Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate

Abstract

:Highlights

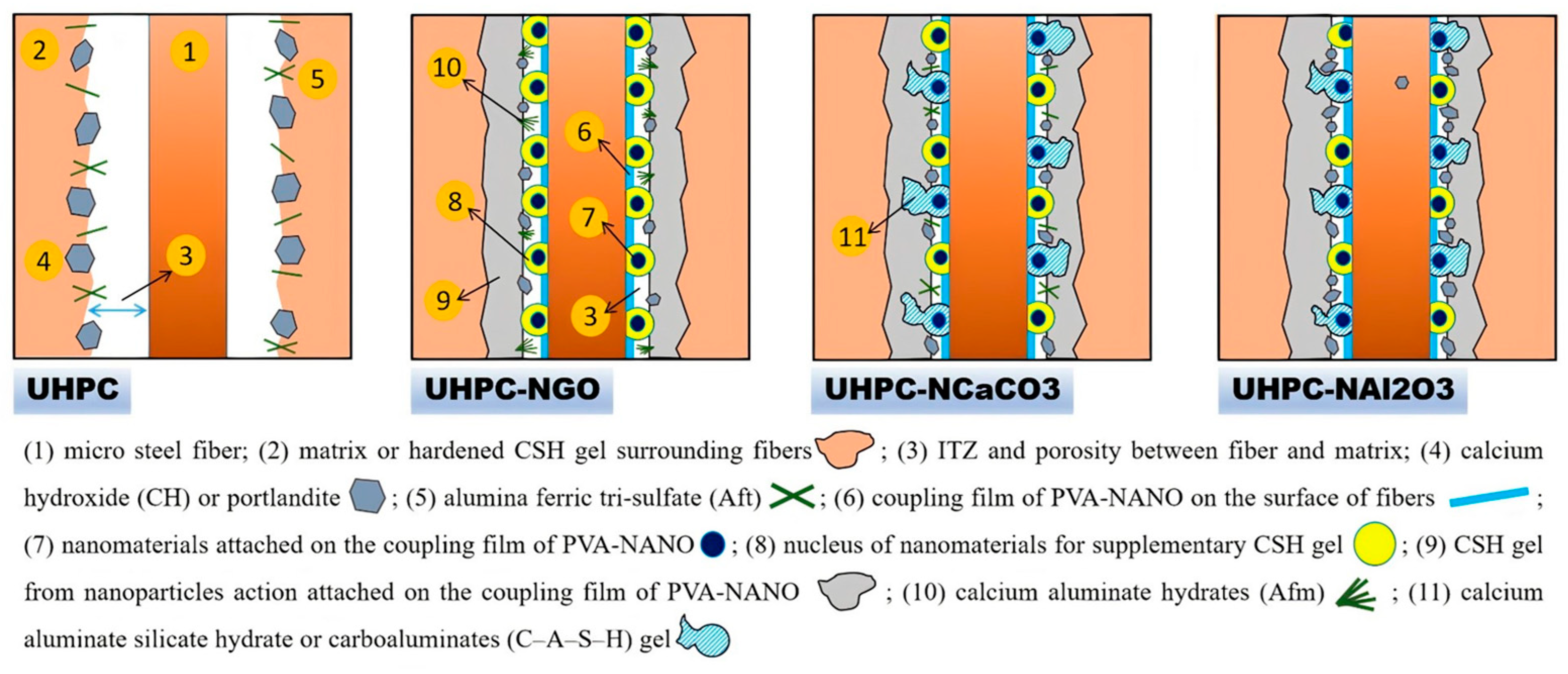

- The use of poly(vinyl alcohol) as a coupling agent proved to be effective in uniformly coating graphene oxide, nano-aluminum oxide, and nano-calcium carbonate on the surfaces of micro steel fibers within the UHPC mixture;

- Applying a coating of graphene oxide, nano-aluminum oxide, and nano-calcium carbonate to the surface of micro steel fibers significantly improved the mechanical characteristics of UHPC.

- Utilizing coated micro steel fibers presents a promising method to reduce the high volume fractions of fibers in UHPC mixtures while maintaining comparable, or even superior, mechanical properties, thereby enhancing the workability of UHPC;

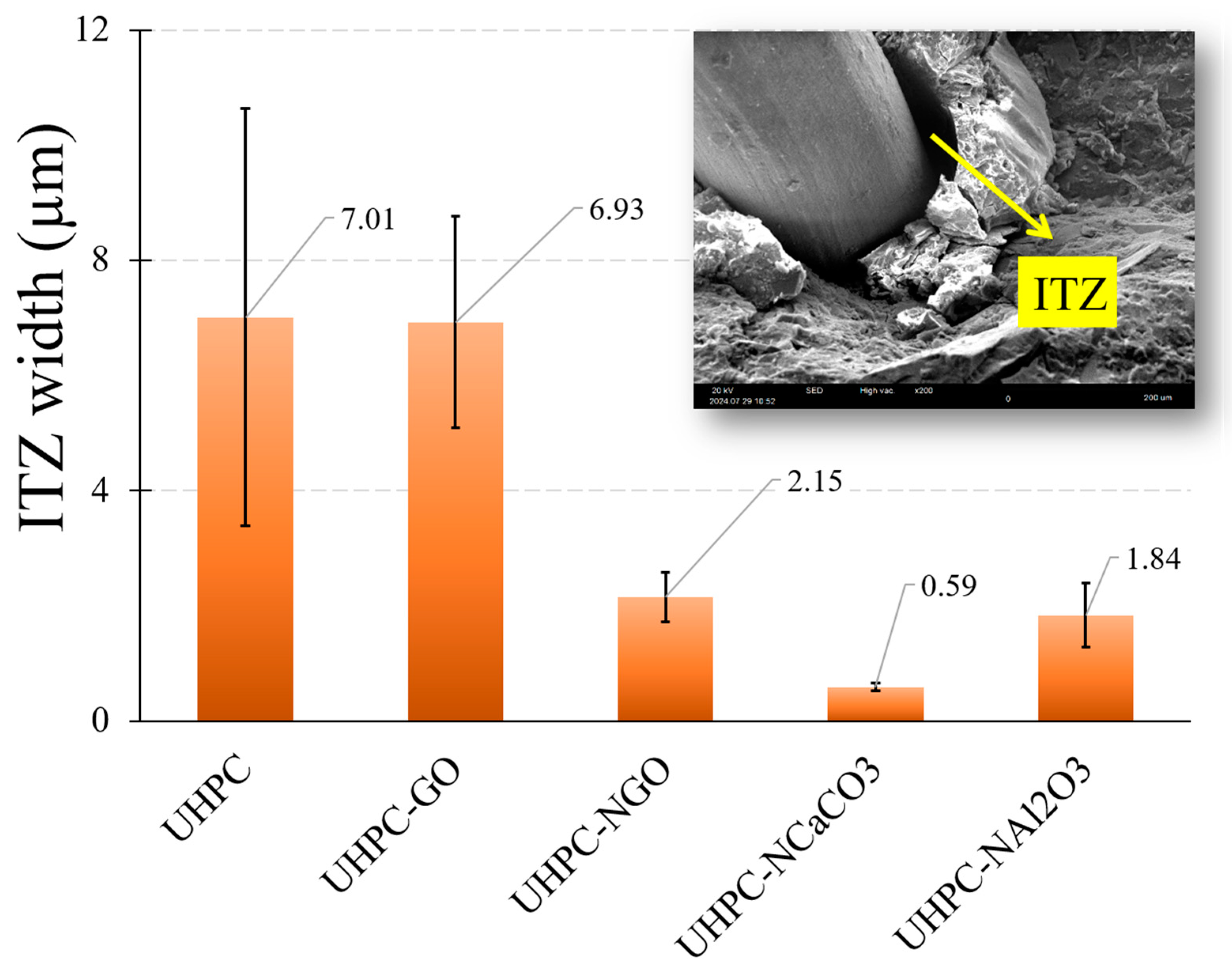

- The suggested coating technique greatly decreased the thickness of the ITZ surrounding the fibers, especially for the coating that contains nano-calcium carbonate, which addresses the durability concerns associated with UHPC.

Abstract

1. Introduction

- What is the effectiveness of the coating technique in improving the mechanical characteristics of HPC?

- How does the type of coating materials impact the efficiency of coated fibers embedded in UHPC?

- What influence do coated fibers have on controlling the thickness of ITZ at the fiber/matrix interaction?

