Production of Long Hemp Fibers Using the Flax Value Chain

Abstract

1. Introduction

2. Materials and Methods

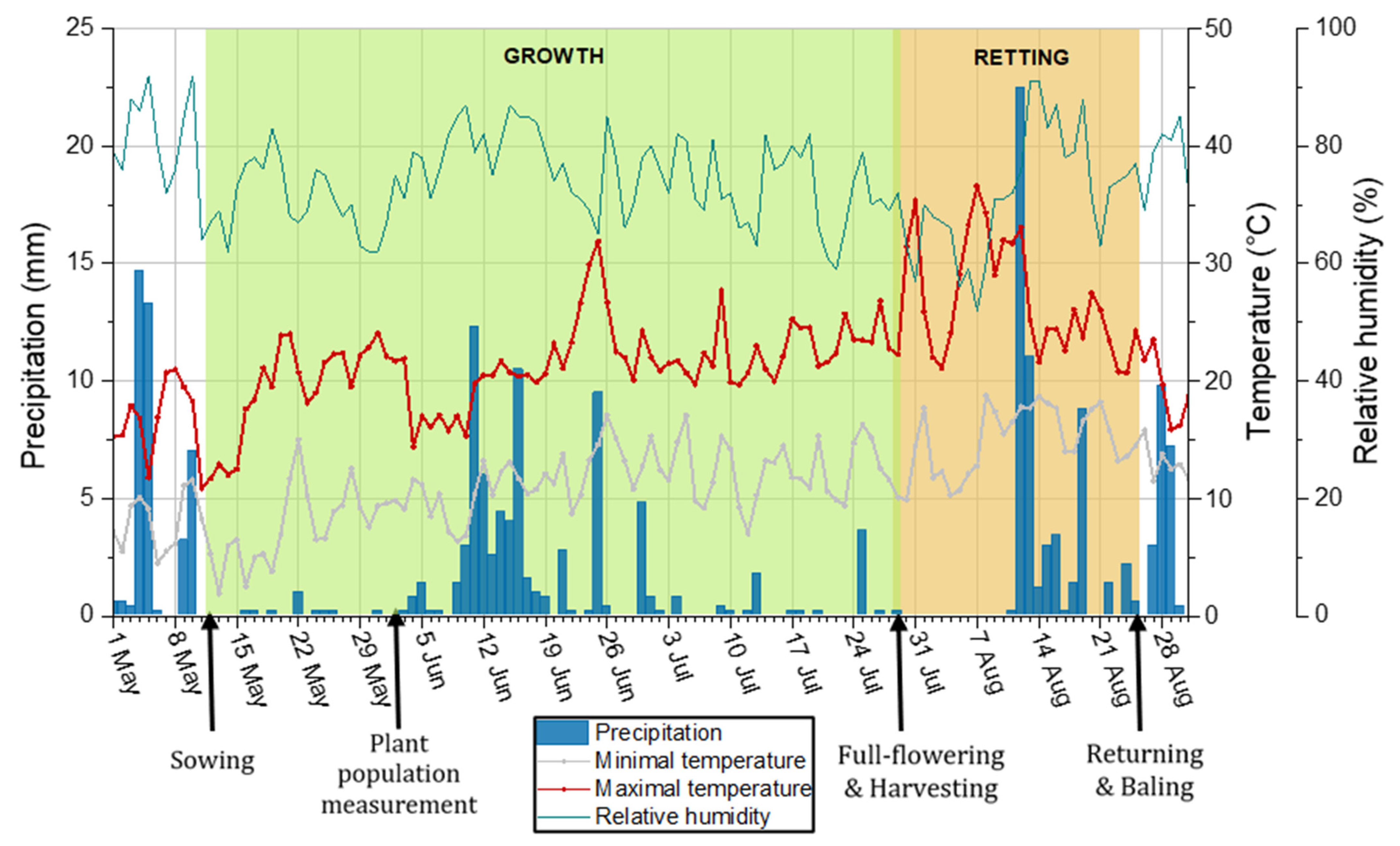

2.1. Variety Tested, Field Trial Set-Up, Microclimatic Condition

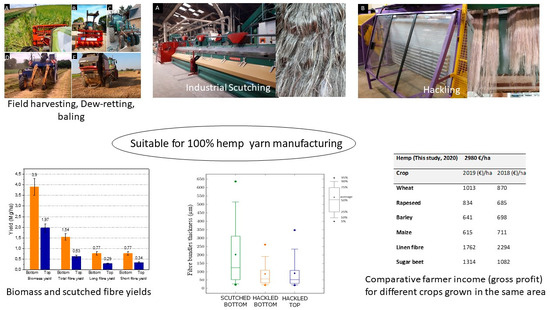

2.2. Harvest, Retting and Storage

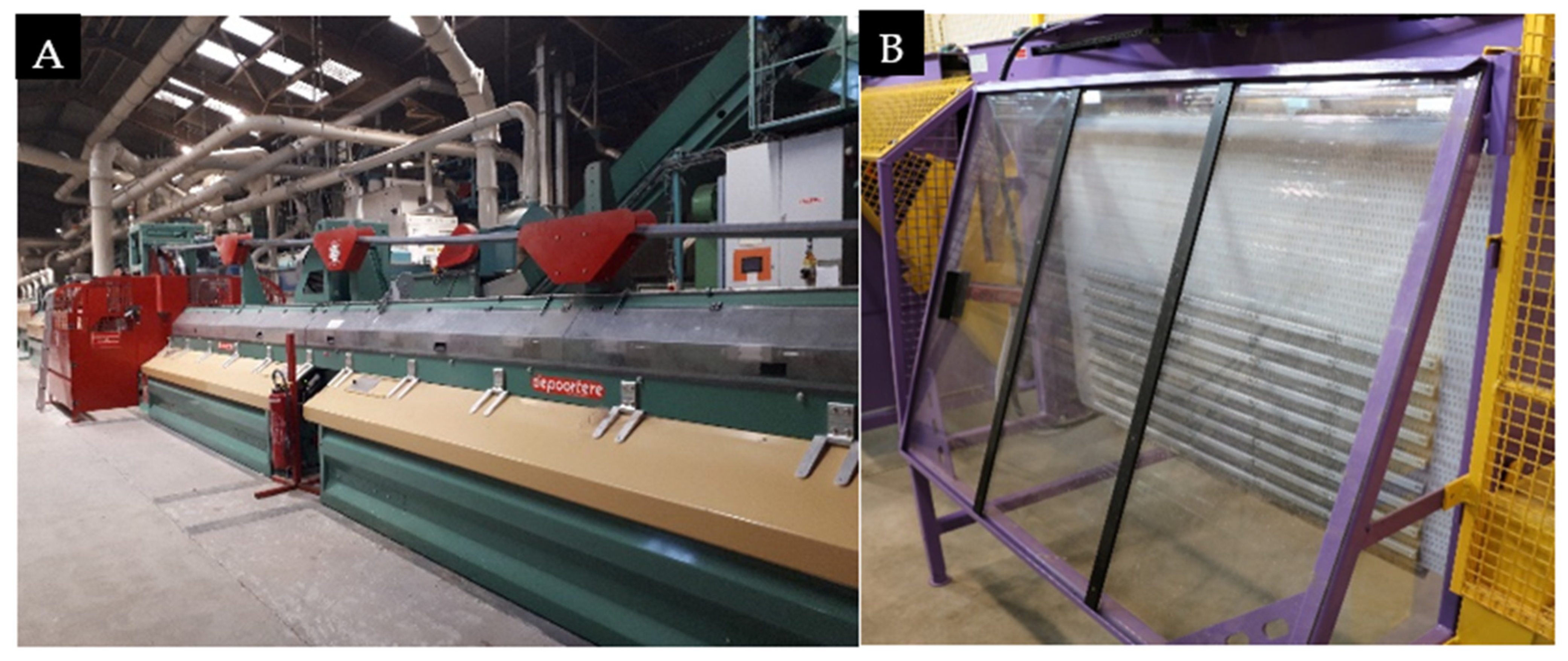

2.3. Fiber Processing, Scutching, and Hackling

2.4. Fiber Diameter

2.5. Single Fiber Tensile Test

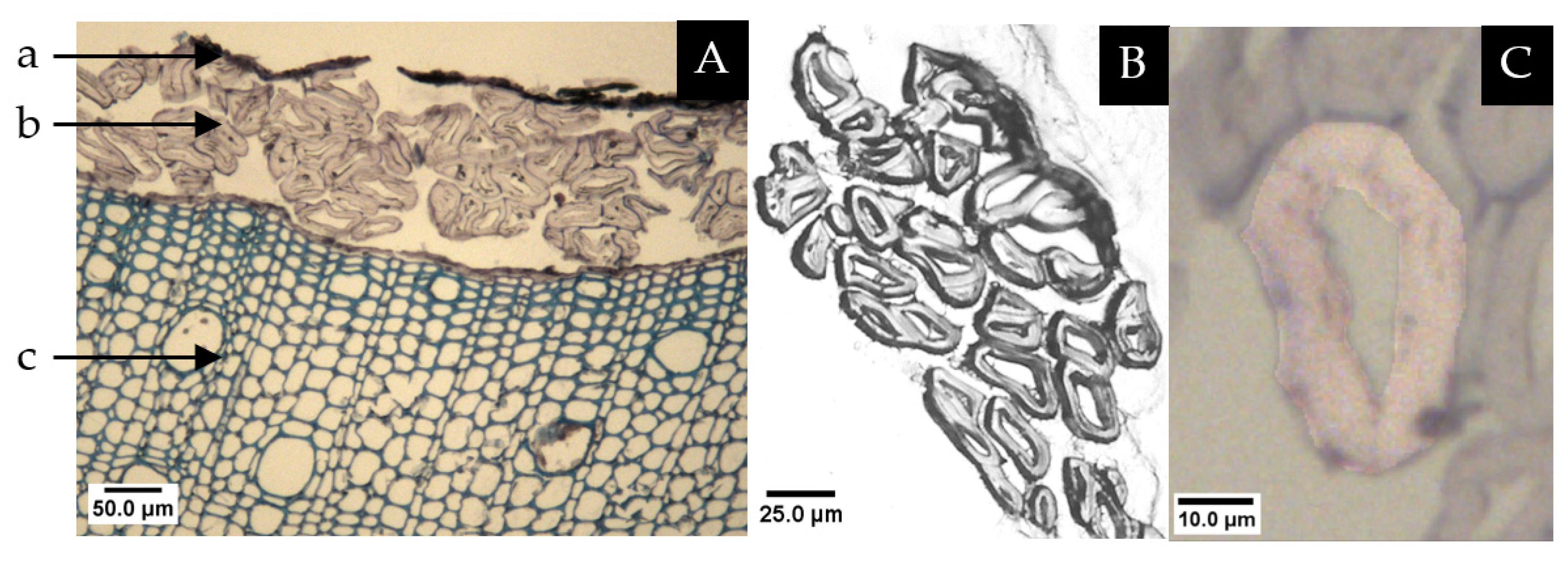

2.6. Histological Analysis

3. Results and Discussion

3.1. Meteorological Data

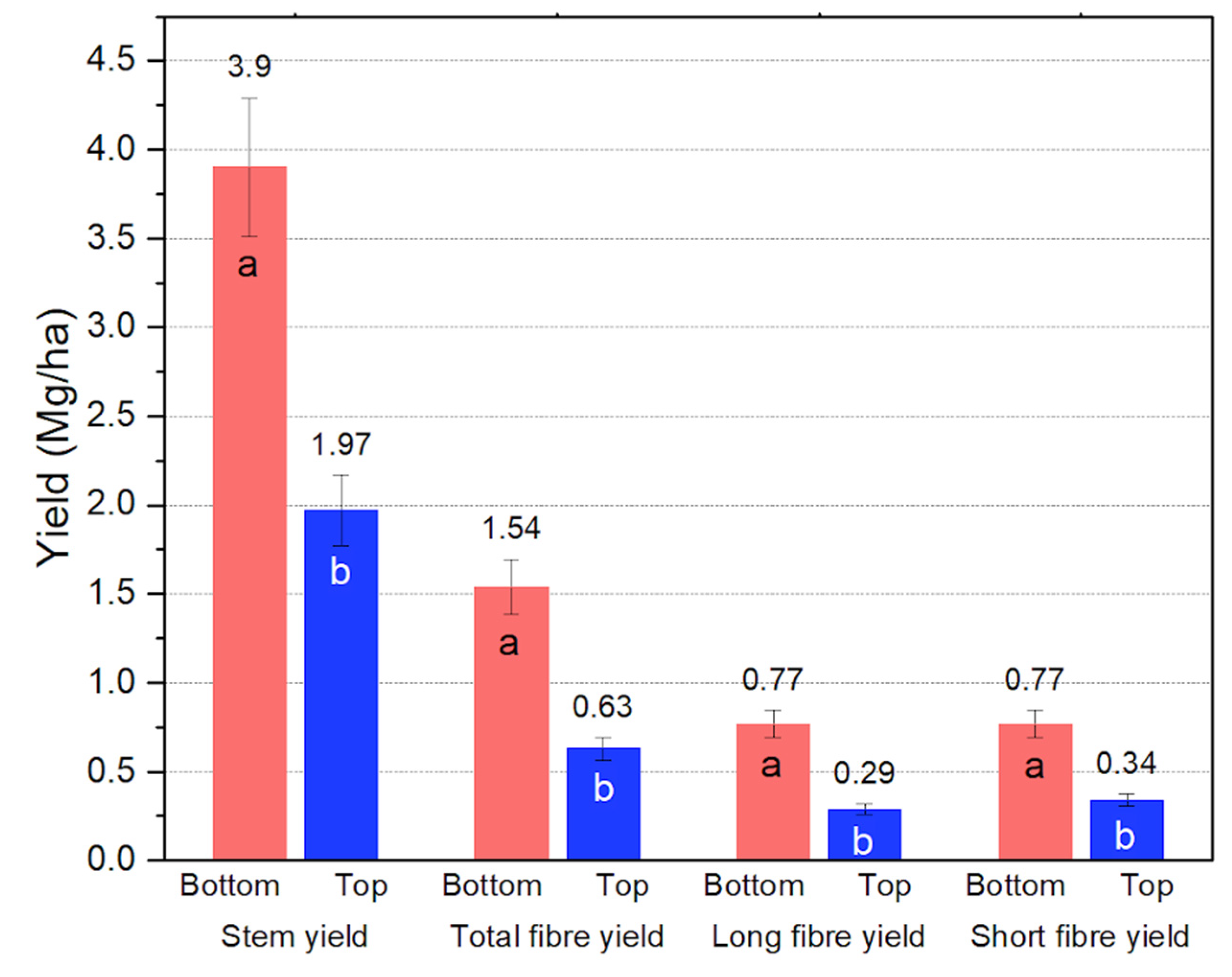

3.2. Hemp Stem Biomass

3.2.1. Hemp Stem Yield

3.2.2. Fiber Extraction: Industrial Scutching

3.3. Hemp Fiber Characterization

