Abstract

Fiber-reinforced polymers (FRPs) are increasingly recognized in sustainable materials research due to their potential environmental advantages. This study presents a focused bibliometric review of the sustainability research on FRPs. An initial search of the Web of Science (WOS) database identified 803 documents, which were refined to 749 relevant articles, reviews, and proceedings. A co-authorship analysis highlights the significant contributions of the USA and India, with European countries forming regional collaborations. The research output has steadily increased since 2011, peaking in 2022 and 2023. The multidisciplinary nature of the research spans materials science, engineering, and environmental sciences, with journals such as *Polymers*, *Sustainability*, and the *Journal of Cleaner Production* emphasizing sustainability themes. This analysis covers key aspects such as keyword co-occurrence, overlay visualizations, co-authorship networks, and the distribution of publications by year, research area, and journal. The findings underscore the evolving research landscape of sustainable FRPs and highlight the ongoing need for life cycle assessments and interdisciplinary collaboration.

1. Introduction

Escalating environmental concerns and a push toward sustainability have driven significant research and innovation in the field of materials science. Among various advanced materials, fiber-reinforced polymers (FRPs) have garnered considerable attention due to their remarkable mechanical properties and versatility [1,2,3,4,5,6,7]. Traditionally, FRPs have been reinforced with synthetic fibers such as glass or carbon, which, while effective, pose substantial environmental challenges, including non-biodegradability and high energy consumption during production [8,9,10,11,12,13,14,15,16]. Sustainable FRPs, particularly those reinforced with natural fibers, offer a promising alternative to conventional materials due to their environmentally friendly characteristics and superior mechanical properties [17,18].

The utilization of fiber-reinforced polymer (FRP) composites in the construction of new structures and the rehabilitation of existing ones has surged significantly in recent decades [19,20]. FRP composites offer several advantages, including lightweight properties, non-corrosiveness, and high specific strength and stiffness [20]. They are also relatively easy to construct and can be customized to meet specific performance requirements [21]. Typically, FRP composites for structural applications are composed of a polymer matrix—such as epoxy, vinylester, or polyester—reinforced with various grades of carbon, glass, and/or aramid fibers [1,22,23]. These materials collectively contribute to their widespread adoption and versatile application in modern engineering projects.

The advantages of fiber-reinforced polymer (FRP) composites are rooted in their exceptional physical properties and their potential to create structural systems with extended service lives compared to traditional materials. The lightweight nature of FRP composites can significantly reduce construction costs and shorten construction times, thereby lowering environmental impacts [19]. Moreover, their high strength and stiffness enable the use of less material to achieve performance levels equivalent to or better than those of conventional materials, which in turn minimizes resource consumption and waste production [24,25]. The true promise of FRP composites lies in their potential to drastically extend the service life of existing structures and facilitate the development of new structures with superior resistance to aging, weathering, and degradation in harsh environments [11,20,26,27]. These benefits underscore the critical role of FRP composites in fostering the development of more durable and sustainable built environments [28]. By leveraging the unique properties of FRPs, it is possible to achieve enhanced durability and performance, ultimately contributing to the creation of resilient and long-lasting infrastructure [21]. By factoring in these benefits, the use of FRP composites can be assessed more comprehensively within the framework of sustainable construction practices [25].

Fiber-reinforced polymer (FRP) composites, while offering numerous advantages in terms of light weight, high strength, and durability, present challenges in terms of recyclability [29]. The sustainability of FRP composites is not only about their performance and lifespan but also about their end-of-life disposal and potential for recycling [30,31,32,33,34].

Traditionally, the recycling of FRP composites has been limited due to the difficulty in separating the fibers from the polymer matrix. Most FRPs are thermosetting plastics, which cannot be remelted and reshaped like thermoplastics, making their recycling process more complex and less economically viable [35]. As a result, end-of-life FRP composites often end up in landfills, posing environmental concerns.

However, advancements in recycling technologies and processes are gradually improving the recyclability of FRP composites. Mechanical recycling methods, such as grinding and milling, can be used to process FRP waste into reusable filler materials, though this often leads to a reduction in material properties [31]. More innovative approaches, like pyrolysis and solvolysis, are being developed to recover fibers from the polymer matrix with minimal degradation of their properties [36]. These methods involve breaking down the polymer matrix through chemical reactions or thermal treatments, allowing the recovery of high-quality fibers that can be reused in new composite materials.

Furthermore, the development of bio-based and biodegradable polymers for FRP composites offers a promising direction for enhancing their sustainability [37,38]. These materials can be designed to degrade under specific environmental conditions, reducing the long-term environmental impact. Additionally, efforts are being made to improve the design for disassembly, making it easier to separate and recycle the components of FRP composites at the end of their service life [39].

Despite these advancements, there is still a significant need for research and development to make FRP recycling more practical and cost-effective. The integration of sustainable practices throughout the lifecycle of FRP composites—from material selection and manufacturing to end-of-life disposal—will be essential in maximizing their environmental benefits and minimizing their impact.

Bibliometric mapping and analysis serve as powerful tools for understanding the evolution, trends, and key players in this rapidly growing field. By examining a vast array of scientific publications, patents, and citations, bibliometric methods can identify influential research articles, prolific authors, leading institutions, and emerging areas of interest. This information is crucial for researchers, policymakers, and industry stakeholders to navigate the landscape of sustainable FRPs effectively.

Bibliometric analysis has been applied in various studies to explore the research trends and developments in FRPs and related fields. For instance, Ferreira et al. [40] conducted a bibliometric analysis of research on natural fiber composites, revealing increasing publications in this field. Leading countries include China (16), USA (14), and Brazil (11). Key terms such as ‘natural fiber’ (61 occurrences), ‘mechanical properties’ (44 occurrences), and ‘composites’ (31 occurrences) dominate the research. Similarly, Baarimah et al. [41] performed a bibliometric analysis of existing literature on kenaf-fiber-reinforced concrete (KFRC) over the past decade, from 2013 to September 2022. The analysis reveals emerging themes such as “Hybrid Composites”, “Impact Strength”, “Water Absorption”, “Scanning Electron Microscopy”, “Polypropylenes”, and “Polymer Composite”, highlighting areas of growing academic interest and potential future research opportunities. Keyword frequency analysis identified three major research domains associated with kenaf fibers in concrete: “Mechanical Properties”, “Fiber Reinforced Plastics”, and “Tensile Strength”.

Related to carbon-reinforced plastics (CRP), the bibliometric analysis [42] revealed that key journals such as Mechanics of Composite Materials and the Journal of Materials Processing Technology serve as prominent platforms for disseminating research within this domain. Notably, Applied Mechanics Reviews emerges as the leading journal in terms of average citation, indicating its widespread influence in the academic community. Geographically, China, Japan, Portugal, and the United Kingdom stand out as the most active countries in CRP research. Leading institutions such as the University of Tokyo (Japan), the Russian Academy of Sciences (Russia), and the Ministry of Education (China) have played pivotal roles in advancing research efforts in this field.

The systematic literature review [43] was conducted on the development of manufacturing, enhancement, and sustainability of fiber-reinforced polymer composites from 1998 to 2020. Utilizing the Web of Science (WOS) database, relevant articles were gathered based on specific keywords related to the aforementioned themes. A total of 151 articles were selected and subjected to citation network analysis to identify key clusters and trends. The analysis revealed seven principal clusters, with emphasis on topics such as fabrication methods, properties of multiscale composites, impact response, natural fibers, rapid curing, nanofillers, and hydrothermal aging.

This study aims to conduct a simplified bibliometric analysis of sustainable FRPs, with a focus on those reinforced with natural fibers. By analyzing articles published from 2000 to 2024 in the Web of Science (WOS) database, this study seeks to uncover significant trends and clusters in the research, thereby providing valuable insights for future research and development efforts.

2. Methodology

A bibliometric study is an essential tool for obtaining a comprehensive overview of various knowledge domains. By employing its two main approaches—performance analysis and mapping—it can thoroughly examine scientific output. Performance analysis involves a quantitative evaluation of publications, assessing data like authors, affiliations, and keywords. Conversely, mapping concentrates on the interconnections within these data, structuring them into networks to reveal relationships and trends within the scientific community [44]. Among the data from publications, an in-depth analysis of keywords is particularly important when the goal is to verify the current scenario and its evolution, providing a comprehensive overview of the field.

