Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Fabric-Reinforced PP-Based Composites

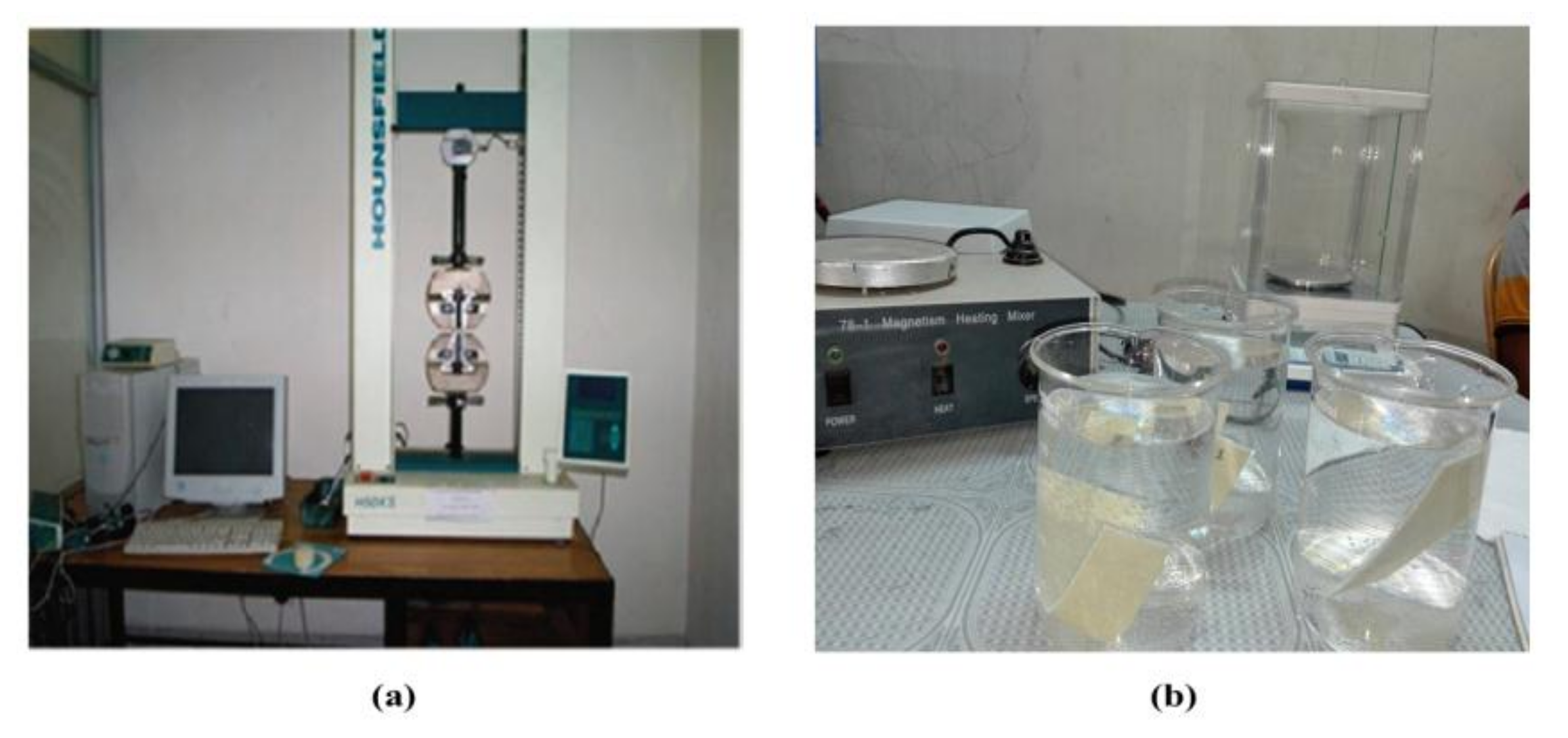

2.3. Mechanical Properties of Composites

2.4. Water Absorption Profile of the Composites

2.5. Effect of Alkali

2.6. Soil Degradation Test of the Composites

3. Results and Discussion

3.1. Mechanical Properties of Composites

3.2. Water Absorption Profile of the Composites

3.3. Effect of Alkali

3.4. Soil Degradation Test of the Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sahadat Hossain, M.D.; Sarwaruddin Chowdhury, A.M.; Khan, R.A. Effect of disaccharide, gamma radiation and temperature on the physico-mechanical properties of jute fabrics reinforced unsaturated polyester resin-based composite. Radiat. Eff. Defects Solids 2017, 172, 517–530. [Google Scholar] [CrossRef]

- Hoque, M.B.; Sahadat Hossain, M.D.; Nahid, A.M.; Solaiman, B.; Khan, A.R. Fabrication and characterization of pineapple fibre-reinforced polypropylene based composites. Nano Hybrids Compos. 2018, 21, 31–42. [Google Scholar] [CrossRef]

- Sahadat Hossain, M.D.; Uddin, M.B.; Razzak, M.D.; Sarwaruddin Chowdhury, A.M.; Khan, R.A. Fabrication and characterization of jute fabrics reinforced polypropylene-based composites: Effects of ionizing radiation and disaccharide (sucrose). Radiat. Eff. Defects Solids 2017, 172, 904–914. [Google Scholar] [CrossRef]

- Wu, L.-P.; Kang, W.-L.; Chen, Y.; Zhang, X.; Lin, X.-H.; Chen, L.-Y.; Gai, Y.-G. Structures and properties of low-shrinkage polypropylene composites. J. Ap. Polym. Sci. 2016, 134, 44275. [Google Scholar] [CrossRef]

- Uawongsuwan, P.; Yang, Y.; Hamada, H. Long jute fiber-reinforced polypropylene composite: Effects of jute fiber bundle and glass fiber hybridization. J. App. Polym. Sci. 2014, 132, 41819. [Google Scholar] [CrossRef]

