Porous Silicon Photonic Crystals Coated with Ag Nanoparticles as Efficient Substrates for Detecting Trace Explosives Using SERS

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of Porous Silicon Photonic Crystals

2.3. In Situ Synthesis of Silver Nanoparticles on Porous Silicon Photonic Crystals

2.4. Characterization

2.5. Raman Measurement

3. Results and Discussion

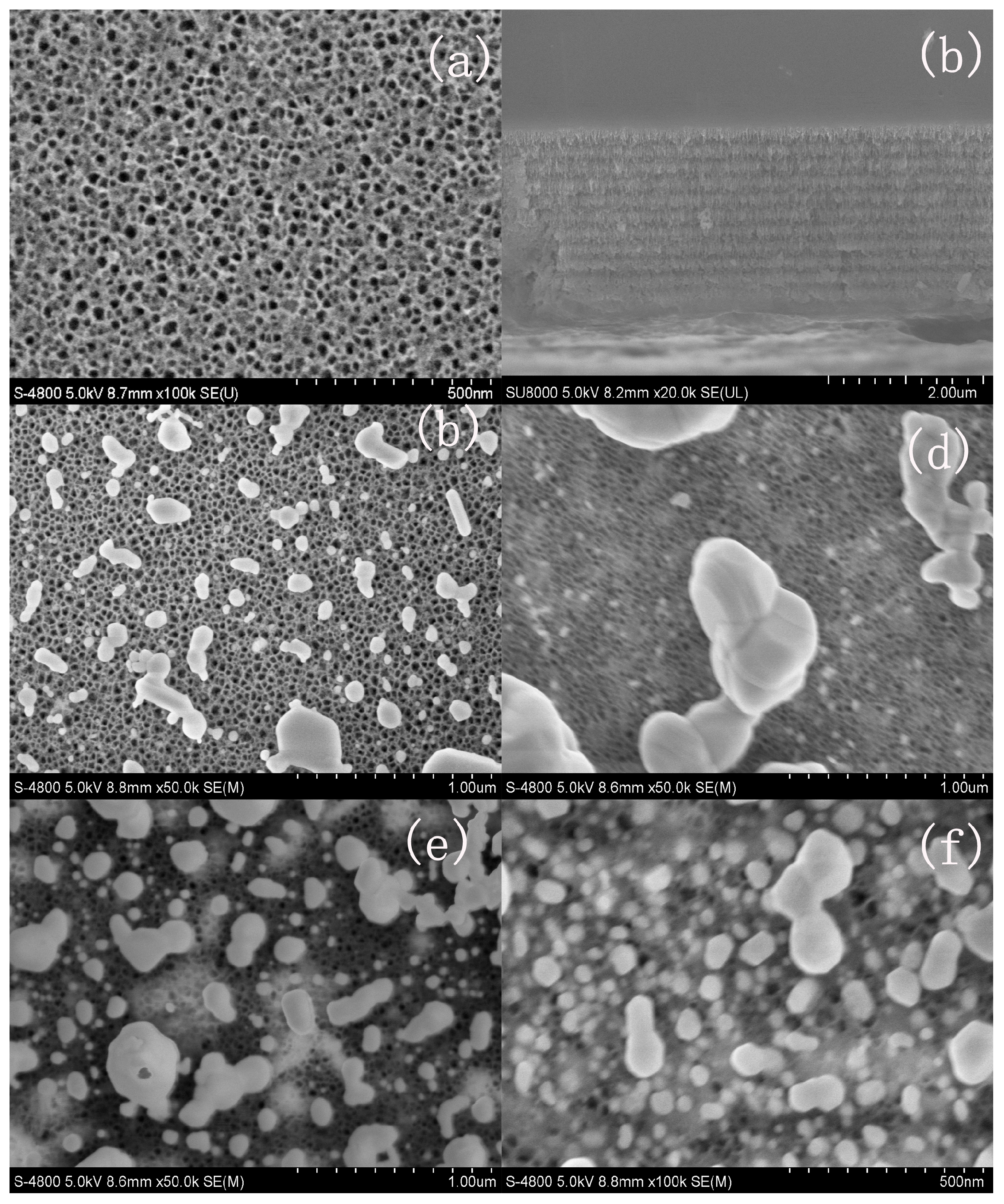

3.1. Structure and Morphological Characteristics

3.2. Reflectance and Raman Spectrum

3.3. Raman Scattering

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, N.; Ding, P.; Shi, Y.; Jin, T.; Su, Y.; Wang, H.; He, Y. Portable and Reliable Surface-Enhanced Raman Scattering Silicon Chip for Signal-on Detection of Trace Trinitrotoluene Explosive in Real Systems. Anal. Chem. 2017, 89, 5072–5078. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Lu, R.; Shen, J.; Han, W.; Sun, X.; Li, J.; Wang, L. Electrospun Flexible Poly(Bisphenol a Carbonate) Nanofibers Decorated with Ag Nanoparticles as Effective 3D SERS Substrates for Trace TNT Detection. Analyst 2017, 142, 4756–4764. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Liu, B.; Dou, X. Silver Nanotriangles-Loaded Filter Paper for Ultrasensitive SERS Detection Application Benefited by Interspacing of Sharp Edges. Sens. Actuators B Chem. 2016, 231, 357–364. [Google Scholar] [CrossRef]

- Cui, Y.; Jin, Y.; Chen, X.; Wu, J. Two-Dimensional Electrochemiluminescence on Porous Silicon Platform for Explosive Detection and Discrimination. ACS Sens. 2018, 3, 1439–1444. [Google Scholar] [CrossRef] [PubMed]

- Gou, Z.; Zuo, Y.; Tian, M.; Lin, W. Siloxane-Based Nanoporous Polymers with Narrow Pore-Size Distribution for Cell Imaging and Explosive Detection. ACS Appl. Mater. Interfaces 2018, 10, 28979–28991. [Google Scholar] [CrossRef] [PubMed]

