Improving the Performance of Lightweight Crumb Rubber Mortar Using Synthetic, Natural, and Hybrid Fiber Reinforcements

Abstract

:1. Introduction

2. Methodology

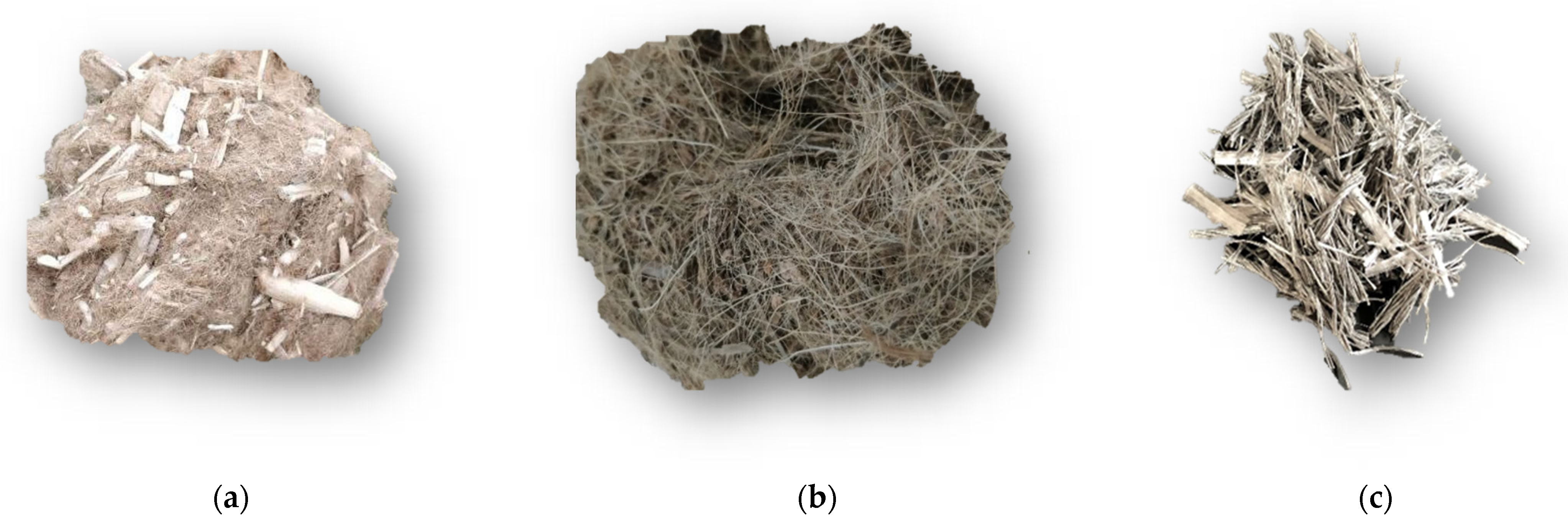

2.1. Materials

2.2. Mix Proportion

2.3. Mixing Sequence

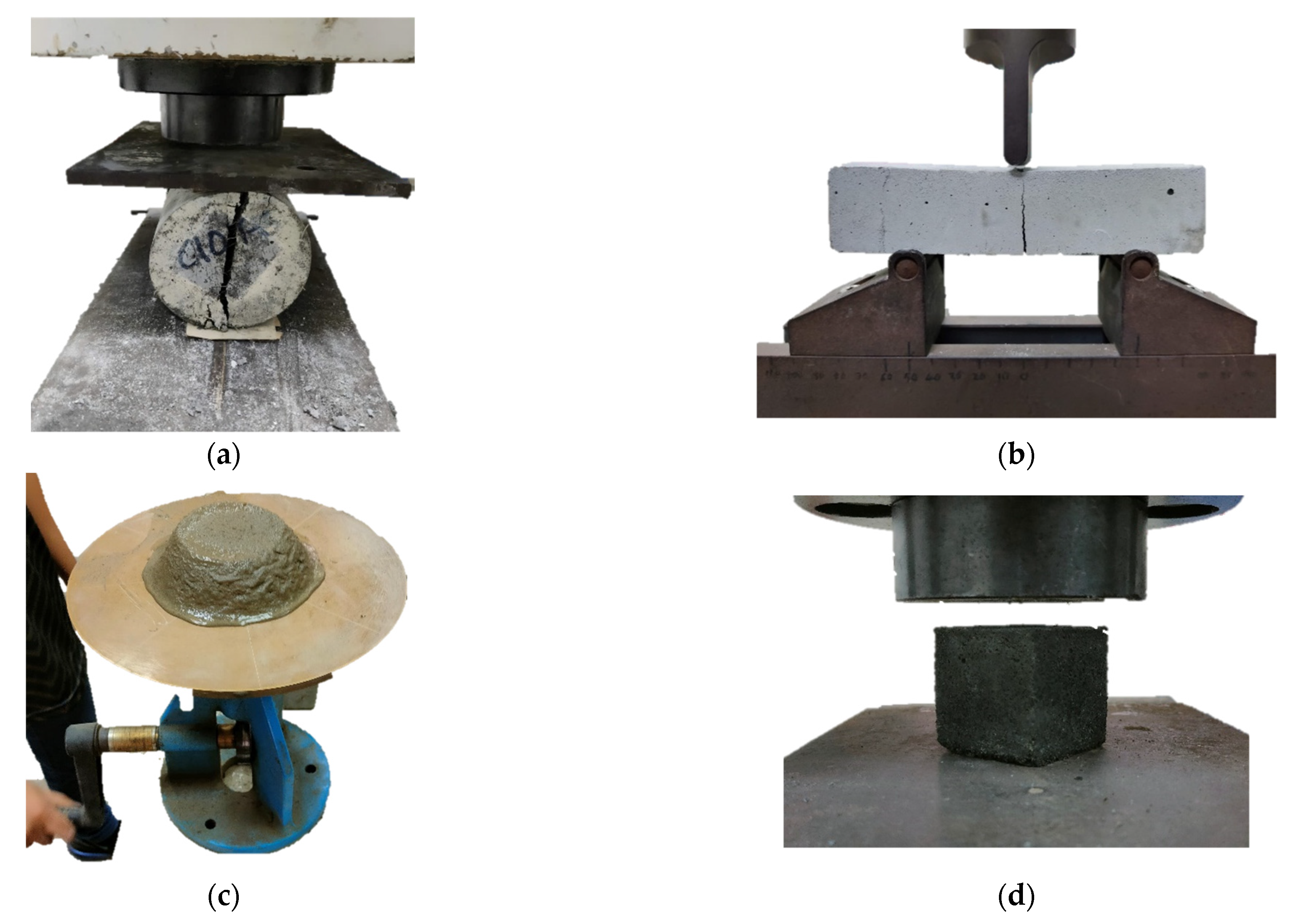

2.4. Experimental Test

3. Results and Discussion

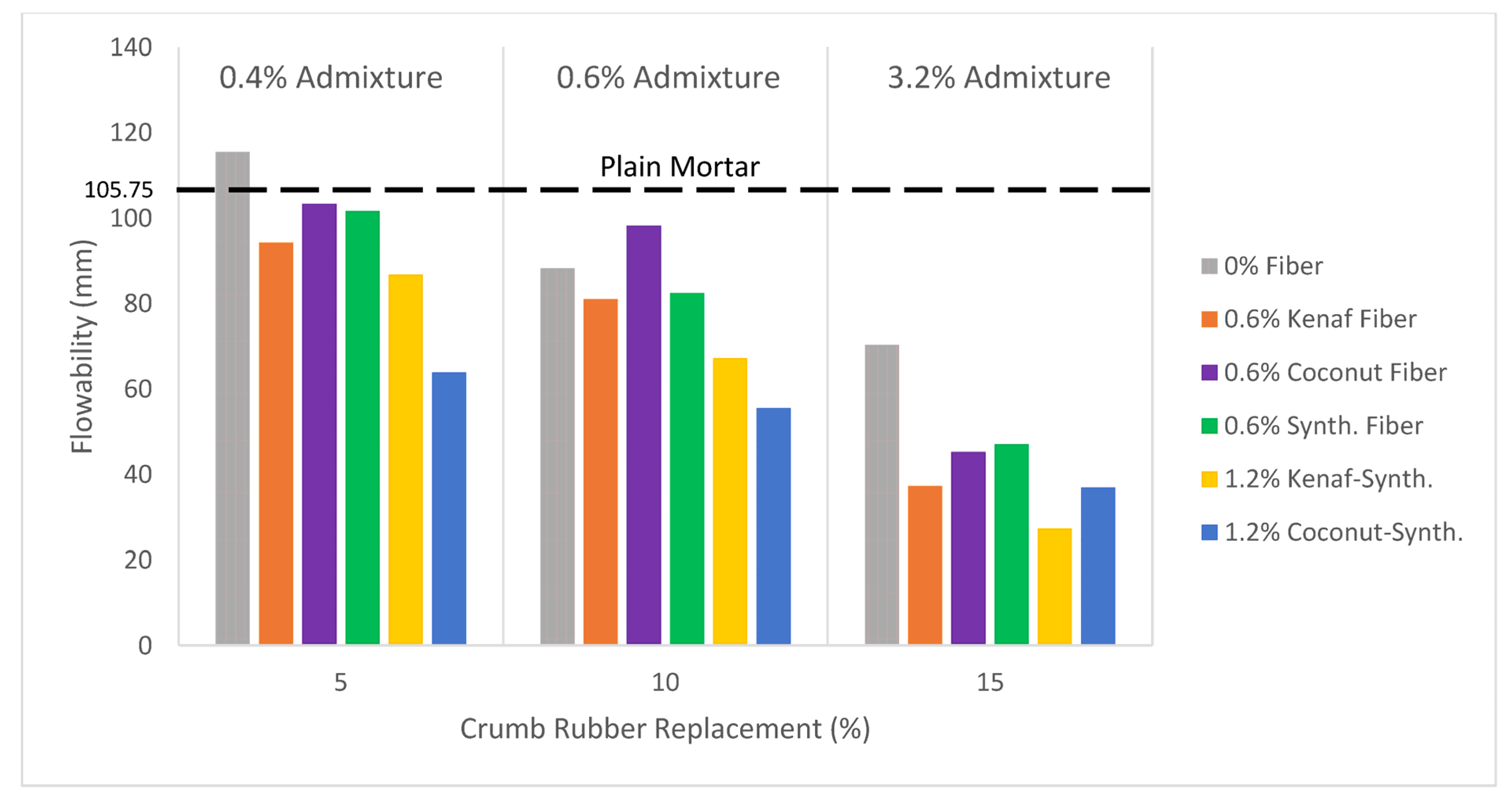

3.1. Workability

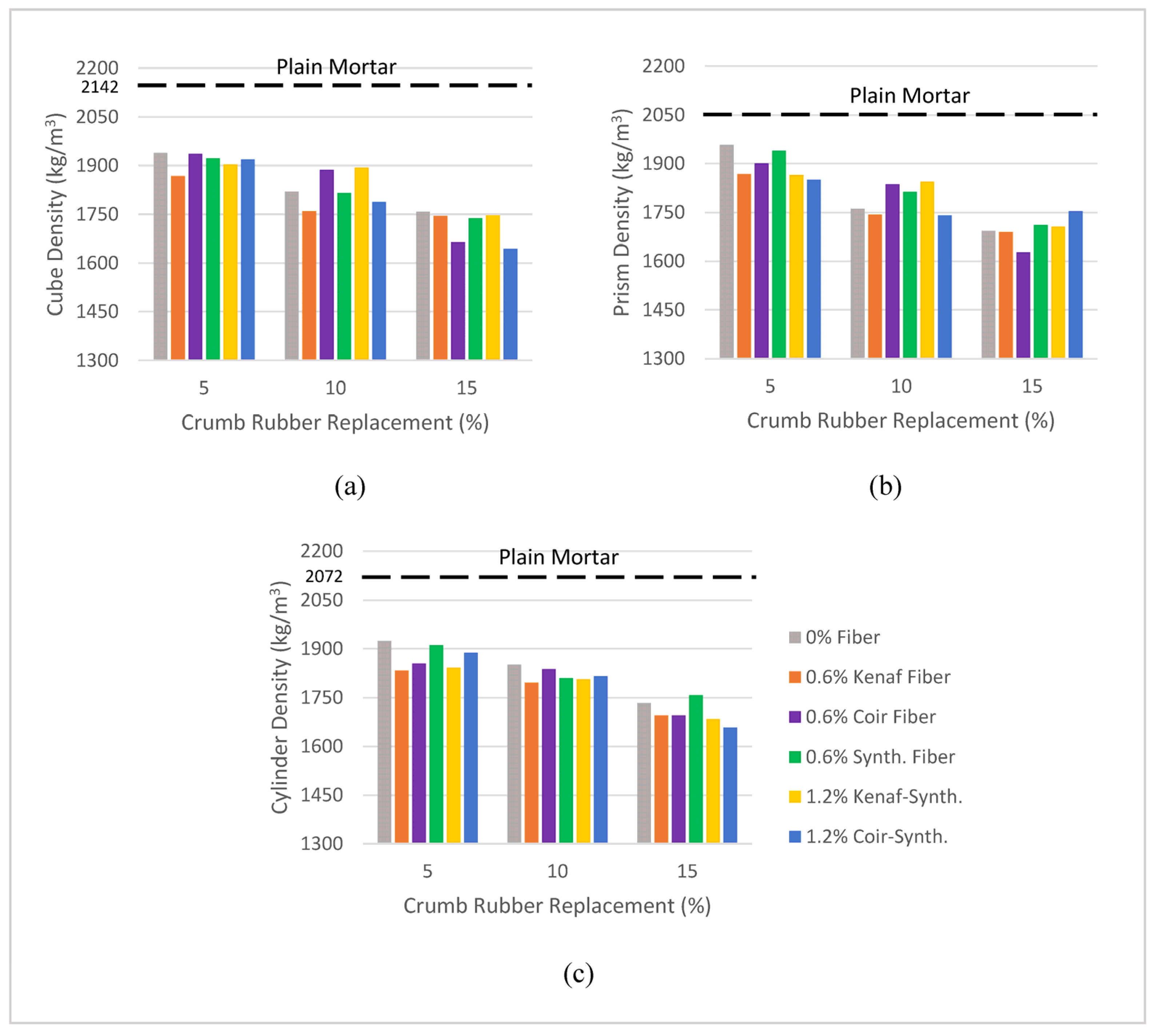

3.2. Density

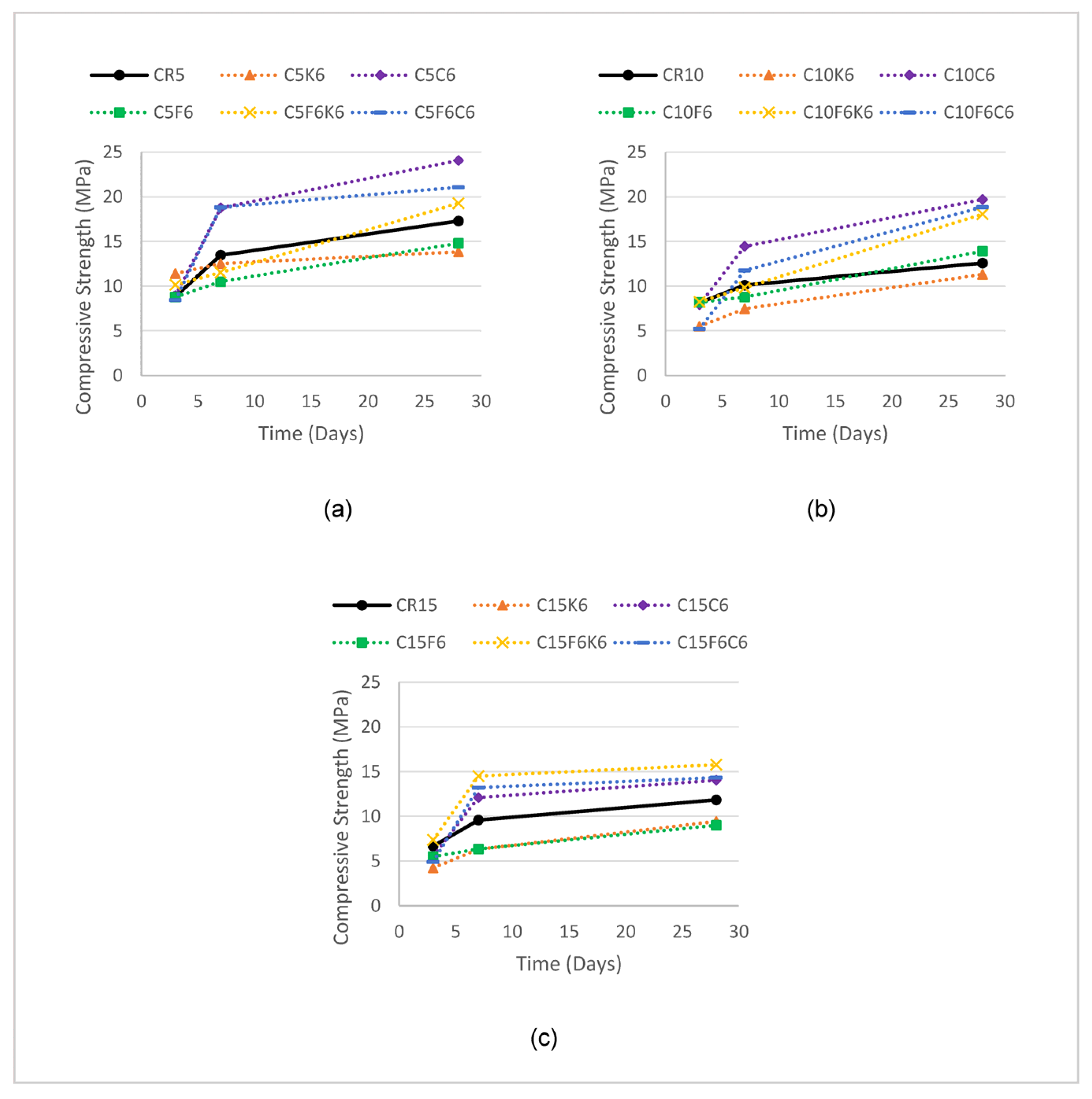

3.3. Compressive Strength

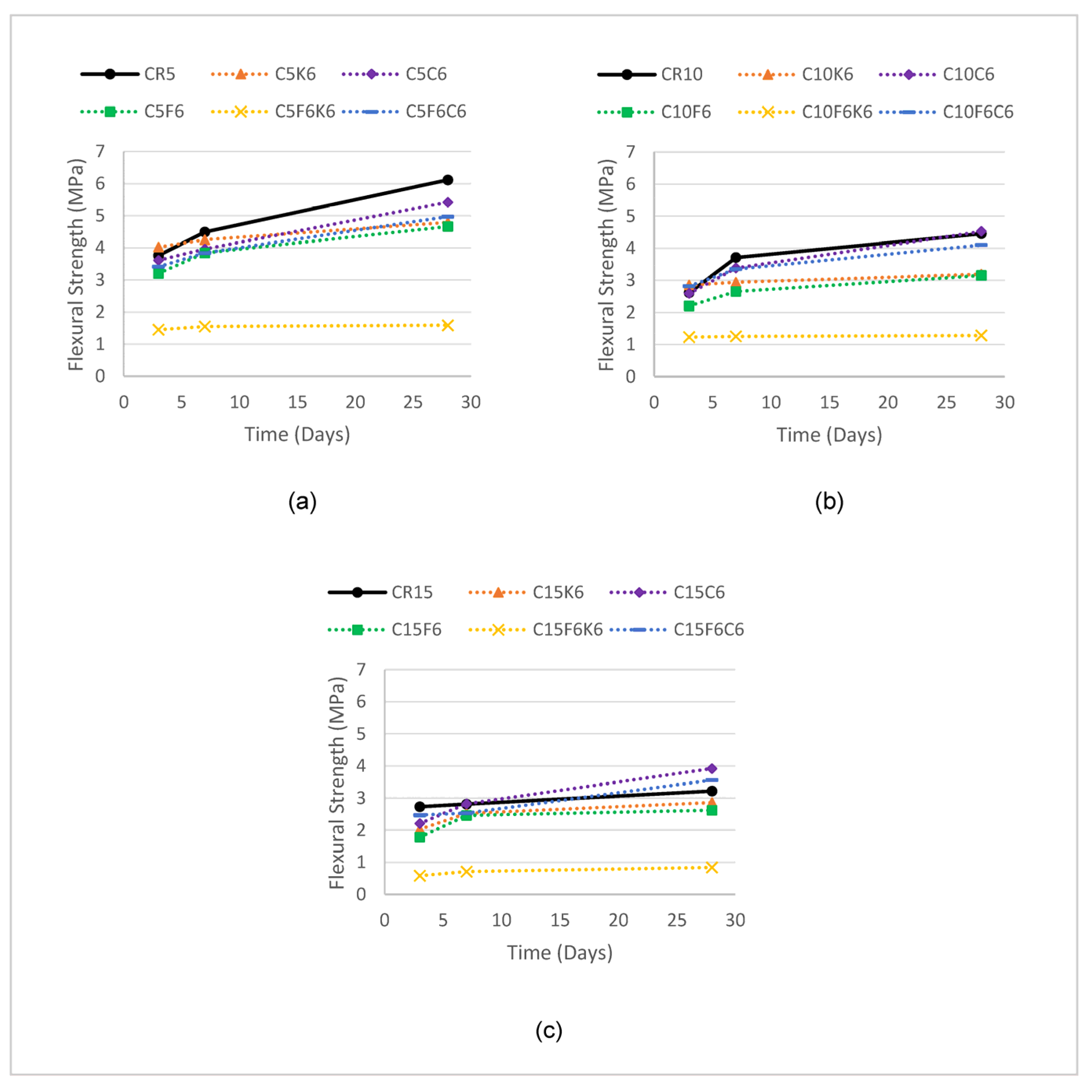

3.4. Flexural Strength

3.5. Tensile Strength

4. Conclusions

- In fresh paste workability, the addition of 0.4–3.2% admixture for 5–15% CR replacement resulted in an average of 27% flowability reduction for all types of fiber reinforcements. It can be observed that increasing the volume of CR aggregates reduces the paste flowability more than adding fibers. Flowability reductions caused by fibers are minimal and only observed when the volume fraction of fibers (Vf) in the CRM is increased.

