Characterization and Simulation of Acoustic Properties of Sugarcane Bagasse-Based Composite Using Artificial Neural Network Model

Abstract

:1. Introduction

2. Materials and Methods

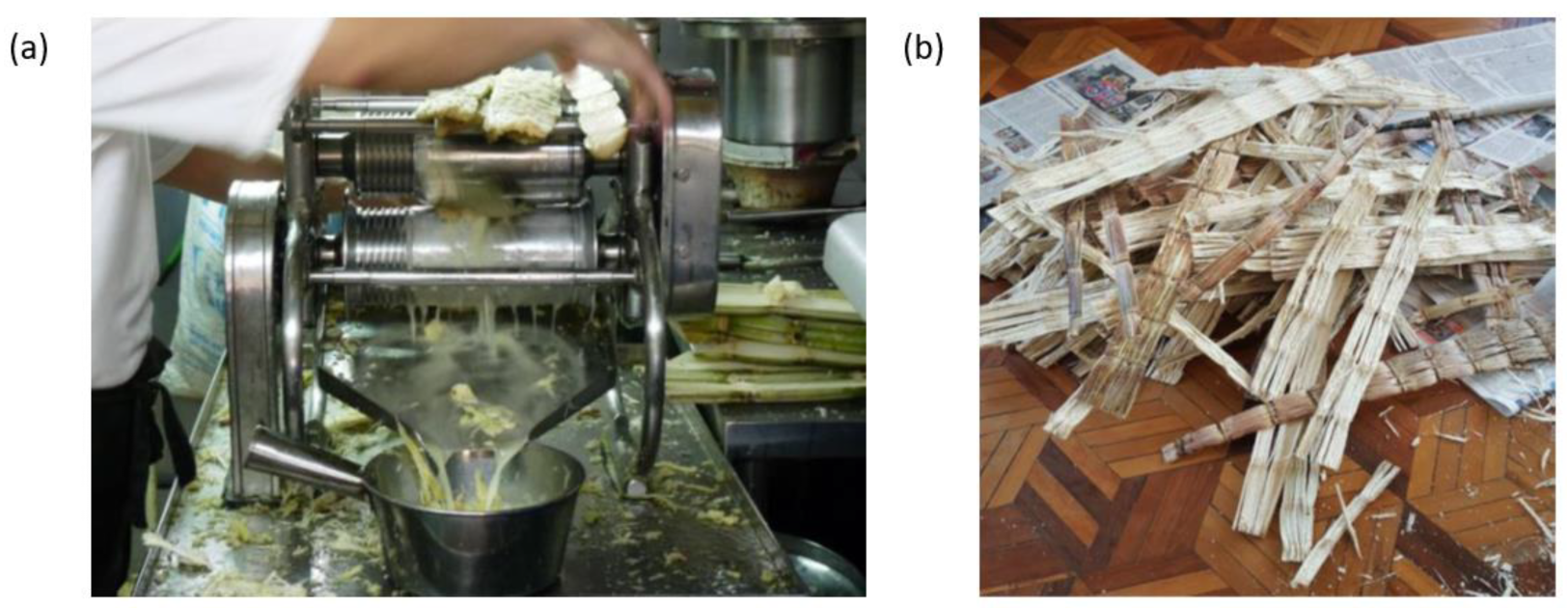

2.1. Preparation of the Samples

- To begin, the bagasse obtained by separating the fibers from the bark was sieved with a metal sieve, obtaining the smallest possible filaments.

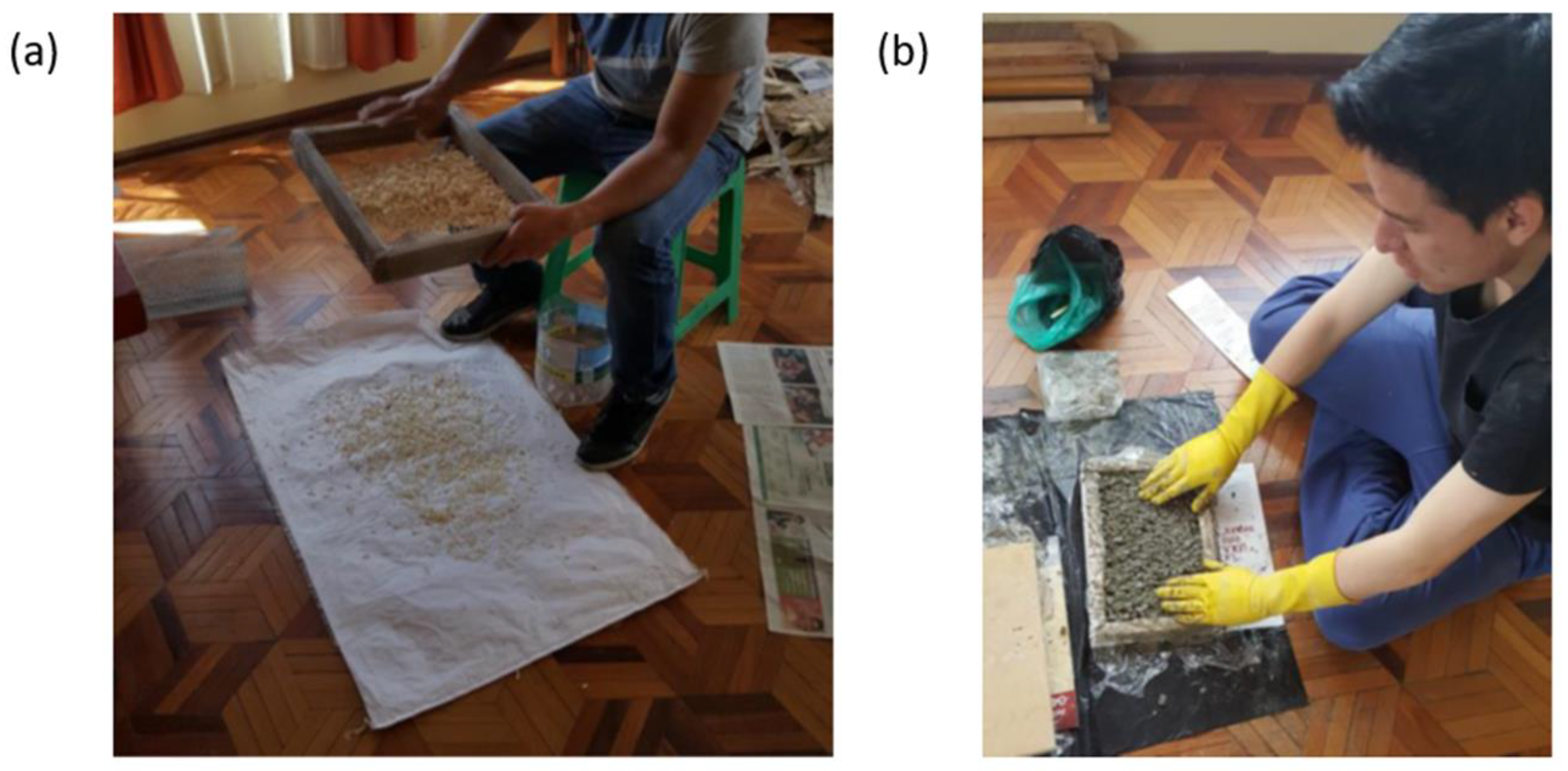

- The sieved bagasse filaments were then placed in a 15 × 25 cm size frame, making sure they completely covered the thickness of the frame, and then the amount of bagasse used in this process was weighed (Figure 3a).

