Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview

Abstract

:1. Introduction

2. Processing of Carbon CNT/Polymer Nanocomposites Using 3DP

3. Applications

4. Conclusions and Future Developments

Acknowledgments

Conflicts of Interest

References

- Wimpenny, D.I.; Pandey, P.M.; Kumar, L.J. Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Berlin, Germany, 2016. [Google Scholar]

- Chua, C.K.; Wong, C.H.; Yeong, W.Y. Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Badiru, A.B.; Valencia, V.V.; Liu, D. Additive Manufacturing Handbook: Product Development for the Defense Industry; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-Dimensional Printing of Continuous-Fiber Composites by In-Nozzle Impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Xiaocong, T.; Jun, J.; Shangqin, Y.; Kai, C.C.; Beng, T.S.; Kun, Z. Emerging 3D-Printed Electrochemical Energy Storage Devices: A Critical Review. Adv. Energy Mater. 2017, 7, 1614–6840. [Google Scholar]

- Lewis, J.; Ahn, B.Y. Device Fabrication: Three-Dimensional Printed Electronics. Nature 2015, 518, 42–43. [Google Scholar] [CrossRef] [PubMed]

- Lewicki, J.P.; Rodriguez, J.N.; Zhu, C.; Worsley, M.A.; Wu, A.S.; Kanarska, Y.; Horn, J.D.; Duoss, E.B.; Ortega, J.M.; Elmer, W.; et al. 3D-Printing of Meso-structurally Ordered Carbon Fiber/Polymer Composites with Unprecedented Orthotropic Physical Properties. Sci. Rep. 2017, 7, 43401. [Google Scholar] [CrossRef] [PubMed]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Kalaskar, D.M. 3D Printing in Medicine; Woodhead Publishing: Duxford, UK, 2017. [Google Scholar]

- Farahani, R.D.; Dubé, M.; Therriault, D. Three-Dimensional Printing of Multifunctional Nanocomposites: Manufacturing Techniques and Applications. Adv. Mater. 2016, 28, 5794–5821. [Google Scholar] [CrossRef] [PubMed]

- Lipson, H.; Francis, C.M.; Jimmy, H.; Paventi, C. 3-D printing the history of mechanisms. J. Mech. Des. 2005, 127, 1029. [Google Scholar] [CrossRef]

- Jacobs, P.F. Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography; Society of Manufacturing Engineers: Dearborn, MI, USA, 1992. [Google Scholar]

- Tian, X.Y.; Tian, T.F.; Yang, C.C.; Wang, Q.R.; Li, D.C. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Acquah, S.F.A.; Leonhardt, B.E.; Nowotarski, M.S.; Magi, J.M.; Chambliss, K.A.; Venzel, T.E.S.; Delekar, S.D.; Al-Hariri, L. Carbon Nanotubes and Graphene as Additives in 3D Printing (Chapter 8). In Carbon Nanotubes—Current Progress of their Polymer Composites; Berber, M.R., Ed.; InTech: Rijeka, Croatia, 2016. [Google Scholar] [CrossRef]

- Liu, H.; Webster, T.J. Enhanced biological and mechanical properties of well-dispersed nanophase ceramics in polymer composites: From 2D to 3D printed structures. Mater. Sci. Eng. C 2011, 31, 77–89. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Cunico, M.W.M.; Carvalho, J.D. Development of novel additive manufacturing technology: An investigation of a selective composite formation process. Rapid Prototyp. J. 2016, 22, 51–66. [Google Scholar] [CrossRef]

- Lukic, M.; Clarke, J.; Tuck, C.; Whittow, W.; Wells, G. Printability of elastomer latex for additive manufacturing or 3D printing. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef] [Green Version]

- Cunico, M.W.M.; Carvalho, J.D. Development of acrylate-based material using a multivariable approach: Additive manufacturing applications. Rapid Prototyp. J. 2014, 20, 121–132. [Google Scholar] [CrossRef]

