; Hofmann, T. Nanopesticides: State of knowledge, environmental fate, and exposure modeling. Crit. Rev. Environ. Sci. Technol. 2013, 43, 1823–1867. [Google Scholar] [CrossRef]

- Kah, M.; Hofmann, T. Nanopesticide research: Current trends and future priorities. Environ. Int. 2014, 63, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Nuruzzaman, M.; Rahman, M.M.; Liu, Y.; Naidu, R. Nanoencapsulation, nano-guard for pesticides: A new window for safe application. J. Agric. Food Chem. 2016, 64, 1447–1483. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Huang, Q.; Wu, Y. A novel chitosan-poly(lactide)copolymer and its submicron particles as imidacloprid carriers. Pest. Manag. Sci. 2011, 67, 831–836. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, M.; Fan, T.; Xu, Q.; Wu, Y.; Chen, C.; Huang, Q. Construction of novel amphiphilic chitosan copolymer nanoparticles for chlorpyrifos delivery. J. Polym. Res. 2013, 20. [Google Scholar] [CrossRef]

- Xu, L.; Cao, L.; Li, F.; Wang, X.; Huang, Q. Utilization of chitosan-lactide copolymer nanoparticles as controlled release pesticide carrier for pyraclostrobin against Colletotrichum gossypii Southw. J. Dispers. Sci. Technol. 2014, 35, 544–550. [Google Scholar] [CrossRef]

- Wu, S.H.; Mou, C.Y.; Lin, H.P. Synthesis of mesoporous silica nanoparticles. Chem. Soc. Rev. 2013, 42, 3862–3875. [Google Scholar] [CrossRef] [PubMed]

- Tarn, D.; Ashley, C.E.; Xue, M.; Carnes, E.C.; Zink, J.I.; Brinker, C.J. Mesoporous silica nanoparticle nanocarriers: Biofunctionality and biocompatibility. Acc. Chem. Res. 2013, 46, 792–801. [Google Scholar] [CrossRef] [PubMed]

- Lehman, S.E.; Larsen, S.C. Zeolite and mesoporous silica nanomaterials: Greener syntheses, environmental applications and biological toxicity. Environ. Sci. Nano 2014, 1, 200–213. [Google Scholar] [CrossRef]

- Sun, R.; Wang, W.; Wen, Y.; Zhang, X. Recent advance on mesoporous silica nanoparticles-based controlled release system: Intelligent switches open up new horizon. Nanomaterials 2015, 5, 2019–2053. [Google Scholar] [CrossRef]

- Kuthati, Y.; Sung, P.J.; Weng, C.F.; Mou, C.Y.; Lee, C.H. Functionalization of mesoporous silica nanoparticles for targeting, biocompatibility, combined cancer therapies and theragnosis. J. Nanosci. Nanotechnol. 2013, 13, 2399–2430. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.X.; Li, Z.Z.; Zou, H.K.; Liu, A.Q.; Chen, J.F. Controlled release of avermectin from porous hollow silica nanoparticles. Pest Manag. Sci. 2005, 61, 583–590. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.-Z.; Xu, S.-A.; Wen, L.-X.; Liu, F.; Liu, A.-Q.; Wang, Q.; Sun, H.-Y.; Yu, W.; Chen, J.-F. Controlled release of avermectin from porous hollow silica nanoparticles: Influence of shell thickness on loading efficiency, UV-shielding property and release. J. Control. Release 2006, 111, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, W.; Yu, Y.; Zhang, X.J. Slow-release formulation of a new biological pesticide, pyoluteorin, with mesoporous silica. J. Agric. Food Chem. 2011, 59, 307–311. [Google Scholar] [CrossRef] [PubMed]

- Popat, A.; Liu, J.; Hu, Q.; Kennedy, M.; Peters, B.; Lu, G.Q.; Qiao, S.Z. Adsorption and release of biocides with mesoporous silica nanoparticles. Nanoscale 2012, 4, 970–975. [Google Scholar] [CrossRef] [PubMed]

- Bernardos, A.; Marina, T.; Žáček, P.; Pérez-Esteve, É.; Martínez-Máñez, R.; Lhotka, M.; Kouřimská, L.; Pulkrábek, J.; Klouček, P. Antifungal effect of essential oil components against Aspergillus niger when loaded into silica mesoporous supports. J. Sci. Food Agric. 2015, 95, 2824–2831. [Google Scholar] [CrossRef] [PubMed]

- Aznar, E.; Oroval, M.; Pascual, L.; Murguía, J.R.; Martínez-Máñez, R.; Sancenón, F. Gated materials for on-command release of guest molecules. Chem. Rev. 2016, 116, 561–718. [Google Scholar] [CrossRef] [PubMed]

- Prado, A.G.S.; Moura, A.O.; Nunes, A.R. Nanosized silica modified with carboxylic acid as support for controlled release of herbicides. J. Agric. Food Chem. 2011, 59, 8847–8852. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; He, S.; Liu, Y.; Geng, Q.; Ding, G.; Guo, M.; Deng, Y.; Zhu, J.; Li, J.; Cao, Y. Preparation and characterization of novel functionalized prochloraz microcapsules using silica-alginate-elements as controlled release carrier materials. ACS Appl. Mater. Interfaces 2014, 6, 11783–11790. [Google Scholar] [CrossRef] [PubMed]

