Advancements in Clothing Thermal Comfort for Cold Intolerance

Abstract

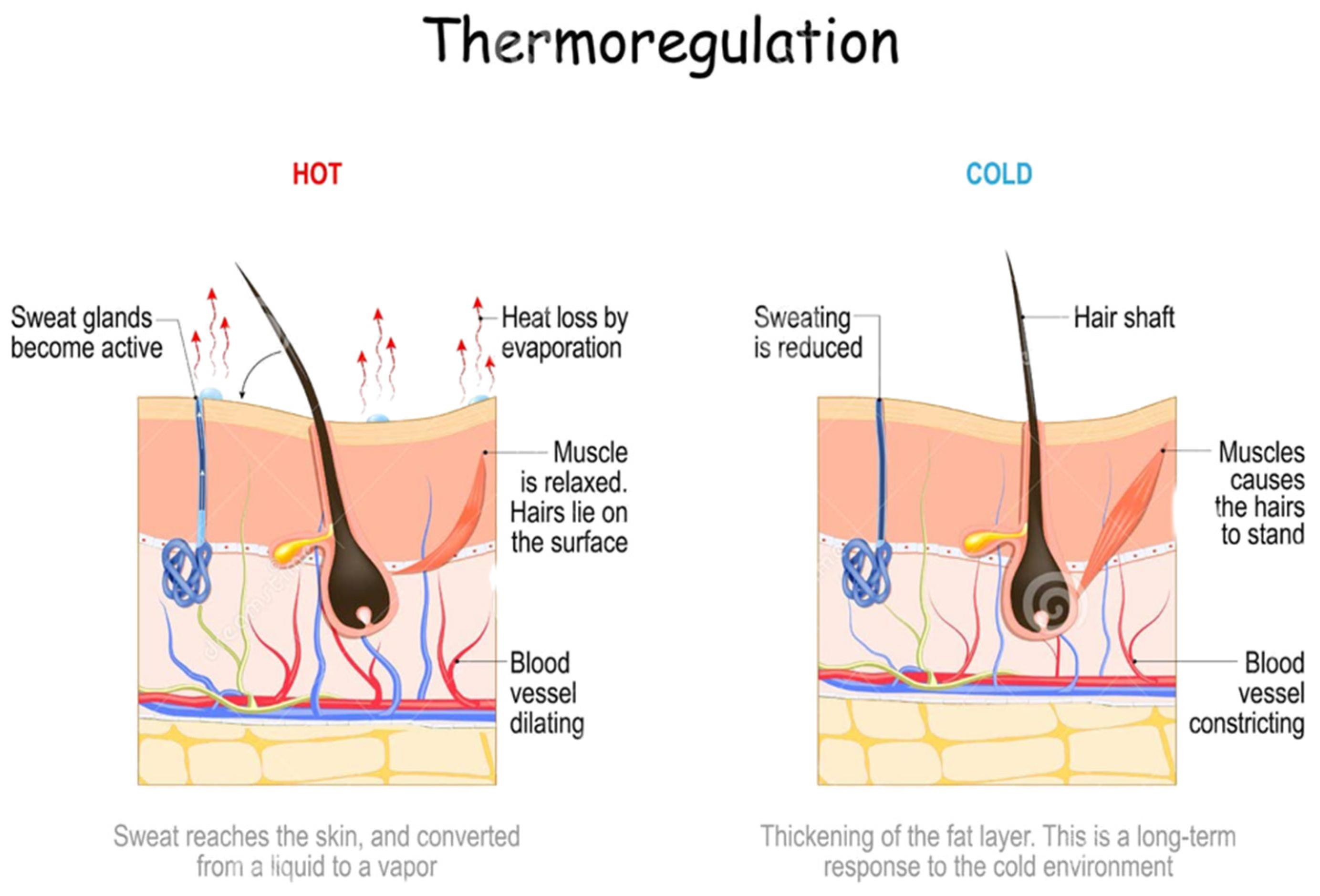

:1. Introduction

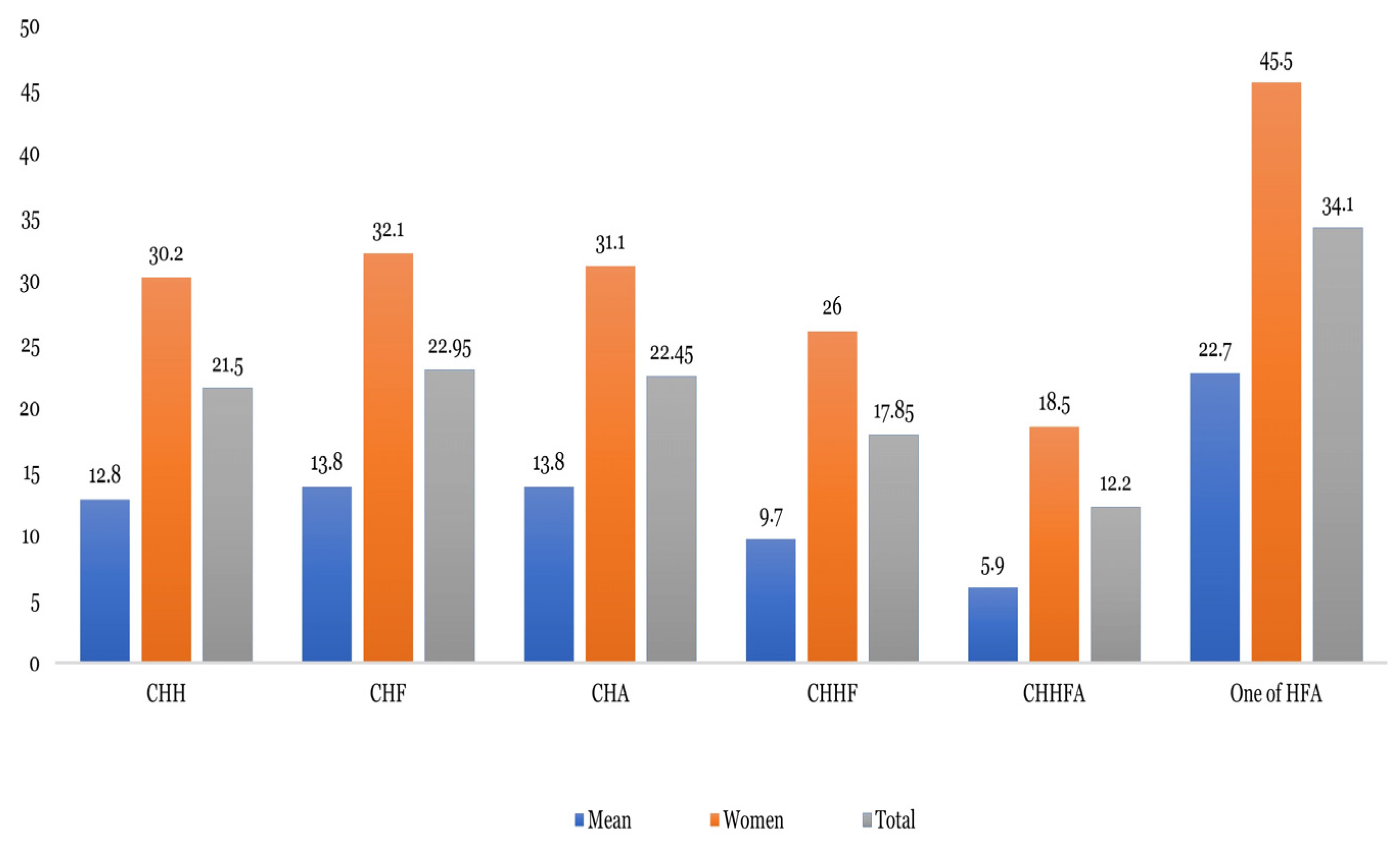

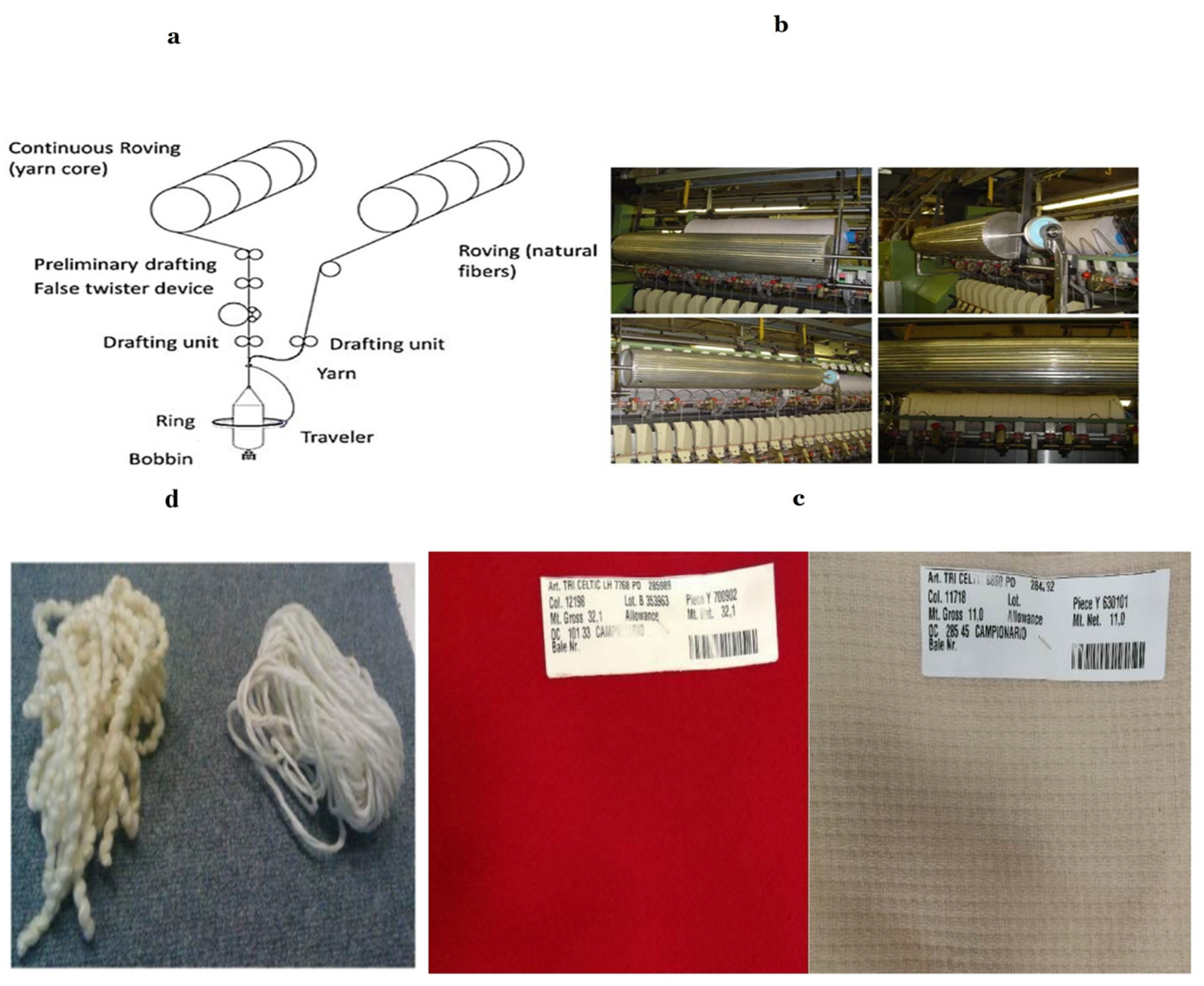

2. Occurrence of Cold Intolerance and Its Thermal Discomfort Challenge

3. Advancements in Textile and Clothing Development for Cold Intolerance

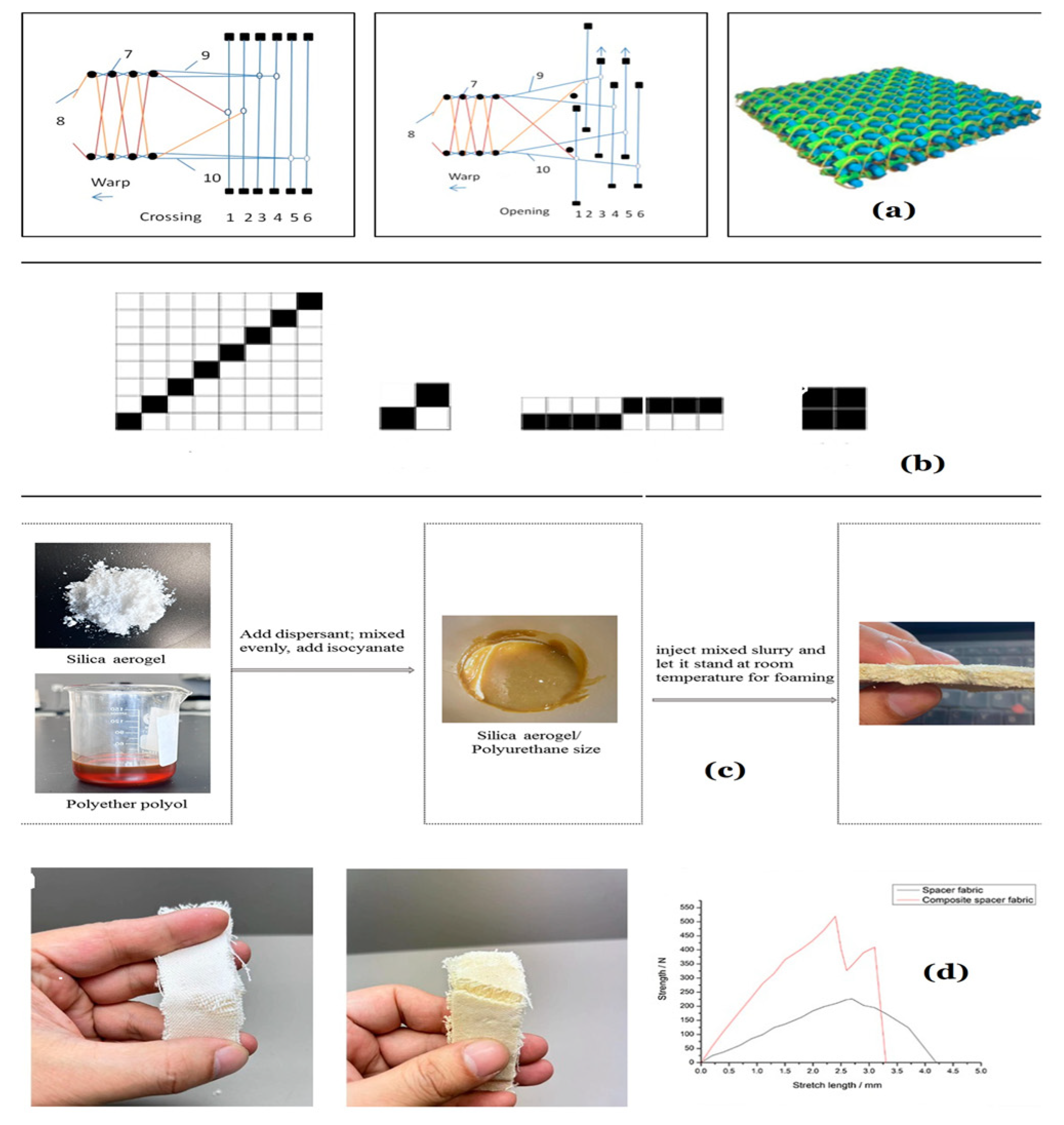