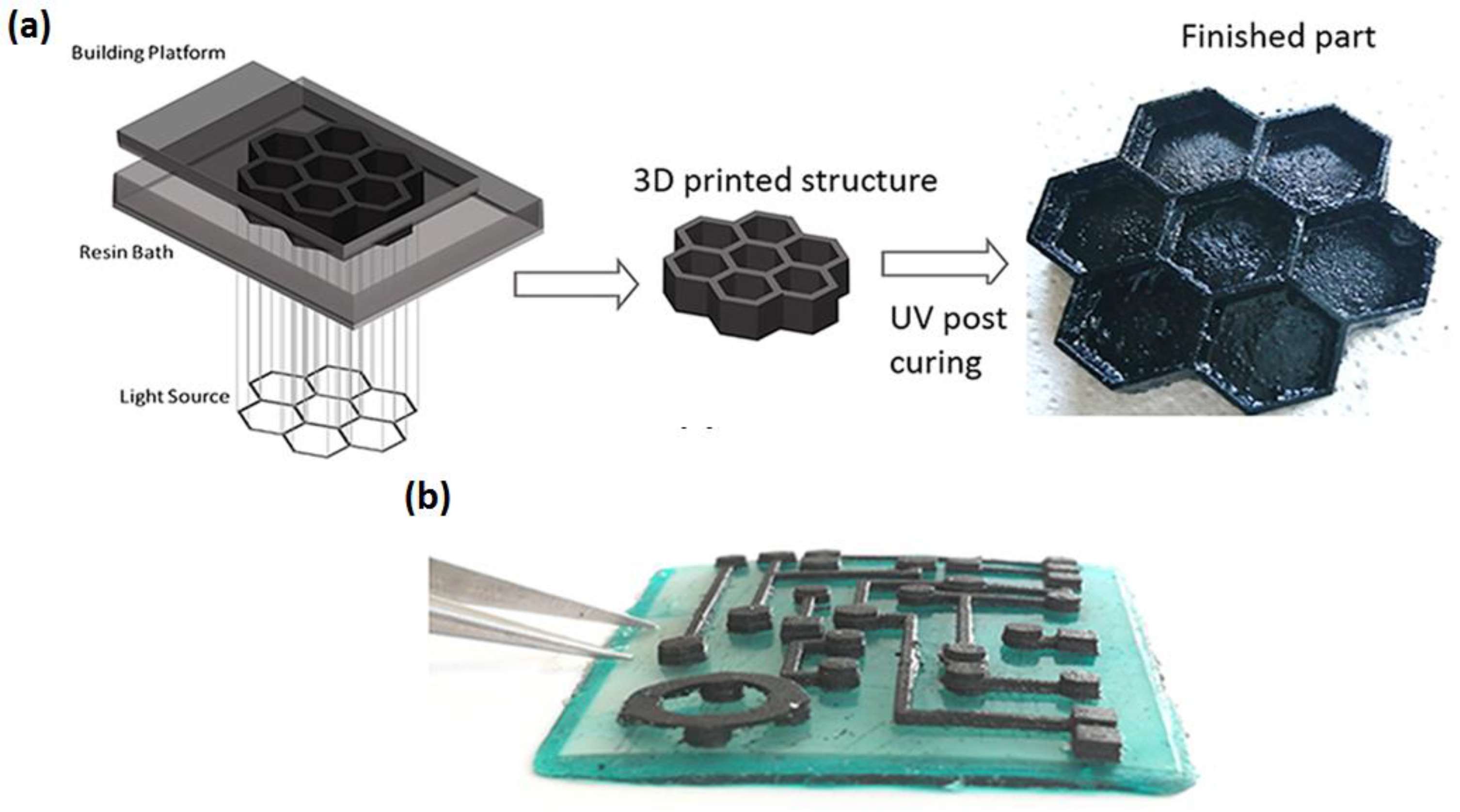

- Weng, Z.X.; Zhou, Y.; Lin, W.X.; Senthil, T.; Wu, L.X. Structure-property relationship of nano enhanced stereolithography resin for desktop SLA 3D printer. Compos. A Appl. Sci. Manuf. 2016, 88, 234–242. [Google Scholar] [CrossRef]

- Amel, H.; Rongong, J.; Moztarzadeh, H.; Hopkinson, N. Effect of section thickness on fatigue performance of laser sintered nylon 12. Polym. Test. 2016, 53, 204–210. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive manufacturing: polymers applicable for laser sintering (LS). Procedia Eng. 2016, 49, 457–464. [Google Scholar] [CrossRef]

- Fu, K.; Yao, Y.Y.; Dai, J.Q.; Hu, L.B. Progress in 3D Printing of Carbon Materials for Energy-Related Applications. Adv. Mater. 2017, 29, 1603486. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.F.; Liu, C.C.; Chai, W.X.; Compaan, A.; Huang, Y. Self-Supporting Nanoclay as Internal Scaffold Material for Direct Printing of Soft Hydrogel Composite Structures in Air. ACS Appl. Mater. Interfaces 2017, 9, 17456–17465. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.Y.; Ma, Y.F.; Hou, C.Y.; Gao, F.; Zhang, Y.Y.; Ruan, C.S.; Pan, H.B.; Lu, W.J.; Liu, W.G. 3D-Printed High Strength Bioactive Supramolecular Polymer/Clay Nanocomposite Hydrogel Scaffold for Bone Regeneration. ACS Biomater. Sci. Eng. 2017, 3, 1109–1118. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 56, 354. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Bachilo, S.M. Structure-assigned optical spectra of single walled carbon nanotubes. Science 2002, 298, 2361–2366. [Google Scholar] [CrossRef] [PubMed]

- Tans, S.J.; Devoret, M.H.; Dai, H.J.; Thess, A.; Smalley, R.E.; Geerligs, L.J.; Dekker, C. Individual single-wall carbon nanotubes as quantum wires. Nature 1997, 386, 474–477. [Google Scholar] [CrossRef]

- Samani, M.K.; Khosravian, N.; Chen, G.C.K.; Shakerzadeh, M.; Baillargeat, D.; Tay, B.K. Thermal conductivity of individual multiwalled carbon nanotubes. Int. J. Therm. Sci. 2012, 62, 40–43. [Google Scholar] [CrossRef]

- Hone, J.; Batlogg, B.; Benes, Z.; Johnson, A.; Fischer, J.E. Quantized phonon spectrum of single-wall carbon nanotubes. Science 2000, 289, 1730–1733. [Google Scholar] [CrossRef] [PubMed]

- Ebbesen, T.W.; Lezec, H.J.; Hiura, H. Electrical-conductivity of individual carbon nanotubes. Nature 1996, 382, 54–56. [Google Scholar] [CrossRef]

- Schlagenhauf, L.; Nüesch, F.; Wang, J. Release of Carbon Nanotubes from Polymer Nanocomposites. Fibers 2014, 2, 108–127. [Google Scholar] [CrossRef]

- Wang, P.; Ghoshal, S.; Gulgunje, P.; Verghese, N.; Kumar, S. Polypropylene nanocomposites with polymer coated multiwall carbon nanotubes. Polymer 2016, 100, 244–258. [Google Scholar] [CrossRef]

- Newcomb, B.A.; Chae, H.G.; Gulgunje, P.V.; Gupta, K.; Liu, Y.D.; Tsentalovich, D.E.; Pasquali, M.; Kumar, S. Stress Transfer in Polyacrylonitrile/Carbon Nanotube Composite Fibers. Polymer 2014, 55, 2734–2743. [Google Scholar] [CrossRef]

- Xie, L.; Xu, F.; Qiu, F.; Lu, H.B.; Yang, Y.L. Single-Walled Carbon Nanotubes Functionalized with High Bonding Density of Polymer Layers and Enhanced Mechanical Properties of Composites. Macromolecules 2007, 40, 3296–3305. [Google Scholar] [CrossRef]