- To produce panels with SCB matrix and plaster or clay-based binders, the frame was divided into 3 parts and 1/3 of the frame is filled with the binder and then weighed. In this way, the proportions of 3/1 which had been indicated were respected. Table 1 shows the quantities of each component in the different types of assembled panels.

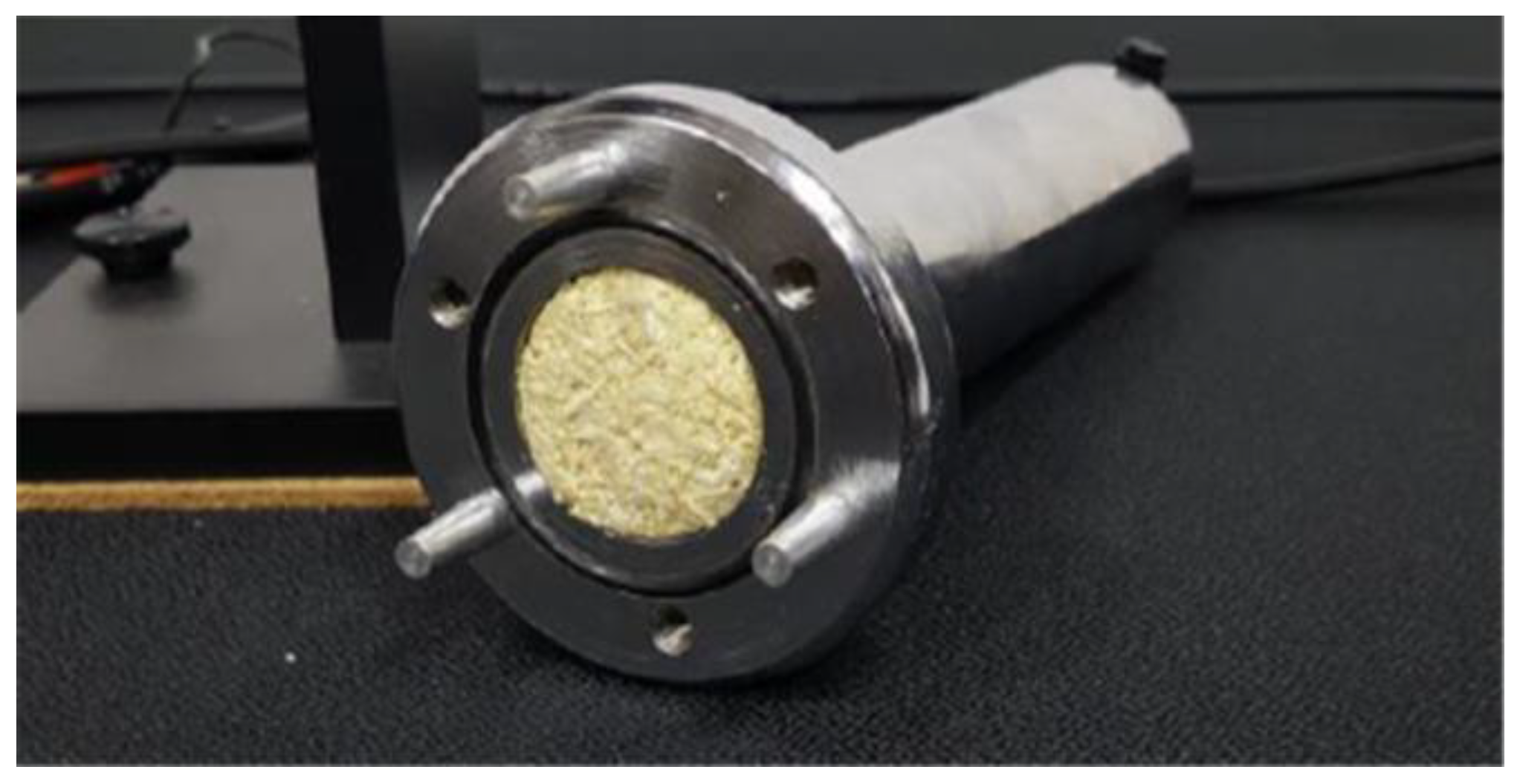

- Once it had been demonstrated that the proportions of the elements were optimal for the construction of panels, the weights of the components necessary to create cylindrical-shaped samples of thicknesses equal to 6, 12 and 25 mm were calculated, to be used for the measurement of the coefficients of sound absorption using the impedance tube (Kundt tube). To obtain these samples, molds were made of the diameter allowed by the Kundt tube, which is about 35 mm. The samples were weighed on a digital scale and the weights obtained are shown in Table 2.

- Finally, 18 samples were obtained, divided into the two binders combined with the SCB: 9 samples of SCB - plaster, and 9 samples of SCB - clay. Several similar samples were then made for each of the three foreseen thicknesses of 6, 12 and 25 mm, as shown in Figure 4.