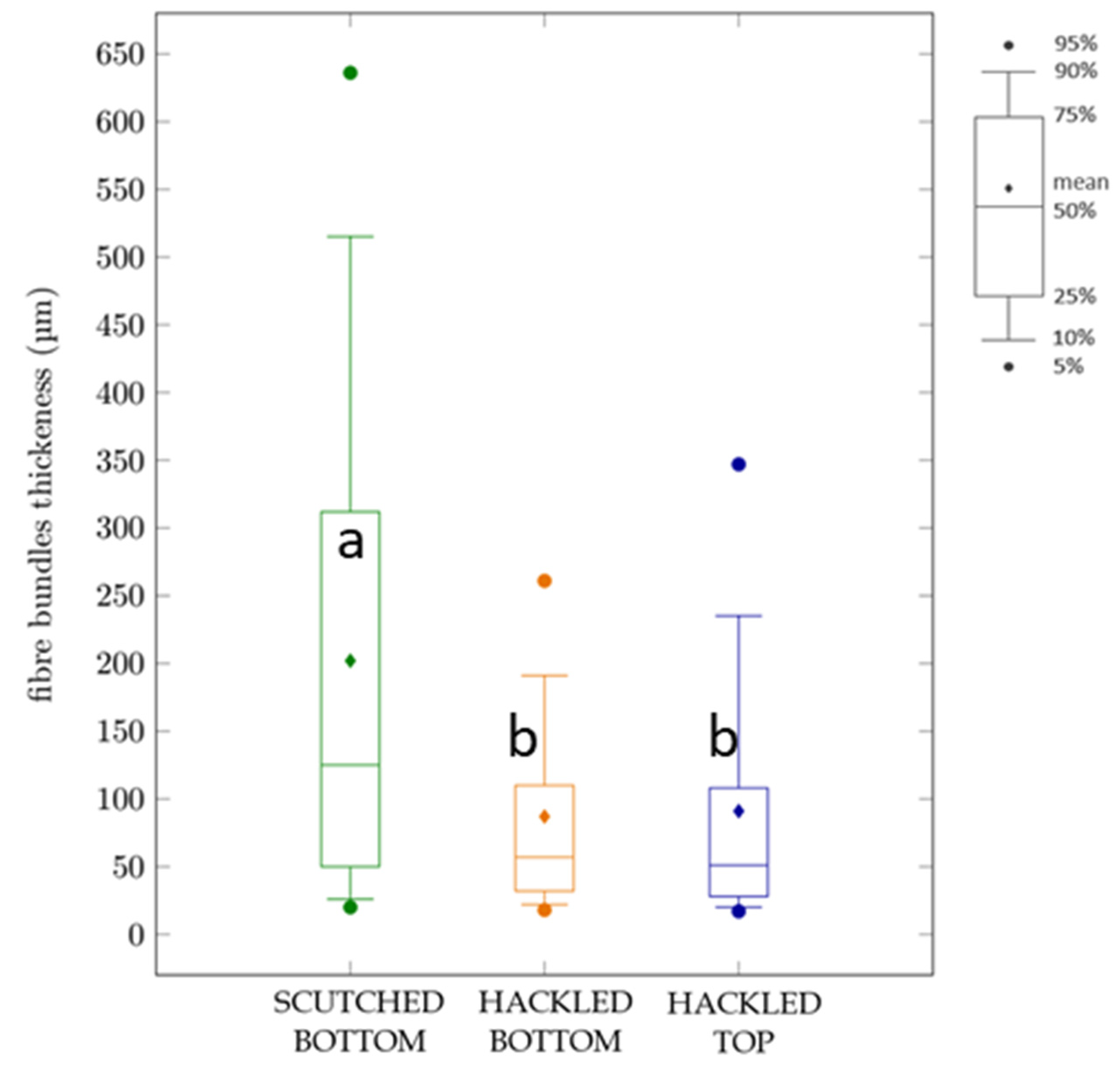

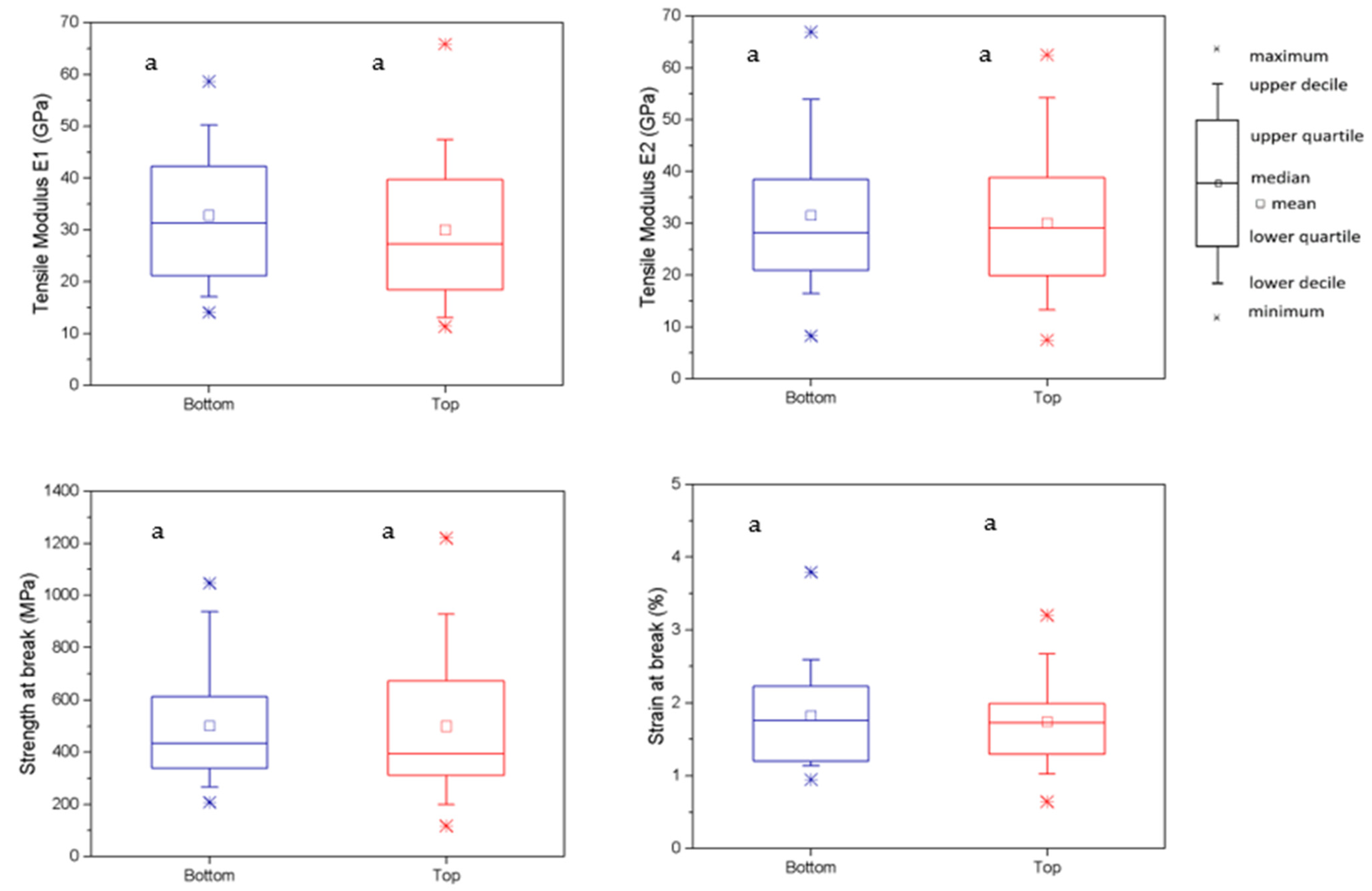

Hemp Fiber Level of Division: Fiber Thickness

3.4. Comparative Valorization of the Hemp Crop

4. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Small, E. Evolution and Classification of Cannabis sativa (Marijuana, Hemp) in Relation to Human Utilization. Bot. Rev. 2015, 81, 189–294. [Google Scholar] [CrossRef]

- Fike, J. Industrial Hemp: Renewed Opportunities for an Ancient Crop. Crit. Rev. Plant Sci. 2016, 35, 406–424. [Google Scholar] [CrossRef]

- Jarrige, F. Quand les eaux de rouissage débordaient dans la cité. In Débordements Industriels: Environnement, Territoire et Conflit (XVIIIe-XXIe Siècle); Letté, M., Le Roux, T., Eds.; Presses