Properties of Ferrite Garnet (Bi, Lu, Y)3(Fe, Ga)5O12 Thin Film Materials Prepared by RF Magnetron Sputtering

Abstract

:1. Introduction

2. Experimental Work

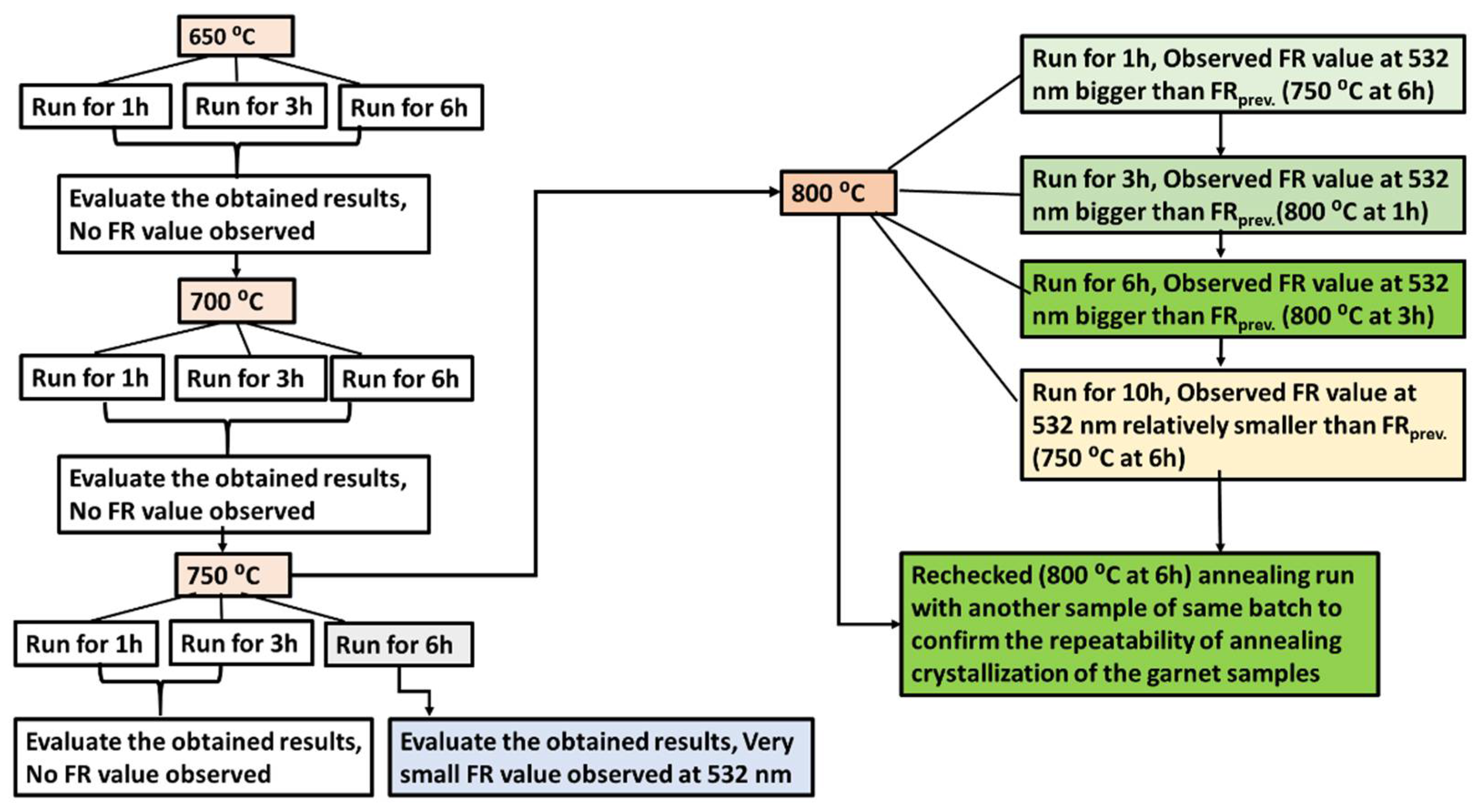

2.1. Thin Film Garnet Layer Preparation

2.2. Structural Investigation

2.3. Optical Properties Measurement

2.4. Magneto-Optical Properties Measurement

3. Results

3.1. X-ray Diffraction Study

3.2. EDS Measurement

3.3. Study of Optical Properties

3.3.1. Optical Transmittance

3.3.2. Calculation of the Refractive Index and Film Thickness

3.3.3. Confirmation of the Film Thickness, Optical Absorption Coefficient Data and Extinction Coefficient Measurement

3.4. Study of Magneto-Optical Properties

3.4.1. Specific Faraday Rotation and MO Figure of Merit

3.4.2. MO Swing Factor and Hysteresis Loop of Specific Faraday Rotation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zvezdin, A.K.; Kotov, V.A. Modern Magnetooptics and Magnetooptical Materials; Institute of Physics Publishing: Bristol, UK, 1997. [Google Scholar]

- Scott, G.B.; Lacklison, D.E. Magnetooptic properties and applications of Bismuth substituted iron garnets. IEEE Trans. Magn. 1976, 12, 292–311. [Google Scholar] [CrossRef]

- Kang, Y.M.; Wee, S.H.; Baik, S.I. Magnetic properties of YIG (Y3Fe5O12) thin films prepared by the post annealing of amorphous films deposited by rf-magnetron sputtering. J. Appl. Phys. 2005, 97, 10A319. [Google Scholar] [CrossRef]

- Boudiar, T.; Gervy, B.P.; Blanc-Mignon, M.F.; Rousseau, J.J.; Berre, M.L.; Joisten, H. Magneto-optical properties of yttrium iron garnet (YIG) thin films elaborated by radio frequency sputtering. J. Magn. Magn. Mater. 2004, 284, 77–85. [Google Scholar] [CrossRef]

- Kumar, N.; Misra, D.S.; Venkataramani, N.; Prasad, S.; Krishnan, R. Magnetic properties of pulsed laser ablated YIG thin films on different substrates. J. Magn. Magn. Mater. 2004, 272–273, 899–900. [Google Scholar] [CrossRef]

