Influence of Roller Configuration on the Fiber–Matrix Distribution and Mechanical Properties of Continuously Produced, Mineral-Impregnated Carbon Fibers (MCFs)

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

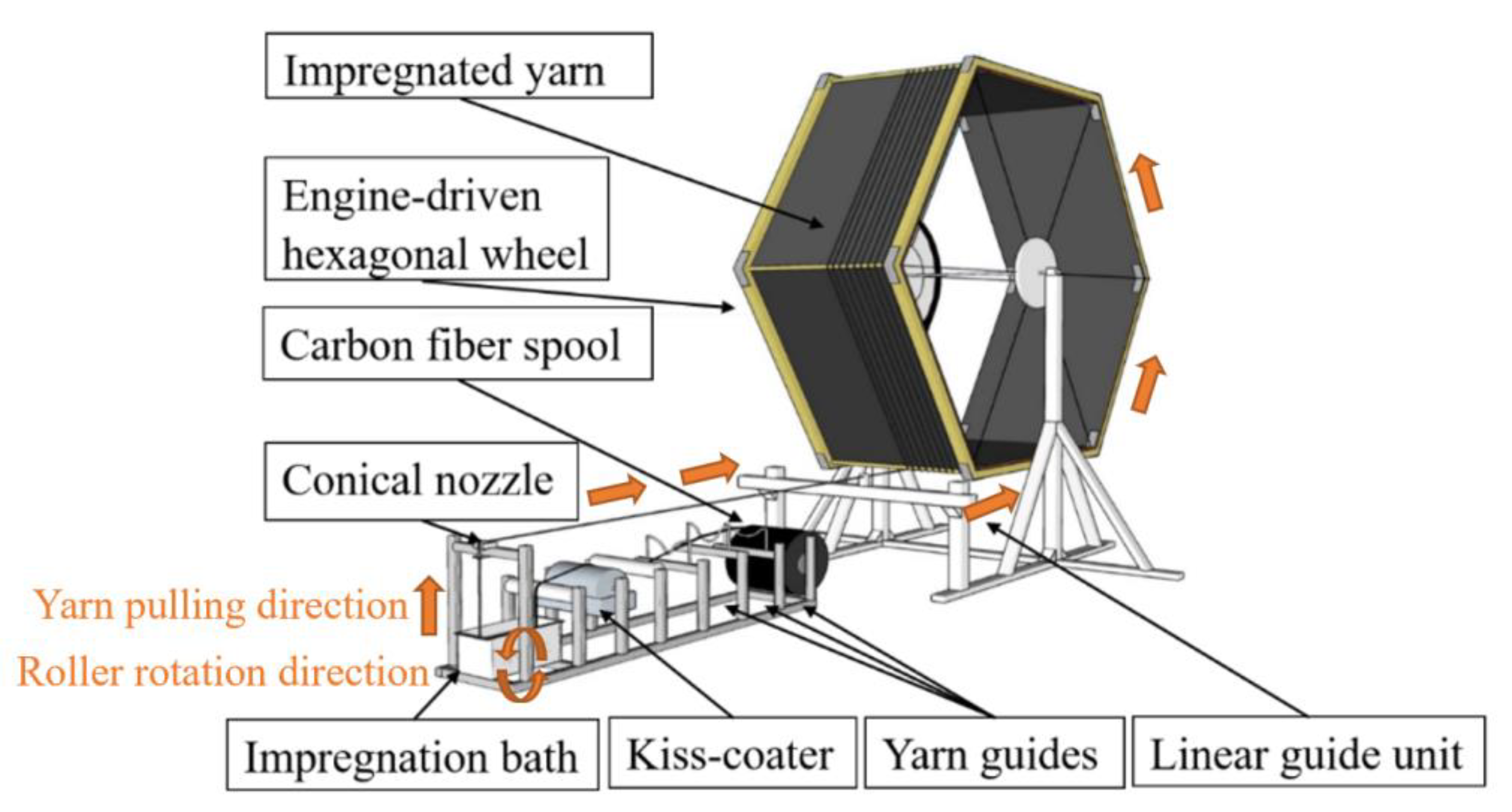

2.2. Fabrication and Post-Treatment of MCF

2.3. Characterization of Fresh-State Properties of MCF

2.4. Mechanical Testing of MCF

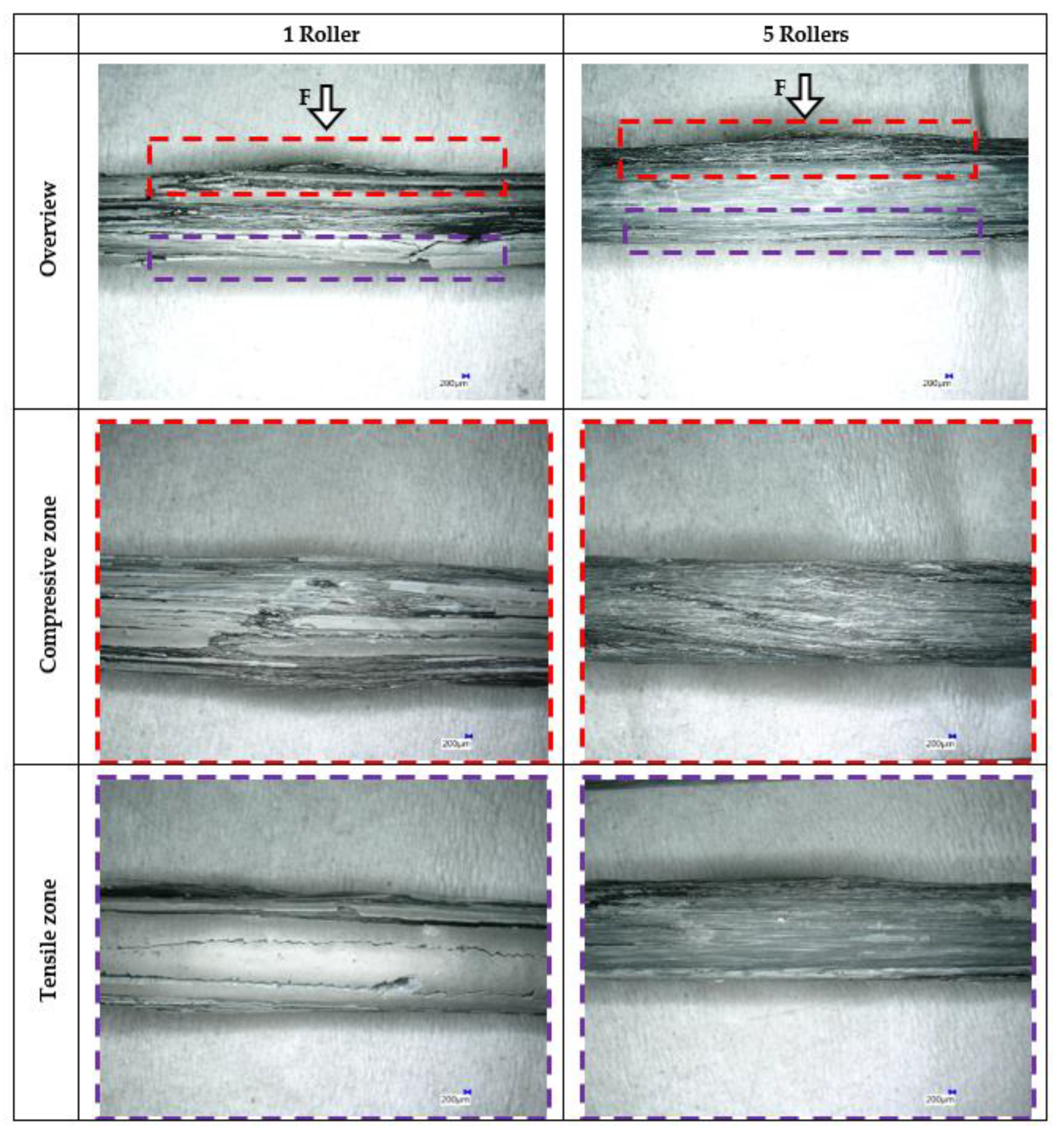

2.5. Morphological Characterization

3. Results

3.1. Morphological Characterization

3.2. Roller Assembly

3.3. Rotation of Rollers

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Seifert, W.; Lieboldt, M. Ressourcenverbrauch im globalen Stahlbetonbau und Potenziale der Carbonbetonbauweise: Globale Herausforderungen des Bauwesens. Beton-Und Stahlbetonbau 2020, 115, 469–478. [Google Scholar] [CrossRef]

- Bohm, R.; Thieme, M.; Wohlfahrt, D.; Wolz, D.S.; Richter, B.; Jager, H. Reinforcement Systems for Carbon Concrete Composites Based on Low-Cost Carbon Fibers. Fibers 2018, 6, 56. [Google Scholar] [CrossRef] [Green Version]

