Paper-Cut Flexible Multifunctional Electronics Using MoS2 Nanosheet

Abstract

:1. Introduction

2. Experiment and Method

3. Result and Discussion

3.1. Concept and Inspiration of Paper-Cut Electronics

3.2. Structure of the Paper-Cut Electronics

3.3. Exfoliation Method and Electrical Characterization of the Sensing Layer

3.4. Fabrication Process and Device Characteristics

3.5. Optimization of the Kirigami Structures

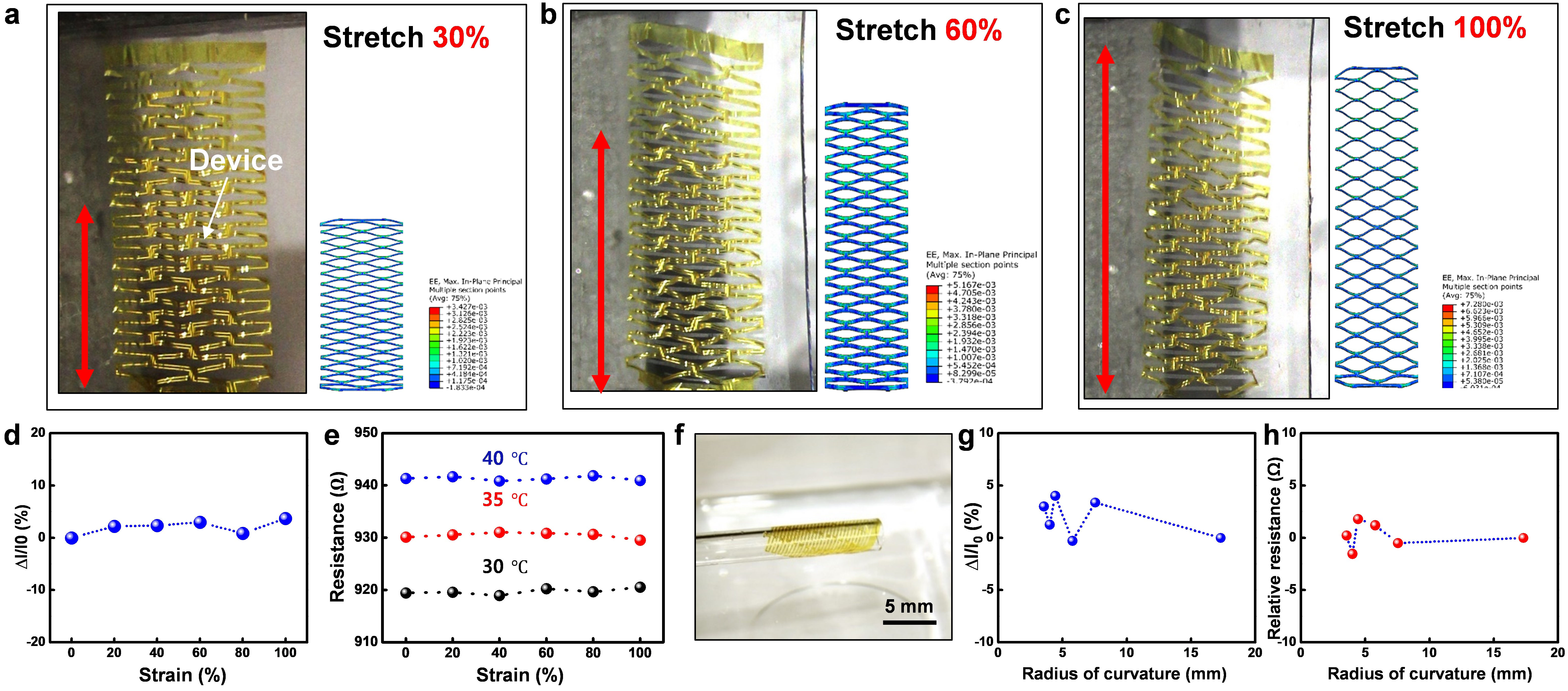

3.6. Stretchability and Flexibility Test

3.7. Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, T.C.; Fu, C.M.; Ma, M.H.M.; Fang, C.C.; Turner, A.M. Healthcare Applications of Smart Watches. A Systematic Review. Appl. Clin. Inf. 2016, 7, 850. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef]

- Lutjeboer, T.; Van Netten, J.J.; Postema, K.; Hijmans, J.M. Validity and Feasibility of a Temperature Sensor for Measuring Use and Non-Use of Orthopaedic Footwear. J. Rehabil. Med. 2018, 50, 920. [Google Scholar] [CrossRef]

