Abstract

The specific interest for the use of bark in materials, instead than for energy recovery, is owed to circular economy considerations, since bark fibers are normally byproducts or even waste from other sectors, and therefore their use would globally reduce the amount of refuse by replacing other materials in the production of composites. For the purpose of promoting their application in polymer composites, mainly under a geometry of short random fibers, bark fibers are extracted and treated, normally chemically by alkali. Following this, investigations are increasingly carried out on their chemical composition. More specifically, this includes measuring cellulose, hemicellulose, and lignin content and their modification with treatment on their thermal properties and degradation profile, and on the mechanical performance of the fibers and of the tentatively obtained composites. This work aims at reviewing the current state of studies, trying to elicit which bark fibers might be most promising among the potentially enormous number of these, clarifying which of these have received some attention in literature and trying to elicit the reason for this specific interest. These can be more thoroughly characterized for the purpose of further use, also in competition with other fibers not from bark, but from bast, leaves, etc., and pertaining to developed production systems (cotton, hemp, flax, jute, etc.). The latter are already widely employed in the production of composites, a possibility scantly explored so far for bark fibers. However, some initial works on bark fiber composites and both thermoplastic and thermosetting are indicated and the importance of some parameters (aspect ratio, chemical treatment) is discussed.

1. Introduction

An epidermis consisting of thin walls covers primary plant stems, fitting tightly to them: also, a significant amount of wax appears to be laid over their outer face [1,2]. Overtime, an external layer of the epidermis is gradually formed by dead cells, which is referred to as “bark”: it constitutes the protection structure for the tree and represents, depending on the species, a weight corresponding to 5–28% of it [3]. Bark, being the outer and more ligneous section of the plants is normally only employed to extract chemicals, reused in low values applications (such as to amend compost) [4], or simply discarded. Sometimes, the use of bark in materials is somewhat discouraged by its tendency to be scaly and to present fissures [5]. However, it is notable that the extent of fissures in bark is considered lately to have a particularly significant importance, as it offers a fast and reliable evaluation of the amount of carbon present in it, hence of its potential whenever the production of biochar is carried out [6]. When proposing hence the use of bark for materials production, the respective morphology of bark in different species modifies in turn thermal properties, the likeliness of species being hosted in it, and the presence of alterations, such as gummosis [7]. Bark density can also be considerably variable, and normally much lower than the specific weight of wood, due to the high amounts of internal voids present. In practice, densities reduced by around 20–30% with respect to the wood density, such as in the case of eucalyptus, appear to be normal [8]. This depends on a number of factors, including obviously tree species, maturity of the plant, and environmental conditions for growth [9]. It needs also to be taken into consideration that bark density and general characteristics can considerably differ from one segment of the tree to another, therefore sampling may require to be optimized. This is normally performed whenever bark is used for other purposes, such as the extraction of polyphenols, which is possible for the different species of the genus Quercus [10], but also for example for willow [11], and spruce [12].

More precisely, the thickening of the stems that leads to the development of the bark accompanies this development just for a limited period; after that, it splits from the rest of the tree [13,14]. Splitting can seriously affect the protective role of the bark: in practice, as the deeper tissues can be vulnerable to pathogens, this damage to the epidermis is detrimental, and due to evaporation, the plant risks withering [15].

In other words, bark development is based on the gradual generation of new epidermis, which reproduces multiple cells in the inner layer of the cortex. These normally replicate parallel to the surface with walls: This would allow developing different dermal tissues, defined as phellom outwards and phelloderm inwards [16]. In most cases, phellom necrose cells rapidly grow, while in other instances a complex polyester, suberin, is sedimented in the cell walls: The process is called suberification [17]. The formation of suberin in bark is characteristics of a number of plants, including, e.g., some oaks and birch: In these species, it can be effectively extracted to be applied as a protection for wood [18]. Where suberification is extensive, such as in cork oak (Quercus suberus), it leads to a light and porous cellular tissue, named as cork, which is in practice the only case where the inner part of bark is commonly exploited so far [19].

Recently, cork has been used in biocomposites, and also in combination with other plant fibers, such as sisal [20] or flax [21]. Another possibility is the extraction of suberin from cork derived from different species, where it can represent between 20 and 50% of the whole hardwood weight [22]. Suberin and lignin from cork can also be employed as compatibilizers for polymers, such as polyolefins, with the idea to represent an alternative to typical grafting agents, such as maleic anhydride, for the production of natural fiber composites (NFCs) [23].

The possibility for a successful use of bark in materials requires evaluating the possibility for biological attack to bark-based materials: tree bark is the home of numerous arthropods, vertebrates, lichens, etc., and does not harm their living ecosystem. On the other side, certain species, such as wood borers, do damage trees. Biological damage is often connected to the presence of heat, resulting in the thermal softening of the structure [24].

The bark has its own resources nonetheless to withstand parasitic attack: the flow of resin inside the bark of pines (Pinus genus) plays a major role, e.g., in defending these trees against woodborers [25]. In addition, pine resin does represent a possible and compatible additive to improve the mechanical and thermal properties of starch-based plastics [26]. It needs also to be noticed that infestation of the bark by parasites, such as beetles, does not represent a factor against the use of the resin as an adhesive for bio-based resins [27].

Another function of the bark is the protection of the life of the tree in a wider sense, regarding in the environment it is living in, and therefore from hazards such as fire, insect pests, and herbivore browsing. It needs to be observed whether fiber extraction from bark still maintains these inherent characteristics from a mechanical point of view. This has been confirmed as regards giant sequoia bark fibers and impact properties [28], while in most cases fire tolerance also has been maintained, although this largely depends on fiber dimensions, water content, and of course species [29,30,31,32,33,34].

Since bark is normally discarded, whenever wood production is carried out, this leads to the availability of a very large amount of bark biomass. A number of applications are possible though for bark taken from different trees, as reported in the last few years. These include the aforementioned extraction of polyphenols through methanol, to offer antimicrobial properties (Vismia rubescens) [35], such as antitussive (Ficus racemosa) [36], antidepressant effects, as in the case of Adansonia digitata [37], or Ficus benghalensis [38], or to be applied in the more general field of ayurvedic medicine (Acacia nilotica) [39]. In contrast, other applications do not involve phenol extraction processes: this is the case for bark from gelam trees, where combustion with the production of active carbons, e.g., for application as water filters, was performed [40]. Another possibility, more linked to the structural engineering field, is the production of bio-aggregates for insulation purposes [41].

For the application of ligno-cellulosic waste, such as bark biomass, in the field of materials, it is also possible to use the lignin extracted from these, which can be compatible with polymers: extraction has been performed, e.g., from oil palm branchlets or licorice roots [42], or from Japan cedar [43]. In other cases, when this is considered suitable and practicable with sufficient yield, the extraction of cellulose nanocrystals (CNC) can also be of interest, on which a large literature regarding obtainment of CNC from lignocellulosic waste is present, e.g., [44,45,46]. Coming back to bark, some examples are more particularly reported on specific biomass types, such as spruce [47].

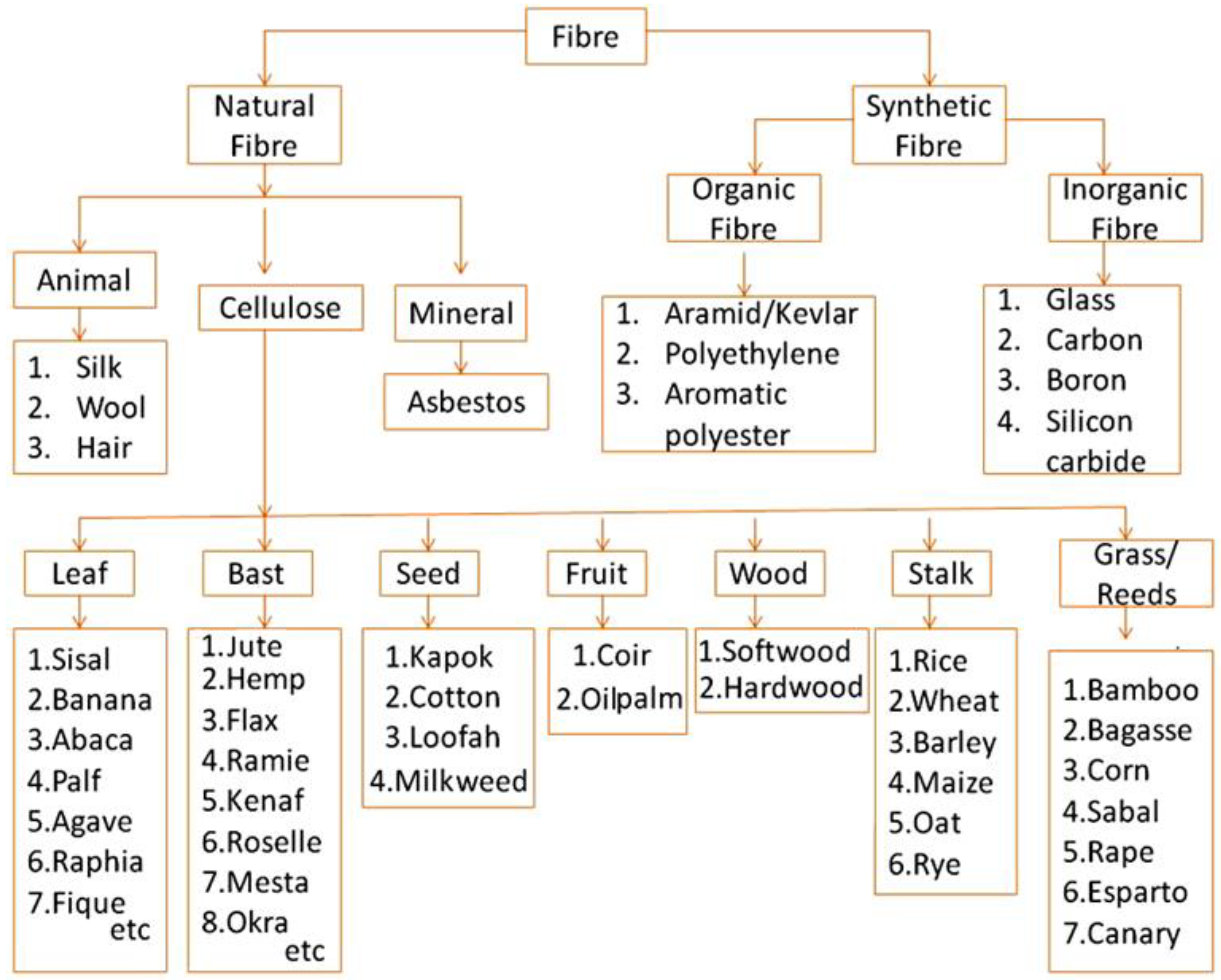

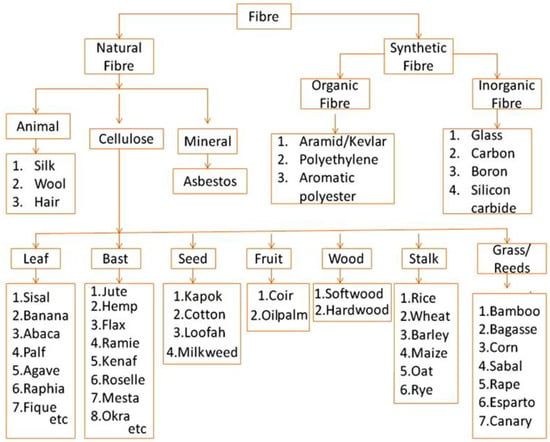

A further possibility, less chemically intensive and convenient when the lignin content is lower, is offered by the use of bark as a source of short fibers to be inserted as a random reinforcement into polymer or even rubber matrices, such as in [48,49,50]. Their effect may be comparable to that obtained with many lignocellulosic fibers from the stem, leaf, fruit hair, or seed hair. On these, a number of comprehensive reviews do exist, such as [51]. A classification is offered in Figure 1, which might be of use when considering the competitors for bark fibers.