- In compression, the average performance of the coconut fiber is 27% better than the plain CRM while the addition of kenaf and synthetic fibers deteriorated the compressive strength by 17% and 13%. For the hybrid fibers, the synthetic-coconut and synthetic-kenaf combinations are 18% and 16% stronger than the plain CRM. Hence, the best single fiber reinforcement is coconut fiber, while the best reinforcement for hybrid fibers is in the order of synthetic-coconut > synthetic-kenaf.

- In flexure, the addition of single fibers weakened the plain CRM by an average of 4% (coconut), 13% (kenaf), and 22% (synthetic). The hybridization between the fibers further deteriorated the unreinforced CRM by 84% (synthetic-coconut) and 70% (synthetic-kenaf). It can be concluded that the addition of fibers did not improve the flexural strength of the cement composites containing crumb rubber aggregates.

- In tension, the average improvements delivered to the plain CRM by coconut and synthetic fiber reinforcement are 10% and 0.10%, respectively. Kenaf fibers deteriorated the tensile strength of the unreinforced CRM by 9%. For the hybrid fibers, the performance is 10% (synthetic-coconut) and 194% (synthetic-kenaf) superior to plain CRM. As a result, the most effective reinforcement for a single fiber is in the order of coconut > synthetic, while the most effective reinforcements for the hybrid fibers are synthetic-kenaf > synthetic-coconut combinations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Halsband, C.; Sørensen, L.; Booth, A.; Herzke, D. Car Tire Crumb Rubber: Does Leaching Produce a Toxic Chemical Cocktail in Coastal Marine Systems? Front. Environ. Sci. 2020, 8, 125. [Google Scholar] [CrossRef]

- Song, W.-J.; Qiao, W.-G.; Yang, X.-X.; Lin, D.-G.; Li, Y.-Z. Mechanical properties and constitutive equations of crumb rubber mortars. Constr. Build. Mater. 2018, 172, 660–669. [Google Scholar] [CrossRef]

- Guo, S.; Hu, J.; Dai, Q. A critical review on the performance of portland cement concrete with recycled organic components. J. Clean. Prod. 2018, 188, 92–112. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ling, T.-C.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef] [Green Version]