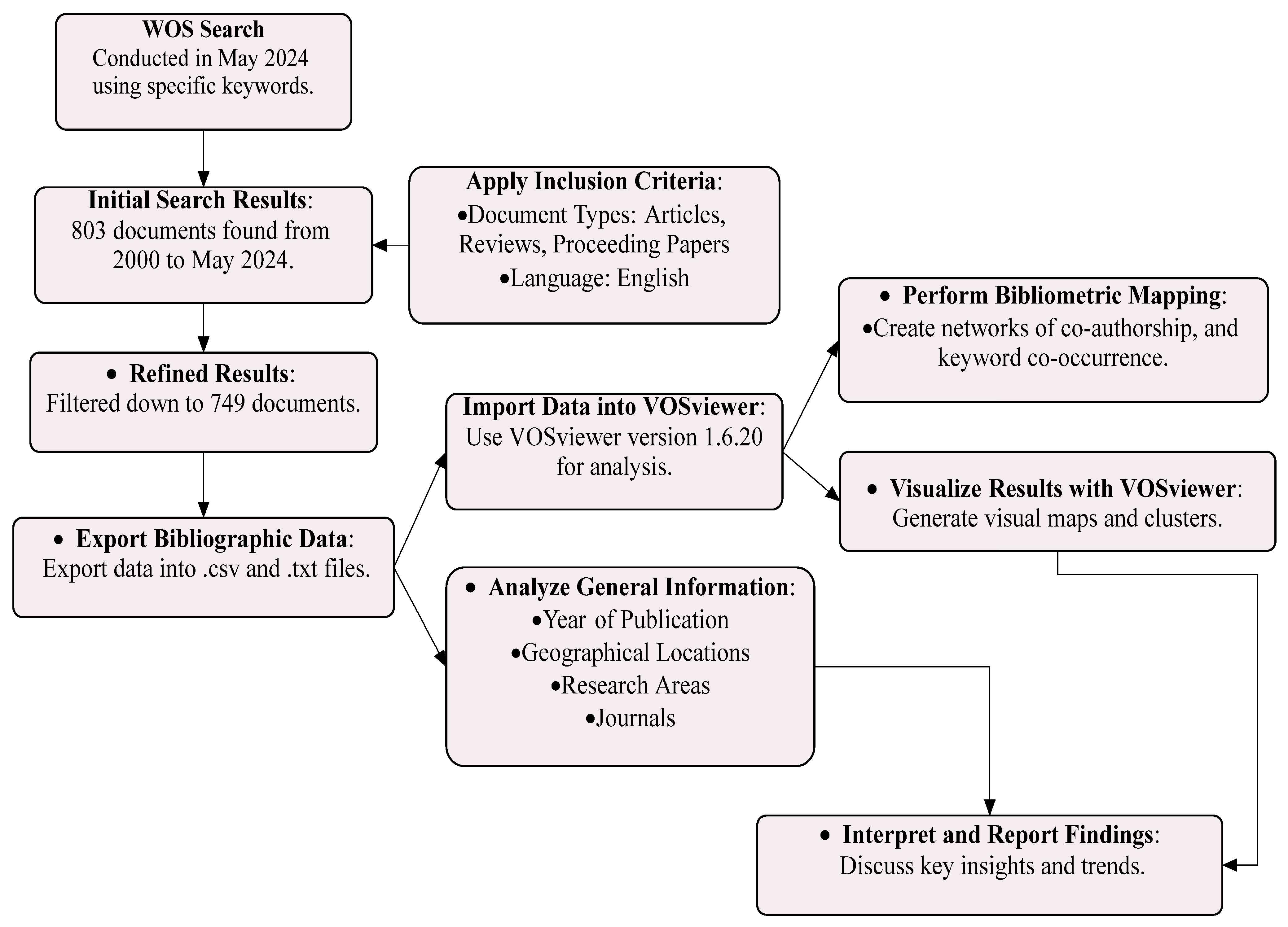

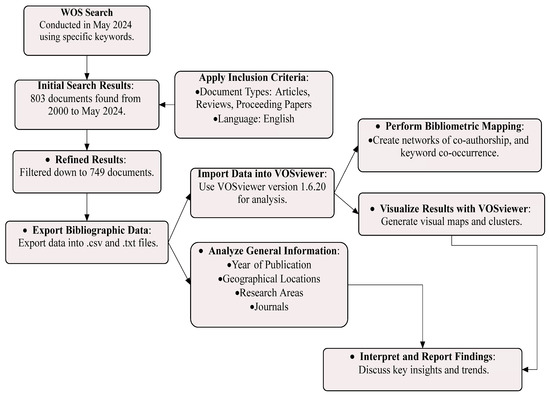

A WOS search was conducted on May 2024, using the keywords (sustainability) AND (FRP OR Fiber Reinforced Polymers). From WOS, the bibliographic data were exported into .csv and .txt files that were used for bibliometric mapping and analysis with the VOSviewer version 1.6.20 software program. The methodology flowchart is presented in Figure 1.

Figure 1.

Flowchart methodology.

The initial Web of Science (WOS) search yielded 803 documents from 2000 up to the search date, as seen Table 1. To refine the analysis, two inclusion criteria were applied: (1) type of document, selecting articles, reviews, and proceedings papers, and (2) language, focusing on documents written in English. After applying these criteria, the total number of documents was reduced to 749, comprising 528 articles, 136 reviews and 85 proceedings papers, as depicted in Figure 1.

Table 1.

Types of identified documents.

To ensure a more comprehensive coverage, the Scopus database was also used for analysis. Using the same words for searching, 1098 sources were found in the Scopus database.

3. Results and Discussion

3.1. VOSViewer Analysis

3.1.1. Keywords Analysis

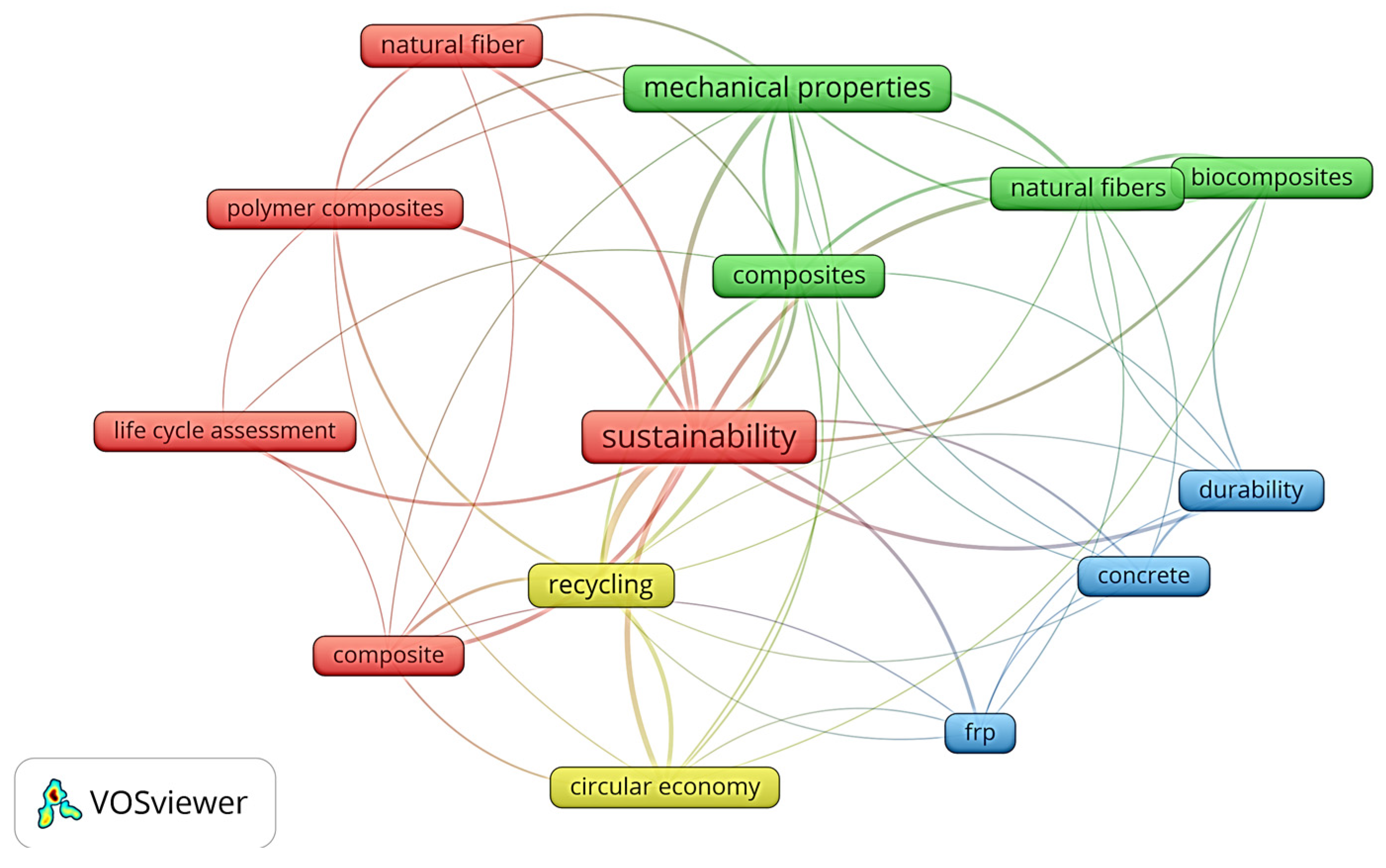

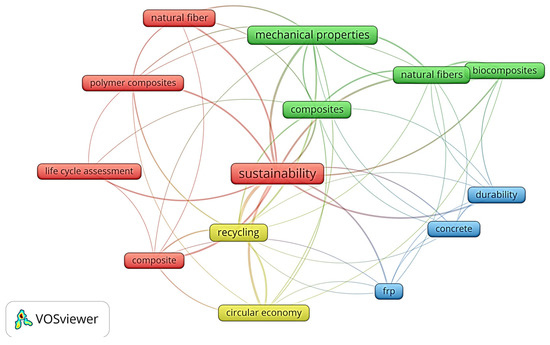

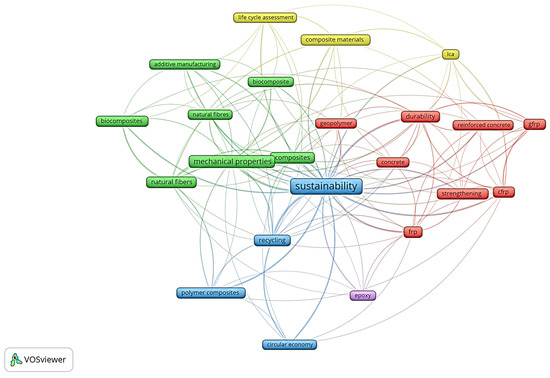

The visualization from Figure 2 shows various key terms and their relationships within the context of research on the sustainability of fiber-reinforced polymers (FRPs). The VOSviewer software utilized a clustering algorithm to group keywords with strong co-occurrence links, displaying them in various colors to denote thematic clusters. The layout was automatically generated by VOSviewer, which spatially arranges nodes based on the strength of their connections. The proximity and links between nodes indicate how closely related certain concepts are within the dataset. It is observed that the keyword ‘Sustainability’ is positioned centrally in the network, indicating it is a core focus in the research on fiber-reinforced polymers. Many other terms are connected to it, suggesting its integral role in this field. Four clusters were identified:

Figure 2.

Co-occurrence of the keywords, with the minimum number of occurrences of 15 (using WOS database).

- ✓

- Red Cluster: Polymer Composites and Related Topics. Polymer composites are essential in the study of sustainable materials. This term is closely linked to other terms such as ‘natural fiber’ and ‘life cycle assessment’, indicating that these aspects are often studied together. The term ‘life cycle assessment’ reflects the importance of evaluating the environmental impact of polymer composites from production to disposal.

- ✓

- Green Cluster: Mechanical Properties and Composites. The term ‘mechanical properties’ is significant, showing that the mechanical performance of sustainable FRPs is a major area of research.

- ✓

- Blue Cluster: Concrete and Durability show that the durability of sustainable materials, especially when used in construction (e.g., concrete), is essential. The term ‘concrete’ is linked with sustainability and durability, indicating research interest in sustainable concrete composites.

- ✓

- Yellow Cluster: Recycling and Circular Economy. ‘Recycling’ is a key aspect of sustainability, emphasizing the importance of reusing materials to reduce waste. The term ‘circular economy’ indicates a focus on sustainable practices that promote the reuse and recycling of materials, aligning with broader environmental goals.

