Damage Investigation on the Carbon Tows during Rewinding and Braiding Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Carbon Tows

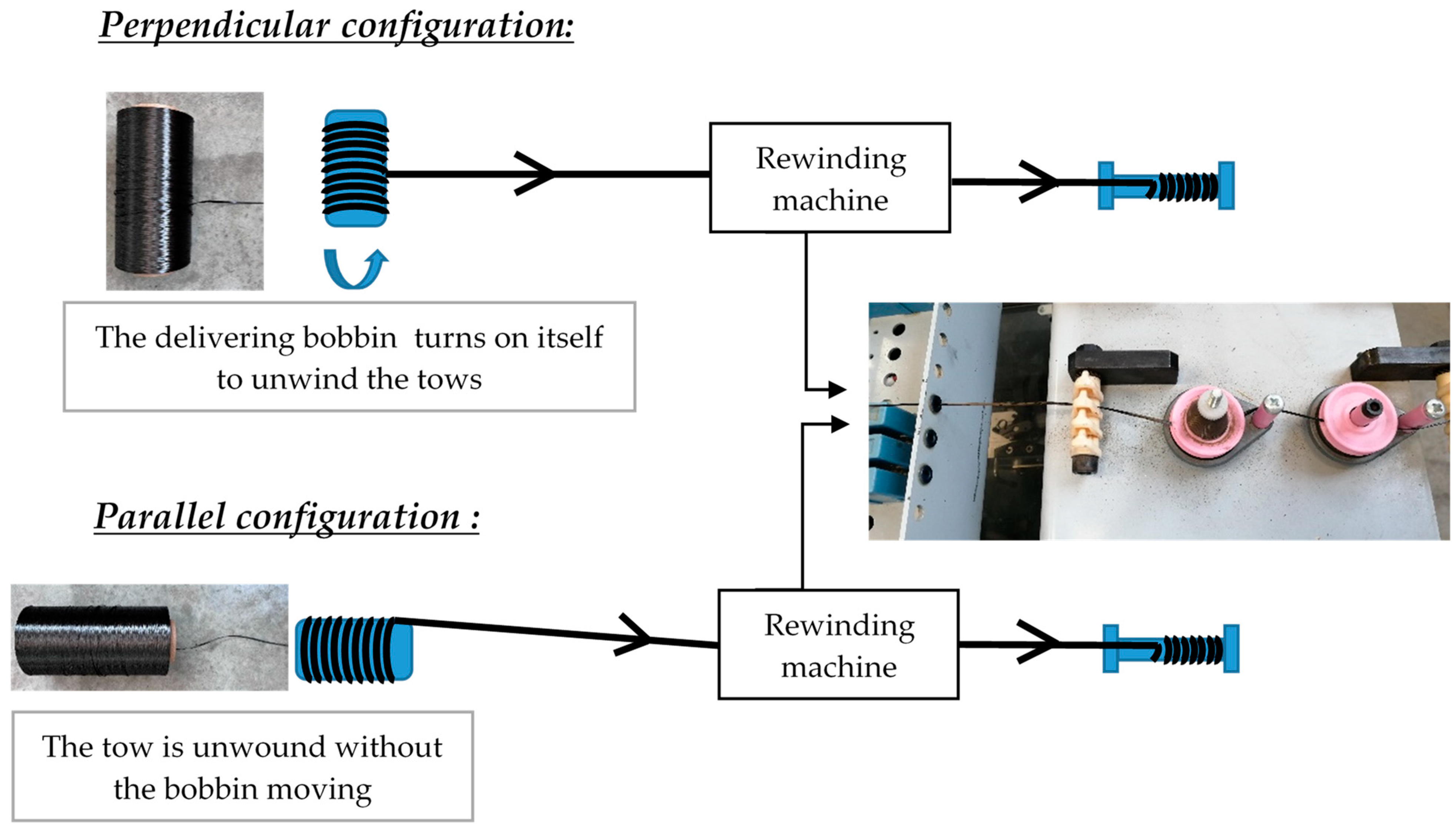

2.2. Rewinding Device

2.3. Braiding Process

2.4. Analysis of Damages

3. Results and Discussion

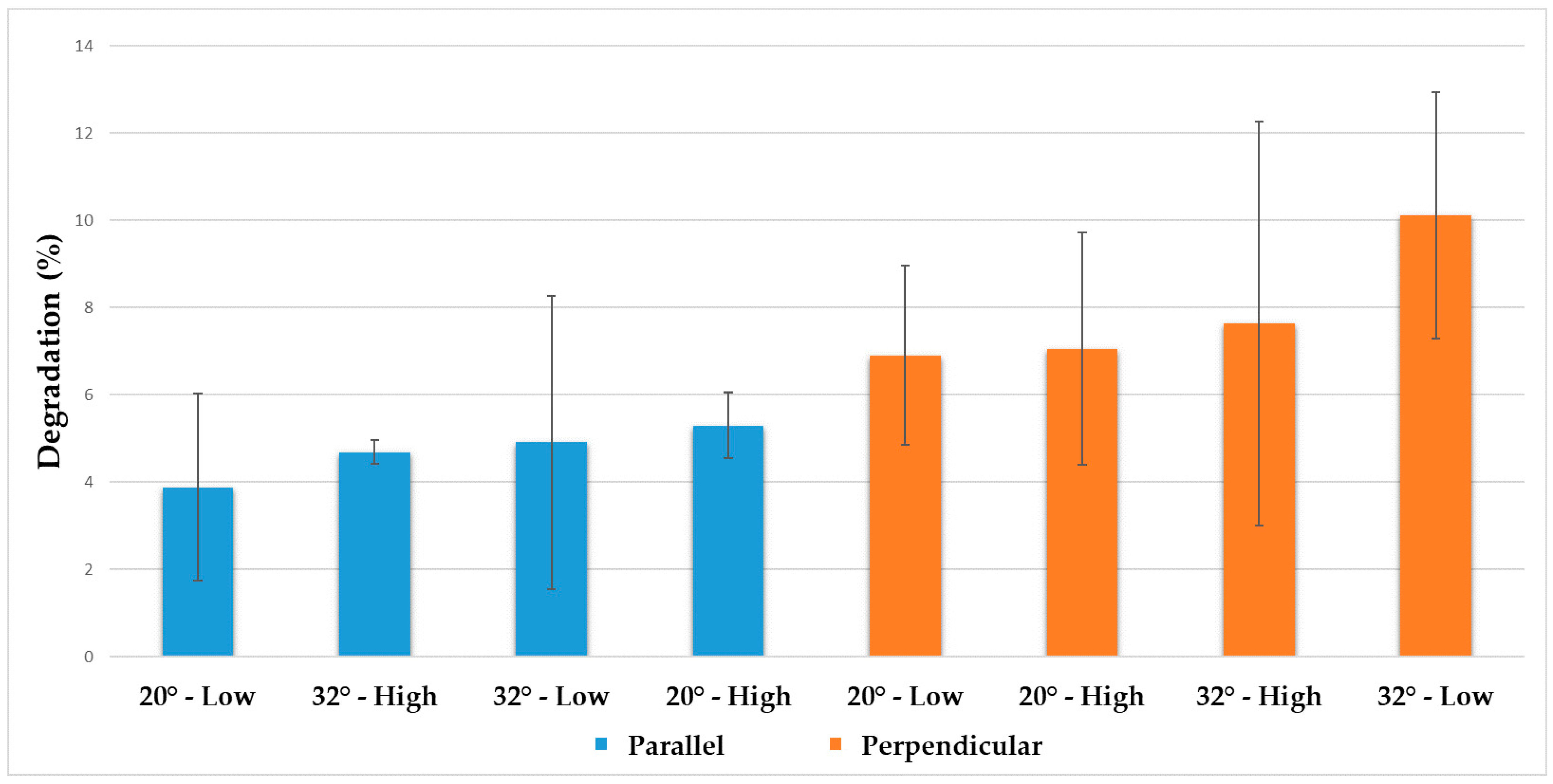

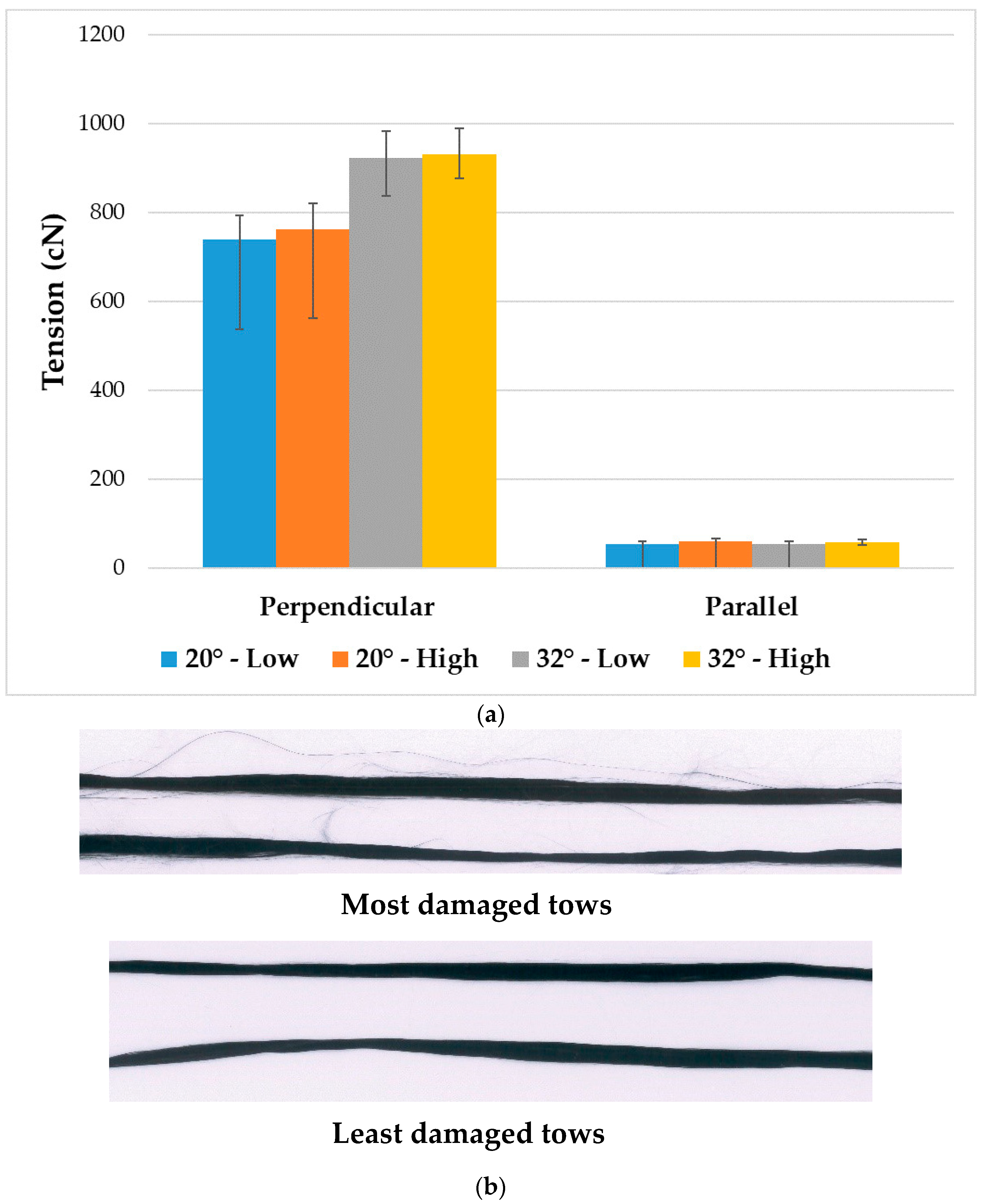

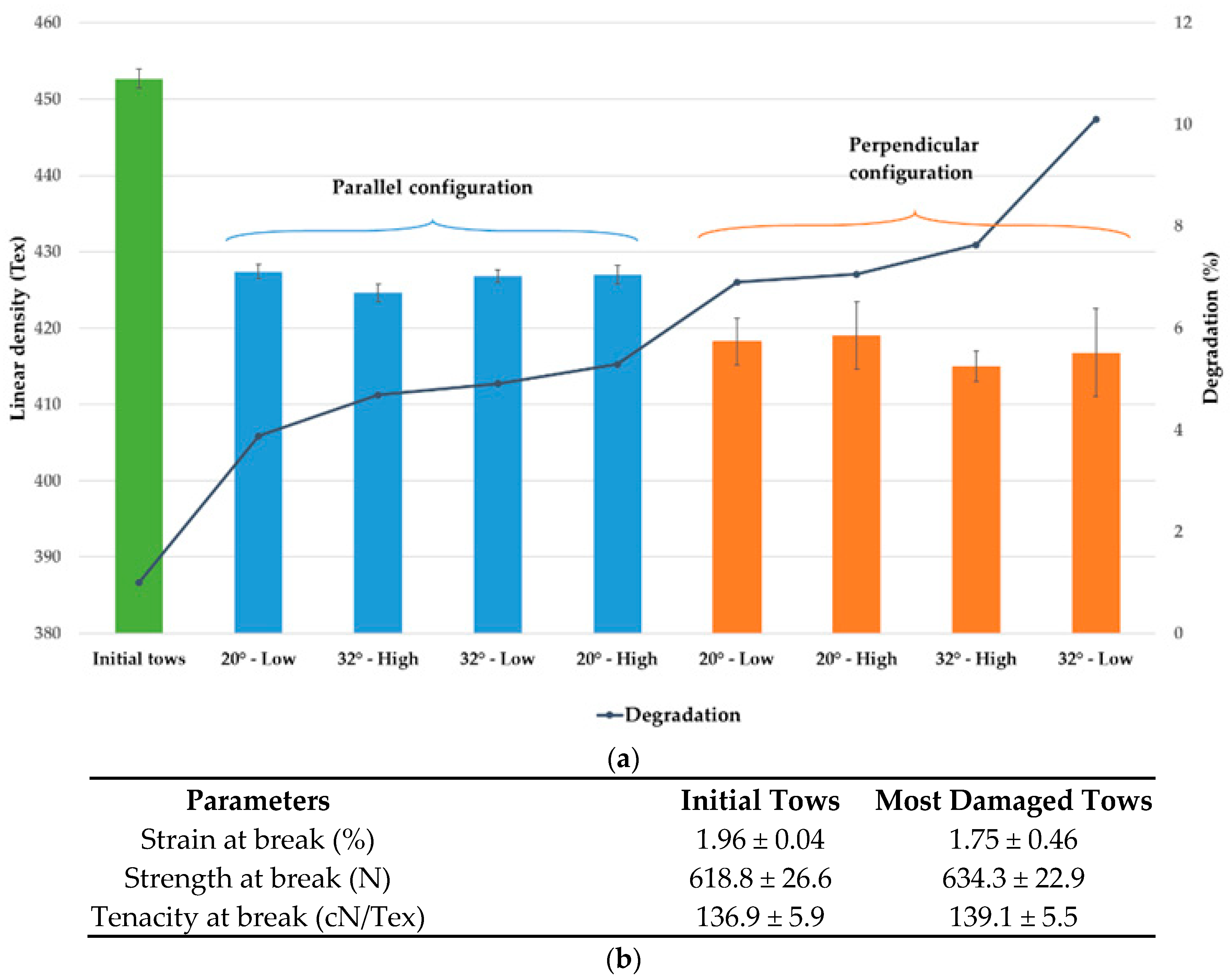

3.1. Degradation during the Rewinding Step

3.2. Degradation during the Braiding Step