- Downes, R.D.; Hao, A.; Park, J.G.; Su, Y.-F.; Liang, R.; Jensen, B.D.; Siochi, E.J.; Wise, K.E. Geometrically Constrained Self-Assembly and Crystal Packing of Flattened and Aligned Carbon Nanotubes. Carbon 2015, 93, 953–966. [Google Scholar] [CrossRef]

- Minus, M.L.; Chae, H.G.; Kumar, S. Polyethylene Crystallization Nucleated by Carbon Nanotubes under Shear. ACS Appl. Mater. Interfaces 2012, 4, 326–330. [Google Scholar] [CrossRef] [PubMed]

- Minus, M.L.; Chae, H.G.; Kumar, S. Single Wall Carbon Nanotube Templated Oriented Crystallization of Poly(Vinyl Alcohol). Polymer 2006, 47, 3705–3710. [Google Scholar] [CrossRef]

- Chae, H.G.; Minus, M.L.; Kumar, S. Oriented and Exfoliated Single Wall Carbon Nanotubes in Polyacrylonitrile. Polymer 2006, 47, 3494–3504. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Song, K.N.; Meng, J.S.; Minus, M.L. Tailoring Polyacrylonitrile Interfacial Morphological Structure by Crystallization in the Presence of Single-Wall Carbon Nanotubes. ACS Appl. Mater. Interfaces 2013, 5, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tajaddod, N.; Song, K.N.; Minus, M.L. Low Temperature Graphitization of Interphase Polyacrylonitrile (PAN). Carbon 2015, 91, 479–493. [Google Scholar] [CrossRef]

- Li, L.; Li, C.Y.; Ni, C.Y. Polymer Crystallization-Driven, Periodic Patterning on Carbon Nanotubes. J. Am. Chem. Soc. 2006, 128, 1692–1699. [Google Scholar] [CrossRef] [PubMed]

- Zong, G.Y.; Zhang, W.; Ning, N.Y.; Tang, C.Y.; Yang, M.B.; Fu, Q. Study of PE and iPP Orientations on the Surface of Carbon Nanotubes by Using Molecular Dynamic Simulations. Mol. Simul. 2013, 39, 1013–1021. [Google Scholar] [CrossRef]

- Rothschild, A.; Sloan, J.; Tenne, R. Growth of WS2 nanotubes phases. J. Am. Chem. Soc. 2000, 122, 5169–5179. [Google Scholar] [CrossRef]

- Nath, M.; Govindaraj, A.; Rao, C.N.R. Simple synthesis of MoS2 and WS2 nanotubes. Adv. Mater. 2001, 13, 283–286. [Google Scholar] [CrossRef]

- Dloczik, L.; Engelhardt, R.; Ernst, K.; Fiechter, S.; Sieber, I.; Könenkamp, R. Hexagonal nanotubes of ZnS by chemical conversion of monocrystalline ZnO columns. Appl. Phys. Lett. 2001, 78, 3687. [Google Scholar] [CrossRef]

- Lourie, O.R.; Jones, C.R.; Bartlett, B.M.; Buhro, W. CVD growth of boron nitride nanotubes. Chem. Mater. 2000, 12, 1808–1810. [Google Scholar] [CrossRef]

- Ye, C.; Ye, C.H.; Meng, G.W.; Jiang, Z.; Zhang, L. Rational growth of Bi2S3 nanotubes from quasi-twodimensional precursors. J. Am. Chem. Soc. 2002, 124, 15180–15181. [Google Scholar] [CrossRef] [PubMed]

- Nath, M.; Rao, C.N.R. New metal disulfide nanotubes. J. Am. Chem. Soc. 2001, 123, 4841–4842. [Google Scholar] [CrossRef] [PubMed]

- Galvan, D.H. Formation of NbSe2 nanotubes by electron irradiation. Fuller. Sci. Technol. 2000, 8, 143–151. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, Z.; Wang, X.Z.; Lu, Y.N.; Chen, X.; Xu, H.; Chen, Y. Synthesis and characterization of faceted hexagonal aluminum nitride nanotubes. J. Am. Chem. Soc. 2003, 125, 10176–10177. [Google Scholar] [CrossRef] [PubMed]

- Goldberger, J.; He, R.; Zhang, Y.F.; Lee, S.; Yan, H.Q.; Chol, H.-J.; Yang, P. Single-crystal gallium nitride nanotubes. Nature 2003, 422, 599–602. [Google Scholar] [CrossRef] [PubMed]

- Bakkers, E.P.A.M.; Verheijen, M.A. Synthesis of InP nanotubes. J. Am. Chem. Soc. 2003, 125, 3440–3441. [Google Scholar] [CrossRef] [PubMed]

- Fan, R. Fabrication of silica nanotube arrays from vertical silicon nanowire templates. J. Am. Chem. Soc. 2003, 125, 5254–5255. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.H.; Xie, S.-Y.; Jiang, Z.-Y.; Zhang, X.; Tian, Z.-Q.; Xie, Z.-X.; Huang, R.-B.; Zheng, L.-S. Rational Design and Fabrication of Zno Nanotubes from Nanowire Templates in a Microwave Plasma System. J. Phys. Chem. B 2003, 107, 10114. [Google Scholar] [CrossRef]

- Baddour, C.E.; Briens, C. Carbon Nanotube Synthesis: A Review. Int. J. Chem. React. Eng. 2005, 3, R3. [Google Scholar] [CrossRef]

- Kong, Y.; Yuan, J.; Wang, Z.M.; Qiu, J. Study on the preparation and properties of aligned carbon nanotubes/polylactide composite fibers. Polym. Compos. 2012, 33, 1613–1619. [Google Scholar] [CrossRef]

- Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.J.; Petit, P.; Robert, J.; Xu, C.H.; Lee, Y.H.; Kim, S.G.; Rinzler, A.G.; et al. Crystalline ropes of metallic carbon nanotubes. Science 1996, 273, 483–487. [Google Scholar] [CrossRef] [PubMed]