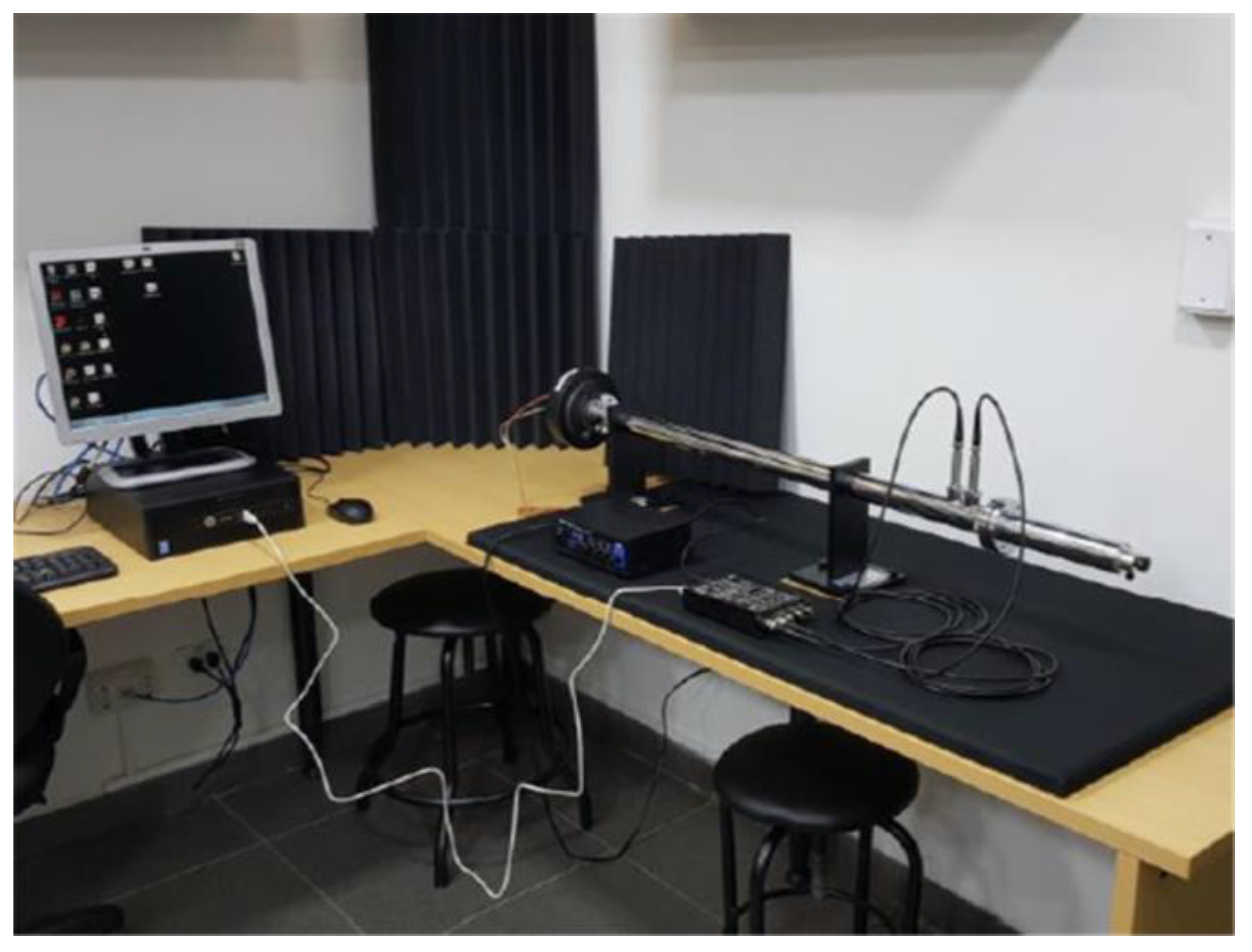

2.2. Sound Absorption Coefficient Measurement

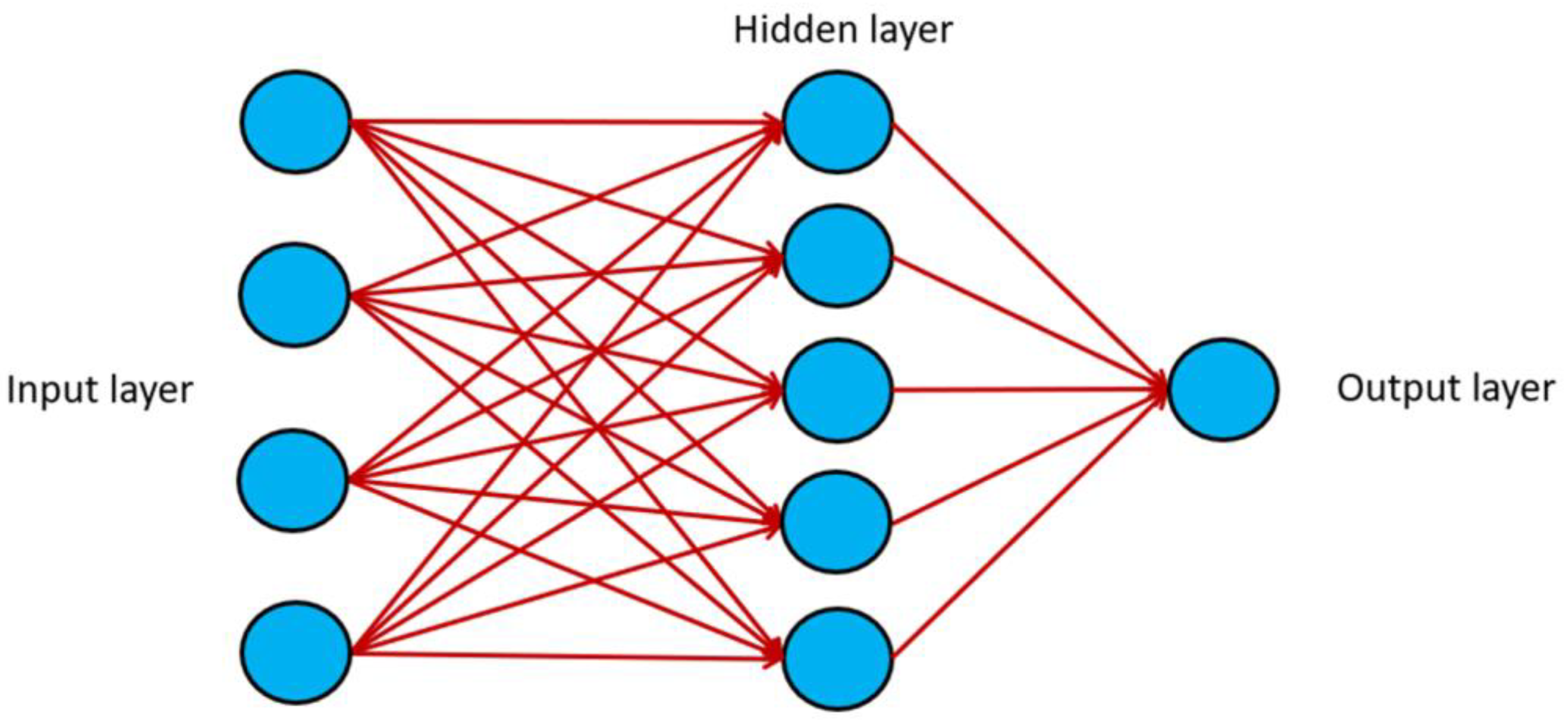

2.3. Artificial Neural Network (ANN) Based Modelling

- xi = input

- wn = weight

- b = bias

- y = output

- y = output expected

- y* = output predicted

- = learning rate

3. Results and Discussion

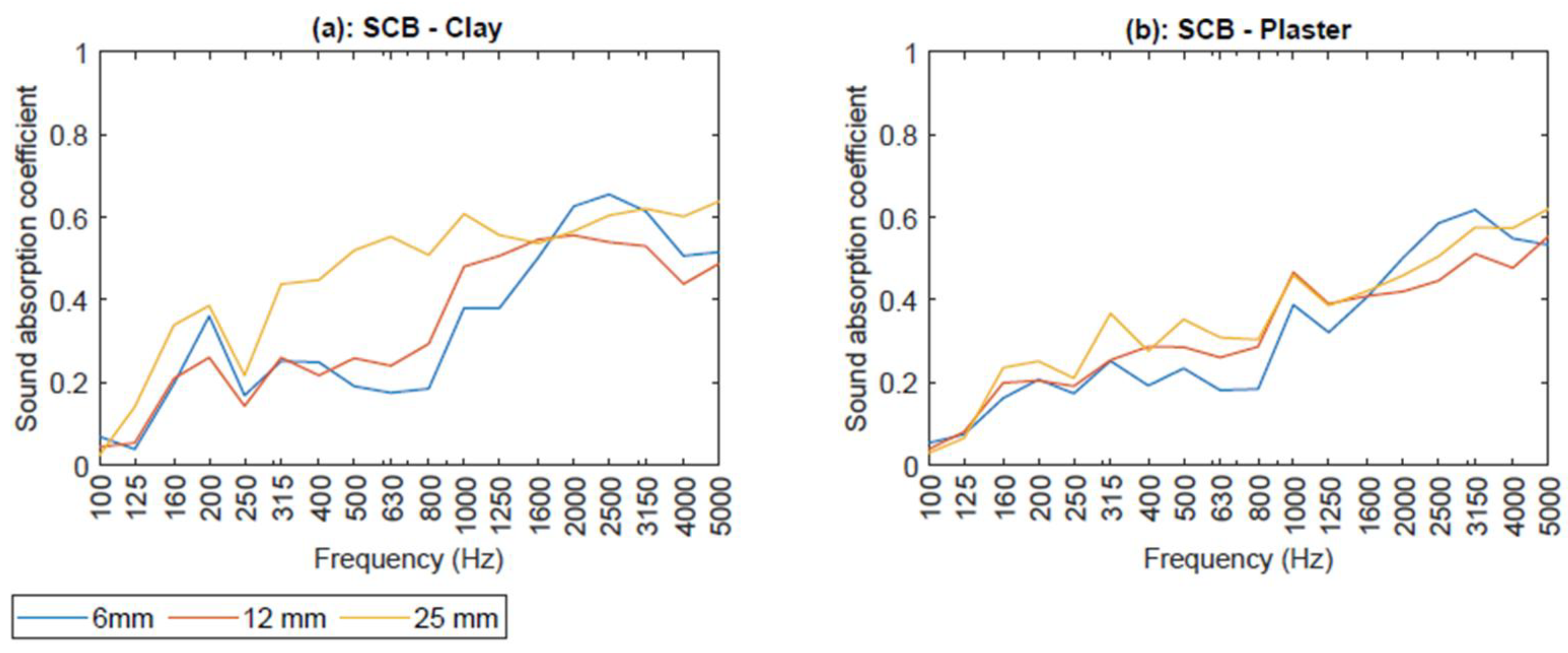

3.1. Sound Absorption Coefficient Measurements

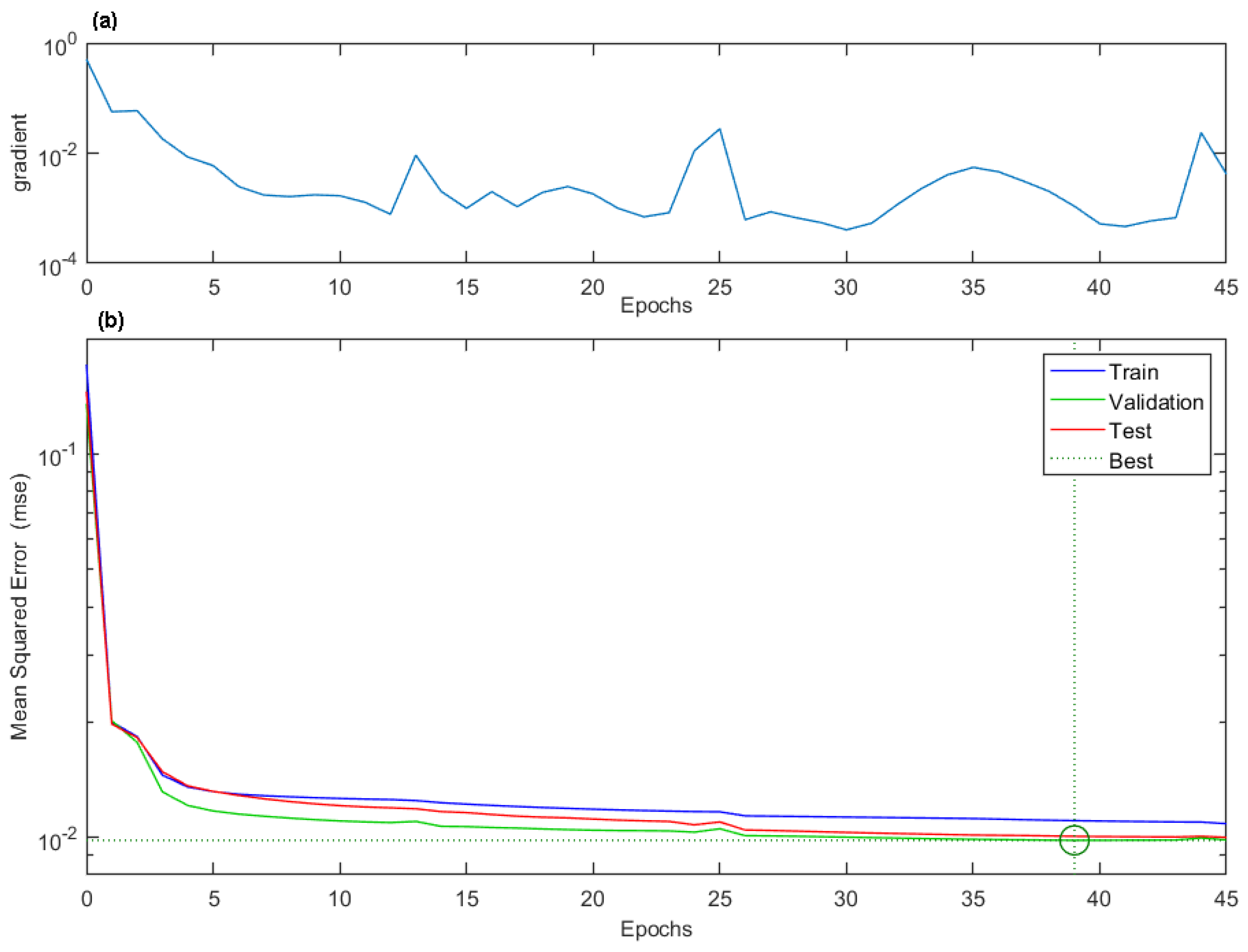

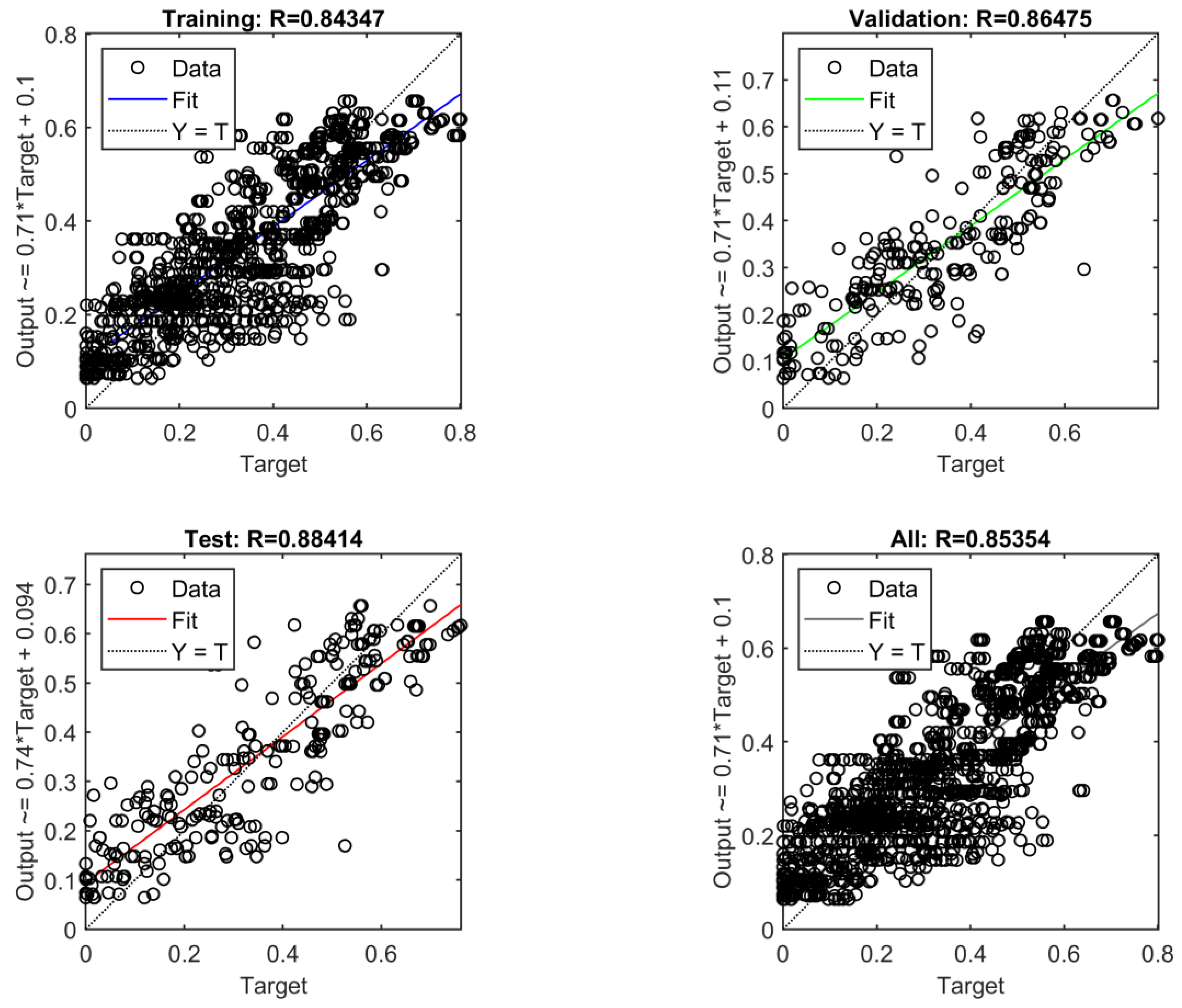

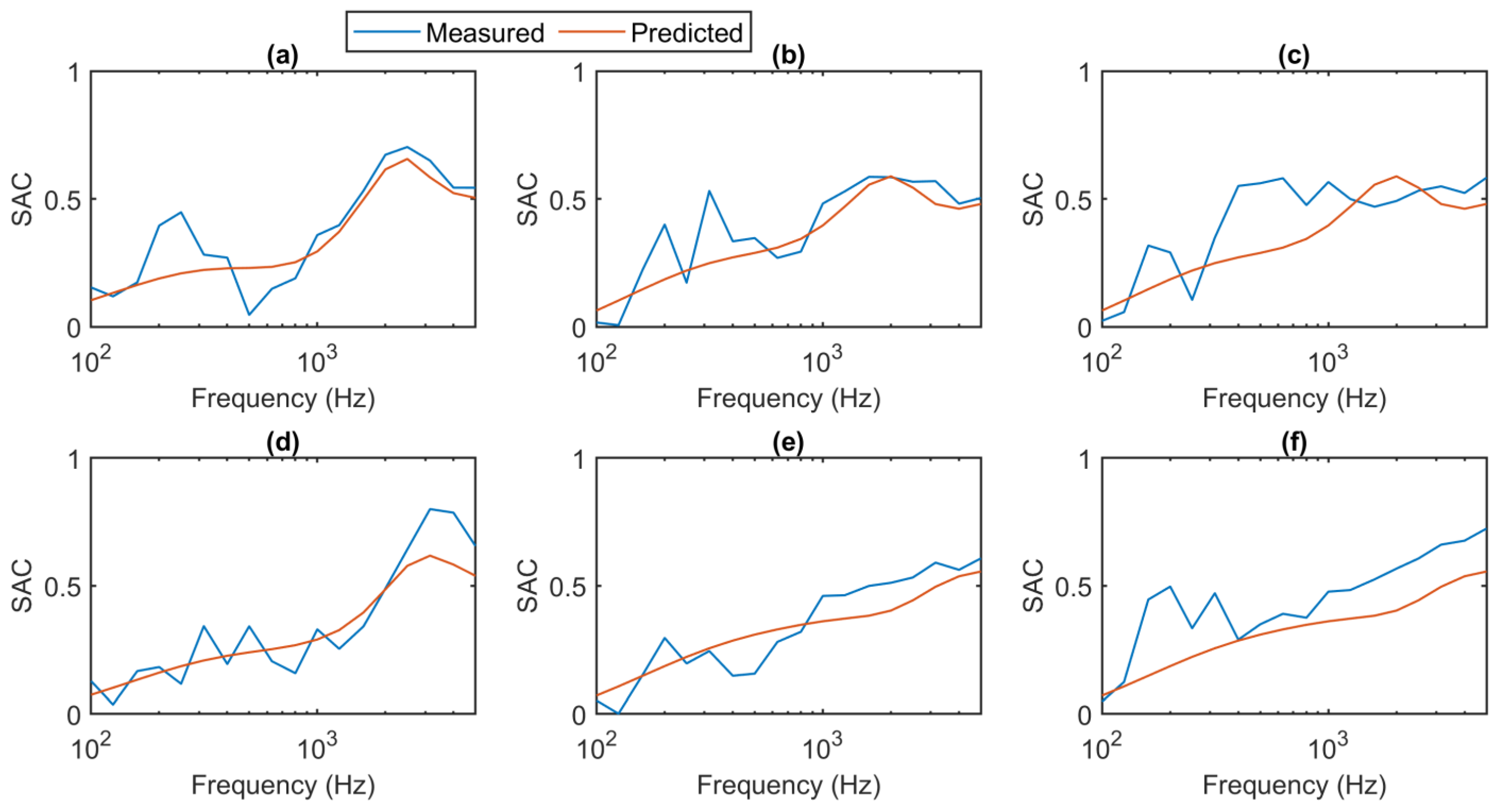

3.2. ANN-Based Model for SAC Prediction

4. Conclusions

- simulated data curve adapted effectively to the measured data, also showing a capacity to correct at the low frequencies those data which had highlighted anomalies,

- a deviation between the measured and predicted data was found for the clay binders for the thicker samples 25 mm,

- the predicted data underlies those measured for the entire frequency range.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goodland, R. The concept of environmental sustainability. Annu. Rev. Ecol. Syst. 1995, 26, 1–24. [Google Scholar] [CrossRef]

- Maywald, C.; Riesser, F. Sustainability—The art of modern architecture. Procedia Eng. 2016, 155, 238–248. [Google Scholar] [CrossRef]

- Parris, T.M.; Kates, R.W. Characterizing and measuring sustainable development. Annu. Rev. Environ. Resour. 2003, 28, 559–586. [Google Scholar] [CrossRef]

