Fully Atomistic Molecular Dynamics Computation of Physico-Mechanical Properties of PB, PS, and SBS

Abstract

:1. Introduction

2. Details of the MD Simulation and Method

2.1. Force Fields

2.2. Constructing the Polymeric Model

2.3. Methodology of MD Simulation

3. Result and Discussions

3.1. Model Verification and Density Prediction

3.2. Glass Transition Temperature (Tg)

3.3. MD Computation of the Mechanical Properties

3.3.1. Internal Energy Evolution

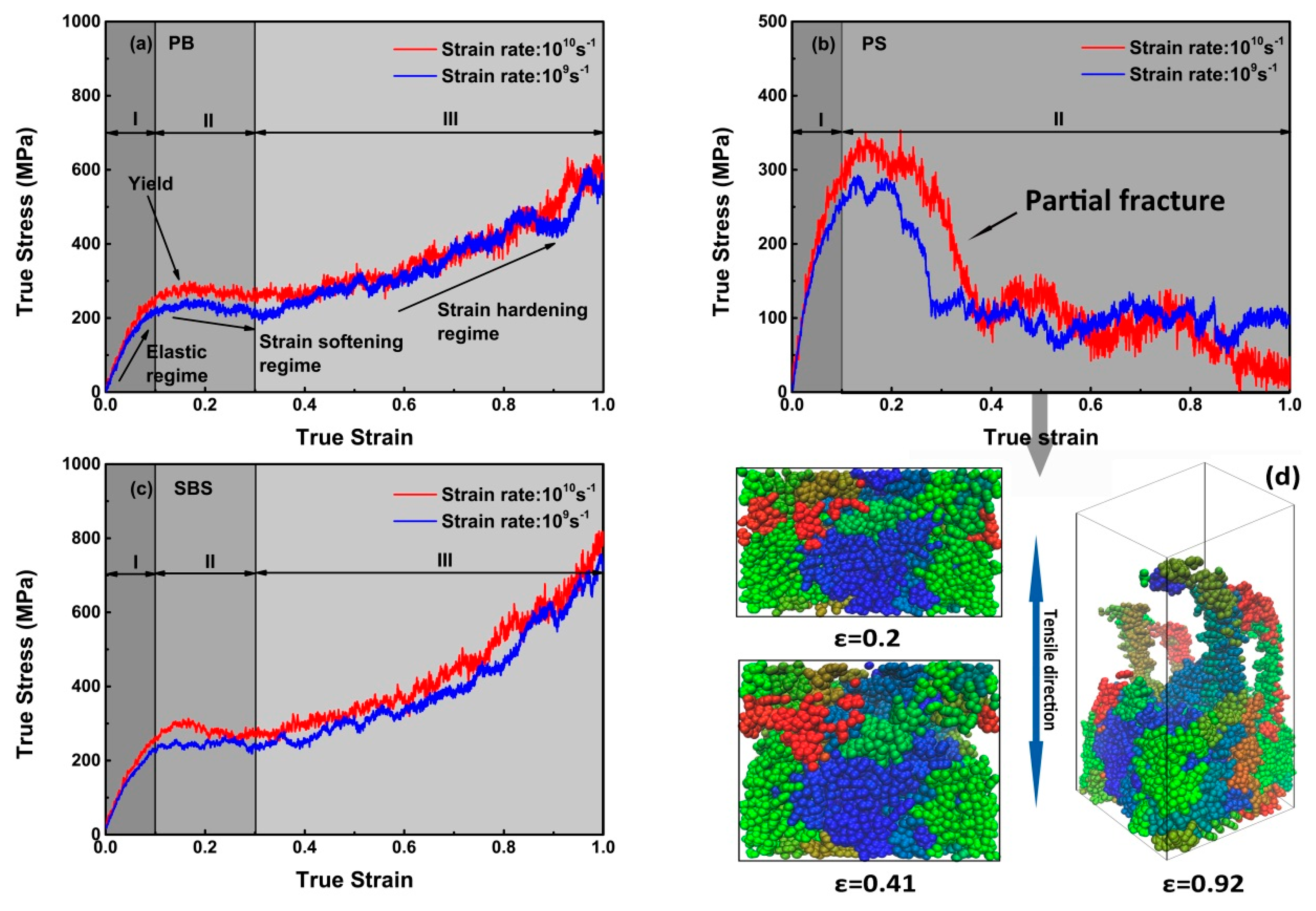

3.3.2. Stress–Strain Curves

3.3.3. Young’s Modulus

4. Conclusions

- (1)