The interconnections between terms such as ‘natural fibers’, ‘biocomposites’, ‘composite’, and ‘sustainability’ highlight a multidisciplinary approach. Researchers are exploring how natural and bio-based materials can enhance the sustainability of polymer composites. Terms like ‘recycling’ and ‘circular economy’ connected to ‘sustainability’ indicate a significant interest in the lifecycle management and environmental impact of these materials. The presence of terms like ‘frp’ (fiber-reinforced polymers) and their connections to ‘concrete’ and ‘durability’ suggest that sustainable FRPs are considered for enhancing the durability and sustainability of construction materials.

Table 2 provides detailed quantitative data for each keyword presented in Figure 2, showcasing both the occurrences and total link strength of these terms, to illustrate the significance and interconnectedness of specific themes in the study. Also, the percentage contribution of each keyword to the overall discussion was calculated, based on the total number of occurrences (sum of all keyword occurrences = 569), showing not just how often a theme is mentioned but also how integral it is to the overall study.

Table 2.

Keyword occurrences and total link strength.

‘Sustainability’ is the most frequently occurring keyword, with 195 occurrences and the highest total link strength of 125. This indicates a strong emphasis on sustainability within the context of fiber-reinforced polymers (FRPs). ‘Recycling’ is another prominent keyword, with 44 occurrences and a total link strength of 62, suggesting a significant focus on recycling processes and their relationship to sustainability in the research. ‘Mechanical properties’ (84 occurrences, 47 total link strength) and ‘natural fibers’ (38 occurrences, 36 total link strength) are also frequently discussed topics, indicating their importance in the study and application of FRPs. The relatively low frequency and link strength indicate that ‘life cycle assessment’ is not a primary focus in the current body of research on fiber-reinforced polymers (FRPs). This suggests that fewer studies have examined the environmental impacts of FRPs throughout their entire lifecycle, from raw material extraction through production, use, and disposal. The underrepresentation of ‘life cycle assessment’ in the current literature on FRPs presents a significant opportunity for future research to explore this area. By addressing this gap, researchers can contribute to the development of more sustainable FRP materials and practices, ultimately enhancing the overall sustainability of this field.

Table 3 categorizes research into distinct clusters based on their primary focus, each identified by specific keywords. For each cluster, significant papers are highlighted, along with their respective purposes and findings.

Table 3.

Cluster analysis.

Table 3.

Cluster analysis.

| Cluster | Keyword | Significant Paper | Article Type | Purpose | Findings |

|---|---|---|---|---|---|

| Red | sustainability | [12] | Review |

|

|

| Natural fibers | [45] | Review |

|

| |

| [46] | Review |

|

| ||

| [47] | Review |

|

| ||

| Polymer composites | [48] | Review |

|

| |

| Life cycle assessment (LCA) | [49] | Book section |

|

| |

| Green | Mechanical properties | [50] | Review |

|

|

| [51] | Review |

|

| ||

| Composites | [8] | Review |

|

| |

| Natural Fibers | [52] | Review |

|

| |

| Biocomposites | [53] | Review |

|

| |

| [54] | Review |

|

| ||

| Blue | Durability | [55] | Review |

|

|

| Concrete | [56] | Review |

|

| |

| Yelow | Recycling | [29] | Review |

|

|

| [57] | Review |

|

| ||

| [58] | Research |

|

| ||

| [59] | Review |

|

| ||

| Circular economy | [60] | Review |

|

| |

| [61] | Review |

|

| ||

| [62] | Review |

|

| ||

| [63] | Research (conference paper) |

|

|

Based on Table 3, the analysis of relevant papers for different FRP composite clusters highlights key insights into their sustainability, mechanical properties, applications, and challenges. Sustainability is a central theme, with FRP composites offering benefits like light weight, durability, and corrosion resistance, but challenges such as production waste and disposal issues remain. Recycling and remanufacturing efforts are essential to reducing environmental impact, with ongoing research into advanced recycling technologies. On the other hand, NFPCs are emerging as sustainable alternatives, enhanced by chemical treatments that improve mechanical and thermal properties. These materials are cost-effective and energy-efficient, making them suitable for automotive and construction sectors. Hybrid composites, combining synthetic and natural fibers, also offer improved performance and environmental benefits.

Life cycle assessments of composites emphasize the advantages of green materials made from natural fibers, while mechanical properties, such as anisotropic stiffness, are critical for industries like aerospace and construction. Recycling methods for FRP, including mechanical and chemical approaches, are being refined, with emerging technologies like additive manufacturing showing promise, though challenges in fiber quality persist.

Biocomposites are gaining attention for their eco-friendly nature, with surface modifications enhancing their strength and durability. Durability concerns, particularly regarding moisture and humidity effects, remain a challenge for FRP composites, requiring predictive models for long-term performance.

Overall, these findings collectively illustrate the multifaceted research on composite materials, emphasizing their potential for sustainability, mechanical performance, and innovative recycling practices.

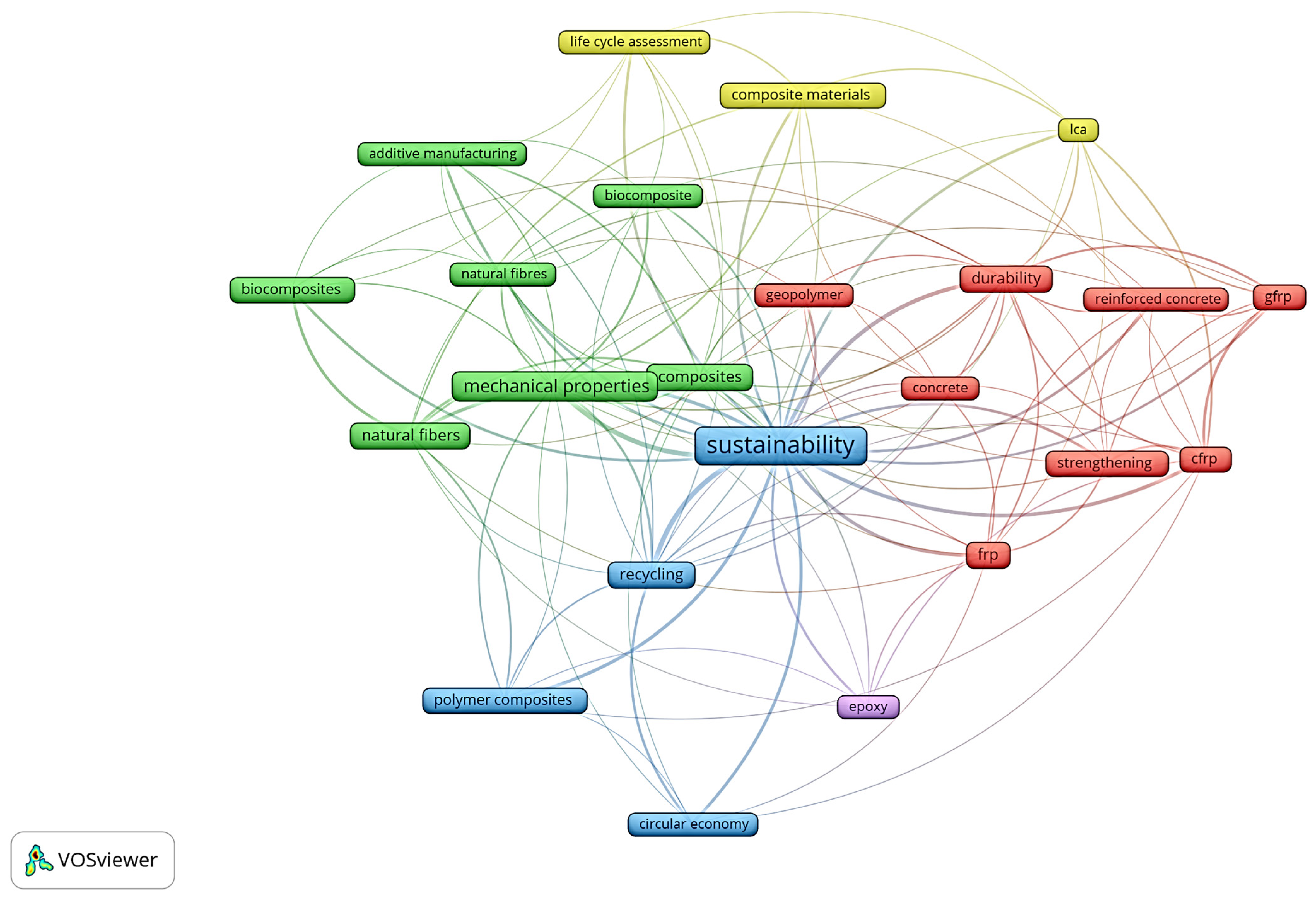

In order to ensure a comprehensive and validated understanding of sustainability research by capturing diverse trends and perspectives across databases, a cluster analysis was performed also for the Scopus database search. The co-occurrence network is presented in Figure 3.

Figure 3.

Co-occurrence of the keywords, with the minimum number of occurrences of 15 (using the Scopus database).

The network visualization from VOSviewer shows clusters related to the central concept of “sustainability”, distinguished by different color groupings. One prominent cluster, represented in green, focuses on materials such as biocomposites and natural fibers. This group includes terms like “biocomposites”, “natural fibers”, “additive manufacturing”, and “mechanical properties”, highlighting research that emphasizes eco-friendly and natural materials, their mechanical properties, and their contribution to sustainability.

Another cluster, shown in yellow, centers around the concept of “life cycle assessment (LCA)” and includes related terms like “composite materials”.

A significant cluster in red covers aspects related to construction and reinforced materials, with terms such as “durability”, “reinforced concrete”, “GFRP”, “CFRP”, and “geopolymer”. This cluster points to sustainability considerations in the context of construction materials, particularly focusing on the strength and durability of reinforced composites.

The blue cluster emphasizes themes like “recycling”, “circular economy”, and “polymer composites”, representing sustainable approaches that incorporate recycling and the broader concept of a circular economy.

The common elements between the Scopus and WOS figures include central themes such as “sustainability”, “mechanical properties”, “natural fibers”, and “recycling”, indicating a shared focus on eco-friendly materials and sustainable practices. Both highlight connections to “biocomposites” and “composites”, suggesting widespread interest in sustainable material development.

