Optoelectronic and Electrothermal Properties of Transparent Conductive Silver Nanowires Films

Abstract

:1. Introduction

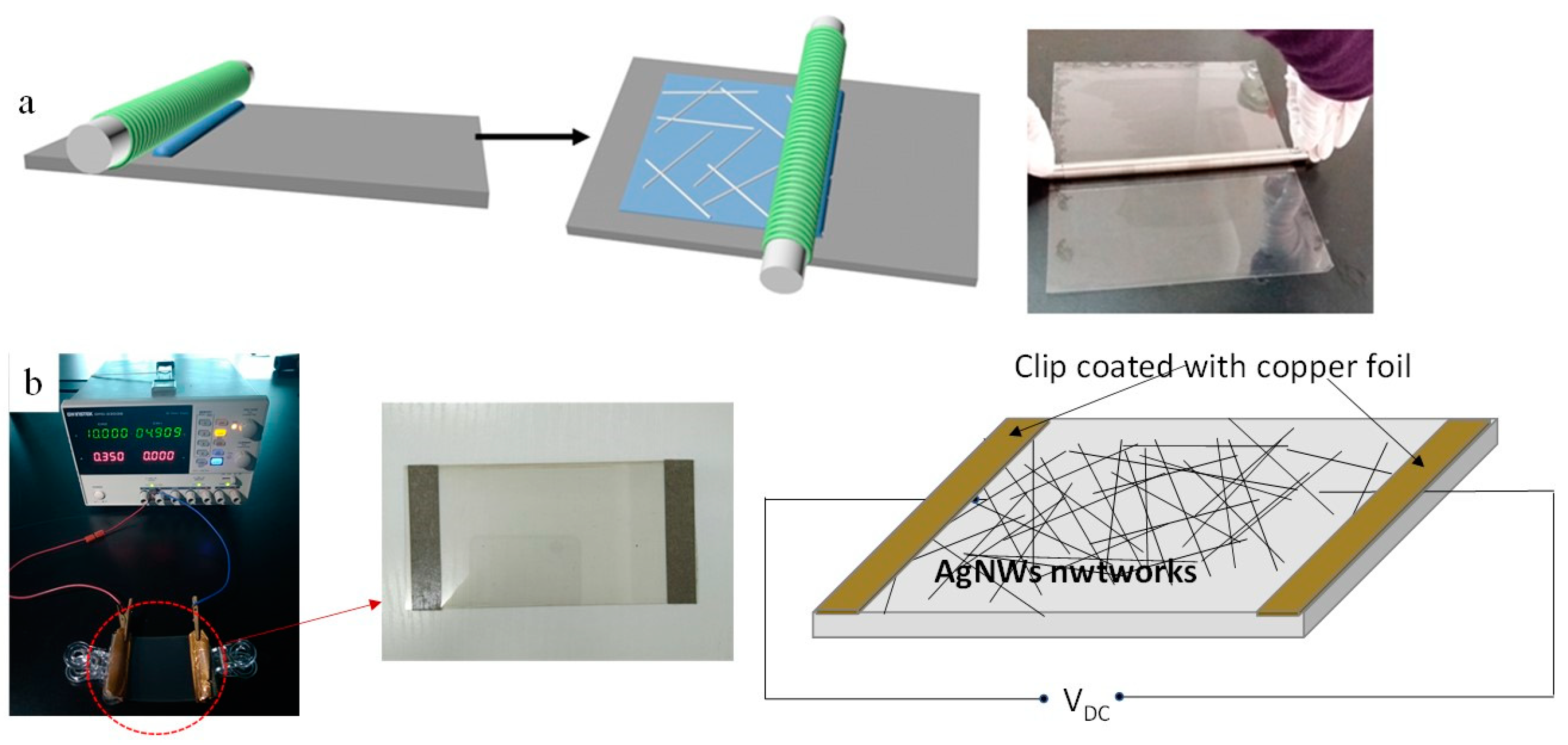

2. Experimental Approach

3. Results and Discussion

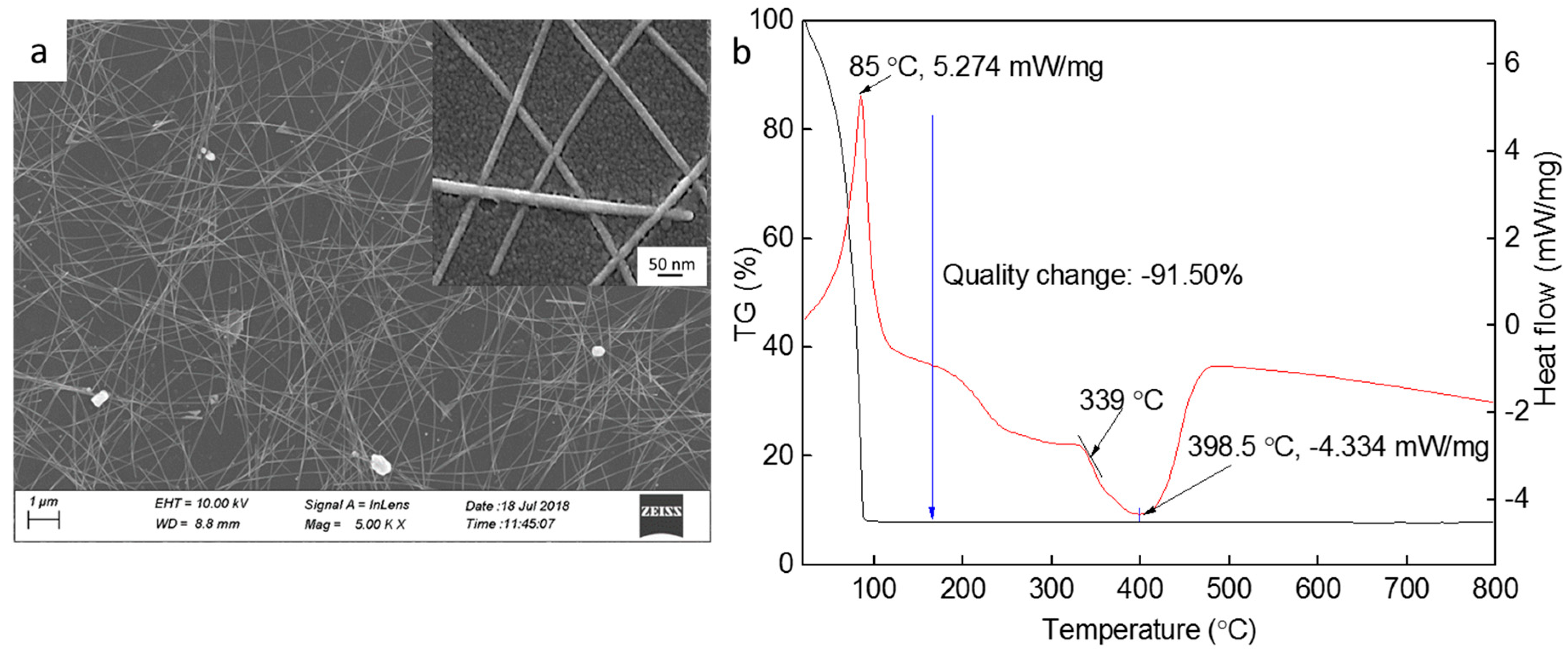

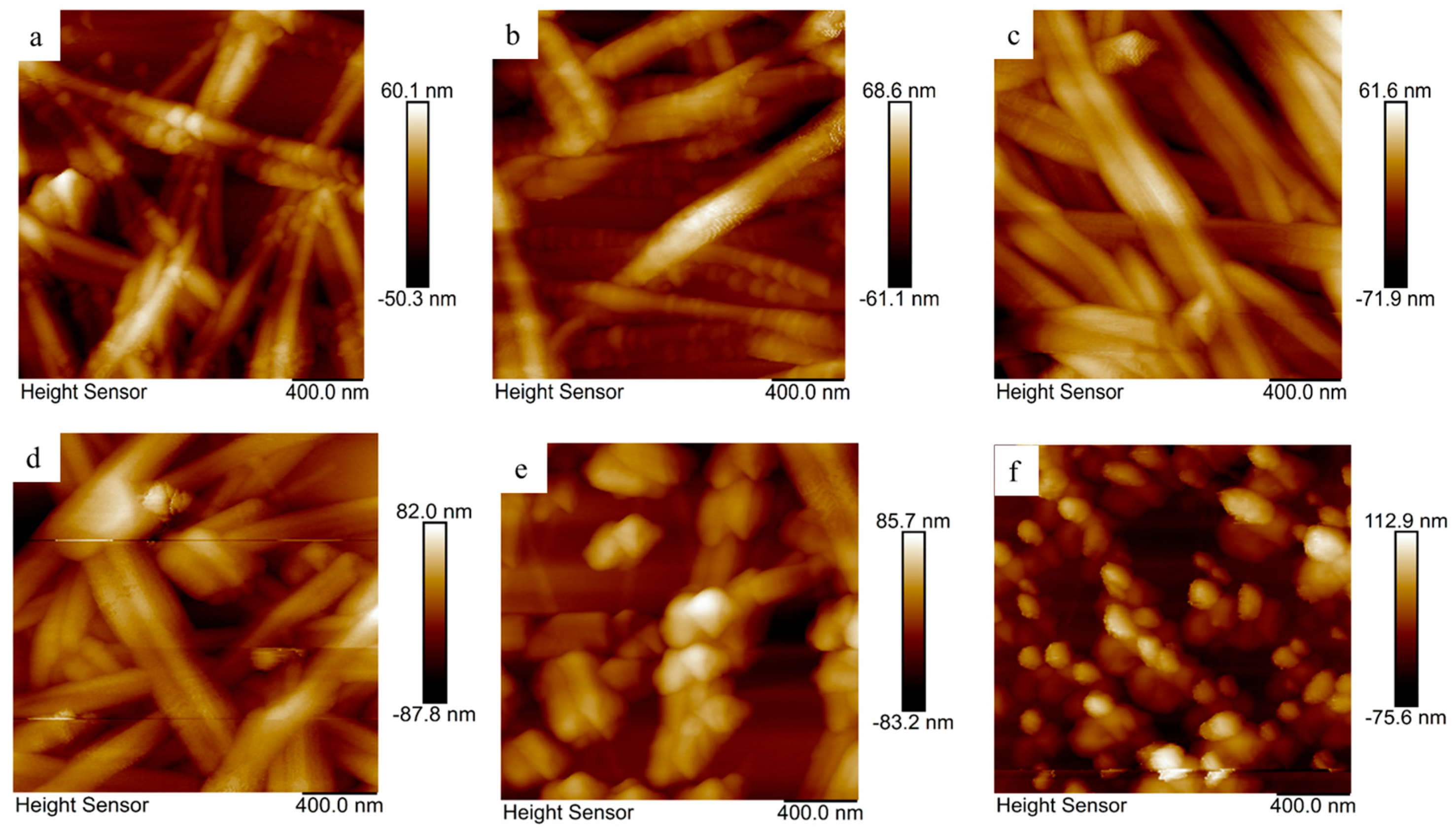

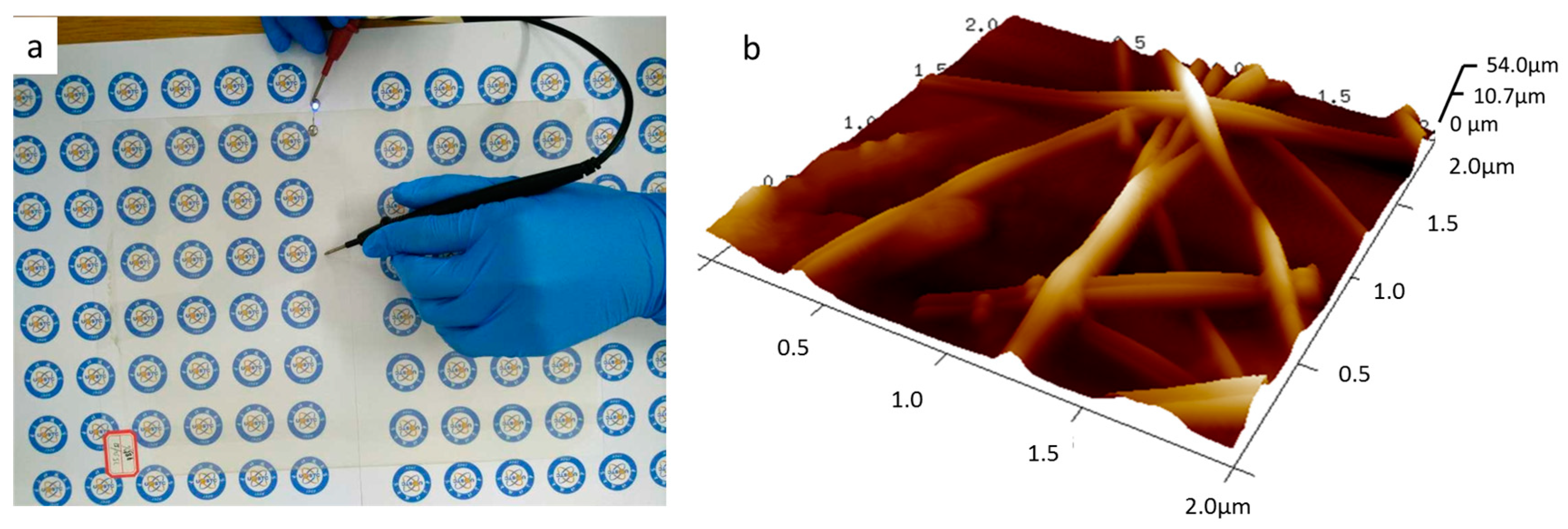

3.1. Characterization of Silver Nanowires

3.2. Characterization of the Silver Nanowires Films

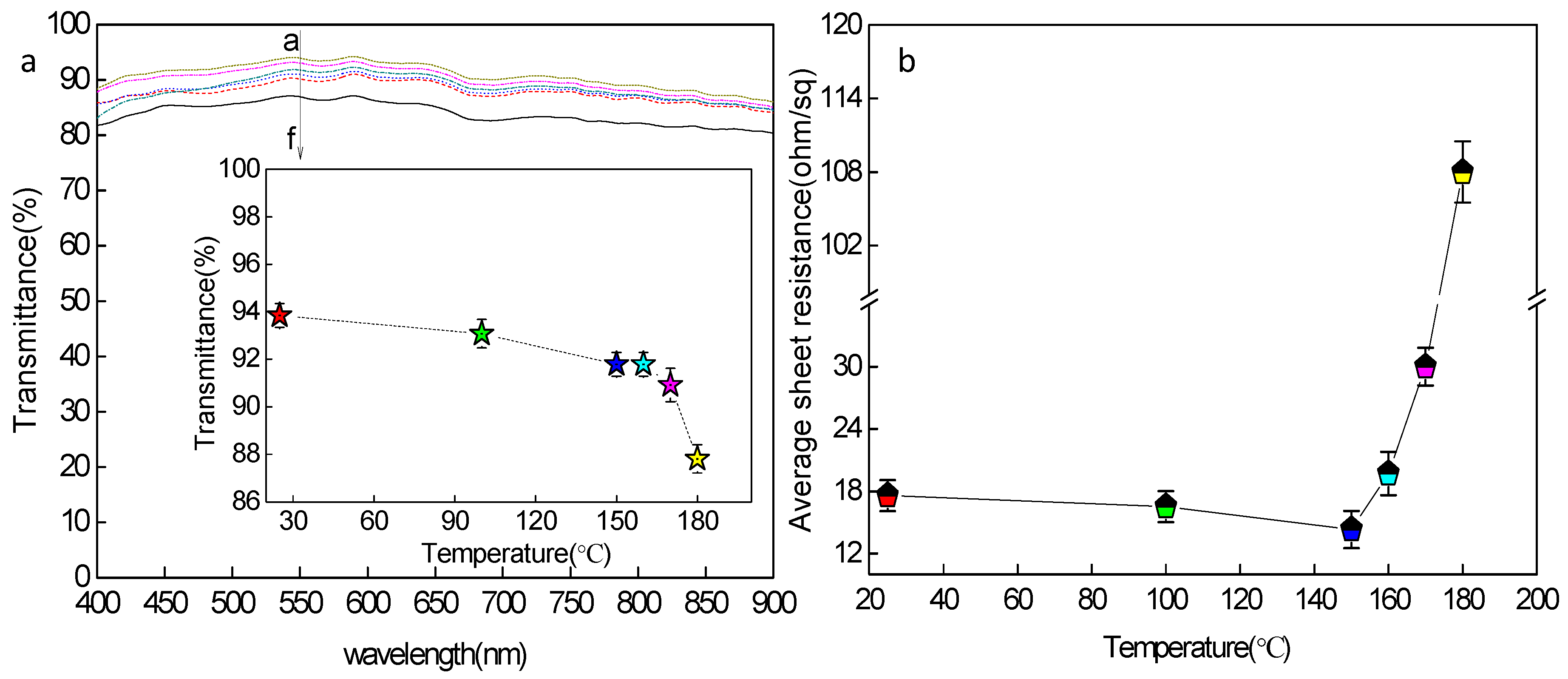