- Murray, A.R.; Kisin, E.R.; Tkach, A.V.; Yanamala, N.; Mercer, R.; Young, S.H.; Fadeel, B.; Kagan, V.E.; Shvedova, A.A. Factoring-in agglomeration of carbon nanotubes and nanofibers for better prediction of their toxicity versus asbestos. Part. Fibre Toxicol. 2012, 9, 10. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.-C.; White, K.L.; Liu, P.L.; Zhang, X.; Sue, H.-J. Electrical conductivity and thermal stability of polypropylene containing well-dispersed multi-walled carbon nanotubes disentangled with exfoliated nanoplatelets. Carbon 2012, 50, 4711–4721. [Google Scholar] [CrossRef]

- Bhattacharyya, A.R.; Sreekumar, T.V.; Liu, T.; Kumar, S.; Ericson, L.M.; Hauge, R.H.; Smalley, R. Crystallization and orientation studies in polypropylene/single wall carbon nanotube composite. Polymer 2003, 44, 2373–2377. [Google Scholar] [CrossRef]

- Zhang, S.; Minus, M.; Zhu, L.B.; Wong, C.-P.; Kumar, S. Polymer transcrystallinity induced by carbon nanotubes. Polymer 2008, 49, 1356–1364. [Google Scholar] [CrossRef]

- Anand, K.A.; Agarwal, U.S.; Joseph, R. Carbon nanotubes induced crystallization of poly(ethylene terephthalate). Polymer 2006, 47, 3976–3980. [Google Scholar] [CrossRef]

- Zhang, S.; Kumar, S. Shaping polymer particles by carbon nanotubes. Macromol. Rapid Commun. 2008, 29, 557–561. [Google Scholar] [CrossRef]

- Wei, X.J.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.J.; Zhang, Z.X.; Sun, Z.Z. 3D printable graphene composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [PubMed]

- Ghoshal, S.; Wang, P.; Gulgunje, P.; Verghese, N.; Kumar, S. High Impact Strength Polypropylene Containing Carbon Nanotubes. Polymer 2016, 100, 259–274. [Google Scholar] [CrossRef]

- Sandoval, J.H.; Soto, K.F.; Murr, L.E.; Wicker, R.B. Nanotailoring Photocrosslinkable Epoxy Resins with Multi-Walled Carbon Nanotubes for Stereolithography Layered Manufacturing. J. Mater. Sci. 2007, 42, 156. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Li, H.M.; Yang, X.; Zhang, T.; Zhu, K.Q.; Si, W.; Liu, Z.L.; Sun, H.J. Additive Manufacturing of Carbon Nanotube-Photopolymer Composite Radar Absorbing Materials. Polym. Compos. 2016. [Google Scholar] [CrossRef]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D Microstructures by Direct 3D Printing of Polymer/Carbon Nanotube Nanocomposites via Liquid Deposition Modeling. Compos. A Appl. Sci. Manuf. 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Guo, S.; Yang, X.; Heuzey, M.-C.; Therriault, D. 3D Printing of a Multifunctional Nanocomposite Helical Liquid Sensor. Nanoscale 2015, 7, 6451–6456. [Google Scholar] [CrossRef] [PubMed]