- Aichele, T.; Lorenz, A.; Hergt, R.; Gornert, P. Garnet layers prepared by liquid phase epitaxy for microwave and magneto-optical applications—A review. Cryst. Res. Technol. 2003, 38, 575–578. [Google Scholar] [CrossRef]

- Novak, A.; Gibbs, G.V. The crystal chemistry of the silicate garnet. Am. Mineral. 1971, 56, 791–825. [Google Scholar]

- Geller, S. Crystal chemistry of garnets. Z. Kristallogr. 1967. [Google Scholar] [CrossRef]

- Kang, S.; Yin, S.; Adyam, V.; Li, Q.; Zhu, Y. Bi3Fe4Ga1O12 garnet properties and its application to ultrafast switching in the visible spectrum. IEEE Trans. Magn. 2007, 43, 3656–3660. [Google Scholar] [CrossRef]

- Challeton, D.; Bechevet, B.; Rolland, B.; Armand, M.F. RF sputtered Bi-substituted garnet film for magneto-optic memory. J. Magn. Magn. Mater. 1990, 83, 37–38. [Google Scholar] [CrossRef]

- Zayets, V.; Ando, K. Magneto-optical devices for optical integrated circuits. In Frontiers in Guided Wave Optics and Optoelectronics; InTech: Rijeka, Croatia, 2010; p. 674. ISBN 978-953-7619-82-4. [Google Scholar]

- Kahl, S.; Grishin, A.M.; Kharestev, S.I.; Kawano, K.; Abell, J.S. Bi3Fe5O12 thin film visualizer. IEEE Trans. Magn. 2001, 37, 2457–2459. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, J.S.; Kim, S.I.; Levy, M. Epitaxial growth and properties of Bi-substituted Yttrium-Iron-garnet film grown on (111) Gadolinium-Gallium-garnet substrates by rf magnetron sputtering. J. Korean Phys. Soc. 2003, 43, 400–405. [Google Scholar]

- Ma, X.; Zhang, S.; Li, F.; Que, D. Preparation of bismuth substituted dysprosium iron garnet film by a sol-gel process. J. Mater. Sci. Mater. Electron. 1998, 9, 347–350. [Google Scholar] [CrossRef]

- Nistor, I.; Holthaus, C.; Mayergoyz, I.D.; Krafft, C. Development of liquid phase epitaxy-grown (Bi, Gd, Lu) substituted thin-film iron garnets. J. Appl. Phys. 2006, 99, 08M702. [Google Scholar] [CrossRef]