- Scholzen, A.; Chudoba, R.; Hegger, J. Dünnwandiges Schalentragwerk aus textilbewehrtem Beton: Entwurf, Bemessung und baupraktische Umsetzung. Beton-Und Stahlbetonbau 2012, 107, 767–776. [Google Scholar] [CrossRef]

- Schumann, A.; May, M.; Schladitz, F.; Scheerer, S.; Curbach, M. Carbonstäbe im bauwesen: Teil 2: Verbundverhalten–verbundversuche an unterschiedlichen Carbonstäben. Beton-Und Stahlbetonbau 2020, 115, 962–971. [Google Scholar] [CrossRef]

- Hollaway, L. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Pendhari, S.S.; Kant, T.; Desai, Y.M. Application of polymer composites in civil construction: A general review. Compos. Struct. 2008, 84, 114–124. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Gand, A.K.; Chan, T.-M.; Mottram, J.T. Civil and structural engineering applications, recent trends, research and developments on pultruded fiber reinforced polymer closed sections: A review. Front. Struct. Civ. Eng. 2013, 7, 227–244. [Google Scholar] [CrossRef]

- Bisby, L.A.; Green, M.F.; Kodur, V.K. Response to fire of concrete structures that incorporate FRP. Prog. Struct. Eng. Mater. 2005, 7, 136–149. [Google Scholar] [CrossRef]

- Holz, K.; Curbach, M. Zugtragverhalten von Carbonbeton unter Hochtemperaturbeanspruchung. Beton-Und Stahlbetonbau 2020, 115, 231–240. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Messori, M.; Nobili, A.; Signorini, C.; Sola, A. Effect of high temperature exposure on epoxy-coated glass textile reinforced mortar (GTRM) composites. Constr. Build. Mater. 2019, 212, 765–774. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, E.; Eedson, R.; Bisby, L.A.; Green, M.F.; Benichou, N. Mechanical characterization of fibre reinforced polymers materials at high temperature. Fire Technol. 2011, 47, 1063–1080. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Butler, M.; Hempel, S.; Toledo Filho, R.D.; Mechtcherine, V. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cem. Concr. Compos. 2014, 48, 26–34. [Google Scholar] [CrossRef]

- Kruppke, I.; Butler, M.; Schneider, K.; Hund, R.-D.; Mechtcherine, V.; Cherif, C. Carbon Fibre Reinforced Concrete: Dependency of Bond Strength on T g of Yarn Impregnating Polymer. Mater. Sci. Appl. 2019, 10, 328. [Google Scholar]

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77. [Google Scholar] [CrossRef]

- Schneider, K.; Michel, A.; Liebscher, M.; Mechtcherine, V. Verbundverhalten mineralisch gebundener und polymergebundener Bewehrungsstrukturen aus Carbonfasern bei Temperaturen bis 500 °C. Beton-Und Stahlbetonbau 2018, 113, 886–894. [Google Scholar] [CrossRef]

- Nadiv, R.; Peled, A.; Mechtcherine, V.; Hempel, S.; Schroefl, C. Micro-and nanoparticle mineral coating for enhanced properties of carbon multifilament yarn cement-based composites. Compos. Part B Eng. 2017, 111, 179–189. [Google Scholar] [CrossRef]

- Signorini, C.; Nobili, A.; Gonzalez, E.C.; Siligardi, C. Silica coating for interphase bond enhancement of carbon and AR-glass Textile Reinforced Mortar (TRM). Compos. Part B Eng. 2018, 141, 191–202. [Google Scholar] [CrossRef] [Green Version]

- Signorini, C.; Sola, A.; Nobili, A.; Siligardi, C. Lime-cement textile reinforced mortar (TRM) with modified interphase. J. Appl. Biomater. Funct. Mater. 2019, 17, 2280800019827823. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Junger, D.; Liebscher, M.; Zhao, J.; Mechtcherine, V. Joule heating as a smart approach in enhancing early strength development of mineral-impregnated carbon-fibre composites (MCF) made with geopolymer. Compos. Part A Appl. Sci. Manuf. 2022, 153, 106750. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Michel, A.; Junger, D.; Trindade, A.C.C.; de Andrade Silva, F.; Mechtcherine, V. Development and testing of fast curing, mineral-impregnated carbon fiber (MCF) reinforcements based on metakaolin-made geopolymers. Cem. Concr. Compos. 2021, 116, 103898. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schmeier, T. Extrusion-based additive manufacturing with carbon reinforced concrete: Concept and feasibility study. Materials 2020, 13, 2568. [Google Scholar] [CrossRef]

