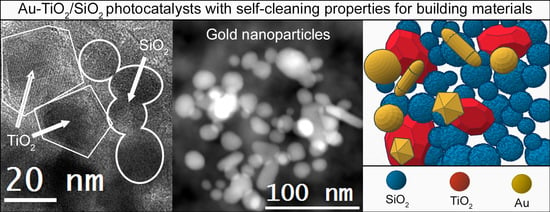

TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of AuNPs

2.2. Au-TiO2/SiO2 Synthesis

2.3. Sol-Gel Characterization

2.4. Application on Building Material and Characterization

3. Results and Discussion

3.1. Sol-Gel Characterization

3.2. Application on Stone and Characterization

- -

- -

- The coating restricts the MB penetration into the substrate and it has a large surface area compared with the stone. Therefore, MB is more exposed to light, oxygen and humidity.

- -

- The stone has a greater absorption in the UV range than the silica coating (see Figure S10). This reduces the amount of high energy light available to produce the MB photolysis.

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Peruchon, L.; Puzenat, E.; Girard-Egrot, A.; Blum, L.; Herrmann, J.M.; Guillard, C. Characterization of self-cleaning glasses using Langmuir–Blodgett technique to control thickness of stearic acid multilayers. J. Photochem. Photobiol. A Chem. 2008, 197, 170–176. [Google Scholar] [CrossRef]

- Chen, J.; Poon, C.S. Photocatalytic construction and building materials: From fundamentals to applications. Build. Environ. 2009, 44, 1899–1906. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical Photolysis of Water at a Semiconductor Electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Watanabe, T.; Nakajima, A.; Wang, R.; Minabe, M.; Koizumi, S.; Fujishima, A.; Hashimoto, K. Photocatalytic activity and photoinduced hydrophilicity of titanium dioxide coated glass. Thin Solid Films 1999, 351, 260–263. [Google Scholar] [CrossRef]

- Xiaohong, W.; Zhaohua, J.; Huiling, L.; Xuandong, L.; Xinguo, H. TiO2 ceramic films prepared by micro-plasma oxidation method for photodegradation of rhodamine B. Mater. Chem. Phys. 2003, 80, 39–43. [Google Scholar] [CrossRef]

- Radeka, M.; Markov, S.; Lončar, E.; Rudić, O.; Vučetić, S.; Ranogajec, J. Photocatalytic effects of TiO2 mesoporous coating immobilized on clay roofing tiles. J. Eur. Ceram. Soc. 2014, 34, 127–136. [Google Scholar] [CrossRef]

- Gherardi, F.; Colombo, A.; D’Arienzo, M.; Di Credico, B.; Goidanich, S.; Morazzoni, F.; Simonutti, R.; Toniolo, L. Efficient self-cleaning treatments for built heritage based on highly photo-active and well-dispersible TiO2 nanocrystals. Microchem. J. 2016, 126, 54–62. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Q.; Zhu, Z.; Zhang, J.; Zhang, B. Application of TiO2 photocatalyst to the stone conservation. Mater. Res. Innov. 2015, 19, S8. [Google Scholar] [CrossRef]

- Bergamonti, L.; Alfieri, I.; Lorenzi, A.; Predieri, G.; Barone, G.; Gemelli, G.; Mazzoleni, P.; Raneri, S.; Bersani, D.; Lottici, P.P. Nanocrystalline TiO2 coatings by sol–gel: Photocatalytic activity on Pietra di Noto biocalcarenite. J. Sol-Gel Sci. Technol. 2015, 75, 141–151. [Google Scholar] [CrossRef]

- Licciulli, A.; Calia, A.; Lettieri, M.; Diso, D.; Masieri, M.; Franza, S.; Amadelli, R.; Casarano, G. Photocatalytic TiO2 coatings on limestone. J. Sol-Gel Sci. Technol. 2011, 60, 437–444. [Google Scholar] [CrossRef]

- Quagliarini, E.; Bondioli, F.; Goffredo, G.B.; Licciulli, A.; Munafò, P. Smart surfaces for architectural heritage: Preliminary results about the application of TiO2-based coatings on travertine. J. Cult. Herit. 2012, 13, 204–209. [Google Scholar] [CrossRef]

