Flammability of Plant-Based Loose-Fill Thermal Insulation: Insights from Wheat Straw, Corn Stalk, and Water Reed

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw LCB

2.2. Processing of Raw LCB

2.2.1. Steam Explosion (SE) Pulping

2.2.2. Chemi-Mechanical Pulping (CMP)

2.2.3. Mechanical Foaming of Processed LCB

2.2.4. Admixture of Fire Retardant and Fungicide

2.3. Determination of Flammability

2.3.1. Sample Designations and Incorporation Density

2.3.2. Cone Calorimetry

2.3.3. Determination of Fire Resistance Class

2.4. Statistical Analysis

3. Results and Discussion

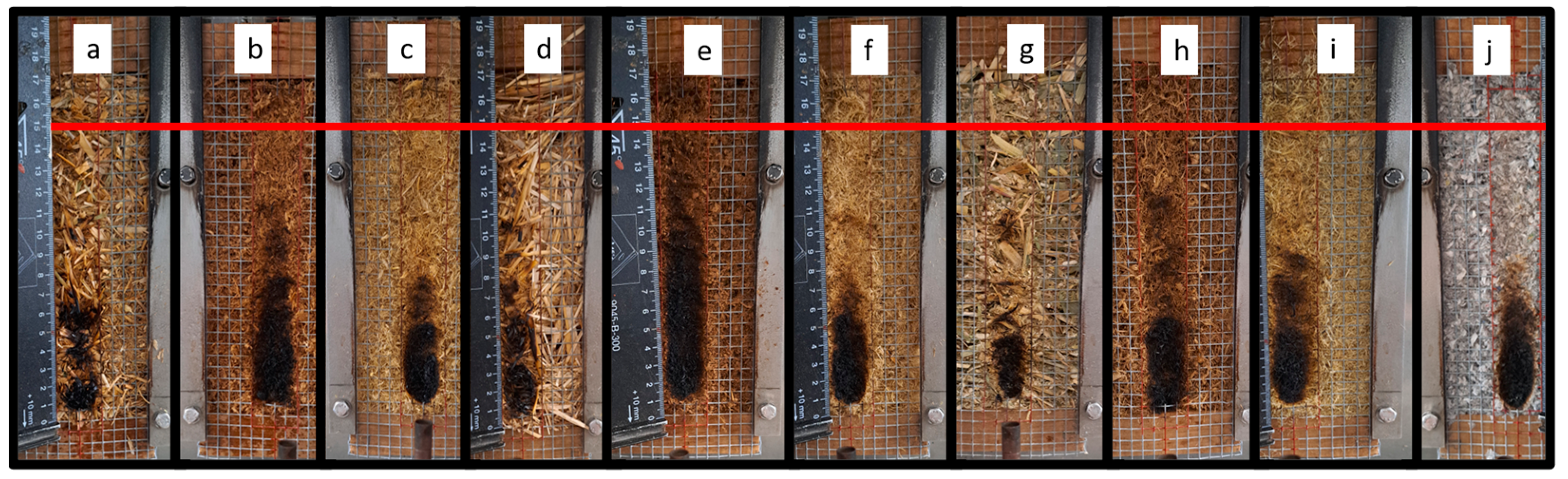

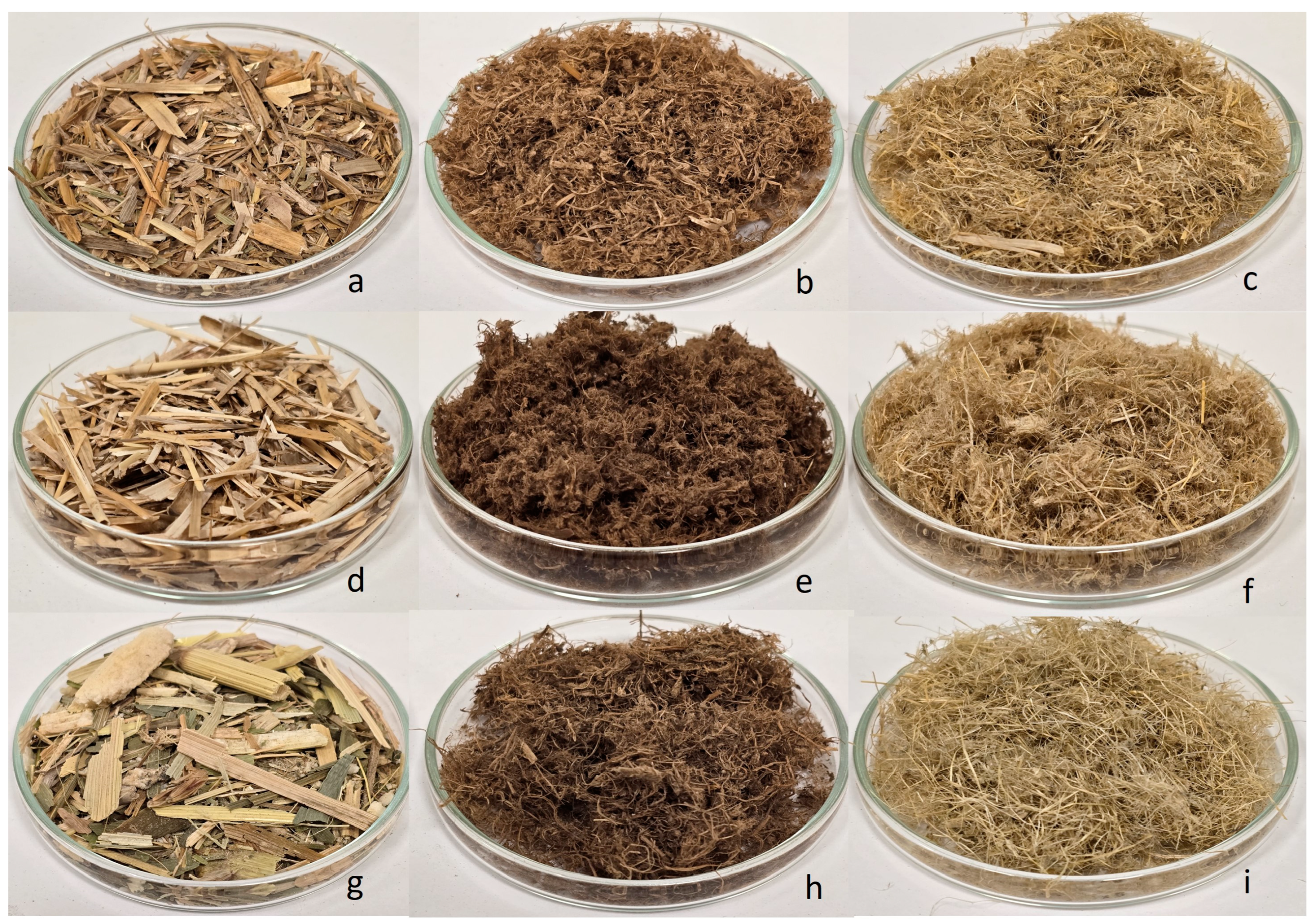

3.1. Visual Characterization of LCB Samples