- Gornert, P.; Aichele, T.; Lorenz, A.; Hergt, R.; Taubert, J. Liquid phase epitaxy (LPE) grown Bi, Ga, Al substituted iron garnets with huge Faraday rotation for magneto-optic applications. Phys. Status Sol. 2004, A201, 1398–1402. [Google Scholar] [CrossRef]

- Kim, H.; Grishin, A.M.; Rao, K.V. Giant Faraday rotation of blue light in epitaxial CexY3−xFe5O12 films grown by pulsed laser deposition. J. Appl. Phys. 2001, 89, 4380–4383. [Google Scholar] [CrossRef]

- Sekhar, M.C.; Hwang, J.Y.; Ferrera, M.; Linson, Y.; Razzari, L.; Harnagea, C.; Zaezjev, M.; Pignolet, A.; Morandotti, R. Strong enhancement of the Faraday rotation in Ce and Bi comodified epitaxial iron garnet thin films. Appl. Phys. Lett. 2009, 94, 181916. [Google Scholar] [CrossRef]

- Elhamali, S.M.; Ibrahim, N.B.; Radiman, S. Structural, optical and magnetic properties of YIG doped with Erbium and Terbium nanofilms using sol-gel method. J. Adv. Nanomater. 2016, 1, 11–20. [Google Scholar] [CrossRef]

- Walker, L. Ferromagnetic resonance in Terbium-doped Yttrium iron garnet. J. Appl. Phys. 1962, 33, 1243–1247. [Google Scholar] [CrossRef]

- Xu, H.; Yang, H. Magnetic properties of YIG doped with cerium and gadolinium ions. J. Mater. Sci. Mater. Electron. 2008, 19, 589–593. [Google Scholar] [CrossRef]

- Nachimuthu, R.K.; Jeffery, R.D.; Martyniuk, M.; Woodward, R.C.; Metaxas, P.J.; Dell, J.M.; Faraone, L. Investigation of Cerium-substituted Europium iron garnets deposited by target ion beam deposition. IEEE Trans. Magn. 2014, 50, 1–7. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Vasiliev, M.; Kotov, V.A.; Alameh, K. Recent developments in magneto-optic garnet-type thin-film materials synthesis. Procedia Eng. 2014, 76, 61–73. [Google Scholar] [CrossRef]

- Sekhar, R.K.; Singh, M.R. Fabrication and characterization of Bismuth-Cerium composite iron garnet epitaxial films for magneto optical applications. J. Appl. Phys. 2012, 112, 083525. [Google Scholar] [CrossRef]

- Vasiliev, M.; Alam, M.N.; Kotov, V.A.; Alameh, K.; Belotelov, V.I.; Burkov, V.I.; Zvezdin, A.K. RF magnetron sputtered (BiDy)3(FeGa)5O12:Bi2O3 composite garnet-oxide materials possessing record magneto-optic quality in the visible spectral region. Opt. Express 2009, 17, 19519–19535. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.N.; Vasiliev, M.; Alameh, K. Bi3Fe5O12:Dy2O3 composite thin film materials for magneto-photonics and magneto-plasmonics. Opt. Mater. Express 2014, 4, 1866–1875. [Google Scholar] [CrossRef]

- Alam, M.N.; Vasiliev, M.; Kotov, V.A.; Alameh, K. Highly bismuth-substituted, record-performance magneto-optic garnet materials with low coercivity for applications in integrated optics, photonic crystals, imaging and sensing. Opt. Mater. Express 2011, 1, 413–427. [Google Scholar] [CrossRef]

- Alam, M.N.; Vasiliev, M.; Alameh, K.; Kotov, V.A.; Demidov, V.; Balabanov, D. YIG:Bi2O3 Nanocomposite thin films for magnetooptic and microwave applications. J. Nanomater. 2015, 182691. [Google Scholar] [CrossRef]

- Alam, M.N.; Vasiliev, M.; Kotov, V.A.; Alameh, K. Garnet Nanocomposite for Use in Magnetic Photonic Crystals Prepared by Composition Adjustment in the Bi3Fe3O12–Bi2Dy1Fe4Ga1 O12 Material System; Bloomsbury Publishing India Pvt. Ltd.: New Delhi, India, 2012; pp. 143–148. [Google Scholar]