- Quagliarini, E.; Bondioli, F.; Goffredo, G.B.; Cordoni, C.; Munafò, P. Self-cleaning and de-polluting stone surfaces: TiO2 nanoparticles for limestone. Constr. Build. Mater. 2012, 37, 51–57. [Google Scholar] [CrossRef]

- Munafò, P.; Goffredo, G.B.; Quagliarini, E. TiO2-based nanocoatings for preserving architectural stone surfaces: An overview. Constr. Build. Mater. 2015, 84, 201–218. [Google Scholar] [CrossRef]

- Mendoza, C.; Valle, A.; Castellote, M.; Bahamonde, A.; Faraldos, M. TiO2 and TiO2–SiO2 coated cement: Comparison of mechanic and photocatalytic properties. Appl. Catal. B Environ. 2015, 178, 155–164. [Google Scholar] [CrossRef]

- Pinho, L.; Elhaddad, F.; Facio, D.S.; Mosquera, M.J. A novel TiO2-SiO2 nanocomposite converts a very friable stone into a self-cleaning building material. Appl. Surf. Sci. 2013, 275, 389–396. [Google Scholar] [CrossRef]

- Rao, K.V.S.; Subrahmanyam, M.; Boule, P. Immobilized TiO2 photocatalyst during long-term use: Decrease of its activity. Appl. Catal. B Environ. 2004, 49, 239–249. [Google Scholar] [CrossRef]

- Calia, A.; Lettieri, M.; Masieri, M. Durability assessment of nanostructured TiO2 coatings applied on limestones to enhance building surface with self-cleaning ability. Build. Environ. 2016, 110, 1–10. [Google Scholar] [CrossRef]

- Poulios, I.; Spathis, P.; Grigoriadou, A.; Delidou, K.; Tsoumparis, P. Protection of marbles against corrosion and microbial corrosion with TiO2 coatings. J. Environ. Sci. Health Part A 1999, 34, 1455–1471. [Google Scholar] [CrossRef]

- Pinho, L.; Mosquera, M.J. Photocatalytic activity of TiO2-SiO2 nanocomposites applied to buildings: Influence of particle size and loading. Appl. Catal. B Environ. 2013, 134–135, 205–221. [Google Scholar] [CrossRef]

- Pinho, L.; Mosquera, M.J. Titania-Silica Nanocomposite Photocatalysts with Application in Stone Self-Cleaning. J. Phys. Chem. C 2011, 115, 22851–22862. [Google Scholar] [CrossRef]

- MacMullen, J.; Radulovic, J.; Zhang, Z.; Dhakal, H.N.; Daniels, L.; Elford, J.; Leost, M.A.; Bennett, N. Masonry remediation and protection by aqueous silane/siloxane macroemulsions incorporating colloidal titanium dioxide and zinc oxide nanoparticulates: Mechanisms, performance and benefits. Constr. Build. Mater. 2013, 49, 93–100. [Google Scholar] [CrossRef]

- Sung-Suh, H.M.; Choi, J.R.; Hah, H.J.; Koo, S.M.; Bae, Y.C. Comparison of Ag deposition effects on the photocatalytic activity of nanoparticulate TiO2 under visible and UV light irradiation. J. Photochem. Photobiol. A Chem. 2004, 163, 37–44. [Google Scholar] [CrossRef]

- Murakami, N.; Ono, A.; Nakamura, M.; Tsubota, T.; Ohno, T. Development of a visible-light-responsive rutile rod by site-selective modification of iron(III) ion on {1 1 1} exposed crystal faces. Appl. Catal. B Environ. 2010, 97, 115–119. [Google Scholar] [CrossRef]

- Sato, S.; Nakamura, R.; Abe, S. Visible-light sensitization of TiO2 photocatalysts by wet-method N doping. Appl. Catal. A Gen. 2005, 284, 131–137. [Google Scholar] [CrossRef]

- Cho, Y.; Choi, W.; Lee, C.H.; Hyeon, T.; Lee, H.I. Visible light-induced degradation of carbon tetrachloride on dye-sensitized TiO2. Environ. Sci. Technol. 2001, 35, 966–970. [Google Scholar] [CrossRef] [PubMed]