- Schneider, K.; Lieboldt, M.; Liebscher, M.; Fröhlich, M.; Hempel, S.; Butler, M.; Schröfl, C.; Mechtcherine, V. Mineral-based coating of plasma-treated carbon fibre rovings for carbon concrete composites with enhanced mechanical performance. Materials 2017, 10, 360. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Michel, A.; Schneider, K.; Foest, R.; Froehlich, M.; Quade, A.; Mechtcherine, V. Plasma-generated silicon oxide coatings of carbon fibres for improved bonding to mineral-based impregnation materials and concrete matrices. Cem. Concr. Compos. 2020, 114, 103667. [Google Scholar] [CrossRef]

- Zhao, J.; Liebscher, M.; Tzounis, L.; Mechtcherine, V. Role of sizing agent on the microstructure morphology and mechanical properties of mineral-impregnated carbon-fiber (MCF) reinforcement made with geopolymers. Appl. Surf. Sci. 2021, 567, 150740. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Michel, A.; Quade, A.; Foest, R.; Mechtcherine, V. Oxygen plasma modification of carbon fiber rovings for enhanced interaction toward mineral-based impregnation materials and concrete matrices. Constr. Build. Mater. 2021, 273, 121950. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Curosu, I.; Choudhury, S.; Hempel, S.; Davoodabadi, M.; Dinh, T.T.; Yang, J.; Mechtcherine, V. Electrophoretic deposition of nano-silica onto carbon fiber surfaces for an improved bond strength with cementitious matrices. Cem. Concr. Compos. 2020, 114, 103777. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Ranjbarian, M.; Hempel, S.; Tzounis, L.; Schröfl, C.; Mechtcherine, V. Electrochemical modification of carbon fiber yarns in cementitious pore solution for an enhanced interaction towards concrete matrices. Appl. Surf. Sci. 2019, 487, 52–58. [Google Scholar] [CrossRef]

- Gaymans, R.; Wevers, E. Impregnation of a glass fibre roving with a polypropylene melt in a pin assisted process. Compos. Part A Appl. Sci. Manuf. 1998, 29, 663–670. [Google Scholar] [CrossRef]

- Kim, T.; Jun, E.; Um, M.; Lee, W. Effect of pressure on the impregnation of thermoplastic resin into a unidirectional fiber bundle. Adv. Polym. Technol. J. Polym. Process. Inst. 1989, 9, 275–279. [Google Scholar] [CrossRef]

- Lee, W.I.; Springer, G.S. A model of the manufacturing process of thermoplastic matrix composites. J. Compos. Mater. 1987, 21, 1017–1055. [Google Scholar] [CrossRef]

- Bijsterbosch, H.; Gaymans, R.J. Impregnation of glass rovings with a polyamide melt. Part 1: Impregnation bath. Compos. Manuf. 1993, 4, 85–92. [Google Scholar] [CrossRef]

- Peled, A.; Sueki, S.; Mobasher, B. Bonding in fabric–cement systems: Effects of fabrication methods. Cem. Concr. Res. 2006, 36, 1661–1671. [Google Scholar] [CrossRef]

- Safonov, A.A.; Carlone, P.; Akhatov, I. Mathematical simulation of pultrusion processes: A review. Compos. Struct. 2018, 184, 153–177. [Google Scholar] [CrossRef]

- Lenting, M.; Orlowsky, J. Einaxiale Zugversuche an textilbewehrten Betonen mit anorganisch getränkten Carbonfasern. Beton-Und Stahlbetonbau 2020, 115, 495–503. [Google Scholar] [CrossRef]

- Hung, T.D.; Pernica, D.; Kroisová, D.; Bortnovsky, O.; Louda, P.; Rylichova, V. Composites base on geopolymer matrices: Preliminary fabrication, mechanical properties and future applications. Adv. Mater. Res. 2008, 55–57, 477–480. [Google Scholar] [CrossRef] [Green Version]

- Tran, D.; Louda, P.; Bortnovsky, O.; Bezucha, P. Mechanical Properties of Silica-Based Geopolymer Composites Cured at Ambient Conditions in Accordance with Size-Independent Method. 2010. Available online: https://www.semanticscholar.org/paper/Mechanical-Properties-of-Silica-Based-Geopolymer-at-Tran-Louda/862e745a78895f11321bc1a448f44aa6b6c76b88 (accessed on 1 April 2022).