- Varshney, D.; Debnath, K.; Singh, I. Mechanical characterization of polypropylene (PP) and polyethylene (PE) based natural fiber reinforced composites. Int. J. Surf. Eng. 2014, 4, 16–23. [Google Scholar]

- Nuruzzaman Khan, M.D.; Roy, J.K.; Akter, N.; Zaman, H.U.; Islam, T.; Khan, R.A. Production and properties of short jute and short e-glass fiber reinforced polypropylene-based composites. Open J. Compos. Mater. 2012, 2, 40–47. [Google Scholar] [CrossRef]

- Nahar, S.; Khan, R.A.; Dey, K.; Sarker, B.; Das, A.K.; Ghoshal, S. Comparative studies of mechanical and interfacial properties between jute and bamboo fiber- Reinforced polypropylene-based composites. J. Thermoplast. Compos. Mater. 2012, 25, 15–32. [Google Scholar] [CrossRef]

- Khan, M.A.; Hinrichsen, G.; Drzal, L.T. Influence of noble coupling agents on mechanical properties of jute reinforced polypropylene composites. J. Mater. Sci. Lett. 2001, 20, 1711–1713. [Google Scholar] [CrossRef]

- Kasim, A.N.; Selamat, M.Z.; Daud, M.A.M.; Yaakob, M.Y.; Putra, A.; Sivakumar, D. Mechanical properties of polypropylene composites reinforced with alkaline treated pineapple leaf fibre from Josapine cultivar. Int. J. Automotive Mech. Eng. IJAME 2016, 1, 3157–3167. [Google Scholar] [CrossRef]

- Kasim, A.N.; Selamat, M.Z.; Aznan, N.; Sahadan, S.N.; Daud, M.A.M.; Jumaidin, R.; Salleh, S. Effect of pineapple leaf fiber loading on the mechanical properties of pineapple leaf fiber–polypropylene composite. J. Teknologi 2015, 77, 117–123. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Regenerated cellulose fibers as impact modifier in long jute fiber reinforced polypropylene composites: Effect on mechanical properties, morphology, and fiber breakage. J. App. Polym. Sci. 2014, 132, 41301. [Google Scholar] [CrossRef]