- Bera, S.; Lee, J.E.; Rawal, S.B.; Lee, W.I. Size-dependent plasmonic effects of Au and Au@SiO2 nanoparticles in photocatalytic CO2 conversion reaction of Pt/TiO2. Appl. Catal. B Environ. 2016, 199, 55–63. [Google Scholar] [CrossRef]

- Levchuk, I.; Sillanpää, M.; Guillard, C.; Gregori, D.; Chateau, D.; Parola, S. TiO2 /SiO2 porous composite thin films: Role of TiO2 areal loading and modification with gold nanospheres on the photocatalytic activity. Appl. Surf. Sci. 2016, 383, 367–374. [Google Scholar] [CrossRef]

- Lee, J.E.; Bera, S.; Choi, Y.S.; Lee, W.I. Size-dependent plasmonic effects of M and M@SiO2 (M = Au or Ag) deposited on TiO2 in photocatalytic oxidation reactions. Appl. Catal. B Environ. 2017, 214, 15–22. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, J.; Xiao, C.; Quan, Q.; Li, X. PPy-assisted fabrication of Ag/TiO2 visible-light photocatalyst and its immobilization on PAN fiber. Mater. Des. 2016, 104, 428–435. [Google Scholar] [CrossRef]

- Yu, J.; Dai, G.; Huang, B. Fabrication and Characterization of Visible-Light-Driven Plasmonic Photocatalyst Ag/AgCl/TiO2 Nanotube Arrays. J. Phys. Chem. C 2009, 113, 16394–16401. [Google Scholar] [CrossRef]

- Awazu, K.; Fujimaki, M.; Rockstuhl, C.; Tominaga, J.; Murakami, H.; Ohki, Y.; Yoshida, N.; Watanabe, T. A plasmonic photocatalyst consisting of silver nanoparticles embedded in titanium dioxide. J. Am. Chem. Soc. 2008, 130, 1676–1680. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-S.; Rai, P.; Yu, Y.-T. Microwave assisted hydrothermal synthesis of Au@TiO2 core–shell nanoparticles for high temperature CO sensing applications. Sens. Actuators B Chem. 2013, 186, 633–639. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.L.; Liu, R.-S.; Tsai, D.P. Plasmonic photocatalysis. Rep. Prog. Phys. 2013, 76, 46401. [Google Scholar] [CrossRef] [PubMed]

- Tryba, B.; Piszcz, M.; Morawski, A.W. Photocatalytic and Self-Cleaning Properties of Ag-Doped TiO2. Open Mater. Sci. J. 2010, 4, 5–8. [Google Scholar] [CrossRef]

- Graziani, L.; Quagliarini, E.; D’Orazio, M. The role of roughness and porosity on the self-cleaning and anti-biofouling efficiency of TiO2-Cu and TiO2-Ag nanocoatings applied on fired bricks. Constr. Build. Mater. 2016, 129, 116–124. [Google Scholar] [CrossRef]

- Goffredo, G.B.; Accoroni, S.; Totti, C.; Romagnoli, T.; Valentini, L.; Munafò, P. Titanium dioxide-based nanotreatments to inhibit microalgal fouling on building stone surfaces. Build. Environ. 2017, 112, 209–222. [Google Scholar] [CrossRef]

- Pinho, L.; Rojas, M.; Mosquera, M.J. Ag–SiO2–TiO2 nanocomposite coatings with enhanced photoactivity for self-cleaning application on building materials. Appl. Catal. B Environ. 2015, 178, 144–154. [Google Scholar] [CrossRef]

- Link, S.; El-Sayed, M.A. Spectral Properties and Relaxation Dynamics of Surface Plasmon Electronic Oscillations in Gold and Silver Nanodots and Nanorods. J. Phys. Chem. B 1999, 103, 8410–8426. [Google Scholar] [CrossRef]

- Desireddy, A.; Conn, B.E.; Guo, J.; Yoon, B.; Barnett, R.N.; Monahan, B.M.; Kirschbaum, K.; Griffith, W.P.; Whetten, R.L.; Landman, U.; et al. Ultrastable silver nanoparticles. Nature 2013, 501, 399–402. [Google Scholar] [CrossRef] [PubMed]

- Haruta, M. When gold is not noble: Catalysis by nanoparticles. Chem. Rec. 2003, 3, 75–87. [Google Scholar] [CrossRef] [PubMed]