- Mosier-Boss, P.A. Review of SERS Substrates for Chemical Sensing. Nanomaterials 2017, 7, 146. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhou, H.; Hu, Z.; Yu, G.; Yang, D.; Zhao, J. Label and Label-Free Based Surface-Enhanced Raman Scattering for Pathogen Bacteria Detection: A Review. Biosens. Bioelectron. 2017, 94, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Hakonen, A.; Andersson, P.O.; Schmidt, M.S.; Rindzevicius, T.; Kall, M. Explosive and Chemical Threat Detection by Surface-Enhanced Raman Scattering: A Review. Anal. Chim. Acta 2015, 893, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Kneipp, J.; Kneipp, H.; Kneipp, K. SERS—A Single-Molecule and Nanoscale Tool for Bioanalytics. Chem. Soc. Rev. 2008, 37, 1052–1560. [Google Scholar] [CrossRef] [PubMed]

- Sharma, B.; Frontiera, R.R.; Henry, A.I.; Ringe, E.; Van Duyne, R.P. SERS: Materials, Applications, and the Future. Mater. Today 2012, 15, 16–25. [Google Scholar] [CrossRef]

- Chou, A.; Jaatinen, E.; Buividas, R.; Seniutinas, G.; Juodkazis, S.; Izake, E.L.; Fredericks, P.M. SERS Substrate for Detection of Explosives. Nanoscale 2012, 4, 7419–7424. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, H.X.; Xue, L.; Zhang, Y.H.; Zhang, Y.F.; Cao, L.Y. Functionalized Gold Nanoparticles Coated Polymer Spheres as SERS Substrate for the Detection of TNT Explosives. Adv. Mater. Res. 2014, 924, 366–370. [Google Scholar] [CrossRef]

- Byram, C.; Moram, S.S.B.; Shaik, A.K.; Soma, V.R. Versatile Gold Based SERS Substrates Fabricated by Ultrafast Laser Ablation for Sensing Picric Acid and Ammonium Nitrate. Chem. Phys. Lett. 2017, 685, 103–107. [Google Scholar] [CrossRef]

- Hakonen, A.; Wang, F.; Andersson, P.O.; Wingfors, H.; Rindzevicius, T.; Schmidt, M.S.; Soma, V.R.; Xu, S.; Li, Y.; Boisen, A.; et al. Hand-Held Femtogram Detection of Hazardous Picric Acid with Hydrophobic Ag Nanopillar SERS Substrates and Mechanism of Elasto-Capillarity. ACS Sens. 2017, 2, 198–202. [Google Scholar] [CrossRef] [PubMed]