3.1. Clothing Thermal Insulation Improvement at the Textile Stage

3.2. Clothing Thermal Insulation Improvement at the Garment Design Stage

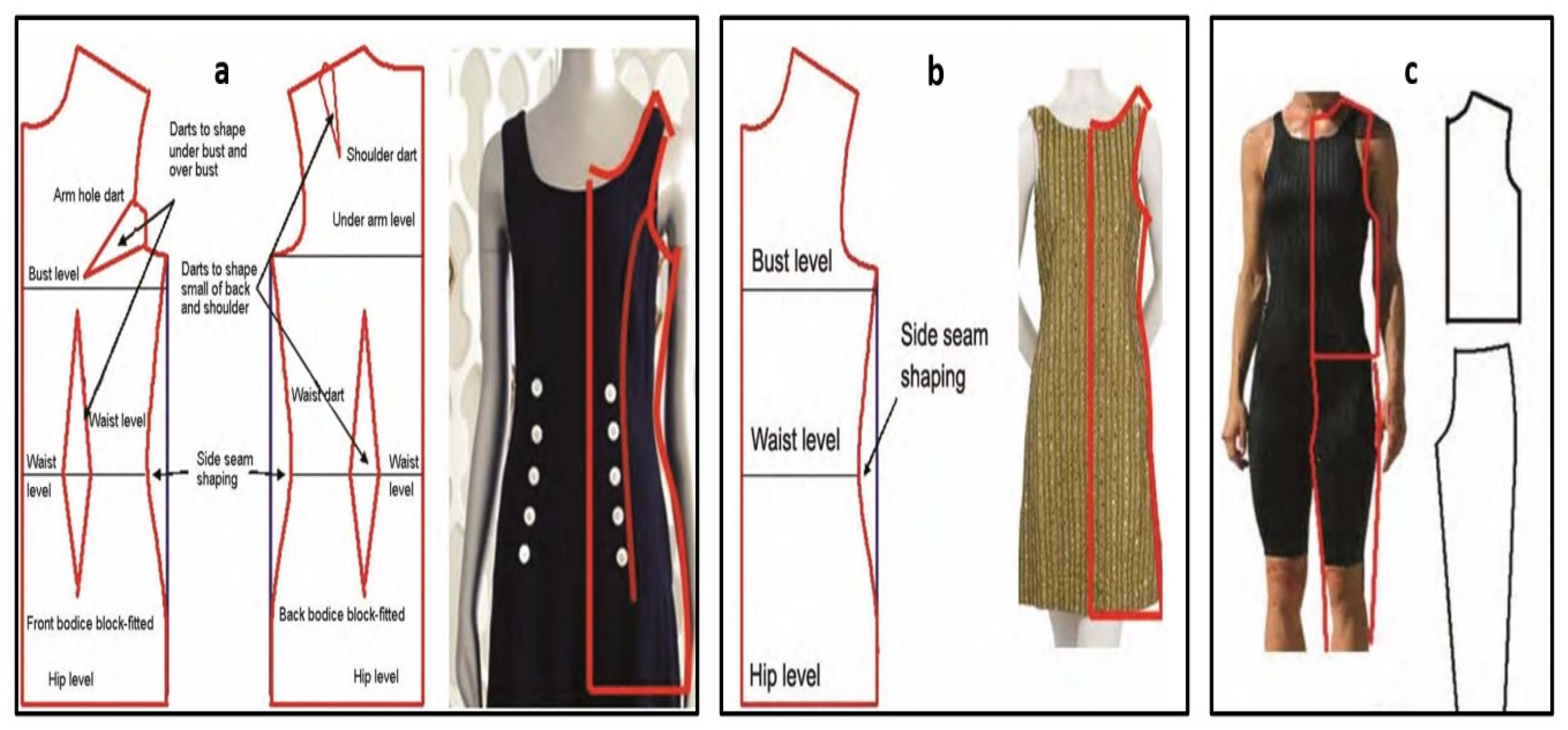

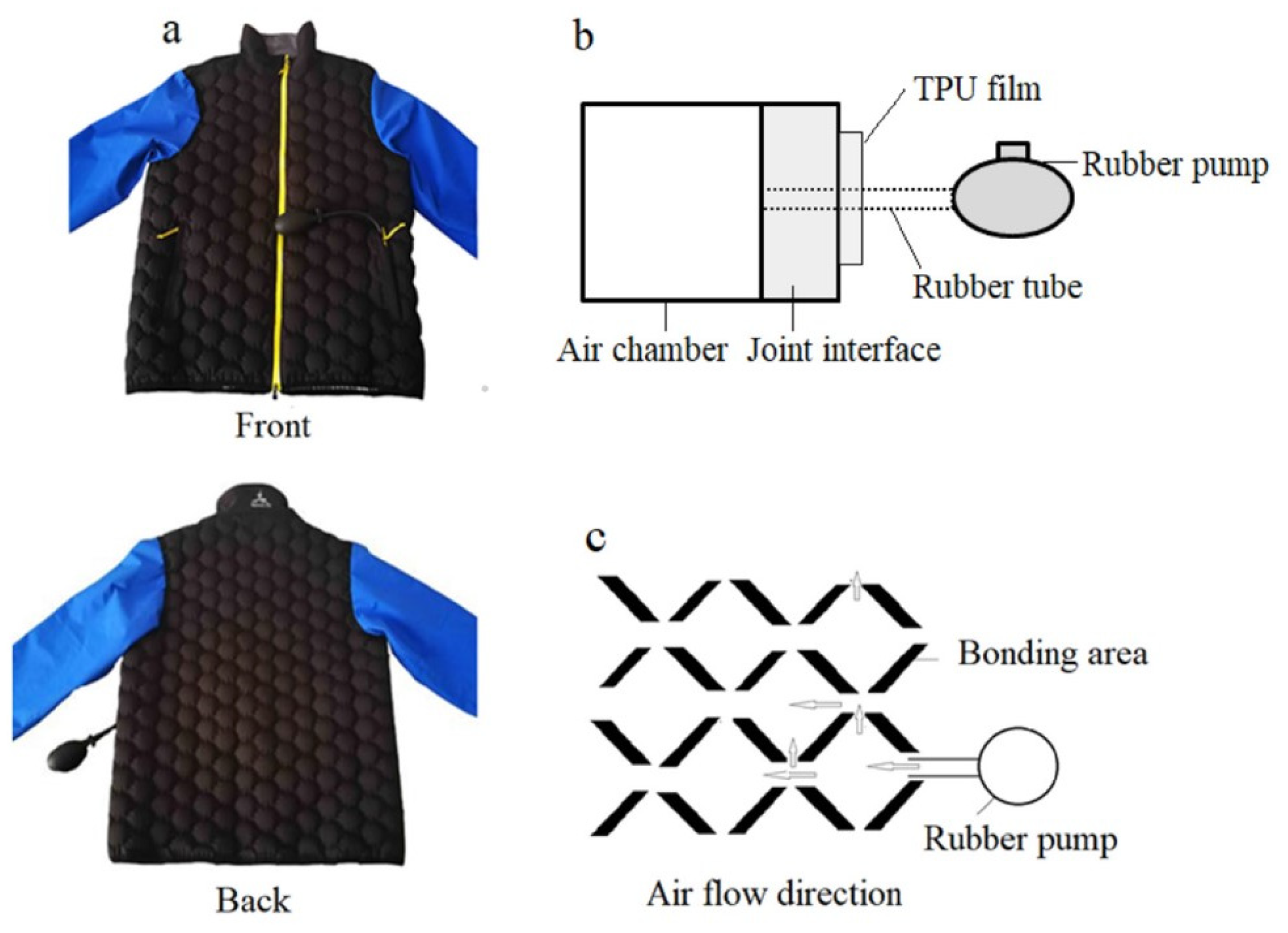

3.2.1. Considerations in Clothing Fit and Size

3.2.2. Considerations in Stitching and Seams

4. Advancements in Moisture Management of Cold Protective Clothing

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO 7730/1994; Moderate Thermal Environments—Determination and Specification of the PMV and PPD Indices of the Conditions for Thermal Comfort. International Organization for Standardization: Geneva, Switzerland, 1994.

- ANS/ASHARE 55; Thermal Environmental Conditions for Human Occupancy. ASHRAE Standard: Peachtree Corners, GA, USA, 2013. Available online: www.ashrae.org/technology (accessed on 23 June 2024).