- The predicted densities of the PB, PS and SBS systems at T = 298.15 K and P = 1 atm match well with those obtained by experiments, and their densities are ca. 0.897 ± 0.0033 g/cm3, 1.021 ± 0.0037 g/cm3 and 0.933 ± 0.0034 g/cm3, respectively.

- (2)

- The glass transition temperatures of PB, PS and SBS were predicted based on the relationship between the specific volumes and temperatures. The predicted values of Tg of PB, PS and SBS are ca. 179 K, 380 K, 189 K and 346 K, respectively.

- (3)

- At 100 K, the tensile curves for PB and SBS systems at the strain rate of 1010 s−1, 109 s−1 show four features, which have been observed in experiments, i.e., elastic, yield, softening and hardening.

- (4)

- At 300 K, for PB, PS and SBS under uniaxial loading conditions with the stress–strain responses being calculated in a range of strain rate from 108 to 1010 s−1, their Young’s moduli were in good agreements with those given by experiments via extrapolation based on the linearized Eyring-like model.

Author Contributions

Funding

Conflicts of Interest

References

- Chum, P.S.; Swogger, K.W. Olefin polymer technologies—History and recent progress at the Dow Chemical Company. Prog. Polym. Sci. 2008, 33, 797–819. [Google Scholar] [CrossRef]

- Van Dijk, M.A.; van den Berg, R. Ordering phenomena in thin block copolymer films studied using atomic force microscopy. Macromolecules 1995, 28, 6773–6778. [Google Scholar] [CrossRef]

- Laurer, J.H.; Hajduk, D.A.; Dreckötter, S.; Smith, S.D.; Spontak, R.J. Bicontinuous morphologies in homologous multiblock copolymers and their homopolymer blends. Macromolecules 1998, 31, 7546–7549. [Google Scholar] [CrossRef]

- Jannasch, P.; Hassander, H.; Wesslén, B. On the macro- and microphase separation of compatibilizers in immiscible polymer blends. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1289–1299. [Google Scholar] [CrossRef]

- Ruokolainen, J. Switching supramolecular polymeric materials with multiple length scales. Science 1998, 280, 557–560. [Google Scholar] [CrossRef] [PubMed]

- Spaans, R.D.; Muhammad, M.; Williams, M.C. Probing the interfacial region of microphase-separated block copolymers by differential scanning calorimetry. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 267–274. [Google Scholar] [CrossRef]

- Sun, H. COMPASS: An ab initio force-field optimized for condensed-phase applicationsoverview with details on alkane and benzene compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Sun, H.; Ren, P.; Fried, J.R. The COMPASS force field: Parameterization and validation for phosphazenes. Comput. Theor. Polym. Sci. 1998, 8, 229–246. [Google Scholar] [CrossRef]

- Barrat, J.-L.; Baschnagel, J.O.; Lyulin, A. Molecular dynamics simulations of glassy polymers. Soft Matter 2010, 6, 3430–3446. [Google Scholar] [CrossRef] [Green Version]

- Sahputra, I.H.; Alexiadis, A.; Adams, M.J. Temperature dependence of the Young’s modules of polymers calculated using a hybrid molecular mechanics-molecular dynamics method. J. Phys. Condens. Matter 2018, 30, 355901. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.S.; Jiang, F.C.; Adharapurapu, R.R. Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 2005, 43, 2318–2335. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Daridony, L. Thermodynamic investigation of yield-stress models for amorphous polymers. Philos. Mag. 2007, 87, 3629–3643. [Google Scholar] [CrossRef]

- Pavlov, A.S.; Khalatur, P.G. Filler reinforcement in cross-linked elastomer nanocomposites: Insights from fully atomistic molecular dynamics simulation. Soft Matter 2016, 12, 5402–5419. [Google Scholar] [CrossRef] [PubMed]