- Tian, B.; Li, C.; Gu, F.; Jiang, H. Synergetic effects of nitrogen doping and Au loading on enhancing the visible-light photocatalytic activity of nano-TiO2. Catal. Commun. 2009, 10, 925–929. [Google Scholar] [CrossRef]

- Ayati, A.; Ahmadpour, A.; Bamoharram, F.F.; Tanhaei, B.; Mänttäri, M.; Sillanpää, M. A review on catalytic applications of Au/TiO2 nanoparticles in the removal of water pollutant. Chemosphere 2014, 107, 163–174. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, V.; Wolf, E.; Kamat, P.V. Semiconductor−Metal Composite Nanostructures. To What Extent Do Metal Nanoparticles Improve the Photocatalytic Activity of TiO2 Films? J. Phys. Chem. B 2001, 105, 11439–11446. [Google Scholar] [CrossRef]

- Primo, A.; Corma, A.; García, H. Titania supported gold nanoparticles as photocatalyst. Phys. Chem. Chem. Phys. 2011, 13, 886–910. [Google Scholar] [CrossRef] [PubMed]

- Bergamonti, L.; Alfieri, I.; Franzò, M.; Lorenzi, A.; Montenero, A.; Predieri, G.; Raganato, M.; Calia, A.; Lazzarini, L.; Bersani, D.; Lottici, P.P. Synthesis and characterization of nanocrystalline TiO2 with application as photoactive coating on stones. Environ. Sci. Pollut. Res. 2014, 21, 13264–13277. [Google Scholar] [CrossRef] [PubMed]

- Mosquera, M.J.; De Los Santos, D.M.; Montes, A.; Valdez-Castro, L. New Nanomaterials for Consolidating Stone. Langmuir 2008, 24, 2772–2778. [Google Scholar] [CrossRef] [PubMed]

- Illescas, J.F.; Mosquera, M.J. Producing Surfactant-Synthesized Nanomaterials In Situ on a Building Substrate, without Volatile Organic Compounds. ACS Appl. Mater. Interfaces 2012, 4, 4259–4269. [Google Scholar] [CrossRef] [PubMed]

- Pinho, L.; Hernández-Garrido, J.C.; Calvino, J.J.; Mosquera, M.J. 2D and 3D characterization of a surfactant-synthesized TiO2–SiO2 mesoporous photocatalyst obtained at ambient temperature. Phys. Chem. Chem. Phys. 2013, 15, 2800–2808. [Google Scholar] [CrossRef] [PubMed]

- Bergamonti, L.; Bondioli, F.; Alfieri, I.; Lorenzi, A.; Mattarozzi, M.; Predieri, G.; Lottici, P.P. Photocatalytic self-cleaning TiO2 coatings on carbonatic stones. Appl. Phys. A 2016, 122, 124. [Google Scholar] [CrossRef]

- Kapridaki, C.; Maravelaki, N.-P. TiO2–SiO2–PDMS nanocomposites with self-cleaning properties for stone protection and consolidation. Geol. Soc. Lond. Spec. Publ. 2016, 416, 285–292. [Google Scholar] [CrossRef]

- Krantz, D.H. Color measurement and color theory: I. Representation theorem for Grassmann structures. J. Math. Psychol. 1975, 12, 283–303. [Google Scholar] [CrossRef]

- Krantz, D.H. Color measurement and color theory: II. Opponent-colors theory. J. Math. Psychol. 1975, 12, 304–327. [Google Scholar] [CrossRef]

- Fuller, M.P.; Griffiths, P.R. Diffuse reflectance measurements by infrared Fourier transform spectrometry. Anal. Chem. 1978, 50, 1906–1910. [Google Scholar] [CrossRef]

- Gil, M.L.A.; Garrido, C.; Cantoral, J.M.; González-Rodríguez, V.E.; Carbu, M.; Cubillana-Aguilera, L.M.; Hidalgo-Hidalgo De Cisneros, J.L.; Naranjo-Rodríguez, I.; Luna, M.J.; Zarzuela, R.; et al. Synthesis of Gold Nanoparticles Using Aged Drago Leaf Extract (Dracanea draco L.): Manufacturing Process and Using. Spanish Patent ES 2580009 B2, 2015. [Google Scholar]

