Effect of Fibre Diameter, Prickle Factor and Coarse Fibre Bias on Yarn Surface Hairiness in South American Camelids (SAC) Fibre

Abstract

:1. Introduction

2. Materials and Methods

Statistics

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

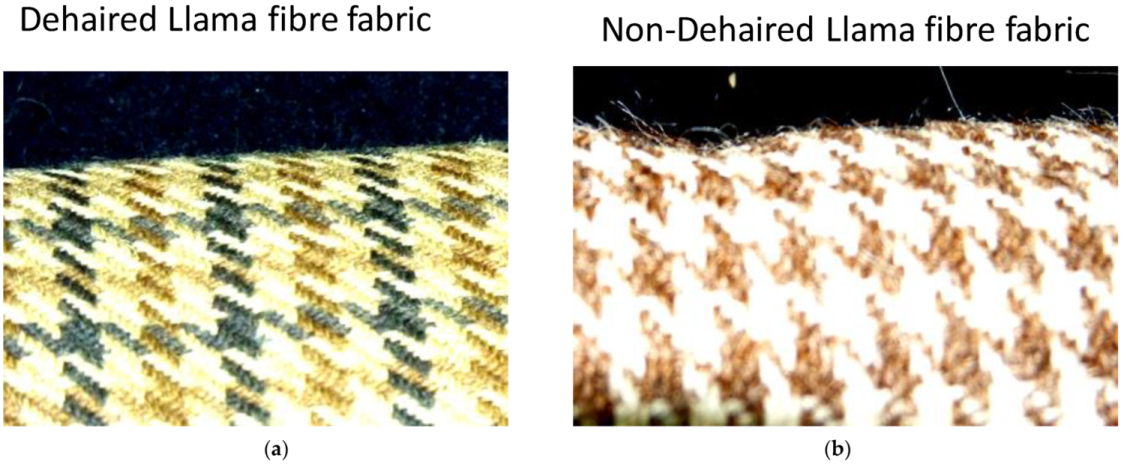

- Frank, E.N.; Hick, M.V.H.; Castillo, M.F.; Prieto, A. Fibre-Based Components Determining Handle/Skin Comfort in Fabrics Made from Dehaired and Non Dehaired Llama Fibre. Int. J. Appl. Sci. Technol. 2014, 4, 51–66. Available online: https://www.ijastnet.com/journal/index/583 (accessed on 19 December 2021).

- Naylor, G.R.S.; Phillips, D.G.; Veitch, C.J.; Dolling, M.; Marland, D.J. Fabric-Evoked Prickle in Worsted Spun Single Jersey Fabrics Part I: The Role of Fiber End Diameter Characteristics. Text. Res. J. 1997, 67, 288–295. [Google Scholar] [CrossRef]

- Naylor, G.R. The Coarse Fibre Component and Fibre End Diameter Characteristics of Australian Wool Tops. J. Text. Inst. 1996, 87, 265–273. [Google Scholar] [CrossRef]

- Gilmour, A.; Atkins, K. Modelling the FFDA fibre diameter histogram of fleece wool as a mixture distribution. Aust. J. Agric. Res. 1992, 43, 1777–1788. [Google Scholar] [CrossRef]

- McGregor, B.A.; Naebe, M.; Stanton, J.; Speijers, J.; Beilby, J.; Pieruzzini, S.; Tester, D. Relationship between wearer prickle response with fibre and garment properties and Wool ComfortMeter assessment. J. Text. Inst. 2013, 104, 618–627. [Google Scholar] [CrossRef] [Green Version]

- Garnsworthy, R.K.; Gully, R.L.; Kenins, P.; Mayfield, R.J.; Westerman, R.A. Identification of the physical stimulus and the neural basis of fabric-evoked prickle. J. Neurophysiol. 1988, 59, 1083–1097. [Google Scholar] [CrossRef] [PubMed]

- Naylor, G.R.S. The role of coarse fibers on fabric prickle using blended acrylic fibers of different diameters. Wool Technol. Sheep Breed. 1992, 40, 14–18. [Google Scholar]

- Naylor, G.R.S. The Relationship between the Fibre Diameter Distributions of Wool Top, Fibre Ends and Yarn Surface Fibres. Wool Technol. Sheep Breed. 1992, 40, 40–43. [Google Scholar]