- Ongwuttiwat, K.; Sudprasert, S. Thermal Balance and the Role of Clothing on Thermal Comfort in Hot and Humid Climate. Int. J. Build. Urban Inter. Landsc. Technol. BUILT 2015, 6, 5–14. [Google Scholar]

- Cao, S.; Li, X.; Yang, B.; Li, F. A review of research on dynamic thermal comfort. Build. Serv. Eng. Res. Technol. 2021, 42, 435–448. [Google Scholar] [CrossRef]

- Baruti, M.M.; Johansson, E.; Åstrand, J. Review of studies on outdoor thermal comfort in warm humid climates: Challenges of informal urban fabric. Int. J. Biometeorol. 2019, 63, 1449–1462. [Google Scholar] [CrossRef]

- Gorji, M.; Mazinani, S.; Gharehaghaji, A.A. A review on emerging developments in thermal and moisture management by membrane-based clothing systems towards personal comfort. J. Appl. Polym. Sci. 2022, 139, e52416. [Google Scholar] [CrossRef]

- Atalie, D.; Tesinova, P.; Tadesse, M.G.; Ferede, E.; Dulgheriu, I.; Loghin, E. Thermo-physiological comfort properties of sportswear with different combination of inner and outer layers. Materials 2021, 14, 6863. [Google Scholar] [CrossRef]

- Islam, M.R.; Golovin, K.; Dolez, P.I. Individual difference in thermal comfort. Textiles 2023, 3, 353–409. [Google Scholar] [CrossRef]

- Varadaraju, R.; Srinivasan, J. Design of sports clothing for hot environments. Appl. Ergon. 2019, 80, 248–255. [Google Scholar] [CrossRef]

- Wang, Z.; de Dear, R.; Luo, M.; Lin, B.; He, Y.; Ghahramani, A.; Zhu, Y. Individual difference in thermal comfort: A literature review. Build. Environ. 2018, 138, 181–193. [Google Scholar] [CrossRef]

- Tansey, E.A.; Johnson, C.D.; Johnson, C.D. Staying Current Recent advances in thermoregulation. Adv. Physiol. Educ. 2015, 39, 139–148. [Google Scholar] [CrossRef]

- Arens, E.A.; Zhang, H. The Skin’s Role in Human Thermoregulation and Comfort; Woodhead Publishing Ltd.: Cambridgeshire, UK, 2006. [Google Scholar]

- Lim, C.L.; Byrne, C.; Lee, J.K. Human Thermoregulation and Measurement of Body Temperature in Exercise and Clinical Settings. Ann. Acad. Med. Singap. 2008, 37, 347–353. [Google Scholar] [CrossRef]

- Périard, J.D.; Racinais, S. Thermophysiology of Health and Performance Heat Stress in Sport and Exercise; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Saghiv, M.S.; Sagiv, M.S. Clinical and Laboratory Perspectives Basic Exercise Physiology; Springer International Publishing: New York, NY, USA, 2020. [Google Scholar]

- Morrison, S.F.; Nakamura, K. Central mechanisms for thermoregulation. Annu. Rev. Physiol. 2019, 10, 285–308. [Google Scholar] [CrossRef] [PubMed]

- Stjernbrandt, A.; Carlsson, D.; Pettersson, H.; Liljelind, I.; Nilsson, T.; Wahlström, J. Cold sensitivity and associated factors: A nested case–control study performed in Northern Sweden. Int. Arch. Occup. Environ. Health 2018, 91, 785–797. [Google Scholar] [CrossRef] [PubMed]

- Ruijs, A.; Jaquet, J.-B.; Daanen, H.; Kalmijn, S.; Hovius, S.E.R. Cold Intolerance Measured by the CISS Questionnaire in a Normative Study Population. J. Reconstr. Microsurg. 2006, 22, A049. [Google Scholar] [CrossRef]

- Oluwasanmi, O.; Mckenzie, D.; Adewole, I.; Aluka, C.O.; Iyasse, J.; Olunu, E.; Fakoya, A.O. Postpolio syndrome: A review of lived experiences of patients. Int. J. Appl. Basic Med. Res. 2019, 9, 129–134. [Google Scholar] [CrossRef]

- Stjernbrandt, A.; Liljelind, I.; Nilsson, T.; Wahlström, J. Defining abnormal cold sensitivity using the Cold Intolerance Symptom Severity questionnaire: A population study. J. Hand Surg. 2021, 46, 731–737. [Google Scholar] [CrossRef]

- Smits, E.S. Cold intolerance from thermoregulation to nerve innervation. In Koude Intolerantie: Van Thermoregulatie Naar Zenuw Innervatie; Erasmus University Rotterdam: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Novak, C.B. Cold intolerance after nerve injury. J. Hand Ther. 2018, 31, 195–200. [Google Scholar] [CrossRef]

- Novak, C.B.; Li, Y.; von Schroeder, H.P.; Anastakis, D.J.; McCabe, S.J. Effect of Forearm Warming Compared to Hand Warming for Cold Intolerance Following Upper Extremity Trauma. J. Hand Surg. 2019, 44, 693.e1–693.e6. [Google Scholar] [CrossRef]

- Bruno, R.L. The Effects of Cold on Polio Survivors. Am. J. Med. 2018, 6, 563–578. Available online: www.papolionetwork.org (accessed on 23 August 2024).

- Li, R.; Yang, J.; Xiang, C.; Song, G. Assessment of thermal comfort of nanosilver-treated functional sportswear fabrics using a dynamic thermal model with human/clothing/environmental factors. Text. Res. J. 2018, 88, 413–425. [Google Scholar] [CrossRef]

- Bajzik, V.; Hes, L.; Dolezal, I. Changes in Thermal Comfort Properties of Sports Wear and Underwear Due to Their Wetting; NISCAIR-CSIR: Delhi, India, 2016. [Google Scholar]

- Greene, B.H.C.; Gudimella, R.; Corkum, J.P.; Boone, H.; Samargandi, O.A.; Williams, J. Managing cold intolerance after hand injury: A systematic review. Hand Surg. Rehabil. 2023, 42, 109–114. [Google Scholar] [CrossRef]

- di Domenico, I.; Hoffmann, S.M.; Collins, P.K. The Role of Sports Clothing in Thermoregulation, Comfort, and Performance During Exercise in the Heat: A Narrative Review. Sports Med. Open 2022, 8, 58. [Google Scholar] [CrossRef] [PubMed]

- de Vecchi, R.; Lamberts, R.; Candido, C.M. The role of clothing in thermal comfort: How people dress in a temperate and humid climate in Brazil. Ambiente Construído 2017, 17, 69–81. [Google Scholar] [CrossRef]

- Suh, M.; Carroll, K.; Cassill, N. Critical Review on Smart Clothing Product Development. J. Text. Appar. Technol. Manag. 2010, 6. Available online: https://fibretronic.com (accessed on 4 September 2024).

- Rossi, R. Comfort and thermoregulatory requirements in cold weather clothing. In Textiles for Cold Weather Apparel; Woodhead Publishing: Sawston, UK, 2009; pp. 3–18. [Google Scholar]

- Siple, P.A. General Principles Governing Selection of Clothing for Cold Climates. Proc. Am. Philos. Soc. 1945, 89, 200–234. [Google Scholar]

- Jussila, K. Clothing Physiological Properties of Cold Protective Clothing and Their Effects on Human Experience; Tampere University of Technology: Tampere, Finland, 2016. [Google Scholar]

- de Dear, A.; Foldvary, R.; Zhang, V.; Arens, E.; Luo, M.; Parkinson, T.; Du, X.; Zhang, W.; Chun, C.; Liu, S. Comfort is in the mind of the beholder: A review of progress in adaptive thermal comfort research over the past two decades. In Proceedings of the 5th International Conference on Human-Environment System, Nagoya, Japan, 29 October–2 November 2016. [Google Scholar]

- de Dear, R.J.; Akimoto, T.; Arens, E.A.; Brager, G.; Candido, C.; Cheong, K.W.D.; Li, B.; Nishihara, N.; Sekhar, S.C.; Tanabe, S.-I.; et al. Progress in thermal comfort research over the last twenty years. Indoor Air 2013, 23, 442–461. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Tian, M. Quantitative characterization of clothing’s cold protective capability to achieve thermal comfort: A systematic review. Build. Environ. 2022, 219, 109226. [Google Scholar] [CrossRef]

- Deng, Y.; Cao, B.; Liu, B.; Zhu, Y. Effects of local heating on thermal comfort of standing people in extremely cold environments. Build. Environ. 2020, 185, 107256. [Google Scholar] [CrossRef]

- Simone, A.; Della Crociata, S.; Martellotta, F. The influence of clothing distribution and local discomfort on the assessment of global thermal comfort. Build Environ. 2013, 59, 644–653. [Google Scholar] [CrossRef]

- Udayraj Li, Z.; Ke, Y.; Wang, F.; Yang, B. Personal cooling strategies to improve thermal comfort in warm indoor environments: Comparison of a conventional desk fan and air ventilation clothing. Energy Build. 2018, 174, 439–451. [Google Scholar] [CrossRef]