- Cubillana-Aguilera, L.M.; Franco-Romano, M.; Gil, M.L.A.; Naranjo-Rodríguez, I.; Hidalgo-Hidalgo De Cisneros, J.L.; Palacios-Santander, J.M. New, fast and green procedure for the synthesis of gold nanoparticles based on sonocatalysis. Ultrason. Sonochem. 2011, 18, 789–794. [Google Scholar] [CrossRef] [PubMed]

- Franco-Romano, M.; Gil, M.L.A.; Palacios-Santander, J.M.; Delgado-Jaén, J.J.; Naranjo-Rodríguez, I.; Hidalgo-Hidalgo De Cisneros, J.L.; Cubillana-Aguilera, L.M. Sonosynthesis of gold nanoparticles from a geranium leaf extract. Ultrason. Sonochem. 2014, 21, 1570–1577. [Google Scholar] [CrossRef] [PubMed]

- Tauc, J. Optical properties and electronic structure of amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Tandon, S.P.; Gupta, J.P. Measurement of Forbidden Energy Gap of Semiconductors by Diffuse Reflectance Spectra. Phys. Status Solidi B 1970, 38, 363–367. [Google Scholar] [CrossRef]

- Thommes, M.; Smarsly, B.; Groenewolt, M.; Ravikovitch, P.I.; Neimark, A.V. Adsorption Hysteresis of Nitrogen and Argon in Pore Networks and Characterization of Novel Micro- and Mesoporous Silicas. Langmuir 2006, 22, 756–764. [Google Scholar] [CrossRef] [PubMed]

- Berns, R.S. Billmeyer and Saltzman’s Principles of Color Technology; Wiley-Interscience: New York, NY, USA, 2000. [Google Scholar]

- Drdácký, M.; Lesák, J.; Rescic, S.; Slížková, Z.; Tiano, P.; Valach, J. Standardization of peeling tests for assessing the cohesion and consolidation characteristics of historic stone surfaces. Mater. Struct. 2012, 45, 505–520. [Google Scholar] [CrossRef] [PubMed]

- Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics); Determination of Photocatalytic Activity of Surfaces in an Aqueous Medium by Degradation of Methylene Blue; ISO 10678; International Organization for Standardization: Geneva, Switzerland, 2010.

- Yan, X.; Ohno, T.; Nishijima, K.; Abe, R.; Ohtani, B. Is methylene blue an appropriate substrate for a photocatalytic activity test? A study with visible-light responsive titania. Chem. Phys. Lett. 2006, 429, 606–610. [Google Scholar] [CrossRef]

- Rochkind, M.; Pasternak, S.; Paz, Y. Using dyes for evaluating photocatalytic properties: A critical review. Molecules 2015, 20, 88–110. [Google Scholar] [CrossRef] [PubMed]

- Mills, A.; Wang, J.; Crow, M. Photocatalytic oxidation of soot by P25 TiO2 films. Chemosphere 2006, 64, 1032–1035. [Google Scholar] [CrossRef] [PubMed]

- Aelion, R.; Loebel, A.; Eirich, F. Hydrolisis of Ethyl Silicate. J. Chem. Soc. 1950, 72, 5705–5712. [Google Scholar] [CrossRef]

- Widegren, J.; Bergström, L. Electrostatic Stabilization of Ultrafine Titania in Ethanol. J. Am. Ceram. Soc. 2002, 85, 523–528. [Google Scholar] [CrossRef]

- Kosmulski, M.; Prochniak, P.; Rosenholm, J.B. Control of the Zeta Potential in Semiconcentrated Dispersions of Titania in Polar Organic Solvents. J. Phys. Chem. C 2009, 113, 12806–12810. [Google Scholar] [CrossRef]

- Prabhu, A.; Gimel, J.-C.; Ayuela, A.; Dolado, J.S. Effect of Nano Seeds in C-S-H Gel Formation: Simulation Study from the Colloidal Point of View. In CONCREEP 10; American Society of Civil Engineers: Reston, VA, USA, 2015; pp. 877–886. [Google Scholar] [Green Version]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M. Gas Adsorption Characterization of Ordered Organic—Inorganic Nanocomposite Materials. Chem. Mater. 2001, 13, 3169–3183. [Google Scholar] [CrossRef]