- De Maeijer, P.K.; Craeye, B.; Blom, J.; Bervoets, L. Crumb Rubber in Concrete—The Barriers for Application in the Construction Industry. Infrastructures 2021, 6, 116. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete–A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Wang, R.; Lei, Y. Performance enhancement of rubberised concrete via surface modification of rubber: A review. Constr. Build. Mater. 2019, 227, 116691. [Google Scholar] [CrossRef]

- da Silva, F.M.; Barbosa, L.A.G.; Lintz, R.C.C.; Jacintho, A.E.P. Investigation on the properties of concrete tactile paving blocks made with recycled tire rubber. Constr. Build. Mater. 2015, 91, 71–79. [Google Scholar] [CrossRef]

- Jokar, F.; Khorram, M.; Karimi, G.; Hataf, N. Experimental investigation of mechanical properties of crumbed rubber concrete containing natural zeolite. Constr. Build. Mater. 2019, 208, 651–658. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Measurement and prediction of the strength of rubberized concrete. Cem. Concr. Compos. 1994, 16, 287–298. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A. Impact Resistance and Mechanical Properties of Self-Consolidating Rubberized Concrete Reinforced with Steel Fibers. J. Mater. Civ. Eng. 2017, 29, 04016193. [Google Scholar] [CrossRef]

- Li, L.-J.; Xie, W.-F.; Liu, F.; Guo, Y.-C.; Deng, J. Fire performance of high-strength concrete reinforced with recycled rubber particles. Mag. Concr. Res. 2011, 63, 187–195. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Ganesan, N.; Raj, J.B.; Shashikala, A. Flexural fatigue behavior of self compacting rubberized concrete. Constr. Build. Mater. 2013, 44, 7–14. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A. Use of metakaolin on enhancing the mechanical properties of self-consolidating concrete containing high percentages of crumb rubber. J. Clean. Prod. 2016, 125, 282–295. [Google Scholar] [CrossRef]

- Alsaif, A.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Freeze-thaw resistance of steel fibre reinforced rubberised concrete. Constr. Build. Mater. 2018, 195, 450–458. [Google Scholar] [CrossRef]

- Khatib, Z.K.; Bayomy, F.M. Rubberized Portland Cement Concrete. J. Mater. Civ. Eng. 1999, 11, 206–213. [Google Scholar] [CrossRef]

- Najim, K.; Hall, M. Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. 2013, 46, 2029–2043. [Google Scholar] [CrossRef]