- Berhanu, T.; Kumar, P.; Singh, I. Mechanical behaviour of jute fibre reinforced polypropylene composites. In Proceedings of the 5 th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, India, 12–14 December 2014. [Google Scholar]

- Motaleb, K.Z.M.A.; Islam, S.; Hoque, M.B. Improvement of physicomechanical properties of pineapple leaf fiber reinforced composite. Int. J. Biomater. 2018. [Google Scholar] [CrossRef] [PubMed]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Lau, K.-T.; Hung, P.-Y.; Zhu, M.H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Sfondrini, M.F.; Cacciafesta, V.; Scribante, A. Shear bond strength of fibre-reinforced composite nets using two different adhesive systems. Eur. J. Orthod. 2011, 33, 66–70. [Google Scholar] [CrossRef]

- Cacciafesta, V.; Sfondrini, M.F.; Lena, A.; Scribante, A.; Vallittu, P.K.; Lassila, L.V. Flexural strengths of fiber-reinforced composites polymerized with conventional light-curing and additional postcuring. Am. J. Orthod. Dentofac. Orthop. 2007, 132, 524–527. [Google Scholar] [CrossRef]

- Lei, W.; Fang, C.; Zhou, X.; Li, Y.; Pu, M. Polyurethane elastomer composites reinforced with waste natural cellulosic fibers from office paper in thermal properties. Carbohydr. Polym. 2018, 197, 385–394. [Google Scholar] [CrossRef]

- Anand, R.S.; Daniel, F.C.; Rodney, E.J.; Roger, M.R. Renewable agricultural fibers as reinforcing fillers in plastics: Mechanical properties of kenaf fibers–polypropylene composites. Ind. Eng. Chem. Res. 1995, 34, 1889–1896. [Google Scholar]

- Ma, C.M.; Tseng, H.; Wu, H. Blocked diisocyanate polyester-toughened novolak-type phenolic resin: Synthesis, characterization, and properties of composites. J. Appl. Polym. Sci. 1998, 69, 1119–1127. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical modification of henequen fibers with an organosilane coupling agent. Compos. Part B 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers and Biocomposites; Taylor & Francis, CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-Gonzalez, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B Eng. 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Yuan, X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J. Reinf. Plast. Compos. 2012, 31, 425–437. [Google Scholar] [CrossRef]

- Liu, Q.; Stuart, T.; Hughes, M.; Sharma, H.S.S.; Lyons, G. Structural biocomposites from flax-part II: The use of PEG and PVA as interfacial compatibilising agents. Compos. Part A Appl. Sci. Manuf. 2017, 38, 1403–1413. [Google Scholar] [CrossRef]

- Carus, L.S.M. Targets for bio-based composites and natural fibres. JEC Compos. Mag. 2011, 8, 31. [Google Scholar]

- Mohanty, K.; Misra, M.; Drzal, L.T. Natural Fibres, Biopolymers and Biocomposites; Taylor & Francis, CRC Press: Oxfordshire, UK, 2005. [Google Scholar]

- Satyanarayana, K.G.; Pillai, S.K.G.; Pai, B.C.; Sukumaran, K. Lignocellulosic fibre reinforced polymer composite. In Handbook of Ceramic and Composites; Cheremisinoff, N.P., Ed.; Marcel Dekker: New York, NY, USA, 1990. [Google Scholar]

- Satyanarayana, K.G.; Sukumaran, K.; Mukherjee, P.S.; Pavithran, C.; Pillai, S.K.G. Natural fibre-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Arib, R.M.N.; Sapuan, S.M.; Hamdan, M.A.M.M.; Paridah, M.T.; Zaman, H.M.D.K. A literature review of pineapple fibre reinforced polymer composites. Polym. Polym. Compos. 2004, 12, 341–348. [Google Scholar] [CrossRef]