3.2. Fire Resistance Analysis

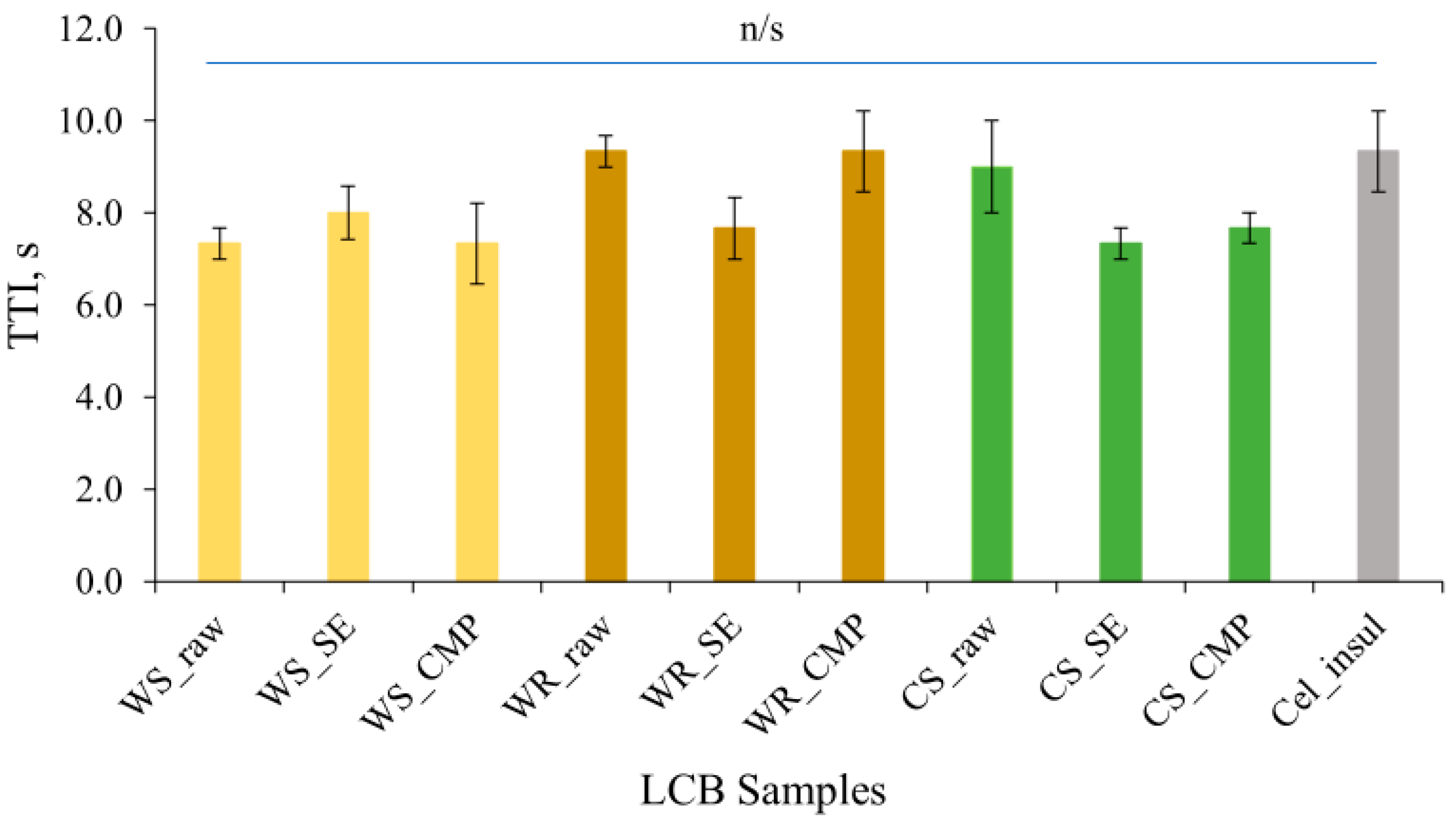

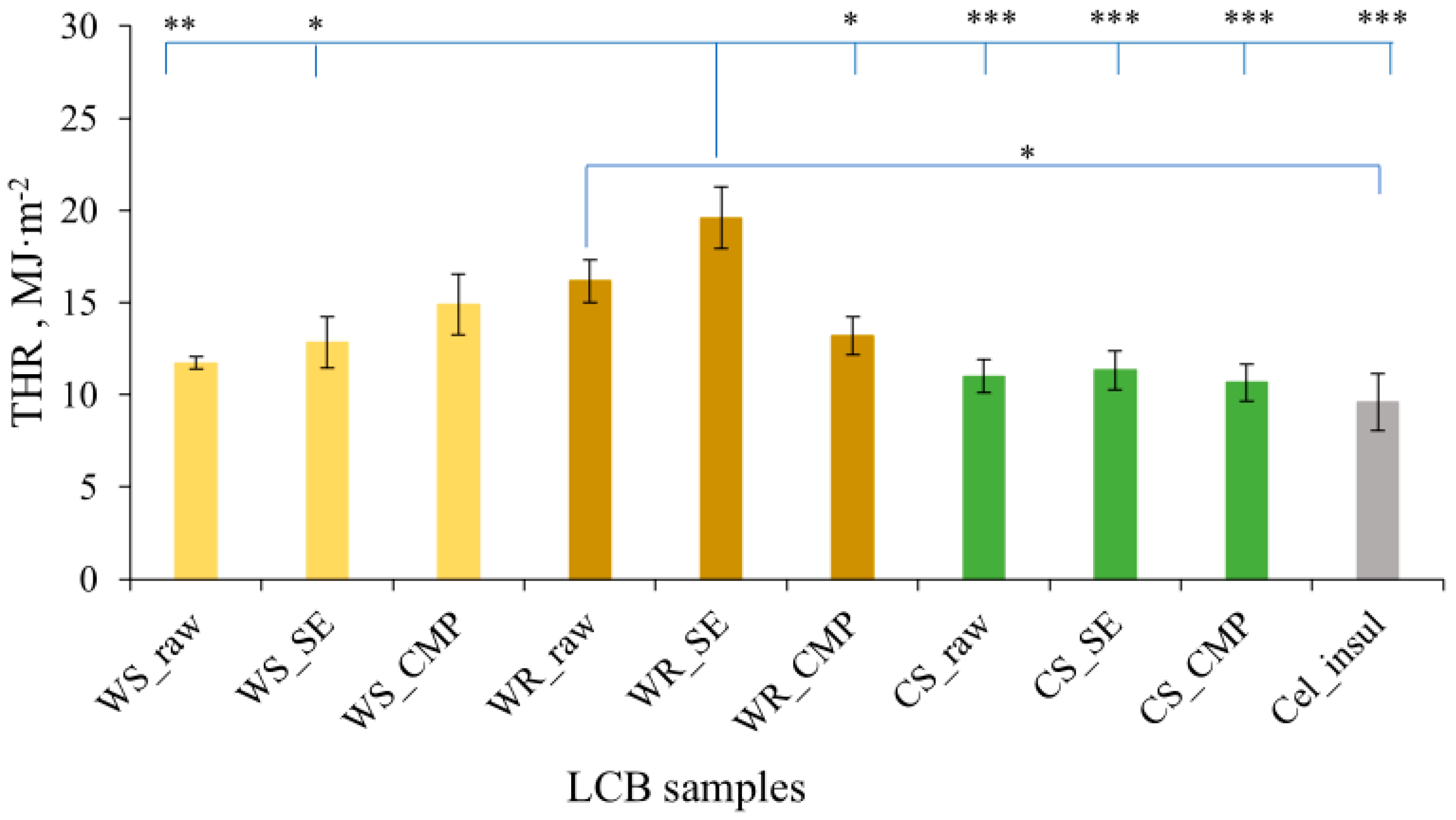

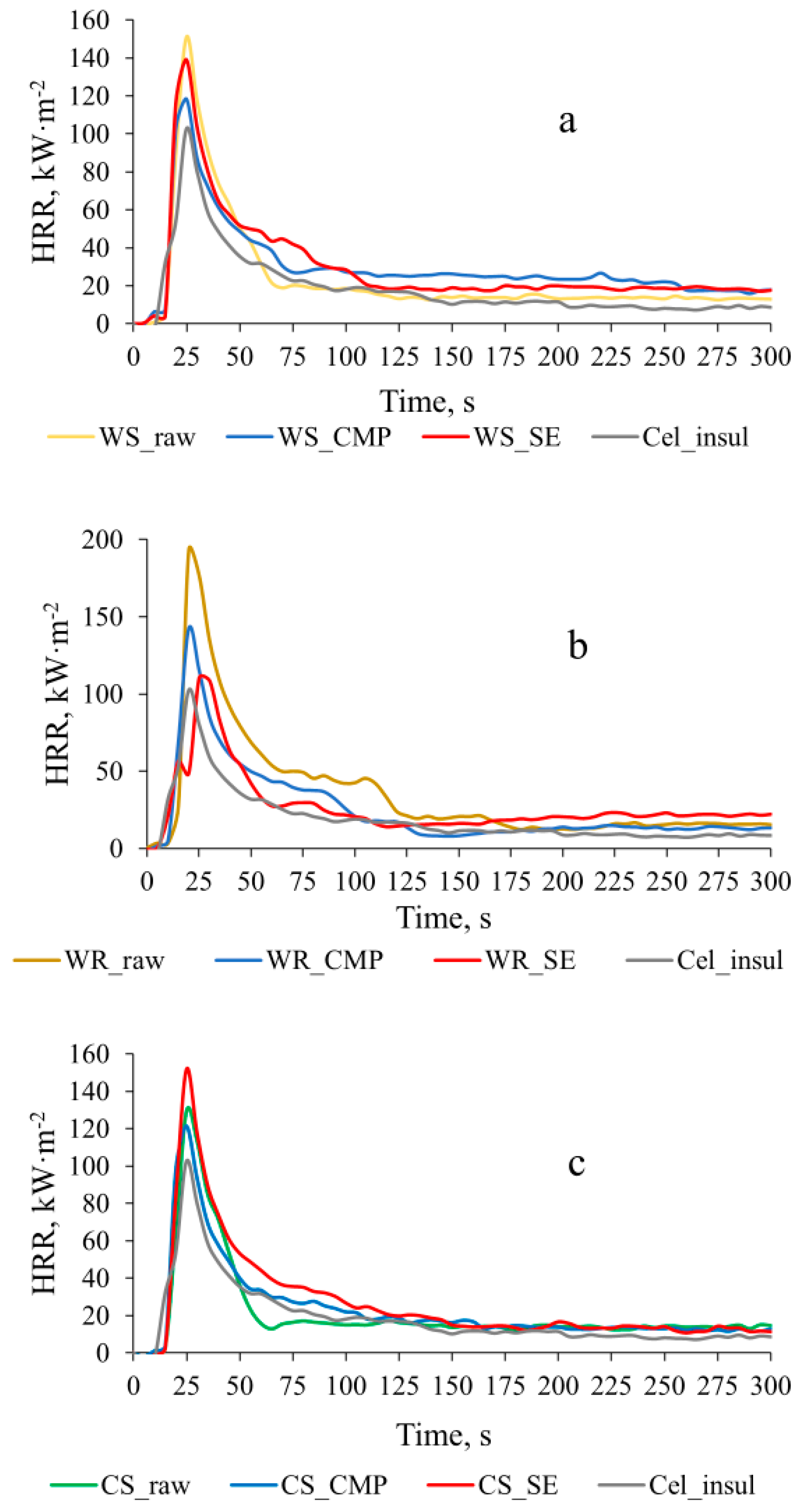

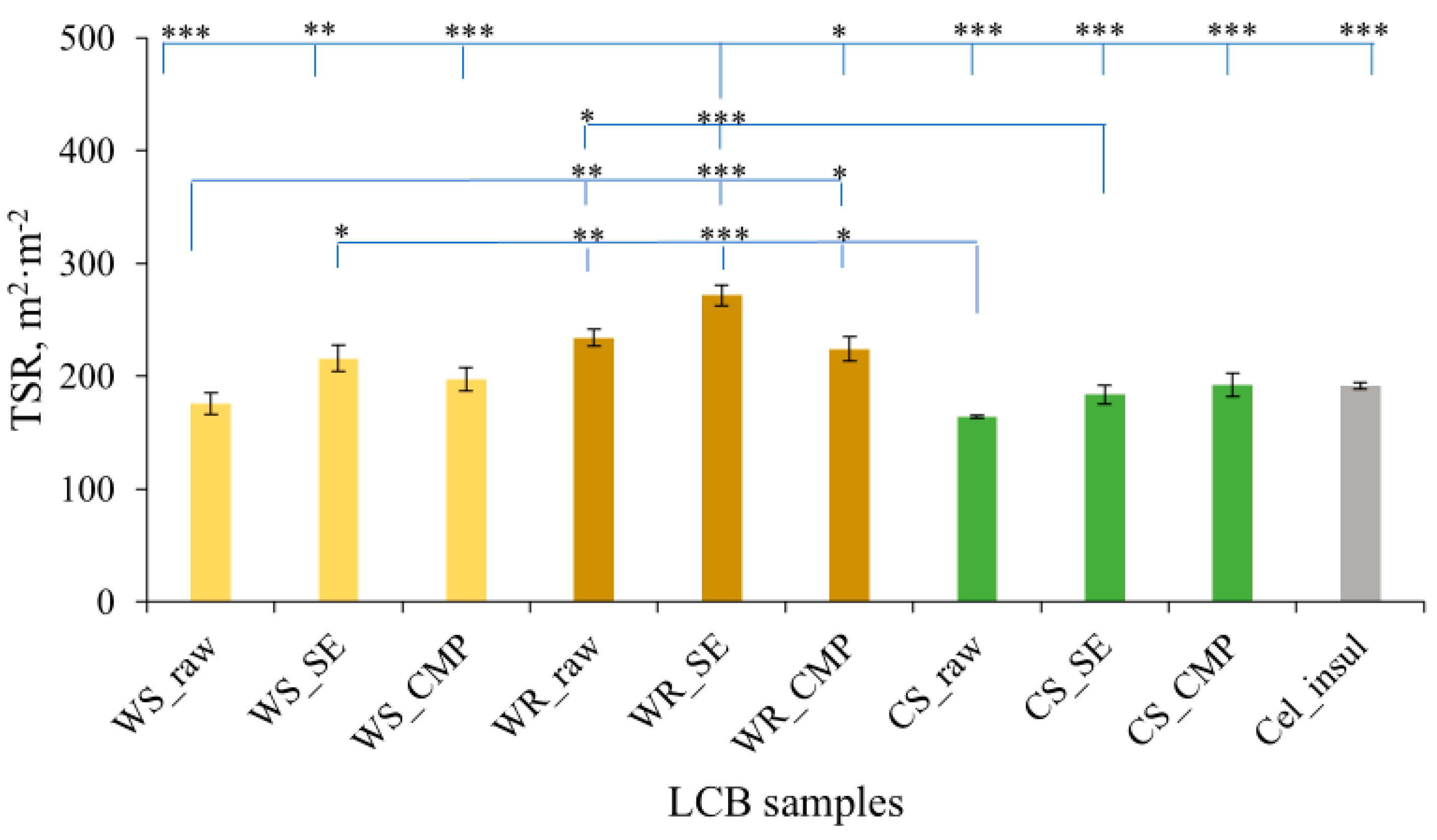

3.2.1. Results of Cone Calorimetry

3.2.2. Reaction to Flame Source

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raja, P.; Murugan, V.; Ravichandran, S.; Behera, L.; Mensah, R.A.; Mani, S.; Kasi, A.K.; Balasubramanian, K.B.N.; Sas, G.; Vahabi, H.; et al. A Review of Sustainable Bio-Based Insulation Materials for Energy-Efficient Buildings. Macromol. Mater. Eng. 2023, 308, 2300086. [Google Scholar] [CrossRef]

- Freivalde, L.; Kukle, S.; Andžs, M.; Bukšans, E.; Gravitis, J. Flammability of Raw Insulation Materials Made of Hemp. Compos. Part B Eng. 2014, 67, 510–514. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Lacasta, A.; Haurie, L. Fire Behavior of Bio-Based Earth Products for Sustainable Buildings. Acad. J. Civ. Eng. 2017, 35, 160–165. [Google Scholar] [CrossRef]

- European Commission. 2050 Long-Term Strategy. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 2 December 2024).