- Yi, Z.; Hussain, H.I.; Feng, C.; Sun, D.; She, F.; Rookes, J.E.; Cahill, D.M.; Kong, L. Functionalized mesoporous silica nanoparticles with redox-responsive short-chain gatekeepers for agrochemical delivery. ACS Appl. Mater. Interfaces 2015, 7, 9937–9946. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, P.L.; Xiang, X.; Heiden, P. Chitosan nanoparticle based delivery systems for sustainable agriculture. Int. J. Biol. Macromol. 2015, 77, 36–51. [Google Scholar] [CrossRef] [PubMed]

- Rwei, R.-P.; Chen, Y.-M.; Lin, W.-Y.; Chiang, W.-Y. Synthesis and rheological characterization of water-soluble glycidyltrimethylammonium-chitosan. Mar. Drugs 2014, 12, 5547–5562. [Google Scholar] [CrossRef] [PubMed]

- Kankala, R.K.; Kuthati, Y.; Liu, C.-L.; Mou, C.-Y.; Lee, C.-H. Killing cancer cells by delivering a nanoreactor for inhibition of catalase and catalytically enhancing intracellular levels of ROS. RSC Adv. 2015, 5, 86072–86081. [Google Scholar] [CrossRef]

- Lim, S.-H.; Hudson, S.M. Synthesis and antimicrobial activity of a watersoluble chitosan derivative with a fiber-reactive group. Carbohydr. Res. 2004, 339, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zheng, L.; Li, C.; Zhang, D.; Xiao, Y.; Guan, G.; Zhu, W. A novel and simple procedure to synthesize chitosan-graft-polycaprolactone in an ionic liquid. Carbohydr. Polym. 2013, 94, 505–510. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhang, C.; Qiao, C.; Mu, X.; Li, T.; Xu, J.; Shi, L.; Zhang, D. A simple and convenient method to synthesize N-[(2-hydroxyl)-propyl-3-trimethylammonium] chitosan chloride in an ionic liquid. Carbohydr. Polym. 2015, 130, 325–332. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Z.; Zhi, Z.Z.; Jiang, T.Y.; Zhang, J.H.; Wang, Z.Y.; Wang, S.L. Spherical mesoporous silica nanoparticles for loading and release of the poorly water-soluble drug telmisartan. J. Control. Release 2010, 145, 257–263. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-H.; Lo, L.-W.; Mou, C.-Y.; Yang, C.-S. Synthesis and characterization of positive-charge functionalized mesoporous silica nanoparticles for oral drug delivery of an anti-inflammatory drug. Adv. Funct. Mater. 2008, 18, 3283–3292. [Google Scholar] [CrossRef]

- Radu, D.R.; Lai, C.-Y.; Jeftinija, K.; Rowe, E.W.; Jeftinija, S.; Lin, V.S.-Y. A polyamidoamine dendrimer-capped mesoporous silica nanosphere-based gene transfection reagent. J. Am. Chem. Soc. 2004, 126, 13216–13217. [Google Scholar] [CrossRef] [PubMed]

| Entry | Pesticide (mg) | HTCC (mg) | LC (%) | Zeta potential (mV) |

|---|---|---|---|---|

| 1 | 30 | 60 | 28.5 | 28.9 |

| 2 | 45 | 60 | 34.8 | 30.2 |

| 3 | 60 | 60 | 40.3 | 32.4 |

| 4 | 75 | 60 | 41.6 | 28.8 |

| 5 | 40 | 40 | 32.4 | 29.2 |

| 6 | 60 | 40 | 39.5 | 31.6 |

| 7 | 60 | 80 | 41.2 | 34.6 |

| 8 | 60 | / | 26.7 | −17.6 |

| Sample | SBET (m2/g) | Vt (cm3/g) | DBJH (nm) |

|---|---|---|---|

| MSNs | 1138.73 | 1.28 | 3.73 |

| Py@MSNs | 543.45 | 0.59 | 3.48 |

| Py@MSNs-HTCC | 29.02 | 0.22 | 59.79 * |

| Py@MSNs-HTCC calcined | 960.17 | 1.14 | 3.88 |

| Sample | Concentration (mg/L) | Colony Diameter (cm) | Percentage of Inhibition (%) |

|---|---|---|---|

| Pyraclostrobin technical (PT) | CK | 6.4 | / |

| 5.0 | 1.1 | 92.98 | |

| 20.0 | 0.9 | 96.49 | |

| Py@MSNs-HTCC (NP) | CK | 6.4 | / |

| 2.5 | 1.4 | 87.72 | |

| 10.0 | 1.0 | 94.74 | |

| MSNs-HTCC (CB) | CK | 6.4 | / |

| 5.0 | 3.7 | 26.32 | |

| 20.0 | 4.9 | 47.37 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Zhang, H.; Cao, C.; Zhang, J.; Li, F.; Huang, Q. Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release. Nanomaterials 2016, 6, 126. https://doi.org/10.3390/nano6070126

Cao L, Zhang H, Cao C, Zhang J, Li F, Huang Q. Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release. Nanomaterials. 2016; 6(7):126. https://doi.org/10.3390/nano6070126

Chicago/Turabian StyleCao, Lidong, Huirong Zhang, Chong Cao, Jiakun Zhang, Fengmin Li, and Qiliang Huang. 2016. "Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release" Nanomaterials 6, no. 7: 126. https://doi.org/10.3390/nano6070126

APA StyleCao, L., Zhang, H., Cao, C., Zhang, J., Li, F., & Huang, Q. (2016). Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release. Nanomaterials, 6(7), 126. https://doi.org/10.3390/nano6070126