- Binarti, F.; Koerniawan, M.D.; Triyadi, S.; Utami, S.S.; Matzarakis, A. A review of outdoor thermal comfort indices and neutral ranges for hot-humid regions. Urban Clim. 2019, 31, 100531. [Google Scholar] [CrossRef]

- Jiang, H.; Cao, B.; Zhu, Y. Improving thermal comfort of individual wearing medical protective clothing: Two personal cooling strategies integrated with the polymer water-absorbing resin material. Build Environ. 2023, 243, 110730. [Google Scholar] [CrossRef]

- Shaid, A.; Wang, L.; Padhye, R. The thermal protection and comfort properties of aerogel and PCM-coated fabric for firefighter garment. J. Ind. Text. 2016, 45, 611–625. [Google Scholar] [CrossRef]

- Huang, D.; Guo, C. Thermal protective performance of silica Aerogel felt bedded firefighters’ protective clothing under fire conditions. Medziagotyra 2017, 23, 335–341. [Google Scholar] [CrossRef]

- Udayraj Talukdar, P.; Das, A.; Alagirusamy, R. Heat and mass transfer through thermal protective clothing—A review. Int. J. Therm. Sci. 2016, 106, 32–56. [Google Scholar] [CrossRef]

- Islam, M.R.; Golovin, K.; Dolez, P.I. Clothing Thermophysiological Comfort: A Textile Science Perspective. Textiles 2023, 3, 353–407. [Google Scholar] [CrossRef]

- Havenith, G.; Holme, Â.I.; Parsons, K. Personal factors in thermal comfort assessment: Clothing properties and metabolic heat production. Energy Build. 2002, 34, 581–591. [Google Scholar] [CrossRef]

- Tartarini, F.; Schiavon, S.; Quintana, M.; Miller, C. Personal comfort models based on a 6-month experiment using environmental parameters and data from wearables. Indoor Air 2022, 32, e13160. [Google Scholar] [CrossRef]

- Haldi, F.; Robinson, D. Modelling occupants’ personal characteristics for thermal comfort prediction. Int. J. Biometeorol. 2011, 55, 681–694. [Google Scholar] [CrossRef]

- Bogatu, D.I.; Shinoda, J.; Aguilera, J.J.; Olesen, B.W.; Watanabe, F.; Kaneko, Y.; Kazanci, O.B. Human physiology for personal thermal comfort-based HVAC control—A review. Build. Environ. 2023, 240, 110418. [Google Scholar] [CrossRef]

- Dempsey, J.A.; Smith, C.A. Pathophysiology of human ventilatory control: Number 6 in the series ‘physiology in respiratory medicine’. Eur. Respir. J. 2014, 44, 495–512. [Google Scholar] [CrossRef]

- Schwartz, I.; Gartsman, I.; Adler, B.; Friedlander, Y.; Manor, O.; Levine, H.; Meiner, Z. The association between post-polio symptoms as measured by the Index of Post-Polio Sequelae and self-reported functional status. J. Neurol. Sci. 2014, 345, 87–91. [Google Scholar] [CrossRef] [PubMed]

- Lithell, M.; Backman, C.; Nyström, Å. Pattern recognition in post-traumatic cold intolerance. J. Hand Surg. 1997, 22, 783–787. [Google Scholar] [CrossRef] [PubMed]

- On, A.Y.; Sungur, U. Patients with post-polio syndrome are more likely to have subclinical involvement as compared to polio survivors without new symptoms. Ann. Indian Acad. Neurol. 2016, 19, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Monga, A.K.; Bais, S. Polio: A Review. Int. J. Pharm. Sci. Res. 2013, 4, 1714–1724. [Google Scholar]

- Gomez-Beldarrain, M.; García-Moncó, J.C. Lumbar Puncture and CSF Analysis and Interpretation: A Clinical Approach, 2nd ed.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Skin Thermoregulation Vector & Photo (Free Trial)|Bigstock. Available online: https://www.bigstockphoto.com/image-345798238/stock-vector-skin-in-thermoregulation-body-temperature-regulation-if-the-body-is-too-hot%2C-blood-vessels-dilate (accessed on 25 August 2024).

- Silver, J.K. Post-Polio Syndrom: A Guide for Polio Survivors and Their Families; Yale University Press: New Haven, CT, USA, 2001; Volume XVI, 280p, ISBN 0-300-08807-8. [Google Scholar]

- Mcclure, J. Richard Owen—He Went from Polio Patient to Pioneering Physician. 2012. Available online: www.mncdd.org (accessed on 26 August 2024).

- Bruno, R.L. Be True to Your PPS and Your Teeth Won’t Be False to You: Preventing Complications in Polio Survivors Undergoing Dental Procedures; Lincolnshire Post-Polio Library; Harvest Center Library: Woodland Park, CO, USA, 1996. [Google Scholar]

- Bruno, R.L. Post-Polio Sequelae and the Paradigms of the 50’s: Newtie, Ozzie and Harriet versus Paradigms of Caring and a Future for Rehabilitation in America. In Proceedings of the 45th Annual John Stanley Coulter Memorial Lecture Presented to the American Congress of Rehabilitation Medicine, Alexandria, VA, USA, 24 June 1995. [Google Scholar]

- Khabbazi, A.; Farzaneh, R.; Mahmoudi, M.; Shahi, M.; Sarmadian, A.J.; Babapour, E.; Alizadeh, L.; Khabbazi, R.; Nouri-Vaskeh, M. Cold intolerance and associated factors: A population study. Sci. Rep. 2022, 12, 18029. [Google Scholar] [CrossRef]

- Sun, Y.C.; Chen, Q.Z.; Chen, J.; Qian, Z.W.; Kong, J.; Gong, Y.P. Prevalence, characteristics and natural history of cold intolerance after the reverse digital artery flap. J. Hand Surg. 2016, 41, 171–176. [Google Scholar] [CrossRef]

- Nijhuis, T.H.J.; Smits, E.S.; Jaquet, J.B.; Van Oosterom, F.J.T.; Selles, R.W.; Hovius, S.E.R. Prevalence and severity of cold intolerance in patients after hand fracture. J. Hand Surg. Am. 2010, 2010, 306–311. [Google Scholar] [CrossRef]

- Bae, K.H.; Lee, Y.; Go, H.Y.; Kim, S.-J.; Lee, S.-W. The Relationship between Cold Hypersensitivity in the Hands and Feet and Health-Related Quality of Life in Koreans: A Nationwide Population Survey. Evid. Based Complement. Altern. Med. 2019, 2019, 6217036. [Google Scholar] [CrossRef]

- Wu, X.; Yoshino, T.; Maeda-Minami, A.; Ishida, S.; Tanaka, M.; Nishi, A.; Tahara, Y.; Inami, R.; Sugiyama, A.; Horiba, Y.; et al. Exploratory study of cold hypersensitivity in Japanese women: Genetic associations and somatic symptom burden. Sci. Rep. 2024, 14, 1918. [Google Scholar] [CrossRef]

- Bhatia, D.; Jaswal, P.; Sinha, S.K. A Review of Emerging Technologies and Future Fabrics for Extreme Cold. Text. Leather Rev. 2024, 7, 265–291. [Google Scholar] [CrossRef]

- Jussila, K.; Valkama, A.; Remes, J.; Anttonen, H.; Peitso, A. The effect of cold protective clothing on comfort and perception of performance. Int. J. Occup. Saf. Ergon. 2010, 16, 185–197. [Google Scholar] [CrossRef] [PubMed]

- Hu, J. The Use of Smart Materials in Cold Weather Apparel. In Textiles for Cold Weather Apparel; Woodhead Publishing: Cambridgeshire, UK, 2009. [Google Scholar]

- Zhang, Q.; Cheng, H.; Zhang, S.; Li, Y.; Li, Z.; Ma, J.; Liu, X. Advancements and challenges in thermoregulating textiles: Smart clothing for enhanced personal thermal management. Chem. Eng. J. 2024, 48, 151040. [Google Scholar] [CrossRef]

- Jiang, S.; Stange, O.; Bätcke, F.O.; Sultanova, S.; Sabantina, L. Applications of Smart Clothing—A Brief Overview. Commun. Dev. Assem. Text. Prod. 2021, 2, 123–140. [Google Scholar] [CrossRef]

- Charkoudian, N. Mechanisms and modifiers of reflex induced cutaneous vasodilation and vasoconstriction in humans. J. Appl. Physiol. 2010, 109, 1221–1228. [Google Scholar] [CrossRef]