- Sun, H. Force field for computation of conformational energies, structures, and vibrational frequencies of aromatic polyesters. J. Comput. Chem. 1994, 15, 752–768. [Google Scholar] [CrossRef]

- Sun, H. Ab initio calculations and force field development for computer simulation of polysilanes. Macromolecules 1995, 28, 701–712. [Google Scholar] [CrossRef]

- Sun, H.; Mumby, S.J.; Maple, J.R.; Hagler, A.T. An ab initio CFF93 all-atom force field for polycarbonates. J. Am. Chem. Soc. 1994, 116, 2978–2987. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Wang, W.-H.; Zhang, Z.; Xu, L.; Li, P. Study of the glass transition temperature and the mechanical properties of PET/modified silica nanocomposite by molecular dynamics simulation. Eur. Polym. J. 2016, 75, 36–45. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.; You, Z.; Bick, A.; Wang, M. Modulus simulation of asphalt binder models using Molecular Dynamics (MD) method. Constr. Build. Mater. 2018, 162, 430–441. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Hossain, D.; Tschopp, M.A.; Ward, D.K.; Bouvard, J.L.; Wang, P.; Horstemeyer, M.F. Molecular dynamics simulations of deformation mechanisms of amorphous polyethylene. Polymer 2010, 51, 6071–6083. [Google Scholar] [CrossRef]

- Yeh, I.-C.; Andzelm, J.W.; Rutledge, G.C. Mechanical and structural characterization of semicrystalline polyethylene under tensile deformation by molecular dynamics simulations. Macromolecules 2015, 48, 4228–4239. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, X.; Liu, L.; Song, M.; Wu, S. Quantitative relationships between intermolecular interaction and damping parameters of irganox-1035/NBR hybrids: A combination of experiments, molecular dynamics simulations, and linear regression analyses. J. Appl. Polym. Sci. 2018, 135, 46202. [Google Scholar] [CrossRef]

- Fetters, L.J.; Lohse, D.J.; Richter, D.; Witten, T.A.; Zirkel, A. Connection between polymer molecular weight, density, chain dimensions, and melt viscoelastic properties. Macromolecules 1994, 27, 4639–4647. [Google Scholar] [CrossRef]

- Galikhanov, M.F.; Luchikhina, T.A. Electret properties of blends of high-density polyethylene and polystyrene. Russ. J. Appl. Chem. 2006, 79, 1153–1157. [Google Scholar] [CrossRef]

- Shin, Y.; Lee, H.; Lee, W.; Ryu, D.Y. Glass transition and thermal expansion behavior of polystyrene films supported on polystyrene-grafted substrates. Macromolecules 2016, 49, 5291–5296. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Okada, O. Molecular dynamics simulation of cis-1,4-polybutadiene. 1. Comparison with experimental data for static and dynamic properties. Polymer 2002, 43, 971–976. [Google Scholar] [CrossRef]

- Zheng, Z.; Shen, J.; Liu, J.; Wu, Y.; Zhang, L.; Wang, W. Tuning the visco-elasticity of elastomeric polymer materials via flexible nanoparticles: Insights from molecular dynamics simulation. RSC Adv. 2016, 6, 28666–28678. [Google Scholar] [CrossRef]

- Zorn, R.; Mopsik, F.I.; McKenna, G.B.; Willner, L.; Richter, D. Dynamics of polybutadienes with different microstructures. 2. Dielectric response and comparisons with rheological behavior. J. Chem. Phys. 1997, 107, 3645–3655. [Google Scholar] [CrossRef]

- Parker, W.O.; Ferrando, A.; Ferri, D.; Canepari, V. Cross-link density of a dispersed rubber measured by129Xe chemical shift. Macromolecules 2007, 40, 5787–5790. [Google Scholar] [CrossRef]

- Masson, J.F.; Bundalo-Perc, S.A.; Delgado, A. Glass transitions and mixed phases in block SBS. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 276–279. [Google Scholar] [CrossRef]

