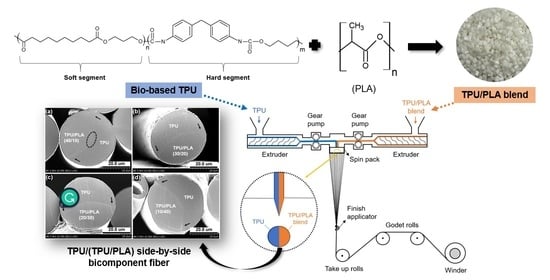

Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

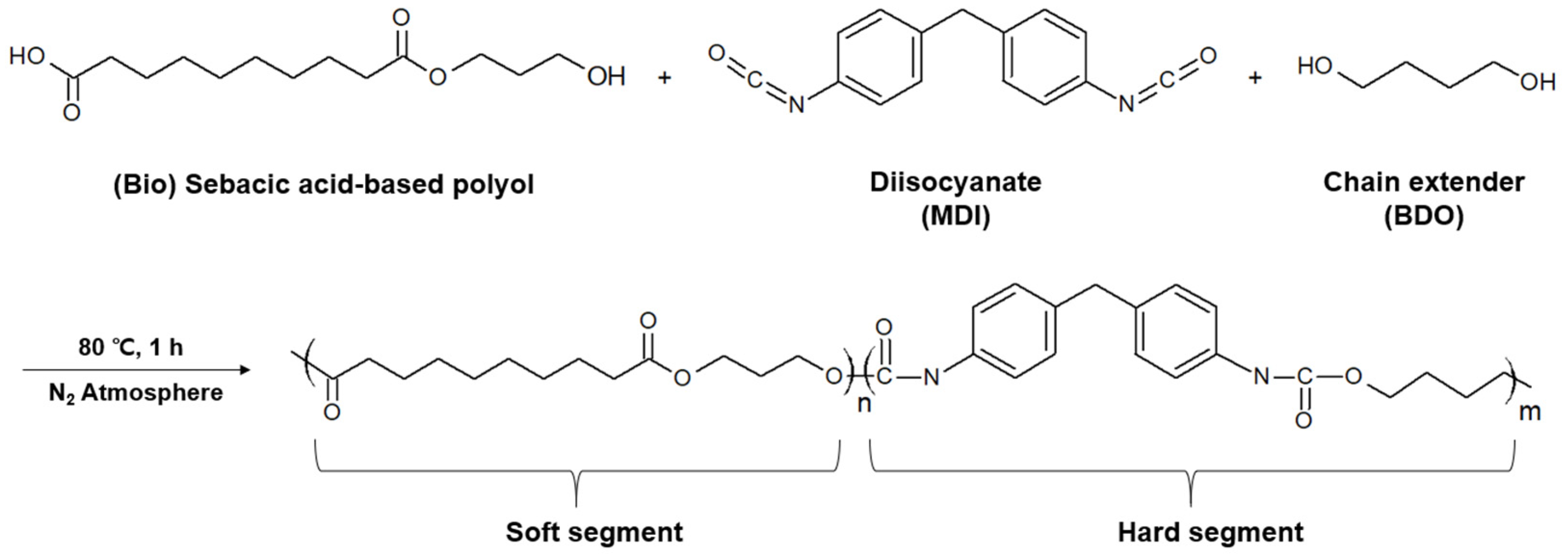

2.2.1. Synthesis of Biomass-Based TPU

2.2.2. Preparation of TPU/PLA Melt Blends

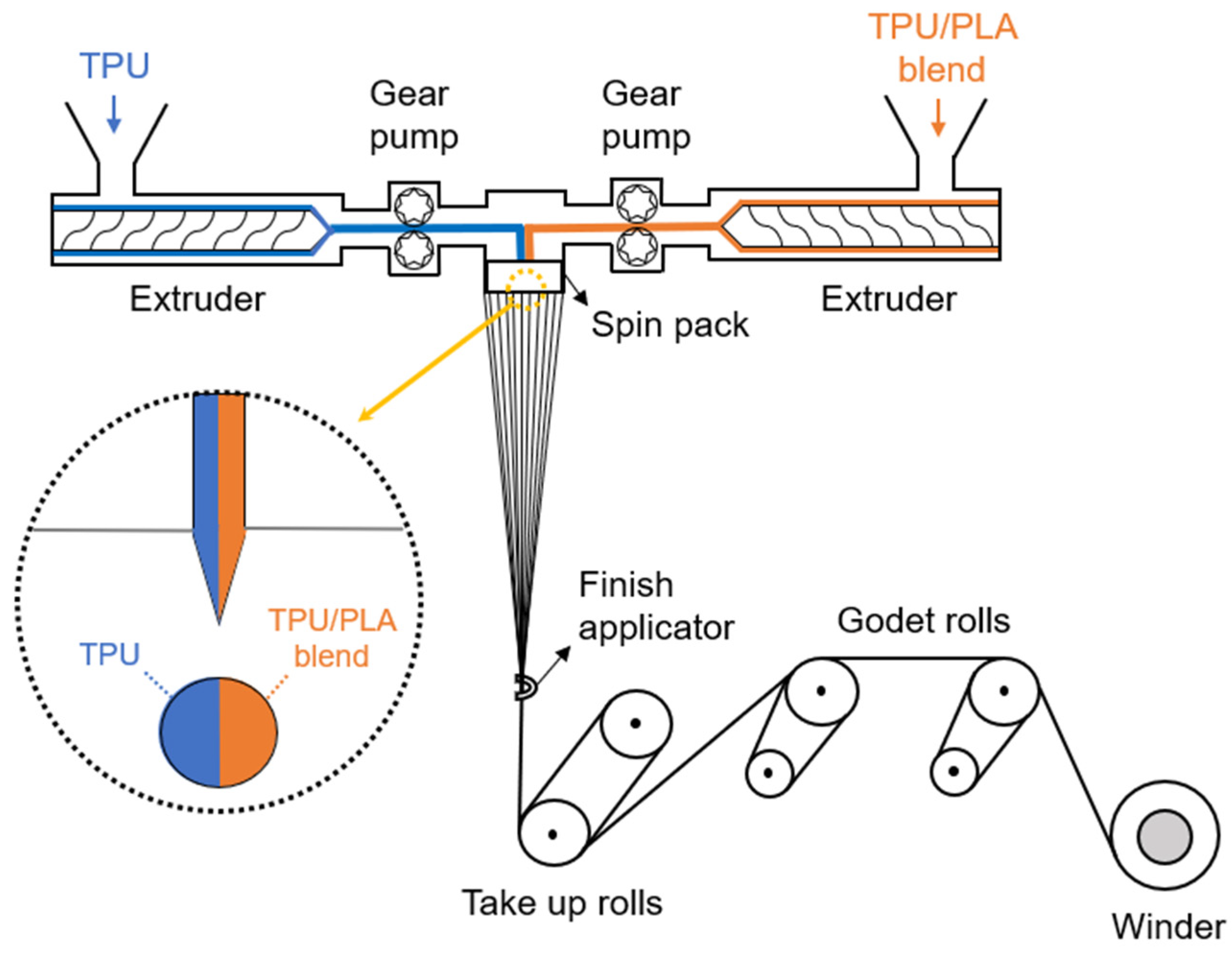

2.2.3. Melt Spinning of TPU/(TPU/PLA) Side-By-side Bicomponent Fibers

2.2.4. Characterization

3. Results and Discussion

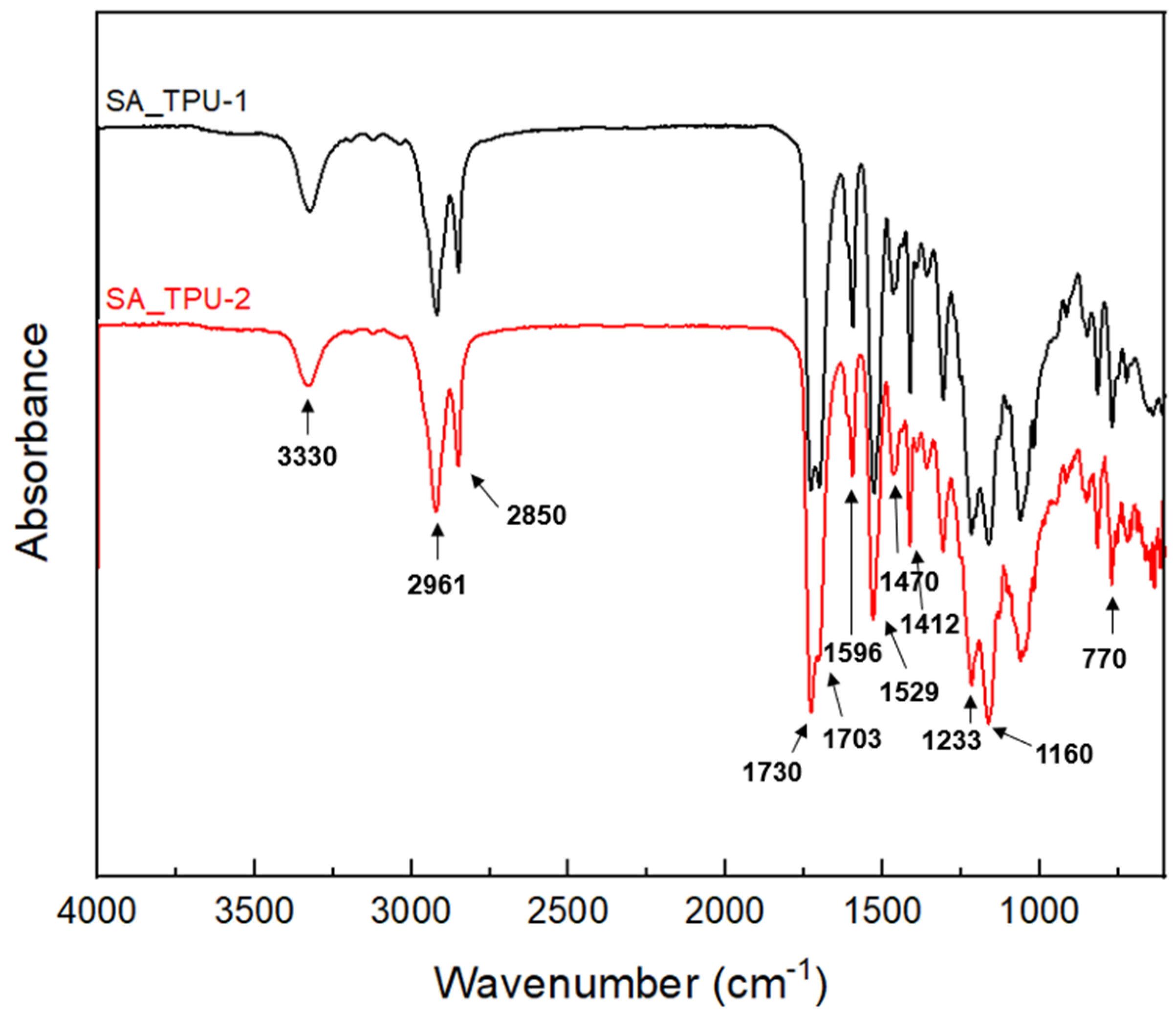

3.1. Characterization of TPU

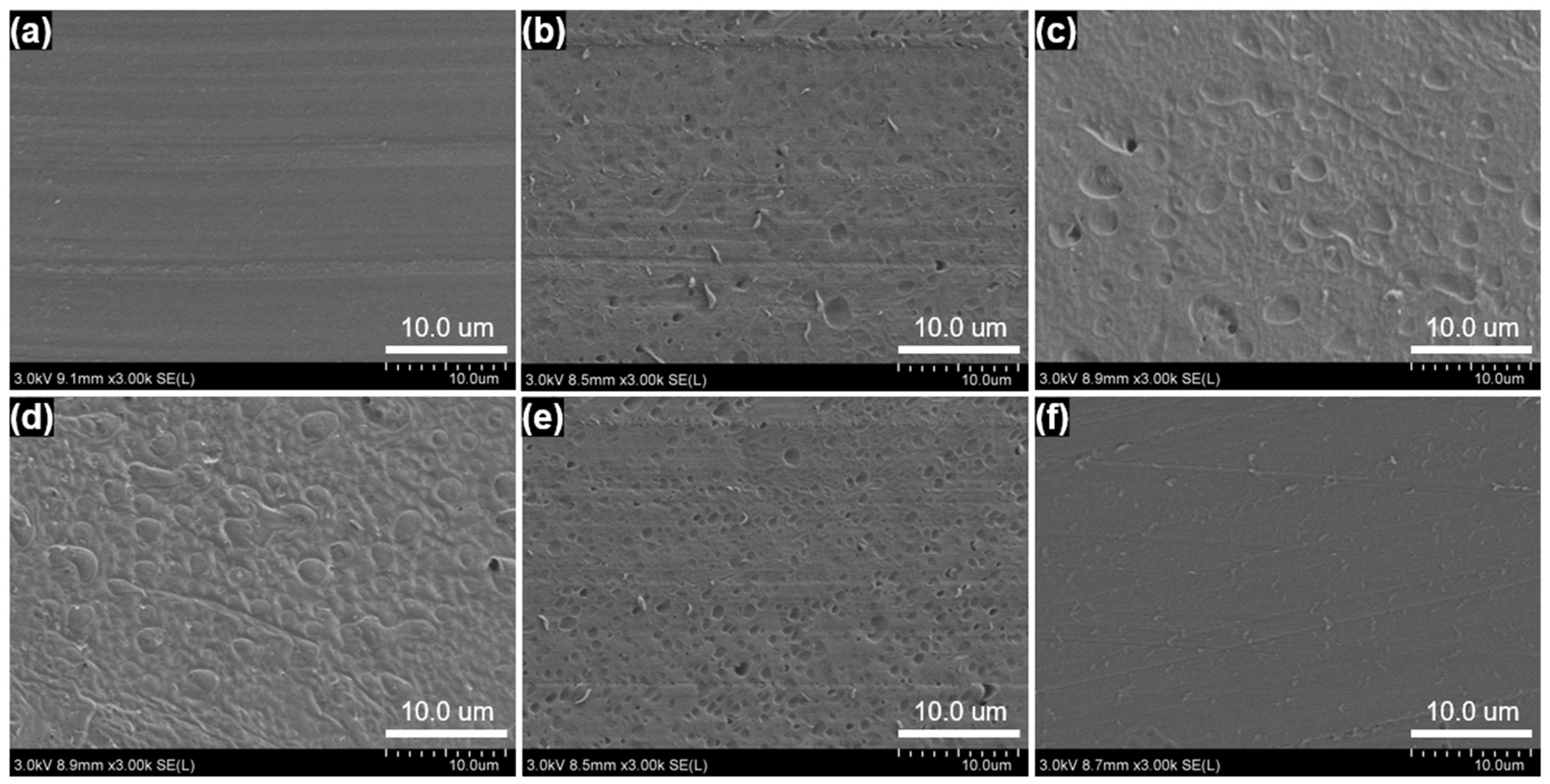

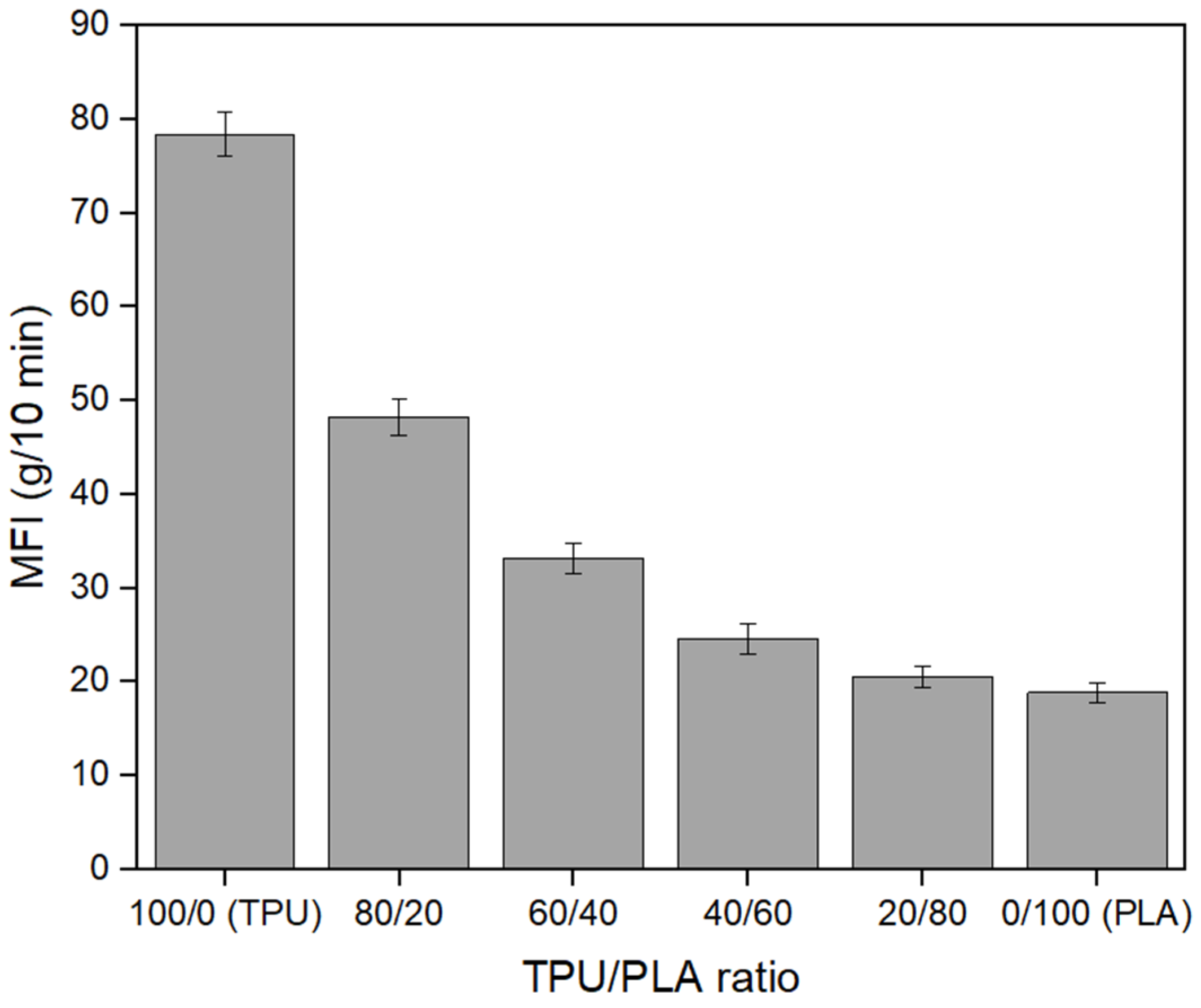

3.2. Characterization of TPU/PLA Blends

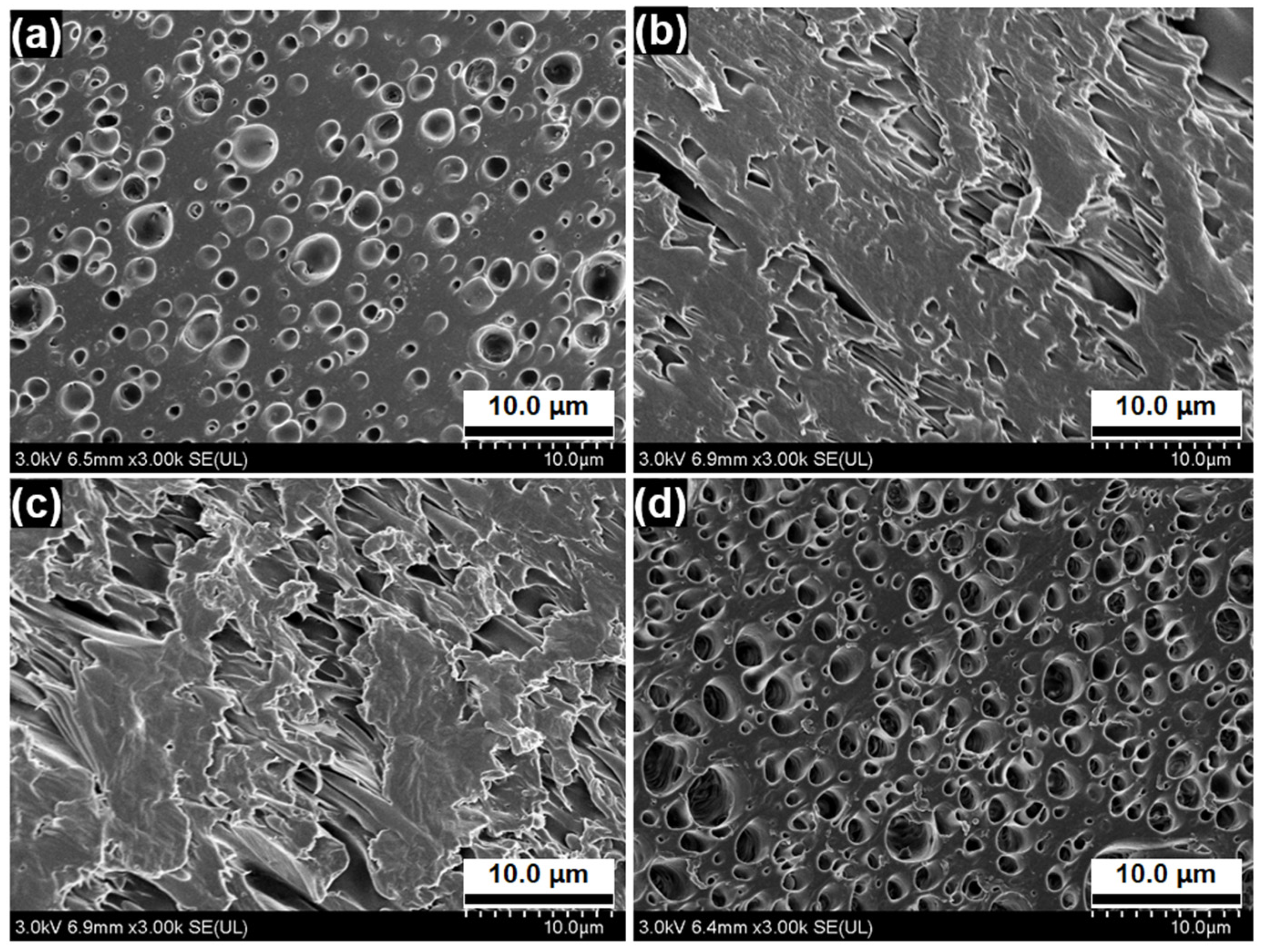

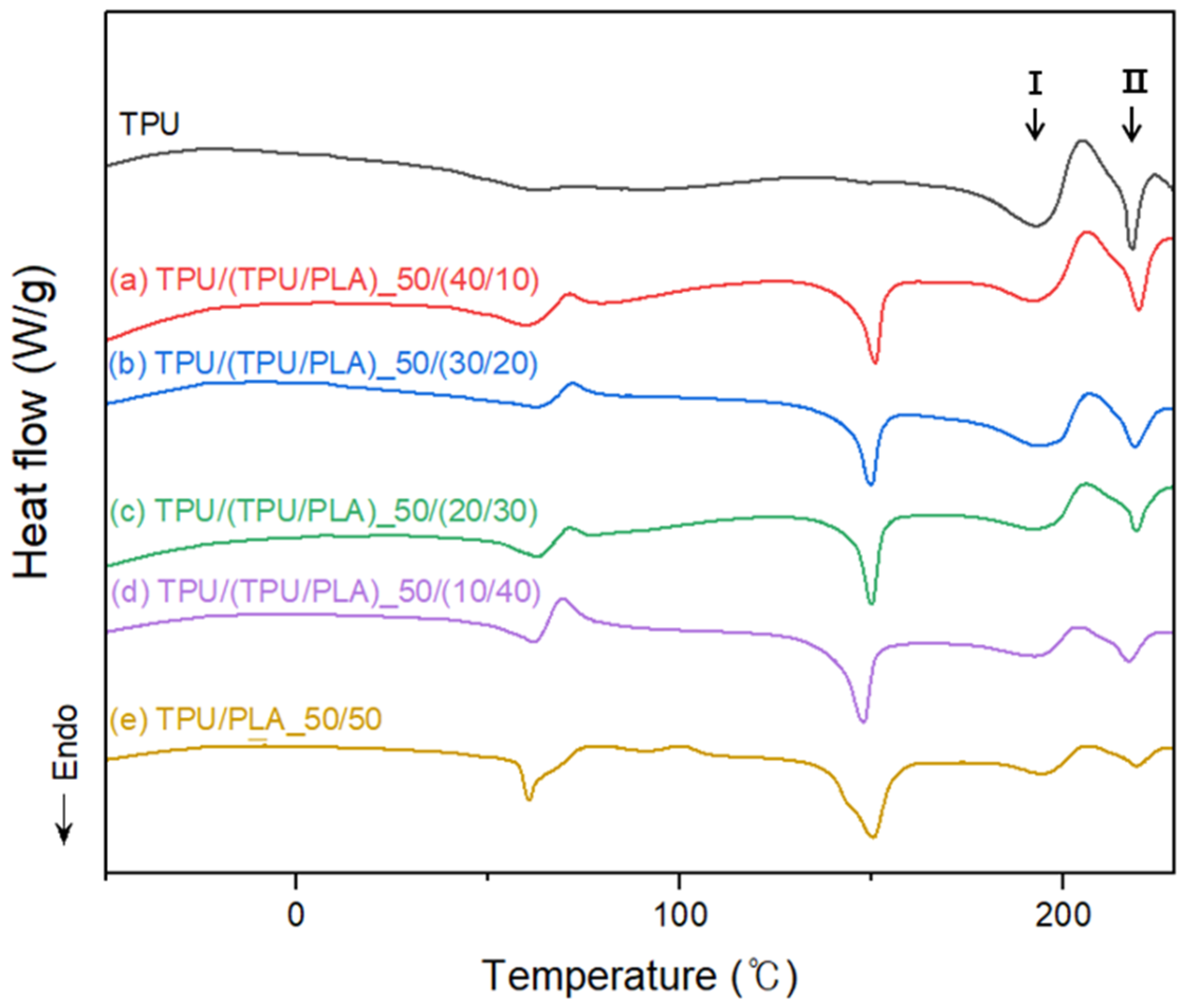

3.3. Characterization of TPU/(TPU/PLA) Side-By-Side Bicomponent Fibers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Varsavas, S.D.; Kaynak, C. Effects of glass fiber reinforcement and thermoplastic elastomer blending on the mechanical performance of polylactide. Compos. Commun. 2018, 8, 24–30. [Google Scholar] [CrossRef]

