Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A

Abstract

:1. Introduction

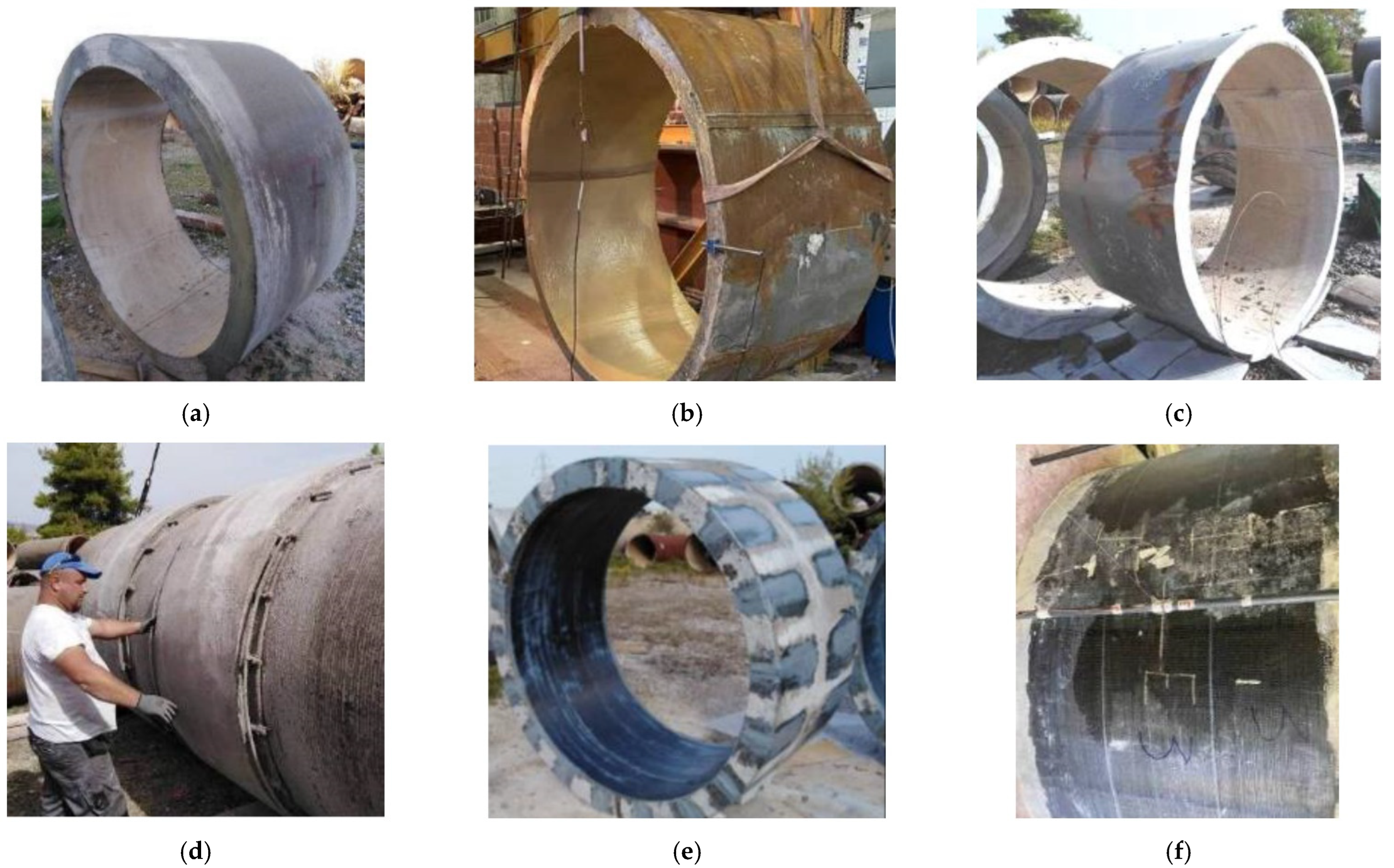

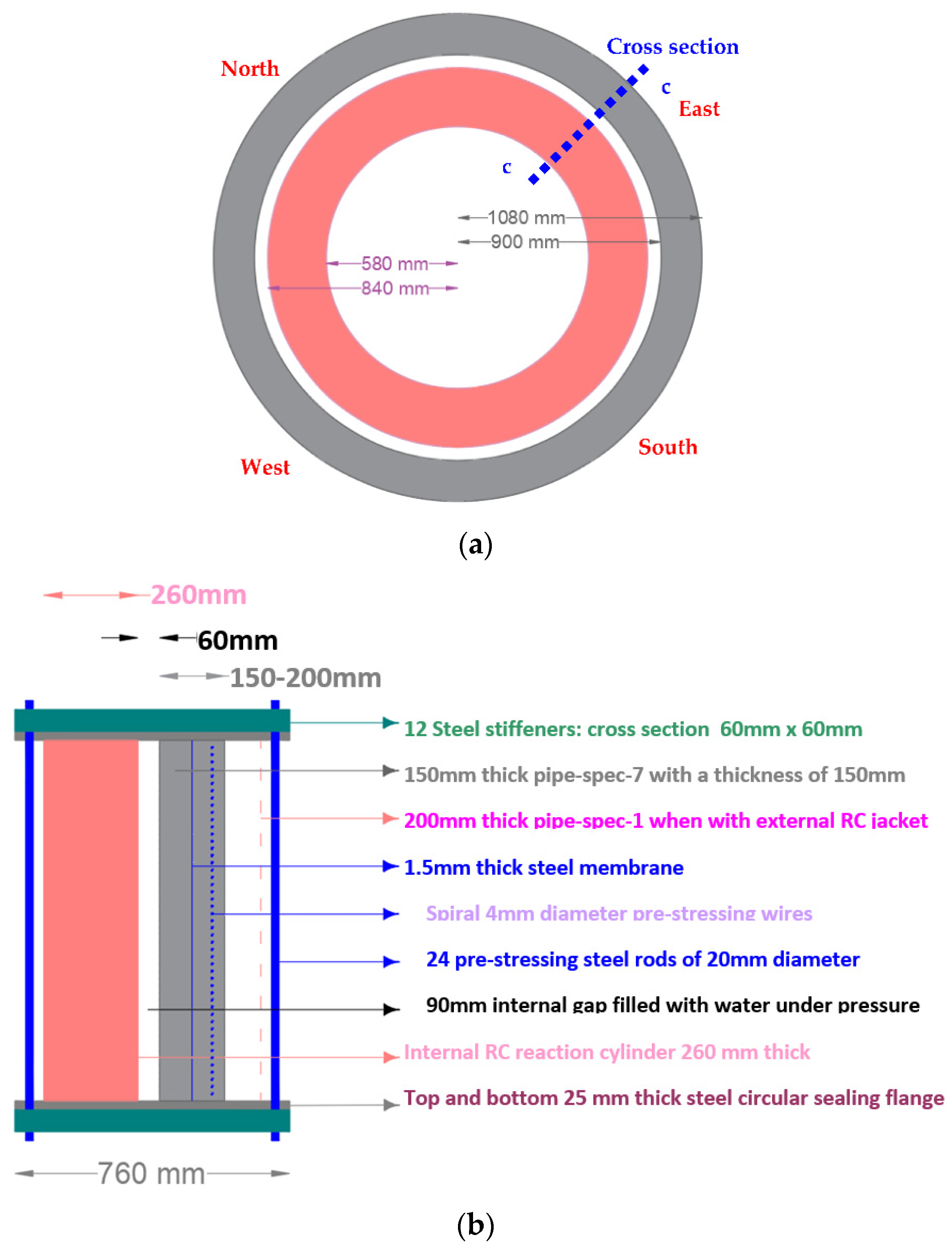

2. Methodology—Description of Specimens

- (a)

- Three-edge bearing test (3EB) according to Government Gazette 253/Β/1984 [28] and the ASTM C-497 standard.