- Tran, D.; Kroisová, D.; Louda, P.; Bortnovsky, O.; Bezucha, P. Effect of curing temperature on flexural properties of silica-based geopolymer-carbon reinforced composite. Manuf. Eng. 2009, 37, 492–497. [Google Scholar]

- SIGRAFIL®. Available online: https://www.sglcarbon.com/en/markets-solutions/material/sigrafil-continuous-carbon-fiber-tows/ (accessed on 28 February 2022).

- Wilhelm, K. Verbundverhalten von Mineralisch und Polymer Gebundenen Carbonbewehrungen und Beton bei Raumtemperatur und Erhöhten Temperaturen bis 500 °C. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2021. [Google Scholar]

- Bates, P.; Charrier, J. Pulling tension monitoring during the melt impregnation of glass roving. Polym. Compos. 2000, 21, 104–113. [Google Scholar] [CrossRef]

- 10406-1, I. Fibre-reinforced polymer. 2008. Available online: https://www.iso.org/standard/45977.html (accessed on 4 April 2022).

- Schütze, E.; Bielak, J.; Scheerer, S.; Hegger, J.; Curbach, M. Einaxialer zugversuch für carbonbeton mit textiler bewehrung. Beton-Und Stahlbetonbau 2018, 113, 33–47. [Google Scholar] [CrossRef]

- Gong, T.; Heravi, A.A.; Alsous, G.; Curosu, I.; Mechtcherine, V. The Impact-Tensile Behavior of Cementitious Composites Reinforced with Carbon Textile and Short Polymer Fibers. Appl. Sci. 2019, 9, 4048. [Google Scholar] [CrossRef] [Green Version]

- Rempel, S.; Ricker, M. Ermittlung der Materialkennwerte der Bewehrung für die Bemessung von textilbewehrten Bauteilen/Determination of the material properties of the reinforcement for textile-reinforced- concrete elements. Bauingenieur 2017, 92, 280–288. [Google Scholar] [CrossRef]

- Hayes, B.S.; Seferis, J.C. The effect of fabric tension and the number of impregnation rollers on woven fabric prepreg quality and cured laminates. Compos. Part A Appl. Sci. Manuf. 1997, 28, 791–799. [Google Scholar] [CrossRef]

- Ren, F.; Yu, Y.; Cao, M.H.; Li, Y.; Xin, C.L.; He, Y.D. Effect of pneumatic spreading on impregnation and fiber fracture of continuous fiber-reinforced thermoplastic composites. J. Reinf. Plast. Compos. 2017, 36, 1554–1563. [Google Scholar] [CrossRef]

- Dvorkin, D.; Poursaee, A.; Peled, A.; Weiss, W.J. Influence of bundle coating on the tensile behavior, bonding, cracking and fluid transport of fabric cement-based composites. Cem. Concr. Compos. 2013, 42, 9–19. [Google Scholar] [CrossRef]

- Lapointe, F.; Lebel, L.L. Fiber Damage and Impregnation during Multi-Die Vacuum Assisted Pultrusion of Carbon/PEEK Hybrid Yarns. Polym. Compos. 2019, 40, E1015–E1028. [Google Scholar] [CrossRef]

- Cherif, C.; Diestel, O.; Engler, T.; Hufnagl, E.; Weiland, S. Weiterverarbeitungsaspekte und Anwendungsbeispiele. In Textile Werkstoffe für den Leichtbau; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Marissen, R.; Th. van der Drift, L.; Sterk, J. Technology for rapid impregnation of fibre bundles with a molten thermoplastic polymer. Compos. Sci. Technol. 2000, 60, 2029–2034. [Google Scholar] [CrossRef]

- Yoon, B.S.; Lee, S.H.; Suh, M.H. Continuous glass-fiber reinforced nylon 6 by using a new impregnation die. Polym. Compos. 1997, 18, 656–662. [Google Scholar] [CrossRef]