- Balaha, M.M.; Badawy, A.A.M.; Hashish, M. Effect of using ground waste tire rubber as fine aggregate on the behaviour of concrete mixes. Indian J. Eng. Mater. Sci. 2007, 14, 427–435. [Google Scholar]

- Dong, Q.; Huang, B.; Shu, X. Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr. Build. Mater. 2013, 48, 116–123. [Google Scholar] [CrossRef]

- Chou, L.-H.; Lin, C.-N.; Lu, C.-K.; Lee, C.-H.; Lee, M.-T. Improving rubber concrete by waste organic sulfur compounds. Waste Manag. Res. J. A Sustain. Circ. Econ. 2009, 28, 29–35. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E. Strength development and chloride penetration in rubberized concretes with and without silica fume. Mater. Struct. 2007, 40, 953–964. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoglu, M.; Özturan, T. Properties of rubberized concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Azevedo, F.; Pacheco-Torgal, F.; Jesus, C.; de Aguiar, J.B.; Camões, A. Properties and durability of HPC with tyre rubber wastes. Constr. Build. Mater. 2012, 34, 186–191. [Google Scholar] [CrossRef] [Green Version]

- Onuaguluchi, O.; Banthia, N. Durability performance of polymeric scrap tire fibers and its reinforced cement mortar. Mater. Struct. Constr. 2017, 50, 158. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Khalid, F.; Irwan, J.; Ibrahim, M.W.; Othman, N.; Shahidan, S. Splitting tensile and pullout behavior of synthetic wastes as fiber-reinforced concrete. Constr. Build. Mater. 2018, 171, 54–64. [Google Scholar] [CrossRef]

- Lerch, J.; Bester, H.; Van Rooyen, A.; Combrinck, R.; de Villiers, W.; Boshoff, W. The effect of mixing on the performance of macro synthetic fibre reinforced concrete. Cem. Concr. Res. 2018, 103, 130–139. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Savastano, H.; Santos, S.F.; Dias, C.M.R.; John, V.M.; Lahr, F.A.R. Hybrid Reinforcement of Sisal and Polypropylene Fibers in Cement-Based Composites. J. Mater. Civ. Eng. 2011, 23, 177–187. [Google Scholar] [CrossRef]

- Lawler, J.S. Hybrid Fiber-Reinforcement in Mortar and Concrete; Northwestern University: Evanston, IL, USA, 2001. [Google Scholar]

- Azevedo, A.R.; Lima, T.E.; Reis, R.H.; Oliveira, M.S.; Candido, V.S.; Monteiro, S.N. Guaruman fiber: A promising reinforcement for cement-based mortars. Case Stud. Constr. Mater. 2022, 16, e01029. [Google Scholar] [CrossRef]

- Nayak, J.R.; Bochen, J.; Gołaszewska, M. Experimental studies on the effect of natural and synthetic fibers on properties of fresh and hardened mortar. Constr. Build. Mater. 2022, 347, 128550. [Google Scholar] [CrossRef]

- ASTM C150-07; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C778-02; Standard Specification for Standard Sand. ASTM International: West Conshohocken, PA, USA, 2002; Volume 96, pp. 1–2.

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2006; pp. 3–7.

- ASTM C1602/C1602M-06; Standard Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2006; pp. 5–8.

- Karahan, O.; Atiş, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Moradi, M.; Valipour, H.; Foster, S.; Bradford, M. Deconstructable steel–fibre reinforced concrete deck slabs with a transverse confining system. Mater. Des. 2015, 89, 1007–1019. [Google Scholar] [CrossRef]

- ASTM C494/C494M-17; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Li, Y.; Chai, J.; Wang, R.; Zhou, Y.; Tong, X. A Review of the Durability-Related Features of Waste Tyre Rubber as a Partial Substitute for Natural Aggregate in Concrete. Buildings 2022, 12, 1975. [Google Scholar] [CrossRef]

- Aziz, F.N.A.A.; Bida, S.M.; Nasir, N.A.M.; Jaafar, M.S. Mechanical properties of lightweight mortar modified with oil palm fruit fibre and tire crumb. Constr. Build. Mater. 2014, 73, 544–550. [Google Scholar] [CrossRef]

- ASTM C305-14; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars. ASTM International: West Conshohocken, PA, USA, 2014; pp. 14–16. [CrossRef]

- ASTM C1437-07; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2007; pp. 7–8.

- ASTM C230/C230M-03; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2010; pp. 4–9.

- ASTM C109M-02; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. Annu. B. ASTM International: West Conshohocken, PA, USA, 2007; Volume 4, pp. 1–6.

- ASTM C348-02; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2002; Volume 4, pp. 1–6.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens ASTM C-496. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–5.

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire–rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef]

- Nosbi, N.; Akil, H.M.; Ishak, Z.A.M.; Bakar, A.A. Behavior of kenaf fibers after immersion in several water conditions. BioResources 2011, 6, 950–960. [Google Scholar]

- Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers 2020, 8, 37. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Oh, T.; Chun, B. Highly ductile ultra-rapid-hardening mortar containing oxidized polyethylene fibers. Constr. Build. Mater. 2021, 277, 122317. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M.; Fashandi, H. An investigation into influence of physical and chemical surface modification of macro-polypropylene fibers on properties of cementitious composites. Constr. Build. Mater. 2020, 244, 118340. [Google Scholar] [CrossRef]

- Hannant, D.J. Fibre reinforcement in the cement and concrete industry. Mater. Sci. Technol. 1995, 11, 853–862. [Google Scholar] [CrossRef]