- (b)

- Internal hydraulic pressure with a gradually increasing amplitude up to an internal pressure limit unless a prior limit-state condition was reached. For this purpose, a special loading set-up was devised, aiming to apply internal hydraulic pressure up to the limit amplitude specified by the client. This internal pressure amplitude limit, approximately equal to 8.5 bar, represents pressure levels due to hydraulic gradient and water surge conditions, which leads to internal pressure requirements that are larger than the hydrostatic pressure amplitude under normal operating conditions (Government Gazette 253/Β/1984 [28]).

Structural Details and Materials of Tested Specimen

3. Three-Edge Bearing Test (3EB)—Results

4. Internal Hydraulic Pressure Test

4.1. Description

4.2. Instrumentation

4.3. Obtained Results

4.4. Summary Observations of Internal Hydraulic Pressure Tests

5. Laboratory Simulation of Defects in the Prestressing Wires

6. Summary Observations

- The 3EB bearing capacity of all strengthened specimens was larger than that of the original pipe. Due to the type of 3EB loading, strengthening with external jacketing with CFRP or RC resulted in a larger 3EB bearing capacity than was obtained with the internal CFRP jacket. It was also established that the simulated partial prestress defect or the full neutralization of the prestress resulted in a very significant reduction in the 3EB bearing capacity.

- All strengthening schemes satisfied the set upper limit of internal hydraulic amplitude, approximately equal to 8.5 bar. Loading the specimens with an internal pressure amplitude higher than this upper limit was tried only for the strengthened specimens following certain safety precautions based on the non-linearity of the measured radial expansion as well as on the strains measured by strain gauges placed at pre-determined locations. Again, the external jacketing, either with the CFRP jacket or with the RC jacket, allowed the increase in the internal hydraulic pressure beyond the 8.5 bar limit, reaching 12 bar and 22 bar, respectively. However, because of the construction of these external jackets, the simulated prestress defect could not be applied.

- This simulated prestress defect was attempted for both the original pipe (Specimen 7) without any strengthening and for Specimen 5 strengthened with an internal FRP jacket. The simulated prestress defect was accomplished by sequentially cutting specific numbers (4, 8 and 20 prestressing wires) of specific prestressing wires, all at the same location (Eastern cross-section). For Specimen 7 (original pipe without strengthening), the radial expansion amplitude increased rapidly after eight prestressing wires were cut. When the number of cut wires reached 20, the measured radial expansion was equal to over 5 mm for an internal pressure amplitude equal to 6.7 bar, a pressure level considerably smaller than the set limit pressure of 8.5 bar. On the contrary, for Specimen 5 (with an internal CFRP jacket) with 20 prestressing wires cut, the radial expansion reached only 1.4 mm for an internal pressure amplitude equal to 10.0 bar, a pressure that is larger than the set pressure limit. The radial expansion remained smaller than 1.0 mm when the number of cut wires was equal to eight (8) or less, although the internal pressure amplitude was kept above 10 bar. Therefore, it can be concluded that the internal CFRP jacket can withstand the set pressure limit for a prestress defect corresponding to the one simulated in the laboratory. Damage patterns at the end of the test sequence are shown in Figure 25a–e.

- Although the simulated prestress defect was tested for the strengthening scheme with an internal CFRP jacket, it could be argued that all three strengthening schemes could perform similarly and thus satisfy the set requirements of withstanding the set upper internal hydraulic pressure limit, even for a relatively minor prestressing defect. In any case, the extent and the degree of such a prestressing wire defect should be quantified by appropriate in situ techniques prior to applying any strengthening scheme to the pipeline in question. Moreover, the choice of the strengthening scheme should also use, apart from the bearing capacity values determined in the current investigation, additional criteria based on durability, cost and operational requirements of the water network that the pipeline in question belongs to.