Figure 1.

Types of fibers and examples of each category.

In general terms and provided the aforementioned issues on fiber extraction are sorted out, bark proves adapted for the fabrication of lightweight materials. This would also require though the microbial attack to be delayed, if not avoided at all, by the insertion of bark fibers as filler in an appropriate resin sufficiently resistant to environmental degradation to promote materials use. This is the reason why in most cases oil-derived resins are used in composites when dealing with bark-extracted fibers. On the other hand, attempts to develop bio-based resins using bark phenols have also been carried out [52].

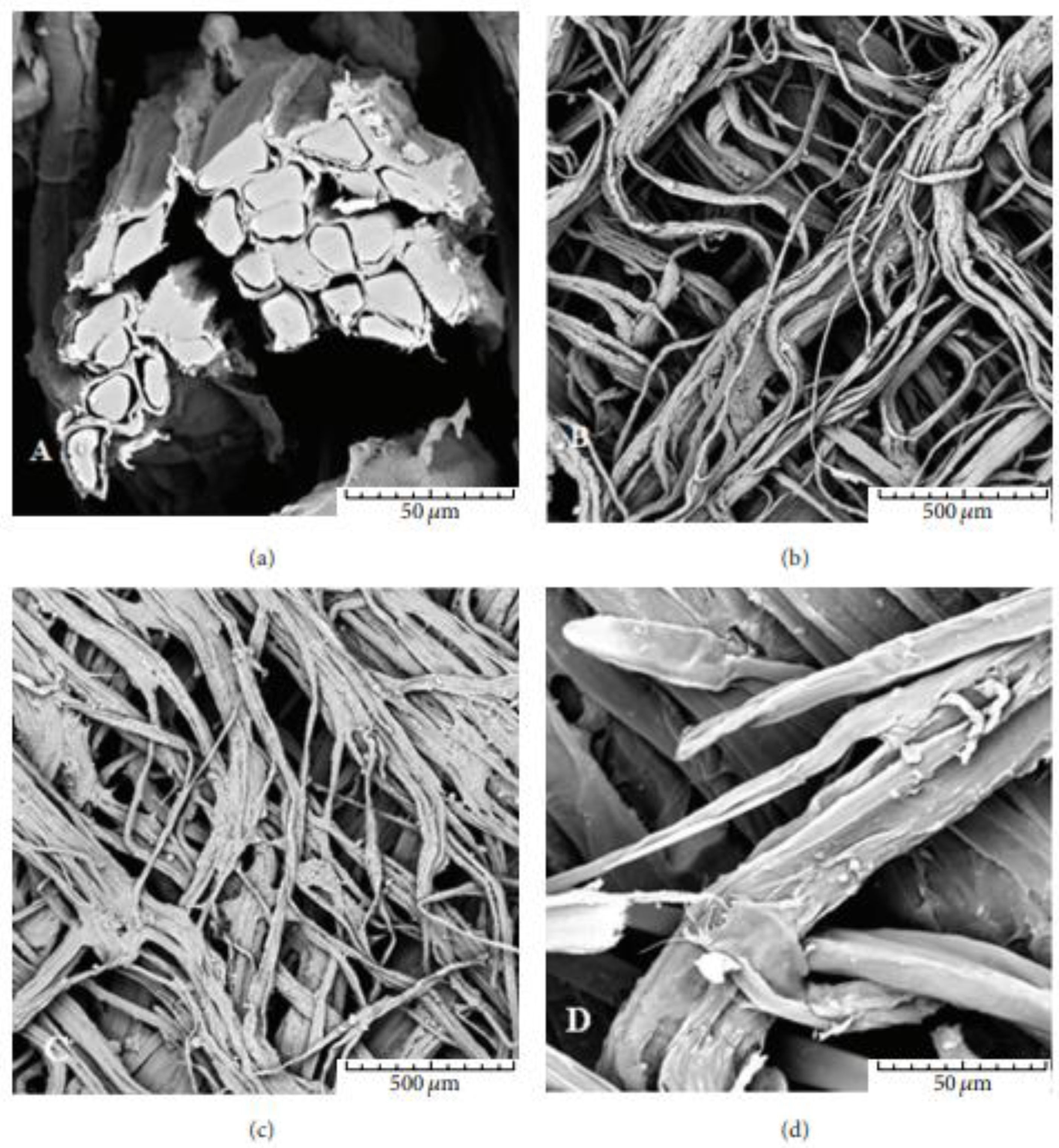

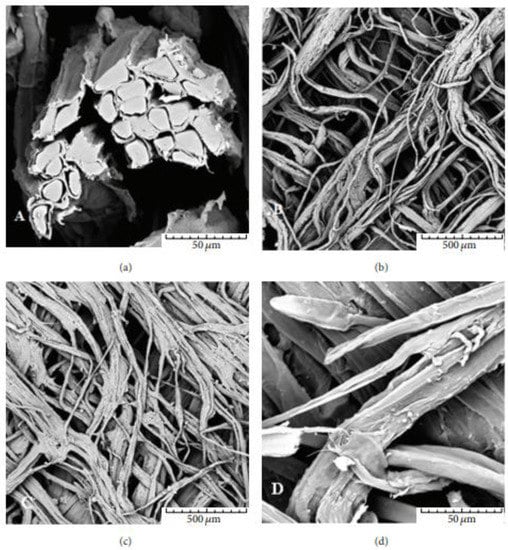

Bark fibers are normally used in the form of short fibers, although in some particular situations also bark cloth are available, though their characterization does appear not simple. However, the characterization of Ficus natalensis bark cloth, intended for its prospective application as a 2-D wood-like natural and hierarchically organized structure, led to some indications, which are of general interest in the case of bark fibers. In particular, its thermal degradation study based on thermogravimetric analysis (TGA) reported a typical mass loss of 10% below 100 °C and a further loss in the region of 60% normally concentrated between 225 and 350 °C. Lignin decomposition is suggested to take place around 375 °C and a residue of 20% approximately at 500 °C, is to be expected. Though variations are always possible depending on the species, this study can be considered as a suitable baseline for thermal degradation of bark fibers [53]. Another result that can be considered well consolidated is the effect of alkali treatment by sodium hydroxide (NaOH) on the delay of thermal degradation of bark, resulting on its improved mechanical properties. Scanning electron microscopy images of NaOH-treated Ficus natalensis bark cloth samples is provided in Figure 2. The production of a bark cloth-reinforced epoxy composite has also been carried out using this time a Ficus brachypoda structure, suggesting that its layout would approximate a ±45° reinforcement, and therefore not far from orthotropic behavior [54]. Further interest for bark cloth and their relevant composites has been raised by indications that it might provide, due to presence of natural waxes, an antimicrobial action, namely against Staphylococcus aureus, which can extend to the case of bark, whenever used in combination of water-permeable matrices, such as poly(lactic acid), therefore providing additional potential to these [55].

Figure 2.

SEM morphology of treated bark cloth at magnifications (a) 50×, (b,c) 100×, and (d) 500×.

A concept that is very similar to bark cloth is the possible use in composites of the internal woody backbone of the Opuntia cladode, which has been considered as a potential replacement with the more consolidated flax fibers. To achieve this aim, two structures have been considered, the former as the reinforcement of a poly(lactic acid) (PLA)/wood flour matrix, increasing the performance of the bare matrix. In the latter cases, a sandwich configuration, to serve as the core for PLA/wood flour skins, by showing a considerable interfacial strength. Both attempts were successful, though the performance obtained was lower than the one obtained with flax/PLA composites [56].

However, in the present situation, which might be deemed to evolve for the aforementioned consideration, most applications of bark fibers are in the form of short fibers. This suggests that performance need to be compared with other composites fabricated using short fibers. With this objective, a list of lignocellulosic fibers (not from bark) used in the form of short random fibers in polymer composites and the relative amount that was employed in the respective studies is reported in Table 1. These data are presented with the idea of a future comparison with the achievements obtainable with bark fibers.

Table 1.

Example of lignocellulosic fibers used in a short random geometry in composites (possible competitors for bark fibers).

To assess the potential of the application of bark fibers in short random form in composites, the characterization of the raw bark material obtained from the tree needs to be carried out. This includes among other tests the measurement of physical properties (density and water absorption), chemical composition (in particular, cellulose, hemicellulose, and lignin content), thermal properties, mainly as far as their degradation with temperature is concerned, and tensile, flexural, and impact performance. However, the process of extraction of the fibers from the bark may be cumbersome, as it is the possibility to obtain a sufficient aspect ratio, i.e., length/diameter, to yield some tensile strengthening effect in composites. To improve these properties, it is sometimes essential to apply a treatment, normally with alkalis, which hardens and strengthens the fibers. All the aforementioned aspects are discussed in Section 2, whereas Section 3 deals especially with fabrication and characterization of bark fiber composites.

2. Bark Fiber Characterization

2.1. Bark Fiber Extraction

Portions of bark that are suitable to extract fibers can be obtained by manual peeling, also defined as “stripping”, provided the cell walls are not too lignified, which results in them being too solidly bound, e.g., by mucilaginous substances, such as it happens in Thespesia populnea [63]. The bare manual peeling is still typically applied in some Acacia species, such as Acacia Mearnsii, up to considerable height, e.g., 1 m, which limits considerably the costs of bark extraction [64]. If this is the case, no particular processes for refining need to be used, apart from chopping. In a study, e.g., on Prosopis juliflora fibers, a metal teeth comb was used to obtain long fiber ribbons, and further chopped using a shear mixture grinder [65]. Since the requirement is to obtain fibers of sufficient length to be introduced with random orientation into composites to provide reinforcement, pulverization is obviously not an option for the purpose.

Manual peeling can also be followed by oven drying at temperatures lower than 100 °C, such as has been the case for Inula viscosa fibers, where it was carried out at 70 °C [66]. In some cases, such as for Grewia damine, water retting for periods as long as 15 days were required to allow for microbial degradation, after which manual extraction from the bark was performed using once again a metal comb [67]. Techniques involving the use of chemicals were used in other cases, such as dealing with bark of cotton stalks, where different concentrations of sodium hydroxide (0.5, 1, and 2 N) for different times (1 or 2 h). The highest yield in fibers (30% with a fineness of 107 ± 8 deniers) was obtained with a 2-hours treatment at 90 °C with 0.5 N sodium hydroxide solution [68]. In most cases, the highest environmental impact was caused by the use of alkali treatment: This can be barely considered the only option applied for bark fiber extraction. However, a wider attention towards optimizing the use of sodium hydroxide to obtain substantial improvements of properties with the lowest possible concentration is recently being witnessed, such as in the case of Dichrostachys cinerea bark fiber and its composites [69]. In the specific case, a treatment with 5 wt.% NaOH with 90 min soaking was recognized to be optimal for the purpose. For prospective work on bark fibers, two considerations need to be drawn. First, a wealth of possible treatments other than are possible on lignocellulosic fibers, such as chemical (acetylation, silane, etc.), physical (UV irradiation, plasma treatment), or enzymatic, yet they are usually applied only on bast or leaf ones, on which more data are available so far [70]. An early treatment with silane on Second, to possibly minimizing the impact of chemicals used in treatment, namely sodium hydroxide in the case of bark fibers, it would be of interest recirculating the solution used for it, in which especially fiber lignin has been dissolved. So far, the recirculation of other alkalis, such as calcium hydroxide, does appear to be simpler and practicable, such as it has been completed for on-farm pre-treatment of lignocellulosic waste [71].