- Scalisi, R.G.; Paleari, M.; Favetto, A.; Stoppa, M.; Ariano, P.; Pandolfi, P.; Chiolerio, A. Inkjet printed flexible electrodes for surface electromyography. Org. Electron. 2015, 18, 89. [Google Scholar] [CrossRef]

- Shi, Y.Z.; Manco, M.; Moyal, D.; Huppert, G.; Araki, H.; Banks, A.; Joshi, H.; McKenzie, R.; Seewald, A.; Griffin, G.; et al. Soft, stretchable, epidermal sensor with integrated electronics and photochemistry for measuring personal UV exposures. PLoS ONE 2018, 13, e0190233. [Google Scholar] [CrossRef]

- Lee, S.P.; Ha, G.; Wright, D.E.; Ma, Y.J.; Sen-Gupta, E.; Haubrich, N.R.; Branche, P.C.; Li, W.H.; Huppert, G.L.; Johnson, M.; et al. Highly flexible, wearable, and disposable cardiac biosensors for remote and ambulatory monitoring. Npj Digit. Med. 2018, 1, 2. [Google Scholar] [CrossRef]

- Krishnan, S.R.; Ray, T.R.; Ayer, A.B.; Ma, Y.J.; Gutruf, P.; Lee, K.; Lee, J.Y.; Wei, C.; Feng, X.; Ng, B.; et al. Epidermal electronics for noninvasive, wireless, quantitative assessment of ventricular shunt function in patients with hydrocephalus. Sci. Transl. Med. 2018, 10, 8437. [Google Scholar] [CrossRef]

- Han, S.; Kim, J.; Won, S.M.; Ma, Y.J.; Kang, D.; Xie, Z.Q.; Lee, K.T.; Chung, H.U.; Banks, A.; Min, S.; et al. Battery-free, wireless sensors for full-body pressure and temperature mapping. Sci. Transl. Med. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.; Ghaffari, R.; Baker, L.B.; Rogers, J.A. Skin-interfaced systems for sweat collection and analytics. Sci. Adv. 2018, 4, 3921. [Google Scholar] [CrossRef]

- Tian, L.M.; Li, Y.H.; Webb, R.C.; Krishnan, S.; Bian, Z.G.; Song, J.Z.; Ning, X.; Crawford, K.; Kurniawan, J.; Bonifas, A.; et al. Flexible and Stretchable 3 omega Sensors for Thermal Characterization of Human Skin. Adv. Funct. Mater. 2017, 27, 1701282. [Google Scholar] [CrossRef]

- Madhvapathy, S.R.; Ma, Y.J.; Patel, M.; Krishnan, S.; Wei, C.; Li, Y.J.; Xu, S.; Feng, X.; Huang, Y.G.; Rogers, J.A. Epidermal Electronic Systems for Measuring the Thermal Properties of Human Skin at Depths of up to Several Millimeters. Adv. Funct. Mater. 2018, 28, 1802083. [Google Scholar] [CrossRef]

- Li, J.H.; Song, E.M.; Chiang, C.H.; Yu, K.J.; Koo, J.; Du, H.N.; Zhong, Y.S.; Hill, M.; Wang, C.; Zhang, J.Z.; et al. Conductively coupled flexible silicon electronic systems for chronic neural electrophysiology. Proc. Natl. Acad. Sci. USA 2018, 115, 9542. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.Q.; Khang, D.Y.; Song, J.Z.; Sun, Y.G.; Huang, Y.G.; Rogers, J.A. Finite deformation mechanics in buckled thin films on compliant supports. Proc. Natl. Acad. Sci. USA 2007, 104, 15607. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.G.; Choi, W.M.; Jiang, H.Q.; Huang, Y.G.Y.; Rogers, J.A. Controlled buckling of semiconductor nanoribbons for stretchable electronics. Nat. Nanotechnol. 2006, 1, 201. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Ahn, J.H.; Choi, W.M.; Kim, H.S.; Kim, T.H.; Song, J.Z.; Huang, Y.G.Y.; Liu, Z.J.; Lu, C.; Rogers, J.A. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507. [Google Scholar] [CrossRef]

- Yang, S.X.; Ng, E.; Lu, N.S. Indium Tin Oxide (ITO) serpentine ribbons on soft substrates stretched beyond 100%. Extrem. Mech. Lett. 2015, 2, 37. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.H.; Cho, J.; Lee, J.; Huang, X.; Jia, L.; Fan, J.A.; Su, Y.W.; Su, J.; Zhang, H.G.; et al. Stretchable batteries with self-similar serpentine interconnects and integrated wireless recharging systems. Nat. Commun. 2013, 4, 1543. [Google Scholar] [CrossRef] [Green Version]