- Myndrul, V.; Viter, R.; Savchuk, M.; Shpyrka, N.; Erts, D.; Jevdokimovs, D.; Silamikelis, V.; Smyntyna, V.; Ramanavicius, A.; Iatsunskyi, I. Porous Silicon Based Photoluminescence Immunosensor for Rapid and Highly-Sensitive Detection of Ochratoxin A. Biosens. Bioelectron. 2018, 102, 661–667. [Google Scholar] [CrossRef] [PubMed]

- Ensafi, A.A.; Rezaloo, F.; Rezaei, B. Department. Electrochemical Sensor Based on Porous Silicon/Silver Nanocomposite for the Determination of Hydrogen Peroxide. Sens. Actuators B Chem. 2016, 231, 239–244. [Google Scholar] [CrossRef]

- Li, Y.; Jia, Z.; Lv, G.; Wen, H.; Li, P.; Zhang, H.; Wang, J. Detection of Echinococcus Granulosus Antigen by a Quantum Dot/Porous Silicon Optical Biosensor. Biomed. Opt. Express 2017, 8, 3458–3469. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jia, Z.; Lv, C. Enhanced Raman Scattering in Porous Silicon Grating. Opt. Express 2018, 26, 6507–6518. [Google Scholar] [CrossRef] [PubMed]

- Dridi, H.; Haji, L.; Moadhen, A. Rough Sers Substrate Based on Gold Coated Porous Silicon Layer Prepared on the Silicon Backside Surface. Superlattices Microstruct. 2017, 104, 266–270. [Google Scholar] [CrossRef]

- Kalimuthu, V.; Rath, S. One-Step Synthesis of Au-Coated Porous Silicon as a Surface Enhanced Raman Scattering Substrate for Biomolecule Detection. Mater. Lett. 2017, 204, 115–119. [Google Scholar] [CrossRef]

- Qiu, C.; Zhou, H.; Yang, H.; Chen, M.; Guo, Y.; Sun, L. Investigation of N-Layer Graphenes as Substrates for Raman Enhancement of Crystal Violet. J. Phys. Chem. C 2011, 115, 10019–10025. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, Y.; Hang, L.; Li, H.; Liu, G.; Zhang, X.; Lyu, X.; Cai, W.; Li, Y. Periodic Porous Alloyed Au-Ag Nanosphere Arrays and Their Highly Sensitive Sers Performance with Good Reproducibility and High Density of Hotspots. ACS Appl. Mater. Interfaces 2018, 10, 9792–9801. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Xi, Y.; LeDuff, P.; Li, E.; Liu, Y.; Cheng, L.J.; Rorrer, G.L.; Tan, H.; Wang, A.X. Optofluidic Sensing from Inkjet-Printed Droplets: The Enormous Enhancement by Evaporation-Induced Spontaneous Flow on Photonic Crystal Biosilica. Nanoscale 2016, 8, 17285–17294. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Zhu, W.; Jin, Y.; Crozier, K.B. Surface-Enhanced Raman Scattering with Ag Nanoparticles Optically Trapped by a Photonic Crystal Cavity. Nano Lett. 2013, 13, 559–563. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.Q.; Ren, B.; Wu, D.Y. Surface-Enhanced Raman Scattering: From Noble to Transition Metals and from Rough Surfaces to Ordered Nanostructures. J. Phys. Chem. B 2002, 106, 9463–9483. [Google Scholar] [CrossRef]

- Najar, A.; Charrier, J.; Pirasteh, P.; Sougrat, R. Ultra-Low Reflection Porous Silicon Nanowires for Solar Cell Applications. Opt. Express 2012, 20, 16861–16870. [Google Scholar] [CrossRef]

- Stewart, M.P.; Buriak, J.M. Chemical and Biological Applications of Porous Silicon Technology. Adv. Mater. 2000, 12, 859–869. [Google Scholar] [CrossRef]

- Sampath, S.; Maydannik, P.; Ivanova, T.; Shestakova, M.; Homola, T.; Bryukvin, A.; Sillanpaa, M.; Nagumothu, R.; Alagan, V. Efficient Solar Photocatalytic Activity of TiO2 Coated Nano-Porous Silicon by Atomic Layer Deposition. Superlattices Microstruct. 2016, 97, 155–166. [Google Scholar] [CrossRef]