- Naylor, G.R.S. Improving the Skin Comfort Characteristics of Wool Fabrics. In Proceedings of the Textile Institute Natural Fibres in Australasia Conference, Dunedin, New Zealand, 15–17 April 2009. [Google Scholar]

- Pillay, K.P.R. A Study of the Hairiness of Cotton Yarns. Part I: Effect of Fiber and Yarn Factors. Text. Res. J. 1964, 34, 663–674. [Google Scholar] [CrossRef]

- Seshan, K.N. An investigation of the taper of cotton fibres. part iv: The differential behaviour of fibre ends during the processing of cotton. J. Text. Inst. 1975, 66, 109–115. [Google Scholar] [CrossRef]

- Oosterban, R.J. Statistical Significance of Segmented Linear Regression with Break-Point Using Variance Analysis (ANOVA) and F-Tests. 2017. Available online: https://www.waterlog.info (accessed on 20 January 2021).

- Frank, E.; Hick, M.; Adot, O. Descriptive differential attributes of type of fleeces in llama fibre and its textile consequence. Part 2: Consequences of the dehairing process. J. Text. Inst. 2011, 102, 41–49. [Google Scholar] [CrossRef]

- Frank, E.N.; Brodtmann, L.I.; Hick, M.H.V. Multivariate Analysis for Fleece Types Classification in Argentine Llamas. J. Text. Sci. Fash. Technol. 2019, 3, 1–4. [Google Scholar] [CrossRef]

- Wortmann, F.J.; Schwann-Jonczk, A. Investigating hair properties relevant fo hair ‘Handle’. Part 1: Hair diameter, bending and frictional properties. Int. J. Cosmet. Sci. 2006, 28, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Veitch, C.J.; Naylor, G.R.S. The mechanisms of fiber buckling in relation to fabric-evoked prickle. Wool Technol. Sheep Breed. 1992, 40, 31–34. [Google Scholar]

- InfoStat, InfoStat versión 1.1; Grupo InfoStat, FCA, Universidad Nacional de Córdoba: Argentina, [Version 1.1 InfoStat. Group InfoStat, FCA. National Unviersity of Cordoba, Argentina]. 2002. Available online: https://www.infostat.com.ar/index.php?mod=page&id=34(accessed on 12 December 2021).

- Lerman, P.M. Fitting Segmented Regression Models. J. R. Stat. Soc. 1980, 29, 77–84. Available online: http://www.jstor.org/stable/2346413 (accessed on 20 June 2019).

- Frank, E.N.; Hick, M.H.V.; de Neyra, L.A.R. The Problem of Prickling on Fabrics of South American Camelids Fibers: Possible Approaches for Mechanical Solutions. Asian Res. J. Agric. 2017, 5, 1–9. [Google Scholar] [CrossRef] [Green Version]

| Sp. | Biotype | Overall | BP | <BP | >BP | Slope < BPMFD | Slope > BPMFD | |

|---|---|---|---|---|---|---|---|---|

| Llama | Q’cara | MFD | 23.69 | 23.20 | 20.40 | 26.20 | ||

| PcF | 11.05 | 5.04 | 5.20 | 17.10 | 1.04 | 4.00 | ||

| Chaqu | MFD | 20.91 | 22.10 | 21.00 | 25.30 | |||

| PcF | 8.81 | 5.54 | 4.70 | 18.00 | 1.10 | 3.90 | ||

| Alpaca | Huacaya | MFD | 23.33 | 23.00 | 20.00 | 27.30 | ||

| PcF | 14.15 | 3.89 | 3.90 | 26.60 | 1.04 | 5.50 | ||

| Suri | MFD | 25.87 | 23.42 | 21.00 | 28.30 | |||

| PcF | 23.38 | 6.69 | 8.30 | 32.00 | 3.14 | 5.13 |

| Treat. | CFs | Sig | CFy | Sig | Diff.S-Y | Sig | MFDs | Sig | MFDy | Sig | Diff.S-Y | Sig |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D:1 | 5.7 | A | 4.7 | A | 1.0 | A | 24.5 | A | 23.1 | A | 1.5 | A |