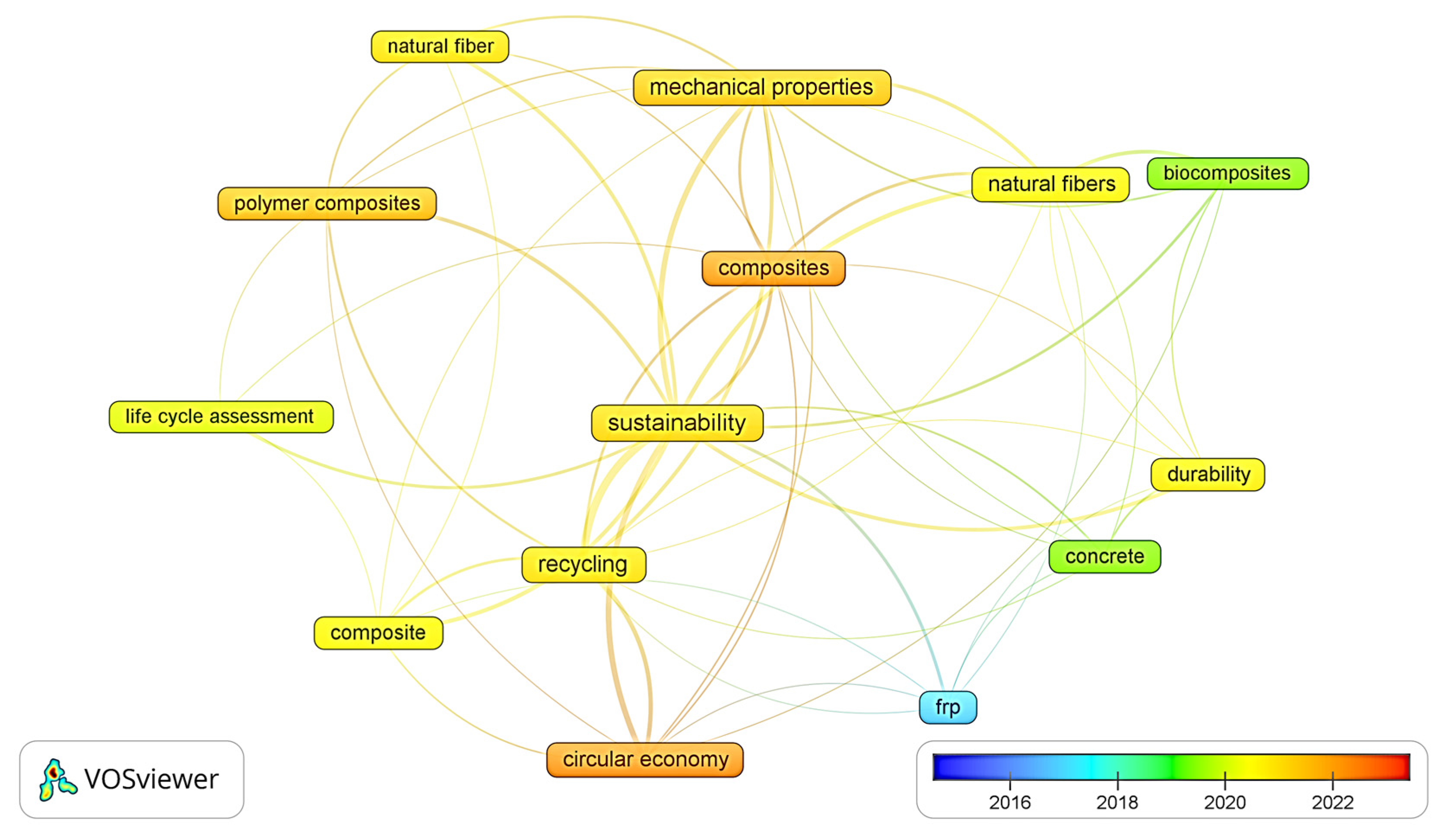

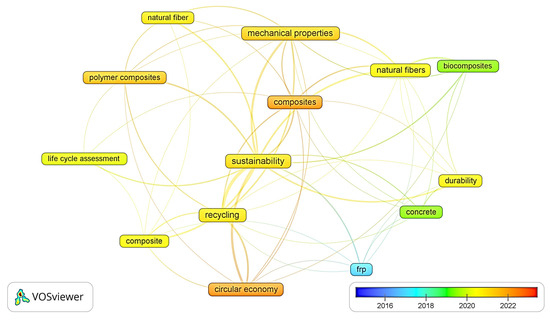

The overlay visualization from VOSviewer is shown in Figure 4. This visualization maps key terms in the context of research on sustainable fiber-reinforced polymers over a period from 2015 to 2023.

Figure 4.

Overlay visualization of keywords.

The color spectrum represents the average publication year of documents linked to each keyword, ranging from blue to red. Blue indicates keywords associated with older publications, around 2016, green represents keywords linked to publications around 2018, while yellow/orange signifies keywords associated with more recent publications, up to 2022.

This analysis offers a comprehensive view of the changing landscape of FRP (fiber-reinforced polymer) research, particularly regarding sustainability and environmental concerns. It highlights a noticeable shift towards prioritizing sustainable practices, as evidenced by the keyword ‘sustainability’ transitioning to a yellow color, indicating increased attention in recent years. This reflects a growing commitment within the research community to address the environmental challenges associated with FRPs. Another significant trend is the emergence of bio-based materials, as seen in the attention given to ‘natural fibers’ and ‘biocomposites’. This trend signifies a broader movement towards utilizing renewable and biodegradable materials in FRP production, aligning with global sustainability objectives. However, the analysis also identifies a notable gap in the integration of life cycle assessment (LCA) within FRP research. While LCA is recognized as important, its underrepresentation in recent studies suggests an area for improvement. Incorporating LCA into future research endeavors is crucial for obtaining a comprehensive understanding of the environmental impacts of FRPs throughout their entire lifecycle. Moving forward, the recommendations for future research focus on addressing this gap by actively integrating LCA methodologies. Additionally, exploring circular economy principles within FRP research can lead to more sustainable production and recycling practices. Furthermore, continued investigation into sustainable material innovations, such as natural fibers and biocomposites, can drive further advancements in developing environmentally friendly FRPs.

3.1.2. Co-Authorship Analysis

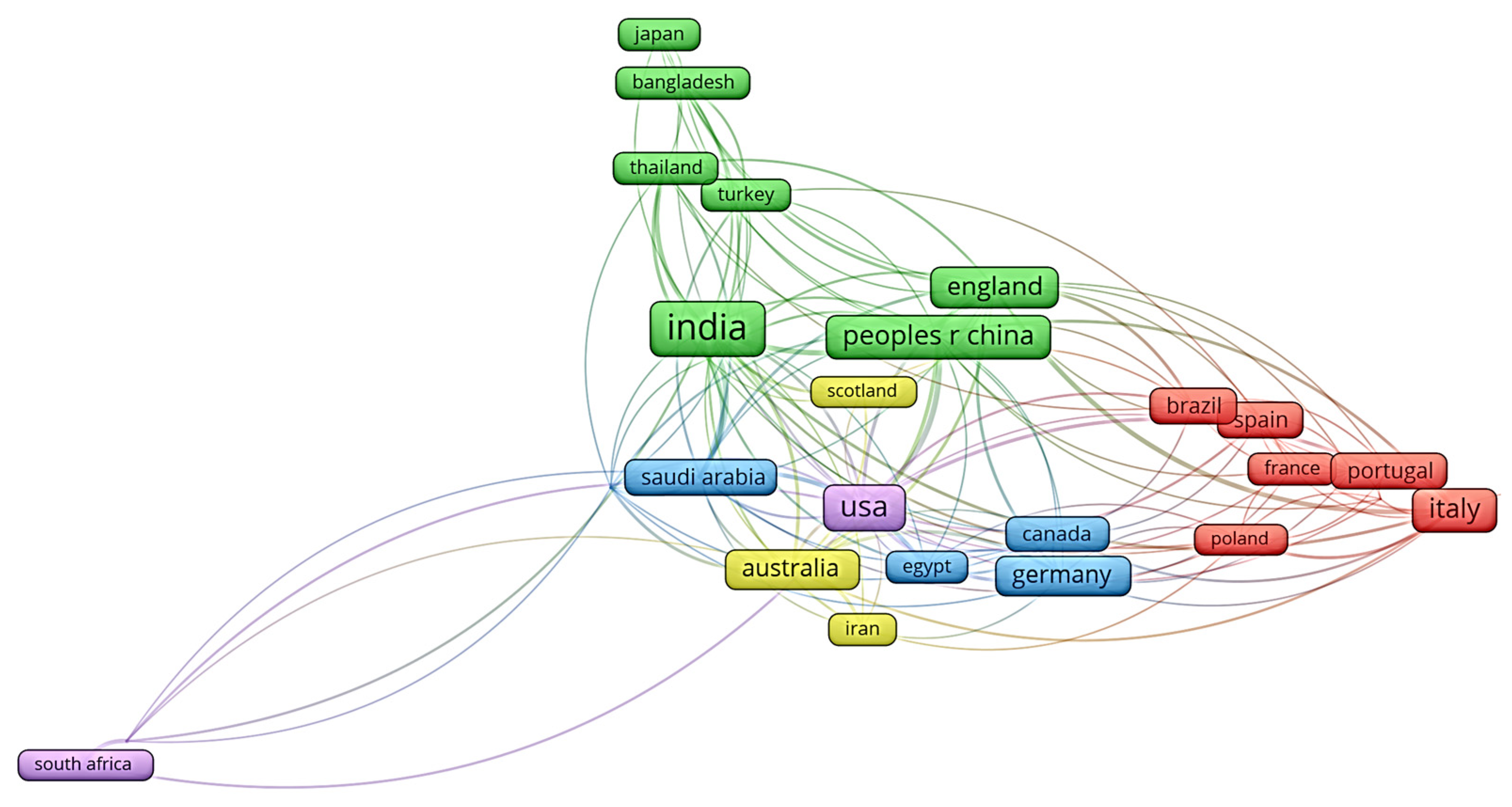

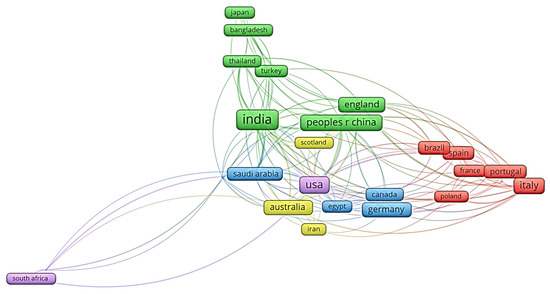

The visualization from Figure 5 depicts the collaboration/co-authorship network among different countries in the context of research on the sustainability of fiber-reinforced polymers.