- Severiano, F.; Gayou, V.L.; Garcia, G.; Macuil, R.D.; Gutierrez, H.M.; Nieto, G.; Diaz, T. In Situ Inclusion of Au Nanoparticles in Porous Silicon Structure. Appl. Phys. A 2017, 123, 83. [Google Scholar] [CrossRef]

- Zhang, X.G. Morphology and Formation Mechanisms of Porous Silicon. J. Electrochem. Soc. 2004, 151, C69–C80. [Google Scholar] [CrossRef]

- Zhong, F.; Jia, Z. Raman Scattering Study on Pristine and Oxidized N-Type Porous Silicon. Physica B Condens. Matter 2013, 411, 77–80. [Google Scholar] [CrossRef]

- Zeiri, L.; Rechav, K.; Porat, Z.E.; Zeiri, Y. Silver Nanoparticles Deposited on Porous Silicon as a Surface-Enhanced Raman Scattering (SERS) Active Substrate. Appl. Spectrosc. 2012, 66, 294–299. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.Y.; Wei, C.M.; Yang, L.; Chou, M.Y. Quantum Confinement and Electronic Properties of Silicon Nanowires. Phys. Rev. Lett. 2004, 92, 236805. [Google Scholar] [CrossRef] [PubMed]

- Piscanec, S.; Cantoro, M.; Ferrari, A.C.; Zapien, J.A.; Lifshitz, Y.; Lee, S.T.; Hofmann, S.; Robertson, J. Raman Spectroscopy of Silicon Nanowires. Phys. Rev. B 2003, 68, 241312. [Google Scholar] [CrossRef]

- Watanabe, H.; Hayazawa, N.; Inouye, Y.; Kawata, S. DFT Vibrational Calculations of Rhodamine 6G Adsorbed on Silver: Analysis of Tip-Enhanced Raman Spectroscopy. J. Phys. Chem. B 2005, 109, 5012–5020. [Google Scholar] [CrossRef] [PubMed]

- Hildebrandt, P.; Stockburger, M. Surface-Enhanced Resonance Raman Spectroscopy of Rhodamine 6G Adsorbed on Colloidal Silver. J. Phys. Chem. 1984, 88, 5935–5944. [Google Scholar] [CrossRef]

- Virga, A.; Rivolo, P.; Frascella, F.; Angelini, A.; Descrovi, E.; Geobaldo, F.; Giorgis, F. Silver Nanoparticles on Porous Silicon: Approaching Single Molecule Detection in Resonant Sers Regime. J. Phys. Chem. C 2013, 117, 20139–20145. [Google Scholar] [CrossRef]

- Lu, G.; Wang, G.; Li, H. Effect of Nanostructured Silicon on Surface Enhanced Raman Scattering. RSC Adv. 2018, 8, 6629–6633. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Wang, A.J.; Chen, S.S.; Luo, X. Feng, J.J Facile Synthesis of AgPt@Ag Core-Shell Nanoparticles as Highly Active Surface-Enhanced Raman Scattering Substrates. Sens. Actuators B Chem. 2018, 260, 945–952. [Google Scholar] [CrossRef]

- Shaik, U.P.; Hamad, S.; Ahamad Mohiddon, M.; Soma, V.R.; Ghanashyam Krishna, M. Morphologically Manipulated Ag/ZnO Nanostructures as Surface Enhanced Raman Scattering Probes for Explosives Detection. J. Appl. Phys. 2016, 119, 093103. [Google Scholar] [CrossRef]

- Jamil, A.K.; Izake, E.L.; Sivanesan, A.; Fredericks, P.M. Rapid Detection of Tnt in Aqueous Media by Selective Label Free Surface Enhanced Raman Spectroscopy. Talanta 2015, 134, 732–738. [Google Scholar] [CrossRef] [PubMed]

- Kosovic, M.; Balarin, M.; Ivanda, M.; Derek, V.; Marcius, M.; Ristic, M.; Gamulin, O. Porous Silicon Covered with Silver Nanoparticles as Surface-Enhanced Raman Scattering (SERS) Substrate for Ultra-Low Concentration Detection. Appl. Spectrosc. 2015, 69, 1417–1424. [Google Scholar] [CrossRef] [PubMed]