2. Experimental Program

2.1. Materials, Mixtures, and Methods

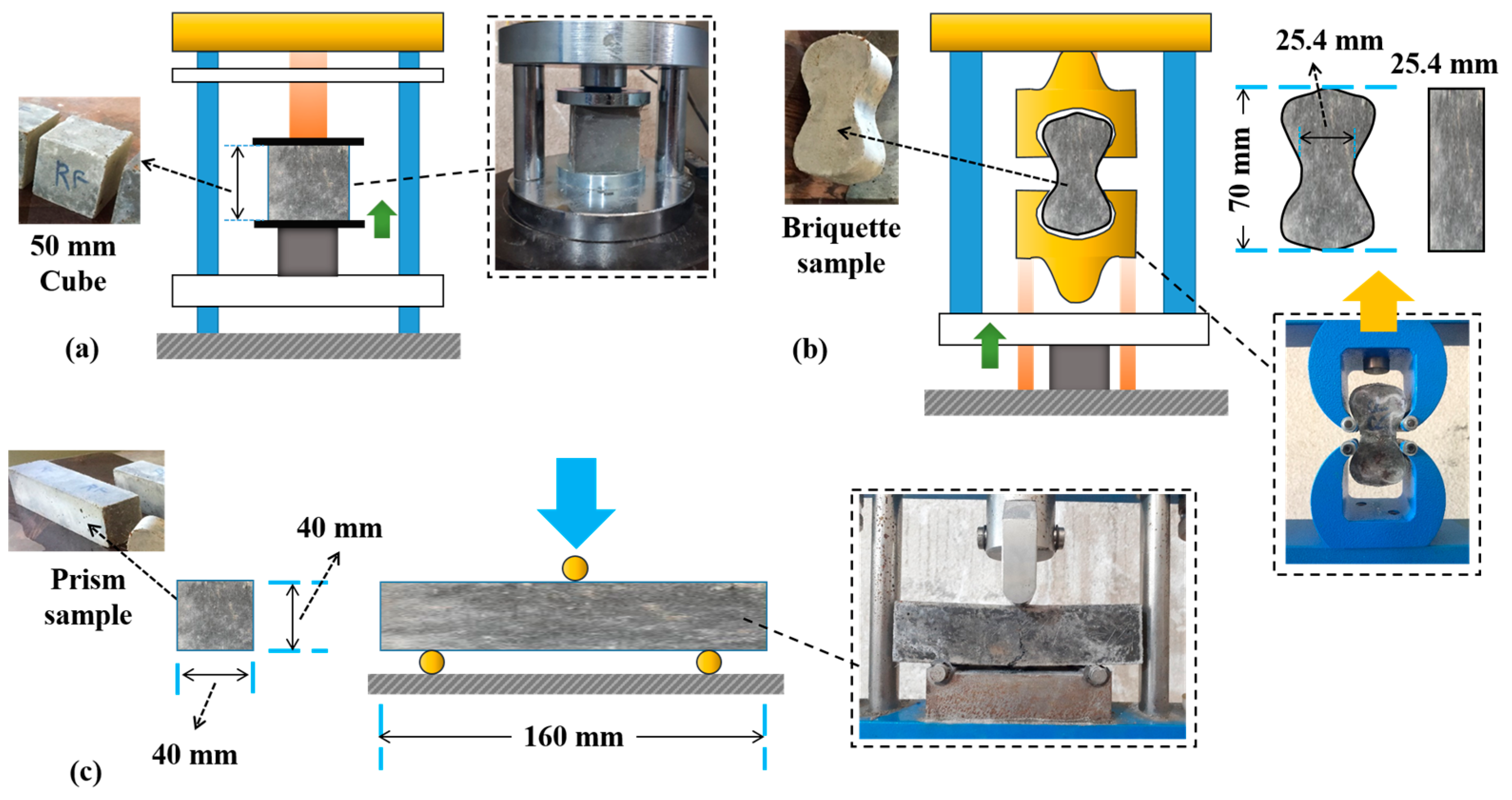

2.2. Test Setups

3. Results

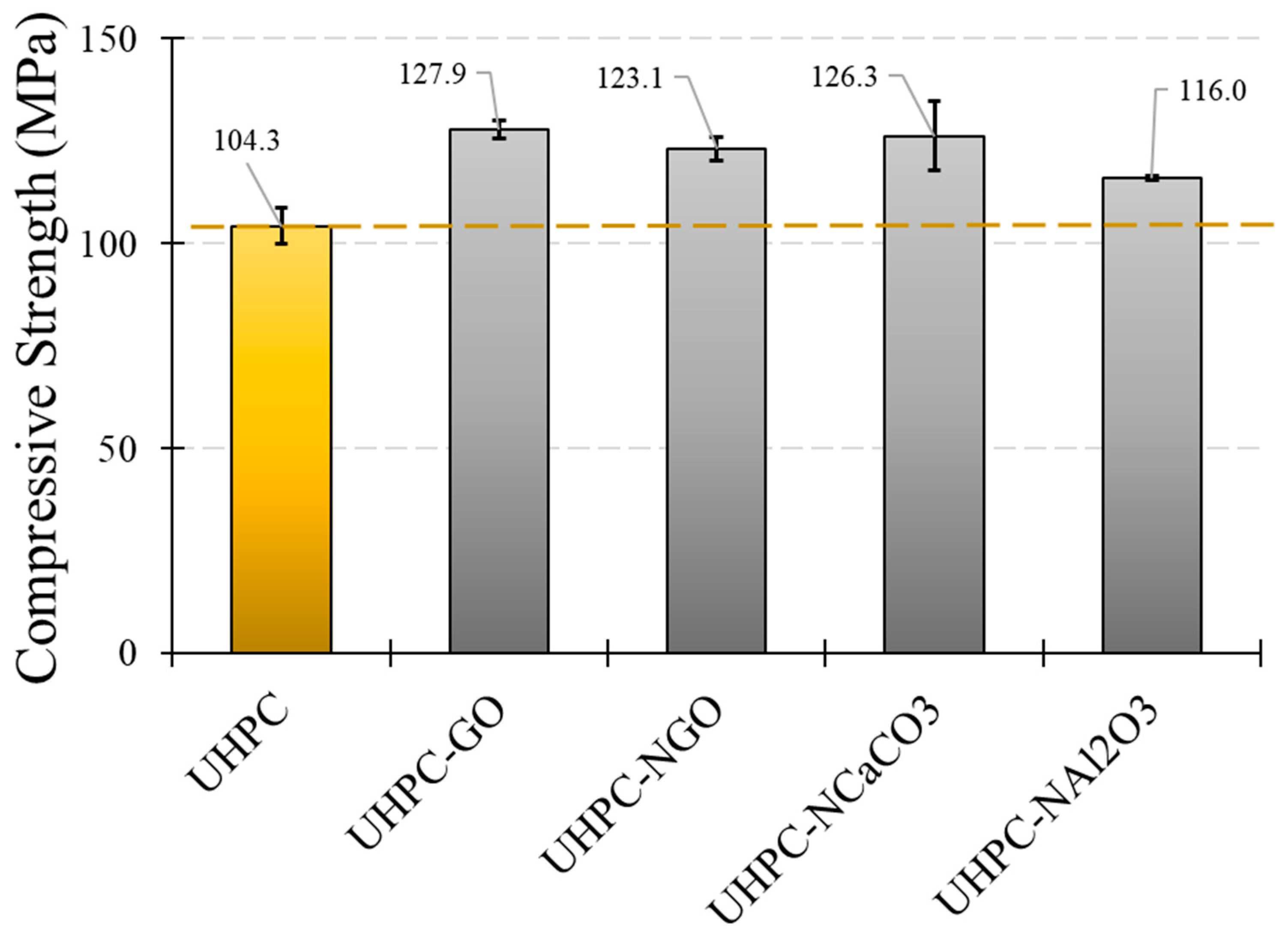

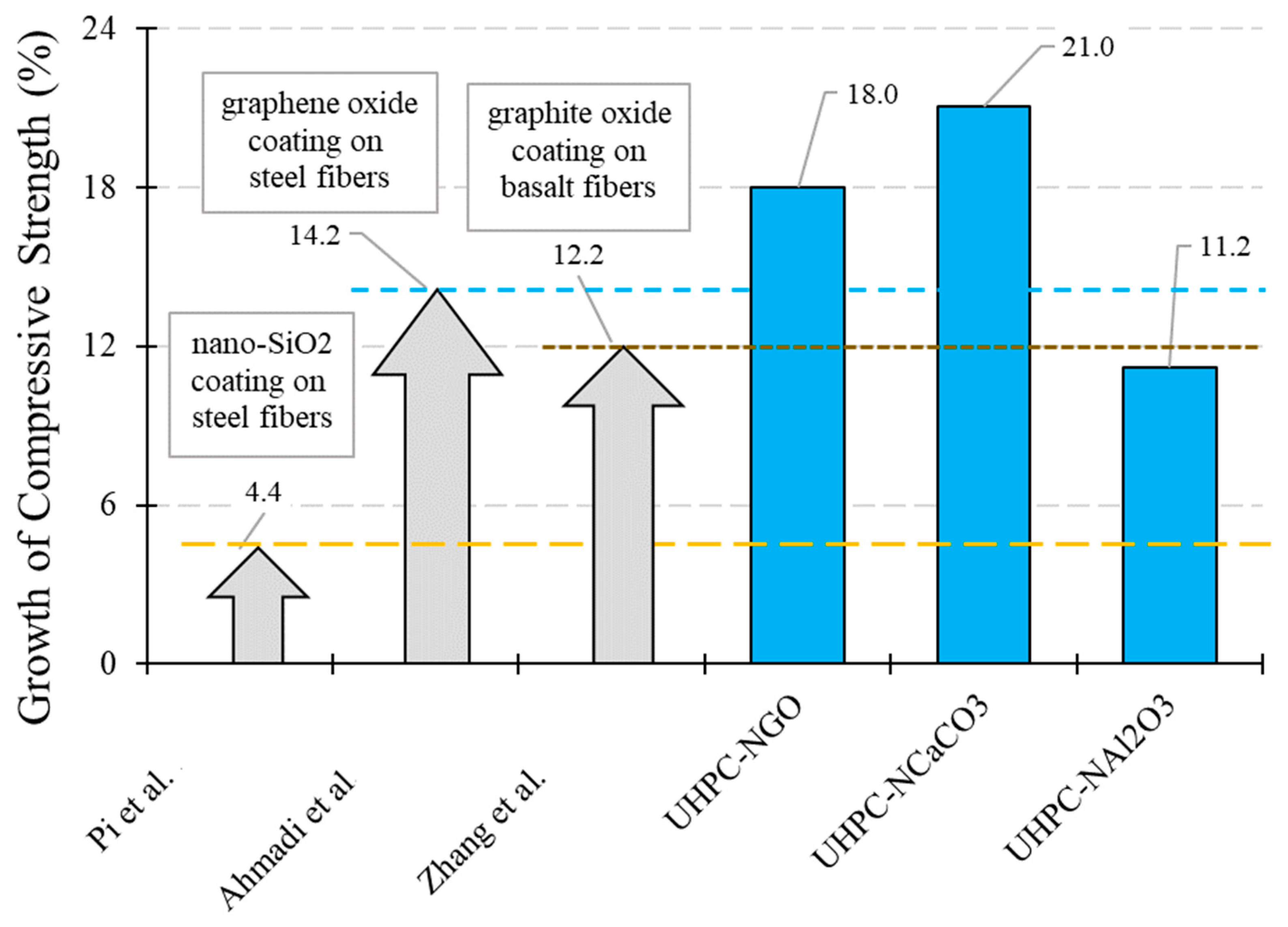

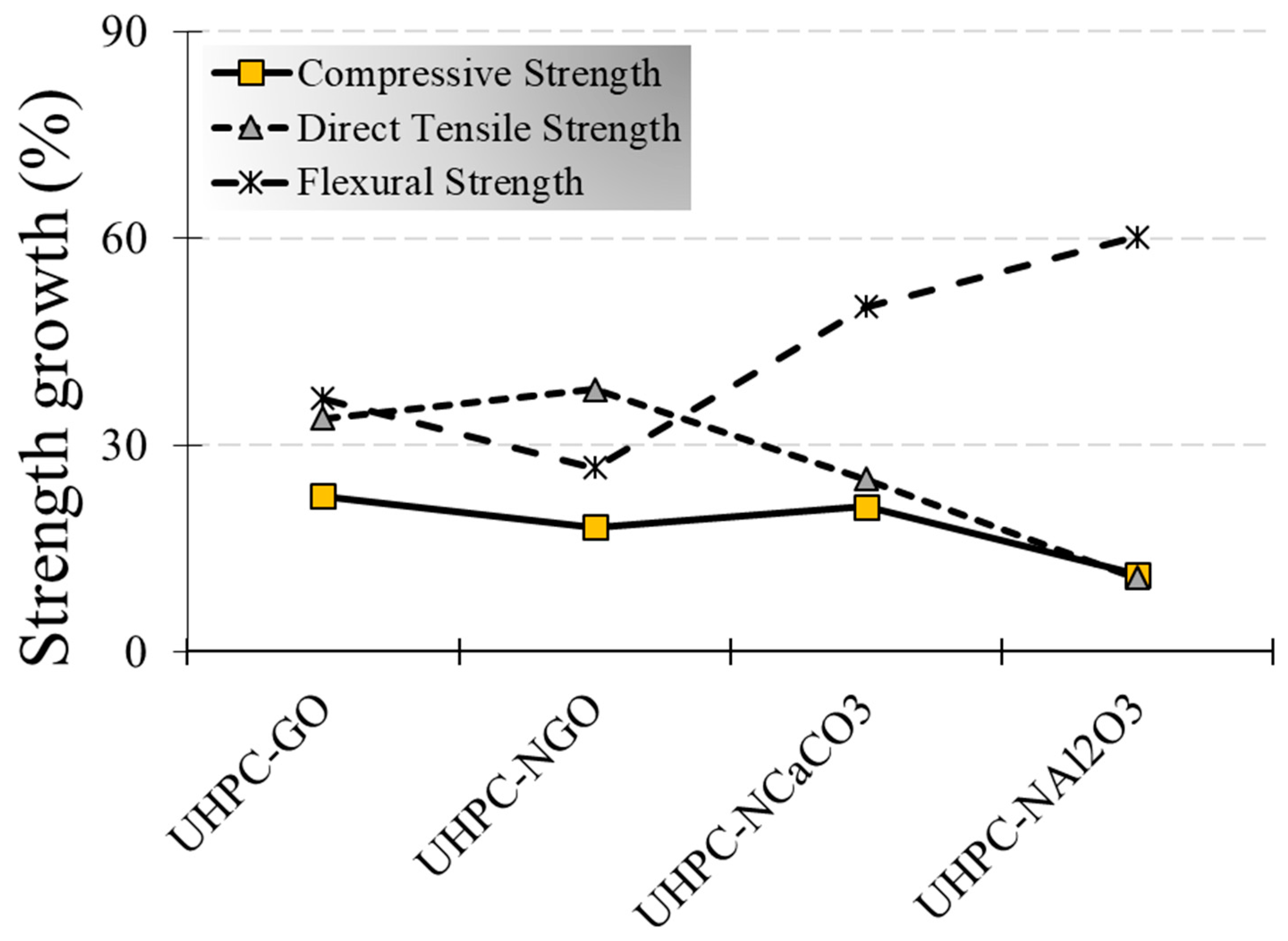

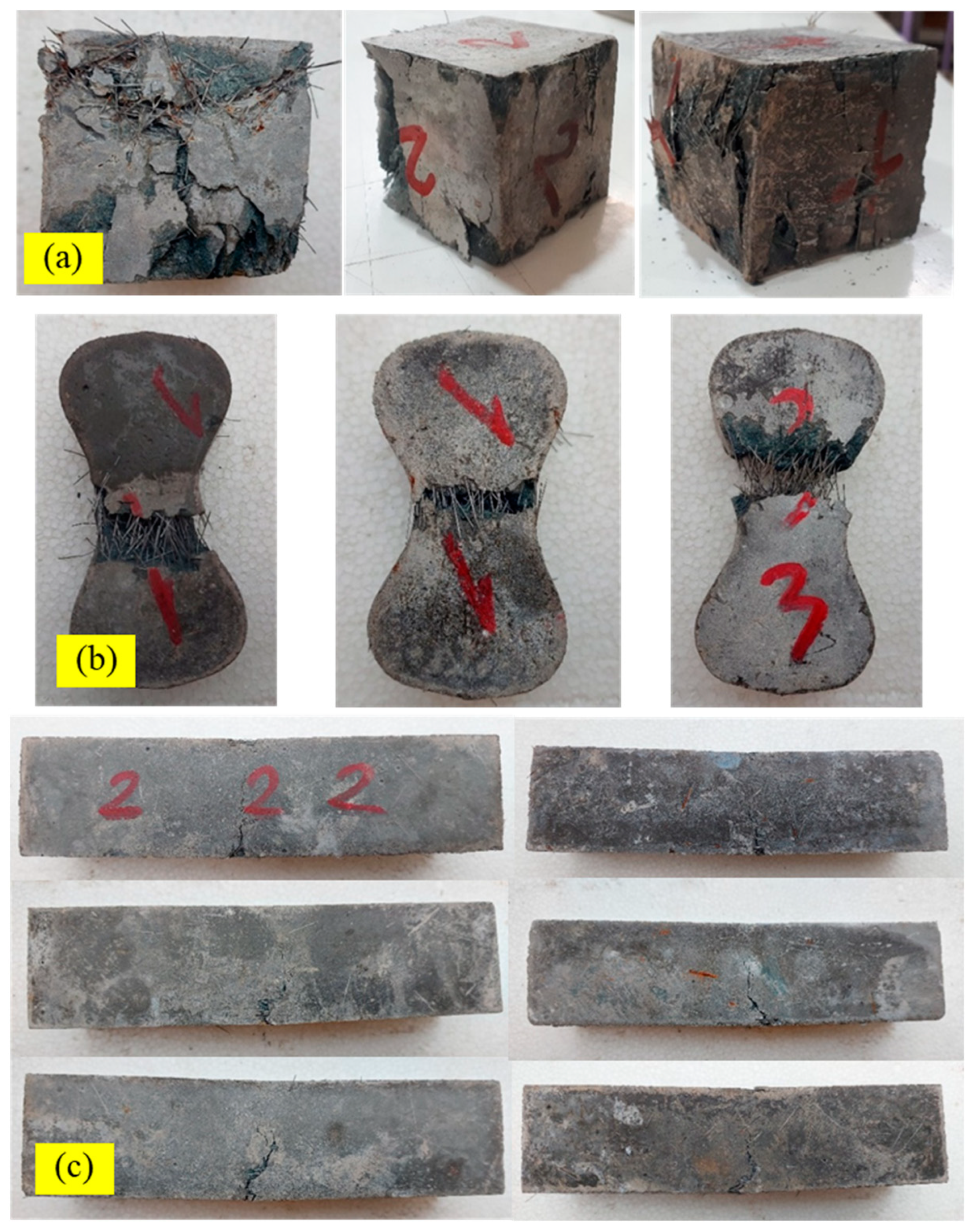

3.1. Compressive Strength

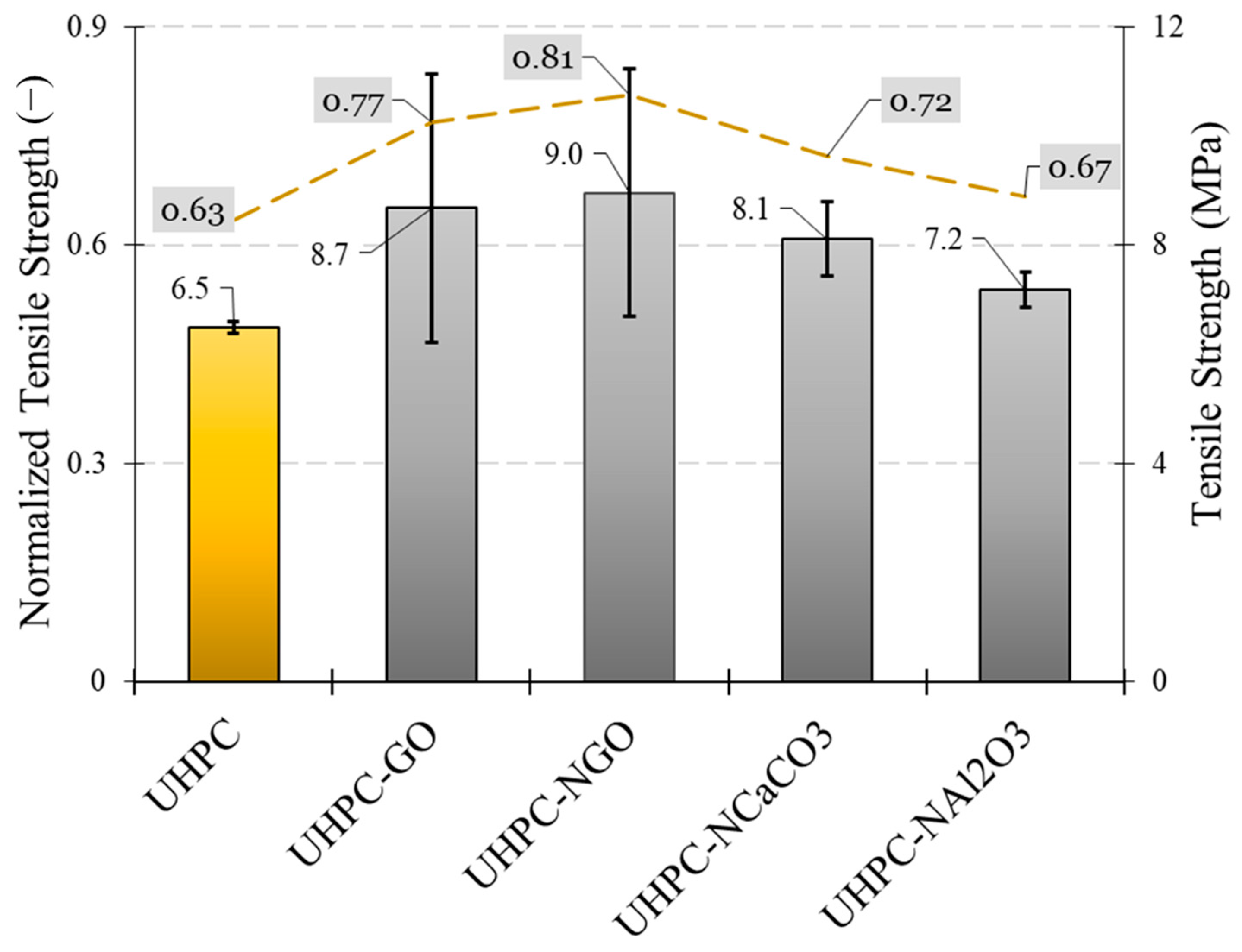