7. Conclusions

- –

- Provided that the prestressing wires are fully active according to design specifications, the original specimen performed satisfactorily for the set internal hydraulic pressure limit of 8.5 bar.

- –

- Specimens retrofitted with jacketing performed satisfactorily for internal hydraulic pressure levels well above this 8.5 bar limit.

- –

- A critical factor is, as expected, the loss of prestress, which may occur for several reasons. When testing a specimen that intentionally had all prestressing wires removed, it was recorded that concrete cracking commenced at an internal hydraulic pressure just above 2.0 bar, and the steel membrane yielded at an internal hydraulic pressure just above the 4.5 bar level.

- –

- An effort was made to simulate a prestress defect by sequentially intentionally removing a number of prestressing wires in two specimens for which this was possible. This was carried out after these specimens were tested with all prestressing wires fully active. One such specimen represented the pipe in its original form, and the other represented the pipe retrofitted with an internal CFRP jacket. It was shown that such a simulated prestress defect noticeably reduced the internal hydraulic pressure capacity below the 8.5 bar limit for the original pipe without a jacket, whereas the presence of the internal CFRP jacket was somewhat instrumental in keeping the internal hydraulic pressure capacity above this 8.5 bar limit.

- –

- All used retrofitting schemes were shown to be satisfactory in upgrading the hydraulic internal bearing capacity. This study was limited to presenting the fundamentals of the structural performance of the studied retrofitting schemes and did not extend to examining issues of durability and construction costs, which can influence the final selection process for retrofitting such a water pipeline.

- –

- This study did not simulate the effect of the internal hydraulic pressure on amplifying concrete cracking after its initial formation. The presence of the internal plastic membrane could inhibit, up to a certain degree, this effect in all of the tested specimens except for Specimen 5, which already had an internal CFRP jacket.

- –

- Finally, it must be underlined that the current study did not examine any performance acceptance criteria that were based on the possibility of the initiation and spreading of leakage under the considered internal hydraulic pressure levels. Obviously, the amplitude of the radial expansion can be used for this purpose.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Romer, A.E.; Ellison, D.; Bell, G.E.C.; Clark, B. Failure of Prestressed: Concrete Cylinder Pipe; AWA Research Foundation: Washington, DC, USA, 2008. [Google Scholar]

- Roberto Gomez, R.; Muñoz, D.; Vera, R.; Escobar, J.A. Structural Model for Stress Evaluation of Pre-Stressed Concrete Pipes of the Cutzamal System; Pipeline Division Specialty Congress; ASCE: Reston, VA, USA, 2004. [Google Scholar] [CrossRef]

- Perrin, M.; Gaillet, L.; Tessier, C.; Idrissi, H. Hydrogen embrittlement of prestressing steel. Corros. Sci. 2010, 52, 1915–1926. [Google Scholar] [CrossRef]

- Price, R.E. The Investigation Cause and Prevention of PCCP Failures. J. AWWA 1990, 82, 663–681. [Google Scholar]

- Price, R.E.; Lewis, R.A.; Erlin, B. Effects of Environment on the Durability of Prestressed Concrete Cylinder Pipe, Pipelines in the Constructed Environment; ASCE: Reston, VA, USA, 1998; pp. 584–593. [Google Scholar]

- Walsh, T.L.; Hodge, D.S. Overcoming the Challenges of Replacing 20 km of Defective 1524 mm Diameter PCCP, Pipelines in the Constructed Environment; ASCE: Reston, VA, USA, 1998; pp. 602–611. [Google Scholar]

- Ojdrovic, R.P.; Zarghamee, M.S.; Hegar, J.R.; Westman, T. Condition Assessment of a PCCP Line Accessible from Outside Only, Pipelines 2001-Advances in Pipeline Engineering & Construction; (CD-ROM); Castronov, J., Ed.; ASCE: Reston, VA, USA, 2001. [Google Scholar]