Figure 5.

Co-authorship network by countries.

The central position of the USA and India indicates their pivotal roles in driving research and fostering international collaborations in the field of sustainable fiber-reinforced polymers. European countries (primarily Italy, Spain, Portugal, France, Poland) form a compact group, indicating regional collaborations. There is a notable link between ‘Australia’ and Middle Eastern countries (Egypt, Iran), suggesting targeted regional collaborations. South Africa’s position shows some degree of isolation but still maintains connections to the broader network.

3.2. Distribution of Articles

3.2.1. Distribution of Articles by Publication Year

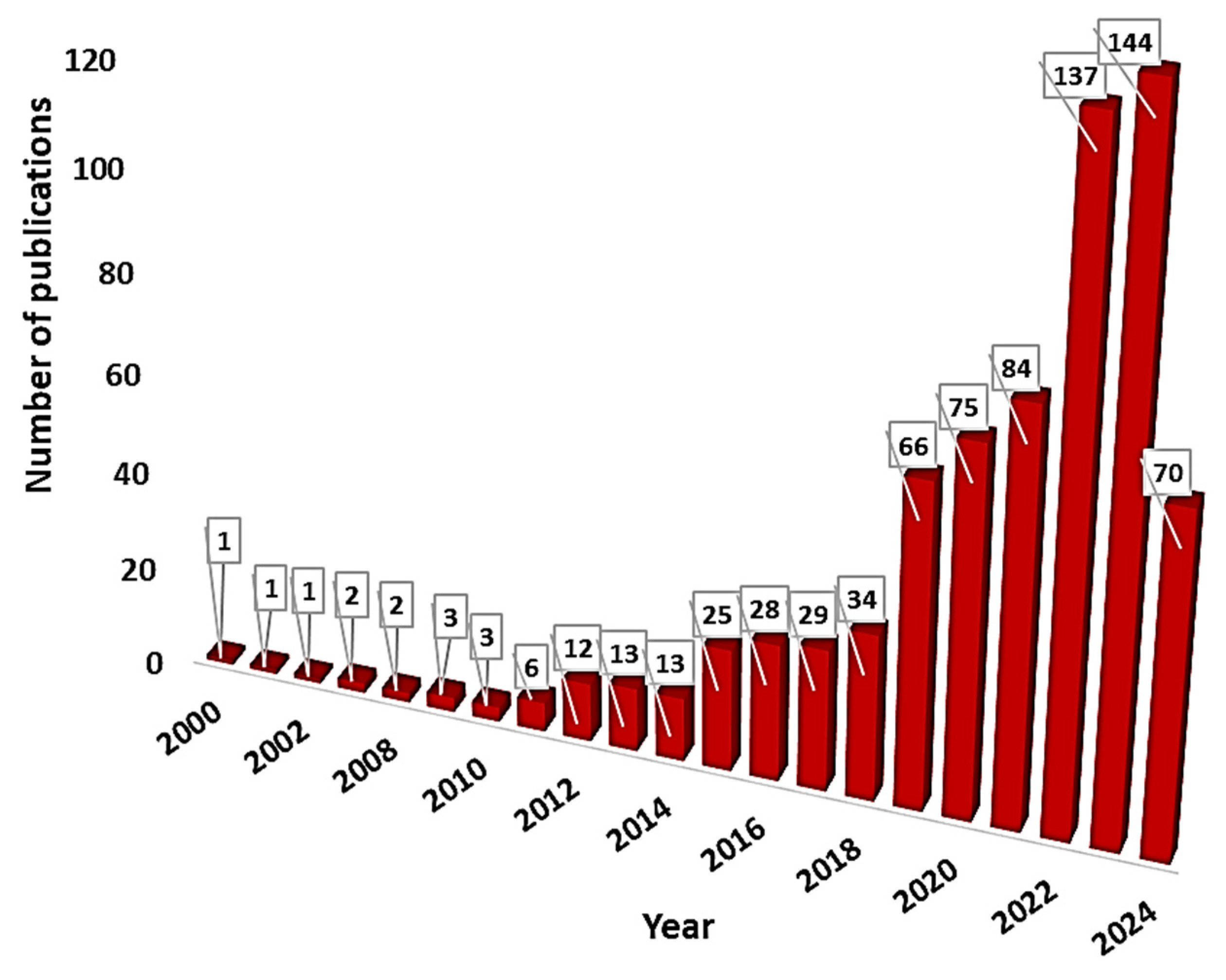

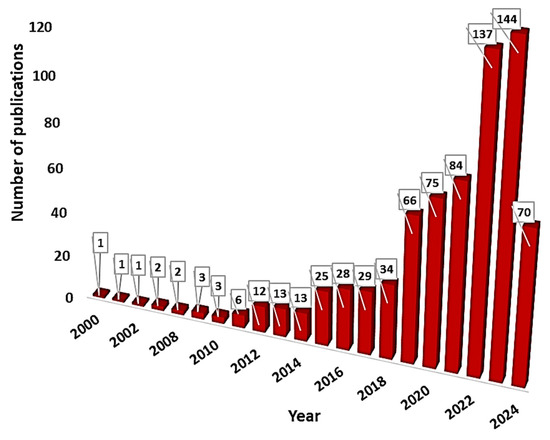

Figure 6 illustrates the distribution of articles published each year from 2000 to 2024.

Figure 6.

Distribution of articles by publication year.

It can be observed that in early years (2000–2010), the research in this field began with minimal activity, with only one publication per year. The interest started to grow slowly, with a gradual increase in publications. By 2009, there were three publications, indicating the beginning of a more focused research effort. In the period 2011–2015, there was a significant increase in research output. The number of publications rose from 6 in 2011 to 25 in 2015. This phase marks the period when the research community began to recognize the importance and potential of sustainable fiber-reinforced polymers. The period 2019–2021 shows a sharp increase in the number of publications. The count grew from 28 in 2016 to 84 in 2021. The rapid expansion indicates that sustainable fiber-reinforced polymers became a major research focus, likely driven by increased awareness of environmental sustainability and advancements in material science. The highest number of publications were recorded in 2022 (137) and 2023 (144), indicating a peak in research activity. This suggests that the field has reached a high level of maturity and widespread interest among researchers.

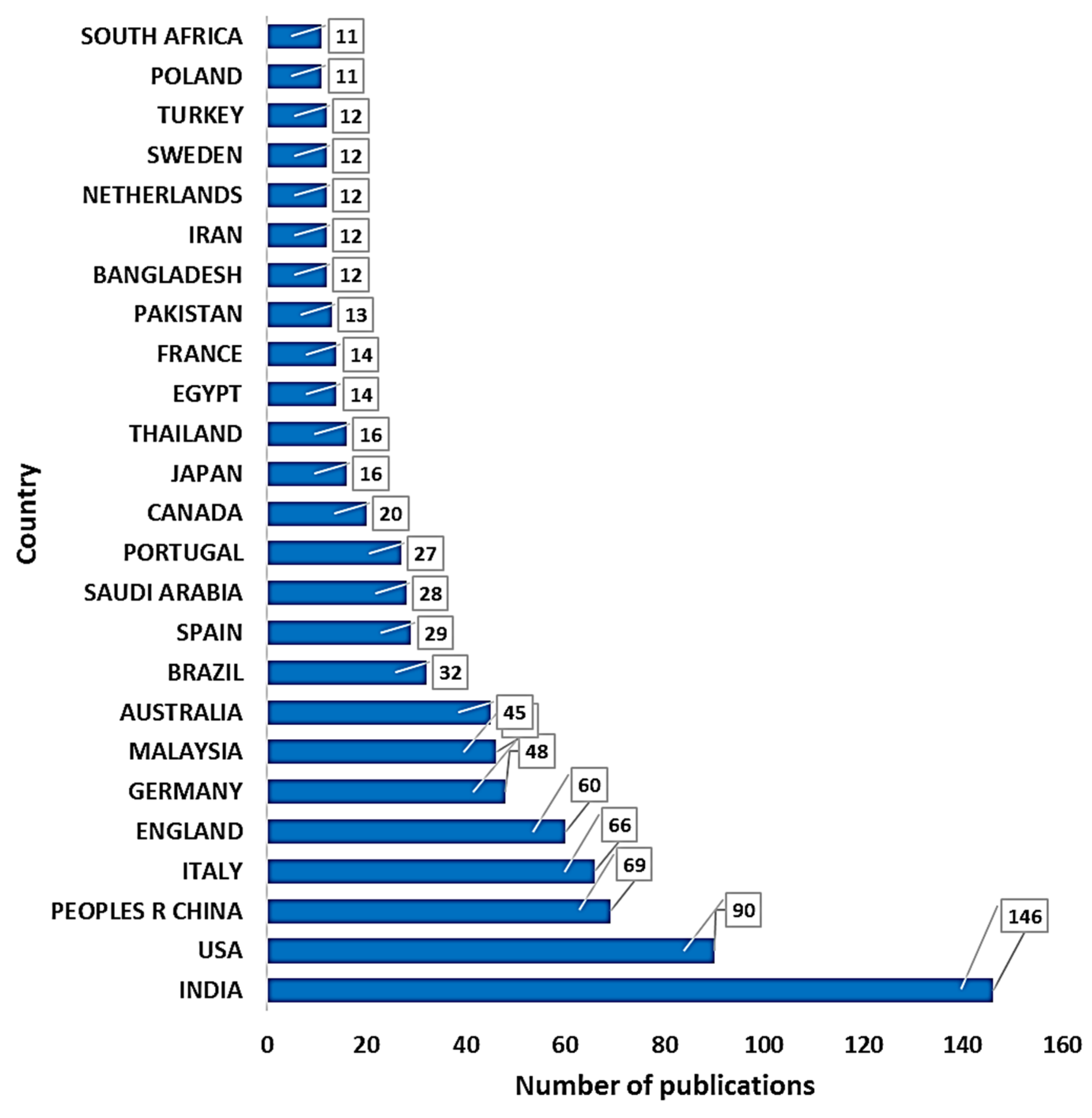

3.2.2. Distribution of Articles by Geographical Location

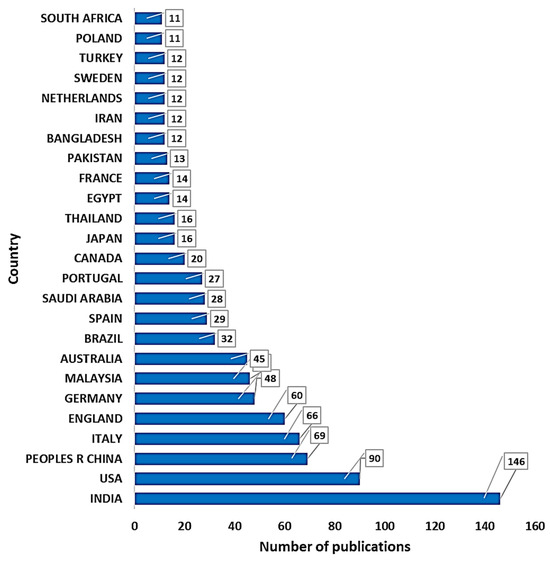

Figure 7 presents the distribution of articles by geographical locations and indicates that India (146 publications) leads the research output in this field, indicating a strong focus on sustainable fiber-reinforced polymers. This aligns with its central position and extensive connections in network visualization. The USA is another major contributor, with significant research activity and collaboration. Its central position in the visualizations also reflects its importance.