- Kumar, N.; Prasad, S.; Misra, D.S.; Venkataramani, N.; Bohra, M.; Krishnan, R. The influence of substrate temperature and annealing on the properties of pulsed laser-deposited YIG films on fused quartz substrate. J. Magn. Magn. Mater. 2008, 320, 2233–2236. [Google Scholar] [CrossRef]

- Tehranchi, M.M.; Hamidi, S.M.; Hasanpour, A.; Mozaffari, M.; Amighian, J. The effect of target rotation rate on structural and morphological properties of thin garnet films fabricated by pulsed laser deposition. Opt. Laser Technol. 2011, 43, 609–612. [Google Scholar] [CrossRef]

- Rojas, R.; Krafft, C.; Nistor, I.; Zhang, D.; Mayergoyz, I.D. Growth effects (rotation rate) on the characteristics of Bi-substituted lutetium iron garnets. J. Appl. Phys. 2004, 95, 6885. [Google Scholar] [CrossRef]

- Alam, M.N.; Vasiliev, M.; Alameh, K. Influence of substrate stage temperature and rotation rate on the magneto-optical quality of RF-sputtered Bi2.1Dy0.9Fe3.9Ga1.1O12 garnet thin films. Appl. Sci. 2018, 8, 456. [Google Scholar] [CrossRef]

- Eschenfelder, A.H. Magnetic Bubble Technology; Springer: Berlin/Heidelberg, Germany, 1980. [Google Scholar]

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Addison-Wesley Publishing Company, Inc.: Boston, MA, USA, 1978. [Google Scholar]

- Manifacier, J.C.; Gasiot, J.; Fillard, J.P. A simple method for the determination of the optical constants n, k and the thickness of a weakly absorbing thin film. J. Phys. E Sci. Instrum. 1976, 9, 1002–1004. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E Sci. Instrum. 1983, 16, 1214–1222. [Google Scholar] [CrossRef]

- Hassanien, A.S.; Aly, K.A.; Akl, A.A. Study of optical properties of thermally evaporated ZnSe thin films annealed at different pulsed laser powers. J. Alloys Compd. 2016, 685, 733–742. [Google Scholar] [CrossRef]

- Xie, G.C.; Fang, L.; Peng, L.P.; Liu, G.B.; Ruan, H.B.; Wu, F.; Kong, C.Y. Effect of In-doping on the optical constants of ZnO thin films. Phys. Procedia 2012, 32, 651–657. [Google Scholar] [CrossRef]

- Ruhela, S.; Srivastava, S.K. Study of XRD pattern of mixed composite of MgTiO3 and ZnO. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 1320–1322. [Google Scholar]

- Emam-Ismail, M.; El-Hagary, M.; Shaaban, E.R.; Al-Hedeib, A.M. Microstructure and optical studies of electron beam evaporated ZnSe1−xTex nanocrystalline thin films. J. Alloys Compd. 2012, 532, 16–24. [Google Scholar] [CrossRef]

- Aly, K.A. Optical band gap and refractive index dispersion parameters of AsxSe70Te30−x (0 ≤ x ≤ 30 at. %) amorphous films. Appl. Phys. A 2010, 99, 913. [Google Scholar] [CrossRef]

- Dahshan, A.; Amer, H.H.; Aly, K.A. Compositional dependence of the optical constants of amorphous GexAs20Se80−x thin films. J. Phys. D Appl. Phys. 2008, 41, 215401. [Google Scholar] [CrossRef]

- Kahl, S. Bismuth Iron Garnet Films for Magneto-Optic Photonic Crystals. Ph.D. Thesis, Mikroelektronik och Informationsteknik, Stockholm, Sweden, 2004. [Google Scholar]

| Sample | Wavelength (nm) | TM | Tm | n1 | d1 (nm) | m0 | M | d2 (nm) | n2 |

|---|---|---|---|---|---|---|---|---|---|

| As-deposited (thickness 650 nm, measured by a quartz sensor during deposition) | 1480 | 0.94699 | 0.735 | 2.11 | - | 2.0 | 2.00 | 700 | 2.112 |