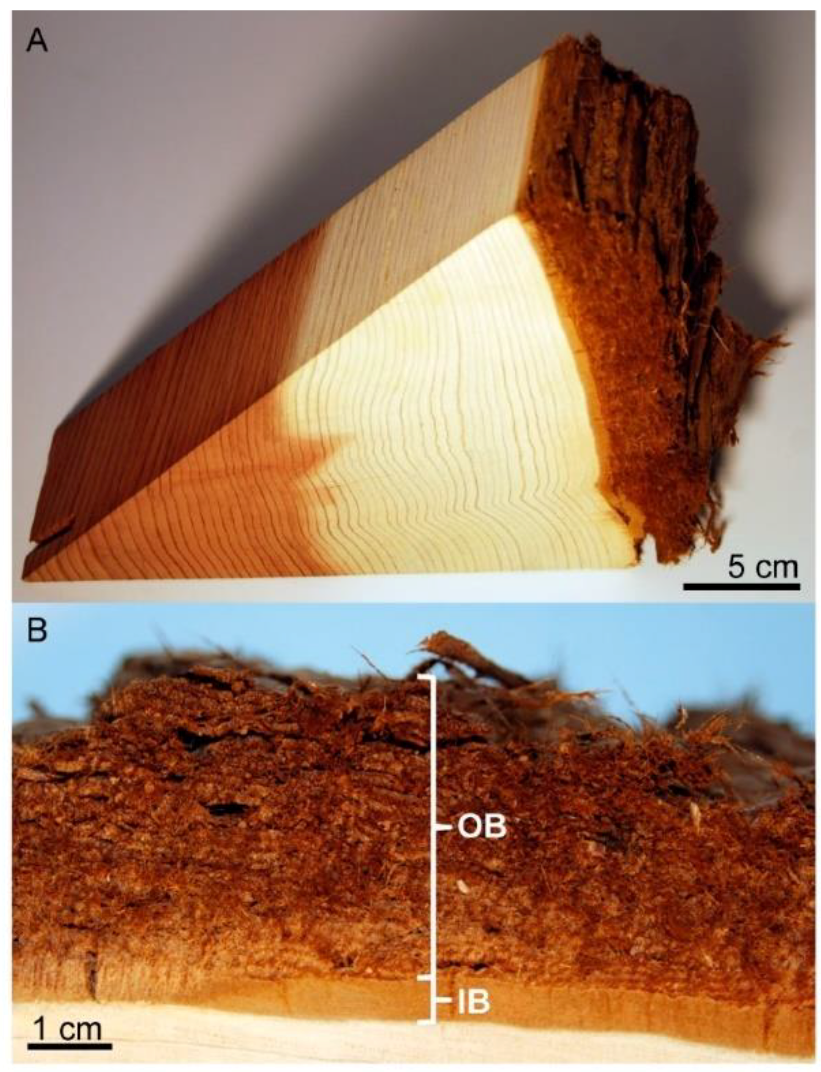

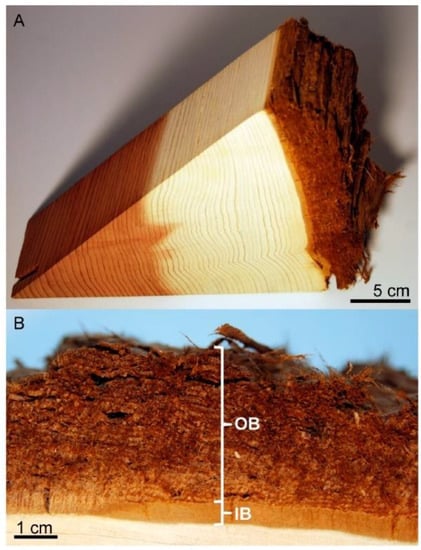

Investigations also suggested that the internal porosity of bark fibers, and hence, their density, might be variable: Indicative average values of the density of some bark fibers are given in Table 2. This is due to the hierarchical structure of the fibers and the degree of maturity of the bark. Additionally, the aforementioned impact resistance offered by sequoia bark is due to the combined presence of differently dense zones in it, which enable the easier absorption of local compression forces. This is reported in Figure 3 [28].

Table 2.

Densities of different fibers extracted from bark.

Figure 3.

(A) A segment of a cross-section (wood and bark) of the giant sequoia (Sequoiadendron giganteum) tree. (B) In the bark of the segment, a dense inner bark (IB) and a less dense, highly fibrous outer bark (OB) are visible [28].

In the case that porosity reaches a very high percent of the bark material, this can be exploited, such as, e.g., in Eucalyptus, which has been proposed for the production of active carbons [85]. This is particularly of interest whenever large amounts of bark waste are available, such as is the case, for example, for date palm, where the development of active carbons for water filtering has also been carried out [86]. However, in both these cases also the possible production of wood-replacement materials has been studied. In particular, for Eucalyptus bark fibers (EBF) as insulation panels, where a life cycle analysis (LCA) study comparing the impact of four different types of EBF over the panel’s life has been completed [87]. The same occurred for date palm bark waste [88]: This also benefited from the interest elicited from the automotive industry for palm leaf fibers [89], which created also improved disposal for its byproducts, such as bark.

2.2. Chemical Composition of Bark Fibers

In Table 3, some information on the chemical composition of bark fibers, limited to cellulose, hemicellulose, and lignin, is reported. General observations on these results can concern the fact that cellulose is always the main component of the extracted fiber, normally more than twice more abundant than hemicellulose and lignin. The quantity of extractives, moisture, wax, pectin, is very variable among the species, so that the total cellulose + hemicellulose + lignin can be more or less close to 100%. It is also noteworthy that in some cases only the three main components have been measured in practice, on completely dry fibers. The different fibers whose composition is reported can be separated in two categories though: the first includes most of them, which have a very low hemicellulose and lignin content, comparable with data from typical non-bark textile fibers, such as is the case, e.g., for untreated hemp [90].

The second group includes Napier grass and Acacia Caesia, where cellulose represents less than 50% of sum of the three components. This is not far from what obtained with a typical source of short fibers, i.e., coir from coconut fruit hair: A study by Muensri et al. [91] reported, for this fiber, values of 42.10, 32.69, and 22.56% for lignin, cellulose, and hemicellulose, respectively.

Table 3.

Quantities of the main chemical components in some untreated bark fibers.

Table 3.

Quantities of the main chemical components in some untreated bark fibers.

| Fiber | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ref. |

|---|---|---|---|---|

| Acacia caesia | 37 | 20 | 18 | [72] |

| Acacia nilotica | 56.46 | 14.14 | 8.33 | [74] |

| Albizia lebbeck | 72.59 | 9.69 | 10.08 | [92] |

| Albizia saman | 59.43 | 12.78 | 14.64 | [93] |

| Calotropis gigantea | 57 | 19 | 18 | [76] |

| Carica papaya | 58.71 | 11.8 | 14.26 | [94] |

| Ceiba pentandra | 60 | 17 | 23 | [77] |

| Cissus populnea | 61.8 | 14.74 | 11.52 | [95] |

| Ficus racemosa | 72.36 | 11.21 | 10.45 | [79] |

| Grewia monticola | 55.74 | 14.65 | 15.39 | [80] |

| Hibiscus tiliaceus | 58.63 | 18 | 23.35 | [96] |

| Napier grass | 45.66 | 33.67 | 20.60 | [97] |

| Pithecellobium dulce | 75.15 | 10.23 | 12.14 | [98] |

| Prosopis juliflora | 61.65 | 16.14 | 17.11 | [83] |

It is also worth noting, as remarked already, that alkali treatment, normally with sodium hydroxide, is able to modify the chemical composition of the fibers by assisting in the decomposition of lignin. On bast fibers, such as hemp, such as reported in [99], it is possible to apply even very high alkali contents, such as 17.5 wt.% sodium hydroxide, optimizing the removal of hemicellulose and lignin, without resulting in the destruction of the fibers. However, more limited amounts of alkalis are normally used on bark fibers: in particular, the measured effect on chemical composition of the tenor of treatment on bark fibers are reported, as regards Acacia planifrons [100] (Table 4a). Another possibility is related to the application of the same amount of sodium hydroxide for different times, as was performed for Grewia flavescens, leading to the conclusion that the maximum amount of cellulose corresponded to an optimal treatment time [101] (Table 4b).

Table 4.

(a) Chemical compositions of Acacia planifrons fiber, untreated and treated with different concentrations of sodium hydroxide for the same time (30 min) [100]. (b) Chemical compositions of Grewia flavescens, untreated and treated with the same concentrations of sodium hydroxide (5 wt.%) for different times [101].

It appears cumbersome to extract other information than this classification as regards the dependence of chemical composition over the age of the plant and the cultivar. This is an aspect not immediately ascertained with bark fibers, since they often come from plants not cultivated for the very purpose of fiber extraction, as mentioned in the introduction, when dealing with other uses of bark. Some indications are offered in [63], with regard to Thespesia Populnea, as concerns the increase in fiber diameter and the consequent decline of tensile strength over maturity. This is due to the higher lignification and lower crystallinity of mature stems, which has been extensively studied in the past in species such as Arundo donax [102]. These studies were considered important in the first place for pulping purposes, which justified investigation on bark fibers, e.g., of redwood [103]. In other cases, it was considered in contrast only suitable to possibly extract the fibers at plant maturity, such as in a recent study on Silybum marianum [84].