3.3. Optoelectronic Properties of Silver Nanowires Films

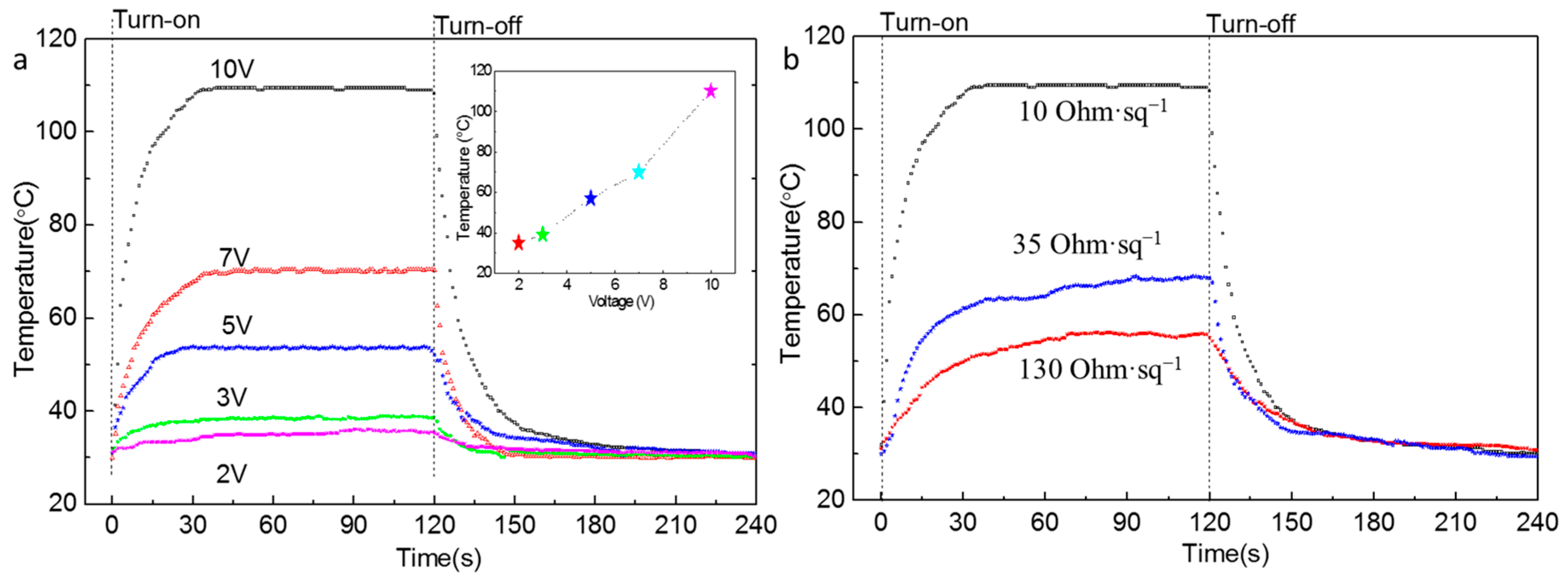

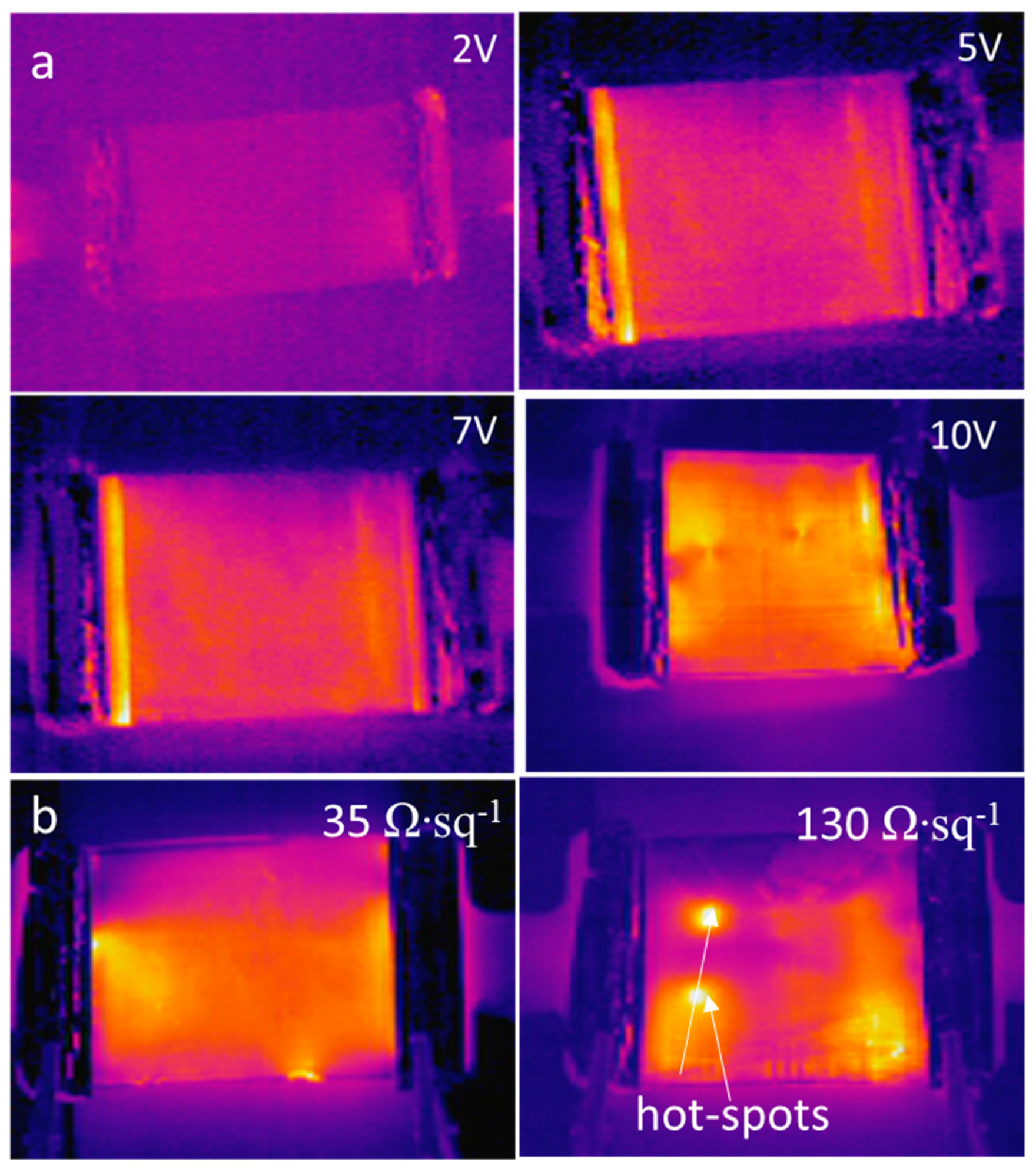

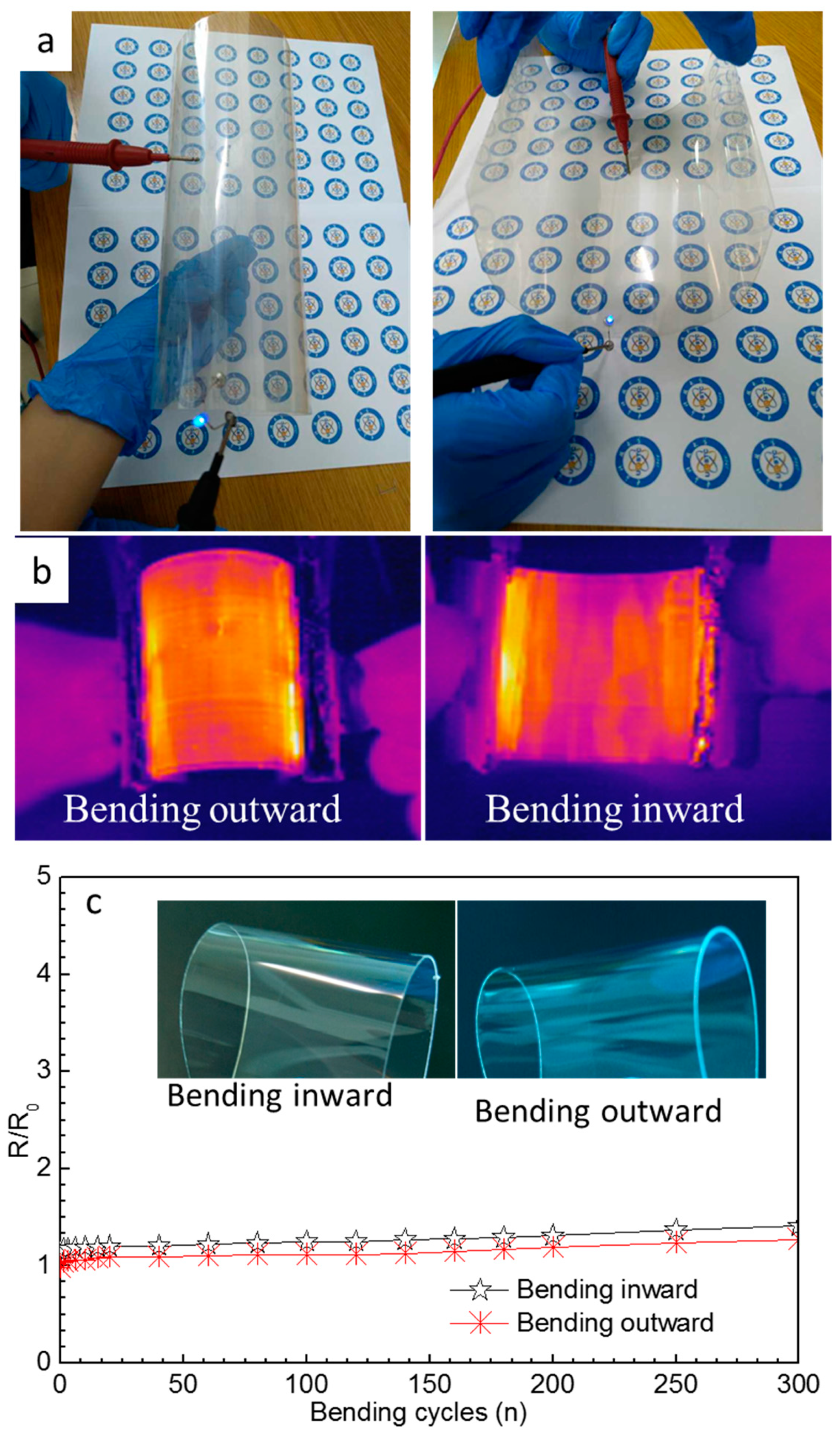

3.4. Electrothermal Performances of the Silver Nanowires Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Leem, D.S.; Edwards, A.; Faist, M.; Nelson, J.; Bradley, D.D.C.; Mello, J.C. Efficient organic solar cells with solution-processed slver nanowire electrodes. Adv. Mater. 2011, 23, 4371–4375. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Stoichkow, V.; Brousseau, E.; Smith, G.C.; Kettle, J. High performing AgNW transparent conducting electrodes with a sheet resistance of 2.5Ω∙sq−1 post-processing technique. Nanoscale 2019, 11, 5760–5769. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure printing of graphene for large-area flexible electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Tung, T.T.; Alotaibi, F.; Nine, M.J.; Silva, R.; Tran, D.N.H.; Janowska, I.; Losic, D. Engineering of highly conductive and ultra-thin nitrogen-doped graphene films by combined methods of microwave irradiation, ultrasonic spraying and thermal annealing. Chem. Eng. J. 2018, 338, 764–773. [Google Scholar] [CrossRef]

- Wang, P.; Peng, Z.; Li, M. Stretchable Transparent conductive films from long carbon nanotube metals. Small 2018, 14, 1802625. [Google Scholar] [CrossRef] [PubMed]

- Araki, T.; Jiu, J.; Nogi, M.; Koga, H.; Nagao, S.; Sugahara, T.; Suganuma, K. Low haze transparent electrodes and highly conducting air dried films with ultra-long silver nanowires synthesized by one-step polyol method. Nano Res. 2014, 7, 236–245. [Google Scholar] [CrossRef]

- Li, D.; Han, T.; Ruan, H. Solution-Assembled Ordered Grids Constructed with Silver Nanowires as Transparent Conductive Electrodes. ACS Omega 2018, 3, 7191–7195. [Google Scholar] [CrossRef]

- Yang, X.; Du, D.; Wang, Y.H. Length-dependent electro-optical properties of silver nanowires-based transparent conducting films. J. Mater. Sci. Mater. Electron. 2019, 30, 6838–6845. [Google Scholar] [CrossRef]

- Schumann, M.F.; Fritz, B.; Eckstein, R.; Lemmer, U.; Gomard, G.; Wegener, M. Cloaking of metal grid electrodes on Lambertian emitters by free-form refractive surfaces. Opt. Lett. 2018, 43, 527–530. [Google Scholar] [CrossRef]

- Abduev, A.; Akmedov, A.; Asvarov, A.; Chiolerio, A. A Revised Growth Model for Transparent Conducting Ga Doped ZnO Films: Improving Crystallinity by Means of Buffer Layers. Plasma Process. Polym. 2015, 12, 725–733. [Google Scholar] [CrossRef]