- Brinker, C.J. Hydrolysis and condensation of silicates: Effects on structure. J. Non-Cryst. Solids 1988, 100, 31–50. [Google Scholar] [CrossRef]

- Yu, H.; Wang, S. Effects of water content and pH on gel-derived TiO2-SiO2. J. Non-Cryst. Solids 2000, 261, 260–267. [Google Scholar] [CrossRef]

- González-Álvarez, R.J.; Naranjo-Rodríguez, I.; Hernández-Artiga, M.P.; Palacios-Santander, J.M.; Cubillana-Aguilera, L.; Bellido-Milla, D. Experimental design applied to optimisation of silica nanoparticles size obtained by sonosynthesis. J. Sol-Gel Sci. Technol. 2016, 80, 378–388. [Google Scholar] [CrossRef]

- Linic, S.; Christopher, P.; Ingram, D.B. Plasmonic-metal nanostructures for efficient conversion of solar to chemical energy. Nat. Mater. 2011, 10, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Primo, A.; Marino, T.; Corma, A.; Molinari, R.; García, H. Efficient visible-light photocatalytic water splitting by minute amounts of gold supported on nanoparticulate CeO2 obtained by a biopolymer templating method. J. Am. Chem. Soc. 2011, 133, 6930–6933. [Google Scholar] [CrossRef] [PubMed]

- Ingram, D.B.; Linic, S. Water Splitting on Composite Plasmonic-Metal/Semiconductor Photoelectrodes: Evidence for Selective Plasmon-Induced Formation of Charge Carriers near the Semiconductor Surface. J. Am. Chem. Soc. 2011, 133, 5202–5205. [Google Scholar] [CrossRef] [PubMed]

- Miliani, C.; Velo-Simpson, M.L.; Scherer, G.W. Particle-modified consolidants: A study on the effect of particles on sol-gel properties and consolidation effectiveness. J. Cult. Herit. 2007, 8, 1–6. [Google Scholar] [CrossRef]

- Illescas, J.F.; Mosquera, M.J. Surfactant-Synthesized PDMS/Silica Nanomaterials Improve Robustness and Stain Resistance of Carbonate Stone. J. Phys. Chem. C 2011, 115, 14624–14634. [Google Scholar] [CrossRef]

- Umrao, S.; Sharma, P.; Bansal, A.; Sinha, R.; Singh, K. Multi-layered graphene quantum dots derived photodegradation mechanism of methylene blue. RSC Adv. 2015, 5, 51790–51798. [Google Scholar] [CrossRef]

- Cenens, J.; Schoonheydt, R.A. Visible Spectroscopy of Methylene Blue on Hectorite, Laponite B, and Barasym in Aqueous Suspension. Clays Clay Miner. 1988, 36, 214–224. [Google Scholar] [CrossRef]

- Dean, J.C.; Oblinsky, D.G.; Rafiq, S.; Scholes, G.D. Methylene Blue Exciton States Steer Nonradiative Relaxation: Ultrafast Spectroscopy of Methylene Blue Dimer. J. Phys. Chem. B 2016, 120, 440–454. [Google Scholar] [CrossRef] [PubMed]

- Houas, A. Photocatalytic degradation pathway of methylene blue in water. Appl. Catal. B Environ. 2001, 31, 145–157. [Google Scholar] [CrossRef]

- Murugan, K.; Rao, T.N.; Gandhi, A.S.; Murty, B.S. Effect of aggregation of methylene blue dye on TiO2 surface in self-cleaning studies. Catal. Commun. 2010, 11, 518–521. [Google Scholar] [CrossRef]

- Murugan, K.; Joardar, J.; Gandhi, A.S.; Murty, B.S.; Borse, P.H. Photo-induced monomer/dimer kinetics in methylene blue degradation over doped and phase controlled nano-TiO2 films. RSC Adv. 2016, 6, 43563–43573. [Google Scholar] [CrossRef]

- Kubelka, P.; Munk, F. Ein Beitrag zur Optik der Farbanstriche. Z. Tech. Phys. 1931, 12, 593–601. [Google Scholar]