- Nurul Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Mohamad Haafiz, M.K.; Saurabh, C.K.; Hussin, M.H.; H.P.S., A.K. Green composites made of bamboo fabric and poly (lactic) acid for packaging applications—A review. Materials 2016, 9, 435. [Google Scholar] [CrossRef] [PubMed]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A 2014, 56, 280–289. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, A.H.; Ireana Yusra, A.F. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Eceiza, A.; Larrañaga, M.; de la Caba, K.; Kortaberria, G.; Marieta, C.; Corcuera, M.A.; Mondragon, I. Structure–property relationships of thermoplastic polyurethane elastomers based on polycarbonate diols. J. Appl. Polym. Sci. 2008, 108, 3092–3103. [Google Scholar] [CrossRef]

- Gupta, T.K.; Singh, B.P.; Tripathi, R.K.; Dhakate, S.R.; Singh, V.N.; Panwar, O.S.; Mathur, R.B. Superior nano-mechanical properties of reduced graphene oxide reinforced polyurethane composites. RSC Adv. 2015, 5, 16921–16930. [Google Scholar] [CrossRef]

- Delebecq, E.; Pascault, J.-P.; Boutevin, B.; Ganachaud, F. On the versatility of urethane/urea bonds: Reversibility, blocked isocyanate, and non-isocyanate polyurethane. Chem. Rev. 2013, 113, 80–118. [Google Scholar] [CrossRef]

- Buckley, C.P.; Prisacariu, C.; Martin, C. Elasticity and inelasticity of thermoplastic polyurethane elastomers: Sensitivity to chemical and physical structure. Polymer 2010, 51, 3213–3224. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress–strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Xu, C.; Huang, Y.; Tang, L.; Hong, Y. Low-initial-modulus biodegradable polyurethane elastomers for soft tissue regeneration. ACS Appl. Mater. Interfaces 2017, 9, 2169–2180. [Google Scholar] [CrossRef] [PubMed]