- Rogers, P.P.; Jalal, K.F.; Boyd, J.A. An Introduction to Sustainable Development; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Armour, M.A. Chemical waste management and disposal. J. Chem. Educ. 1988, 65, A64. [Google Scholar] [CrossRef]

- Williams, E.; Kahhat, R.; Allenby, B.; Kavazanjian, E.; Kim, J.; Xu, M. Environmental, social, and economic implications of global reuse and recycling of personal computers. Environ. Sci. Technol. 2008, 42, 6446–6454. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life cycle assessment of concrete structures with reuse and recycling strategies: A novel framework and case study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Ciaburro, G. Recycled Materials for Sound Absorbing Applications. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2021; Volume 1034, pp. 169–175. [Google Scholar]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of natural fibers and its composites: An overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of natural fibers. Part I—Vegetable fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S. Natural fibers as perspective materials. Appl. Sci. Eng. Prog. 2018, 11, 233. [Google Scholar] [CrossRef]

- Laufenberg, G.; Kunz, B.; Nystroem, M. Transformation of vegetable waste into value added products: (A) the upgrading concept; (B) practical implementations. Bioresour. Technol. 2003, 87, 167–198. [Google Scholar] [CrossRef]

- Loh, Y.R.; Sujan, D.; Rahman, M.E.; Das, C.A. Sugarcane bagasse—The future composite material: A literature review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Han, G.; Wu, Q.; Vlosky, R. Physical and Mechanical Properties of Sugarcane Rind and Mixed Hardwood Oriented Strandboard Bonded with PF Resin. For. Prod. J. 2005, 55, 28–36. [Google Scholar]