Figure 7.

Distribution of articles by geographical locations.

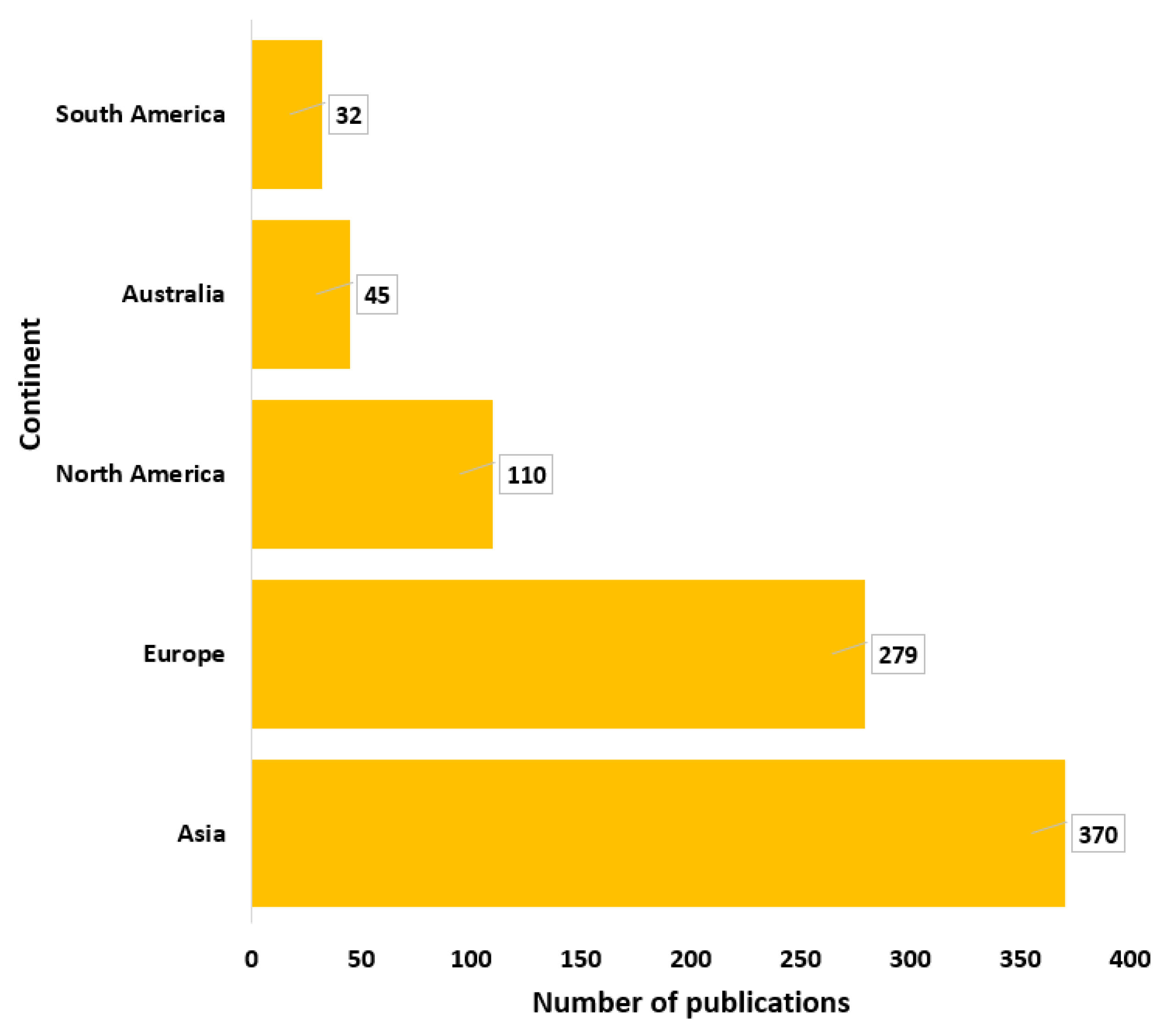

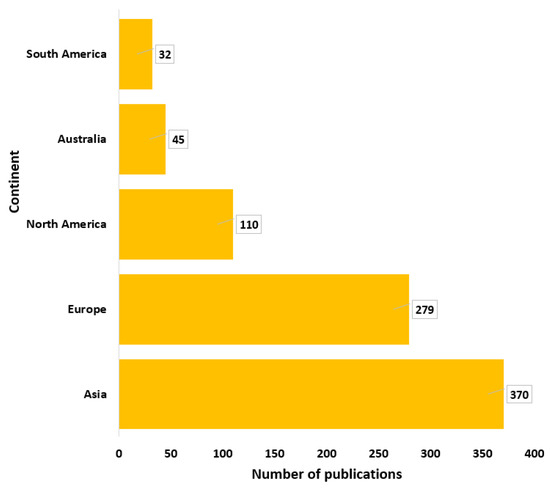

Figure 8 illustrates the geographic distribution of articles by continent, highlighting the research output from different regions. This visualization provides insight into the global focus of the study, with Asia leading in article contributions, followed by Europe and North America.

Figure 8.

Geographic distribution of articles, by continent.

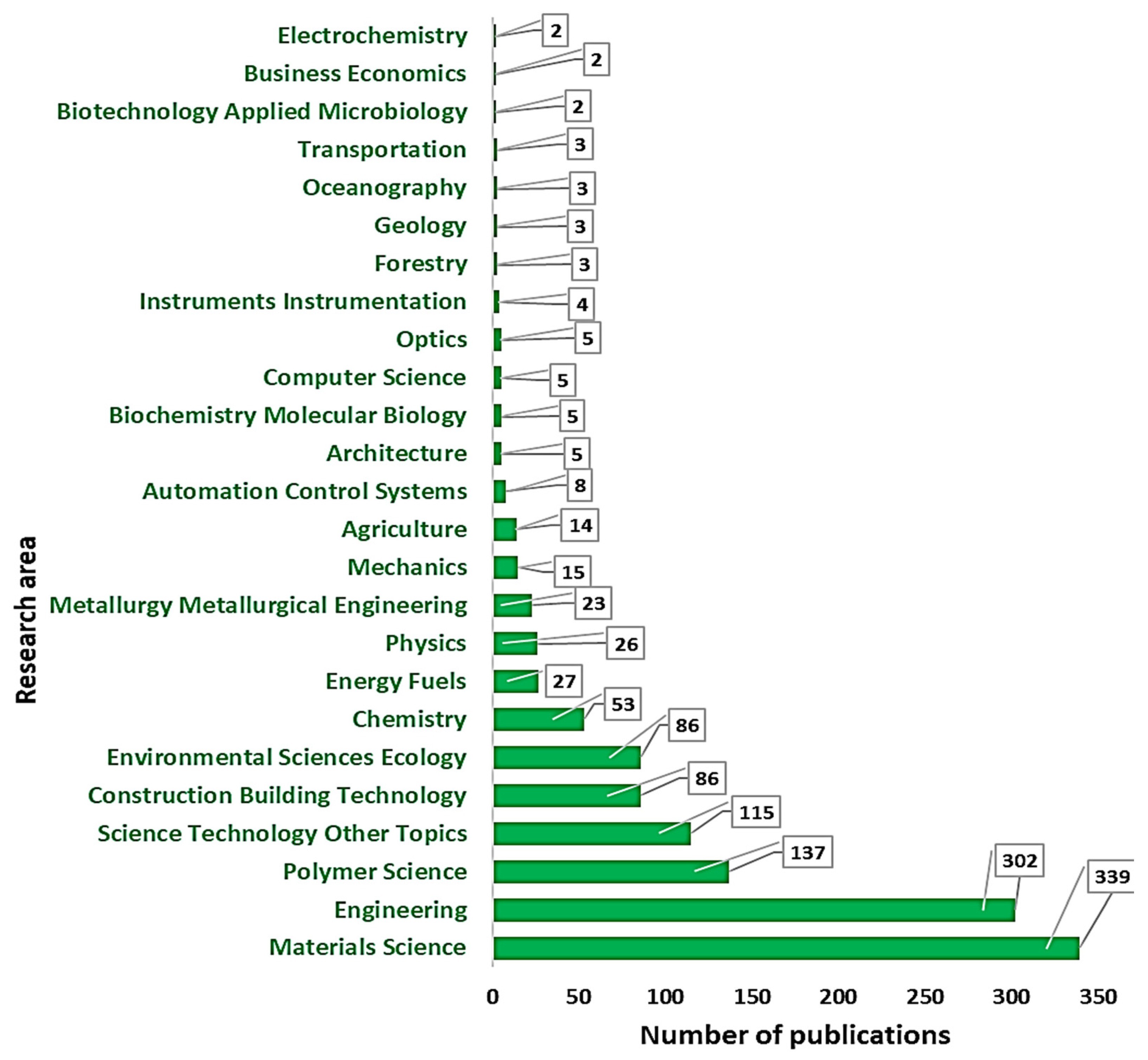

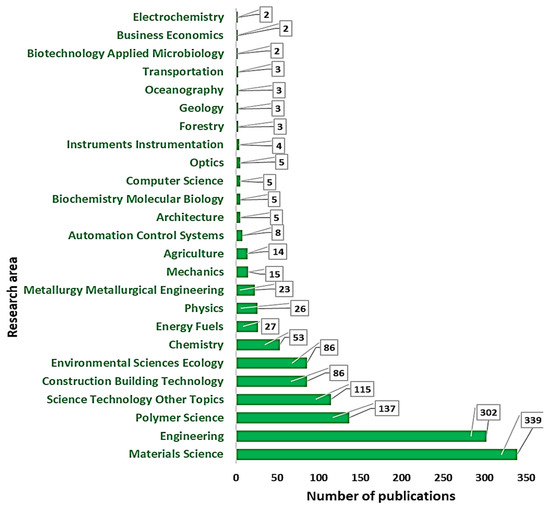

3.2.3. Distribution of Articles by Research Area

The provided data in Figure 9 list the number of records (publications) across various research areas related to the sustainability of fiber-reinforced polymers, in order to help in understanding the multidisciplinary nature and the primary focus areas within this field. The publication data across research areas reveal the multidisciplinary and evolving nature of research on the sustainability of fiber-reinforced polymers. Materials science, engineering, and polymer science are the core areas driving this field, supported by significant contributions from construction building technology and environmental sciences and ecology. The data also highlight the broad and diverse applications, ranging from energy and fuels to agriculture and automation. This comprehensive view of research areas, combined with network and overlay visualizations, underscores the dynamic and interconnected research landscape dedicated to advancing sustainable fiber-reinforced polymers.