Universitaires de Rennes: Rennes, France, 2013; pp. 137–153. Available online: http://books.openedition.org/pur/111302 (accessed on 9 March 2021).

- van der Werf, H.M.; Turunen, L. The environmental impacts of the production of hemp and flax textile yarn. Ind. Crop. Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- European Environment Agency. Microplastics from Textiles: Towards A Circular Economy for Textiles in Europe; Publications Office of the European Union: Luxembourg, 2022; Available online: https://data.europa.eu/doi/10.2800/863646 (accessed on 15 June 2022).

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. 2017. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/A-New-Textiles-Economy_Full-Report_Updated_1-12-17.pdf (accessed on 9 March 2021).

- Linger, P.; Müssig, J.; Fischer, H.; Kobert, J. Industrial hemp (Cannabis sativa L.) growing on heavy metal contaminated soil: Fibre quality and phytoremediation potential. Ind. Crops Prod. 2002, 16, 33–42. [Google Scholar] [CrossRef]

- EIHA. Hemp Cultivation & Production in Europe in 2018. Available online: https://eiha.org/wp-content/uploads/2020/10/2018-Hemp-agri-report.pdf (accessed on 15 June 2022).

- InterChanvre. Le Chanvre Une Culture «Verte» Incroyable. Available online: https://www.interchanvre.org/documents/1.Interchanvre/202005_PPT_Le%20Chanvre.pdf (accessed on 15 June 2022).