- Bilba, K.; Arsene, M.A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Doherty, W.; Halley, P.; Edye, L.; Rogers, D.; Cardona, F.; Park, Y.; Woo, T. Studies on polymers and composites from lignin and fiber derived from sugar cane. Polym. Adv. Technol. 2007, 18, 673–678. [Google Scholar] [CrossRef]

- Trindade, W.G.; Hoareau, W.; Razera, I.A.; Ruggiero, R.; Frollini, E.; Castellan, A. Phenolic thermoset matrix reinforced with sugar cane bagasse fibers: Attempt to develop a new fiber surface chemical modification involving formation of quinones followed by reaction with furfuryl alcohol. Macromol. Mater. Eng. 2004, 289, 728–736. [Google Scholar] [CrossRef]

- Frias, M.; Villar-Cocina, E.; Valencia-Morales, E. Characterisation of sugar cane straw waste as pozzolanic material for construction: Calcining temperature and kinetic parameters. Waste Manag. 2007, 27, 533–538. [Google Scholar] [CrossRef]

- Mulinari, D.R.; Voorwald, H.J.; Cioffi MO, H.; Da Silva ML, C.; da Cruz, T.G.; Saron, C. Sugarcane bagasse cellulose/HDPE composites obtained by extrusion. Compos. Sci. Technol. 2009, 69, 214–219. [Google Scholar] [CrossRef]

- Jariwala, H.J.; Syed, H.S.; Pandya, M.J.; Gajera, Y.M. Noise pollution & human health: A review. Indoor Built Env. 2017. [Google Scholar]