| ND:1 | 15.7 | B | 9.7 | AB | 6.0 | B | 27.2 | AB | 24.8 | A | 2.5 | AB |

| D: 0 | 18.0 | BC | 9.1 | AB | 8.9 | B | 28.9 | B | 24.8 | A | 4.2 | B |

| ND:0 | 23.2 | C | 11.1 | B | 13.5 | B | 29.1 | B | 25.3 | A | 3.8 | B |

| Treat. | CMFs | Sig | CMFy | Sig | Diff.S-Y | Sig | LMFs | Sig | LMFy | Sig | Diff.S-Y | Sig |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D:1 | 28.4 | A | 22.3 | A | 6.1 | A | 1.1 | A | 1.6 | A | −0.5 | A |

| ND:1 | 22.3 | A | 23.7 | A | −1.4 | A | 3.5 | B | 4.1 | B | −0.6 | A |

| D: 0 | 33.7 | A | 23.7 | A | 10.0 | B | 3.6 | B | 5.2 | B | −1.6 | A |

| ND:0 | 41.1 | A | 23.7 | A | 17.5 | B | 2.1 | A | 3.6 | B | −1.6 | A |

| Means with a common letter are not significantly different (p > 0.05) | ||||||||||||

| Fineness | MFDc | Sig | El | Sig | Br | Sig | Bl | Sig |

|---|---|---|---|---|---|---|---|---|

| SF | 24.35 | A | 1.19 | A | 5.86 × 109 | A | 19.60 | A |

| F | 32.55 | B | 1.28 | A | 1.12 × 1010 | A | 47.13 | A |

| M | 44.09 | C | 1.43 | B | 3.36 × 1010 | B | 841.38 | B |

| S | 52.06 | D | 1.60 | C | 5.63 × 1010 | C | 1954.59 | C |

| SS | 80.28 | E | 1.68 | C | 2.48 × 1011 | D | 6548.33 | D |

| Wave | ||||||||

| 6 | 24.35 | A | 1.19 | A | 5.86 × 109 | A | 19.60 | A |

| 4 | 33.09 | B | 1.33 | B | 1.51 × 1010 | AB | 446.33 | B |

| 5 | 41.14 | C | 1.44 | C | 2.22 × 1010 | AB | 500.90 | B |

| 3 | 45.41 | D | 1.47 | C | 3.16 × 1010 | B | 816.73 | C |

| 2 | 54.62 | E | 1.49 | C | 5.54 × 1010 | C | 1009.63 | C |

| 1 | 79.31 | F | 1.88 | D | 2.54 × 1011 | D | 4410.57 | D |

| Medulla | ||||||||

| Nm | 31.53 | A | 1.11 | A | 3.67 × 109 | A | 61.11 | A |

| F | 32.46 | A | 1.17 | A | 5.51 × 109 | A | 438.66 | B |

| I | 36.99 | B | 1.28 | B | 1.21 × 1010 | A | 411.35 | B |

| C | 47.4 | C | 1.61 | C | 4.43 × 1010 | B | 833.56 | C |

| L | 59.71 | D | 1.80 | D | 1.02 × 1011 | C | 3753.72 | D |

| Means with a common letter are not significantly different (p > 0.05). | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamani-Cato, R.H.; Frank, E.N.; Prieto, A.; Castillo, M.F.; Condori-Rojas, N.; Hick, M.V.H. Effect of Fibre Diameter, Prickle Factor and Coarse Fibre Bias on Yarn Surface Hairiness in South American Camelids (SAC) Fibre. Fibers 2022, 10, 18. https://doi.org/10.3390/fib10020018

Mamani-Cato RH, Frank EN, Prieto A, Castillo MF, Condori-Rojas N, Hick MVH. Effect of Fibre Diameter, Prickle Factor and Coarse Fibre Bias on Yarn Surface Hairiness in South American Camelids (SAC) Fibre. Fibers. 2022; 10(2):18. https://doi.org/10.3390/fib10020018

Chicago/Turabian StyleMamani-Cato, Ruben Herberht, Eduardo Narciso Frank, Alejandro Prieto, Maria Flavia Castillo, Nicoll Condori-Rojas, and Michel Victor Hubert Hick. 2022. "Effect of Fibre Diameter, Prickle Factor and Coarse Fibre Bias on Yarn Surface Hairiness in South American Camelids (SAC) Fibre" Fibers 10, no. 2: 18. https://doi.org/10.3390/fib10020018