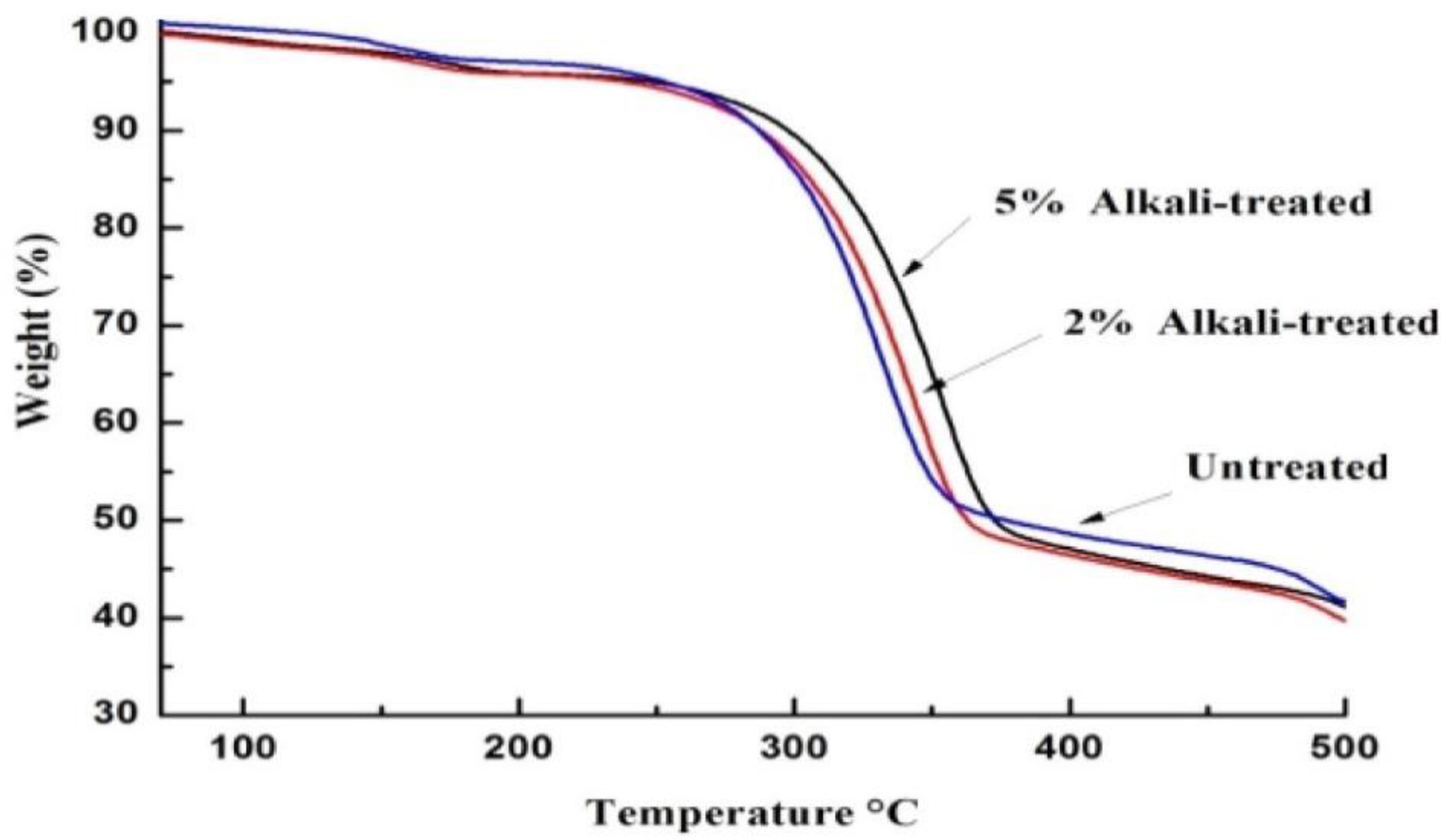

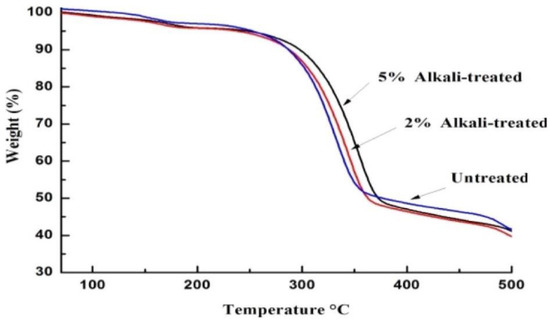

2.3. Thermal Properties of Bark Fibers

The typical thermal profile for bark fibers involves, after the removal of moisture occurring just below 100 °C, an initial degradation taking place around 175 °C, which mostly concerns hemicelluloses and generally loosely linked material. This is followed by an interval of cellulose degradation that can be usually in a range between 250 and 370 °C, peaking around 320 °C, and is indicated in differential scanning calorimetry (DSC) by an exothermal peak [63]. In Acacia Planifrons, the three steps were indicated as 50–200 °C for the loss of moisture and other volatiles, 200–275 °C for the degradation of hemicelluloses and a part of the lignin, and 275–400 °C for the decomposition of cellulose and lignin [100]. A typical degradation curve is reported in Figure 4. However, the latter two phases are not always clearly discernible, so that weight loss can be quasi-linear with temperature from the onset of cellulose degradation upwards [93]. Alkali treatment may have an effect on hindering thermal degradation of cellulose contained in bark fibers: In particular, the treatment with 5% sodium hydroxide for 60 min allowed moving up cellulose degradation temperature of Pongamia Pinnata fibers from 332 to 348 °C [104].

Figure 4.

Typical thermal degradation curve for Acacia planifrons bark fiber (redrawn from [100]).

A recent study on Malva sylvestris bark fibers referred weight loss due to moisture evaporation up to 110 °C equal to 6.33%, and a virtual stability of the fibers from 110 to 225 °C. Following this, the depolymerization of hemicellulose and cellulose starts, namely concerning the main component of the former and the glycosidic linkages of the latter, and peaking at 311 °C with a 66% wt. loss, and some depolymerisation of lignin. A further stage, located between 355 and 485 °C, is attributed to the degradation of non-cellulosic materials, such as lignin and pectin [105].

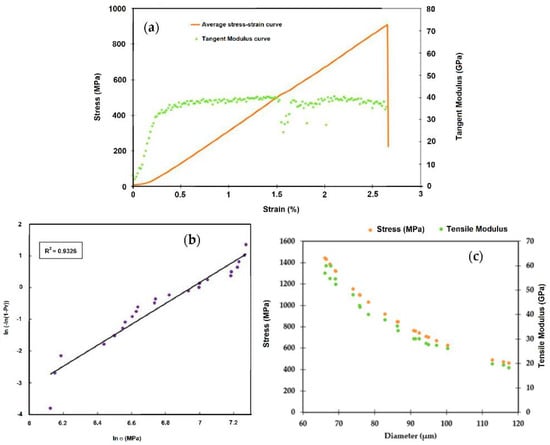

2.4. Mechanical Properties of Bark Fibers

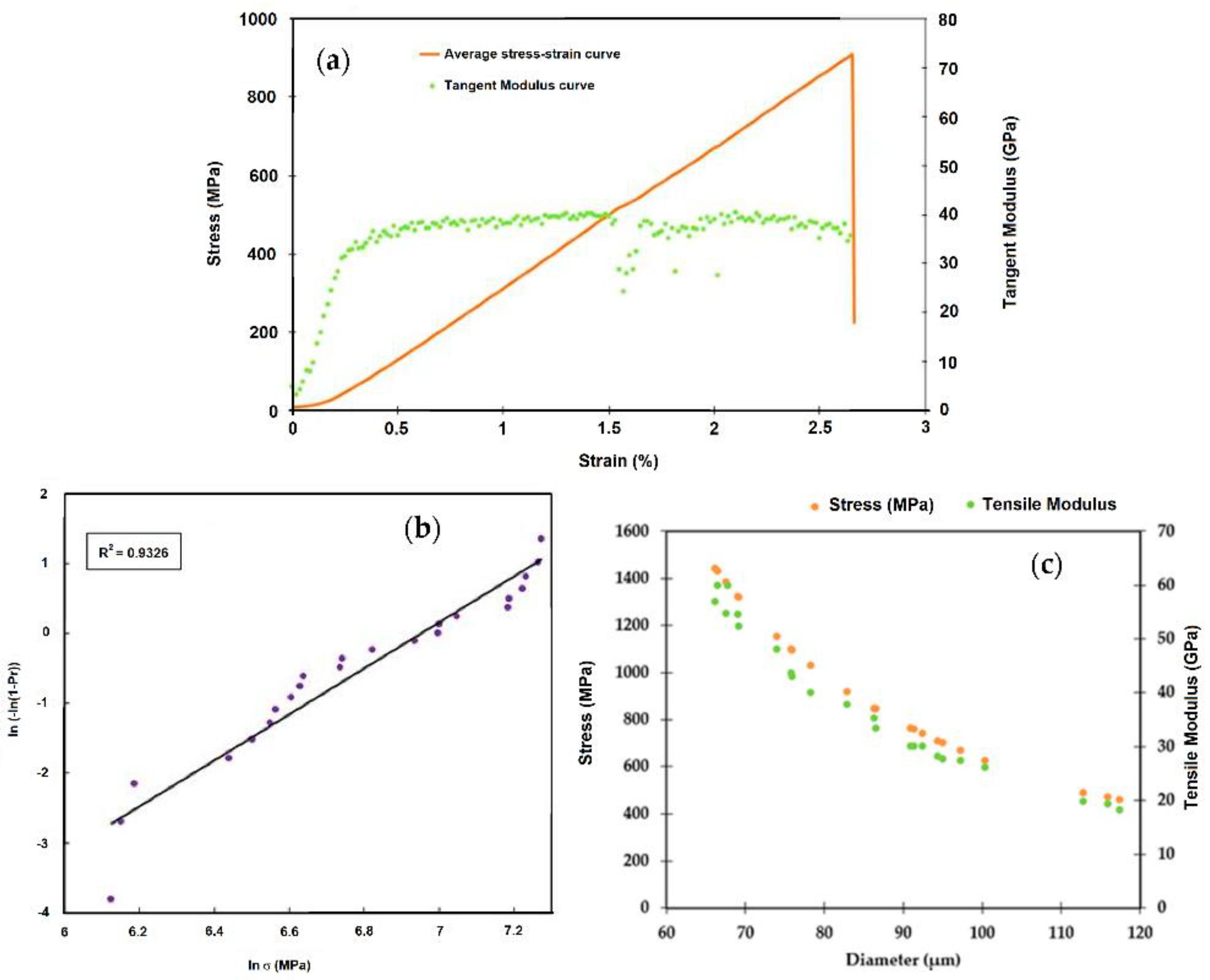

As regards mechanical properties, the data on short fibers, such as bark ones, are largely scattered, due not only to the length of the extracted fibers, but also to the large number of cultivars. The structural differences among fibers obtained across cultivars have started recently to be thoroughly examined for large productive systems, such as it is the case for pineapple in India [61] or hemp in Italy [106]. Stress-strain curve indicates normally that natural fibers normally retain their elastic behavior until fracture occurs, while on the other side a larger diameter results, due to the higher presence of internal voids between fibrils, into lower ultimate stress. An example of the data obtained is depicted in Figure 5, referred to the bark of Cola Lepidota African shrubs [107].

Figure 5.

(a) Typical stress–strain curve and tangent modulus during loading of Cola Lepidota fibers: (b) Weibull distribution of ultimate stress. (c) Tensile modulus and ultimate stress as the function of diameter [107].