- Kubelka, P. New Contributions to the Optics of Intensely Light-Scattering Materials. Part I. J. Opt. Soc. Am. 1948, 38, 448–457. [Google Scholar] [CrossRef] [PubMed]

- Julson, A.J.; Ollis, D.F. Kinetics of dye decolorization in an air–solid system. Appl. Catal. B Environ. 2006, 65, 315–325. [Google Scholar] [CrossRef]

- Yamauchi, Y.; Takeuchi, F.; Todoroki, S.; Sakka, Y.; Inoue, S. Spherical Mesoporous Silica Particles with Titanium Dioxide Nanoparticles by an Aerosol-assisted Coassembly. Chem. Lett. 2008, 37, 72–73. [Google Scholar] [CrossRef]

- Suzuki, N.; Jiang, X.; Radhakrishnan, L.; Takai, K.; Shimasaki, K.; Huang, Y.T.; Miyamoto, N.; Yamauchi, Y. Hybridization of Photoactive Titania Nanoparticles with Mesoporous Silica Nanoparticles and Investigation of Their Photocatalytic Activity. Bull. Chem. Soc. Jpn. 2011, 84, 812–817. [Google Scholar] [CrossRef]

- Zhang, P.; Tian, J.; Xu, R.; Ma, G. Hydrophilicity, photocatalytic activity and stability of tetraethyl orthosilicate modified TiO2 film on glazed ceramic surface. Appl. Surf. Sci. 2013, 266, 141–147. [Google Scholar] [CrossRef]

- Ting, H.F.; Chen, C.M.; Lu, F.H.; Suen, S.Y. Adsorption and photodegradation of methylene blue using a bulk Ti material with porous titania layer prepared by chemical oxidation. J. Taiwan Inst. Chem. Eng. 2014, 45, 617–624. [Google Scholar] [CrossRef]

- Jawad, A.H.; Mubarak, N.S.A.; Ishak, M.A.M.; Ismail, K.; Nawawi, W.I. Kinetics of photocatalytic decolourization of cationic dye using porous TiO2 film. J. Taibah Univ. Sci. 2016, 10, 352–362. [Google Scholar] [CrossRef]

- Zhang, J.; Grabstanowicz, L.R.; Gao, S.; Hosmane, N.S.; Huang, B.; Dai, Y.; Liu, D.; Xu, T. Visible-light photocatalytic SiO2/TiO2−xCx/C nanoporous composites using TiCl4 as the precursor for TiO2 and polyhydroxyl tannin as the carbon source. Catal. Sci. Technol. 2012, 2, 390–399. [Google Scholar] [CrossRef]

- Sopyan, I.; Watanabe, M.; Murasawa, S.; Hashimoto, K.; Fujishima, A. A film-type photocatalyst incorporating highly active TiO2 powder and fluororesin binder: Photocatalytic activity and long-term stability. J. Electroanal. Chem. 1996, 415, 183–186. [Google Scholar] [CrossRef]

- Fattakhova-Rohlfing, D.; Szeifert, J.M.; Yu, Q.; Kalousek, V.; Rathouský, J.; Bein, T. Low-Temperature Synthesis of Mesoporous Titania−Silica Films with Pre-Formed Anatase Nanocrystals. Chem. Mater. 2009, 21, 2410–2417. [Google Scholar] [CrossRef]

- Beyers, E.; Biermans, E.; Ribbens, S.; De Witte, K.; Mertens, M.; Meynen, V.; Bals, S.; Van Tendeloo, G.; Vansant, E.F.; Cool, P. Combined TiO2/SiO2 mesoporous photocatalysts with location and phase controllable TiO2 nanoparticles. Appl. Catal. B Environ. 2009, 88, 515–524. [Google Scholar] [CrossRef]