- Amaducci, S.; Zatta, A.; Pelatti, F.; Venturi, G. Influence of agronomic factors on yield and quality of hemp (Cannabis sativa L.) fibre and implication for an innovative production system. Field Crop. Res. 2008, 107, 161–169. [Google Scholar] [CrossRef]

- Westerhuis, W. Hemp for Textiles: Plant Size Matters. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crop. Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Shen, C.; Liang, S.; Liang, J.; Liu, H.; Huang, J.; Tian, K.; Zhang, B.; Yin, G. Status of hemp field production mechanization and research thoughts for China’s hemp production areas. Int. Agric. Eng. J. 2020, 29, 194–204. [Google Scholar]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers. Ind. Crop. Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Amaducci, S.; Pelatti, F.; Bonatti, P.M. Fibre Development in Hemp (Cannabis sativa L.) as Affected by Agrotechnique. J. Ind. Hemp. 2005, 10, 31–48. [Google Scholar] [CrossRef]

- Müssig, J.; Amaducci, S. Scanner based image analysis to characterise the influence of agronomic factors on hemp (Cannabis sativa L.) fibre width. Ind. Crop. Prod. 2018, 113, 28–37. [Google Scholar] [CrossRef]

- Abot, A. Caractérisation des Fibres Longues de Chanvre (Cannabis sativa) en Vue de Leurs Utilisations dans des Matériaux Composites. Ph.D. Thesis, University of Poitiers, Poitiers, France, 2010. [Google Scholar]

- Hernandez, A.; Westerhuis, W.; Van Dam, J.E.G. Microscopic Study on Hemp Bast Fibre Formation. J. Nat. Fibers 2007, 3, 1–12. [Google Scholar] [CrossRef]