- Chen, W.C.; Lien, H.T.; Cheng, T.W.; Su, C.; Chong, C.W.; Ganguly, A.; Chen, K.H.; Chen, L.C. Side group of poly(3-alkylthiophene)s controlled dispersion of single-walled carbon nanotubes for transparent conducting Film. ACS Appl. Mater. Interfaces 2015, 7, 4616–4622. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kim, B.; Im, I.; Kim, D.; Lee, H.; Nam, J.; Chung, H.K.; Lee, H.J.; Cho, S.M. Employment of gold-coated silver nanowires as transparent conductive electrode for organic light emitting diodes. Nanotechnology 2017, 28, 345201. [Google Scholar] [CrossRef]

- Sohn, H.; Woo, Y.S.; Shin, W.; Yun, D.J.; Lee, T.; Kim, F.S.; Hwang, J. Novel transparent conductor with enhanced conductivity: Hybrid of silver nanowires and dual-doped grapheme. Appl. Surf. Sci. 2017, 419, 63–66. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Wei, W.; Tao, J.; Lei, G.D.; Wan, M.; Li, S.; Ji, S.; Ye, C. Fabrication of silver nanowire transparent conductive films with an ultra-low haze and ultra-high uniformity and their application in transparent electronics. J. Mater. Chem. C 2017, 5, 2240–2246. [Google Scholar] [CrossRef]

- Hemmati, S.; Barkey, D.P. Parametric Study, Sensitivity Analysis, and Optimization of Polyol Synthesis of Silver Nanowires. ECS J. Solid State Sci. Technol. 2017, 6, 132–137. [Google Scholar] [CrossRef]

- Kwon, J.; Suh, Y.D.; Lee, J.; Lee, P.; Han, S.; Hong, S.; Yeo, J.; Lee, H.; Ko, S.H. Recent progress in silver nanowire based flexible/wearable optoelectronics. J. Mater. Chem. C 2018, 6, 7445–7461. [Google Scholar] [CrossRef]

- Bergin, S.M.; Chen, Y.H.; Rathmell, A.R.; Charbonneau, P.; Li, Z.Y.; Wiley, B.J. The effect of nanowire length and diameter on the properties of transparent, conducting nanowire films. Nanoscale 2012, 4, 1996–2004. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jia, Y.G.; Chen, C.; Jia, D.; Li, S.X.; Ji, S.L.; Ye, C.H. Silver Nanowire Transparent Conductive Films with High Uniformity Fabricated via a Dynamic Heating Method. ACS Appl. Mater. Interfaces 2016, 8, 9865–9871. [Google Scholar] [CrossRef]

- Liu, R.; Tan, M.; Zhang, X.; Xu, L.; Chen, J.; Chen, Y.; Tang, X.; Wan, L. Solution-processed composite electrodes composed of silver nanowires and aluminum-doped zinc oxide nanoparticles for thin-film solar cells applications. Sol. Energy Mater. Sol. Cells 2018, 174, 584–592. [Google Scholar] [CrossRef]

- Jo, W.; Kang, H.S.; Choi, J.; Lee, H.; Kim, H.-T. Plasticized Polymer Interlayer for Low-Temperature Fabrication of a High-Quality Silver Nanowire-Based Flexible Transparent and Conductive Film. ACS Appl. Mater. Interfaces 2017, 9, 15114–15121. [Google Scholar] [CrossRef]

- Lagrange, M.; Langley, D.P.; Giusti, G.; Jimenez, C.; Bréchet, Y.; Bellet, D. Optimization of silver nanowire-based transparent electrodes: Effects of density, size and thermal annealing. Nanoscale 2015, 7, 17410–17423. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiu, J.; Araki, T.; Nogi, M.; Sugahara, T.; Nagao, S.; Koga, H.; He, P.; Suganuma, K. Silver Nanowire Electrodes: Conductivity Improvement Without Post-treatment and Application in Capacitive Pressure Sensors. Nano-Micro Lett. 2015, 7, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Xu, Q.S.; Huang, Q.J.; Tan, R.Q.; Shen, W.F.; Song, W.J. Fabrication of Flexible Transparent Conductive Films with Silver Nanowire by Vacuum Filtration and PET Mold Transfer. J. Mater. Sci. Technol. 2016, 32, 158–161. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, J.; Dong, L.; Pan, Y.; Yang, C.; Li, M.; Ruan, Y.; Ma, J.; Lu, H. Coating-free, air-stable silver nanowires for high-performance transparent conductive film. Nanotechnology 2018, 29, 375601. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Guo, J.N.; Xu, D.; Sun, Y.; Yan, F. One-pot synthesis and purification of ultra-long silver nanowires for flexible transparent conductive electrodes. ACS Appl. Mater. Interfaces 2017, 9, 25465–25473. [Google Scholar] [CrossRef]

- Sorel, S.; Lyons, P.E.; De, S.; Dickerson, J.C.; Coleman, J.N. The dependence of the optoelectrical properties of silver nanowire networks on nanowire length and diameter. Nanotechnology 2012, 23, 185201. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, Y.Y.; Shi, R.; Cao, L.; Wang, Z.; Sun, T.; Lin, J.; Liu, J.; Huang, W. High-yield and rapid synthesis of ultrathin silver nanowires for low-haze transparent conductors. RSC Adv. 2017, 7, 4891–4895. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.H.; Chiang, K.M.; Kang, H.W.; Chi, W.J.; Chang, J.H.; Wu, C.I.; Lin, H.W. A solution-processed molybdenum oxide treated silver nanowire network: A highly conductive transparent conducting electrode with superior mechanical and hole injection properties. Nanoscale 2015, 7, 4572–4579. [Google Scholar] [CrossRef]