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Carey, J.P. Introduction to braided composites. In Handbook of Advances in Braided Composite Materials; Carey, J.P., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 1–21. [Google Scholar] [CrossRef]

- Hao, W.; Huang, Z.; Zhang, L.; Zhao, G.; Luo, Y. Study on the torsion behavior of 3-D braided composite shafts. Compos. Struct. 2019, 229, 111384. [Google Scholar] [CrossRef]

- Ayranci, C.; Carey, J.P. 2D braided composites: A review for stiffness critical applications. Compos. Struct. 2008, 85, 43–58. [Google Scholar] [CrossRef]

- Kyosev, Y. Advances in Braiding Technology: Specialized Techniques and Applications. In Woodhead Publishing Series in Textiles; Woodhead Publishing: Oxford, UK, 2016; ISBN 978-0-08-100926-0. [Google Scholar]

- Emonts, C.; Grigat, N.; Merkord, F.; Vollbrecht, B.; Idrissi, A.; Sackmann, J.; Gries, T. Innovation in 3D Braiding Technology and Its Applications. Textiles 2021, 1, 185–205. [Google Scholar] [CrossRef]

- Melenka, G.W.; Carey, J.P. Experimental analysis of diamond and regular tubular braided composites using three-dimensional digital image correlation. J. Compos. Mater. 2017, 51, 3887–3907. [Google Scholar] [CrossRef]

- Potluri, P. Braiding. In Wiley Encyclopedia of Composites; Nicolais, L., Borzacchiello, A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Potluri, P.; Manan, A. Mechanics of non-orthogonally interlaced textile composites. Compos. Part A 2007, 38, 1216–1226. [Google Scholar] [CrossRef]