- Westerhuis, W.; van Delden, S.; van Dam, J.; Marinho, J.P.; Struik, P.; Stomph, T. Plant weight determines secondary fibre development in fibre hemp (Cannabis sativa L.). Ind. Crop. Prod. 2019, 139, 111493. [Google Scholar] [CrossRef]

- Jankauskienė, Z.; Butkutė, B.; Gruzdevienė, E.; Cesevičienė, J.; Fernando, A.L. Chemical composition and physical properties of dew- and water-retted hemp fibers. Ind. Crop. Prod. 2015, 75, 206–211. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.-C.; Malhautier, L. A Comparative Study of the Effect of Field Retting Time on the Properties of Hemp Fibres Harvested at Different Growth Stages. Fibers 2019, 7, 108. [Google Scholar] [CrossRef]

- Chambre d’Agriculture Normandie. Le Lin en Normandie 2019. Available online: https://normandie.chambres-agriculture.fr/ (accessed on 7 February 2022).

- Statistiques FAO. Production, Quantité—Lin, Fibres et Etoupe. February 2022. Available online: https://www.fao.org/faostat/fr/#data/QCL (accessed on 16 July 2022).

- The European Confederation of Flax and Hemp (CELC). Baromètre du Lin 2021. Available online: http://news.europeanflax.com/wp-content/uploads/2021/06/DP_WEB_FR.pdf (accessed on 16 July 2022).

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Cromack. Agronomy of fibre hemp (Cannabis sativa L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Amaducci, S.; Errani, M.; Venturi, G. Plant Population Effects on Fibre Hemp Morphology and Production. J. Ind. Hemp 2002, 7, 33–60. [Google Scholar] [CrossRef]

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A Review on the Current State of Knowledge of Growing Conditions, Agronomic Soil Health Practices and Utilities of Hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef]

- Réquilé, S.; Mazian, B.; Grégoire, M.; Musio, S.; Gautreau, M.; Nuez, L.; Day, A.; Thiébeau, P.; Philippe, F.; Chabbert, B.; et al. Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites. Ind. Crop. Prod. 2021, 164, 113337. [Google Scholar] [CrossRef]

- Bleuze, L.; Chabbert, B.; Lashermes, G.; Recous, S. Hemp harvest time impacts on the dynamics of microbial colonization and hemp stems degradation during dew retting. Ind. Crop. Prod. 2020, 145, 112122. [Google Scholar] [CrossRef]

- Grégoire, M.; Bar, M.; De Luycker, E.; Musio, S.; Amaducci, S.; Gabrion, X.; Placet, V.; Ouagne, P. Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind. Crop. Prod. 2021, 172, 114045. [Google Scholar] [CrossRef]

- Garat, W.; Corn, S.; Le Moigne, N.; Beaugrand, J.; Bergeret, A. Analysis of the morphometric variations in natural fibres by automated laser scanning: Towards an efficient and reliable assessment of the cross-sectional area. Compos. Part A Appl. Sci. Manuf. 2018, 108, 114–123. [Google Scholar] [CrossRef]

- Sankari, H.S. Comparison of bast fibre yield and mechanical fibre properties of hemp (Cannabis sativa L.) cultivars. Ind. Crops Prod. 2000, 11, 73–84. [Google Scholar] [CrossRef]

- Adamovics, A.; Ivanovs, S.; Stramkale, V. Investigations about the impact of norms of the fertilisers and cultivars upon the crop capacity biomass of industrial hemp. Agron. Res. 2016, 14, 641–649. [Google Scholar]

- Musio, S.; Müssig, J.; Amaducci, S. Optimizing hemp fiber production for high performance composite applications. Front. Plant Sci. 2018, 9, 1702. [Google Scholar] [CrossRef] [PubMed]

- Mediavilla, V.; Leupin, M.; Keller, A. Influence of the growth stage of industrial hemp on the yield formation in relation to certain fibre quality traits. Ind. Crop. Prod. 2001, 13, 49–56. [Google Scholar] [CrossRef]

- Placet, V.; Cissé, O.; Boubakar, M.L. Nonlinear tensile behaviour of elementary hemp fibres. Part I: Investigation of the possible origins using repeated progressive loading with in situ microscopic observations. Compos. Part A Appl. Sci. Manuf. 2014, 56, 319–327. [Google Scholar] [CrossRef]

- Duval, A.; Bourmaud, A.; Augier, L.; Baley, C. Influence of the sampling area of the stem on the mechanical properties of hemp fibers. Mater. Lett. 2011, 65, 797–800. [Google Scholar] [CrossRef]