- Sreenivas, H.; Krishnamurthy, N.; Arpitha, G. A comprehensive review on light weight kenaf fiber for automobiles. Int. J. Light. Mater. Manuf. 2020, 3, 328–337. [Google Scholar] [CrossRef]

- Lomelí-Ramírez, M.G.; Anda, R.R.; Satyanarayana, K.G.; De Muniz, G.I.B.; Iwakiri, S. Comparative Study of the Characteristics of Green and Brown Coconut Fibers for the Development of Green Composites. Bioresources 2017, 13, 1637–1660. [Google Scholar] [CrossRef] [Green Version]

- Koerner, R.M. Geotextiles: From Design to Applications; Woodhead: Derbyshire, UK, 2016; pp. 1–617. [Google Scholar] [CrossRef]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Babatunde, O.E.; Yatim, J.M.; Razavi, M.; Yunus, I.M.; Azzmi, N.M. Experimental Study of Kenaf Bio Fibrous Concrete Composites. Adv. Sci. Lett. 2018, 24, 3922–3927. [Google Scholar] [CrossRef]

- Liu, X.; Wang, H.; Fei, Z.; Dai, L.; Zhang, G.; Ai, S.; Guo, Y.; Wang, S. Effect of slightly cadmium-enriched kenaf straw on the mechanical and thermal properties of cement mortar. Eur. J. Environ. Civ. Eng. 2020, 26, 4093–4111. [Google Scholar] [CrossRef]

- Ogunbode, E.B.; Jamaludin, M.Y.; Bin Affendi, H.; Aziz, A.A.; Ishak, Y.M.; Hamid, H.A. An Evaluation of the Interfacial Bond Strength of Kenaf Fibrous Concrete and Plain Concrete Composite. Int. J. Built Environ. Sustain. 2019, 6, 1–6. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Norizan, M.N. Kenaf Fibre Reinforced Cementitious Composites. Fibers 2022, 10, 3. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Esmaeili, M.; Ghahari, S.; Najafi, M. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Richardson, A.E. Compressive strength of concrete with polypropylene fibre additions. Struct. Surv. 2006, 24, 138–153. [Google Scholar] [CrossRef]

- Sainz-Aja, J.A.; Sanchez, M.; Gonzalez, L.; Tamayo, P.; del Angel, G.G.; Aghajanian, A.; Diego, S.; Thomas, C. Recycled Polyethylene Fibres for Structural Concrete. Appl. Sci. 2022, 12, 2867. [Google Scholar] [CrossRef]

- Nkomo, N.; Masu, L.; Nziu, P. Effects of Polyethylene Terephthalate Fibre Reinforcement on Mechanical Properties of Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 4899298. [Google Scholar] [CrossRef]

- Baruah, P.; Talukdar, S. A comparative study of compressive, flexural, tensile and shear strength of concrete with fibres of different origins. Indian Concr. J. 2007, 81, 17–24. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Slate, F.O. Coconut Fibers in Concrete. Eng. J. Singap. 1976, 3, 51–54. [Google Scholar]

- Mashrei, M.A.; Sultan, A.A.; Mahdi, A.M. Effects of polypropylene fibers on compressive and flexural strength of concrete material. Int. J. Civ. Eng. Technol. 2018, 9, 2208–2217. [Google Scholar]

- Turlanbekov, A.; Kaish, A. Early Strength Properties of Concrete Incorporating Plastic Fibers Derived from Waste Plastic Bags; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; Li, Z. Physical and mechanical properties of Crumb Rubber Mortar(CRM)with interfacial modifiers. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 845–848. [Google Scholar] [CrossRef]

- Aiello, M.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Toutanji, H. The use of rubber tire particles in concrete to replace mineral aggregates. Cem. Concr. Compos. 1996, 18, 135–139. [Google Scholar] [CrossRef]

- Pederneiras, C.M.; Veiga, R.; de Brito, J. Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars. Materials 2021, 14, 823. [Google Scholar] [CrossRef] [PubMed]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Savino, V.; Lanzoni, L.; Tarantino, A.; Viviani, M. An extended model to predict the compressive, tensile and flexural strengths of HPFRCs and UHPFRCs: Definition and experimental validation. Compos. Part B Eng. 2019, 163, 681–689. [Google Scholar] [CrossRef] [Green Version]

- Batayneh, M.K.; Marie, I.; Asi, I. Promoting the use of crumb rubber concrete in developing countries. Waste Manag. 2007, 28, 2171–2176. [Google Scholar] [CrossRef] [PubMed]