- Ayranci, A.; Carey, J.P. Predicting the longitudinal elastic modulus of braided tubular composites using a curved unit-cell geometry. Compos. Part B 2010, 41, 229–235. [Google Scholar] [CrossRef]

- Heieck, F.; Hermann, F.; Middendorf, P.; Schladitz, K. Influence of the cover factor of 2D biaxial and triaxial braided carbon composites on their in-plane mechanical properties. Compos. Struct. 2017, 163, 114–122. [Google Scholar] [CrossRef]

- Birkefeld, K.; Röder, M.; Von Reden, T.; Bulat, M.; Drechler, K. Characterization of Biaxial and Triaxial Braids: Fiber Architecture and Mechanical Properties. Appl. Compos. Mater. 2012, 19, 259–273. [Google Scholar] [CrossRef]

- Armanfard, A.; Melenka, G.W. Experimental evaluation of carbon fibre, fibreglass and aramid tubular braided composites under combined tension–torsion loading. Compos. Struct. 2021, 269, 114049. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, L.; Cheng, X.; Xiang, Z.; Hu, X. Transverse impact behavior and residual axial compression characteristics of braided composite tubes: Experimental and numerical study. Int. J. Impact Eng. 2020, 142, 103578. [Google Scholar] [CrossRef]

- McGregor, C.; Vaziri, R.; Poursartip, A.; Xiao, X. Axial crushing of triaxially braided composite tubes at quasi-static and dynamic rates. Compos. Struct. 2016, 157, 197–206. [Google Scholar] [CrossRef]

- Czichos, R.; Bareiro, O.; Pickett, A.K.; Middendorf, P.; Gries, T. Experimental and numerical studies of process variabilities in biaxial carbon fiber braids. Int. J. Mater. Form. 2021, 14, 39–54. [Google Scholar] [CrossRef]

- Wang, C.; Tang, M.; Liu, W.; Zhu, T. Study on Microstructure Characteristics of Axially Braided Carbon/Carbon Composites Based on SEM and Micro-CT. Materials 2020, 13, 1414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chai, Y.; Wang, Y.; Yousaf, Z.; Storm, M.; Vo, N.T.; Wanelik, K.; Burnett, T.L.; Potluri, P.; Withers, P.J. Following the effect of braid architecture on performance and damage of carbon fibre/epoxy composite tubes during torsional straining. Compos. Sci. Technol. 2020, 200, 108451. [Google Scholar] [CrossRef]

- Archer, E.; Buchanan, S.; Mcllhagger, A.T.; Quinn, J.P. The effect of 3D weaving and consolidation on carbon fiber tows, fabrics and composites. J. Reinf. Plast. Compos. 2010, 29, 3162–3170. [Google Scholar] [CrossRef]

- Lee, B.; Leong, K.H.; Herszberg, I. Effect of weaving on the tensile properties of carbon fibre tows and woven composites. J. Reinf. Plast. Compos. 2001, 20, 652–670. [Google Scholar] [CrossRef]

- Rudov-Clark, S.; Mouritz, A.P.; Lee, L.; Bannister, M.K. Fibre damage in the manufacture of advanced three-dimensional woven composites. Compos. Part A 2003, 34, 963–970. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Yarn degradation during weaving process and its effect on the mechanical behaviours of 3D warp interlock p-aramid fabric for industrial applications. J. Ind. Text. 2022, 51 (Suppl. S5), 9047S–9070S. [Google Scholar] [CrossRef]

- Ebel, C.; Mierzwa, A.; Kind, K. Yarn damage during braiding of reinforcement fibers for composites. In Chapter 13 of Advances in Braiding Technology; Woodhead Publishing Series in Textiles; Woodhead Publishing: Oxford, UK, 2016. [Google Scholar] [CrossRef]

- Kyosev, Y. Yarn winding operations in braiding. In Chap.10 of Braiding Technology for Textiles; Kyosev, Y., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Oxford, UK, 2015. [Google Scholar]

- Roy, S.S.; Zao, W.; Potluri, P. Influence of Braid Carrier Tension on Carbon Fibre Braided Preforms. In Recent Developments in Braiding and Narrow Weaving; Kiosev, Y., Ed.; Springer International Publishing Switzerland: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- NF EN ISO 5084; Textiles-Determination of Thickness of Textiles and Textile Products. AFNOR: Saint-Denis, France, 1996.