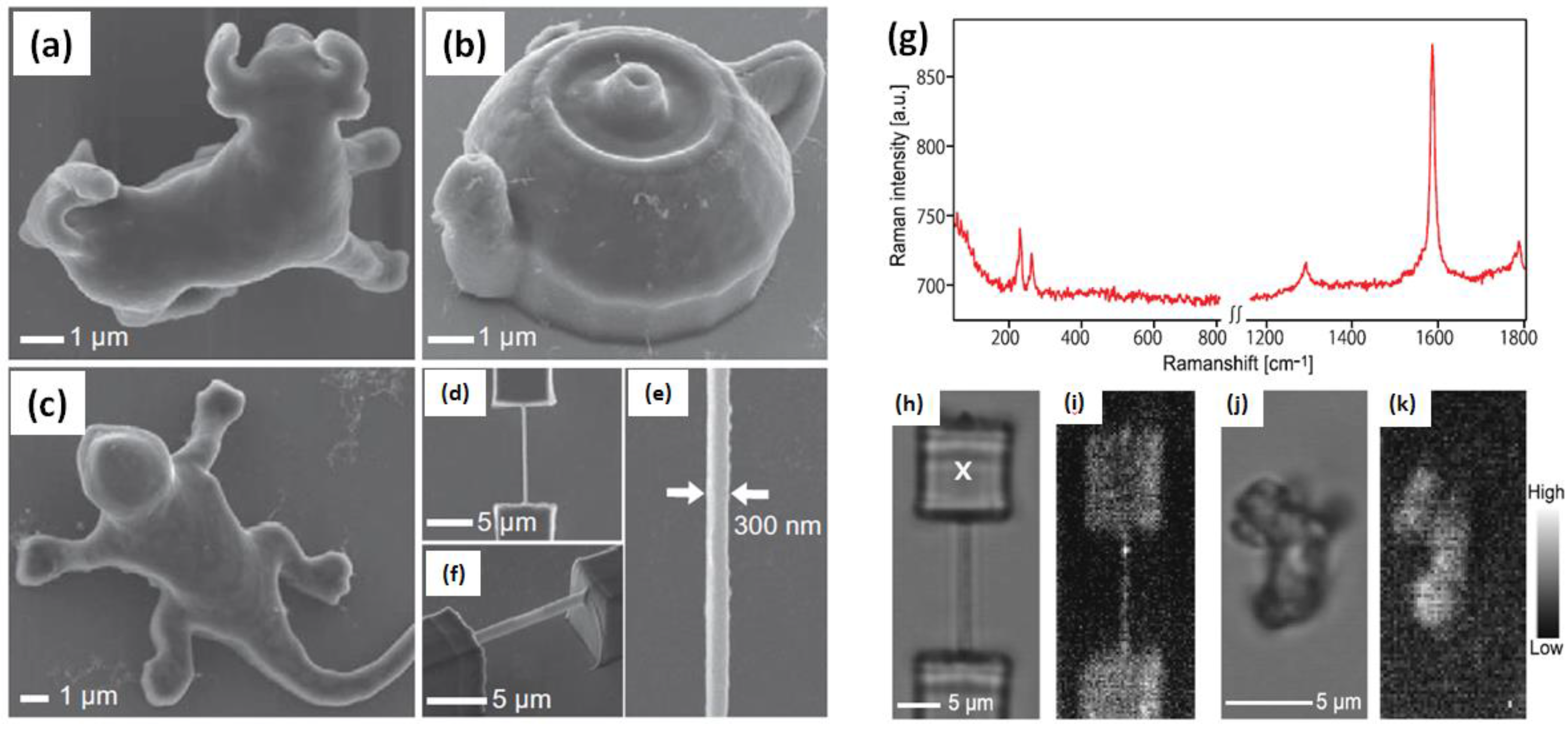

- Ushiba, S.; Shoji, S.; Masui, K.; Kuray, P.; Kono, J.; Kawata, S. 3D Microfabrication of Single-Wall Carbon Nanotube/Polymer Composites by Two-Photon Polymerization Lithography. Carbon 2013, 59, 283–288. [Google Scholar] [CrossRef]

- Li, Y.; Qi, F.J.; Yang, H.; Gong, Q.H.; Dong, X.Z.; Duan, X.M. Nonuniform shrinkage and stretching of polymerized nanostructures fabricated by two-photon polymerization. Nanotechnology 2008, 19, 055303. [Google Scholar] [CrossRef] [PubMed]

- Takada, K.; Wu, D.; Chen, Q.-D.; Shoji, S.; Xia, H.X.; Kawata, S.; Sun, H.-B. Size-dependent behaviors of femtosecond laser-phototyped polymer micronanowires. Opt. Lett. 2009, 34, 566–568. [Google Scholar] [CrossRef] [PubMed]

- Gnanasekaran, K.; Heijmans, T.; Bennekom, S.V.; Woldhuis, H.; Wijnia, S.; With, G.D.; Friedrich, H. 3D Printing of CNT- and Graphene-Based Conductive Polymer Nanocomposites by Fused Deposition Modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Gonzalez, G.; Chiappone, A.; Roppolo, L.; Fantino, E.; Bertanna, V.; Perrucci, F.; Scaltrito, L.; Pirri, F.; Sangermano, M. Development of 3D Printable Formulations Containing CNT with Enhanced Electrical Properties. Polymer 2017, 109, 246–253. [Google Scholar] [CrossRef]

- Tsiakatouras, G.; Chiappone, A.; Roppolo, I.; Fantino, E.; Bertana, V.; Perrucci, F.; Scaltrito, L.; Pirri, F.; Sangermano, M. Comparative Study on Nanotubes Reinforced with Carbon Filaments for the 3D Printing of Mechanical Parts. World Trans. Eng. Technol. Educ. 2014, 12, 392–396. [Google Scholar]