- Kucinska-Lipka, J.; Gubanska, I.; Janik, H.; Sienkiewicz, M. Fabrication of polyurethane and polyurethane based composite fibres by the electrospinning technique for soft tissue engineering of cardiovascular system. Mater. Sci. Eng. C 2015, 46, 166–176. [Google Scholar] [CrossRef] [PubMed]

- Im, H.G.; Ka, K.R.; Kim, C.K. Characteristics of polyurethane elastomer blends with poly(acrylonitrile-co-butadiene) rubber as an encapsulant for underwater sonar devices. Ind. Eng. Chem. Res. 2010, 49, 7336–7342. [Google Scholar] [CrossRef]

- Feng, F.; Ye, L. Morphologies and mechanical properties of polylactide/thermoplastic polyurethane elastomer blends. J. Appl. Polym. Sci. 2011, 119, 2778–2783. [Google Scholar] [CrossRef]

- Tan, L.; Su, Q.; Zhang, S.; Huang, H. Preparing thermoplastic polyurethane/thermoplastic starch with high mechanical and biodegradable properties. RSC Adv. 2015, 5, 80884–80892. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Kessler, M.R. Bio-based polyurethane foam made from compatible blends of vegetable-oil-based polyol and petroleum-based polyol. ACS Sustain. Chem. Eng. 2015, 3, 743–749. [Google Scholar] [CrossRef]

- Sawpan, M.A. Polyurethanes from vegetable oils and applications: A review. J. Polym. Res. 2018, 25, 184. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Zeng, W.; Zhou, Q. High biobased carbon content polyurethane dispersions synthesized from fatty acid-based isocyanate. Ind. Eng. Chem. Res. 2019, 58, 5195–5201. [Google Scholar] [CrossRef]

- Pillai, P.K.S.; Floros, M.C.; Narine, S.S. Elastomers from renewable metathesized palm oil polyols. ACS Sustainable Chem. Eng. 2017, 5, 5793–5799. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Toughening of polylactide by melt blending with a biodegradable poly(ether)urethane elastomer. Macromol. Biosci. 2007, 7, 921–928. [Google Scholar] [CrossRef] [PubMed]

- Jašo, V.; Cvetinov, M.; Rakić, S.; Petrović, Z.S. Bio-plastics and elastomers from polylactic acid/thermoplastic polyurethane blends. J. Appl. Polym. Sci. 2014, 131, 41104. [Google Scholar] [CrossRef]