- Knowles, W.L.C. Failure of Prestressed Concrete Embedded Cylinder Pipe, Design and Installation; Kienow, K., Ed.; ASCE: New York, NY, USA, 1990; pp. 434–441. [Google Scholar]

- Galleher, J.J.; Stift, M.T. Internal Inspection and Database Development of PCCP, Pipelines in the Constructed Environment; ASCE: Reston, VA, USA, 1998; pp. 721–730. [Google Scholar]

- Parks, R.R.; Drager, J.K.; Ojdrovic, R.P. Condition Assessment and Rehabilitation of the Windy Gap Pipeline—An Owner’s Perspective, Pipelines 2001-Advances in Pipeline Engineering & Construction; (CD-ROM); Castronov, J., Ed.; ASCE: Reston, VA, USA, 2001. [Google Scholar]

- Rahman, S.; Smith, G.; Mielke, R.; Keil, B. Rehabilitation of Large Diameter PCCP: Relining and Slip-Lining with Steel Pipe, Pipelines 2012: Innovations in Design, Construction, Operations, and Maintenance—Doing More with Less ©; ASCE: Reston, VA, USA, 2012. [Google Scholar]

- Johannes, S. Hydraulic Analysis in Constant Flow and Unstable Flow (Water Hammer) with Estimation of Strength Limits of the Walls of the Connecting Pipe Klidi—Dafnoula, Report to EYDAP S.A; Democritus University of Thrace Report: Xanthi, Greece, 2009. (In Greek) [Google Scholar]

- American Water Works Association. AWWA M11 Steel Pipe—A Guide for Design and Installing; AWWA: Denver, CO, USA, 2004. [Google Scholar]

- Zarghamee, M.S.; Fok, K.L. Analysis of prestressed concrete pipe under combined loads. J. Struct. Eng. 1990, 116, 2022–2039. [Google Scholar] [CrossRef]

- Zarghamee, M.S.; Heger, F.J.; Dana, W.R. Experimental evaluation of design methods for prestressed concrete pipe. J. Transp. Eng. 1988, 114, 635–655. [Google Scholar] [CrossRef]

- Zarghamee, M.S. Evaluation of Combined Load Tests of Prestressed Concrete Cylinder Pipe; Pipeline Design and Installation; ASCE: Reston, VA, USA, 1990. [Google Scholar]

- Zarghamee, M.S.; Ojdrovic, R.P. Risk assessment and repair priority of PCCP with broken wires. In Proceedings of the ASCE Pipeline Division Specialty Conference, San Diego, CA, USA, 15–18 July 2001; ASCE: Reston, VA, USA, 2001; pp. 1–8. [Google Scholar]

- Zarghamee, M.S.; Engindeniz, M.; Wang, N. Report CFRP Renewal of Prestressed Concrete Cylinder Pipe; Web Report #4352; Water Research Foundation: Denver, CO, USA, 2013; Available online: https://www.waterrf.org/system/files/resource/2019-07/INFR1SG09d-4352.pdf (accessed on 1 May 2022).

- Lee, D.C.; Karbhari, V.M. Rehabilitation of Large Diameter Prestressed Cylinder Concrete Pipe (PCCP) with FRP Composites—Experimental Investigation. Adv. Struct. Eng. 2005, 8, 31–44. [Google Scholar] [CrossRef]

- Wong, L.S.; Nehdi, M.L. Critical Analysis of International Precast Concrete Pipe Standards. Infrastructures 2018, 3, 18. [Google Scholar] [CrossRef]

- Cheng, B.; Dou, T.; Xia, S.; Zhao, L.; Yang, J.; Zhang, Q. Mechanical properties and loading response of pre-stressed concrete cylinder pipes under internal water pressure. Eng. Struct. 2020, 216, 110674. [Google Scholar] [CrossRef]