Figure 9.

Distribution of articles by research areas.

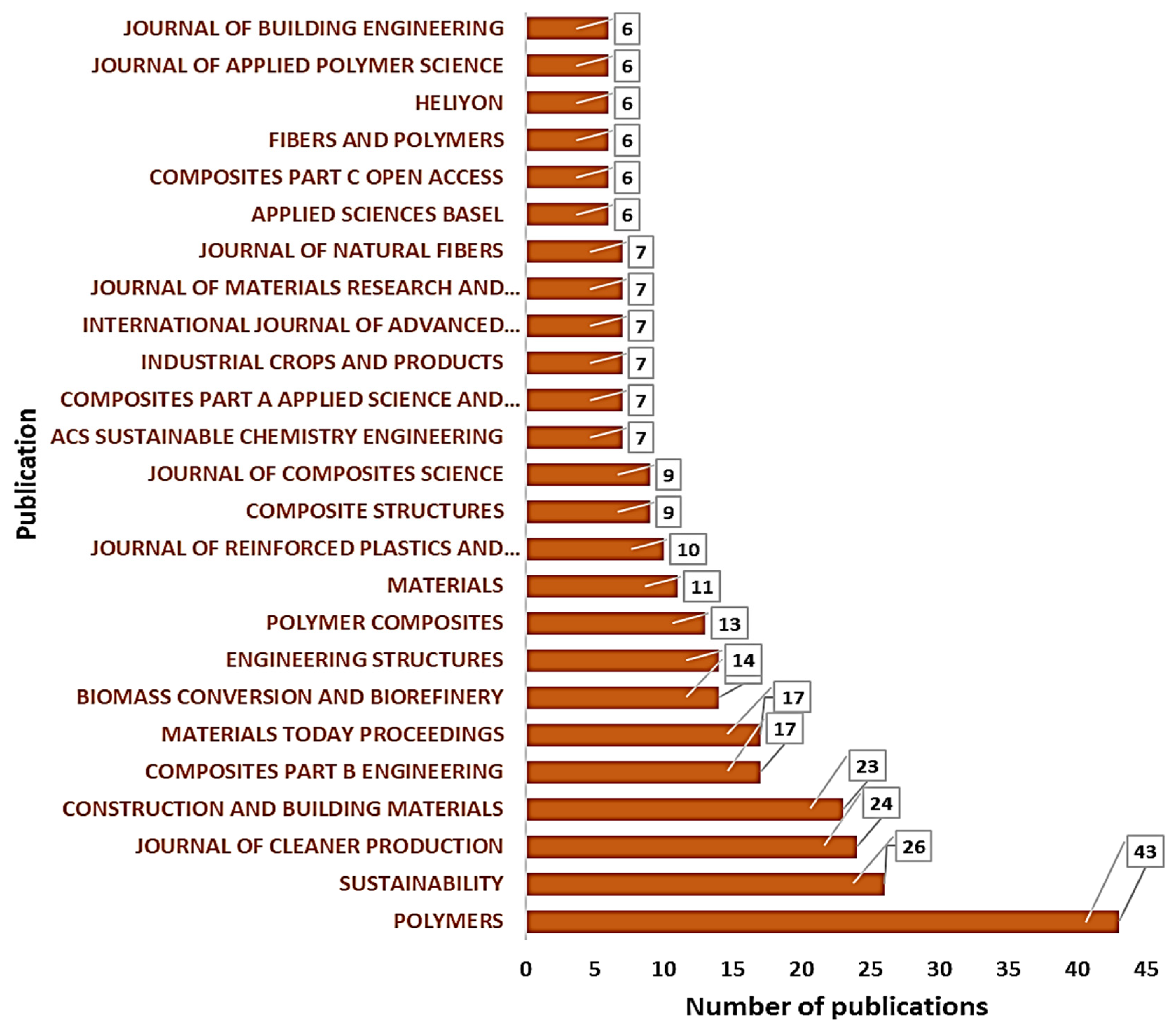

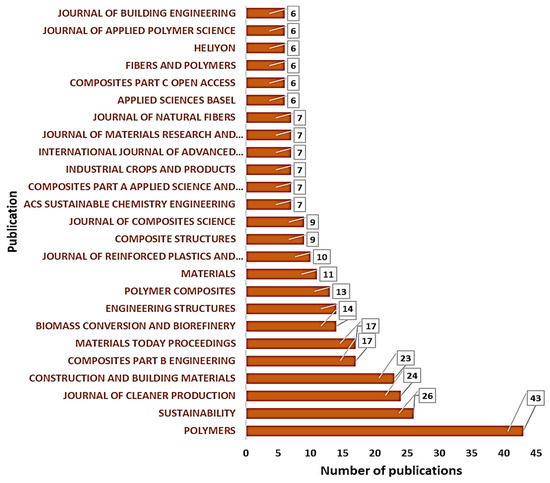

3.2.4. Distribution of Articles by Publication Title

Figure 10 presents the number of records (publications) across various journals related to the sustainability of fiber-reinforced polymers, for understanding the key publication venues and the focus areas within this research field.

Figure 10.

Distribution of articles by publication title.

The publication data across journals reveal the multidisciplinary nature and key focus areas within the research on sustainable fiber-reinforced polymers. ‘Polymers’ is the leading journal, reflecting the core focus on polymer science. ‘Sustainability’ and ‘Journal of cleaner production’ highlight the strong emphasis on sustainability. ‘Construction and building materials’ underscores the practical applications in construction. Specialized journals like ‘Composites part B engineering’ and ‘Engineering structures’ cover specific aspects of composites and structural applications. The diverse range of journals, from materials science to environmental sciences, showcases the wide-ranging interest and collaborative efforts in advancing sustainable fiber-reinforced polymers. This comprehensive view of publication venues, combined with network and overlay visualizations, provides a detailed understanding of the research landscape and key themes driving this field.

4. Conclusions

This comprehensive bibliometric analysis provides a nuanced understanding of the research landscape surrounding the sustainability of fiber-reinforced polymers (FRPs). By delving into co-occurrence patterns of keywords, overlay visualizations, co-authorship networks among countries, and distribution of articles across various dimensions, this study presents critical trends and areas of focus within the field.

The prominence of sustainability-related keywords highlights the increasing attention on environmental considerations within the field. However, the limited focus on LCA suggests a critical gap in the current research that warrants further investigation. LCA, as a tool for evaluating the environmental impact of FRPs, could provide a more comprehensive understanding of their sustainability throughout the product lifecycle.

The analysis of key papers, as shown in Table 3, reveals important insights into the sustainability, mechanical properties, applications, and challenges of various FRP composite clusters. Sustainability remains a prominent focus, with FRP composites offering advantages such as light weight, durability, and corrosion resistance. However, challenges persist, particularly in relation to production waste and disposal, underscoring the need for further advances in recycling and remanufacturing technologies. In contrast, NFPCs have emerged as promising sustainable alternatives. These composites, especially when enhanced with chemical treatments, demonstrate improved mechanical and thermal properties, making them cost-effective and energy-efficient choices for industries such as automotive and construction. Hybrid composites, which combine synthetic and natural fibers, also show considerable promise, offering a balance of enhanced performance and environmental benefits. Life cycle assessments of composite materials highlight the advantages of bio-based composites made from natural fibers. Recycling techniques, including both mechanical and chemical methods, are being refined to improve the sustainability of FRP composites, and emerging technologies such as additive manufacturing hold great potential for enhancing recycling processes. However, challenges remain in terms of fiber quality and performance when recycled fibers are used.

Furthermore, the co-authorship analysis highlights the significant roles of the USA and India in advancing research, alongside strong collaborative networks among European countries and focused regional partnerships, underscoring the global scope of FRP research. This interconnectedness fosters knowledge exchange and accelerates advancements in sustainable materials science.

The upward trajectory of research output over the years, coupled with the multidisciplinary nature of research areas, reflects a maturing field with diverse applications and growing recognition. This evolution underscores the collective commitment to addressing environmental challenges and advancing sustainable FRP solutions.

Also, the performed investigation highlights that future research on FRP sustainability should focus on more specific and interdisciplinary approaches. Collaboration between experts in materials science, environmental engineering, and economics is essential to address the challenges of FRP composites. Additionally, incorporating LCA in future studies will help better understand the environmental impacts of FRPs throughout their life, from production to disposal.