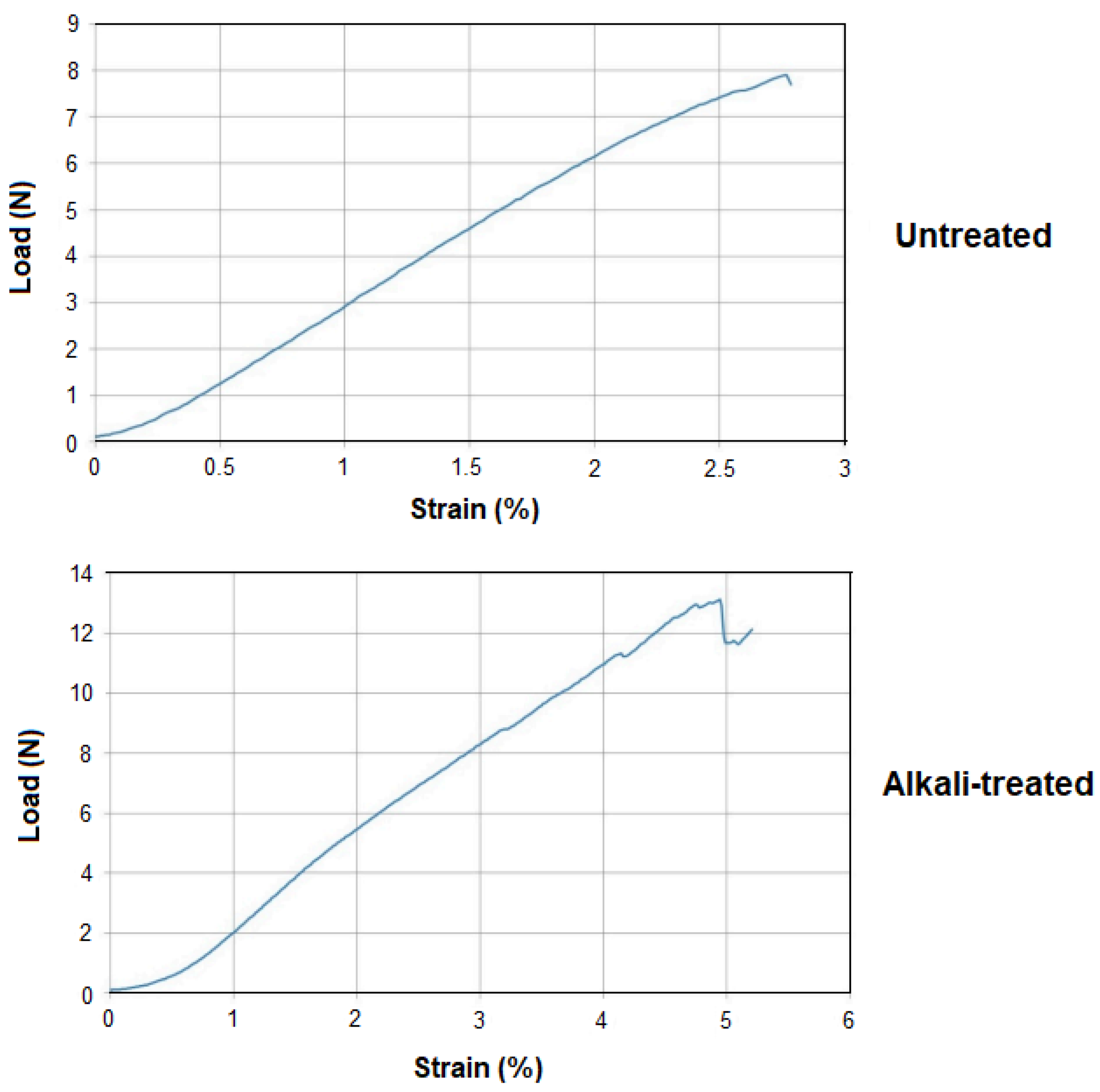

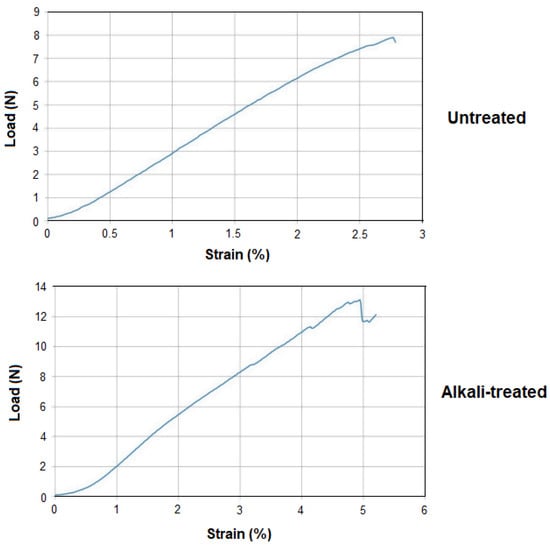

The wide application of alkali treatment with sodium hydroxide on lignocellulosic fibers has been discussed already as a preparatory step to obtain a better interaction with polymer matrices and stronger interfaces [108,109]. As the consequence, since this treatment produces, as previously discussed, a reduction in the lignin content and more generally the regularization of the fiber morphology, it consequently leads also to a non-negligible modification of the stress-strain curve, in the sense of an increase in the modulus, as reported in Figure 6 [42].

Figure 6.

Typical stress-strain curve for Acacia Caesia (soapbark) fibers: untreated (top) and 5% NaOH treated (bottom) [48].

Further work on Sterculia urens bark fibers also demonstrated the possibility of potassium hydroxide to compete with sodium hydroxide as a treatment leading to improvement of tensile and flexural performance of the fibers [110].

Mechanical data obtained on bark fibers with respect to other commonly used natural fibers are summarized in Table 5. The information available so far shows considerable variability, which might represent a limitation to use, especially in case elongation not sufficient to an effective technical use in composites, i.e., much lower even than that of the typical thermosetting resins, such as epoxies.

Table 5.

(a) Tensile properties of non-bark fibers. (b) Tensile properties of untreated bark fibers.

3. Bark Fiber Composites

The use of ligno-cellulosic byproducts or agrowaste into polymer resins has received some attention waste over last two decades, as has been the case for example for rice husk into phenol-formaldehyde resins [117]. The idea for use of bark in composites started initially from providing it as a hardening additive into polymer matrices, especially thermoplastics [118]. This is a typical procedure followed in the production and improvement of performance for wood-plastic composites (WPC), normally for woodcutting waste, and hence to be extended also to bark, whose value is even lower [119]. In other cases, such as in [120], the use of biodegradable matrices, such as poly(lactic acid) (PLA), has also been attempted by using crushed pine bark in the form of sawmill waste. The early studies did not pose the issue of the influence of aspect ratio (length/diameter) on the effectiveness of reinforcement, hence to the effect on mechanical properties. In contrast, they tended to use powder from bark in a sawdust geometry, to ensure easy production: This was completed, e.g., with a poly(vinylchloride) (PVC) matrix using Acacia bark powder, known in India as Babool [121]. Another possibility explored has been the filling with eggshell powder (7%) together with oak bark (29%) nanoparticles in a high-density polyethylene (HDPE) matrix: This allowed recovering the tensile strength that decreased by the bare addition of 36% oak bark [122].

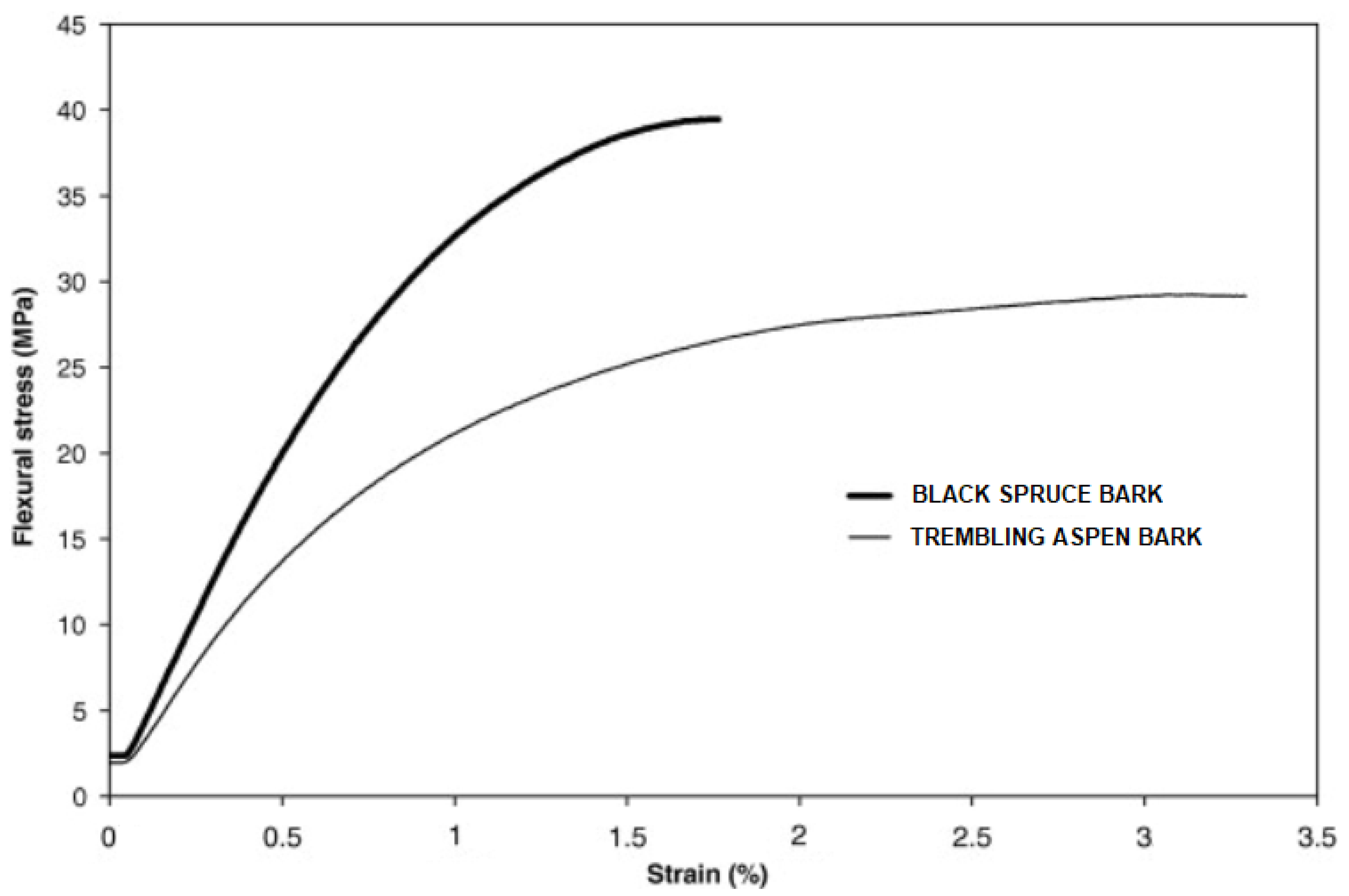

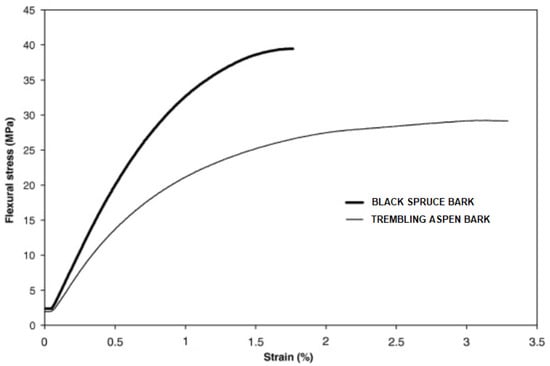

In this sense, two types of wood bark, from black spruce (Picea Mariana) and trembling aspen (Populus Tremuloides), respectively, have been used in different degrees of fineness (from 0.18 to 1 mm) and contents (50 or 60%) into a high-density polyethylene (HDPE) matrix. In this case, where a low aspect ratio, in the region of 10, is obtained from the fibers by using sawmill and preparing them for extrusion, the main strengthening effect is obtained from the amount rather than from the size. It needs to be observed that the addition of wood bark led also to an increase in weight of the material, since the density of the two wood bark types was in the order of 1.1, while that of HDPE is only around 0.95 [123]. In Figure 7, the differences between the flexural behavior of black spruce bark and trembling aspen reinforced HDPE composites are reported. It is evident from the stress-strain curve that they show a completely different extent of plastic behavior.

Figure 7.

Flexural stress strain curve for 60% black spruce or trembling aspen bark fiber-HDPE composites redrawn from [123].

The use of bark with low aspect ratio quite obviously allowed its introduction in larger amounts in the composite, as normally experimented in biocomposites [124]. This is also the case whenever a significant chemical treatment is applied, which allows modifying the bark surface, therefore making it more compatible with the polymer matrix. In the case for example of isora fibers, these are obtained from the bark of the Helicteres isora plant by bacterial retting [125], although in some cases are presented as “bast fibers” [126], yet they are separated from the bark in reality. After alkali treatment, the pores of the fibers become cleaner and the fiber diameter is reduced, so that aspect ratio is conversely increased, while the fiber surface roughens, therefore enhancing interlocking effect with polymer matrices [127]. The increasing interest for the production of bark fiber composites also suggested the need to optimize the chemical treatment for the fibers. In particular, a recent study was performed on Ziziphus nummularia fibers, which had already been used as a source of cellulose for matrix reinforcement [128], this time aimed at the manufacture of composites by preserving the lignocellulosic structure of the fibers as much as possible. The research indicated that they could be optimally alkalized by being immersed in a 5 wt.% NaOH solution for 60 min, leading, in the case of an epoxy composite with 20 wt.% fibers, to a tensile strength of 40.31 MPa [129]. The application of a combined treatment with alkali (6%) and silane (0.75%) on Hibiscus tiliaceus fibers led to considerable effects about the tensile properties, improving both tensile stress and strain in 0/0, 0/90 and 0/45 unsaturated polyester composites [130].

Finally, other possibilities for the use of bark-extracted material in composites are hybridization with other synthetic fibers, or the use of nanopowder as a filler for plant fiber composites. In particular, for the former possibility, hybrid composites with glass and carbon fibers were fabricated using Prosopis Juliflora (PJ) fibers chopped down to a length of 6 mm and treated in a 6% (wt./vol) sodium hydroxide solution for 45 minutes. This allowed introducing a total of 40 wt.% reinforcement (glass + carbon + PJ) in five different combinations, using a maximum of 27 wt.% of PJ fibers [131]. The latter solution has in contrast being proposed using Vachellia nilotica bark nanopowder to improve the thermal resistance and reduce water absorption in milkweed fiber-reinforced polymer composites (MFPCs) [132]. Another possible hybrid solution has been experimented with by coupling chicken-extracted keratin fibers, which have some history in the application as the reinforcement of polymer composites (a comprehensive review on this aspect is offered, e.g., in [133]), with Ceiba pentandra bark fibers, in a bio-epoxy resin as the filler for carbon fibers [134].