- NF G07-316; Textiles-Tests of Yarns-Determination of Linear Density. AFNOR: Saint-Denis, France, 1988.

- NF EN ISO 2062; Textiles–Yarns from Packages–Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester. AFNOR: Saint-Denis, France, 2010.

- Ratera® Winding Machines. Available online: https://ratera.com/en/applications/auxiliary-machines/ (accessed on 22 November 2022).

- Cherif, C. Textile Werkstoffe für den Leichtbau; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Ebel, C.; Brand, M.; Drechsler, K. Effects of fiber damage on the efficiency of the braiding process. In Proceedings of the Composites Week in Leuven and TexComp-11 Conference, Leuven, Belgium, 16–20 September 2013. [Google Scholar] [CrossRef]

- Duchamp, B.; Soulat, D.; Legrand, X. The tensile behaviour of biaxial and triaxial braided fabrics. J. Ind. Text. 2018, 47, 2184–2204. [Google Scholar] [CrossRef]

- Jacquot, P.B.; Wang, P.; Soulat, D.; Legrand, X. Analysis of the preforming behaviour of the braided and woven flax/polyamide fabrics. J. Ind. Text. 2016, 46, 698–718. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, P.; Soulat, D.; Gao, H. An exploration of the deformability behaviour dominated by braiding angle during the forming of the triaxial carbon fibre braids. Compos. Part A 2020, 133, 1058990. [Google Scholar] [CrossRef]

- Zhai, W.; Soulat, D.; Legrand, X.; Wang, P. Influence of the Unit Cell Parameters on the Thermomechanical Non-Symmetric In-Plane Shear Behavior of 2D Biaxial Braided Preform for Thermoplastic Biocomposites. Polymers 2022, 14, 1117. [Google Scholar] [CrossRef] [PubMed]

- Tourlonias, M.; Bueno, M.A.; Fassi, G.; Aktas, I.; Wielhorski, Y. Influence of friction angle between carbon single fibres and tows: Experimental analysis and analytical model. Compos. Part A 2019, 124, 105478. [Google Scholar] [CrossRef]

- Smerdova, O.; Benchekroun, O.; Brunetiere, N. Transversal friction of epoxy-lubricated and dry carbon tows: From initial stages to stabilised state. Compos. Part A 2021, 143, 1062363. [Google Scholar] [CrossRef]

- Wu, N.; Xie, X.; Wang, J.; Feng, Y.; Jiao, Y.; Chen, L.; Xu, J.; Jian, X. Effect of normal load on the frictional and wear behaviour of carbon fiber in tow-on-tool contact during three-dimensional weaving process. J. Ind. Text. 2022, 51 (Suppl. S2), 2753S–2773S. [Google Scholar] [CrossRef]

- Image J: An Open Platform for Scientific Image Analysis. Available online: http://imagej.net/Welcome (accessed on 1 July 2022).