- Ko, H.C.; Shin, G.; Wang, S.D.; Stoykovich, M.P.; Lee, J.W.; Kim, D.H.; Ha, J.S.; Huang, Y.G.; Hwang, K.C.; Rogers, J.A. Curvilinear Electronics Formed Using Silicon Membrane Circuits and Elastomeric Transfer Elements. Small 2009, 5, 2703. [Google Scholar] [CrossRef]

- Ghosh, T. Stretch, wrap, and relax to smartness. Science 2015, 349, 382. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Y.; Zhang, N.N.; Zou, H.Y.; Liu, R.Y.; Tao, C.Y.; Fan, X.; Wang, Z.L. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 2016, 1, 16138. [Google Scholar] [CrossRef]

- Pang, C.; Lee, G.Y.; Kim, T.I.; Kim, S.M.; Kim, H.N.; Ahn, S.H.; Suh, K.Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Park, J.; Um, D.S.; Lee, Y.; Ko, H. Bioinspired Interlocked and Hierarchical Design of ZnO Nanowire Arrays for Static and Dynamic Pressure-Sensitive Electronic Skins. Adv. Funct. Mater. 2015, 25, 2841. [Google Scholar] [CrossRef]

- Xu, R.; Zverev, A.; Hung, A.; Shen, C.; Irie, L.; Ding, G.; Whitmeyer, M.; Ren, L.; Griffin, B.; Melcher, J.; et al. Kirigami-inspired, highly stretchable micro-supercapacitor patches fabricated by laser conversion and cutting. Microsyst. Nanoeng. 2018, 4, 36. [Google Scholar] [CrossRef]

- Lamoureux, A.; Lee, K.; Shlian, M.; Forrest, S.R.; Shtein, M. Dynamic kirigami structures for integrated solar tracking. Nat. Commun. 2015, 6, 8092. [Google Scholar] [CrossRef]

- Blees, M.K.; Barnard, A.W.; Rose, P.A.; Roberts, S.P.; McGill, K.L.; Huang, P.Y.; Ruyack, A.R.; Kevek, J.W.; Kobrin, B.; Muller, D.A.; et al. Graphene kirigami. Nature 2015, 524, 204. [Google Scholar] [CrossRef]

- Shyu, T.C.; Damasceno, P.F.; Dodd, P.M.; Lamoureux, A.; Xu, L.Z.; Shlian, M.; Shtein, M.; Glotzer, S.C.; Kotov, N.A. A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat. Mater. 2015, 14, 785. [Google Scholar] [CrossRef]

- Tang, Y.C.; Lin, G.J.; Yang, S.; Yi, Y.K.; Kamien, R.D.; Yin, J. Programmable Kiri-Kirigami Metamaterials. Adv. Mater. 2017, 29, 1604262. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhang, L.; Duan, S.S.; Jiang, H.; Shen, J.H.; Li, C.Z. Kirigami-patterned highly stretchable conductors from flexible carbon nanotube-embedded polymer films. J. Mater. Chem. C 2017, 5, 8714. [Google Scholar] [CrossRef]

- Xu, L.Z.; Shyu, T.C.; Kotov, N.A. Origami and Kirigami Nanocomposites. ACS Nano 2017, 11, 7587. [Google Scholar] [CrossRef]

- Xu, S.; Yan, Z.; Jang, K.I.; Huang, W.; Fu, H.R.; Kim, J.; Wei, Z.; Flavin, M.; McCracken, J.; Wang, R.; et al. Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling. Science 2015, 347, 154. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Yan, Z.; Nan, K.W.; Xiao, D.Q.; Liu, Y.H.; Luan, H.W.; Fu, H.R.; Wang, X.Z.; Yang, Q.L.; Wang, J.C.; et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc. Natl. Acad. Sci. USA 2015, 112, 11757. [Google Scholar] [CrossRef]

- Naumis, G.G.; Barraza-Lopez, S.; Oliva-Leyva, M.; Terrones, H. Electronic and optical properties of strained graphene and other strained 2D materials: A review. Rep. Prog. Phys. 2017, 80, 096501. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147. [Google Scholar] [CrossRef]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497. [Google Scholar] [CrossRef]

- Shokri, A.; Salami, N. Gas sensor based on MoS2 monolayer. Sens. Actuat. B Chem. 2016, 236, 378. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, Y.H.; Park, S.Y.; Kim, S.Y.; Jang, H.W. Two-Dimensional Transition Metal Disulfides for Chemoresistive Gas Sensing: Perspective and Challenges. Chemosensors 2017, 5, 15. [Google Scholar] [CrossRef]