Author Contributions

Conceptualization, M.T.; Methodology, A.D. and M.T.; Validation, D.R.P.; Investigation, C.C., A.D., D.R.P., E.-E.S. and A.I.P.; Writing—original draft, M.T., A.D., D.R.P., C.C., E.-E.S. and A.I.P.; Writing—review & editing, M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

All data are presented within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An Assessment of the Processing Parameters and Application of Fibre-Reinforced Polymers (FRPs) in the Petroleum and Natural Gas Industries: A Review. Results Eng. 2023, 18, 101091. [Google Scholar] [CrossRef]

- Ortiz, J.D.; Khedmatgozar Dolati, S.S.; Malla, P.; Nanni, A.; Mehrabi, A. FRP-Reinforced/Strengthened Concrete: State-of-the-Art Review on Durability and Mechanical Effects. Materials 2023, 16, 1990. [Google Scholar] [CrossRef] [PubMed]

- Van Den Einde, L.; Zhao, L.; Seible, F. Use of FRP Composites in Civil Structural Applications. Constr. Build. Mater. 2003, 17, 389–403. [Google Scholar] [CrossRef]

- Tafsirojjaman, T.; Ur Rahman Dogar, A.; Liu, Y.; Manalo, A.; Thambiratnam, D.P. Performance and Design of Steel Structures Reinforced with FRP Composites: A State-of-the-Art Review. Eng. Fail. Anal. 2022, 138, 106371. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Fibre Reinforced Polymer Structures. Fibers 2022, 10, 27. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A Critical Review of Fused Deposition Modeling 3D Printing Technology in Manufacturing Polylactic Acid Parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Sumithra, G.; Reddy, R.N.; Dheeraj Kumar, G.; Ojha, S.; Jayachandra, G.; Raghavendra, G. Review on Composite Classification, Manufacturing, and Applications. Mater. Today Proc. 2023, 2023, S2214785323025725. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Bhatt, A.T.; Gohil, P.P.; Chaudhary, V. Primary Manufacturing Processes for Fiber Reinforced Composites: History, Development & Future Research Trends. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012107. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Kalla, D.K.; Dhanasekaran, P.S.; Zhang, B.; Asmatulu, R. Sustainability of Fiber Reinforced Composites: Status and Vision for Future. In Proceedings of the Volume 3: Design and Manufacturing; ASMEDC: Denver, CO, USA, 2011; pp. 167–173. [Google Scholar]

- Donnini, J.; Bompadre, F.; Corinaldesi, V. Tensile Behavior of a Glass FRCM System after Different Environmental Exposures. Processes 2020, 8, 1074. [Google Scholar] [CrossRef]

- Elhenawy, Y.; Fouad, Y.; Marouani, H.; Bassyouni, M. Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades. Processes 2021, 9, 622. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.S. Multi-Objective Optimization of Drilling GFRP Composites Using ANN Enhanced by Particle Swarm Algorithm. Processes 2023, 11, 2418. [Google Scholar] [CrossRef]

- Isik, B.; Gultekin, M.S.; Fidan, I.; Jun, M.B.-G. Optimum Cutting Parameters for Carbon-Fiber-Reinforced Polymer Composites: A Synergistic Approach with Simulated Annealing and Genetic Algorithms in Drilling Processes. Processes 2024, 12, 1477. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/Synthetic Fibre Reinforced Polymer Hybrid Composites: A Review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Bank, L. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-471-68126-7. [Google Scholar]

- Hollaway, L.C. A Review of the Present and Future Utilisation of FRP Composites in the Civil Infrastructure with Reference to Their Important In-Service Properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction—State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon Fiber Reinforced Polymer for Cable Structures—A Review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef]

- Vara Prasad, V.; Talupula, S. A Review on Reinforcement of Basalt and Aramid (Kevlar 129) Fibers. Mater. Today: Proc. 2018, 5, 5993–5998. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Teng, J.G. Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Woodhead Publishing: Sawston, UK, 2008; ISBN 978-1-84569-448-7. [Google Scholar]

- Lee, L.S.; Jain, R. The Role of FRP Composites in a Sustainable World. Clean Techn Env. Policy 2009, 11, 247–249. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A Review on FRP Composites Applications and Durability Concerns in the Construction Sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Yağar, A.C.; İNce, C.; Derogar, S. FRP Strengthening of RC Structures: Sustainable, Environmental and Structural Evaluations. J. Sustain. Constr. Mater. Technol. 2022, 7, 358–374. [Google Scholar] [CrossRef]

- Woodhead Publishing Series in Civil and Structural Engineering. In Rehabilitation of Metallic Civil Infrastructure Using Fiber Reinforced Polymer (FRP) Composites; Karbhari, V.M., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. xvii–xix. ISBN 978-0-85709-653-1. [Google Scholar]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Halliwell, S. FRPs—The Environmental Agenda. Adv. Struct. Eng. 2010, 13, 783–791. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L. A Critical Review of Research on Reuse of Mechanically Recycled FRP Production and End-of-Life Waste for Construction. Polymers 2014, 6, 1810–1826. [Google Scholar] [CrossRef]

- Ziemińska-Stolarska, A.; Sobulska, M.; Pietrzak, M.; Zbiciński, I. Application of Life Cycle Assessment to Analysis of Fibre Composite Manufacturing Technologies in Shipyards Industry. Processes 2024, 12, 461. [Google Scholar] [CrossRef]

- Butenegro, J.A.; Bahrami, M.; Martínez, M.Á.; Abenojar, J. Reuse of Carbon Fibers and a Mechanically Recycled CFRP as Rod-like Fillers for New Composites: Optimization and Process Development. Processes 2023, 11, 366. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials—Current Status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Maurya, A.K.; De Souza, F.M.; Dawsey, T.; Gupta, R.K. Biodegradable Polymers and Composites: Recent Development and Challenges. Polym. Compos. 2023, 45, 2896–2918. [Google Scholar] [CrossRef]

- Matykiewicz, D. Biochar as an Effective Filler of Carbon Fiber Reinforced Bio-Epoxy Composites. Processes 2020, 8, 724. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; Van Heerden, D.-J.; Kuiper, P.; De Wit, H. Recycling of Composite Materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Ferreira, G.M.G.; Cecchin, D.; Azevedo, A.R.G.; Valadão, I.C.R.P.; Costa, K.A.; Silva, T.R.; Ferreira, F.; Amaral, P.I.S.; Huther, C.M.; Sousa, F.A.; et al. Bibliometric Analysis on the Use of Natural Fibers in Construction Materials. Eest. Maaülikooli 2021, 19, 474.7Kb. [Google Scholar] [CrossRef]

- Baarimah, A.O.; Alaloul, W.S.; Liew, M.S.; Baarimah, S.O.; Musarat, M.A.; Bin Mokaizh, A.A. A Bibliometric Review of Research Trends on Kenaf Fiber Reinforced Concrete. Constr. Technol. Archit. 2023, 4, 57–65. [Google Scholar]

- Singh, R. A Bibliometric Analysis and Visualisation of Research Trends in Carbon Reinforced Plastics. Mater. Today Proc. 2023, 81, 899–903. [Google Scholar] [CrossRef]

- Or, I.K.-H.; Lo, C.K.-Y.; Kan, C.-W. A Systematic Literature Network Analysis: Development of Manufacturing, Enhancement and Sustainability of Fiber-Reinforced Polymer Composites (1998–2020) and Future Research Agenda. Fibers Polym 2023, 24, 789–800. [Google Scholar] [CrossRef]

- Sousa, F.D.B.D. A Simplified Bibliometric Mapping and Analysis about Sustainable Polymers. Mater. Today Proc. 2022, 49, 2025–2033. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and Properties of Natural Fiber Polymer Composites: A Comprehensive Review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of Natural and Synthetic Fiber Reinforced Polymer in Infrastructure: A Suitability Assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Cicala, G. LCA of Fibre-Reinforced Composites. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 301–323. ISBN 978-0-08-100169-1. [Google Scholar]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef]

- Sbahieh, S.; Rabie, M.; Ebead, U.; Al-Ghamdi, S.G. The Mechanical and Environmental Performance of Fiber-Reinforced Polymers in Concrete Structures: Opportunities, Challenges and Future Directions. Buildings 2022, 12, 1417. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on Mechanical Properties of Natural Fiber Composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Harle, S.M. Durability and Long-Term Performance of Fiber Reinforced Polymer (FRP) Composites: A Review. Structures 2024, 60, 105881. [Google Scholar] [CrossRef]

- Majumdar, K.; Thakur, B.; Majumdar, A. Natural Fiber Reinforced Concrete: Bibliometric and Network Analyses to Delineate the Current Status and Future Pathways. J. Nat. Fibers 2022, 19, 15963–15983. [Google Scholar] [CrossRef]

- Aldosari, S.M.; AlOtaibi, B.M.; Alblalaihid, K.S.; Aldoihi, S.A.; AlOgab, K.A.; Alsaleh, S.S.; Alshamary, D.O.; Alanazi, T.H.; Aldrees, S.D.; Alshammari, B.A. Mechanical Recycling of Carbon Fiber-Reinforced Polymer in a Circular Economy. Polymers 2024, 16, 1363. [Google Scholar] [CrossRef]

- Romani, A.; Mantelli, A.; Suriano, R.; Levi, M.; Turri, S. Additive Re-Manufacturing of Mechanically Recycled End-of-Life Glass Fiber-Reinforced Polymers for Value-Added Circular Design. Materials 2020, 13, 3545. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A Critical Review on Recycling of End-of-Life Carbon Fibre/Glass Fibre Reinforced Composites Waste Using Pyrolysis towards a Circular Economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Ahmed, W.; Arshad, H.; Ullah, S. Recycling of the Glass/Carbon Fibre Reinforced Polymer Composites: A Step towards the Circular Economy. Polym.-Plast. Technol. Mater. 2022, 61, 761–788. [Google Scholar] [CrossRef]

- Elango, I.; Henderson, L.C.; Arumugam, V. Recycled Milled Fibres in Sustainable Composite Materials: A Comprehensive Review and Future Prospects. J. Reinf. Plast. Compos. 2024, 2024, 07316844241243128. [Google Scholar] [CrossRef]

- Julian, I.; García-Jiménez, A.; Aguado, A.; Arenal, C.; Calero, A.; Campos, V.; Escobar, G.; López-Buendía, A.M.; Romero, D.; Verdejo, E.; et al. Advances in the Circularity of End-of-Life Fibre-Reinforced Polymers by Microwave Intensification. Chem. Eng. Process.—Process Intensif. 2022, 178, 109015. [Google Scholar] [CrossRef]

- André, A.; Magdalena, J.; Cecilia, M.; Georgi, N.; Haghani, R. The Re-Use of End-of-Life Fiber Reinforced Polymer Composites in Construction. In 10th International Conference on FRP Composites in Civil Engineering; Ilki, A., Ispir, M., Inci, P., Eds.; Lecture Notes in Civil Engineering; Springer International Publishing: Cham, Switzerland, 2022; Volume 198, pp. 1183–1195. ISBN 978-3-030-88165-8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).