- Johnson, J.M.; Kellogg, D.L. Skin vasoconstriction as a heat conservation thermoeffector. In Handbook of Clinical Neurology; Elsevier: Amsterdam, The Netherlands, 2018; pp. 175–192. [Google Scholar]

- Gao, S.; Ooka, R.; Oh, W. Experimental investigation of the effect of clothing insulation on thermal comfort indices. Build. Environ. 2020, 187, 107393. [Google Scholar] [CrossRef]

- McKemy, D.D. Molecular basis of peripheral innocuous cold sensitivity. In Handbook of Clinical Neurology; Elsevier: Amsterdam, The Netherlands, 2018; pp. 57–67. [Google Scholar]

- Marriott, B.M.; Newberry, S.J. Nutritional Needs in Cold and in High-Altitude Environments: Applications for Military Personnel in Field Operations; National Academy Press: Washington, DC, USA, 1996. [Google Scholar]

- Romanovsky, A.A. Skin temperature: Its role in thermoregulation. Acta Physiol. 2014, 210, 498–507. [Google Scholar] [CrossRef]

- ISO 15831:2004; Clothing-Physiological Effects-Measurement of Thermal Insulation by Means of a Thermal Manikin. International Organization for Standardization: Geneva, Switzerland, 2004.

- Zemzem, M.; Hallé, S.; Vinches, L. Thermal Insulation of Protective Clothing Materials in Extreme Cold Conditions. Saf. Health Work. 2023, 14, 107–117. [Google Scholar] [CrossRef]

- Mäkinen, H.; Jussila, K. Cold-protective clothing: Types, design and standards. In Protective Clothing: Managing Thermal Stress; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 3–38. [Google Scholar]

- Matusiak, M.; Kowalczyk, S. Thermal-insulation properties of multilayer textile packages. Autex Res. J. 2014, 14, 299–307. [Google Scholar] [CrossRef]

- Frydrych, I.; Dziworska, G.; Bilska, J. Comparative Analysis of the Thermal Insulation Properties of Fabrics Made of Natural and Man-Made Cellulose Fibres. Fibres Text. East. Eur. 2002, 10, 40–44. [Google Scholar]

- Marolleau, A.; Salaun, F.; Dupont, D.; Gidik, H.; Ducept, S. Influence of textile properties on thermal comfort. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 182007. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, S.; Sun, H.; Sun, X.; Tao, L.; Yan, D. Effect of Fiber Content on Properties of Fiber Reinforced Nano-SiO2 Thermal Insulation Material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 678, 012038. [Google Scholar] [CrossRef]

- Halaoua, S.; Romdhani, Z.; Jemni, A. Effect of textile woven fabric parameters on its thermal properties. Ind. Textila 2019, 70, 15–20. [Google Scholar]

- Matusiak, M.; Sikorski, K. Influence of the Structure of Woven Fabrics on Their Thermal Insulation Properties. Fibres Text. East. Eur. 2011, 19, 88. [Google Scholar]

- Shaker, K.; Umair, M.; Jabbar, M.; Baitab, D.M.; Nawab, Y.; Afzal, A.; Ahmad, S. Effect of fabric structural design on the thermal properties of woven fabrics. Therm. Sci. 2018, 2018, 3059–3066. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Tokarska, M.; Frydrych, I. Application of Coating Mixture Based on Silica Aerogel to Improve Thermal Protective Performance of Fabrics. Autex Res. J. 2023, 23, 48–54. [Google Scholar] [CrossRef]

- Bajzik, V.; Hes, L. The effect of finishing treatment on thermal insulation and thermal contact properties of wet fabrics. Text. Appar. 2012, 22, 26–31. [Google Scholar]

- Palani Rajan, T.; Kandhavadivu, P.; Periyasamy, A.P. Influence of Porosity and Yarn Linear Density on the Thermal Behaviour of Polyester Warp Knitted Spacer Fabrics. Fibers Polym. 2021, 22, 3212–3221. [Google Scholar] [CrossRef]

- Abu-Rous, M.; Dabolina, I.; Lapkovska, E. Fabric physical properties and clothing comfort. IOP Conf. Ser. Mater. Sci. Eng. 2018, 459, 012028. [Google Scholar] [CrossRef]

- Erkan, G. Enhancing The Thermal Properties of Textiles With Phase Change Materials. Res. J. Text. Appar. 2004, 8, 57–64. [Google Scholar] [CrossRef]

- Black, C.P.; Matthew, J.A. 16—The physical properties of fabrics in relation to clothing: Part III—Heat insulation by fabrics used as body clothing. J. Text. Inst. Trans. 1934, 25, T249–T276. [Google Scholar] [CrossRef]

- Kumar, B.; Singh, J.; Das, A.; Alagirusamy, R. Comfort and compressional characteristics of padding bandages. Mater. Sci. Eng. C 2015, 57, 215–221. [Google Scholar] [CrossRef] [PubMed]

- Chemeh, Z.K.; Montazer, M.; Tavanaie, M.; Mahmoudirad, M. Effective Method for Multifunctionalization of Non-Woven Polyester Fabric Using Carbon Black Nanoparticles/Vinyl Acrylic Dispersion by Padding Technique. Fibers Polym. 2023, 24, 4253–4268. [Google Scholar] [CrossRef]

- Kim, S.; Kim, E.; Park, Y. Thermal insulation and morphology of natural and synthetic filled outdoor sportswear by repeated water washing and dry cleaning. Int. J. Cloth. Sci. Technol. 2018, 30, 428–443. [Google Scholar] [CrossRef]

- Yu, B.; Chang, Q.; Zhao, T.; Wang, L. Determination for thickness of the multilayer thermal insulation clothing based on the inverse problems. Math. Probl. Eng. 2019, 2019, 5193729. [Google Scholar] [CrossRef]

- Greszta, A.; Bartkowiak, G.; Dabrowska, A.; Gliścińska, E.; Machnowski, W.; Kozikowski, P. Multilayer Nonwoven Inserts with Aerogel/PCMs for the Improvement of Thermophysiological Comfort in Protective Clothing against the Cold. Materials 2022, 15, 2307. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Kotresh, T.M.; Militky, J.; Jamshaid, H. Aerogels for thermal insulation in high-performance textiles. Text. Prog. 2016, 48, 55–118. [Google Scholar] [CrossRef]

- Sun, C.; Fan, J.; Wu, H.; Wu, Y.; Wan, X. Cold protective clothing with reflective nano-fibrous interlayers for improved comfort. Int. J. Cloth. Sci. Technol. 2013, 25, 380–388. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Fang, K.; Shu, D.; Gong, J.; Liu, X. Effect of the water content of padded cotton fabrics on reactive dye fixation in the pad-steam process. Color. Technol. 2017, 133, 57–64. [Google Scholar] [CrossRef]

- Furferi, R.; Mantellassi, F.; Volpe, Y. Design and manufacturing of an innovative triple-layer thermo-insulated fabric. Appl. Sci. 2020, 10, 680. [Google Scholar] [CrossRef]

- PrimaLoft Ft F ® Fiber Wool Fiber. Available online: www.primaloft.com (accessed on 1 September 2024).