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Abbott, B.P.; Abbott, R.; Abbott, T.D.; Abbott, B.P.; Abbott, R.; Abbott, T.D.; Titirici, M.; Baird, S.G.; Sparks, T.D.; Yang, S.M.; et al. The Sustainable Materials Roadmap. J. Phys. Mater. 2022, 5, 032001. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Z.; Zhang, Y.; Liu, Y.; Osman, A.I.; Farghali, M.; Hua, J.; Al-Fatesh, A.; Ihara, I.; Rooney, D.W.; et al. Artificial Intelligence-Based Solutions for Climate Change: A Review; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; Volume 21, ISBN 0123456789. [Google Scholar]

- Iroegbu, A.O.C.; Ray, S.S. Bamboos: From Bioresource to Sustainable Materials and Chemicals. Sustainability 2021, 13, 12200. [Google Scholar] [CrossRef]

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance. Energies 2023, 16, 7440. [Google Scholar] [CrossRef]

- Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T. Analysis of the Thermal Insulation and Fire-Resistance Capacity of Particleboards Made from Vine (Vitis vinifera L.) Prunings. Polymers 2020, 12, 1147. [Google Scholar] [CrossRef]

- Geß, A.; Lorenz, M.; Tolsdorf, A.; Albrecht, S. Environmental Impacts of Renewable Insulation Materials. Sustainability 2021, 13, 8505. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Saharudin, D.M.; Azapagic, A. Environmental Sustainability of Negative Emissions Technologies: A Review. Sustain. Prod. Consum. 2022, 33, 608–635. [Google Scholar] [CrossRef]

- Andrusiak, A.; Borysiuk, P. Lignocellulosic Materials from the Stems of Annual Plants. Ann. WULS For. Wood Technol. 2024, 125, 38–51. [Google Scholar] [CrossRef]

- Mujtaba, M.; Fernandes Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo de Medeiros, G.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Schnabel, T.; Huber, H.; Petutschnigg, A.; Jäger, A. Analysis of Plant Materials Pre-Treated by Steam Explosion Technology for Their Usability as Insulating Materials. Agron. Res. 2019, 17, 1191–1198. [Google Scholar] [CrossRef]

- Pavelek, M.; Adamová, T. Bio-Waste Thermal Insulation Panel for Sustainable Building Construction in Steady and Unsteady-State Conditions. Materials 2019, 12, 2004. [Google Scholar] [CrossRef]

- Ninikas, K.; Mitani, A.; Koutsianitis, D.; Ntalos, G.; Taghiyari, H.R.; Papadopoulos, A.N. Thermal and Mechanical Properties of Green Insulation Composites Made from Cannabis and Bark Residues. J. Compos. Sci. 2021, 5, 132. [Google Scholar] [CrossRef]

- Elbashiry, E.M.A.; Chen, J.; Tuo, W.; Ren, Y.; Guo, Z. Review of the Pretreatment Methods for Wheat Straw Building Materials. J. Reinf. Plast. Compos. 2018, 37, 35–48. [Google Scholar] [CrossRef]

- Amatosa, T.A.; Loretero, M.E.; Manilhig, M.G.; Laksono, A.D.; Yen, Y.-W. Determination of Thermal Properties and Fire Retardant Ability of Philippine Bamboo as Natural Thermal Insulation. Int. J. Appl. Eng. Res. 2019, 14, 1764–1771. [Google Scholar]

- Schritt, H.; Pleissner, D. Recycling of Organic Residues to Produce Insulation Composites: A Review. Clean. Waste Syst. 2022, 3, 100023. [Google Scholar] [CrossRef]

- Cosentino, L.; Fernandes, J.; Mateus, R. A Review of Natural Bio-Based Insulation Materials. Energies 2023, 16, 4676. [Google Scholar] [CrossRef]

- Ali, A.; Issa, A.; Elshaer, A. A Comprehensive Review and Recent Trends in Thermal Insulation Materials for Energy Conservation in Buildings. Sustainability 2024, 16, e00102. [Google Scholar] [CrossRef]

- Zou, S.; Li, H.; Liu, L.; Wang, S.; Zhang, X.; Zhang, G. Experimental Study on Fire Resistance Improvement of Wheat Straw Composite Insulation Materials for Buildings. J. Build. Eng. 2021, 43, 103172. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Zhou, Y.; Trabelsi, A.; Mankibi, M. El A Review on the Properties of Straw Insulation for Buildings. Constr. Build. Mater. 2022, 330, 127215. [Google Scholar] [CrossRef]

- Theng, D.; El Mansouri, N.E.; Arbat, G.; Ngo, B.; Delgado-Aguilar, M.; Pèlach, M.A.; Fullana-i-Palmer, P.; Mutjé, P. Fiberboards Made from Corn Stalk Thermomechanical Pulp and Kraft Lignin as a Green Adhesive. BioResources 2017, 12, 2379–2393. [Google Scholar] [CrossRef]

- Köbbing, J.F.; Thevs, N.; Zerbe, S. The Utilisation of Reed (Phragmites australis): A Review. Mires Peat 2013, 13, 1–14. [Google Scholar]

- Yang, Y.; Haurie, L.; Wang, D.Y. Bio-Based Materials for Fire-Retardant Application in Construction Products: A Review. J. Therm. Anal. Calorim. 2022, 147, 6563–6582. [Google Scholar] [CrossRef]