| Product | % TiO2 a | % Water Content b | % Au/TiO2 c |

|---|---|---|---|

| S0Au | 0 | 0 | 0 |

| ST0Au | 1 | 0 | 0 |

| ST5Au | 1 | 0.33 | 0.05 |

| ST12Au | 1 | 0.83 | 0.12 |

| ST25Au | 1 | 1.67 | 0.25 |

| ST38Au | 1 | 2.50 | 0.38 |

| ST50Au | 1 | 3.33 | 0.50 |

| Product | Viscosity (mPa·s) | Gel Time | Stotal (m2/g) | Vpore (cm3/g) |

|---|---|---|---|---|

| S0Au | 4.61 | 24 h | 240 | 0.32 |

| ST0Au | 5.43 | 12 h | 316 | 0.58 |

| ST5Au | 5.80 | 8 h | 217 | 0.57 |

| ST12Au | 6.57 | 6 h | 329 | 0.74 |

| ST25Au | 8.37 | 3 h | 155 | 0.51 |

| ST38Au | * | 5 min | # | # |

| ST50Au | * | 1 min | # | # |

| Sample | Uptake (g/m2) | Dry Matter (g/m2) | ΔE * | Peeling Test (mg/cm2) |

|---|---|---|---|---|

| Untreated | - | - | - | 0.079 ± 0.014 |

| S0Au | 480 ± 60 | 258 ± 40 | 5.2 ± 0.6 | 0.019 ± 0.016 |

| ST0Au | 428 ± 60 | 246 ± 40 | 5.0 ± 0.3 | 0.011 ± 0.015 |

| ST5Au | 381 ± 90 | 203 ± 60 | 3.5 ± 0.6 | 0.021 ± 0.015 |

| ST12Au | 302 ± 90 | 171 ± 60 | 3.4 ± 0.5 | 0.016 ± 0.018 |

| ST25Au | 281 ± 60 | 153 ± 40 | 3.5 ± 0.6 | 0.019 ± 0.013 |

| Sample | Degradation | k1 (min−1) | k2 (min−1) | x | R2 |

|---|---|---|---|---|---|

| Untreated | Overall | 0.030 | 1.59 × 10−3 | 0.812 | 0.964 |

| Monomer | 0.039 | 1.33 × 10−16 | 0.620 | 0.991 | |

| Dimer | 0.027 | 1.95 × 10−3 | 0.798 | 0.966 | |

| S0Au | Overall | 0.124 | 6.31 × 10−3 | 0.345 | 0.959 |

| Monomer | 0.185 | 9.85 × 10−3 | 0.223 | 0.981 | |

| Dimer | 0.061 | 9.19 × 10−3 | 0.613 | 0.993 | |

| ST0Au | Overall | 0.163 | 1.67 × 10−2 | 0.259 | 0.999 |

| Monomer | 0.207 | 1.38 × 10−2 | 0.095 | 0.999 | |

| Dimer | 0.071 | 5.72 × 10−3 | 0.185 | 0.995 | |

| ST5Au | Overall | 0.265 | 2.22 × 10−2 | 0.282 | 0.996 |

| Monomer | 0.309 | 1.95 × 10−2 | 0.132 | 0.999 | |

| Dimer | 0.105 | 9.84 × 10−3 | 0.244 | 0.998 | |

| ST12Au | Overall | 0.437 | 5.54 × 10−2 | 0.246 | 0.998 |

| Monomer | 0.471 | 5.30 × 10−2 | 0.094 | 0.999 | |

| Dimer | 0.136 | 1.87 × 10−2 | 0.152 | 0.997 | |

| ST25Au | Overall | 0.269 | 3.34 × 10−2 | 0.234 | 0.999 |

| Monomer | 0.322 | 3.16 × 10−2 | 0.107 | 0.999 | |

| Dimer | 0.099 | 1.14 × 10−2 | 0.148 | 0.999 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luna, M.; Delgado, J.J.; Gil, M.L.A.; Mosquera, M.J. TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials. Nanomaterials 2018, 8, 177. https://doi.org/10.3390/nano8030177

Luna M, Delgado JJ, Gil MLA, Mosquera MJ. TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials. Nanomaterials. 2018; 8(3):177. https://doi.org/10.3390/nano8030177

Chicago/Turabian StyleLuna, Manuel, Juan J. Delgado, M. L. Almoraima Gil, and María J. Mosquera. 2018. "TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials" Nanomaterials 8, no. 3: 177. https://doi.org/10.3390/nano8030177

APA StyleLuna, M., Delgado, J. J., Gil, M. L. A., & Mosquera, M. J. (2018). TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials. Nanomaterials, 8(3), 177. https://doi.org/10.3390/nano8030177