4. Conclusions

The recent emphasis on the extraction of bark fibers for potential use in polymer composites, has some significance due to the possibility to obtain them from waste or as a byproduct, therefore reducing the carbon footprint of composite manufacturing. The use of bark fibers in materials is therefore in competition with other possible uses, such as the production of active carbons, and possibly with reduced environmental impact. Some difficulties are present in the way of obtaining sufficient performance, comparable to short fiber biocomposites. In particular, two main issues are particularly significant. These include first the effective extraction of fibers from the plant with not very scattered dimensions and sufficiently high aspect ratio. Secondly, it would also be important to assess the possibility to use them not just with thermosetting matrices, such as epoxy (or bio-epoxy), but also in extruded compounds with thermoplastic ones, such as those originated from polyolefin. This would also allow a possible recyclability, in view of the fact that most bark fibers suffer limited biodegradation at temperatures lower than 250 °C. This can be achieved by the optimization of chemical treatment in terms of concentration and soaking time: the most common treatment is performed with alkali, namely sodium hydroxide, yet also the silanization process, or a combination of the two, has been attempted with interesting results. Due to this potential and to the growing variety of bark fibers available, the research on the theme of application of bark fibers in composites is quickly developing in the last few years and new progresses are likely to arise in the next future.

Author Contributions

Conceptualization, S.P. and R.N.; data curation, S.P., M.K., C.S. and J.M.F.M.; writing—original draft preparation, S.P., R.N. and M.K.; writing—review and editing, S.P. and C.S.; supervision, R.N., M.K. and J.M.F.M.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chahal, A.; Ciolkosz, D. A review of wood-bark adhesion: Methods and mechanics of debarking for woody biomass. Wood Fiber Sci. 2019, 51, 1–12. [Google Scholar] [CrossRef]

- Heebink, B.G. Particleboards from Lodgepole Pine Forest Residue; Forest Products Lab: Madison WI USA, 1974.

- Wagner, K.; Roth, C.; Willför, S.; Musso, M.; Petutschnigg, A.; Oostingh, G.J.; Schnabel, T. Identification of antimicrobial compounds in different hydrophilic larch bark extracts. BioResources 2019, 14, 5807. [Google Scholar]

- Kulikowska, D.; Bernat, K. Waste willow-bark from salicylate extraction successfully reused as an amendment for sewage sludge composting. Sustainability 2021, 13, 6771. [Google Scholar] [CrossRef]

- Nicolai, V. The bark of trees: Thermal properties, microclimate and fauna. Oecologia 1986, 69, 148–160. [Google Scholar] [CrossRef] [PubMed]

- Neumann, M.; Lawes, M.J. Quantifying carbon in tree bark: The importance of bark morphology and tree size. Methods Ecol. Evol. 2021, 12, 646–654. [Google Scholar] [CrossRef] [PubMed]

- Morris, M.J.; Wingfield, M.J.; de Beer, C. Gummosis and wilt of Acacia mearnsii in South Africa caused by Ceratocystis fimbriata. Plant Pathol. 1993, 42, 814–817. [Google Scholar] [CrossRef]

- Miranda, I.; Pereira, H. Variation of wood and bark density and production in coppiced Eucalyptus globulus trees in a second rotation. iForest 2015, 9, 270. [Google Scholar] [CrossRef]

- Wassenberg, M.; Chiu, H.S.; Guo, W.; Spiecker, H. Analysis of wood density profiles of tree stems: Incorporating vertical variations to optimize wood sampling strategies for density and biomass estimations. Trees 2015, 29, 551–561. [Google Scholar] [CrossRef]

- Bouras, M.; Chadni, M.; Barba, F.J.; Grimi, N.; Bals, O.; Vorobiev, E. Optimization of microwave-assisted extraction of polyphenols from Quercus bark. Ind. Crops Prod. 2015, 77, 590–601. [Google Scholar] [CrossRef]

- Nahrstedt, A.; Schmidt, M.; Jäggi, R.; Metz, J.; Khayyal, M.T. Willow bark extract: The contribution of polyphenols to the overall effect. Wien. Med. Wochenschr. 2007, 157, 348–351. [Google Scholar] [CrossRef]

- Ghitescu, R.E.; Volf, I.; Carausu, C.; Bühlmann, A.M.; Gilca, I.A.; Popa, V.I. Optimization of ultrasound-assisted extraction of polyphenols from spruce wood bark. Ultrason. Sonochem. 2015, 22, 535–541. [Google Scholar] [CrossRef] [PubMed]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The effect of bark content on quality parameters of Scots pine (Pinus sylvestris L.) pellets. Biomass Bioenergy 2011, 35, 3342. [Google Scholar] [CrossRef]

- Fodor, F. Fásult személyi-Az árulkodó fakéreg. Természetbúvár 2004, 59, 2. [Google Scholar]

- Ghosh, D. Bark is the hallmark. Resonance 2006, 11, 41. [Google Scholar] [CrossRef]

- Graça, J. Suberin: The biopolyester at the frontier of plants. Front Chem. 2015, 3, 62. [Google Scholar] [CrossRef] [PubMed]

- Gil, L.C. Materials for Construction and Civil Engineering; Gonçalves, M.C., Margarido, F., Eds.; Springer: Cham, Switzerland, 2015; pp. 585–627. [Google Scholar]

- Sudakova, I.G.; Ivanov, I.P.; Ivanchenko, N.M.; Kuznetsov, B.N. Protective compositions for wood on the basis of the suberin of birch bark. Chem. Plant Raw Mater. 2005, 1, 59–63. [Google Scholar]

- De Oliveira, H.; Yoon, B.; Michaud, V.; Nam, J.D.; Suhr, J. All natural cork composites with suberin-based polyester and lignocellulosic residue. Ind. Crops Prod. 2017, 109, 843–849. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Mano, J.F.; Reis, R.L. Hybrid cork–polymer composites containing sisal fibre: Morphology, effect of the fibre treatment on the mechanical properties and tensile failure prediction. Comp. Struct. 2013, 105, 153–162. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Jiang, C.; Sit, M.; Zhang, Z.; Khalfallah, M.; Grossmann, E. Moisture Absorption Effects on the Mechanical Properties of Sandwich Biocomposites with Cork Core and Flax/PLA Face Sheets. Molecules 2021, 26, 7295. [Google Scholar] [CrossRef]

- Gandini, A.; Neto, C.P.; Silvestre, A.J. Suberin: A promising renewable resource for novel macromolecular materials. Prog. Polym. Sci. 2006, 31, 878–892. [Google Scholar] [CrossRef]

- González-López, M.E.; Robledo-Ortíz, J.R.; Manríquez-González, R.; Silva-Guzmán, J.A.; Pérez-Fonseca, A.A. Polylactic acid functionalization with maleic anhydride and its use as coupling agent in natural fiber biocomposites: A review. Compos. Interfaces 2018, 25, 515–538. [Google Scholar] [CrossRef]

- Chow, S.Z.; Pickles, K.J. Thermal softening and degradation of wood and bark. Wood Fiber Sci. 1971, 3, 166–178. [Google Scholar]

- Popp, M.P.; Johnson, J.D.; Massey, T.L. Stimulation of resin flow in slash and loblolly pine by bark beetle vectored fungi. Can. J. Res. 1991, 21, 1124–1126. [Google Scholar] [CrossRef]

- Bauer, G.; Speck, T.; Blömer, J.; Bertling, J.; Speck, O. Insulation capability of the bark of trees with different fire adaptation. J. Mater. Sci. 2010, 45, 5950–5959. [Google Scholar] [CrossRef]

- Yan, N.; Zhang, B.; Zhao, Y.; Farnood, R.R.; Shi, J. Application of biobased phenol formaldehyde novolac resin derived from beetle infested lodgepole pine barks for thermal molding of wood composites. Ind. Eng. Chem. Res. 2017, 56, 6369–6377. [Google Scholar] [CrossRef]

- Bold, G.; Langer, M.; Börnert, L.; Speck, T. The protective role of bark and bark fibers of the giant sequoia (Sequoiadendron giganteum) during high-energy impacts. Int. J. Mol. Sci. 2020, 21, 3355. [Google Scholar] [CrossRef]

- Catry, F.X.; Rego, F.; Moreira, F.; Fernandes, P.M.; Pausas, J.G. Post-fire tree mortality in mixed forests of central Portugal. Ecol. Manag. 2010, 260, 1184–1192. [Google Scholar] [CrossRef]

- Dickinson, M.B. Heat transfer and vascular cambium necrosis in the boles of trees during surface fires. In Forest Fire Research & Wildland Fire Safety; Viegas, Ed.; Millpress: Rotterdam, The Netherlands, 2002; pp. 1–10. ISBN 90-77017-72-0. [Google Scholar]

- Hengst, G.E.; Dawson, J.O. Bark thermal properties of selected central hardwood species. United States Department of Agriculture Report. In Proceedings of the 9th Central Hardwood Forest Conference: Proceedings of a Meeting, West Lafayette, IN, USA, 8–10 March 1993; pp. 55–75. [Google Scholar]

- Lawes, M.J.; Richards, A.; Dathe, J.; Midgley, J.J. Bark thickness determines fire resistance of selected tree species from fire-prone tropical savanna in north Australia. Plant Ecol. 2011, 212, 2057–2069. [Google Scholar] [CrossRef]

- Wang, G.G.; Wangen, S.R. Does frequent burning affect longleaf pine bark thickness? Can. J. Res. 2011, 41, 1562–1565. [Google Scholar] [CrossRef]

- Valentín, L.; Kluczek-Turpeinen, B.; Willför, S.; Hemming, J.; Hatakka, A.; Steffen, K.; Tuomela, M. Scots pine (Pinus sylvestris) bark composition and degradation by fungi: Potential substrate for bioremediation. Bioresour. Technol. 2003, 101, 2203–2209. [Google Scholar] [CrossRef]

- Tamokou, J.D.; Tala, M.F.; Wabo, H.K.; Kuiate, J.R.; Tane, P. Antimicrobial activities of methanol extract and compounds from stem bark of Vismia rubescens. J. Ethnopharmacol. 2009, 124, 571–575. [Google Scholar] [CrossRef] [PubMed]

- Bhaskara Rao, R.; Murugesan, T.; Pal, M.; Saha, B.P.; Mandal, S.C. Antitussive potential of methanol extract of stem bark of Ficus racemosa Linn. Phytother. Res. 2003, 17, 1117–1118. [Google Scholar] [CrossRef] [PubMed]

- Shehu, A.; Magaji, M.G.; Yau, J.; Mahmud, B.; Ahmed, A. Antidepressant effect of methanol stem bark extract of Adansonia digitata L. Malvaceae in Mice. Trop. J. Nat. Prod. Res. 2018, 2, 87–91. [Google Scholar]

- Malik, H.; Javaid, S.; Fawad Rasool, M.; Samad, N.; Rizwan Ahamad, S.; Alqahtani, F.; Imran, I. Amelioration of scopolamine-induced amnesic, anxiolytic and antidepressant effects of Ficus benghalensis in behavioral experimental models. Medicina 2020, 56, 144. [Google Scholar] [CrossRef]

- Venkateshwarlu, G.; Santhosh, A.; Naik, E.R.; Suma, G.; Swapna, K.; Pranitha, D. Traditional and folklore use of Acacia nilotica (l.) in ayurvedic system. Asian J. Pharm. Technol. 2014, 4, 98–99. [Google Scholar]