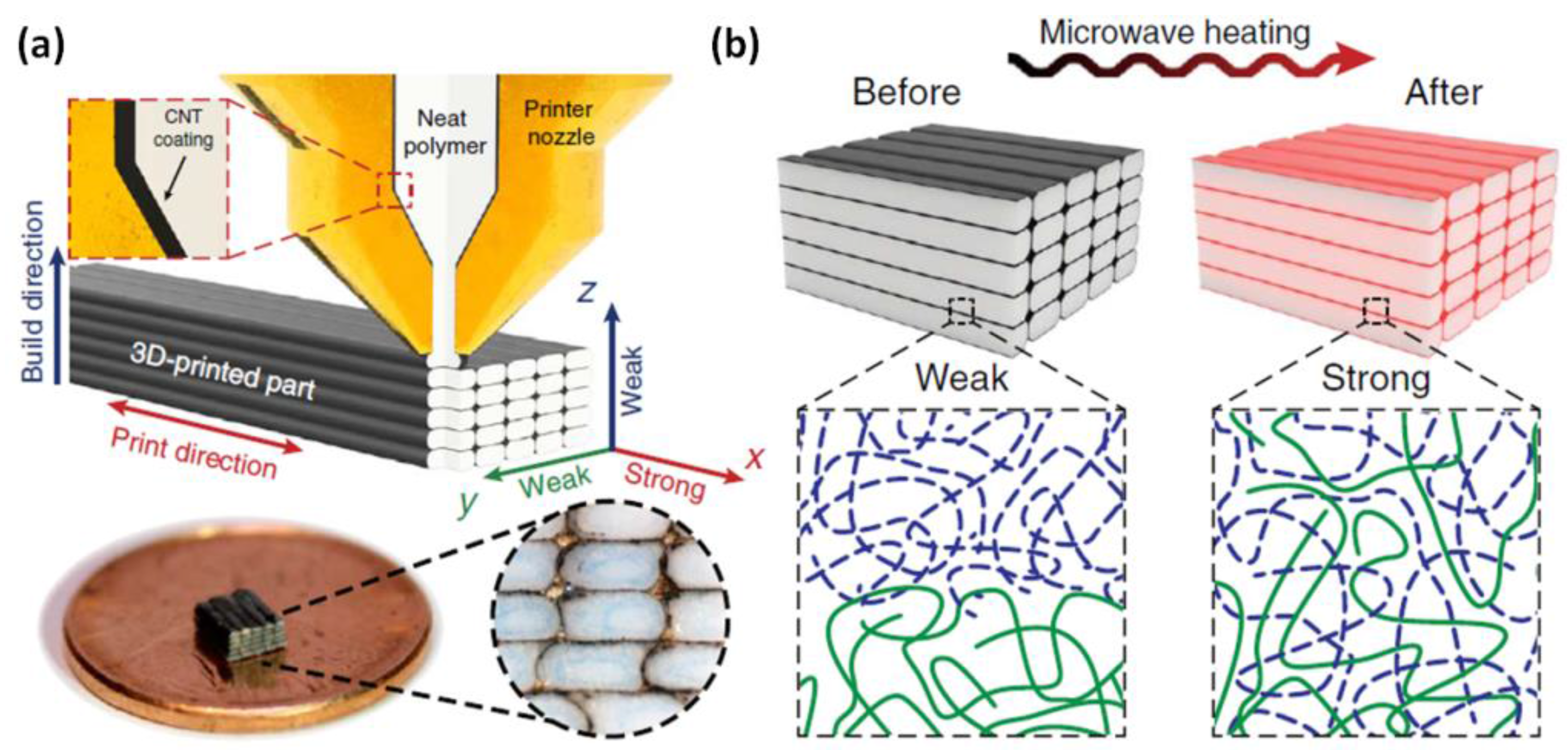

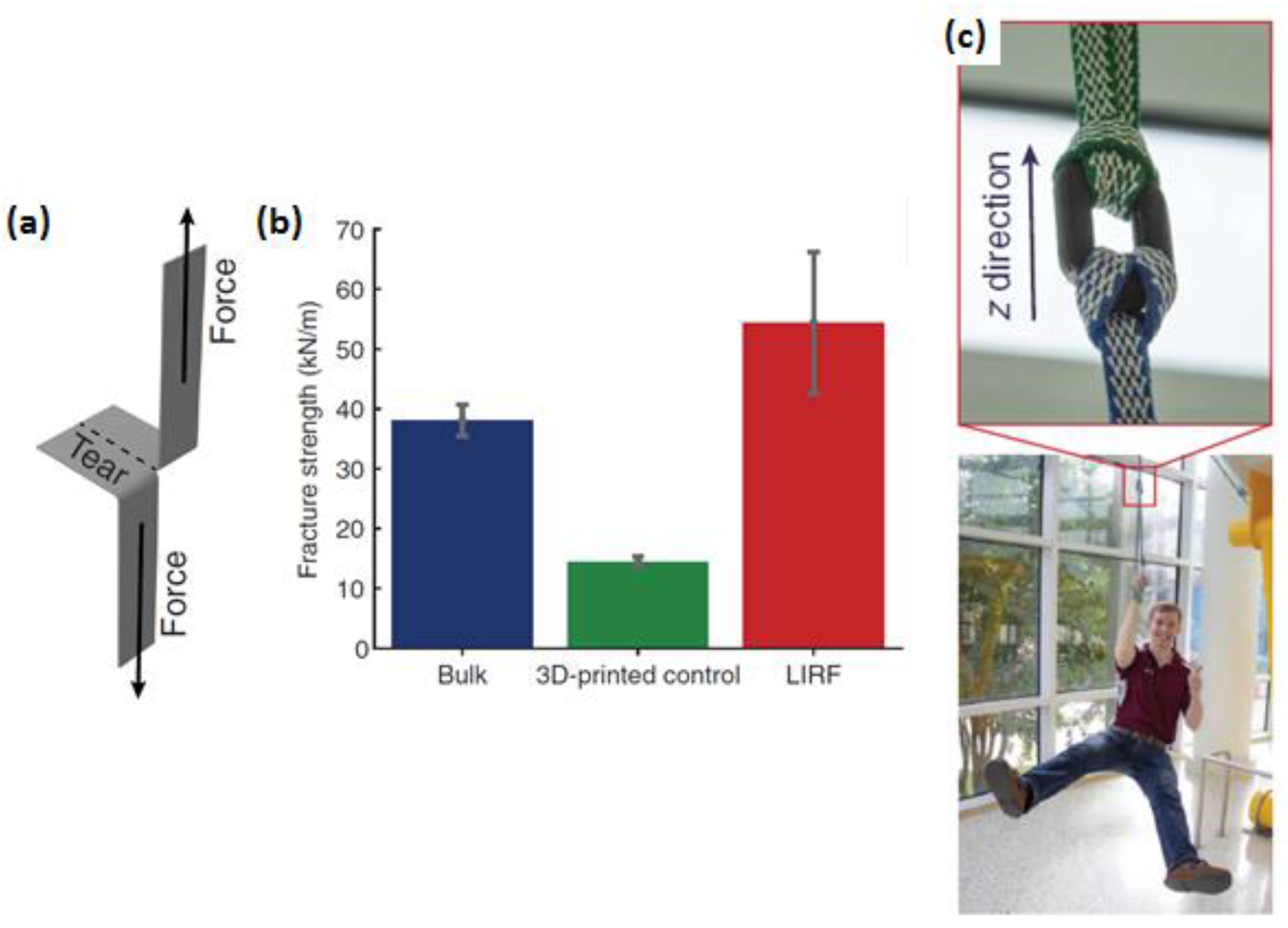

- Sweeney, C.B.; Lackey, B.A.; Pospisil, M.J.; Achee, T.C.; Hicks, V.K.; Moran, A.G.; Teipel, B.R.; Saed, M.A.; Green, M.J. Welding of 3D-Printed Carbon Nanotube—Polymer Composites by Locally Induced Microwave Heating. Sci. Adv. 2017, 3, 1700262. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xiong, W.; Jiang, L.J.; Zhou, Y.S.; Lu, Y.F. Precise 3D Printing of Micro/Nanostructures using Highly Conductive Carbon Nanotube-Thiol-Acrylate Composites. SPIE Proc. 2016, 9738, 973808. [Google Scholar]

- Yu, W.; Zhou, H.; Li, B.Q.; Ding, S.J. 3D Printing of Carbon Nanotubes-Based Microsupercapacitors. ACS Appl. Mater. Interfaces 2017, 9, 4597–4604. [Google Scholar] [CrossRef] [PubMed]