- Hahn, L.; Rittner, S.; Bauer, C.; Cherif, C. Development of alternative bondings for the production of stitch-free non-crimp fabrics made of multiple carbon fiber heavy tows for construction industry. J. Ind. Text. 2018, 48, 660–681. [Google Scholar] [CrossRef]

| Property | C T50-4.4/255-E100 | |

|---|---|---|

| Number of filaments | [-] | 50,000 |

| Fineness of the yarn | [tex] | 3070 |

| Density | [g/cm³] | 1.8 |

| Net yarn cross-section | [mm²] | 1.9 |

| Filament diameter | [µm] | 6.9 |

| Tensile strength | [MPa] | 4400 |

| Tensile modulus | [GPa] | 255 |

| Sizing type | [-] | Epoxy |

| Sizing content | [m%] | 1.0 |

| Mixture Constituent | Density [g/cm³] | Mass Ratio [%] | Mass [g/L] |

|---|---|---|---|

| Micro-cement MIKRODUR R-X | 2.9 | 22 | 345.4 |

| Micro-cement MIKRODUR P-U | 3.1 | 22 | 345.4 |

| Micro-silica suspension Centrilit Fume SX | 1.38 | 22 | 345.4 |

| Plasticiser MasterRheobuild 30 (start) | 1.08 | 2 | 13 |

| Plasticiser MasterRheobuild 30 (end) | 18.1 | ||

| Water | 1 | 32 | 493.3 |

| Number of Rollers | Feature (Deflection + Rotation of Central Rollers) | |||||

|---|---|---|---|---|---|---|

| 1 Roller | Low deflection + Freely rotatable | High deflection + Freely rotatable | ||||

| 3 Rollers | Low deflection + Freely rotatable | High deflection + Freely rotatable | Low deflection + Fixed roller | Low deflection + Pressed roller | Low deflection + Counter-rotating | Low deflection + Co-rotating |

| 5 Rollers | Low deflection + Freely rotatable | High deflection + Freely rotatable | ||||

| Feature | Force [N] | Mass [g/m] | |

|---|---|---|---|

| 1 Roller | High deflection + Freely rotatable | 5.07 (0.72) | 17.56 (0.13) |

| 3 Rollers | High deflection + Freely rotatable | 10.46 (2.06) | 19.48 (0.24) |

| 5 Rollers | High deflection + Freely rotatable | 15.02 (2.16) | 19.48 (0.07) |

| Feature | Force [N] | Mass [g/m] | |

|---|---|---|---|

| 3 Rollers | Low deflection + freely rotatable | 7.28 (1.14) | 18.41 (0.27) |

| 3 Rollers | High deflection + freely rotatable | 10.46 (2.06) | 19.48 (0.24) |

| 5 Rollers | Low deflection + freely rotatable | 10.98 (1.20) | 18.97 (0.11) |

| 5 Rollers | High deflection + freely rotatable | 15.02 (2.16) | 19.48 (0.07) |

| Feature | Force [N] | Mass [g/m] | |

|---|---|---|---|

| 3 Rollers | Low deflection + all freely rotatable | 7.28 (1.14) | 18.41 (0.27) |

| 3 Rollers | Low deflection + fixed | 9.51 (1.31) | 17.98 (0.13) |

| 3 Rollers | Low deflection + pressed | 10.41 (0.99) | 18.54 (0.13) |

| 3 Rollers | Low deflection + counter-rotating | 10.25 (1.32) | 18.45 (0.02) |

| 3 Rollers | Low deflection + co-rotating | 4.49 (0.45) | 19.01 (0.65) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liebscher, M.; Zhao, J.; Wilms, G.; Michel, A.; Wilhelm, K.; Mechtcherine, V. Influence of Roller Configuration on the Fiber–Matrix Distribution and Mechanical Properties of Continuously Produced, Mineral-Impregnated Carbon Fibers (MCFs). Fibers 2022, 10, 42. https://doi.org/10.3390/fib10050042

Liebscher M, Zhao J, Wilms G, Michel A, Wilhelm K, Mechtcherine V. Influence of Roller Configuration on the Fiber–Matrix Distribution and Mechanical Properties of Continuously Produced, Mineral-Impregnated Carbon Fibers (MCFs). Fibers. 2022; 10(5):42. https://doi.org/10.3390/fib10050042

Chicago/Turabian StyleLiebscher, Marco, Jitong Zhao, Gregor Wilms, Albert Michel, Kai Wilhelm, and Viktor Mechtcherine. 2022. "Influence of Roller Configuration on the Fiber–Matrix Distribution and Mechanical Properties of Continuously Produced, Mineral-Impregnated Carbon Fibers (MCFs)" Fibers 10, no. 5: 42. https://doi.org/10.3390/fib10050042