- Rasmussen, B.; Rindel, J.H. Sound insulation between dwellings–Descriptors applied in building regulations in Europe. Appl. Acoust. 2010, 71, 171–180. [Google Scholar] [CrossRef]

- Zhu, X.; Kim, B.J.; Wang, Q.; Wu, Q. Recent advances in the sound insulation properties of bio-based materials. BioResources 2014, 9, 1764–1786. [Google Scholar] [CrossRef]

- Doost-Hoseini, K.; Taghiyari, H.R.; Elyasi, A. Correlation between sound absorption coefficients with physical and mechanical properties of insulation boards made from sugar cane bagasse. Compos. Part B Eng. 2014, 58, 10–15. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane bagasse waste fibers as novel thermal insulation and sound-absorbing materials for application in sustainable buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Malawade, U.A.; Jadhav, M.G. Investigation of the acoustic performance of bagasse. J. Mater. Res. Technol. 2020, 9, 882–889. [Google Scholar] [CrossRef]

- Othmani, C.; Taktak, M.; Zein, A.; Hentati, T.; Elnady, T.; Fakhfakh, T.; Haddar, M. Experimental and theoretical investigation of the acoustic performance of sugarcane wastes based material. Appl. Acoust. 2016, 109, 90–96. [Google Scholar] [CrossRef]

- Nor MJ, M.; Jamaludin, N.; Tamiri, F.M. A preliminary study of sound absorption using multi-layer coconut coir fibers. Electron. J. Tech. Acoust. 2004, 3, 1–8. [Google Scholar]

- Bozkurt, T.S.; Demirkale, S.Y. Laboratory analyses and numerical simulation for sound absorption of plasters in historical buildings. J. Cult. Herit. 2019, 36, 103–117. [Google Scholar] [CrossRef]