- Abdullah, A.H.; Kassim, A.; Zainal, Z.; Hussien, M.Z.; Kuang, D.; Ahmad, F.; Wooi, O.S. Preparation and characterization of activated carbon from gelam wood bark (Melaleuca cajuputi). Malays J. Anal. Sci. 2001, 7, 65–68. [Google Scholar]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree bark utilization in insulating bio-aggregates: A review. Biofuel. Bioprod. Biorefin. 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Gabrielli, S.; Pastore, G.; Stella, F.; Marcantoni, E.; Sarasini, F.; Tirillò, J.; Santulli, C. Chemical and mechanical characterization of licorice root and palm leaf waste incorporated into poly (urethane-acrylate) (PUA). Molecules 2021, 26, 7682. [Google Scholar] [CrossRef]

- Watanabe, M.; Kanaguri, Y.; Smith Jr., R.L. Hydrothermal separation of lignin from bark of Japanese cedar. J. Supercrit. Fluids 2018, 133, 696–703. [Google Scholar] [CrossRef]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J.M. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef]

- Schiavi, D.; Francesconi, S.; Taddei, A.R.; Fortunati, E.; Balestra, G.M. Exploring cellulose nanocrystals obtained from olive tree wastes as sustainable crop protection tool against bacterial diseases. Sci. Rep. 2022, 12, 1–14. [Google Scholar]

- Fortunati, E.; Kenny, J.M.; Torre, L. Lignocellulosic materials as reinforcements in sustainable packaging systems: Processing, properties, and applications. In Biomass, Biopolymer-Based Materials, and Bioenergy; Woodhead Publishing: Sawston, UK, 2019; pp. 87–102. [Google Scholar]

- Le Normand, M.; Moriana, R.; Ek, M. Isolation and characterization of cellulose nanocrystals from spruce bark in a biorefinery perspective. Carbohydr. Polym. 2014, 111, 979–987. [Google Scholar] [CrossRef] [PubMed]

- Sivasubramanian, P.; Kalimuthu, M.; Palaniappan, M.; Alavudeen, A.; Rajini, N.; Santulli, C. Effect of alkali treatment on the properties of acacia caesia bark fibres. Fibers 2021, 9, 49. [Google Scholar] [CrossRef]

- Palanisamy, S.; Mayandi, K.; Palaniappan, M.; Alavudeen, A.; Rajini, N.; Vannucchi de Camargo, F.; Santulli, C. Mechanical properties of phormium tenax reinforced natural rubber composites. Fibers 2021, 9, 11. [Google Scholar] [CrossRef]

- Bensalah, H.; Gueraoui, K.; Essabir, H.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E. Mechanical, thermal, and rheological properties of polypropylene hybrid composites-based clay and graphite. J. Compos. Mater. 2017, 51, 3563–3576. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Wang, Z.; Gnanasekar, P.; Sudhakaran Nair, S.; Farnood, R.; Yi, S.; Yan, N. Biobased epoxy synthesized from a vanillin derivative and its reinforcement using lignin-containing cellulose nanofibrils. ACS Sustain. Chem. Eng. 2020, 8, 11215–11223. [Google Scholar] [CrossRef]

- Rwawiire, S.; Luggya, G.W.; Tomkova, B. Morphology, Thermal, and Mechanical Characterization of Bark Cloth from Ficus natalensis. ISRN Text. 2013, 2013, 925198. [Google Scholar] [CrossRef]

- Rwawiire, S.; Tomkova, B. Thermal, static, and dynamic mechanical properties of bark cloth (ficus brachypoda) laminar epoxy composites. Polym. Compos. 2017, 38, 199–204. [Google Scholar] [CrossRef]

- Butler, J.A.; Slate, A.J.; Todd, D.B.; Airton, D.; Hardman, M.; Hickey, N.A.; Scott, K.; Venkatraman, P.D. A traditional Ugandan Ficus natalensis bark cloth exhibits antimicrobial activity against Methicillin-Resistant Staphylococcus aureus. J. Appl. Microbiol. 2021, 131, 2–10. [Google Scholar] [CrossRef]

- Castellano, J.; Marrero, M.D.; Ortega, Z. Opuntia Fiber and its potential to obtain sustainable materials in the composites field: A review. J. Nat. Fibers 2022, 19, 10053–10067. [Google Scholar] [CrossRef]

- Chou, T.N.; Young, W.B. Strength of untreated and alkali-treated bamboo fibers and reinforcing effects for short fiber composites. J. Aeronaut. Astronaut. Aviat. 2018, 50, 237–246. [Google Scholar]

- Reddy, K.O.; Shukla, M.; Maheswari, C.U.; Rajulu, A.V. Evaluation of mechanical behavior of chemically modified Borassus fruit short fiber/unsaturated polyester composites. J. Compos. Mater. 2017, 46, 2987–2998. [Google Scholar] [CrossRef]

- Martin, N.; Mouret, N.; Davies, P.; Baley, C. Influence of the degree of retting of flax fibers on the tensile properties of single fibers and short fiber/polypropylene composites. Ind. Crops Prod. 2013, 49, 755–767. [Google Scholar] [CrossRef]

- Wang, K.; Addiego, F.; Laachachi, A.; Kaouache, B.; Bahlouli, N.; Toniazzo, V.; Ruch, D. Dynamic behavior and flame retardancy of HDPE/hemp short fiber composites: Effect of coupling agent and fiber loading. Compos. Struct. 2014, 113, 74–82. [Google Scholar] [CrossRef]

- Jagadish; Rajakumaran, M.; Ray, A. Investigation on mechanical properties of pineapple leaf–based short fiber–reinforced polymer composite from selected Indian (northeastern part) cultivars. J. Compos. Mater. 2020, 33, 324–342. [Google Scholar] [CrossRef]

- Singha, A.S.; Kumar Thakur, V. Saccaharum cilliare fiber reinforced polymer composites. E-J. Chem. 2008, 5, 782–791. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.P.; Saravanakumar, S.S. Assessment of cellulose in bark fibers of Thespesia populnea: Influence of stem maturity on fiber characterization. Carbohydr. Polym. 2019, 15, 439–449. [Google Scholar] [CrossRef]

- Chan, J.M.; Day, P.; Feely, J.; Thompson, R.; Little, K.M.; Norris, C.H. Acacia mearnsii industry overview: Current status, key research and development issues. South 2015, 77, 19–30. [Google Scholar] [CrossRef]

- Rajan, B.S.; Saibalaji, M.A.; Mohideen, S.R. Tribological performance evaluation of epoxy modified phenolic FC reinforced with chemically modified Prosopis juliflora bark fiber. Mater. Res. Expr. 2019, 6, 075313. [Google Scholar] [CrossRef]

- Moussaoui, N.; Rokbi, M.; Osmani, H.; Jawaid, M.; Atiqah, A.; Asim, M.; Benhamadouche, L. Extraction and characterization of fiber treatment Inula viscosa fibers as potential polymer composite reinforcement. J. Polym. Environ. 2021, 29, 3779–3793. [Google Scholar] [CrossRef]

- Arul Marcel Moshi, A.; Ravindran, D.; Sundara Bharathi, S.R.; Padma, S.R.; Indran, S.; Divya, D. Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant′s stem. Int. J. Biol. Macromol. 2020, 164, 1246–1255. [Google Scholar]

- Reddy, N.; Yang, Y. Properties and potential applications of natural cellulose fibers from the bark of cotton stalks. Bioresour. Technol. 2009, 100, 3563–3569. [Google Scholar] [CrossRef] [PubMed]

- Baskaran, P.G.; Kathiresan, M.; Pandiarajan, P. Effect of alkali-treatment on structural, thermal, tensile properties of dichrostachys cinerea bark fiber and its composites. J. Nat. Fibers 2022, 19, 433–449. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of different natural fiber treatments: A literature review. Int. J. Environ. Sci. Technol. 2019, 16, 629–642. [Google Scholar] [CrossRef]

- Sympson, W.; Nokes, S.E.; Hickman, A.N. Recirculating calcium hydroxide solution: A practical choice for on-farm high solids lignocellulose pretreatment. Ind. Crops Prod. 2017, 97, 492–497. [Google Scholar] [CrossRef]

- Palanisamy, S.; Kalimuthu, M.; Palaniappan, M.; Alavudeen, A.; Rajini, N.; Santulli, C. Morphological characterization of soapbark fibers. J. Mater. Sci. Res. Rev. 2021, 8, 19. [Google Scholar]

- Amutha, V.; Senthilkumar, B. Physical, chemical, thermal, and surface morphological properties of the bark fiber extracted from acacia concinna plant. J. Nat. Fibers 2021, 18, 1661–1674. [Google Scholar] [CrossRef]

- Kumar, R.; Sivaganesan, S.; Senthamaraikannan, P.; Saravanakumar, S.S.; Khan, A.; Ajith Arul Daniel, S.; Loganathan, L. Characterization of new cellulosic fiber from the bark of Acacia nilotica L. plant. J. Nat. Fibers 2022, 19, 199–208. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Investigation of physico-chemical, mechanical, and thermal properties of new cellulosic bast fiber extracted from the bark of bauhinia purpurea. J. Nat. Fibers 2022, 19, 9624–9641. [Google Scholar] [CrossRef]

- Ashori, A.; Bahreini, Z. Evaluation of Calotropis gigantea as a promising raw material for fiber-reinforced composite. J. Compos. Mater. 2009, 43, 1297–1304. [Google Scholar] [CrossRef]

- Kumar, R.; Hynes, N.R.; Senthamaraikannan, P.; Saravanakumar, S.; Sanjay, M.R. Physicochemical and thermal properties of ceiba pentandra bark fiber. J. Nat. Fibers 2018, 15, 822–829. [Google Scholar] [CrossRef]

- Baskaran, P.G.; Kathiresan, M.; Senthamaraikannan, P.; Saravanakumar, S.S. Characterization of new natural cellulosic fiber from the bark of dichrostachys cinerea. J. Nat. Fibers 2018, 15, 62–68. [Google Scholar] [CrossRef]

- Manimaran, P.; Saravanan, S.P.; Prithiviraj, M. Investigation of physico chemical properties and characterization of new natural cellulosic fibers from the bark of Ficus Racemosa. J. Nat. Fibers 2021, 18, 274–284. [Google Scholar] [CrossRef]

- Almeshaal, M.; Palanisamy, S.; Murugesan, T.M.; Palaniappan, M.; Santulli, C. Physico-chemical characterization of Grewia Monticola Sond (GMS) fibers for prospective application in biocomposites. J. Nat. Fibers 2022, 19, 15276–15290. [Google Scholar] [CrossRef]

- Vinod, A.; Gowda, T.Y.; Vijay, R.; Sanjay, M.R.; Gupta, M.K.; Jamil, M.; Kushvaha, V.; Siengchin, S. Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: A sustainable and green material for cleaner production. J. Clean. Prod. 2021, 294, 126337. [Google Scholar] [CrossRef]

- Ramkumar, R.; Saravanan, P. Characterization of the cellulose fibers extracted from the bark of piliostigma racemosa. J. Nat. Fibers 2022, 19, 5101–5115. [Google Scholar] [CrossRef]

- Saravanakumar, S.S.; Kumaravel, A.; Nagarajan, T.; Sudhakar, P.; Baskaran, R. Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr. Polym. 2013, 92, 1928–1933. [Google Scholar] [CrossRef]

- Laifa, F.; Rokbi, M.; Amroune, S.; Zaoui, M.; Seki, Y. Investigation of mechanical, physicochemical, and thermal properties of new fiber from Silybum marianum bark fiber. J. Compos. Mater. 2022, 56, 2227–2238. [Google Scholar] [CrossRef]