| Thickness (mm) | 2.5 ± 0.04 |

| Linear density (Tex) | 452.68 ± 1.25 |

| Tenacity (cN/Tex) | 136.9 ± 5.9 |

| Strain at break (%) | 1.96± 0.04 |

| Parameters | Level 1 | Level 2 |

|---|---|---|

| Orientation of the bobbin | Perpendicular | Parallel |

| Rewinding speed | Low | High |

| Position of the delivering bobbin | 32° | 20° |

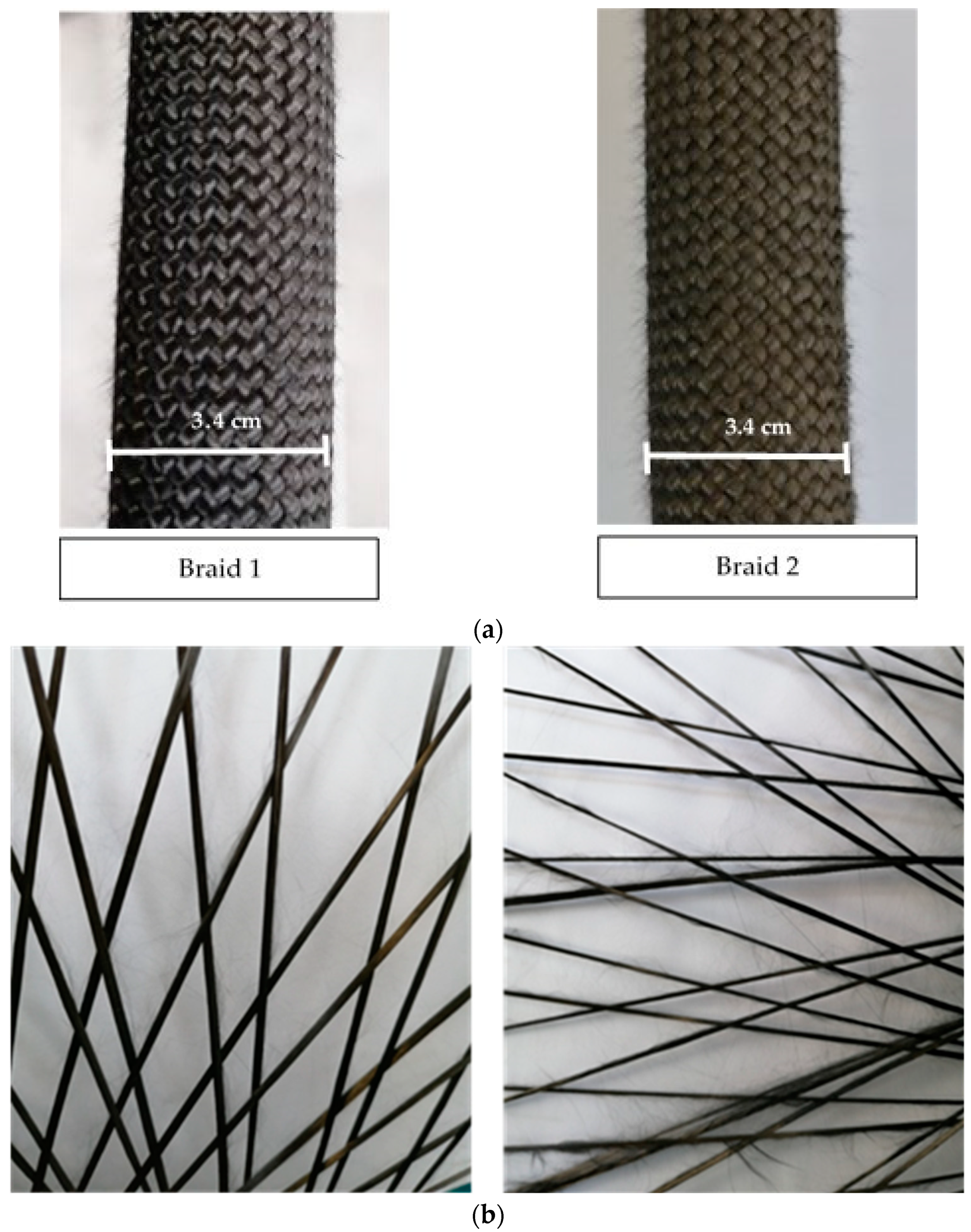

| Parameters | Braid 1 | Braid 2 |

|---|---|---|

| Tension of springs used (cN) | 115 | 200 |

| Number of tows | 96 | 96 |

| Type of braids | biaxial | biaxial |

| Braiding angle (°) | 45 | 45 |

| Carrier rotational speed (tr/min) | 90 | 90 |

| Production speed (m/h) | 30 | 30 |

| Sample Name | Pictures of Samples | Degradation |

|---|---|---|

| Initial tows |  | 1.4% |

| 32–High–Parallel |  | 4.7% |

| 32–High–Perpendicular |  | 7.6% |

| 32–Low–Perpendicular |  | 10.1% |

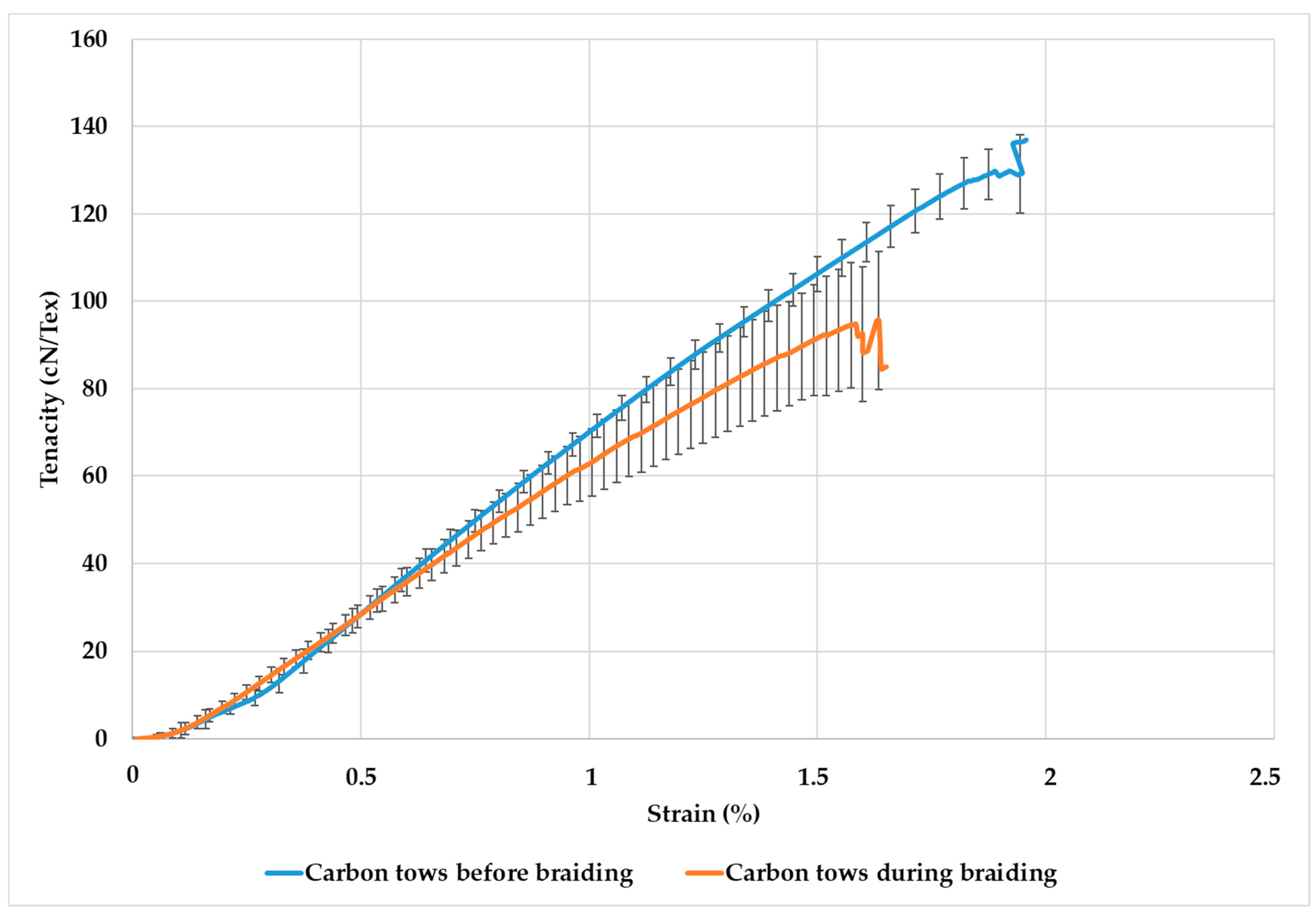

| Parameters | Before Braiding | During Braiding |

|---|---|---|

| Strain at break (%) | 1.93 ± 0.04 | 1.61 ± 0.03 |

| Load at break (N) | 584.74 ± 26.51 | 409.08 ± 62.42 |

| Tenacity at break (cN/Tex) | 131.40 ± 5.96 | 96.03 ± 14.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calba, J.; Soulat, D.; Legrand, X.; Renauld, S. Damage Investigation on the Carbon Tows during Rewinding and Braiding Processes. Fibers 2023, 11, 30. https://doi.org/10.3390/fib11030030

Calba J, Soulat D, Legrand X, Renauld S. Damage Investigation on the Carbon Tows during Rewinding and Braiding Processes. Fibers. 2023; 11(3):30. https://doi.org/10.3390/fib11030030

Chicago/Turabian StyleCalba, Justine, Damien Soulat, Xavier Legrand, and Sébastien Renauld. 2023. "Damage Investigation on the Carbon Tows during Rewinding and Braiding Processes" Fibers 11, no. 3: 30. https://doi.org/10.3390/fib11030030

APA StyleCalba, J., Soulat, D., Legrand, X., & Renauld, S. (2023). Damage Investigation on the Carbon Tows during Rewinding and Braiding Processes. Fibers, 11(3), 30. https://doi.org/10.3390/fib11030030