- Puyana-Romero, V.; Iannace, G.; Cajas-Camacho, L.G.; Garzón-Pico, C.; Ciaburro, G. Acoustic characterization and modeling of silicone-bonded cocoa crop waste using a model based on the gaussian support vector machine. Fibers 2022, 10, 25. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Puyana-Romero, V.; Trematerra, A. A comparison between numerical simulation models for the prediction of acoustic behavior of giant reeds shredded. Appl. Sci. 2020, 10, 6881. [Google Scholar] [CrossRef]

- Wu, R.T.; Liu, T.W.; Jahanshahi, M.R.; Semperlotti, F. Design of one-dimensional acoustic metamaterials using machine learning and cell concatenation. Struct. Multidiscip. Optim. 2021, 63, 2399–2423. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Numerical simulation for the sound absorption properties of ceramic resonators. Fibers 2020, 8, 77. [Google Scholar] [CrossRef]

- Sadat, S.M.; Wang, R.Y. A machine learning based approach for phononic crystal property discovery. J. Appl. Phys. 2020, 128, 025106. [Google Scholar] [CrossRef]

- ISO 10534–2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes-Part 2: Transfer-Function Method. International Organization for Standardization: Geneva, Switzerland, 1998.

- Bull, T.A.; Glasziou, K.T. Sugar cane. In Crop Physiology: Some Case Histories; Evans, L.T., Ed.; Cambridge University Press: London, UK, 1975; pp. 51–72. [Google Scholar]

- FAO (Food, and Agriculture Organization of the United Nations). Available online: https://www.fao.org/home/en (accessed on 11 November 2022).

- Meade, G.P.; Chen, J.C. Cane Sugar Handbook; John Wiley & Sons: Hoboken, NJ, USA, 1977. [Google Scholar]

- Pessoa, A., Jr.; De Mancilha, I.M.; Sato, S. Evaluation of sugar cane hemicellulose hydrolyzate for cultivation of yeasts and filamentous fungi. J. Ind. Microbiol. Biotechnol. 1997, 18, 360–363. [Google Scholar]

- Ciaburro, G.; Puyana-Romero, V.; Iannace, G.; Jaramillo-Cevallos, W.A. Characterization and modeling of corn stalk fibers tied with clay using support vector regression algorithms. J. Nat. Fibers 2021, 19, 7141–7156. [Google Scholar] [CrossRef]

- Maxit, L.; Yang, C.; Cheng, L.; Guyader, J.L. Modeling of micro-perforated panels in a complex vibro-acoustic environment using patch transfer function approach. J. Acoust. Soc. Am. 2012, 131, 2118–2130. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Membrane-type acoustic metamaterial using cork sheets and attached masses based on reused materials. Appl. Acoust. 2022, 189, 108605. [Google Scholar] [CrossRef]

- Dutilleux, G.; Vigran, T.E.; Kristiansen, U.R. An in situ transfer function technique for the assessment of the acoustic absorption of materials in buildings. Appl. Acoust. 2001, 62, 555–572. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Modeling acoustic metamaterials based on reused buttons using data fitting with neural network. J. Acoust. Soc. Am. 2021, 150, 51–63. [Google Scholar] [CrossRef]

- Mohri, M.; Rostamizadeh, A.; Talwalkar, A. Foundations of Machine Learning; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Allen, M.P. Understanding Regression Analysis; Springer Science & Business Media: Berlin, Germany, 2004. [Google Scholar]

- Iannace, G.; Ciaburro, G. Modelling sound absorption properties for recycled polyethylene terephthalate-based material using Gaussian regression. Build. Acoust. 2021, 28, 185–196. [Google Scholar] [CrossRef]

- Zhang, G.; Patuwo, B.E.; Hu, M.Y. Forecasting with artificial neural networks: The state of the art. Int. J. Forecast. 1998, 14, 35–62. [Google Scholar] [CrossRef]

- Basheer, I.A.; Hajmeer, M. Artificial neural networks: Fundamentals, computing, design, and application. J. Microbiol. Methods 2000, 43, 3–31. [Google Scholar] [CrossRef] [PubMed]

- Ciaburro, G.; Iannace, G. Acoustic characterization of rooms using reverberation time estimation based on supervised learning algorithm. Appl. Sci. 2021, 11, 1661. [Google Scholar] [CrossRef]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tien Bui, D.; Tuan, T.A.; Klempe, H.; Pradhan, B.; Revhaug, I. Spatial prediction models for shallow landslide hazards: A comparative assessment of the efficacy of support vector machines, artificial neural networks, kernel logistic regression, and logistic model tree. Landslides 2016, 13, 361–378. [Google Scholar] [CrossRef]

- Anitescu, C.; Atroshchenko, E.; Alajlan, N.; Rabczuk, T. Artificial neural network methods for the solution of second order boundary value problems. Comput. Mater. Contin. 2019, 59, 345–359. [Google Scholar] [CrossRef]

- Leung, H.; Haykin, S. The complex backpropagation algorithm. IEEE Trans. Signal Process. 1991, 39, 2101–2104. [Google Scholar] [CrossRef]

- Baldi, P. Gradient descent learning algorithm overview: A general dynamical systems perspective. IEEE Trans. Neural Netw. 1995, 6, 182–195. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Anannya, F.R. Sugarcane bagasse-A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef]

- Soltani, P.; Norouzi, M. Prediction of the sound absorption behavior of nonwoven fabrics: Computational study and experimental validation. J. Sound Vib. 2020, 485, 115607. [Google Scholar] [CrossRef]

- Carvalho ST, M.; Mendes, L.M.; Cesa, A.A.D.S.; Flórez, J.B.; Mori, F.A.; Rabelo, G.F. Acoustic characterization of sugarcane bagasse particleboard panels (Saccharum officinarum L). Mater. Res. 2015, 18, 821–827. [Google Scholar] [CrossRef]

- Delany, M.E.; Bazley, E.N. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Champoux, Y.; Allard, J.-F. Dynamic tortuosity and bulk modulus in air-saturated porous media. J. Appl. Phys. 1991, 70, 1975–1979. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical properties of porous materials-Modifications of Delany-Bazley models. J. Acoust. Soc. Jpn. 1990, 11, 19–24. [Google Scholar] [CrossRef]

- Hamet, J.F.; Berengier, M. Acoustical Characteristics of Porous Pavements: A New Phenomenological Model. In Proceedings of the 1993 International Congress on Noise Control Engineering, Leuven, Belgium, 24–26 August 1993. [Google Scholar]

- Miller, J.L.; Erickson, M.L. On dummy variable regression analysis: A description and illustration of the method. Sociol. Methods Res. 1974, 2, 409–430. [Google Scholar] [CrossRef]

- Moré, J.J. The Levenberg-Marquardt Algorithm: Implementation and Theory. In Numerical Analysis; Springer: Berlin/Heidelberg, Germany, 1978; pp. 105–116. [Google Scholar]

- Wedderburn, R.W. Quasi-likelihood functions, generalized linear models, and the Gauss—Newton method. Biometrika 1974, 61, 439–447. [Google Scholar]

- Hu, T.; Wu, Q.; Zhou, D.X. Distributed kernel gradient descent algorithm for minimum error entropy principle. Appl. Comput. Harmon. Anal. 2020, 49, 229–256. [Google Scholar] [CrossRef]

- MATLAB. Available online: https://www.mathworks.com/products/matlab.html (accessed on 11 November 2022).

