A Universal Solution of Controlling the Distribution of Multimaterials during Macroscopic Manipulation via a Microtopography-Guided Substrate

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

3.1. Deposition Mathematical Model

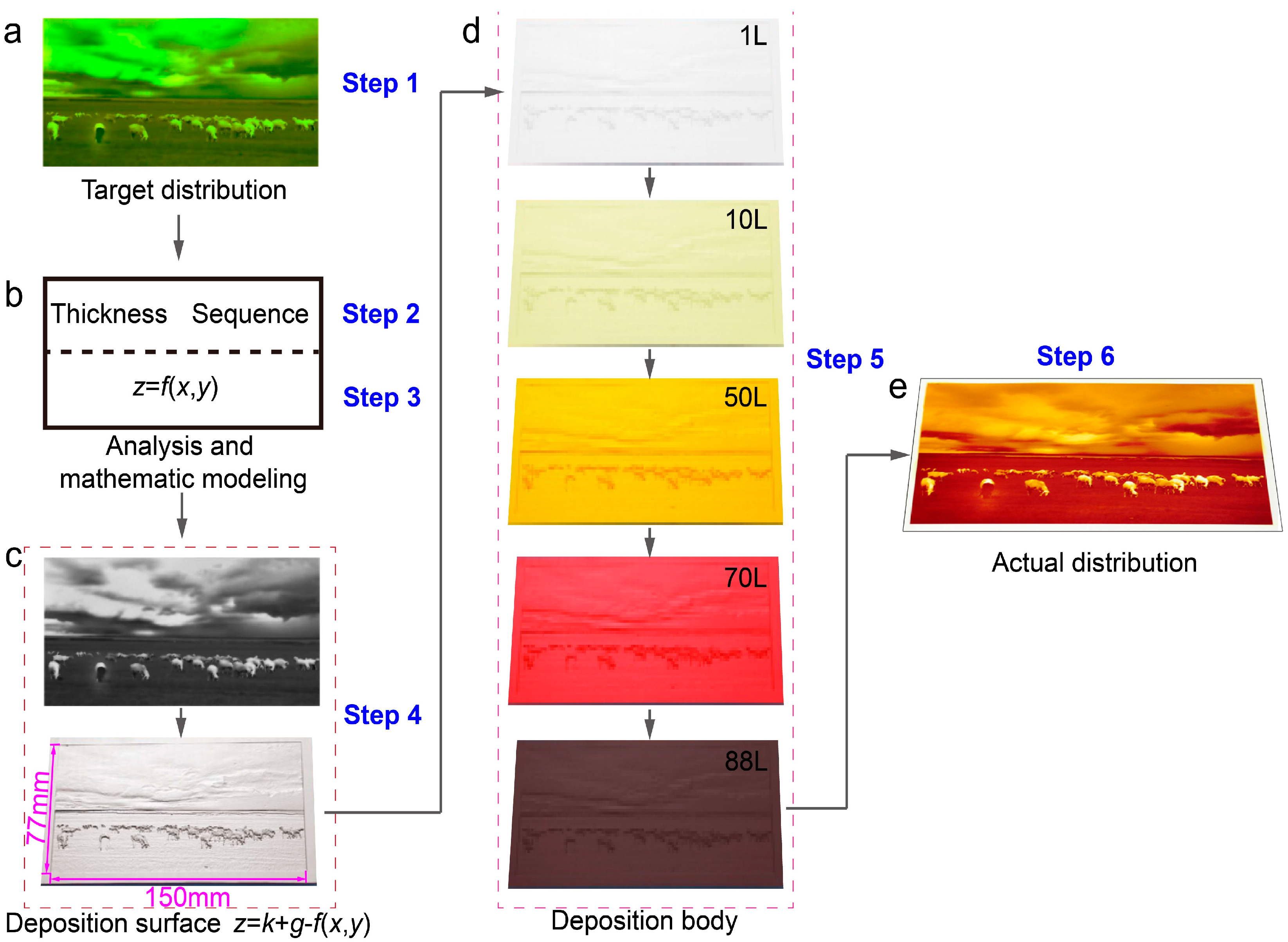

3.2. LMP-Method

3.3. Accuracy of LMP-Method of Manipulating Multimaterials

3.4. Example 1: Mimic of Cell Distribution on Quartz by Using Different Rate of Tungsten/Aluminum Composites via Magnetron Sputtering

3.5. Examples 2: Distributing Landscape Image through LMP-Method Using Sublimation Manipulation

3.6. Discussion about Materials and Techniques Dependent Constrains

4. Summary

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Binnig, G.; Rohrer, H.; Gerber, C.; Weibel, E. Tunneling through a controllable vacuum gap. Appl. Phys. Lett. 1982, 40, 178–180. [Google Scholar] [CrossRef]

- Binnig, G.; Rohrer, H.; Gerber, C.; Weibel, E. Surface studies by scanning tunneling micscopy. Phys. Rev. Lett. 1982, 49, 57–61. [Google Scholar] [CrossRef]