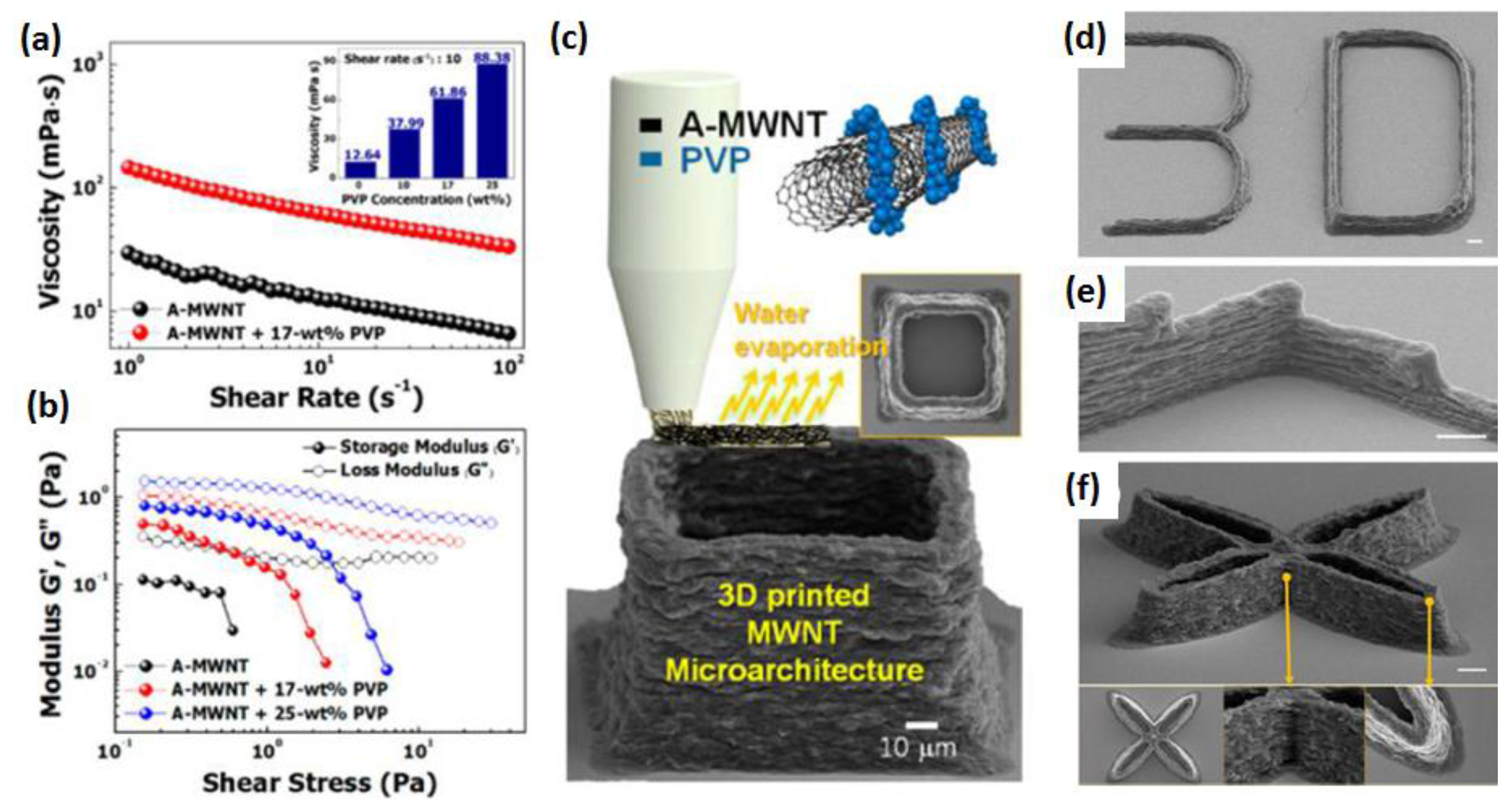

- Kim, J.H.; Zhou, H.; Li, B.Q.; Ding, S.J. Three-Dimensional Printing of Highly Conductive Carbon Nanotube Microarchitectures with Fluid Ink. ACS Nano 2016, 10, 8879–8887. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.T.; Seol, S.K.; Pyo, J.; Lee, J.S.; Je, J.H.; Margaritondo, G. Three-Dimensional Writing of Conducting Polymer Nanowire Arrays by Meniscus-Guided Polymerization. Adv. Mater. 2011, 23, 1968–1970. [Google Scholar] [CrossRef] [PubMed]

- Chizari, K.; Daoud, M.A.; Ravindran, A.R.; Therriault, D. 3D Printing of Highly Conductive Nanocomposites for the Functional Optimization of Liquid Sensors. Small 2016, 12, 6076–6082. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, E.M.; Oliveira, F.J.; Silva, R.F.; Neto, M.A.; Fernandes, M.H.; Amaral, M.; Vallet-Regi, M.; Vila, M. Three-Dimensional Printed PCL-Hydroxyapatite Scaffolds Filled with CNTs for Bone Cell Growth Stimulation. J. Biomed. Mater. Res. B 2016, 104, 1210–1219. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.C.; Wang, Z.H.; Gan, X.P.; Fu, D.H.; Fei, G.X.; Xia, H.S. Selective Laser Sintering 3D Printing: A Way to Construct 3D Electrically Conductive Segregated Network in Polymer Matrix. Macromol. Mater. Eng. 2017. [Google Scholar] [CrossRef]

- Yang, D.J.; Zhang, Q.; Chen, G.; Yoon, S.F.; Ahn, J.; Wang, S.G.; Zhou, Q.; Wang, Q.; Li, J.Q. Thermal conductivity of multiwalled carbon nanotubes. Phys. Rev. B 2002, 66, 165440. [Google Scholar] [CrossRef]

- McWilliams, A. Advanced Materials for 3D Printing: Technologies and Global Markets; BCC Research: Wellesley, MA, USA, 2014. [Google Scholar]