- McNamee, M.; Meacham, B.J. Conceptual Basis for a Sustainable and Fire Resilient Built Environment. Fire Technol. 2023, 61, 29–62. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-Based Flame Retardants: When Nature Meets Fire Protection. Mater. Sci. Eng. R. Rep. 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Lee, M.; Lee, S.M.; Kang, E.C.; Son, D.W. Combustibility and Characteristics of Wood-Fiber Insulation Boards Prepared with Four Different Adhesives. BioResources 2019, 14, 6316–6330. [Google Scholar] [CrossRef]

- Guo, H.; Luković, M.; Mendoza, M.; Schlepütz, C.M.; Griffa, M.; Xu, B.; Gaan, S.; Herrmann, H.; Burgert, I. Bioinspired Struvite Mineralization for Fire-Resistant Wood. ACS Appl. Mater. Interfaces 2019, 11, 5427–5434. [Google Scholar] [CrossRef]

- Kilinc, M. Silicon Based Flame Retardants. In Non-Halogenated Flame Retardant Handbook; Morgan, A.B., Wilkie, C.A., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2014; pp. 169–199. [Google Scholar]

- Andrew, J.J.; Sain, M.; Ramakrishna, S.; Jawaid, M.; Dhakal, H.N. Environmentally Friendly Fire Retardant Natural Fibre Composites: A Review. Int. Mater. Rev. 2024, 69, 267–308. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Popielarczyk, T.; Sowa, T. Nanotechnology in Fire Protection—Application and Requirements. Materials 2021, 14, 7849. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Cai, J.; Li, H.; Lu, F.; Qin, D.; Fei, B. Effects of Boric Acid and/or Borax Treatments on the Fire Resistance of Bamboo Filament. BioResources 2017, 12, 5296–5307. [Google Scholar] [CrossRef]

- Sabee, M.M.S.M.; Itam, Z.; Beddu, S.; Zahari, N.M.; Kamal, N.L.M.; Mohamad, D.; Zulkepli, N.A.; Shafiq, M.D.; Hamid, Z.A.A. Flame Retardant Coatings: Additives, Binders, and Fillers. Polymers 2022, 14, 2911. [Google Scholar] [CrossRef]

- Dogan, M.; Dogan, S.D.; Savas, L.A.; Ozcelik, G.; Tayfun, U. Flame Retardant Effect of Boron Compounds in Polymeric Materials. Compos. Part. B Eng. 2021, 222, 109088. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Giraldo, M.P.; Lesar, B. Improvement of Fire Reaction and Mould Growth Resistance of a New Bio-Based Thermal Insulation Material. Constr. Build. Mater. 2017, 139, 531–539. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Berzins, A.; Pavlovics, G.; Bikovens, O.; Filipova, I.; Andze, L.; Andzs, M. Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics. Materials 2023, 16, 3654. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Orlovskis, Z.; Blums, K.T.; Liepins, J.; Berzins, A.; Pavlovics, G.; Andzs, M. Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed. Polymers 2024, 16, 562. [Google Scholar] [CrossRef]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovics, G. Potential of Some Latvian Industrial Crops Residuals for Conversion to Bio-Based Thermal Insulation Material. Mater. Sci. Forum 2022, 1071, 139–146. [Google Scholar] [CrossRef]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovichs, G. Development of Thermal Insulation Materials from Plant Fibres by Steam Explosion Pre-Treatment. In Proceedings of the 18th Annual Meeting of the Northern European Network for Wood Science and Engineering, Göttingen, Germany, 21–22 September 2022; Brischke, C., Buschalsky, A., Eds.; University of Göttingen: Göttingen, Germany, 2022; pp. 177–180. [Google Scholar]

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 11925-2:2020; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame. Part 2: Single-Flame Source Test. ISO (International Organization for Standardization): Geneva, Switzerland, 2020.

- Albert, C.M.; Liew, K.C. Recent Development and Challenges in Enhancing Fire Performance on Wood and Wood-Based Composites: A 10-Year Review from 2012 to 2021. J. Bioresour. Bioprod. 2024, 9, 27–42. [Google Scholar] [CrossRef]

- Ao, X.; Vázquez-López, A.; Mocerino, D.; González, C.; Wang, D.Y. Flame Retardancy and Fire Mechanical Properties for Natural Fiber/Polymer Composite: A Review. Compos. Part B Eng. 2024, 268, 111069. [Google Scholar] [CrossRef]

- Horváthová, M.; Makovická Osvaldová, L. Testing of Natural Insulation Materials Using a Conical Calorimeter. Proc. CBU Nat. Sci. ICT 2020, 1, 14–20. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, R.; John, S.; Ma, J.; Wang, C.H. Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium—Biomass Composite Materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef] [PubMed]