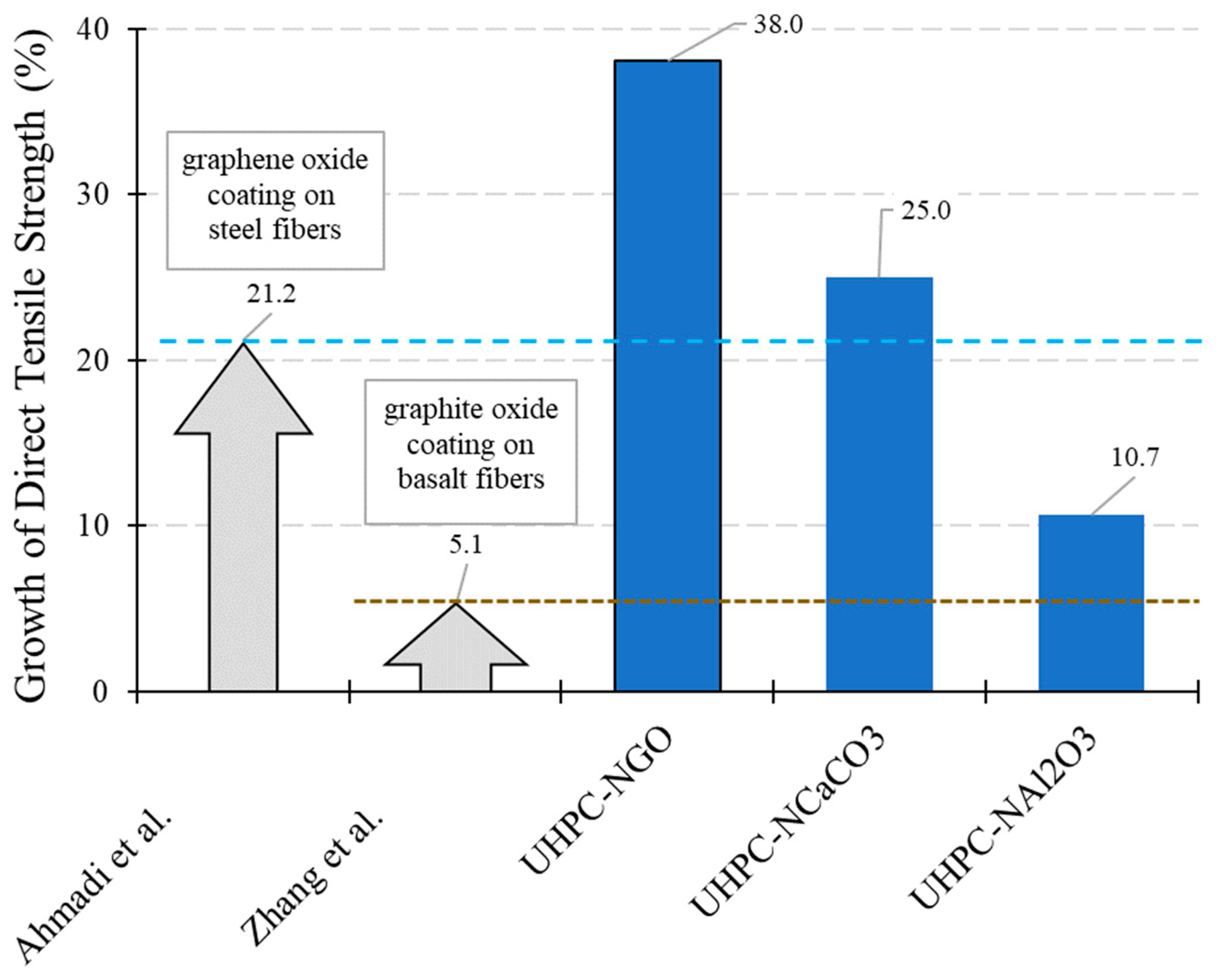

3.2. Tensile Strength

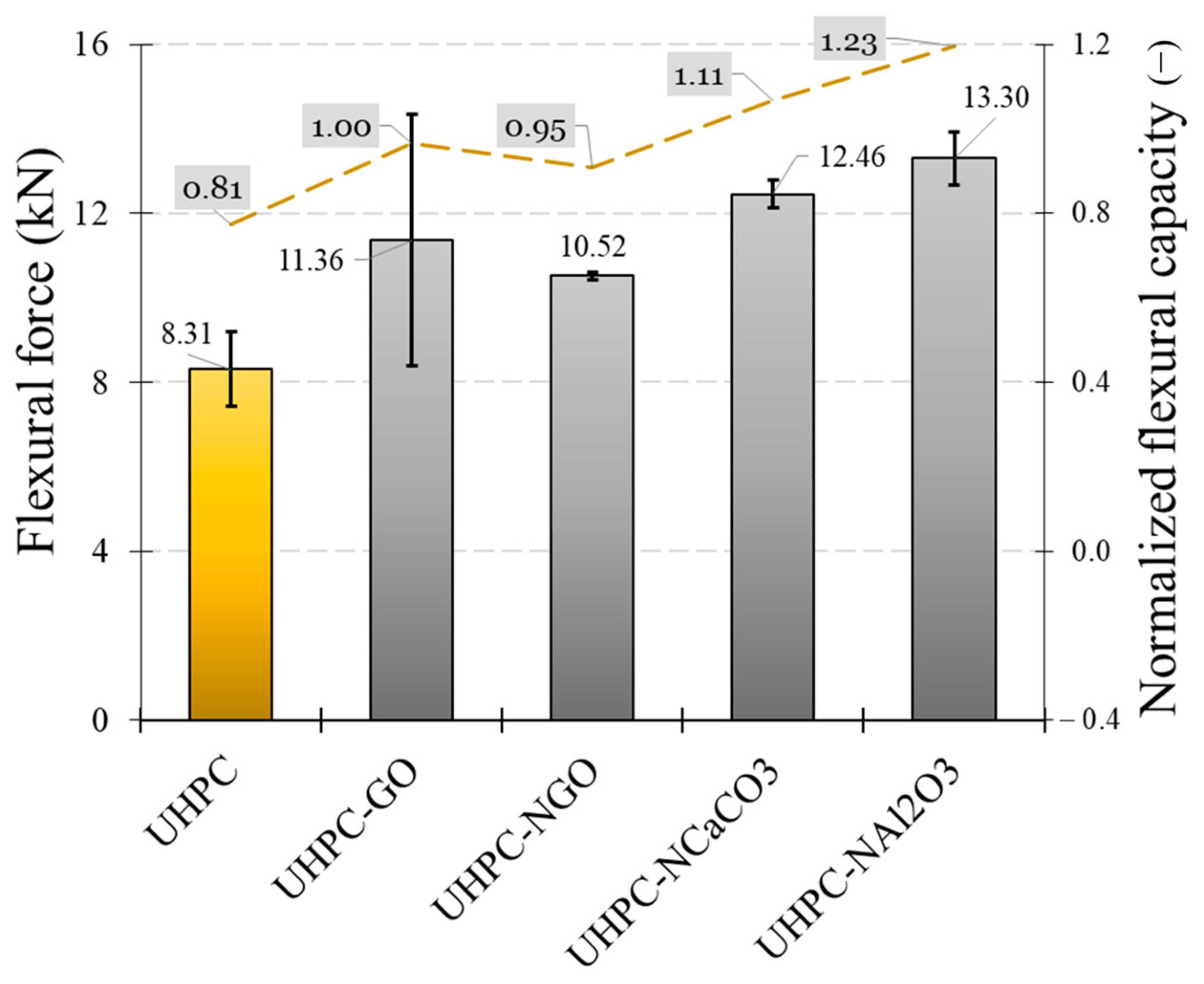

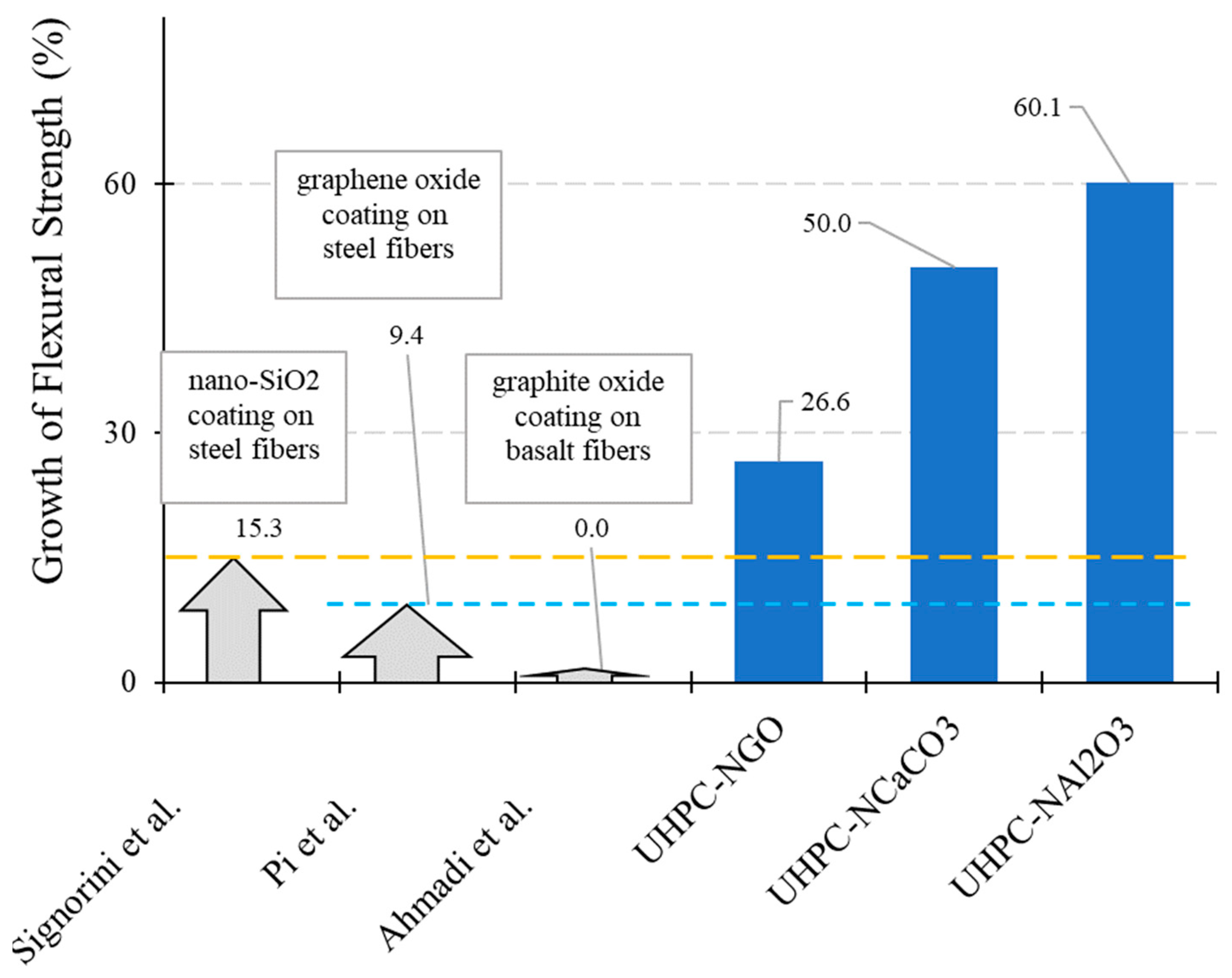

3.3. Flexural Strength

4. Discussion

5. Conclusions

- -

- Coating techniques showed very promising findings concerning compressive strength; so, using GO, nano calcium carbonate, and nano alumina caused +18.0%, 21.1%, and 11.2% improvements in the compressive strength of UHPC, respectively. Using PVA as a coupling agent showed better performance in placing homogenous nanomaterials on the surface of steel fibers;

- -

- Among coating techniques, findings showed that GO/PVA composite had the best performance regarding direct tensile strength with about a +38.5% enhancement compared to the reference UHPC;

- -

- In the case of the flexural test, the results indicated that using nano alumina/PVA nanocomposite coating on the steel fibers resulted in a +60.0% increase in bending strength, which is the optimum coating among the studied nanomaterials. Moreover, the proposed coating technique best influences flexural strength among the mechanical properties;