- Binnig, G.; Rohrer, H. Scanning tunnelling microscope. Surf. Sci. 1983, 126, 236–244. [Google Scholar] [CrossRef]

- Eigler, D.M.; Schweizer, E.K. Positioning single atoms with a scanning tunnelling microscope. Nature 1990, 344, 524–526. [Google Scholar] [CrossRef]

- Drexler, K.E. Molecular manufacturing: Perspectives on the ultimate limits of fabrication. Phil. Trans. R. Soc. Lond. A 1995, 353, 323–331. [Google Scholar] [CrossRef]

- Crommie, M.F.; Lutz, C.P.; Eigler, D.M. Confinement of electrons to quantum corrals on a metal surface. Science 1993, 262, 218–220. [Google Scholar] [CrossRef] [PubMed]

- Sager, R.J.; Klein, P.J.; Lagoudas, D.C.; Zhang, Q.; Liu, J.; Dai, L.; Baur, J.W. Effect of carbon nanotubes on the interfacial shear strength of T650 carbon fiber in an epoxy matrix. Compos. Sci. Technol. 2009, 69, 898–904. [Google Scholar] [CrossRef]

- Reina, A.; Jia, X.; Ho, J.; Nezich, D.; Son, H.; Bulovic, V.; Dresselhaus, M.S.; Kong, J. Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett. 2009, 9, 30–35. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Luna, E.; Aoki, T.; Steenbergen, E.H.; Zhang, Y.; Smith, D.J. Evaluation of antimony segregation in InAs/InAs1−xSbx type-II superlattices grown by molecular beam epitaxy. J. Appl. Phys. 2016, 119, 95702. [Google Scholar] [CrossRef]

- Ferrante, F.; Armata, N.; Cavallaro, G.; Lazzara, G. Adsorption studies of molecules on the halloysite surfaces: A computational and experimental investigation. J. Phys. Chem. C 2017, 121, 2951–2958. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Fishlock, T.W.; Oral, A.; Egdell, R.G.; Pethica, J.B. Manipulation of atoms across a surface at room temperature. Nature 2000, 404, 743–745. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oyabu, N.; Sugimoto, Y.; Abe, M.; Custance, O.; Morita, S. Lateral manipulation of single atoms at semiconductor surfaces using atomic force microscopy. Nanotechnology 2005, 16, S112. [Google Scholar] [CrossRef]

- Trevethan, T.; Watkins, M.; Kantorovich, L.N.; Shluger, A.L. Controlled manipulation of atoms in insulating surfaces with the virtual atomic force microscope. Phys. Rev. Lett. 2007, 98, 028101. [Google Scholar] [CrossRef] [PubMed]

- Sugimoto, Y.; Pou, P.; Custance, O.; Jelinek, P.; Abe, M.; Perez, R.; Morita, S. Complex Patterning by Vertical Interchange Atom Manipulation Using Atomic Force Microscopy. Science 2008, 322, 413–417. [Google Scholar] [CrossRef]

- Custance, O.; Perez, R.; Morita, S. Atomic force microscopy as a tool for atom manipulation. Nat. Nanotech. 2009, 4, 803–810. [Google Scholar] [CrossRef] [PubMed]

- Swart, I.; Sonnleitner, T.; Niedenführ, J.; Repp, J. Controlled lateral manipulation of molecules on insulating films by STM. Nano Lett. 2012, 12, 1070–1074. [Google Scholar] [CrossRef] [PubMed]

- Torbrugge, S.; Custance, O.; Morita, S.; Reichling, M. Manipulation of individual water molecules on CeO2(111). J. Phys. Condens. Matter 2012, 24, 084010. [Google Scholar] [CrossRef] [PubMed]

- Kawai, S.; Foster, A.S.; Canova, F.F.; Onodera, H.; Kitamura, S.; Meyer, E. Atom manipulation on an insulating surface at room temperature. Nat. Commun. 2014, 5, 4403. [Google Scholar] [CrossRef] [Green Version]

- Bamidele, J.; Lee, S.H.; Kinoshita, Y.; Turanský, R.; Naitoh, Y.; Li, Y.J.; Sugawara, Y.; Štich, I.; Kantorovich, L. Vertical atomic manipulation with dynamic atomic-force microscopy without tip change via a multi-step mechanism. Nat. Commun. 2014, 5, 4476. [Google Scholar] [CrossRef]

- Hla, S.W. Atom-by-atom assembly. Rep. Prog. Phys. 2014, 77, 056502. [Google Scholar] [CrossRef] [PubMed]

- Pavliček, N.; Schuler, B.; Collazos, S.; Moll, N.; Pérez, D.; Guitián, E.; Meyer, G.; Peña, D.; Gross, L. On-surface generation and imaging of arynes by atomic force microscopy. Nat. Chem. 2015, 7, 623–628. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, H.Y.; Schouteden, K.; Lauwaet, K.; Janssens, E.; Haesendonck, C.; Van Pacchioni, G.; Lievens, P. Lateral Manipulation of atomic vacancies in ultrathin insulating films. ACS Nano 2015, 9, 5318–5325. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Chen, J.; Fan, L.; Dieguez, O.; Cao, J.; Pan, Z.; Wang, Y.; Wang, J.; Kim, M.; Deng, S.; et al. Giant polarization in super-tetragonal thin films through interphase strain. Science 2018, 361, 494–497. [Google Scholar] [PubMed]