- Varotto, A. Global Markets for 3D Printing; Report No.: IAS102A; BCC Research: Wellesley, MA, USA, 2015. [Google Scholar]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer Nanocomposites Based on Functionalized Carbon Nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Gong, S.; Zhu, Z.H.; Li, J.; Meguid, S.A. Modeling and Characterization of Carbon Nanotube Agglomeration Effect on Electrical Conductivity of Carbon Nanotube Polymer Composites. J. Appl. Phys. 2014, 116, 194306. [Google Scholar] [CrossRef]

| Abbreviations | Elaborations |

|---|---|

| AM | Additive manufacturing |

| 3DP | 3D printing |

| CNT | Carbon nanotubes (CNT) |

| SWCNTs | Single-wall carbon nanotubes |

| MWCNTs | Multi-wall carbon nanotubes |

| GO | Graphene oxide |

| CAD | Computer-aided design |

| RP | Rapid prototyping |

| FDM | Fused deposition modeling |

| SL | Stereolithography |

| MSL | Micro-stereolithography |

| DOPsL | Dynamic optical projection stereolithography |

| DW | Direct-write assembly |

| SLS | Selective laser sintering |

| SC-3DP | Solvent-cast 3DP |

| C-3DP | Conformal 3DP |

| TPP | Two-photon polymerization |

| DLP | Digital light processing |

| ABS | Acrylonitrile-butadiene-styrene |

| PLA | Poly(lactic acid) |

| PBT | Polybutylene terephthalate |

| PCL | Poly(caprolactone) |

| PEGDA | Poly(-ethylene glycol) diacrylate |

| PEGMEMA | Poly(ethylene glycol) methyl ether methacrylate |

| BAPO | Bis(2,4,6-trimethylbenzoyl)-phosphineoxide |

| PVP | Poly(vinylpyrrolidone) |

| CVD | Chemical vapor deposition |

| LDM | Liquid deposition modeling |

| CF | Carbon fiber |

| SEM | Scanning electron microscopy |

| MTA | Multi-walled carbon nanotube-thiol-acrylate |

| MSCs | Microsupercapacitors |

| DCM | Dichloromethane |

| HA | Hydroxyapatite |

| TPU | Polyurethane |

| Technique | Polymer | CNT Type | CNT Concentration | Potential Applications/Additional Information | Year Published | Ref. |

|---|---|---|---|---|---|---|

| Stereolithography (SLA) | Epoxy | MWCNTs | 0.05% (w/v) | Nanocomposites with high tensile and fracture stress | 2007 | [69] |

| Stereolithography (SLA) | Acrylic ester photopolymer | MWCNTs | 0.5% to 1.5% wt. % | Radar absorbing materials (RAM) and novel RAM structures | 2016 | [70] |

| Liquid deposition modeling (LDM) | Poly(lactic acid) (PLA) | MWCNTs | Not available (NA) | Conductive polymer-based 3D microstructures | 2015 | [71] |

| Solvent-cast 3D printing | Poly(lactic acid) (PLA) | MWCNTs | 5% | High electrical conductivity and an excellent sensitivity for low power consumption devices | 2015 | [72] |

| Two-photon polymerization (TPP) lithography | Acrylic photopolymer | SWCNTs | 0.01 wt.% | Functional applications in micro- and nano-electromechanical systems | 2013 | [73] |

| Fused deposition modeling (FDM) | Polybutylene terephtha-late (PBT) | MWCNTs (+ graphene) | ~ 0.5 wt. % | Sufficient mechanical strength, stiffness, and chemical resistance for user specific application | 2017 | [76] |

| Digital light processing (DLP) | PEGDA and PEGMEMA | MWCNTs | Up to 0.3 wt. % | Structure with high electrical properties applications | 2017 | [77] |

| Fused deposition modeling (FDM) | Acrylonitrile butadiene styrene (ABS) | CNTs (+ carbon fiber) | 0.5%, 1% and 3% | Comparative study between conventional injection molding and 3D printing | 2014 | [78] |

| Locally induced RF (LIRF) welding of 3DP parts | Feedstock polylactide (PLA) | MWCNTs | Up to 20 wt. % in the film | For the enhancements of 3D-printed weld strength | 2017 | [79] |

| Two-photon polymerization (TPP) lithography | Thiol-acrylate resins (MTA) | MWCNTs | 0.05, 0.1, 0.15 and 0.2 wt. % | Precise 3D printing for device applications | 2016 | [80] |

| A new/novel technique based on inkjet and extrusion based 3D printing | Poly(vinyl alcohol) (PVA) | MWCNTs | 70 wt. % of dispersion agent wt. in the ink | Microsupercapacitors (MSCs), energy storage devices | 2017 | [81] |

| Meniscus-guided printing | Polyvinylpyrrolidone (PVP) | MWCNTs | ~75 wt. % | Electronic components such as sensing transducers, emitters, and radio frequency inductors | 2016 | [82] |

| Solvent cast 3D printing method | Polylactic acid (PLA) | MWCNTs | UP to 40 wt. % | Scaffold structures as Liquid sensors | 2016 | [84] |

| Nozzle-deposition method/layer-by-layer dispensing | Hydroxyapatite (HA) and polycaprolactone (PCL) | MWCNTs | Up to 10 wt. % | Scaffold for bone regeneration | 2016 | [85] |

| Selective laser sintering (SLS) | Polyurethane (TPU) | MWCNTs | 0.1 to 1 wt. % | Flexible circuit, wearable devices, implantable devices, electronic skin, dielectric elastomer actuators | 2017 | [86] |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghoshal, S. Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview. Fibers 2017, 5, 40. https://doi.org/10.3390/fib5040040

Ghoshal S. Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview. Fibers. 2017; 5(4):40. https://doi.org/10.3390/fib5040040

Chicago/Turabian StyleGhoshal, Sushanta. 2017. "Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview" Fibers 5, no. 4: 40. https://doi.org/10.3390/fib5040040

APA StyleGhoshal, S. (2017). Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview. Fibers, 5(4), 40. https://doi.org/10.3390/fib5040040