- -

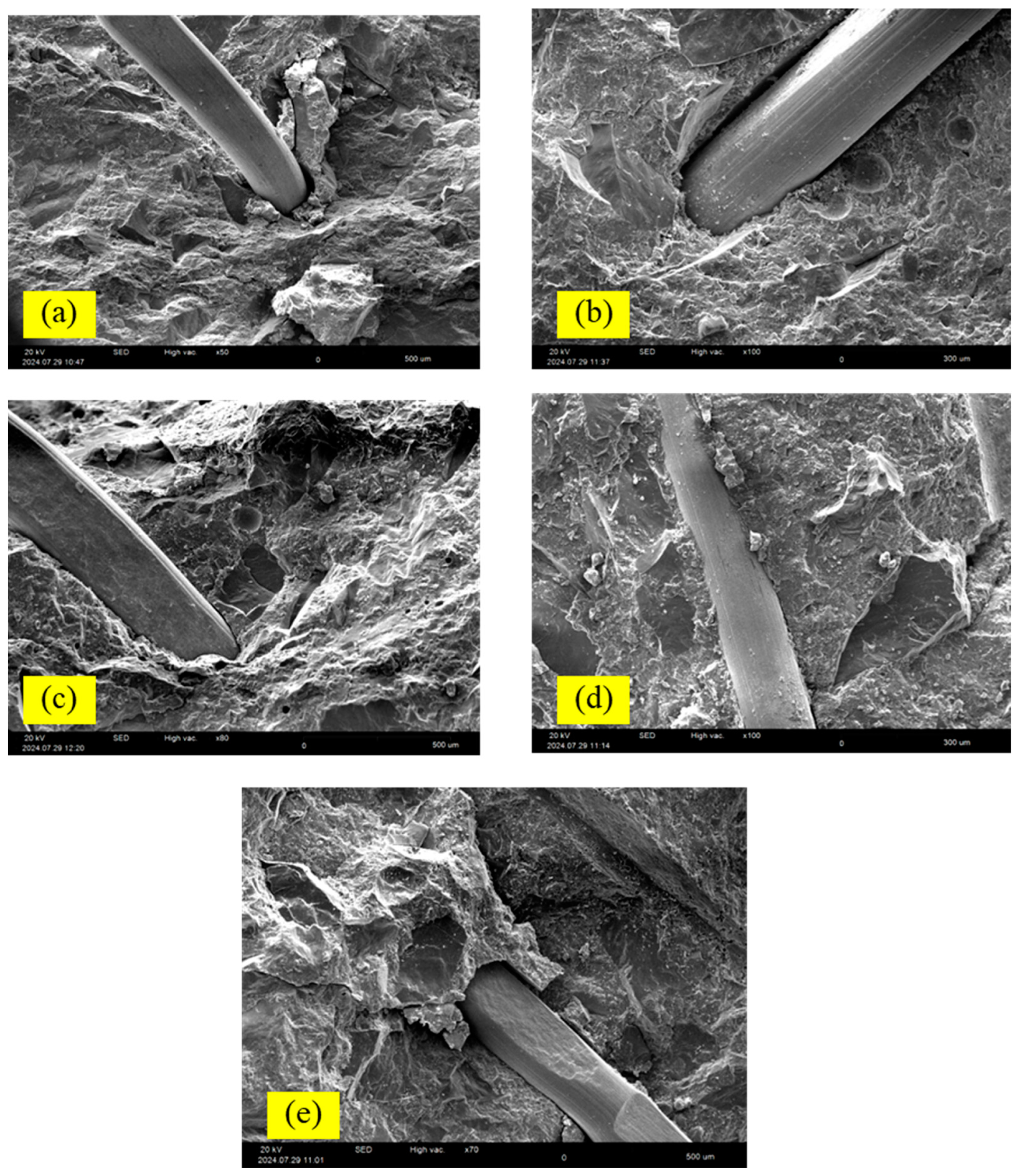

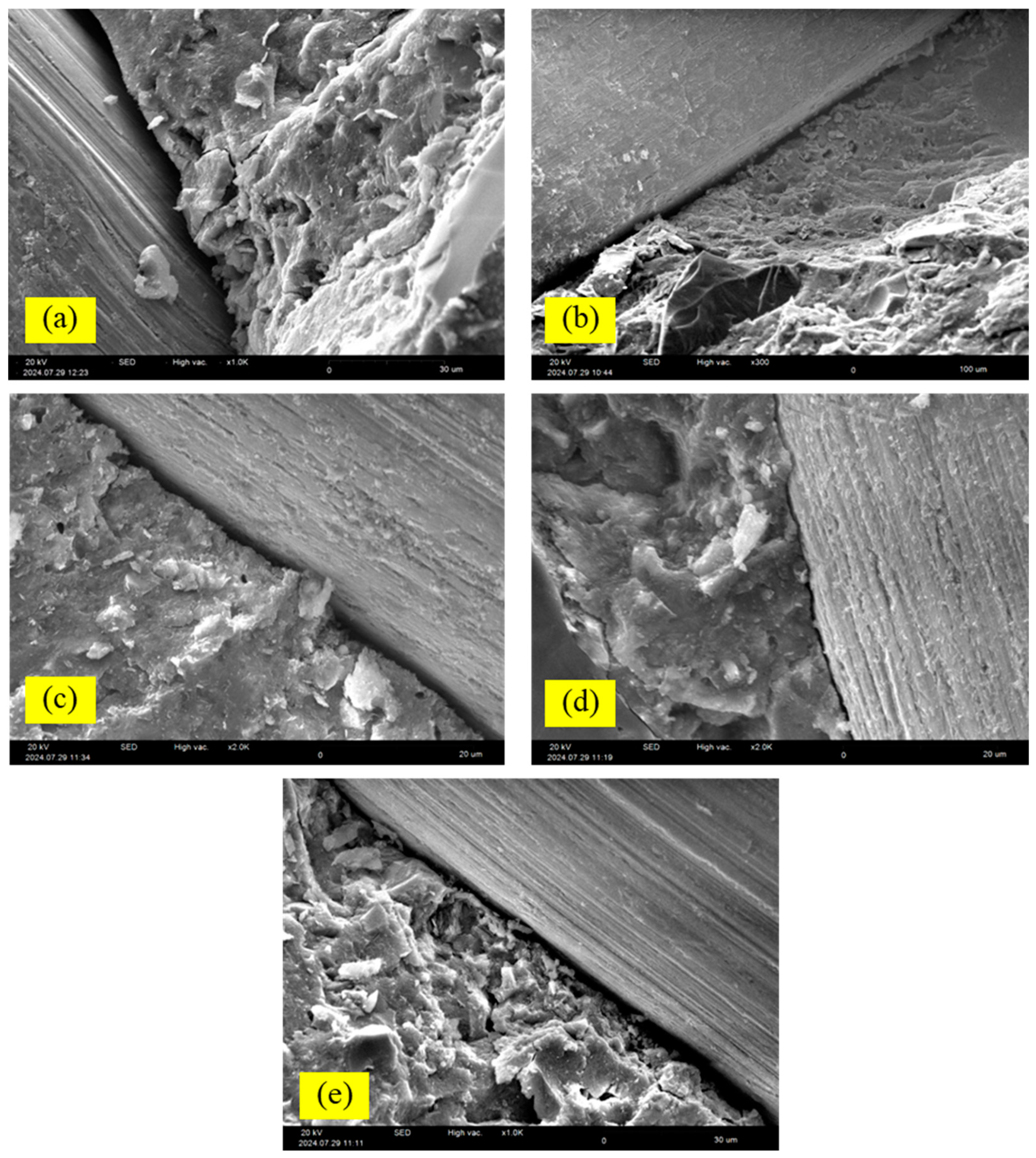

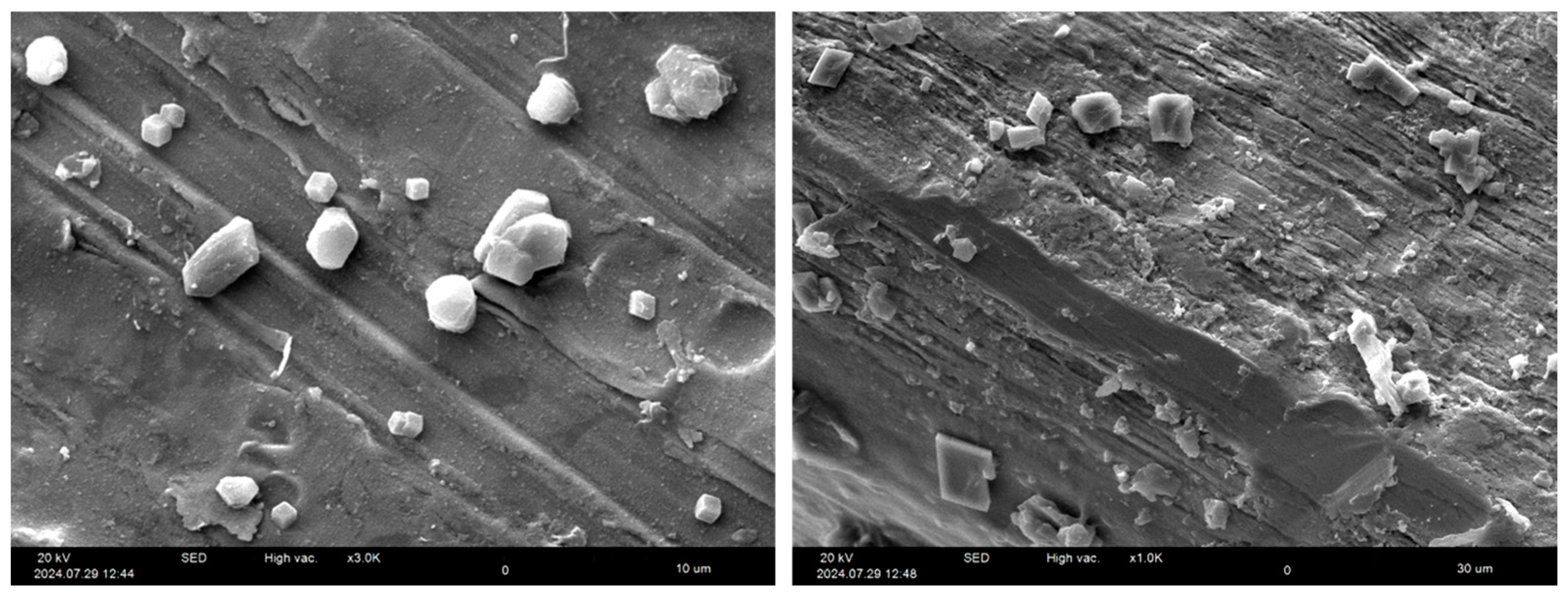

- The SEM analysis of coated fibers showed that all the proposed coating techniques significantly reduced the ITZ thickness surrounding the fibers, which was considerably better than using nanomaterials dispersing within the matrix. Among the nanomaterials used, nano calcium carbonate showed the best performance with 91.6% reductions in porosity width at the fiber/matrix interface.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, L.; Chen, Y.; Li, T.; Gao, P.; Sun, L. Microstructure and bonding behavior of fiber-mortar interface in fiber-reinforced concrete. Constr. Build. Mater. 2020, 232, 117235. [Google Scholar]

- Du, J.; Xiao, H.; Liu, R.; Wang, W. Contribution of fiber–matrix interface enhancement on flexural properties of Ultra–high–performance concrete. Cem. Concr. Compos. 2023, 137, 104926. [Google Scholar]

- Lu, M.; Xiao, H.; Liu, M.; Li, X.; Li, H.; Sun, L. Improved interfacial strength of SiO2 coated carbon fiber in cement matrix. Cem. Concr. Compos. 2018, 91, 21–28. [Google Scholar]

- Ahmadi, K.; Mousavi, S.S.; Dehestani, M. Influence of nano-coated micro steel fibers on mechanical and self-healing properties of 3D printable concrete using graphene oxide and polyvinyl alcohol. J. Adhes. Sci. Technol. 2024, 38, 1312–1333. [Google Scholar] [CrossRef]

- Gao, S.-L.; Mäder, E.; Plonka, R. Nanocomposite coatings for healing surface defects of glass fibers and improving interfacial adhesion. Compos. Sci. Technol. 2008, 68, 2892–2901. [Google Scholar] [CrossRef]

- Zhang, Y.; Mi, C. Strengthening bonding strength in NiTi SMA fiber-reinforced polymer composites through acid immersion and Nanosilica coating. Compos. Struct. 2020, 239, 112001. [Google Scholar]

- Wei, B.; Song, S.; Cao, H. Strengthening of basalt fibers with nano-SiO2–epoxy composite coating. Mater. Des. 2011, 32, 4180–4186. [Google Scholar]

- Siddiqui, N.A.; Sham, M.-L.; Tang, B.Z.; Munir, A.; Kim, J.-K. Tensile strength of glass fibres with carbon nanotube–epoxy nanocomposite coating. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1606–1614. [Google Scholar]