- Jašo, V.; Rodić, M.V.; Petrović, Z.S. Biocompatible fibers from thermoplastic polyurethane reinforced with polylactic acid microfibers. Eur. Polym. J. 2015, 63, 20–28. [Google Scholar] [CrossRef]

- Hong, H.; Wei, J.; Yuan, Y.; Chen, F.-P.; Wang, J.; Qu, X.; Liu, C.-S. A novel composite coupled hardness with flexibleness—Polylactic acid toughen with thermoplastic polyurethane. J. Appl. Polym. Sci. 2011, 121, 855–861. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Kotek, R.; Esmaeely Neisiany, R.; Nouri Khorasani, S.; Ramakrishna, S. Recent advances in core/shell bicomponent fibers and nanofibers: A review. J. Appl. Polym. Sci. 2018, 135, 46265. [Google Scholar] [CrossRef]

- Hufenus, R.; Affolter, C.; Camenzind, M.; Reifler, F.A. Design and characterization of a bicomponent melt-spun fiber optimized for artificial turf applications. Macromol. Mater. Eng. 2013, 298, 653–663. [Google Scholar] [CrossRef]

- Tallury, S.S.; Pourdeyhimi, B.; Pasquinelli, M.A.; Spontak, R.J. Physical microfabrication of shape-memory polymer systems via bicomponent fiber spinning. Macromol. Rapid Commun. 2016, 37, 1837–1843. [Google Scholar] [CrossRef]

- Yan, X.; Yu, M.; Ramakrishna, S.; Russell, S.J.; Long, Y.-Z. Advances in portable electrospinning devices for in situ delivery of personalized wound care. Nanoscale 2019, 11, 19166–19178. [Google Scholar] [CrossRef]

- Gupta, P.; Wilkes, G.L. Some investigations on the fiber formation by utilizing a side-by-side bicomponent electrospinning approach. Polymer 2003, 44, 6353–6359. [Google Scholar] [CrossRef]

- Peng, H.; Xie, R.; Fang, K.; Cao, C.; Qi, Y.; Ren, Y.; Chen, W. Effect of diethylene glycol on the inkjet printability of reactive dye solution for cotton fabrics. Langmuir 2021, 37, 1493–1500. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Fan, T.; Zhou, R.; Li, J.; Long, Y.; Zhuang, X.; Cheng, B. Fabrication of electrospun sulfonated poly(ether sulfone) nanofibers with amino modified SiO2 nanosphere for optimization of nanochannels in proton exchange membrane. Solid State Ionics 2020, 349, 115300. [Google Scholar] [CrossRef]

- Zhu, S.; Meng, X.; Yan, X.; Chen, S. Evidence for bicomponent fibers: A review. e-Polymers 2021, 21, 636–653. [Google Scholar] [CrossRef]

- Pattamaprom, C.; Wu, C.-H.; Chen, P.-H.; Huang, Y.-L.; Ranganathan, P.; Rwei, S.-P.; Chuan, F.-S. Solvent-free one-shot synthesis of thermoplastic polyurethane based on bio-poly(1,3-propylene succinate) glycol with temperature-sensitive shape memory behavior. ACS Omega 2020, 5, 4058–4066. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Charlon, M.; Heinrich, B.; Matter, Y.; Couzigné, E.; Donnio, B.; Avérous, L. Synthesis, structure and properties of fully biobased thermoplastic polyurethanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur. Polym. J. 2014, 61, 197–205. [Google Scholar] [CrossRef]

- Oh, J.; Kim, Y.K.; Hwang, S.-H.; Kim, H.-C.; Jung, J.-H.; Jeon, C.-H.; Kim, J.; Lim, S.K. Synthesis of thermoplastic polyurethanes containing bio-based polyester polyol and their fiber property. Polymers 2022, 14, 2033. [Google Scholar] [CrossRef] [PubMed]

- Parcheta, P.; Głowińska, E.; Datta, J. Effect of bio-based components on the chemical structure, thermal stability and mechanical properties of green thermoplastic polyurethane elastomers. Eur. Polym. J. 2020, 123, 109422. [Google Scholar] [CrossRef]

- Haverly, M.R.; Fenwick, S.R.; Patterson, F.P.K.; Slade, D.A. Biobased carbon content quantification through ams radiocarbon analysis of liquid fuels. Fuel 2019, 237, 1108–1111. [Google Scholar] [CrossRef]

- Sánchez-Calderón, I.; Bernardo, V.; Santiago-Calvo, M.; Naji, H.; Saiani, A.; Rodríguez-Pérez, M.Á. Effect of the molecular structure of tpu on the cellular structure of nanocellular polymers based on pmma/tpu blends. Polymers 2021, 13, 3055. [Google Scholar] [CrossRef]

- Bockorny, G.d.A.; Forte, M.M.C.; Stamboroski, S.; Noeske, M.; Keil, A.; Leite Cavalcanti, W. Modifying a thermoplastic polyurethane for improving the bonding performance in an adhesive technical process. Appl. Adhes. Sci. 2016, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Ng, H.N.; Allegrezza, A.E.; Seymour, R.W.; Cooper, S.L. Effect of segment size and polydispersity on the properties of polyurethane block polymers. Polymer 1973, 14, 255–261. [Google Scholar] [CrossRef]

- Hu, W.; Koberstein, J.T. The effect of thermal annealing on the thermal properties and molecular weight of a segmented polyurethane copolymer. J. Polym. Sci. Part B: Polym. Phys. 1994, 32, 437–446. [Google Scholar] [CrossRef]

- Kwei, T.K. Phase separation in segmented polyurethanes. J. Appl. Polym. Sci. 1982, 27, 2891–2899. [Google Scholar] [CrossRef]

- Lin, S.B.; Hwang, K.S.; Tsay, S.Y.; Cooper, S.L. Segmental orientation studies of polyether polyurethane block copolymers with different hard segment lengths and distributions. Colloid Polym. Sci. 1985, 263, 128–140. [Google Scholar] [CrossRef]

- Hundiwale, D.G.; Kapadi, U.R.; Pandya, M.V. Effect of macroglycol structure and its molecular weight on physicomechanical properties of polyurethanes. J. Appl. Polym. Sci. 1995, 55, 1329–1333. [Google Scholar] [CrossRef]

- Sohn, M.H.; Li, X.X.; Cho, U.R. Synthesis of polyurethane elastomers by different kinds of acids. Polymer 2019, 43, 824–830. [Google Scholar]