- Kasavan, B.L.; Baglay, R.R.; Roth, C.B. Local glass transition temperature Tg(z) profile in polystyrene next to polybutadiene with and without plasticization effects. Macromol. Chem. Phys. 2018, 219, 1700328. [Google Scholar] [CrossRef]

- Rieger, J. The glass transition temperature of polystyrene. J. Therm. Anal. 1996, 46, 965–972. [Google Scholar] [CrossRef]

- Fox, T.G.; Flory, P.J. Second-order transition temperatures and related properties of polystyrene. I. Influence of molecular weight. J. Appl. Phys. 1950, 21, 581–591. [Google Scholar] [CrossRef]

- Vollmayr-Lee, K.; Kob, W.; Binder, K.; Zippelius, A. Cooling rate dependence and dynamic heterogeneity below the glass transition in a Lennard–Jones glass. Int. J. Mod. Phys. C 1999, 10, 1443–1451. [Google Scholar] [CrossRef]

- Kennedy, J.E.; Devine, D.M.; Lyons, J.G.; Geever, L.M.; Higginbotham, C.L. The synthesis and characterisation of grafted random styrene butadiene for biomedical applications. J. Mater. Sci. 2008, 44, 889–896. [Google Scholar] [CrossRef]

- Mohammady, S.Z.; Mansour, A.A.; Knoll, K.; Stoll, B. Detection of the glass relaxation process of the PS-phase in block copolymers. Polymer 2002, 43, 2467–2478. [Google Scholar] [CrossRef]

- Kennedy, J.E.; Higginbotham, C.L. Synthesis and Characterisation of Styrene Butadiene Styrene Based Grafted Copolymers for Use in Potential Biomedical Applications; InTech: London, UK, 2011. [Google Scholar] [CrossRef]

- Kennedy, J.E.; Lyons, J.G.; Geever, L.M.; Higginbotham, C.L. Synthesis and characterisation of styrene butadiene styrene-g-acrylic acid for potential use in biomedical applications. Mater. Sci. Eng. C 2009, 29, 1655–1661. [Google Scholar] [CrossRef]

- Mohammady, S.Z.; Mansour, A.A.; Stoll, B. Dynamic mechanical relaxation behavior of block copolymers at high temperatures. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 2198–2206. [Google Scholar] [CrossRef]

- Pedemonte, E.; Dondero, G.; Alfonso, G.C.; Candia, F.D. Three-block copolymers: Morphologies and stress-strain properties of samples prepared under various experimental conditions. Polymer 1975, 16, 531–538. [Google Scholar] [CrossRef]

- Capaldi, F.M.; Boyce, M.C.; Rutledge, G.C. Enhanced mobility accompanies the active deformation of a glassy amorphous polymer. Phys. Rev. Lett. 2002, 89, 175505. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Mulder, T.; Vorselaars, B.; Lyulin, A.V.; Michels, M.A.J. Monte Carlo simulation of uniaxial tension of an amorphous polyethylene-like polymer glass. Macromolecules 2006, 39, 7774–7782. [Google Scholar] [CrossRef]

- Min, K.; Silberstein, M.; Aluru, N.R. Crosslinking PMMA: Molecular dynamics investigation of the shear response. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 444–449. [Google Scholar] [CrossRef]

- Cao, A.; Qu, J. Study on the mechanical behavior of tilt bicrystal graphene by molecular dynamics simulations: Bulk verse nanoribbons. J. Appl. Phys. 2012, 112, 043519. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zhang, H.; Cheng, X. The effect of temperature, defect and strain rate on the mechanical property of multi-layer graphene: Coarse-grained molecular dynamics study. Phys. E Low Dimens. Syst. Nanostruct. 2017, 85, 97–102. [Google Scholar] [CrossRef]

- Maebayashi, M.; Matsuoka, T.; Koda, S.; Hashitani, R.; Nishio, T.; Kimura, S.-I. Evaluation of Young’s Modulus for polymer thin film on isotropic substrate by ComplexV(z) curve. Jpn. J. Appl. Phys. 2004, 43, 2920–2923. [Google Scholar] [CrossRef]