- Bana, H.; Travaglia, E.; Bignardi, L.; Lacovig, P.; Sanders, C.E.; Dendzik, M.; Michiardi, M.; Bianchi, M.; Lizzit, D.; Presel, F.; et al. Epitaxial growth of single-orientation high-quality MoS2 monolayers. 2D Mater. 2018, 5, 3. [Google Scholar] [CrossRef]

- Akinwande, D.; Petrone, N.; Hone, J. Two-dimensional flexible nanoelectronics. Nat. Commun. 2014, 5. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, K.; Lee, B.; Kim, Y.; Hong, B.H. Materials for Flexible, Stretchable Electronics: Graphene and 2D Materials. Annu. Rev. Mater. Res. 2015, 45, 63–84. [Google Scholar] [CrossRef]

- Gao, L. Flexible Device Applications of 2D Semiconductors. Small 2017, 13, 1603994. [Google Scholar] [CrossRef]

- Plechinger, G.; Mann, J.; Preciado, E.; Barroso, D.; Nguyen, A.; Eroms, J.; Schuller, C.; Bartels, L.; Korn, T. A direct comparison of CVD-grown and exfoliated MoS2 using optical spectroscopy. Semicond. Sci. Tech. 2014, 29, 064008. [Google Scholar] [CrossRef]

- Chen, X.; Park, Y.J.; Kang, M.; Kang, S.K.; Koo, J.; Shinde, S.M.; Shin, J.; Jeon, S.; Park, G.; Yan, Y.; et al. CVD-grown monolayer MoS2 in bioabsorbable electronics and biosensors. Nat. Commun. 2018, 9, 1690. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.Y.; Song, Y.; Cho, K.; Amani, M.; Ahn, G.H.; Kim, J.K.; Pak, J.; Chung, S.; Javey, A.; Lee, T. Analysis of the interface characteristics of CVD-grown monolayer MoS2 by noise measurements. Nanotechnology 2017, 28, 145702. [Google Scholar] [CrossRef] [PubMed]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.Y.; Galli, G.; Wang, F. Emerging photoluminescence in monolayer MoS2. Nano Lett. 2010, 10, 1271. [Google Scholar] [CrossRef] [PubMed]

- Bertolazzi, S.; Brivio, J.; Kis, A. Stretching and breaking of ultrathin MoS2. ACS Nano 2011, 5, 9703–9709. [Google Scholar] [CrossRef] [PubMed]

- Desai, S.B.; Madhvapathy, S.R.; Amani, M.; Kiriya, D.; Hettick, M.; Tosun, M.; Zhou, Y.; Dubey, M.; Ager, J.W., 3rd; Chrzan, D.; et al. Gold-Mediated Exfoliation of Ultralarge Optoelectronically-Perfect Monolayers. Adv. Mater. 2016, 28, 4053. [Google Scholar] [CrossRef] [PubMed]

- Hanakata, P.Z.; Qi, Z.A.; Campbell, D.K.; Park, H.S. Highly stretchable MoS2 kirigami. Nanoscale 2016, 8, 458. [Google Scholar] [CrossRef]

- Zheng, W.; Huang, W.C.; Gao, F.; Yang, H.H.; Dai, M.J.; Liu, G.B.; Yang, B.; Zhang, J.; Fu, Y.Q.; Chen, X.S.; et al. Kirigami-Inspired Highly Stretchable Nanoscale Devices Using Multidimensional Deformation of Monolayer MoS2. Chem. Mater. 2018, 30, 6063. [Google Scholar] [CrossRef]

- Cai, L.; Shearer, M.J.; Zhao, Y.Z.; Hu, Z.L.; Wang, F.; Zhang, Y.; Eliceiri, K.W.; Hamers, R.J.; Yan, W.S.; Wei, S.Q.; et al. Chemically Derived Kirigami of WSe2. J. Am. Chem. Soc. 2018, 140, 10980. [Google Scholar] [CrossRef]

- SIMULIA. Abaqus 6.14 Theory Manual; Dassault Systemes SIMULIA Corporation: Johnston, RI, USA, 2014; p. 651. [Google Scholar]

- Chiolerio, A.; Roppolo, I.; Cauda, V.; Crepaldi, M.; Bocchini, S.; Bejtka, K.; Verna, A.; Pirri, C.F. Ultraviolet mem-sensors: Flexible anisotropic composites featuring giant photocurrent enhancement. Nano Res. 2015, 8, 1956. [Google Scholar] [CrossRef]