- Kaushik, A.; Ahuja, D.; Salwani, V. Synthesis and characterization of organically modified clay/castor oil based chain extended polyurethane nanocomposites. Compos. Part A 2011, 42, 1534–1541. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, B.; Jiang, Y.; Lei, J.; Zhou, C.; Zhang, J.; Wang, J. Solvent-free and self-catalysis synthesis and properties of waterborne polyurethane. Polymer 2018, 143, 129–136. [Google Scholar] [CrossRef]

- Irusta, L.; Fernandez-Berridi, M.J. Aromatic poly(ester–urethanes): Effect of the polyol molecular weight on the photochemical behaviour. Polymer 2000, 41, 3297–3302. [Google Scholar] [CrossRef]

- Kaushiva, B.D.; McCartney, S.R.; Rossmy, G.R.; Wilkes, G.L. Surfactant level influences on structure and properties of flexible slabstock polyurethane foams. Polymer 2000, 41, 285–310. [Google Scholar] [CrossRef]

- Senich, G.A.; MacKnight, W.J. Fourier transform infrared thermal analysis of a segmented polyurethane. Macromolecules 1980, 13, 106–110. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.F.; Li, Y.; Yao, Z.; Cao, K.; Zeng, C. TPU/PLA blend foams: Enhanced foamability, structural stability, and implications for shape memory foams. J. Appl. Polym. Sci. 2019, 136, 47416. [Google Scholar] [CrossRef]

- Sharudin, R.W.B.; Ohshima, M. Preparation of microcellular thermoplastic elastomer foams from polystyrene-b-ethylene-butylene-b-polystyrene (SEBS) and their blends with polystyrene. J. Appl. Polym. Sci. 2013, 128, 2245–2254. [Google Scholar] [CrossRef]

- Song, J.J.; Chang, H.H.; Naguib, H.E. Design and characterization of biocompatible shape memory polymer (SMP) blend foams with a dynamic porous structure. Polymer 2015, 56, 82–92. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Development of multifunctional polyurethane elastomer composites containing fullerene: Mechanical, damping, thermal, and flammability behaviors. J. Elastomers Plast. 2018, 51, 262–279. [Google Scholar] [CrossRef]

- Karagiannis, A.; Mavridis, H.; Hrymak, A.N.; Vlachopoulos, J. Interface determination in bicomponent extrusion. Polym. Eng. Sci. 1988, 28, 982–988. [Google Scholar] [CrossRef]

- Ayad, E.; Cayla, A.; Rault, F.; Gonthier, A.; LeBlan, T.; Campagne, C.; Devaux, E. Influence of rheological and thermal properties of polymers during melt spinning on bicomponent fiber morphology. J. Mater. Eng. Perform. 2016, 25, 3296–3302. [Google Scholar] [CrossRef]

- Oliaei, E.; Kaffashi, B.; Davoodi, S. Investigation of structure and mechanical properties of toughened poly(l-lactide)/thermoplastic poly(ester urethane) blends. J. Appl. Polym. Sci. 2016, 133, 43104. [Google Scholar] [CrossRef]

- Siahsarani, A.; Behravesh, A.H.; Barmouz, M. Compressive shape memory behavior of spring-shaped polylactic acid alloy type. J. Appl. Polym. Sci. 2017, 134, 45115. [Google Scholar] [CrossRef]

- Kaynak, C.; Meyva, Y. Use of maleic anhydride compatibilization to improve toughness and other properties of polylactide blended with thermoplastic elastomers. Polym. Adv. Technol. 2014, 25, 1622–1632. [Google Scholar] [CrossRef]

- Davachi, S.M.; Kaffashi, B. Preparation and characterization of poly l-lactide/triclosan nanoparticles for specific antibacterial and medical applications. Int. J. Polym. Mater. Polym. Biomater. 2015, 64, 497–508. [Google Scholar] [CrossRef]

- Shakouri, Z.; Nazockdast, H. Microstructural development and mechanical performance of pla/tpu blends containing geometrically different cellulose nanocrystals. Cellulose 2018, 25, 7167–7188. [Google Scholar] [CrossRef]

- Saiani, A.; Daunch, W.A.; Verbeke, H.; Leenslag, J.W.; Higgins, J.S. Origin of multiple melting endotherms in a high hard block content polyurethane. 1. Thermodynamic investigation. Macromolecules 2001, 34, 9059–9068. [Google Scholar] [CrossRef]

- Yahiaoui, M.; Denape, J.; Paris, J.Y.; Ural, A.G.; Alcalá, N.; Martínez, F.J. Wear dynamics of a tpu/steel contact under reciprocal sliding. Wear 2014, 315, 103–114. [Google Scholar] [CrossRef]

| Samples | Mw (g/mol) | Mn (g/mol) | PDI (Mw/Mn) | HS Content (wt%) | Bio-Based C (%) | Reference |

|---|---|---|---|---|---|---|

| SA_TPU-1 | 196,107 | 94,030 | 2.0 | 35.9 | 54.8 | This work |

| SA_TPU-2 | 136,489 | 89,659 | 1.5 | 22.1 | 56.1 | This work |

| CA_TPU-1 | 120,158 | 88,125 | 1.3 | 38.8 | 54.1 | [35] |

| CA_TPU-2 | 113,738 | 84,906 | 1.3 | 22.3 | 53.0 | [35] |

| Samples | Biobased C (%) |

|---|---|

| (a) TPU/(TPU/PLA)_50/(40/10) | 56.6 |

| (b) TPU/(TPU/PLA)_50/(30/20) | 59.2 |

| (c) TPU/(TPU/PLA)_50/(20/30) | 63.8 |

| (d) TPU/(TPU/PLA)_50/(10/40) | 68.4 |

| (e) TPU/PLA_50/50 | 71.5 |

| Samples | Tg, PLA (°C) | Tc (°C) | Tm, PLA (°C) | Tm,I (°C) | Tm,II (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| TPU | - | 69.62 | - | 193.29 | 217.92 | 0.44 |