- Siddiqui, N.A.; Li, E.L.; Sham, M.-L.; Tang, B.Z.; Gao, S.L.; Mäder, E.; Kim, J.-K. Tensile strength of glass fibres with carbon nanotube–epoxy nanocomposite coating: Effects of CNT morphology and dispersion state. Compos. Part A Appl. Sci. Manuf. 2010, 41, 539–548. [Google Scholar] [CrossRef]

- Ma, P.-C.; Liu, J.-W.; Gao, S.-L.; Mäder, E. Development of functional glass fibres with nanocomposite coating: A comparative study. Compos. Part A Appl. Sci. Manuf. 2013, 44, 16–22. [Google Scholar]

- Liu, M.-Y.; Zhu, H.-G.; Siddiqui, N.A.; Leung, C.K.; Kim, J.-K. Glass fibers with clay nanocomposite coating: Improved barrier resistance in alkaline environment. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2051–2059. [Google Scholar] [CrossRef]

- Asadi, A.; Miller, M.; Moon, R.J.; Kalaitzidou, K. Improving the interfacial and mechanical properties of short glass fiber/epoxy composites by coating the glass fibers with cellulose nanocrystals. Express Polym. Lett. 2016, 10, 587–597. [Google Scholar] [CrossRef]

- Özen, S.; Benlioğlu, A.; Mardani, A.; Altın, Y.; Bedeloğlu, A. Effect of graphene oxide-coated jute fiber on mechanical and durability properties of concrete mixtures. Constr. Build. Mater. 2024, 448, 138225. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, Q. Surface modification of miscanthus fiber with hydrophobic silica aerogel for high performance bio-lightweight concrete. Constr. Build. Mater. 2024, 411, 134478. [Google Scholar] [CrossRef]

- Xin, Q.; Hu, X.; Li, Z.; Lu, S.; Ma, H. Effect of recycled fiber modified by CNTs-epoxy resin composite coating on mechanical properties of mortar. Constr. Build. Mater. 2024, 446, 138055. [Google Scholar] [CrossRef]

- Han, K.; Jia, X.; Li, T.; Sun, M.; Yin, B.; Hou, D. Performance augmentation of fiber reinforced concrete through in situ mineralization of polycrystalline calcium carbonate on fiber surfaces. Constr. Build. Mater. 2024, 455, 139141. [Google Scholar] [CrossRef]

- You, X.; Zhang, J.; Zhong, J.; Fu, B.; Yu, T. Properties of ultra-high-performance concrete with recycled macro fibers: Effects of fiber coating with graphene oxide. Constr. Build. Mater. 2024, 456, 139283. [Google Scholar] [CrossRef]

- Zhao, L.; Ding, Y.; Li, S.; Song, Y.; Zhang, Y. The synergistic effect of surface coating SCA/SiO2 NPs on the degradation resistance and interfacial bond of sisal fibers in cementitious composites. Cem. Concr. Compos. 2024, 152, 105671. [Google Scholar] [CrossRef]

- Du, J.; Wang, Y.; Guo, P.; Meng, W. Tailoring of steel fiber surface by coating cellulose nanocrystal for enhanced flexural properties of UHPC. Cem. Concr. Compos. 2024, 154, 105773. [Google Scholar] [CrossRef]

- Deng, Y.; Li, Y. Evaluating the chemical stability and performance of zinc phosphate-coated steel fibers in concrete corrosion simulations. Mater. Today Commun. 2024, 41, 110363. [Google Scholar]

- Rodríguez-Uicab, O.; Avilés, F.; Gonzalez-Chi, P.; Canché-Escamilla, G.; Duarte-Aranda, S.; Yazdani-Pedram, M.; Toro, P.; Gamboa, F.; Mazo, M.; Nistal, A. Deposition of carbon nanotubes onto aramid fibers using as-received and chemically modified fibers. Appl. Surf. Sci. 2016, 385, 379–390. [Google Scholar]

- Kumar, A.; Vlach, T.; Chira, A.; Laiblova, L.; Škapin, A.S.; Tywoniak, J.; Hajek, P. Nanocoating on alkali-resistant glass fibers by octadecyltrichlorosilane to improve the mechanical strength of fibers and fibers/epoxy composites. Text. Res. J. 2018, 88, 1038–1046. [Google Scholar]

- Gao, Y.; Cheng, Z.; Yu, J.; Guo, X.; Liu, Y.; Chen, W. Mechanical performance enhancement of UHPC via ITZ improvement using graphene oxide-coated steel fibers. Cem. Concr. Compos. 2025, 157, 105931. [Google Scholar]

- Wang, P.; Li, W.; Fu, H.; Zhao, H.; Xiong, C.; Liu, T.; Li, C. Effect of copper-coated carbon fiber on the electromechanical and chloride extraction properties of cement-based anode materials. Cem. Concr. Compos. 2025, 159, 106006. [Google Scholar]

- Lian, X.; Liu, X.; Lyu, X.; Yang, Q.; Chen, J.; Yu, X.; Jiang, Y.; Zuo, J.; Shah, S.P. Research on the conductivity and self-sensing properties of high strength cement-based material with oriented copper-coated steel fibers. J. Build. Eng. 2024, 86, 108845. [Google Scholar]

- Shiotani, T.; Ogura, N.; Okude, N.; Watabe, K.; Van Steen, C.; Tsangouri, E.; Lacidogna, G.; Czarnecki, S.; Chai, H.K.; Yang, Y. Non-destructive inspection technologies for repair assessment in materials and structures. Dev. Built Environ. 2024, 18, 100443. [Google Scholar]

- Mpalaskas, A.C.; Kytinou, V.K.; Zapris, A.G.; Matikas, T.E. Optimizing building rehabilitation through nondestructive evaluation of fire-damaged steel-fiber-reinforced concrete. Sensors 2024, 24, 5668. [Google Scholar] [CrossRef]

- Mathews, M.E.; Kiran, T.; Anand, N.; Lubloy, E.; Naser, M.; Arulraj, G.P. Effect of protective coating on axial resistance and residual capacity of self-compacting concrete columns exposed to standard fire. Eng. Struct. 2022, 264, 114444. [Google Scholar]

- Santos, A.; Chiquito, M.; Castedo, R.; López, L.; Gomes, G.; Mota, C.; Fangueiro, R.; Mingote, J.L. Experimental and numerical study of polyurea coating systems for blast mitigation of concrete masonry walls. Eng. Struct. 2023, 284, 116006. [Google Scholar]

- Pi, Z.; Xiao, H.; Liu, R.; Li, H. Combination usage of nano-SiO2-coated steel fiber and silica fume and its improvement effect on SFRCC. Compos. Part B Eng. 2021, 221, 109022. [Google Scholar] [CrossRef]

- Zhang, B.; Fang, L.; Ding, Z.; Li, M. The effect of modified basalt fiber on mechanical properties of oil well cement slurry. Case Stud. Constr. Mater. 2024, 20, e03228. [Google Scholar] [CrossRef]

- Musale, A.; Hunashyal, A.M.; Patil, A.Y.; Kumar, R.; Ahamad, T.; Kalam, M.; Patel, M. Study on Nanomaterials Coated Natural Coir Fibers as Crack Arrestor in Cement Composite. Adv. Civ. Eng. 2024, 2024, 6686655. [Google Scholar] [CrossRef]

- Bhojaraju, C.; Mousavi, S.S.; Brial, V.; DiMare, M.; Ouellet-Plamondon, C.M. Fresh and hardened properties of GGBS-contained cementitious composites using graphene and graphene oxide. Constr. Build. Mater. 2021, 300, 123902. [Google Scholar] [CrossRef]

- Bhojaraju, C.; Mousavi, S.S.; Ouellet-Plamondon, C.M. Influence of GGBFS on corrosion resistance of cementitious composites containing graphene and graphene oxide. Cem. Concr. Compos. 2023, 135, 104836. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M. Influence of latex and vinyl disposable gloves as recycled fibers in 3D printing sustainable mortars. Sustainability 2022, 14, 9908. [Google Scholar] [CrossRef]

- Korayem, A.H.; Ghoddousi, P.; Javid, A.S.; Oraie, M.; Ashegh, H. Graphene oxide for surface treatment of concrete: A novel method to protect concrete. Constr. Build. Mater. 2020, 243, 118229. [Google Scholar] [CrossRef]

- Antolín-Rodríguez, A.; Merino-Maldonado, D.; Rodríguez-González, Á.; Fernández-Raga, M.; González-Domínguez, J.M.; Juan-Valdés, A.; García-González, J. Statistical study of the effectiveness of surface application of graphene oxide as a coating for concrete protection. Coatings 2023, 13, 213. [Google Scholar] [CrossRef]

- Antolín-Rodríguez, A.; Merino-Maldonado, D.; Fernández-Raga, M.; González-Domínguez, J.M.; Morán-del Pozo, J.M.; García-González, J.; Juan-Valdés, A. Microstructural, durability and colorimetric properties of concrete coated with a controlled application of graphene oxide. J. Build. Eng. 2024, 86, 108920. [Google Scholar] [CrossRef]

- Muzenski, S.; Flores-Vivian, I.; Sobolev, K. Ultra-high strength cement-based composites designed with aluminum oxide nano-fibers. Constr. Build. Mater. 2019, 220, 177–186. [Google Scholar] [CrossRef]

- Younus, S.J.; Mosaberpanah, M.A.; Alzeebaree, R. The performance of alkali-activated self-compacting concrete with and without nano-Alumina. Sustainability 2023, 15, 2811. [Google Scholar] [CrossRef]