- Zhong, W.; Deng, S.; Wang, K.; Li, G.; Li, G.; Chen, R.; Kwok, H. Feasible route for a large area few-layer MoS2 with magnetron sputtering. Nanomaterials 2018, 8, 590. [Google Scholar] [CrossRef] [PubMed]

- Poh, S.M.; Tan, S.J.R.; Zhao, X.; Chen, Z.; Abdelwahab, I.; Fu, D.; Xu, H.; Bao, Y.; Zhou, W.; Loh, K.P. Large area synthesis of 1D-MoSe2 using molecular beam epitaxy. Adv. Mater. 2017, 29, 1605641. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Yin, A.; Mao, J.; Xia, Y.; Kempf, N.; He, Q.; Wang, Y.; Chen, C.; Zhang, Y.; Ozolins, V.; et al. Scalable solution-phase epitaxial growth of symmetry-mismatched heterostructures on two-dimensional crystal soft template. Sci. Adv. 2016, 2, e1600993. [Google Scholar] [CrossRef]

- Rodofili, A.; Wolke, W.; Kroely, L.; Bivour, M.; Cimiotti, G.; Bartsch, J.; Glatthaar, M.; Nekarda, J. Laser transfer and firing of NiV seed layer for the metallization of silicon heterojunction solar cells by cu-plating. Solar RRL 2017, 1, 1700085. [Google Scholar] [CrossRef]

- Tung, H.; Guan, Z.; Liu, T.; Chen, H. Vapor sublimation and deposition to build porous particles and composites. Nat. Commun. 2018, 9, 2564. [Google Scholar] [CrossRef]

- Li, S.-C.; Jia, J.-F.; Xue, Q.-K. Fabricating artificial nanostructures through manipulation of large numbers of atoms. Sciencepaper Online 2007, 2, 243–247. [Google Scholar]

- Drexler, K.E. Engines of Creation: The Coming Era of Nanotechnology; Anchor Press: New York, NY, USA, 1986; pp. 12–51. [Google Scholar]

- Hardin, J.O.; Ober, T.J.; Valentine, A.D.; Lewis, J.A. Microfluidic Printheads for Multimaterial 3D Printing of Viscoelastic Inks. Adv. Mater. 2015, 27, 3279–3284. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.; Ueda, K.; Gantumur, E.; Taya, M.; Nakamura, M. Drop-on-drop multimaterial 3d bioprinting realized by peroxidase-mediated cross-linking. Macromol. Rapid Commun. 2018, 39, 1700534. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Pohl, R.; Qi, L.; Römer, G.; Sun, C.; Lohse, D.; Visser, C.W. Printing functional 3D microdevices by laser-induced forward transfer. Small 2017, 13, 1602553. [Google Scholar] [CrossRef] [PubMed]

- Zadpoor, A.A.; Malda, J. Additive manufacturing of biomaterials, tissues, and organs. Ann. Biomed. Eng. 2017, 45, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Feng, P.; Akhtar, F. Aluminium matrix tungsten aluminide and tungsten reinforced composites by solid-state diffusion mechanism. Sci. Rep. 2017, 7, 12391. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Song, J.; Pan, L.; Zhang, X.; Wang, L.; Zou, J. Tungsten oxides for photocatalysis, electrochemistry, and phototherapy. Adv. Mater. 2015, 27, 5309–5327. [Google Scholar] [CrossRef]

- Angarita, G.; Palacio, C.; Trujillo, M.; Arroyave, M. Synthesis of alumina thin films using reactive magnetron sputtering method. J. Phys. Confer. Ser. 2017, 850, 012022. [Google Scholar] [CrossRef]

- Sinha, A.K. Cryogenic Technology and Applications; Jha, A.R., Ed.; Butterworth-Heinemann: Burlington, NJ, USA, 2006. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhang, F.; Zhang, J.; Guo, B.; Wang, Z. A Universal Solution of Controlling the Distribution of Multimaterials during Macroscopic Manipulation via a Microtopography-Guided Substrate. Nanomaterials 2018, 8, 1036. https://doi.org/10.3390/nano8121036

Li C, Zhang F, Zhang J, Guo B, Wang Z. A Universal Solution of Controlling the Distribution of Multimaterials during Macroscopic Manipulation via a Microtopography-Guided Substrate. Nanomaterials. 2018; 8(12):1036. https://doi.org/10.3390/nano8121036

Chicago/Turabian StyleLi, Changhai, Fengqiang Zhang, Jia Zhang, Bin Guo, and Zhenlong Wang. 2018. "A Universal Solution of Controlling the Distribution of Multimaterials during Macroscopic Manipulation via a Microtopography-Guided Substrate" Nanomaterials 8, no. 12: 1036. https://doi.org/10.3390/nano8121036