- Chiang, K.M.; Huang, Z.Y.; Tsai, W.L.; Lin, H.W. Orthogonally weaved silver nanowire networks for very efficient organic optoelectronic devices. Org. Electron. 2017, 43, 15–20. [Google Scholar] [CrossRef]

- Kang, S.; Kim, T.; Cho, S.; Lee, Y.; Choe, A.; Walker, B.; Ko, S.J.; Kim, J.Y.; Ko, H. Capillary Printing of Highly Aligned Silver Nanowire Transparent Electrodes for High-Performance Optoelectronic Devices. Nano Lett. 2015, 15, 7933–7942. [Google Scholar] [CrossRef]

- Novara, C.; Petracca, F.; Virga, A.; Rivolo, P.; Ferrero, S.; Chiolerio, A.; Geobaldo, F.; Porro, S.; Fabrizio Giorgis, F. SERS active silver nanoparticles synthesized by inkjet printing on mesoporous silicon. Nanoscale Res. Lett. 2014, 9, 527. [Google Scholar] [CrossRef] [PubMed]

- Castellino, M.; Chiolerio, A.; Shahzad, M.I.; Jagdale, P.V.; Tagliaferro, A. Electrical conductivity phenomena in an epoxy resin-carbon-based materials composite. Compos. Part A Appl. Sci. Manuf. 2014, 61, 108–114. [Google Scholar] [CrossRef]

- Marus, M.; Hubarevich, A.; Lim, R.J.W.; Huang, H.; Smirnov, A.; Wong, H.; Fan, W.J.; Sun, X.W. Effect of silver nanowire length in a broad range on optical and electrical properties as a transparent conductive film. Opt. Mater. Express 2017, 7, 1105–1112. [Google Scholar] [CrossRef]

- Mayoral, A.; Allard, L.F.; Ferrer, D.; Esparza, R.; Yacaman, M.J. On the behavior of Ag nanowires under high temperature: In situ characterization by aberration-corrected STEM. J. Mater. Chem. 2011, 21, 893–898. [Google Scholar] [CrossRef]

- Komoda, N.; Nogi, M.; Suganuma, K.; Kohno, K.; Akiyama, Y.; Otsuka, K. Printed silver nanowire antennas with low signal loss at high-frequency radio. Nanoscale 2012, 4, 3148–3153. [Google Scholar] [CrossRef] [PubMed]

- Chiolerio, A.; Cotto, M.; Pandolfi, P.; Martino, P.; Camarchia, V.; Pirola, M.; Ghione, G. Ag nanoparticle-based inkjet printed planar transmission lines for RF and microwave applications: Considerations on ink composition, nanoparticle size distribution and sintering time. Microelectron. Eng. 2012, 97, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.; Ryu, J.; Kim, H.; Hahn, H. Sintering of Inkjet-Printed Silver Nanoparticles at Room Temperature using Intense Pulsed Light. J. Electron. Mater. 2011, 40, 2268–2277. [Google Scholar] [CrossRef]

- Hwang, H.-Y.; Malhotra, R. Shape-Tuned Junction Resistivity and Self-Damping Dynamics in Intense Pulsed Light Sintering of Silver Nanostructure Films. ACS Appl. Mater. Interfaces 2019, 11, 3536–3546. [Google Scholar] [CrossRef]

- Wang, F.; Tang, Z.; He, H. Stress-Dislocation Interaction Mechanism in Low-Temperature Thermo-Compression Sintering of Ag NPs. AIP Adv. 2018, 8, 045012. [Google Scholar] [CrossRef]

- Wakai, F.; Brakke, K.A. Mechanics of Sintering for Coupled Grain Boundary and Surface Diffusion. Acta Mater. 2011, 59, 5379–5387. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Du, D.; Yang, X.; Zhang, X.; Zhao, Y. Optoelectronic and Electrothermal Properties of Transparent Conductive Silver Nanowires Films. Nanomaterials 2019, 9, 904. https://doi.org/10.3390/nano9060904

Wang Y, Du D, Yang X, Zhang X, Zhao Y. Optoelectronic and Electrothermal Properties of Transparent Conductive Silver Nanowires Films. Nanomaterials. 2019; 9(6):904. https://doi.org/10.3390/nano9060904

Chicago/Turabian StyleWang, Yuehui, Dexi Du, Xing Yang, Xianfeng Zhang, and Yuzhen Zhao. 2019. "Optoelectronic and Electrothermal Properties of Transparent Conductive Silver Nanowires Films" Nanomaterials 9, no. 6: 904. https://doi.org/10.3390/nano9060904

APA StyleWang, Y., Du, D., Yang, X., Zhang, X., & Zhao, Y. (2019). Optoelectronic and Electrothermal Properties of Transparent Conductive Silver Nanowires Films. Nanomaterials, 9(6), 904. https://doi.org/10.3390/nano9060904