- Novara, C.; Dalla Marta, S.; Virga, A.; Lamberti, A.; Angelini, A.; Chiado, A.; Rivolo, P.; Geobaldo, F.; Sergo, V.; Bonifacio, A.; et al. SERS-Active Ag Nanoparticles on Porous Silicon and Pdms Substrates: A Comparative Study of Uniformity and Raman Efficiency. J. Phys. Chem. C 2016, 120, 16946–16953. [Google Scholar] [CrossRef]

- Lai, Y.C.; Ho, H.C.; Shih, B.W.; Tsai, F.Y.; Hsueh, C.H. High Performance and Reusable Sers Substrates Using Ag/ZnO Heterostructure on Periodic Silicon Nanotube Substrate. Appl. Surf. Sci. 2018, 439, 852–858. [Google Scholar] [CrossRef]

- Alessandri, I. Enhancing Raman Scattering without Plasmons: Unprecedented Sensitivity Achieved by TiO2 Shell-Based Resonators. J. Am. Chem. Soc. 2013, 135, 5541–5544. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Ni, H.; Zhang, D.; Wang, D.; Fu, D.; Chen, H.; Gu, Z.; Zhao, X. Ultrasensitive Detection of Protein with Wide Linear Dynamic Range Based on Core-Shell Sers Nanotags and Photonic Crystal Beads. ACS Sens. 2017, 2, 1035–1043. [Google Scholar] [CrossRef] [PubMed]

| PA Raman Shift (cm−1) | Assignment [3] | R6G Raman Shift (cm−1) | Assignment [35,36] |

|---|---|---|---|

| 825 | C–H bending | 612 | C−C ring in-plane bending in xanthene/phenyl rings |

| 938 | ring breathing | 772 | C−H out-of-plane bending |

| 1088 | phenolic C–O stretching | 797 | hybrid mode (xanthene/phenyl rings and NHC2H5 group) |

| 1330 | C–C stretching | 1127 | C−H in-plane bending in xanthene/phenyl rings |

| 1335 | NO2 symmetric stretching | 1187 | C−H in-plane bending in xanthene ring |

| 1564 | C–NO2 asymmetric stretching | 1204 | hybrid mode (xanthene/phenyl rings) |

| 1275 | C−O−C stretching in COOC2H5 group on phenyl ring | ||

| 1312 | hybrid mode (xanthene/phenyl rings and NHC2H5 group) | ||

| 1363 | C−C stretching in xanthene ring | ||

| 1449 | C−N stretching in NHC2H5 | ||

| 1509 | C−C stretching in xanthene ring | ||

| 1575 | C−C stretching in phenyl ring | ||

| 1595 | hybrid mode (phenyl ring with COOC2H5 | ||

| 1651 | C−C stretching in xanthene ring |

| Substrate | Detection Limit (mol/L) | Ref. |

|---|---|---|

| Positively charged silver nanoparticles | 2.5 × 10−5 | [11] |

| Versatile gold-based SERS substrates | 10−6 | [13] |

| Ag nanotriangles-loaded filter paper | 10−6 | [3] |

| Ag nanoparticles-loaded porous silicon | 10−8 | This work |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, F.; Wu, Z.; Guo, J.; Jia, D. Porous Silicon Photonic Crystals Coated with Ag Nanoparticles as Efficient Substrates for Detecting Trace Explosives Using SERS. Nanomaterials 2018, 8, 872. https://doi.org/10.3390/nano8110872

Zhong F, Wu Z, Guo J, Jia D. Porous Silicon Photonic Crystals Coated with Ag Nanoparticles as Efficient Substrates for Detecting Trace Explosives Using SERS. Nanomaterials. 2018; 8(11):872. https://doi.org/10.3390/nano8110872

Chicago/Turabian StyleZhong, Furu, Zhaofeng Wu, Jixi Guo, and Dianzeng Jia. 2018. "Porous Silicon Photonic Crystals Coated with Ag Nanoparticles as Efficient Substrates for Detecting Trace Explosives Using SERS" Nanomaterials 8, no. 11: 872. https://doi.org/10.3390/nano8110872

APA StyleZhong, F., Wu, Z., Guo, J., & Jia, D. (2018). Porous Silicon Photonic Crystals Coated with Ag Nanoparticles as Efficient Substrates for Detecting Trace Explosives Using SERS. Nanomaterials, 8(11), 872. https://doi.org/10.3390/nano8110872