| No. | Designation | Crumb Rubber (%) |

Total Fiber Volume Fraction, Vf (%) | Admixture (%) | |||

|---|---|---|---|---|---|---|---|

| Synthetic Fibers | Coconut Fibers | Kenaf Fibers | |||||

| 1 | CR5 | 5 | - | - | - | - | 0.4 |

| 2 | CR10 | 10 | - | - | - | - | 0.6 |

| 3 | CR10 | 15 | - | - | - | - | 3.2 |

| 4 | C5K6 | 5 | - | - | 0.6 | 0.6 | 0.4 |

| 5 | C10K6 | 10 | - | - | 0.6 | 0.6 | 0.6 |

| 6 | C15K6 | 15 | - | - | 0.6 | 0.6 | 3.2 |

| 7 | C5C6 | 5 | - | 0.6 | - | 0.6 | 0.4 |

| 8 | C10C6 | 10 | - | 0.6 | - | 0.6 | 0.6 |

| 9 | C15C6 | 15 | - | 0.6 | - | 0.6 | 3.2 |

| 10 | C5F6 | 5 | 0.6 | - | - | 0.6 | 0.4 |

| 11 | C10F6 | 10 | 0.6 | - | - | 0.6 | 0.6 |

| 12 | C15F6 | 15 | 0.6 | - | - | 0.6 | 3.2 |

| 13 | C5F6K6 | 5 | 0.6 | - | 0.6 | 1.2 | 0.4 |

| 14 | C10F6K6 | 10 | 0.6 | - | 0.6 | 1.2 | 0.6 |

| 15 | C15F6K6 | 15 | 0.6 | - | 0.6 | 1.2 | 3.2 |

| 16 | C5F6C6 | 5 | 0.6 | 0.6 | - | 1.2 | 0.4 |

| 17 | C10F6C6 | 10 | 0.6 | 0.6 | - | 1.2 | 0.6 |

| 18 | C15F6C6 | 15 | 0.6 | 0.6 | - | 1.2 | 3.2 |

| No. | Designation | Cement (g/m3) | Sand (g/m3) | Crumb Rubber (g/m3) | Synthetic Fibers (g/m3) | Coconut Fibers (g/m3) | Kenaf Fibers (g/m3) | Water (g/m3) | w/c Ratio | Admixture (g/m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | CR5 | 1999.36 | 3298.94 | - | - | - | - | 1199.61 | 0.6 | - |

| 2 | CR10 | 1999.36 | 3133.99 | 164.95 | - | - | - | 1151.63 | 0.6 | 8.00 |

| 3 | CR15 | 1999.36 | 2969.04 | 329.89 | - | - | - | 1127.64 | 0.6 | 12.00 |

| 4 | C5K6 | 1999.36 | 2804.10 | 494.84 | - | - | - | 1103.64 | 0.6 | 63.98 |

| 5 | C10K6 | 1999.36 | 3133.99 | 164.95 | - | - | 12.00 | 1151.63 | 0.6 | 8.00 |

| 6 | C15K6 | 1999.36 | 2969.04 | 329.89 | - | - | 12.00 | 1127.64 | 0.6 | 12.00 |

| 7 | C5C6 | 1999.36 | 2804.10 | 494.84 | - | - | 12.00 | 1103.64 | 0.6 | 63.98 |

| 8 | C10C6 | 1999.36 | 3133.99 | 164.95 | - | 12.00 | - | 1151.63 | 0.6 | 8.00 |

| 9 | C15C6 | 1999.36 | 2969.04 | 329.89 | - | 12.00 | - | 1127.64 | 0.6 | 12.00 |

| 10 | C5F6 | 1999.36 | 2804.10 | 494.84 | - | 12.00 | - | 1103.64 | 0.6 | 63.98 |

| 11 | C10F6 | 1999.36 | 3133.99 | 164.95 | 12.00 | - | - | 1151.63 | 0.6 | 8.00 |

| 12 | C15F6 | 1999.36 | 2969.04 | 329.89 | 12.00 | - | - | 1127.64 | 0.6 | 12.00 |

| 13 | C5F6K6 | 1999.36 | 2804.10 | 494.84 | 12.00 | - | - | 1103.64 | 0.6 | 63.98 |

| 14 | C10F6K6 | 1999.36 | 3133.99 | 164.95 | 6.00 | 6.00 | 6.00 | 1151.63 | 0.6 | 8.00 |

| 15 | C15F6K6 | 1999.36 | 2969.04 | 329.89 | 6.00 | 6.00 | 6.00 | 1127.64 | 0.6 | 12.00 |

| 16 | C5F6C6 | 1999.36 | 2804.10 | 494.84 | 6.00 | 6.00 | 6.00 | 1103.64 | 0.6 | 63.98 |

| 17 | C10F6C6 | 1999.36 | 3133.99 | 164.95 | 6.00 | 6.00 | 6.00 | 1151.63 | 0.6 | 8.00 |

| 18 | C15F6C6 | 1999.36 | 2969.04 | 329.89 | 6.00 | 6.00 | 6.00 | 1127.64 | 0.6 | 12.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zainal, S.M.I.S.; Mattius, D.; Baba, Z.; Rizalman, A.N.; Hejazi, F. Improving the Performance of Lightweight Crumb Rubber Mortar Using Synthetic, Natural, and Hybrid Fiber Reinforcements. Fibers 2023, 11, 9. https://doi.org/10.3390/fib11010009

Zainal SMIS, Mattius D, Baba Z, Rizalman AN, Hejazi F. Improving the Performance of Lightweight Crumb Rubber Mortar Using Synthetic, Natural, and Hybrid Fiber Reinforcements. Fibers. 2023; 11(1):9. https://doi.org/10.3390/fib11010009

Chicago/Turabian StyleZainal, S. M. Iqbal S., Debbie Mattius, Zulhelmi Baba, Ahmad Nurfaidhi Rizalman, and Farzad Hejazi. 2023. "Improving the Performance of Lightweight Crumb Rubber Mortar Using Synthetic, Natural, and Hybrid Fiber Reinforcements" Fibers 11, no. 1: 9. https://doi.org/10.3390/fib11010009

APA StyleZainal, S. M. I. S., Mattius, D., Baba, Z., Rizalman, A. N., & Hejazi, F. (2023). Improving the Performance of Lightweight Crumb Rubber Mortar Using Synthetic, Natural, and Hybrid Fiber Reinforcements. Fibers, 11(1), 9. https://doi.org/10.3390/fib11010009