- Mishra, S.; Naik, J.B. Effect of treatment of maleic anhydride on mechanical properties of natural fiber: Polystyrene composites. Polym. Plast. Technol. Eng. 2005, 44, 663–675. [Google Scholar] [CrossRef]

- Lempesis, N.; Vogiatzis, G.G.; Boulougouris, G.C.; van Breemen, L.C.A.; Hütter, M.; Theodorou, D.N. Tracking a glassy polymer on its energy landscape in the course of elastic deformation. Mol. Phys. 2013, 111, 3430–3441. [Google Scholar] [CrossRef]

- Alkadasi, N.A.N.; Sarwade, B.D.; Hundiwale, D.G.; Kapadi, U.R. Studies on the effect of titanate coupling agent (2.0%) on the mechanical properties of flyash-filled polybutadiene rubber. J. Appl. Polym. Sci. 2004, 93, 1293–1298. [Google Scholar] [CrossRef]

- Peng, C.; Dong, B.; Zhang, C.; Hu, Y.; Liu, L.; Zhang, X. A host−guest interaction assisted approach for fabrication of polybutadiene nanocomposites reinforced with well-dispersed cellulose nanocrystals. Macromolecules 2018, 51, 4578–4587. [Google Scholar] [CrossRef]

- Zhang, Y.; Mark, J.E.; Zhu, Y.; Ruoff, R.S.; Schaefer, D.W. Mechanical properties of polybutadiene reinforced with octadecylamine modified graphene oxide. Polymer 2014, 55, 5389–5395. [Google Scholar] [CrossRef]

- Hong, C.K.; Kim, H.; Ryu, C.; Nah, C.; Huh, Y.-I.; Kaang, S. Effects of particle size and structure of carbon blacks on the abrasion of filled elastomer compounds. J. Mater. Sci. 2007, 42, 8391–8399. [Google Scholar] [CrossRef]

- Borba, P.M.; Tedesco, A.; Lenz, D.M. Effect of reinforcement nanoparticles addition on mechanical properties of SBS/Curauá fiber composites. Mater. Res. 2014, 17, 412–419. [Google Scholar] [CrossRef]

- Wu, H.; Thakur, V.K.; Kessler, M.R. Novel low-cost hybrid composites from asphaltene/SBS tri-block copolymer with improved thermal and mechanical properties. J. Mater. Sci. 2016, 51, 2394–2403. [Google Scholar] [CrossRef]

| Polymers (-) | Chain No. (-) | Repeat Unit (-) | Molecular Formula (-) | Atom No. (-) | Cubic Cell Length (Å) |

|---|---|---|---|---|---|

| PB | 6 | 120 | 2880C + 4332H | 7212 | 47.596 |

| PS | 4 | 120 | 3840C + 3848H | 7688 | 51.724 |

| SBS | 2 | 10 | 3280C + 4284H | 7564 | 49.458 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Y.; Zhou, D.; Wu, Q.; Duan, F.; Yao, R.; Cai, K. Fully Atomistic Molecular Dynamics Computation of Physico-Mechanical Properties of PB, PS, and SBS. Nanomaterials 2019, 9, 1088. https://doi.org/10.3390/nano9081088

Kang Y, Zhou D, Wu Q, Duan F, Yao R, Cai K. Fully Atomistic Molecular Dynamics Computation of Physico-Mechanical Properties of PB, PS, and SBS. Nanomaterials. 2019; 9(8):1088. https://doi.org/10.3390/nano9081088

Chicago/Turabian StyleKang, Yang, Dunhong Zhou, Qiang Wu, Fuyan Duan, Rufang Yao, and Kun Cai. 2019. "Fully Atomistic Molecular Dynamics Computation of Physico-Mechanical Properties of PB, PS, and SBS" Nanomaterials 9, no. 8: 1088. https://doi.org/10.3390/nano9081088

APA StyleKang, Y., Zhou, D., Wu, Q., Duan, F., Yao, R., & Cai, K. (2019). Fully Atomistic Molecular Dynamics Computation of Physico-Mechanical Properties of PB, PS, and SBS. Nanomaterials, 9(8), 1088. https://doi.org/10.3390/nano9081088