- Kim, D.H.; Lu, N.S.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.D.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal Electronics. Science 2011, 333, 838. [Google Scholar] [CrossRef]

- Kim, J.; Banks, A.; Cheng, H.Y.; Xie, Z.Q.; Xu, S.; Jang, K.I.; Lee, J.W.; Liu, Z.J.; Gutruf, P.; Huang, X.; et al. Epidermal Electronics with Advanced Capabilities in Near-Field Communication. Small 2015, 11, 906. [Google Scholar] [CrossRef]

- Liu, Y.H.; Norton, J.J.S.; Qazi, R.; Zou, Z.N.; Ammann, K.R.; Liu, H.; Yan, L.Q.; Tran, P.L.; Jang, K.I.; Lee, J.W.; et al. Epidermal mechano-acoustic sensing electronics for cardiovascular diagnostics and human-machine interfaces. Sci. Adv. 2016, 2. [Google Scholar] [CrossRef]

- Velusamy, D.B.; Kim, R.H.; Cha, S.; Huh, J.; Khazaeinezhad, R.; Kassani, S.H.; Song, G.; Cho, S.M.; Cho, S.H.; Hwang, I.; et al. Flexible transition metal dichalcogenide nanosheets for band-selective photodetection. Nat. Commun. 2015, 6, 8063. [Google Scholar] [CrossRef]

- Jeong, S.; Shin, H.Y.; Shin, R.H.; Jo, W.; Yoon, S.; Rubhausen, M. Raman scattering studies of the lattice dynamics in layered MoS2. J. Korean Phys. Soc. 2015, 66, 1575. [Google Scholar] [CrossRef]

- Seo, S.J.; Choi, C.G.; Hwang, Y.H.; Bae, B.S. High performance solution-processed amorphous zinc tin oxide thin film transistor. J. Phys. D Appl. Phys. 2009, 42, 035106. [Google Scholar] [CrossRef]

- Lin, M.W.; Kravchenko, I.I.; Fowlkes, J.; Li, X.F.; Puretzky, A.A.; Rouleau, C.M.; Geohegan, D.B.; Xiao, K. Thickness-dependent charge transport in few-layer MoS2 field-effect transistors. Nanotechnology 2016, 27. [Google Scholar] [CrossRef]

- Menard, E.; Lee, K.J.; Khang, D.Y.; Nuzzo, R.G.; Rogers, J.A. A printable form of silicon for high performance thin film transistors on plastic substrates. Appl. Phys. Lett. 2004, 84, 5398. [Google Scholar] [CrossRef]

- De Fazio, D.; Goykhman, I.; Yoon, D.; Bruna, M.; Eiden, A.; Milana, S.; Sassi, U.; Barbone, M.; Dumcenco, D.; Marinov, K.; et al. High Responsivity, Large-Area Graphene/MoS2 Flexible Photodetectors. ACS Nano 2016, 10, 8252. [Google Scholar] [CrossRef]

- Mueller, T.; Xia, F.N.A.; Avouris, P. Graphene photodetectors for high-speed optical communications. Nat. Photonics 2010, 4, 297. [Google Scholar] [CrossRef]

- Rafsanjani, A.; Zhang, Y.R.; Liu, B.Y.; Rubinstein, S.M.; Bertoldi, K. Kirigami skins make a simple soft actuator crawl. Sci. Robot 2018, 3, 1126. [Google Scholar] [CrossRef]

- Ouyang, H.; Liu, Z.; Li, N.; Shi, B.J.; Zou, Y.; Xie, F.; Ma, Y.; Li, Z.; Li, H.; Zheng, Q.; et al. Symbiotic cardiac pacemaker. Nat. Commun. 2019, 10, 1821. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Wang, H.; Luo, S.; Wang, C.; Zhang, S.; Guo, S. Paper-Cut Flexible Multifunctional Electronics Using MoS2 Nanosheet. Nanomaterials 2019, 9, 922. https://doi.org/10.3390/nano9070922

Yang D, Wang H, Luo S, Wang C, Zhang S, Guo S. Paper-Cut Flexible Multifunctional Electronics Using MoS2 Nanosheet. Nanomaterials. 2019; 9(7):922. https://doi.org/10.3390/nano9070922

Chicago/Turabian StyleYang, Dong, Hao Wang, Shenglin Luo, Changning Wang, Sheng Zhang, and Shiqi Guo. 2019. "Paper-Cut Flexible Multifunctional Electronics Using MoS2 Nanosheet" Nanomaterials 9, no. 7: 922. https://doi.org/10.3390/nano9070922