| 1186 | 0.9465 | 0.73351 | 2.12 | 710 | 2.5 | 2.50 | 700 | 2.116 | |

| 998 | 0.92997 | 0.72 | 2.13 | 692 | 3.0 | 3.00 | 704 | 2.136 | |

| 858 | 0.928 | 0.71101 | 2.15 | 694 | 3.5 | 3.50 | 698 | 2.143 | |

| 762 | 0.89588 | 0.685 | 2.17 | 712 | 4.0 | 4.00 | 701 | 2.175 | |

| 682 | 0.86 | 0.65927 | 2.19 | 749 | 4.5 | 4.50 | 701 | 2.190 | |

| 628 | 0.77032 | 0.6 | 2.21 | - | - | - | - | - | |

| d1 (ave) = 712 nm, δ1 = 22.8 nm (3.21%), d2 (ave) = 701 nm, δ2 = 1.8 nm (0.25%), d(mpcmf) = 701 nm | |||||||||

| Annealed at 800 °C for 6 h | 1440 | 0.91145 | 0.71 | 2.124 | - | 2.0 | 2.00 | 678 | 2.118 |

| 1154 | 0.91 | 0.70869 | 2.126 | 697 | 2.5 | 2.50 | 679 | 2.122 | |

| 974 | 0.8894 | 0.693 | 2.136 | 692 | 3.0 | 3.00 | 684 | 2.149 | |

| 838 | 0.888 | 0.68786 | 2.149 | 684 | 3.5 | 3.50 | 682 | 2.157 | |

| 744 | 0.87132 | 0.67 | 2.175 | 654 | 4.0 | 4.00 | 684 | 2.189 | |

| 662 | 0.845 | 0.64618 | 2.204 | 681 | 4.5 | 4.50 | 676 | 2.191 | |

| 608 | 0.80114 | 0.615 | 2.224 | 658 | 5.0 | 5.00 | 684 | 2.236 | |

| 556 | 0.75 | 0.57274 | 2.274 | 710 | 5.6 | 5.50 | 672 | 2.249 | |

| 528 | 0.64661 | 0.505 | 2.303 | - | - | - | - | - | |

| d1 (ave) = 682 nm, δ1 = 17.7 nm (2.58%), d2 (ave) = 680 nm, δ2 = 4.3 nm (0.63%), d(mpcmf) = 684 nm | |||||||||

| Sample | Wavelength (nm) | TM | Tm | n1 | d1 (nm) | m0 | M | d2 (nm) | n2 |

|---|---|---|---|---|---|---|---|---|---|

| As-deposited (thickness 1292 nm, measured by a quartz sensor during deposition) | 2208 | 0.905 | 0.70915 | 2.115 | - | 2.3 | 2.5 | 1305 | 2.148 |

| 1840 | 0.92007 | 0.715 | 2.125 | 1264 | 2.8 | 3.0 | 1299 | 2.148 | |

| 1578 | 0.918 | 0.71022 | 2.136 | 1247 | 3.3 | 3.5 | 1293 | 2.149 | |

| 1382 | 0.91221 | 0.702 | 2.150 | 1251 | 3.8 | 4.0 | 1285 | 2.151 | |

| 1230 | 0.9122 | 0.7 | 2.156 | 1302 | 4.3 | 4.5 | 1283 | 2.153 | |

| 1114 | 0.89607 | 0.689 | 2.161 | 1320 | 4.7 | 5.0 | 1289 | 2.167 | |

| 1014 | 0.896 | 0.6887 | 2.162 | 1318 | 5.2 | 5.5 | 1290 | 2.170 | |

| 934 | 0.88012 | 0.678 | 2.166 | 1314 | 5.6 | 6.0 | 1294 | 2.180 | |

| 864 | 0.878 | 0.6753 | 2.171 | 1339 | 6.1 | 6.5 | 1294 | 2.185 | |

| 808 | 0.85129 | 0.658 | 2.176 | 1273 | 6.5 | 7.0 | 1300 | 2.201 | |

| 754 | 0.84 | 0.64701 | 2.191 | 1247 | 7.1 | 7.5 | 1291 | 2.202 | |

| 716 | 0.78892 | 0.61 | 2.215 | 1218 | 7.5 | 8.0 | 1293 | 2.229 | |

| 674 | 0.77 | 0.59379 | 2.235 | 1010 | 8.1 | 8.5 | 1282 | 2.229 | |

| 646 | 0.69356 | 0.53 | 2.318 | 899 | 8.7 | 9.0 | 1254 | 2.262 | |

| 610 | 0.648 | 0.49496 | 2.362 | 1007 | 9.4 | 9.5 | 1227 | 2.255 | |

| 592 | 0.52763 | 0.414 | 2.419 | - | - | - | - | - | |

| d1 (ave) = 1215 nm, δ1 = 138.5 nm (11%), d2 (ave) = 1285 nm, δ2 = 19.9 nm (2%), d(mpcmf) = 1310 nm | |||||||||