- Asuero, A.G.; Sayago, A.; González, A.G. The correlation coefficient: An overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

- Köksoy, O. Multiresponse robust design: Mean square error (MSE) criterion. Appl. Math. Comput. 2006, 175, 1716–1729. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, H.; Lian, Z.; Tan, B.; Zheng, Y.; Erdun, E. Numerical Simulation for Porous Hemp Plastic Composites Sound Absorption Properties. J. Mater. Res. Technol. 2022, 19, 2458–2469. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Kanthavel, K. Optimizing various parameters influencing mechanical properties of banana/coir natural fiber composites using grey relational analysis and artificial neural network models. J. Ind. Text. 2022, 51 (Suppl. 4), 6705S–6727S. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Wang, F.; Zhang, D. Optimization and prediction of ultra-fine glass fiber felt process parameters based on artificial neural network. J. Eng. Fibers Fabr. 2020, 15, 1558925020910730. [Google Scholar] [CrossRef]

| Panel Type | Thickness (mm) | SCB (g) | Binder (g) | Water (g) |

|---|---|---|---|---|

| SCB-plaster | 6 | 20 (6.06%) | 60 (18.2%) | 250 (75.8%) |

| SCB-plaster | 12 | 30 (4.61%) | 120 (18.4%) | 500 (76.9%) |

| SCB-plaster | 25 | 60 (5.61%) | 260 (24.3%) | 750 (70.1%) |

| SCB-clay | 6 | 20 (4.76%) | 150 (35.7%) | 250 (59.5%) |

| SCB-clay | 12 | 30 (4.16%) | 190 (26.4%) | 500 (69.4%) |

| SCB-clay | 25 | 60 (4.58%) | 500 (38.2%) | 750 (57.3%) |

| Title 1 | Thickness (mm) | Weight (g) |

|---|---|---|

| SCB-plaster | 6 | 8.37 |

| SCB-plaster | 12 | 4.25 |

| SCB-plaster | 25 | 2.69 |

| SCB–clay | 6 | 9.10 |

| SCB–clay | 12 | 3.91 |

| SCB–clay | 25 | 2.83 |

| SCB-Clay | SCB-Plaster | |||||

|---|---|---|---|---|---|---|

| Frequency (Hz) | 6 mm | 12 mm | 25 mm | 6 mm | 12 mm | 25 mm |

| 100 | 0.05537 | 0.05236 | 0.02008 | 0.03179 | 0.03484 | 0.02029 |

| 125 | 0.04705 | 0.04502 | 0.09607 | 0.03929 | 0.04604 | 0.04886 |

| 160 | 0.07248 | 0.09294 | 0.06864 | 0.06639 | 0.09405 | 0.08359 |

| 200 | 0.09794 | 0.09028 | 0.09249 | 0.09576 | 0.09920 | 0.09353 |

| 250 | 0.08369 | 0.09001 | 0.09513 | 0.08006 | 0.07764 | 0.08141 |

| 315 | 0.08338 | 0.09793 | 0.08338 | 0.08905 | 0.09781 | 0.07158 |

| 400 | 0.08749 | 0.07029 | 0.08558 | 0.05815 | 0.07825 | 0.08075 |

| 500 | 0.05474 | 0.06549 | 0.07011 | 0.06253 | 0.06091 | 0.04812 |

| 630 | 0.03421 | 0.03147 | 0.01452 | 0.03791 | 0.04048 | 0.06693 |

| 800 | 0.01712 | 0.01037 | 0.05724 | 0.02366 | 0.02495 | 0.07276 |

| 1000 | 0.01476 | 0.00566 | 0.05398 | 0.05010 | 0.00673 | 0.02378 |

| 1250 | 0.02401 | 0.03003 | 0.08326 | 0.06363 | 0.00376 | 0.07901 |

| 1600 | 0.04914 | 0.04745 | 0.08951 | 0.00962 | 0.00201 | 0.08443 |

| 2000 | 0.05788 | 0.03840 | 0.07811 | 0.06646 | 0.09806 | 0.08101 |

| 2500 | 0.06058 | 0.04491 | 0.00320 | 0.08833 | 0.09820 | 0.07516 |

| 3150 | 0.04779 | 0.05657 | 0.00721 | 0.08333 | 0.09048 | 0.06392 |

| 4000 | 0.05711 | 0.06059 | 0.07270 | 0.09979 | 0.09992 | 0.07745 |

| Input Layer | Hidden Layer | Output Layer | Training Algorithm |

|---|---|---|---|

| 4 nodes | 10 nodes | 1 node | Levenberg Marquardt |

| Parameter | Initial Value | Stopped Value | Target Value |

|---|---|---|---|

| Epoch | 0 | 48 | 1000 |

| Performance | 0.18 | 0.0127 | 0 |

| Gradient | 0.391 | 0.00259 | 1.00 10−7 |

| Observations | MSE | R | |

|---|---|---|---|

| Training | 1134 | 0.0111 | 0.8434 |

| Validation | 243 | 0.0098 | 0.8647 |

| Test | 243 | 0.0101 | 0.8841 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puyana-Romero, V.; Chuquín, J.S.A.; Chicaiza, S.I.M.; Ciaburro, G. Characterization and Simulation of Acoustic Properties of Sugarcane Bagasse-Based Composite Using Artificial Neural Network Model. Fibers 2023, 11, 18. https://doi.org/10.3390/fib11020018

Puyana-Romero V, Chuquín JSA, Chicaiza SIM, Ciaburro G. Characterization and Simulation of Acoustic Properties of Sugarcane Bagasse-Based Composite Using Artificial Neural Network Model. Fibers. 2023; 11(2):18. https://doi.org/10.3390/fib11020018

Chicago/Turabian StylePuyana-Romero, Virginia, Jorge Santiago Arroyo Chuquín, Saúl Israel Méndez Chicaiza, and Giuseppe Ciaburro. 2023. "Characterization and Simulation of Acoustic Properties of Sugarcane Bagasse-Based Composite Using Artificial Neural Network Model" Fibers 11, no. 2: 18. https://doi.org/10.3390/fib11020018

APA StylePuyana-Romero, V., Chuquín, J. S. A., Chicaiza, S. I. M., & Ciaburro, G. (2023). Characterization and Simulation of Acoustic Properties of Sugarcane Bagasse-Based Composite Using Artificial Neural Network Model. Fibers, 11(2), 18. https://doi.org/10.3390/fib11020018