- Moghaddam, H.H.; Lotfollahi-Yaghin, M.A.; Maleki, A. Comprehensive analysis of mechanical characteristics in self-compacting concrete (SCC) with aluminum oxide (Al2O3) nanoparticles and glass fibers: An experimental and analytical investigation. Case Stud. Constr. Mater. 2025, 22, e04095. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; He, K.; Li, L.; Shen, S. Effect of macro-, micro-and nano-calcium carbonate on properties of cementitious composites—A review. Materials 2019, 12, 781. [Google Scholar] [CrossRef]

- Sldozian, R.J.A.; Hamad, A.J.; Al-Rawe, H.S. Mechanical properties of lightweight green concrete including nano calcium carbonate. J. Build. Pathol. Rehabil. 2023, 8, 3. [Google Scholar] [CrossRef]

- Salih, A.; Rafiq, S.; Mahmood, W.; Hind, A.-D.; Noaman, R.; Ghafor, K.; Qadir, W. Systemic multi-scale approaches to predict the flowability at various temperature and mechanical properties of cement paste modified with nano-calcium carbonate. Constr. Build. Mater. 2020, 262, 120777. [Google Scholar] [CrossRef]

- Li, G.; Zhuang, Z.; Lv, Y.; Wang, K.; Hui, D. Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3. Nanotechnol. Rev. 2020, 9, 998–1008. [Google Scholar] [CrossRef]

- Muhsin, Z.F.; Fawzi, N.M. Effect of nano calcium Carbonate on some properties of reactive powder concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 856, 012026. [Google Scholar] [CrossRef]

- Chen, X.; Ai, Y.; Wu, Q.; Cheng, S.; Wei, Y.; Xu, X.; Fan, T. Potential use of nano calcium carbonate in polypropylene fiber reinforced recycled aggregate concrete: Microstructures and properties evaluation. Constr. Build. Mater. 2023, 400, 132871. [Google Scholar] [CrossRef]

- Wang, T.; Gong, J.; Chen, B.; Gong, X.; Guo, W.; Zhang, Y.; Li, F. Mechanical Properties and Shrinkage of Ultrahigh-Performance Concrete Containing Lithium Carbonate and Nano-Calcium Carbonate. Adv. Civ. Eng. 2021, 2021, 6646272. [Google Scholar] [CrossRef]

- Ariyagounder, J.; Veerasamy, S. Experimental investigation on the strength, durability and corrosion properties of concrete by partial replacement of cement with Nano-SiO2, Nano-CaCO3 and Nano-Ca (OH)2. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 201–222. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M. On the possibility of using waste disposable gloves as recycled fibers in sustainable 3D concrete printing using different additives. Sci. Rep. 2023, 13, 10812. [Google Scholar]

- Wu, Y.-Y.; Que, L.; Cui, Z.; Lambert, P. Physical properties of concrete containing graphene oxide nanosheets. Materials 2019, 12, 1707. [Google Scholar] [CrossRef]

- Gong, K.; Pan, Z.; Korayem, A.H.; Qiu, L.; Li, D.; Collins, F.; Wang, C.M.; Duan, W.H. Reinforcing effects of graphene oxide on portland cement paste. J. Mater. Civ. Eng. 2015, 27, A4014010. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N. Influence of graphene oxide as dispersed phase in cement mortar matrix in defining the crystal patterns of cement hydrates and its effect on mechanical, microstructural and crystallization properties. Rsc Adv. 2015, 5, 52642–52657. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N. Comparative effects of pristine and ball-milled graphene oxide on physico-chemical characteristics of cement mortar nanocomposites. Constr. Build. Mater. 2016, 115, 256–268. [Google Scholar] [CrossRef]

- Devi, S.; Khan, R. Effect of graphene oxide on mechanical and durability performance of concrete. J. Build. Eng. 2020, 27, 101007. [Google Scholar] [CrossRef]

- Signorini, C.; Sola, A.; Malchiodi, B.; Nobili, A.; Gatto, A. Failure mechanism of silica coated polypropylene fibres for Fibre Reinforced Concrete (FRC). Constr. Build. Mater. 2020, 236, 117549. [Google Scholar] [CrossRef]

- Kong, D.; Huang, S.; Corr, D.; Yang, Y.; Shah, S.P. Whether do nano-particles act as nucleation sites for CSH gel growth during cement hydration? Cem. Concr. Compos. 2018, 87, 98–109. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Yue, Y.; Zhou, Y.; Xing, F.; Gong, G.; Hu, B.; Guo, M. An industrial applicable method to improve the properties of recycled aggregate concrete by incorporating nano-silica and micro-CaCO3. J. Clean. Prod. 2020, 259, 120920. [Google Scholar]

- Zhan, P.-m.; He, Z.-h.; Ma, Z.-m.; Liang, C.-f.; Zhang, X.-x.; Abreham, A.A.; Shi, J.-y. Utilization of nano-metakaolin in concrete: A review. J. Build. Eng. 2020, 30, 101259. [Google Scholar]

- Meng, T.; Ying, K.; Yang, X.; Hong, Y. Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials. Nanotechnol. Rev. 2021, 10, 370–384. [Google Scholar]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar]

- Leon, N.; Massana, J.; Alonso, F.; Moragues, A.; Sanchez-Espinosa, E. Effect of nano-Si2O and nano-Al2O3 on cement mortars for use in agriculture and livestock production. Biosyst. Eng. 2014, 123, 1–11. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete–a review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar]

- Oltulu, M.; Şahin, R. Effect of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strengths and capillary water absorption of cement mortar containing fly ash: A comparative study. Energy Build. 2013, 58, 292–301. [Google Scholar]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef]

- Li, C.; Li, G.; Du, Q.; Wu, X.; Wang, F.; Lin, J.; Yue, J.; Zhang, H.; Tang, L.; Jia, H. Effects of nano-alumina on Portland concrete at low temperatures (5 °C). Case Stud. Constr. Mater. 2024, 20, e02922. [Google Scholar]

| Compound | OPC | GGBS | SF |

|---|---|---|---|

| SiO2 | 20.73 | 34.92 | 85.62 |

| CaO | 46.21 | 30.65 | 0.96 |

| Al2O3 | 3.01 | 9.48 | 0.90 |

| Fe2O3 | 2.47 | 0.55 | 3.63 |

| MgO | 1.02 | 6.30 | 1.79 |

| Na2O | 0.36 | 0.61 | 0.94 |

| K2O | 0.997 | 0.96 | 2.30 |

| TiO2 | 0.17 | 0.55 | 0.07 |

| MnO | 0.063 | 1.057 | 0.24 |

| P2O5 | 0.16 | 0.001 | 0.127 |

| LOI | 21.8 | N | 3.01 |

| Shape | Material | Length (mm) | Aspect Ratio (L/d) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|

| Straight | High-carbon steel | 16 | 64 | 2720 | 210 |

| Cement | SF | GGBFS | Silica Sand | w/b Ratio | Micro Steel Fiber (Volume Fraction) |

|---|---|---|---|---|---|

| 580 | 131 | 588 | 652 | 0.19 | 2.0% |

| Coating Materials | Morphology | Molecular Mass (g/mol) | Density (g/cm3) | Average Flake Thickness | Particle Size |

|---|---|---|---|---|---|

| graphene oxide (GO) | Sheet | 4.24 | 2.1 | Less than 2 nm | 2–7 µm |

| nano-calcium carbonate | Cubic or hexagonal | 100.09 | 2.93 | - | 15–40 nm |

| nano-aluminum oxide | Semi-sphere | 101.96 | 3.65 | - | 50–80 nm |

| Mix | Coating for Fiber | Coupling Agent for Coating Technique | Fillers Used Within the Mixture |

|---|---|---|---|

| UHPC | - | - | - |

| UHPC-GO | - | - | Graphene oxide (GO) |

| UHPC-NGO | Graphene oxide (GO) | Poly(vinyl alcohol) | - |

| UHPC-NCaCO3 | Nano-calcium carbonate | Poly(vinyl alcohol) | - |

| UHPC-NAl2O3 | Nano-aluminum oxide | Poly(vinyl alcohol) | - |

| Reference | Fiber Type | Coating Materials | Concrete Type | w/p Ratio |

|---|---|---|---|---|

| Signorini et al. [58] | Polypropylene draw-wire | Silica coating | Fiber-reinforced concrete | 0.20 |

| Pi et al. [30] | Micro steel fibers | Nano-SiO2 | Steel fiber-reinforced cement-based composite | 0.35 |

| Ahmadi et al. [4] | Micro steel fibers | Graphene oxide (GO) | 3D-printable concrete | 0.42 |

| Zhang et al. [31] | Basalt fiber | Graphene oxide (GO) | Oil well cement slurry | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousavi, S.S.; Ahmadi, K.; Dehestani, M.; Yeon, J.H. Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate. Fibers 2025, 13, 37. https://doi.org/10.3390/fib13040037

Mousavi SS, Ahmadi K, Dehestani M, Yeon JH. Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate. Fibers. 2025; 13(4):37. https://doi.org/10.3390/fib13040037

Chicago/Turabian StyleMousavi, Seyed Sina, Khatereh Ahmadi, Mehdi Dehestani, and Jung Heum Yeon. 2025. "Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate" Fibers 13, no. 4: 37. https://doi.org/10.3390/fib13040037

APA StyleMousavi, S. S., Ahmadi, K., Dehestani, M., & Yeon, J. H. (2025). Influence of Coated Steel Fibers on Mechanical Properties of UHPC Considering Graphene Oxide, Nano-Aluminum Oxide, and Nano-Calcium Carbonate. Fibers, 13(4), 37. https://doi.org/10.3390/fib13040037