- Lastn, A.L. A History of the Development of an Armor Ensemble for Mine Clearance Personnel; Army Natick Labs Ma Clothing and Personal Life Support Equipment Lab: Natick, MA, USA, 1970. [Google Scholar]

- Cui, Y.; Gong, H.; Wang, Y.; Li, D.; Bai, H. A Thermally Insulating Textile Inspired by Polar Bear Hair. Adv. Mater. 2018, 30, e1706807. [Google Scholar] [CrossRef]

- Maghsoudian, A.; Alvani, S.; Moaref, R.; Jamalpour, S.; Tamsilian, Y.; Kiasat, A. The concept of biomimetics in the development of protective textiles. In Protective Textiles from Natural Resources; Elsevier: Amsterdam, The Netherlands, 2022; pp. 133–173. [Google Scholar]

- Wang, Z.; Yang, H.; Li, Y.; Zheng, X. Robust Silk Fibroin/Graphene Oxide Aerogel Fiber for Radiative Heating Textiles. ACS Appl. Mater. Interfaces 2020, 12, 15726–15736. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, Y.; Liang, X.; Zhang, Y. Smart Fibers and Textiles for Personal Health Management. ACS Nano 2021, 15, 12497–12508. [Google Scholar] [CrossRef] [PubMed]

- Křemenáková, D.; Militký, J.; Venkataraman, M.; Mishra, R. Thermal Insulation and Porosity—From Macro-to Nanoscale; Springer: Cham, Switzerland, 2017; pp. 425–448. [Google Scholar]

- Kucukali Ozturk, M.; Venkataraman, M.; Mishra, R. Influence of structural parameters on thermal performance of polypropylene nonwovens. Polym. Adv. Technol. 2018, 29, 3027–3034. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, J.; Lu, S. Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel. Materials 2023, 16, 6954. [Google Scholar] [CrossRef] [PubMed]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J.; Arıcı, M. Investigation of the Effect of Air Layer Thickness on the Thermal Performance of the PCM Integrated Roof. Buildings 2023, 13, 488. [Google Scholar] [CrossRef]

- Song, G. Cothing air gap layers and thermal protective performance in single layer garment. J. Ind. Text. 2007, 36, 193–205. [Google Scholar] [CrossRef]

- Zheng, L.; Aouraghe, M.A.; Zhang, K.; Xu, F. Ultra-light 3D fabric Reinforced Composite with Distinct Thermal Insulation and Superior Sound-Absorbing Properties. J. Phys. Conf. Ser. 2021, 1790, 012065. [Google Scholar] [CrossRef]

- Zhi, C.; Du, M.; Sun, Z.; Wu, M.; He, X.; Meng, J.; Yu, L. Warp-knitted spacer fabric reinforced syntactic foam: A compression modulus meso-mechanics theoretical model and experimental verification. Polymers 2020, 12, 286. [Google Scholar] [CrossRef]

- Li, N.W.; Yick, K.L.; Yu, A.; Ning, S. Mechanical and Thermal Behaviours of Weft-Knitted Spacer Fabric Structure with Inlays for Insole Applications. Polymers 2022, 14, 619. [Google Scholar] [CrossRef]

- Mao, N.; Russell, S.J. The Thermal Insulation Properties of Spacer Fabrics with a Mechanically Integrated Wool Fiber Surface. Text. Res. J. 2007, 77, 914–922. [Google Scholar] [CrossRef]

- Eom, R.I.; Lee, H.; Lee, Y. Evaluation of thermal properties of 3D spacer technical materials in cold environments using 3D printing technology. Polymers 2019, 11, 1438. [Google Scholar] [CrossRef] [PubMed]

- McNeil, S.J.; Gupta, H. Emerging applications of aerogels in textiles. Polym. Test. 2021, 106, 107426. [Google Scholar] [CrossRef]

- Sheng, Z.; Liu, Z.; Hou, Y.; Jiang, H.; Li, Y.; Li, G.; Zhang, X. The Rising Aerogel Fibers: Status, Challenges, and Opportunities. Adv. Sci. 2023, 10, e2205762. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Chen, W.; Zhou, X. Thermal insulation fibers with a Kevlar aerogel core and a porous Nomex shell. RSC Adv. 2021, 11, 34828–34835. [Google Scholar] [CrossRef]

- Ziaei, M.; Ghane, M. Thermal insulation property of spacer fabrics integrated by ceramic powder impregnated fabrics. J. Ind. Text. 2013, 43, 20–33. [Google Scholar] [CrossRef]

- Abbas, A.; Zhao, Y.; Ali, U.; Lin, T. Improving heat-retaining property of cotton fabrics through surface coatings. J. Text. Inst. 2017, 108, 1808–1814. [Google Scholar] [CrossRef]

- Militký, J.; Mishra, R.; Yang, T.; Xiong, X.; Kanai, H. Thermal and compression characteristics of aerogel-encapsulated textiles. J. Ind. Text. 2018, 47, 1998–2013. [Google Scholar]

- Rosace, G.; Guido, E.; Colleoni, C.; Barigozzi, G. Influence of textile structure and silica based finishing on thermal insulation properties of cotton fabrics. Int. J. Polym. Sci. 2016, 2016, 1726475. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Liu, Z.; Cheng, H.; Li, C. Continuous, strong, porous silk firoin-based aerogel fibers toward textile thermal insulation. Polymers 2019, 11, 1899. [Google Scholar] [CrossRef]

- Devi, S.; Jeet Singh, S.S. Use of aerogel in textile and apparel industry. Pharma Innov. J. 2019, 8, 329–332. [Google Scholar]

- Ratke, L. Aerogels-Structure, properties and applications. In Proceedings of the 13th Meeting on Supercritical Fluids ISASF, The Hague, The Netherlands, 9–12 October 2011. [Google Scholar]

- Karamikamkar, S.; Naguib, H.E.; Park, C.B. Advances in precursor system for silica-based aerogel production toward improved mechanical properties, customized morphology, and multifunctionality: A review. Adv. Colloid Interface Sci. 2020, 276, 102101. [Google Scholar] [CrossRef] [PubMed]

- Fijalkowski, M.; Coufal, R.; Ali, A.; Adach, K.; Petrik, S.; Bu, H.; Karl, C.W. Flexible Hybrid and Single-Component Aerogels: Synthesis, Characterization, and Applications. Langmuir 2023, 39, 16760–16775. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xu, T.; Zhang, F.; Du, C.; He, S. Preparation of Super-Flexible Silica Aerogel and Its Application in Oil–Water Separation. Gels 2023, 9, 739. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.; Chen, X.; Song, H.; Guo, K.; Hu, Z. Highly flexible silica aerogels derived from methyltriethoxysilane and polydimethylsiloxane. N. J. Chem. 2015, 39, 7832–7838. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; Portugal, A. Synthesis of lightweight polymer-reinforced silica aerogels with improved mechanical and thermal insulation properties for space applications. Microporous Mesoporous Mater. 2014, 197, 116–129. [Google Scholar] [CrossRef]

- Fu, Y.W.; Zhang, Y.Q.; Sun, W.F.; Wang, X. Functionalization of Silica Nanoparticles to Improve Crosslinking Degree, Insulation Performance and Space Charge Characteristics of UV-initiated XLPE. Molecules 2020, 25, 3794. [Google Scholar] [CrossRef]

- Mahtabani, A.; Rytöluoto, I.; Anyszka, R.; He, X.; Saarimäki, E.; Lahti, K.; Paajanen, M.; Dierkes, W.; Blume, A. On the Silica Surface Modification and Its Effect on Charge Trapping and Transport in PP-Based Dielectric Nanocomposites. ACS Appl. Polym. Mater. 2020, 2, 3148–3160. [Google Scholar] [CrossRef]

- Maia, J.; Pedroso, M.; Ramos, N.M.M.; Flores-Colen, I.; Pereira, P.F.; Silva, L. Durability of a new aerogel cement-based rendering system under distinct accelerated aging conditions. Materials 2021, 14, 5413. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, A.P.I.; Popoola, O.M. Silica nanofillers-reinforced polyimide composites for mechanical, thermal, and electrical insulation applications and recommendations: A review. J. Phys. Conf. Ser. 2022, 2368, 012001. [Google Scholar] [CrossRef]

- Katoueizadeh, E.; Rasouli, M.; Zebarjad, S.M. A comprehensive study on the gelation process of silica gels from sodium silicate. J. Mater. Res. Technol. 2020, 9, 10157–10165. [Google Scholar] [CrossRef]

- Abreu, M.J.; Catarino, A.; Tama, D. Evaluating the effect of fabric type on thermal insulation properties of sports clothing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012005. [Google Scholar] [CrossRef]

- Ullah, H.M.K.; Lejeune, J.; Cayla, A.; Monceaux, M.; Campagne, C.; Devaux, É. A review of noteworthy/major innovations in wearable clothing for thermal and moisture management from material to fabric structure. Text. Res. J. 2022, 92, 3351–3386. [Google Scholar] [CrossRef]

- Güney, S. Virtualization of Clothing Thermal Comfort in 3D Simulations. Eur. J. Sci. Technol. 2021, 28, 29–33. [Google Scholar] [CrossRef]

- Atasağun, H.G.; Okur, A.; Psikuta, A.; Rossi, R.M.; Annaheim, S. The effect of garment combinations on thermal comfort of office clothing. Text. Res. J. 2019, 89, 4425–4437. [Google Scholar] [CrossRef]

- Chen, Y.S.; Fan, J.; Qian, X.; Zhang, W. Effect of Garment Fit on Thermal Insulation and Evaporative Resistance. Text. Res. J. 2004, 74, 742–748. [Google Scholar] [CrossRef]

- Lu, Y.; Song, G.; Li, J.; Wang, F. The impact of air gap on thermal performance of protective clothing against hot water spray. Text. Res. J. 2015, 85, 709–721. [Google Scholar] [CrossRef]

- Bizuneh, B.; Destaw, A.; Mamo, B. Analysis of garment fit satisfaction and fit preferences of Ethiopian male consumers. Res. J. Text. Appar. 2023, 27, 228–245. [Google Scholar] [CrossRef]

- Anand, N. Pattern Engineering and Functional Clothing; NISCAIR-CSIR: Delhi, India, 2011; Available online: https://www.researchgate.net/publication/297514997 (accessed on 15 September 2024).