| Annealed at 800 °C for 6 h | 2130 | 0.89 | 0.69541 | 2.129 | - | 2.4 | 2.5 | 1251 | 2.174 |

| 1786 | 0.8811 | 0.685 | 2.145 | 1213 | 2.9 | 3.0 | 1249 | 2.188 | |

| 1534 | 0.87 | 0.67214 | 2.166 | 1353 | 3.4 | 3.5 | 1240 | 2.192 | |

| 1348 | 0.85031 | 0.658 | 2.174 | 1193 | 3.8 | 4.0 | 1273 | 2.201 | |

| 1200 | 0.845 | 0.64917 | 2.193 | 1091 | 4.4 | 4.5 | 1229 | 2.205 | |

| 1086 | 0.81894 | 0.631 | 2.203 | 1192 | 4.9 | 5.0 | 1232 | 2.217 | |

| 988 | 0.815 | 0.62326 | 2.223 | 1154 | 5.4 | 5.5 | 1222 | 2.219 | |

| 910 | 0.8 | 0.61 | 2.240 | 1180 | 5.9 | 6.0 | 1218 | 2.229 | |

| 844 | 0.79 | 0.6 | 2.257 | 1219 | 6.4 | 6.5 | 1215 | 2.240 | |

| 788 | 0.77543 | 0.59 | 2.263 | 1244 | 6.9 | 7.0 | 1219 | 2.252 | |

| 738 | 0.77 | 0.58519 | 2.270 | 1253 | 7.4 | 7.5 | 1219 | 2.260 | |

| 698 | 0.73543 | 0.562 | 2.283 | 1203 | 7.9 | 8.0 | 1223 | 2.280 | |

| 658 | 0.72 | 0.54988 | 2.297 | 1217 | 8.4 | 8.5 | 1217 | 2.284 | |

| 628 | 0.67623 | 0.521 | 2.312 | 1217 | 8.9 | 9.0 | 1222 | 2.308 | |

| 598 | 0.66 | 0.50732 | 2.334 | 1134 | 9.4 | 9.5 | 1217 | 2.319 | |

| 574 | 0.61721 | 0.476 | 2.367 | 986 | 9.9 | 10.0 | 1213 | 2.344 | |

| 548 | 0.58 | 0.44593 | 2.416 | 1063 | 10.6 | 10.5 | 1191 | 2.349 | |

| 532 | 0.49716 | 0.392 | 2.444 | - | - | - | - | - | |

| d1 (ave) = 1185 nm, δ1 = 84.7 nm (7%), d2 (ave) = 1226 nm, δ2 = 18.5 nm (2%), d(mpcmf) = 1272 nm | |||||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nur-E-Alam, M.; Vasiliev, M.; Belotelov, V.; Alameh, K. Properties of Ferrite Garnet (Bi, Lu, Y)3(Fe, Ga)5O12 Thin Film Materials Prepared by RF Magnetron Sputtering. Nanomaterials 2018, 8, 355. https://doi.org/10.3390/nano8050355

Nur-E-Alam M, Vasiliev M, Belotelov V, Alameh K. Properties of Ferrite Garnet (Bi, Lu, Y)3(Fe, Ga)5O12 Thin Film Materials Prepared by RF Magnetron Sputtering. Nanomaterials. 2018; 8(5):355. https://doi.org/10.3390/nano8050355

Chicago/Turabian StyleNur-E-Alam, Mohammad, Mikhail Vasiliev, Vladimir Belotelov, and Kamal Alameh. 2018. "Properties of Ferrite Garnet (Bi, Lu, Y)3(Fe, Ga)5O12 Thin Film Materials Prepared by RF Magnetron Sputtering" Nanomaterials 8, no. 5: 355. https://doi.org/10.3390/nano8050355

APA StyleNur-E-Alam, M., Vasiliev, M., Belotelov, V., & Alameh, K. (2018). Properties of Ferrite Garnet (Bi, Lu, Y)3(Fe, Ga)5O12 Thin Film Materials Prepared by RF Magnetron Sputtering. Nanomaterials, 8(5), 355. https://doi.org/10.3390/nano8050355