- Marrot, L.; Lefeuvre, A.; Pontoire, B.; Bourmaud, A.; Baley, C. Analysis of the hemp fiber mechanical properties and their scattering (Fedora 17). Ind. Crop. Prod. 2013, 51, 317–327. [Google Scholar] [CrossRef]

- Placet, V.; Trivaudey, F.; Cisse, O.; Gucheret-Retel, V.; Boubakar, M.L. Diameter dependence of the apparent tensile modulus of hemp fibres: A morphological, structural or ultrastructural effect? Compos. Part A Appl. Sci. Manuf. 2012, 43, 275–287. [Google Scholar] [CrossRef]

- Placet, V.; Day, A.; Beaugrand, J. The influence of unintended field retting on the physicochemical and mechanical properties of industrial hemp bast fibres. J. Mater. Sci. 2017, 52, 5759–5777. [Google Scholar] [CrossRef]

- Richely, E.; Durand, S.; Melelli, A.; Kao, A.; Magueresse, A.; Dhakal, H.; Gorshkova, T.; Callebert, F.; Bourmaud, A.; Beaugrand, J.; et al. Novel Insight into the Intricate Shape of Flax Fibre Lumen. Fibers 2021, 9, 24. [Google Scholar] [CrossRef]

- Müssig, J.; Amaducci, S.; Bourmaud, A.; Beaugrand, J.; Shah, D.U. Transdisciplinary top-down review of hemp fibre composites: From an advanced product design to crop variety selection. Compos. Part C Open Access 2020, 2, 100010. [Google Scholar] [CrossRef]

- Chernova, T.; Mikshina, P.; Salnikov, V.; Ibragimova, N.; Sautkina, O.; Gorshkova, T. Development of distinct cell wall layers both in primary and secondary phloem fibers of hemp (Cannabis sativa L.). Ind. Crop. Prod. 2018, 117, 97–109. [Google Scholar] [CrossRef]

- CERFRANCE. Etude Annuelle Cultures Calvados Récolte 2019. Available online: www.cerfrance.fr. (accessed on 7 February 2022).

| Authors | Hemp Variety | Testing Conditions | Tensile Modulus E (GPa) | Strength at Break (MPa) | Strain at Break (%) | |

|---|---|---|---|---|---|---|

| A | Vandepitte et al., 2020 [12] | USO-31 | fibers bundle | - | 597 | - |

| Liu et al., 2015 [14] | USO-31 | fibers bundle | 34.9 ± 4.4 | 954 ± 162 | 6.2 ± 1.2 | |

| Sankari, 2000 [32] | USO-31 | fibers bundle | - | 860 ± 670 | 4.3 ± 4.4 | |

| B | Marrot et al., 2013 [38] | Fedora 17 | single fiber | 35.5 ± 17.3 | 889 ± 472 | 2.6 ± 2.2 |

| Placet et al., 2012 [39] | - | single fiber | 24.7 ± 11.4 | 636 ± 253 | 2.1 ± 0.7 | |

| Grégoire et al., 2021 [30] | Futura 75 | single fiber | 49 ± 19 | 875 ± 367 | - | |

| This study | USO 31 | single fiber | 32.2 ± 13.5 | 500 ± 286 | 1.7 ± 0.6 |

| Crop | 2019 (€) | 2018 (€) |

|---|---|---|

| Wheat | 1013 | 870 |

| Rapeseed | 834 | 685 |

| Barley | 641 | 698 |

| Maize | 615 | 711 |

| Linen fiber | 1762 | 2294 |

| Sugar beet | 1314 | 1082 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinsard, L.; Revol, N.; Pomikal, H.; De Luycker, E.; Ouagne, P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers 2023, 11, 38. https://doi.org/10.3390/fib11050038

Pinsard L, Revol N, Pomikal H, De Luycker E, Ouagne P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers. 2023; 11(5):38. https://doi.org/10.3390/fib11050038

Chicago/Turabian StylePinsard, Lola, Nathalie Revol, Henri Pomikal, Emmanuel De Luycker, and Pierre Ouagne. 2023. "Production of Long Hemp Fibers Using the Flax Value Chain" Fibers 11, no. 5: 38. https://doi.org/10.3390/fib11050038

APA StylePinsard, L., Revol, N., Pomikal, H., De Luycker, E., & Ouagne, P. (2023). Production of Long Hemp Fibers Using the Flax Value Chain. Fibers, 11(5), 38. https://doi.org/10.3390/fib11050038