| (a) TPU/(TPU/PLA)_50/(40/10) | 62.81 | 70.56 | 149.92 | 193.92 | 218.62 | 1.19 |

| (b) TPU/(TPU/PLA)_50/(30/20) | 62.97 | 70.95 | 149.75 | 193.22 | 218.42 | 1.70 |

| (c) TPU/(TPU/PLA)_50/(20/30) | 61.52 | 70.13 | 149.99 | 194.45 | 218.95 | 2.01 |

| (d) TPU/(TPU/PLA)_50/(10/40) | 61.45 | 70.01 | 149.85 | 193.46 | 217.89 | 2.28 |

| (e) TPU/PLA_50/50 | 60.98 | 150.28 | 193.50 | 218.08 | - |

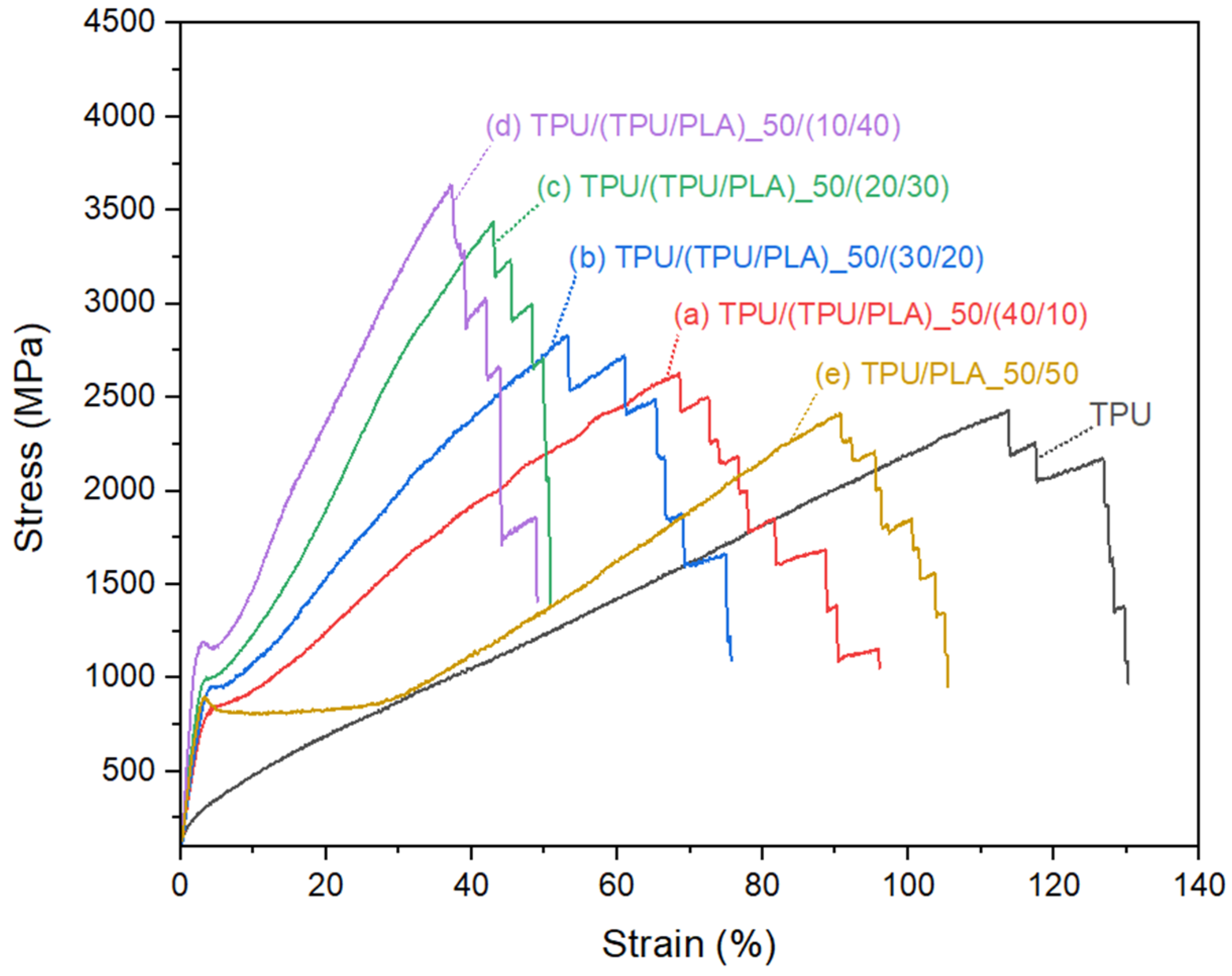

| Samples | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) |

|---|---|---|---|---|

| TPU | 2432 ± 114 | - | 113 ± 36 | 1452 ± 81 |

| (a) TPU/(TPU/PLA)_50/(40/10) | 2627 ± 101 | 864 ± 84 | 68 ± 11 | 2820 ± 60 |

| (b) TPU/(TPU/PLA)_50/(30/20) | 2796 ± 145 | 960 ± 26 | 53 ± 8 | 2880 ± 53 |

| (c) TPU/(TPU/PLA)_50/(20/30) | 3410 ± 113 | 994 ± 30 | 43 ± 5 | 3011 ± 45 |

| (d) TPU/(TPU/PLA)_50/(10/40) | 3624 ± 128 | 1235 ± 101 | 37 ± 4 | 3125 ± 49 |

| (e) TPU/PLA_50/50 | 2152 ± 109 | 909 ± 54 | 90 ± 20 | 2979 ± 55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, J.; Kim, Y.K.; Hwang, S.-H.; Kim, H.-C.; Jung, J.-H.; Jeon, C.-H.; Kim, J.; Lim, S.K. Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends. Fibers 2022, 10, 95. https://doi.org/10.3390/fib10110095

Oh J, Kim YK, Hwang S-H, Kim H-C, Jung J-H, Jeon C-H, Kim J, Lim SK. Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends. Fibers. 2022; 10(11):95. https://doi.org/10.3390/fib10110095

Chicago/Turabian StyleOh, Jiyeon, Young Kwang Kim, Sung-Ho Hwang, Hyun-Chul Kim, Jae-Hun Jung, Cho-Hyun Jeon, Jongwon Kim, and Sang Kyoo Lim. 2022. "Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends" Fibers 10, no. 11: 95. https://doi.org/10.3390/fib10110095

APA StyleOh, J., Kim, Y. K., Hwang, S.-H., Kim, H.-C., Jung, J.-H., Jeon, C.-H., Kim, J., & Lim, S. K. (2022). Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends. Fibers, 10(11), 95. https://doi.org/10.3390/fib10110095