- Lu, Y.; Song, G.; Li, J. A novel approach for fit analysis of thermal protective clothing using three-dimensional body scanning. Appl. Ergon. 2014, 45, 1439–1446. [Google Scholar] [CrossRef]

- Mert, E.; Böhnisch, S.; Psikuta, A.; Bueno, M.-A.; Rossi, R.M. Contribution of garment fit and style to thermal comfort at the lower body. Int. J. Biometeorol. 2016, 60, 1995–2004. [Google Scholar] [CrossRef]

- Špelić, I.; Rogale, D.; Mihelić Bogdanić, A.; Petrak, S.; Naglić, M.M. Changes in Ensembles’ Thermal Insulation According to Garment’s Fit and Length Based on Athletic Figure. Fibers Polym. 2018, 19, 1278–1287. [Google Scholar] [CrossRef]

- Młynarczyk, M.; Orysiak, J.; Jankowski, J.; Prus, P. Impact of Clothing Size on Thermal Insulation—A Pilot Study. Fibres Text. East. Eur. 2023, 31, 1–8. [Google Scholar] [CrossRef]

- Lim, J.; Choi, H.; Roh, E.K.; Yoo, H.; Kim, E. Assessment of airflow and microclimate for the running wear jacket with slits using CFD simulation. Fash. Text. 2015, 2, 1. [Google Scholar] [CrossRef]

- Li, S.; Wang, R.; Qian, X.; Zhao, Z.J. Effect of wind velocity on clothing thermal resistance and indoor comfortable temperature design. Adv. Mater. Res. 2011, 332–334, 1600–1603. [Google Scholar] [CrossRef]

- Hou, Y. Effect of wind speed on human thermal sensation and thermal comfort. AIP Conf. Proc. 2018, 1971, 030012. [Google Scholar] [CrossRef]

- Song, W.; Lu, Y.; Su, W.; Wang, F.; Wang, M. Investigation on the thermal insulation regulating performance of a newly developed air inflatable garment. J. Clean. Prod. 2021, 293, 126110. [Google Scholar] [CrossRef]

- Jana, P. Assembling Technologies for Functional Garments—An Overview; NISCAIR-CSIR: Delhi, India, 2011; Available online: https://www.researchgate.net/publication/297687236 (accessed on 13 October 2024).

- Colovic, G. Sewing, stitches and seams. In Garment Manufacturing Technology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 247–273. [Google Scholar]

- Mazari, A. Effect of needle heating on the sewing of medical textiles. Polymers 2021, 13, 4405. [Google Scholar] [CrossRef]

- Stylios, G.K.; Zhu, R. The mechanism of sewing damage in knitted fabrics. J. Text. Inst. 1998, 89, 411–421. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Forming characteristics and surface damages of stitched multi-layered para-aramid fabrics with various stitching parameters for soft body armour design. Compos. Part A Appl. Sci. Manuf. 2018, 109, 517–537. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Sikka, M.P.; Bansal, P. The study of sewing damages and defects in garments. Res. J. Text. Appar. 2018, 22, 109–125. [Google Scholar] [CrossRef]

- Suh, H.W.; Ko, H.S. Optimal Stitch Forming Line Identification for Attaching Patches on Non-Developable Clothing Surfaces. CAD Comput. Aided Des. 2021, 139, 103051. [Google Scholar] [CrossRef]

- Beaudette, E.; Park, H. Impact of seam types on thermal properties of athletic bodywear. Text. Res. J. 2017, 87, 1052–1059. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Kumari, D. Seams for Protective Clothing—An Overview. World 2017, 3, 17. [Google Scholar]

- Song, G.; Mandal, S.; Rossi, R.M. Thermal Protective Clothing for Firefighters; Iowa State University: Ames, IA, USA; University of Alberta: Edmonton, AB, Canada; Empa: Duebendorf, Switzerland; The Textile Institute and Woodhead Publishing: Cambridgeshire, UK, 2017. [Google Scholar]

- Mishra, R.; Jamshaid, H.; Basra, S.A.; Jiang, G.; Gao, Z.; Ma, P.; Petru, M.; Raza, A.; Muller, M. Effect of Stitch Characteristics on Flammability and Thermo-Physiological Comfort Properties of Knitted Fabrics. Fibers Polym. 2020, 21, 2652–2663. [Google Scholar] [CrossRef]

- Ai, S.; Mao, Y.; Pei, Y.; Fang, D.; Tang, L. Effect of stitch on thermodynamic properties of sandwiched thermal protection structures. Compos. Struct. 2013, 99, 41–47. [Google Scholar] [CrossRef]

- Boles, K.; Ghosh, S.; Chipot, N. Examination of Alternative Fabric Joining Techniques Compared to Traditional Sewing. McNair Sch. Res. J. 2012, 5, 3. [Google Scholar]

- Saeed, H.; Rödel, H.; Krzywinski, S.; Hes, L. A New Stitching Technology for Improved Thermal Insulation of 3D Nowoven Assemblies. Appl. Compos. Mater. 2019, 26, 409–421. [Google Scholar] [CrossRef]

- Moisture Management for Cold Weather: Stay Dry, Warm, and Protected This Season. Available online: https://www.thinknsa.com/blog/moisture-management-for-cold-weather (accessed on 4 September 2024).

- Master Cold Stress Safety|Top PPE Tips & Gear for Winter Workers|LibertySafety.com. Available online: https://www.libertysafety.com/safety-blog/safety-compliance/beating-the-chill-cold-stress-prevention-and-the-power-of-proper-ppe/ (accessed on 4 September 2024).

- Wang, S.X.; Li, Y.; Tokura, H.; Hu, J.; Han, Y.; Kwok, Y.; Au, R. Effect of Moisture Management on Functional Performance of Cold Protective Clothing. Text. Res. J. 2007, 77, 968–980. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, J.; Guo, X.; Hu, Y.; Niu, X.; Wang, F. Personal Wearable Thermal and Moisture Management Clothing: A Review on Its Recent Trends and Performance Evaluation Methods. Processes 2023, 11, 3063. [Google Scholar] [CrossRef]

- Chinta, S.K.; Gujar, P.D. Significance of Moisture Management for High-Performance Textile Fabrics. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 814–819. [Google Scholar]

- Burlington®. Moisture Control System. Available online: https://www.burlingtonfabrics.com/performance-technology/moisture-control-system/ (accessed on 24 August 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuhay, A.; Tadesse, M.G.; Berhanu, B.; Malengier, B.; Langenhove, L.V. Advancements in Clothing Thermal Comfort for Cold Intolerance. Fibers 2025, 13, 13. https://doi.org/10.3390/fib13020013

Abuhay A, Tadesse MG, Berhanu B, Malengier B, Langenhove LV. Advancements in Clothing Thermal Comfort for Cold Intolerance. Fibers. 2025; 13(2):13. https://doi.org/10.3390/fib13020013

Chicago/Turabian StyleAbuhay, Amare, Melkie Getnet Tadesse, Baye Berhanu, Benny Malengier, and Lieva Van Langenhove. 2025. "Advancements in Clothing Thermal Comfort for Cold Intolerance" Fibers 13, no. 2: 13. https://doi.org/10.3390/fib13020013

APA StyleAbuhay, A., Tadesse, M. G., Berhanu, B., Malengier, B., & Langenhove, L. V. (2025). Advancements in Clothing Thermal Comfort for Cold Intolerance. Fibers, 13(2), 13. https://doi.org/10.3390/fib13020013