- Irbe, I.; Kirpluks, M.; Kampuss, M.; Andze, L.; Milbreta, U.; Filipova, I. Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions. Materials 2024, 17, 6111. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.D.; Hassan, M.K.; Akl, M.; Pathirana, S.; Rahnamayiezekavat, P.; Douglas, G.; Bhat, T.; Saha, S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire 2022, 5, 81. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Candan, Z.; White, R. Physical, Mechanical, and Fire Properties of Oriented Strandboard with Fire Retardant Treated Veneers. Eur. J. Wood Wood Prod. 2007, 65, 449–458. [Google Scholar] [CrossRef]

- Hansen-Bruhn, I.; Hull, T.R. Flammability and Burning Behaviour of Fire Protected Timber. Fire Saf. J. 2023, 140, 103918. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Deborde, L.; Sonnier, R.; Dumazert, L.; Lanos, C.; Colson, V. Characterization of Hemp Fiber Fire Reaction. J. Vinyl. Addit. Technol. 2023, 29, 259–267. [Google Scholar] [CrossRef]

- Ahmadi, M.; Zabihi, O.; Nia, Z.K.; Unnikrishnan, V.; Barrow, C.J.; Naebe, M. Engineering Flame and Mechanical Properties of Natural Plant-Based Fibre Biocomposites. Adv. Ind. Eng. Polym. Res. 2024, in press. [Google Scholar] [CrossRef]

- Augaitis, N.; Vaitkus, S.; Kairytė, A.; Vėjelis, S.; Šeputytė-Jucikė, J.; Balčiūnas, G.; Kremensas, A. Research on Thermal Stability and Flammability of Wood Scob-Based Loose-Fill Thermal Insulation Impregnated with Multicomponent Suspensions. Materials 2024, 17, 2809. [Google Scholar] [CrossRef] [PubMed]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner Production of Polyurethane Foam: Replacement of Conventional Raw Materials, Assessment of Fire Resistance and Environmental Impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-Based Polyurethane-Polyisocyanurate Composites with an Intumescent Flame Retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Roger, M.; Mark, A. Thermal Properties, Combustion, and Fire Retardancy of Wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2012; pp. 127–149. [Google Scholar]

- Teslík, J. Analysis of the Fire Properties of Blown Insulation from Crushed Straw in the Buildings. Materials 2021, 14, 4336. [Google Scholar] [CrossRef]

- Soares, I.; Ferreira, J.L.; Silva, H.; Rodrigues, M.P. Fire-Retardant and Fire-Resistant Coatings: From Industry to the Potential Use on Cultural Heritage. J. Cult. Herit. 2024, 68, 316–327. [Google Scholar] [CrossRef]

| LCB | Treatment | Designation | Density, kg·m−3 |

|---|---|---|---|

| Wheat straw | Chopped | WS_raw | 115 |

| Steam explosion | WS_SE | 60 | |

| Chemi-mechanical pulping | WS_CMP | 60 | |

| Water reed | Chopped | WR_raw | 145 |

| Steam explosion | WR_SE | 85 | |

| Chemi-mechanical pulping | WR_CMP | 60 | |

| Corn stalks | Chopped | CS_raw | 135 |

| Steam explosion | CS_SE | 85 | |

| Chemi-mechanical pulping | CS_CMP | 60 | |

| Commercial cellulose insulation material | Cel_insul | 60 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andzs, M.; Tupciauskas, R.; Berzins, A.; Pavlovics, G.; Rizikovs, J.; Milbreta, U.; Andze, L. Flammability of Plant-Based Loose-Fill Thermal Insulation: Insights from Wheat Straw, Corn Stalk, and Water Reed. Fibers 2025, 13, 24. https://doi.org/10.3390/fib13030024

Andzs M, Tupciauskas R, Berzins A, Pavlovics G, Rizikovs J, Milbreta U, Andze L. Flammability of Plant-Based Loose-Fill Thermal Insulation: Insights from Wheat Straw, Corn Stalk, and Water Reed. Fibers. 2025; 13(3):24. https://doi.org/10.3390/fib13030024

Chicago/Turabian StyleAndzs, Martins, Ramunas Tupciauskas, Andris Berzins, Gunars Pavlovics, Janis Rizikovs, Ulla Milbreta, and Laura Andze. 2025. "Flammability of Plant-Based Loose-Fill Thermal Insulation: Insights from Wheat Straw, Corn Stalk, and Water Reed" Fibers 13, no. 3: 24. https://doi.org/10.3390/fib13030024

APA StyleAndzs, M., Tupciauskas, R., Berzins, A., Pavlovics, G., Rizikovs, J., Milbreta, U., & Andze, L. (2025). Flammability of Plant-Based Loose-Fill Thermal Insulation: Insights from Wheat Straw, Corn Stalk, and Water Reed. Fibers, 13(3), 24. https://doi.org/10.3390/fib13030024