- Yadav, N.; Hashmi, S.A. Hierarchical porous carbon derived from eucalyptus-bark as a sustainable electrode for high-performance solid-state supercapacitors. Sustain. Energy Fuels 2020, 4, 1730–1746. [Google Scholar] [CrossRef]

- Haghbin, M.R.; Shahrak, M.N. Process conditions optimization for the fabrication of highly porous activated carbon from date palm bark wastes for removing pollutants from water. Powder Technol. 2021, 377, 890–899. [Google Scholar] [CrossRef]

- Casas-Ledón, Y.; Salgado, K.D.; Cea, J.; Arteaga-Pérez, L.E.; Fuentealba, C. Life cycle assessment of innovative insulation panels based on eucalyptus bark fibers. J. Clean. Prod. 2020, 249, 119356. [Google Scholar] [CrossRef]

- Alishiri, M.; Hooman Hemmasi, A.; Khademi Eslam, H.; Basirjafari, S.; Talaeipour, M. Evaluation and Comparison the Properties of Acoustic Boards Made of Date Palm Fiber. BioResources 2021, 16, 7702–7715. [Google Scholar] [CrossRef]

- Hamouda, T.; Aly, N.M. Date Palm Fiber Composites for Automotive Applications. In Date Palm Fiber Composites; Springer: Singapore, 2020; pp. 387–405. [Google Scholar]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Muensri, P.; Kunanopparat, T.; Menut, P.; Siriwattanayotin, S. Effect of lignin removal on the properties of coconut coir fiber/wheat gluten biocomposite. Compos. Part A 2011, 42, 173–179. [Google Scholar] [CrossRef]

- Manimaran, P.; Solai Senthil Kumar, K.; Prithiviraj, M. Investigation of physico chemical, mechanical and thermal properties of the albizia lebbeck bark fibers. J. Nat. Fibers 2021, 18, 1151–1162. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Physicochemical and thermal properties of cellulosic fiber extracted from the bark of albizia saman. J. Nat. Fibers 2021, 1–17. [Google Scholar] [CrossRef]

- Saravana Kumaar, A.; Senthilkumar, A.; Sornakumar, T.; Saravanakumar, S.S.; Arthanariesewaran, V.P. Physicochemical properties of new cellulosic fiber extracted from Carica papaya bark. J. Nat. Fibers 2019, 16, 175–184. [Google Scholar] [CrossRef]

- Azeez, T.O.; Onukwuli, D.O.; Nwabanne, J.T.; Banigo, A.T. Cissus populnea fiber-unsaturated polyester composites: Mechanical properties and interfacial adhesion. J. Nat. Fibers 2020, 17, 1281. [Google Scholar] [CrossRef]

- Wirawan, W.A.; Choiron, M.A.; Siswanto, E.; Widodo, T.D. Morphology, Structure, and Mechanical Properties of New Natural Cellulose Fiber Reinforcement from Waru (Hibiscus Tiliaceus) Bark. J. Nat. Fibers 2022, 19, 12385–12397. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Rajulu, A.V. Chemical composition and structural characterization of Napier grass fibers. Mater. Lett. 2012, 67, 35–38. [Google Scholar] [CrossRef]

- Manimaran, P.; Sanjay, M.R.; Senthamaraikannan, P.; Yogesha, B.; Barile, C.; Siengchin, S. A new study on characterization of Pithecellobium dulce fiber as composite reinforcement for light-weight applications. J. Nat. Fibers 2020, 17, 359–370. [Google Scholar] [CrossRef]

- Pejic, B.M.; Kostic, M.M.; Skundric, P.D.; Praskalo, J.Z. The effects of hemicelluloses and lignin removal on water uptake behavior of hemp fibers. Bioresour. Technol. 2008, 99, 7152–7159. [Google Scholar] [CrossRef] [PubMed]

- Senthamaraikannan, P.; Saravanakumar, S.S.; Sanjay, M.R.; Jawaid, M.; Siengchin, S. Physico-chemical and thermal properties of untreated and treated Acacia planifrons bark fibers for composite reinforcement. Mater. Lett. 2019, 240, 221–224. [Google Scholar] [CrossRef]

- Tiwari, Y.M.; Sarangi, S.K. Characterization of raw and alkali treated cellulosic Grewia Flavescens natural fiber. Int. J. Biol. Macromol. 2022, 209, 1933–1942. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef]

- Lewis, H.F.; Brauns, F.E.; Buchanan, M.A.; Kurth, E.F. Chemical composition of redwood bark. J. Ind. Eng. Chem. 1944, 36, 759–764. [Google Scholar] [CrossRef]

- Umashankaran, M.; Gopalakrishnan, S. Effect of sodium hydroxide treatment on physico-chemical, thermal, tensile and surface morphological properties of Pongamia Pinnata L. bark fiber. J. Nat. Fibers 2021, 18, 2063–2076. [Google Scholar] [CrossRef]

- Meddah, M.; Rokbi, M.; Zaoui, M. Extraction and characterization of novel natural lignocellulosic fibers from Malva sylvestris L. J. Compos. Mater. 2022, 00219983221146355. [Google Scholar] [CrossRef]

- Angelini, L.G.; Tavarini, S.; Di Candilo, M. Performance of new and traditional fiber hemp (Cannabis sativa L.) cultivars for novel applications: Stem, bark, and core yield and chemical composition. J. Nat. Fibers 2016, 13, 238–252. [Google Scholar] [CrossRef]

- Ndoumou, R.L.; Soulat, D.; Labanieh, A.R.; Ferreira, M.; Meva’a, L.; Atangana Ateba, J. Characterization of tensile properties of cola lepidota fibers. Fibers 2022, 10, 6. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Letman, M.; Viksne, A.; Rence, L. A comparison of compounding processes and wood type for wood fibre—PP composites. Compos. Part A 2005, 36, 789–797. [Google Scholar] [CrossRef]

- Reddy, K.H.; Reddy, R.M.; Ramesh, M.; Krishnudu, D.M.; Reddy, B.M.; Rao, H.R. Impact of alkali treatment on characterization of tapsi (Sterculia urens) natural bark fiber reinforced polymer composites. J. Nat. Fibers 2021, 18, 378–389. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Zeronian, S.H. The mechanical properties of cotton fibers. J. Appl. Polym. Sci. 1991, 47, 445. [Google Scholar] [CrossRef]

- Ugbolue, S.C. Structure/property relationships in textile fibres. Text Prog. 1990, 20, 1–43. [Google Scholar] [CrossRef]

- Bisanda, E.T.; Ansell, M.P. Properties of sisal-CNSL composites. J. Mater. Sci. 1992, 27, 1690–1700. [Google Scholar] [CrossRef]

- Arthanarieswaran, V.P.; Kumaravel, A.; Kathirselvam, M.; Saravanakumar, S.S. Mechanical and thermal properties of Acacia leucophloea fiber/epoxy composites: Influence of fiber loading and alkali treatment. Int. J. Polym. Anal. Charact. 2016, 21, 571–583. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Characterization studies on new natural cellulosic fiber extracted from the bark of erythrina variegata. J. Nat. Fibers 2021, 1–20. [Google Scholar] [CrossRef]

- Ndazi, B.S.; Nyahumwa, C.W.; Tesha, J. Chemical and thermal stability of rice husks against alkali treatment. BioResources 2008, 3, 1267–1277. [Google Scholar]

- Safdari, V.; Khodadadi, H.; Hosseinihashemi, S.K.; Ganjian, E. The effects of poplar bark and wood content on the mechanical properties of wood-polypropylene composites. BioResources 2011, 6, 5180–5192. [Google Scholar] [CrossRef]

- Lopez, Y.M.; Paes, J.B.; Gonçalves, F.G.; de Alcântara, P.G.; da Silva, L.F.; Nicácio, M.A.; da Silva, E.S.G.; de Medeiros, J.R.; dos Santos Moreira, J.G.; Nantet, A.C.T. Characterization of the production process of wood plastic composite from sawdust of pinus and recycled thermoplastics. Eng. Florest. Desafios Lte. E Potencialidade 2020, 236–247. [Google Scholar] [CrossRef]

- Borysiuk, P.; Boruszewski, P.; Auriga, R.; Danecki, L.; Auriga, A.; Rybak, K.; Nowacka, M. Influence of a bark-filler on the properties of PLA biocomposites. J. Mater. Sci. 2021, 56, 9196–9208. [Google Scholar] [CrossRef]

- Saini, G.; Bhardwaj, R.; Choudhary, V.; Narula, A.K. Poly(vinyl chloride)–Acacia bark flour composite: Effect of particle size and filler content on mechanical, thermal, and morphological characteristics. J. Appl. Polym. Sci. 2010, 117, 1309–1318. [Google Scholar] [CrossRef]

- Banaei, N.; Ahmadi, S. High-density polyethylene surface modification for the attachment of Eggshell and Oak Bark Nanoparticles. Adv. Appl. NanoBio-Technol. 2020, 1, 67–71. [Google Scholar]

- Yemele, M.C.N.; Koubaa, A.; Cloutier, A.; Soulounganga, P.; Wolcott, M. Effect of bark fiber content and size on the mechanical properties of bark/HDPE composites. Compos. Part A 2010, 41, 131–137. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Joshy, M.K.; Mathew, L.; Joseph, R. Effect of alkali treatment on the mechanical properties of short randomly oriented isora fibre-polyester composites. Prog. Rubber Plast. Recycl. Technol. 2008, 24, 255–272. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Isora fibre: Morphology, chemical composition, surface modification, physical, mechanical and thermal properties–A potential natural reinforcement. J. Nat. Fibers 2007, 3, 13–27. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Joy, J.; Mathew, L.; Mozetic, M.; Koetz, J.; Thomas, S. Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind. Crops Prod. 2014, 59, 27–34. [Google Scholar] [CrossRef]

- Sivaraj Vijaya, G.; Gounder, R.I.; Natarajan, S.S. Characterization of natural cellulose fibers from the barks of ziziphus nummularia as a reinforcement for lightweight composite applications. J. Nat. Fibers 2022, 19, 15663–15679. [Google Scholar] [CrossRef]

- Gurupranes, S.V.; Rajendran, I.; Shanmuga Sundaram, N. Suitability assessment of raw-alkalized Ziziphus nummularia bark fibers and its polymeric composites for lightweight applications. Polym. Compos. 2022, 43, 5059–5075. [Google Scholar]

- Wirawan, W.A.; Setyabudi, S.A.; Widodo, T.D.; Choiron, M.A. Surface modification with silane coupling agent on tensile properties of natural fiber composite. J. Energy Mech. Mater. Manuf. Eng. 2017, 2, 98–103. [Google Scholar] [CrossRef]

- Madhu, P.; Mavinkere Rangappa, S.; Khan, A.; Al Otaibi, A.; Al-Zahrani, S.A.; Pradeep, S.; Gupta, M.K.; Boonyasopon, P.; Siengchin, S. Experimental investigation on the mechanical and morphological behavior of Prosopis juliflora bark fibers/E-glass/carbon fabrics reinforced hybrid polymeric composites for structural applications. Polym. Compos. 2020, 41, 4983–4993. [Google Scholar] [CrossRef]

- Ramesh, M.; Tamil Selvan, M.; Rajeshkumar, L.; Deepa, C.; Ahmad, A. Influence of Vachellia nilotica Subsp. indica tree trunk bark nano-powder on properties of milkweed plant fiber reinforced epoxy composites. J. Nat. Fibers 2022, 19, 13776–13789. [Google Scholar] [CrossRef]

- Khan, A.A.; Parikh, H.; Qureshi, M.R.N. A review on chicken feather fiber (CFF) and its application in Composites. J. Nat. Fibers 2022, 1–21. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S.; Jawaid, M.; Ozbakkaloglu, T. Bioepoxy based hybrid composites from nano-fillers of chicken feather and lignocellulose Ceiba Pentandra. Sci. Rep. 2022, 12, 1–18. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).