- Cheng, B.; Dou, T.; Xia, S.; Zhao, L.; Yang, J.; Zhang, Q. Experimental study on mechanical properties of pre-stressed concrete cylinder pipes (PCCPs) under external load. Int. J. Press. Vessel. Pip. 2021, 191, 104365. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Ni, P.; Wu, H.; Wang, F. Full-scale experiment and numerical simulation of prestressed concrete cylinder pipe with broken wires strengthened by prestressed CFRP. Tunn. Undergr. Space Technol. 2021, 115, 104021. [Google Scholar] [CrossRef]

- Zhao, L.; Dou, T.; Cheng, B.; Xia, S.; Yang, J.; Zhang, Q.; Li, M.; Li, X. Experimental Study on the Reinforcement of Pre-stressed Concrete Cylinder Pipes with External Prestressed Steel Strands. Appl. Sci. 2019, 9, 149. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Yan, Z.G.; Zhu, H.H.; Woody, J. Experimental study on the structural behaviors of jacking pre-stressed concrete cylinder pipe. Tunn. Undergr. Space Technol. 2018, 73, 60–70. [Google Scholar] [CrossRef]

- Xu, Z.; Feng, X.; Zhong, S.; Wu, W. Surface Crack Detection in Prestressed Concrete Cylinder Pipes Using BOTDA Strain Sensors. Hindawi Math. Probl. Eng. 2017, 2017, 9259062. [Google Scholar] [CrossRef] [Green Version]

- Doanides, P.J. Reinforced and Prestressed Concrete Pipes for the Water Supply of Greater Teheran. Betonstein-Zeitung, 1965. [Google Scholar]

- Ministry of Public Works, Approval of Specification for Reinforced Concrete Pipes for Conveyance of Domestic Sewage, Industrial Waste and Stormwater. Greek Government Gazette. 253/Β/1984. 1984. Available online: http://www.et.gr/api/DownloadFeksApi/?fek_pdf=19840200253 (accessed on 21 August 2022). (In Greek).

| Description of Tested Specimens and Code Names | |||||

|---|---|---|---|---|---|

| Type of load | Neutralized prestressed original pipe | Fully active prestressed original pipe | Fully active prestressed with internal CFRP jacket | Fully active prestressed with external CFRP jacket | Fully active pre-stressed with external RC jacket |

| Three-edge bending | Spec. 9 Ex-D = 1980 mm In-D = 1790 mm | Spec. 8 Ex-D = 2100 mm In-D = 1790 mm | Spec. 6 Ex-D = 2100 mm In-D = 1790 mm | Spec. 4 Ex-D = 2100 mm In-D = 1800 mm | Spec. 2 Ex-D = 2220 mm In-D = 1790 mm |

| Internal pressure | Spec. 10 Ex-D = 1980 mm In-D = 1790 mm | Spec. 7 Ex-D = 2120 mm In-D = 1800 mm | Spec. 5 Ex-D = 2100 mm In-D = 1790 mm | Spec. 3 Ex-D = 2100 mm In-D = 1800 mm | Spec. 1 Ex-D = 2220 mm In-D = 1790 mm |

| Pipe Parameters | Units | Measurement | Source |

|---|---|---|---|

| Pipe Type | ECP | EYDAP | |

| Di = Internal diameter of the pipe | mm | 1800 | EYDAP |

| Earth cover depth | m | 0.3048 | Assumed |

| Dy = Outside diameter of the steel cylindrical membrane | mm | 1980 | Measured |

| ty = Thickness of the steel membrane | mm | 1.5 | Laboratory testing |

| Steel membrane cylinder gauge | 16 | ||

| fyy = Steel membrane cylinder yield strength | MPa | 296.7 | Laboratory testing |

| hc = Thickness of the concrete core | mm | 141.5 | Field measurements |

| fc = Concrete core compressive strength | MPa | 61.11 | Laboratory testing |

| hm = Minimum mortar coating thickness | mm | 47.5 | Field measurements |

| ds = Prestressing wire diameter | mm | 4 | Laboratory testing |

| Prestressing wire gauge | 8 | ||

| nw = Number of wraps per metre | 1/m | 54.4 | Field measurements |

| fsg = Wire wrapping stress | MPa | 1370 | AWWA C304-07 |

| fsu = Wire ultimate strength | MPa | 1756 | Laboratory testing |

| Prestressing wire class | III | ||

| CFRP thickness per layer (total 3 layers) | mm | 0.167 | SikaWrapp300C |

| CFRP sheet tensile strength (total 3 layers) | MPa | 3129 | Laboratory testing |

| CFRP sheet Young’s modulus (total 3 layers) | GPa | 250 | Laboratory testing |

| Sprayed concrete jacket—thickness | mm | 50 | Specified |

| Sprayed concrete compressive strength | MPa | 40 | Specified |

| Diameter of radial reinforcement of RC jacket | mm | 14 | Laboratory testing |

| Yield stress of radial reinforcement of RC jacket | MPa | 481.9 | Laboratory testing |

| Ultimate stress of radial reinf. of RC jacket | MPa | 657.2 | Laboratory testing |

| Code Name of Specimen | Properties of Specimen | Vertical Load for Concrete Cracking Larger Than 0.3 mm (kN/m) | Maximum Vertical Load (kN/m) | Shortening of Vertical Diameter at Maximum Load (mm) | Elongation of Horizontal Diameter at Maximum Load (mm) |

|---|---|---|---|---|---|

| (1) | (2) | (4) | (5) | (6) | (7) |

| Spec. 2 | External RC jacket | 240 | 441 | 68 | −48 |

| Spec. 4 | External jacket with 3 layers of CFRP | 210 | 401 | 142 | −90 |

| Spec. 6 | Internal jacket with 3 layers of CFRP | 175 | 300 | 65 | −44 |

| Spec. 8 | Active prestress | 170 | 267 | 75 | −55 |

| Spec. 9 | Neutralized prestress | 25 | 75 | 51 | −46 |

| Code Name of Specimen | Description of Specimen | Max. Applied Pressure (bar) | Pressure at Change in Lateral Stiffness * (bar) | Radial Expansion at Max. Pressure (mm) | Radial Expansion at Change in Lateral Stiffness * (mm) | Remaining Radius Expansion at Unloading ** (mm) |

|---|---|---|---|---|---|---|

| Spec. 10 | No prestress | 5.18 | 2.7 | 3.44 | 0.38 | 3.16 |

| Spec. 7 | Fully active prestress | 8.55 | 7.4 | 0.21 | 0.12 | 0.06 |

| Spec. 5 | Internal FRP jacket | 9.92 | 8.0 | 0.25 | 0.1 | 0.10 |

| Spec. 3 | External FRP jacket | 12.0 | 8.0 | 0.39 | 0.1 | 0.14 |

| Spec. 1 | External RC jacket | 22.76 | 11.0 | 1.01 | 0.23 | 0.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manos, G.; Katakalos, K.; Soulis, V.; Melidis, L.; Bardakis, V. Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A. Fibers 2022, 10, 71. https://doi.org/10.3390/fib10090071

Manos G, Katakalos K, Soulis V, Melidis L, Bardakis V. Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A. Fibers. 2022; 10(9):71. https://doi.org/10.3390/fib10090071

Chicago/Turabian StyleManos, George, Konstantinos Katakalos, Vassilios Soulis, Lazaros Melidis, and Vassilios Bardakis. 2022. "Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A" Fibers 10, no. 9: 71. https://doi.org/10.3390/fib10090071

APA StyleManos, G., Katakalos, K., Soulis, V., Melidis, L., & Bardakis, V. (2022). Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A. Fibers, 10(9), 71. https://doi.org/10.3390/fib10090071