- Pavithran, C.; Mukherjee, P.S.; Brahmakumar, M.; Damodaran, A.D. Impact properties of natural fibre composites. J. Mater. Sci. Lett. 1987, 6, 882–884. [Google Scholar] [CrossRef]

- Mishra, S.; Misra, M.; Tripathy, S.S.; Nayak, S.K.; Mohanty, A.K. Potentiality of pineapple leaf fibre as reinforcement in PALF-polyester composite: Surface modification and mechanical performance. J. Reinf. Plast. Compos. 2001, 20, 321–334. [Google Scholar] [CrossRef]

- Harzallah, O.; Benzina, H.; Drean, J.-Y. Physical and mechanical properties of cotton fibers: Single-fiber failure. 2009, 80, 1093–2013. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Khan, R.A.; Khan, M.A.; Sultana, S.; Noor, F.G. Mechanical, degradation, and interfacial properties of synthetic degradable fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 29, 466–476. [Google Scholar] [CrossRef]

- Garcia, M.; Vliet, G.V.; Jain, S.; Zyl, W.E.V.; Boukamp, B. Polypropylene/SiO2 nano composites with improved mechanical properties. Rev. Adv. Mater. Sci. 2004, 6, 169–175. [Google Scholar]

- Karmaker, A.C.; Hinrichsen, G. Processing and characterization of jute fiber reinforced thermoplastic polymers. Polym. Plast. Technol. Eng. 1999, 30, 609–621. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. J. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Wambua, P.; Ivan, J.; Verport, I. Natural fibers: Can they replace glass in fiber reinforced plastics. J. Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Czvikovszky, T. Reactive recycling of multiphase polymer systems. Nucl. Instrum. Methods Phys. Res. B 1995, 105, 233–237. [Google Scholar] [CrossRef]

- Zhu, J.; Abhyankar, H.; Njuguna, J. Effect of fibre treatment on water absorption and tensile properties of flax/tannin composites. In Proceedings of the 11th International Conference on Manufacturing Research (ICMR2013), Bedford, UK, 19–20 September 2013; pp. 387–392. [Google Scholar]

- Kumar, B.; Lin, S.T. Redox state of iron and its related effects in the CaOP2O5- Fe2O3 glasses. J. Am. Ceram. Soc. 1991, 74, 226–229. [Google Scholar] [CrossRef]

- Ray, D.; Sarker, B.K.; Rana, A.K.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef] [Green Version]

- Khan, R.A.; Parsons, A.J.; Jones, I.A.; Walker, G.S.; Rudd, C.D. Surface teatment of phosphate glass fibers using 2-Hydroxyethyl methacrylate: Fabrication of poly(caprolactone)-based composites. J. Appl. Polym. Sci. 2009, 111, 246–254. [Google Scholar] [CrossRef]

| Tensile Properties | |||

|---|---|---|---|

| Materials | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

| PP | 28 ± 1.5 | 338 ± 25 | 75 ± 4.75 |

| Fabric/PP | 58 ± 3.15 | 867 ± 56 | 22.38 ± 1.6 |

| Bending Properties | ||

|---|---|---|

| Materials | Bending Strength (MPa) | Bending Modulus (MPa) |

| PP | 20 ± 1.45 | 230 ± 16 |

| Fabric/PP | 42 ± 2.78 | 495 ± 26 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoque, M.B.; Solaiman; Alam, A.B.M.H.; Mahmud, H.; Nobi, A. Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites. Fibers 2018, 6, 94. https://doi.org/10.3390/fib6040094

Hoque MB, Solaiman, Alam ABMH, Mahmud H, Nobi A. Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites. Fibers. 2018; 6(4):94. https://doi.org/10.3390/fib6040094

Chicago/Turabian StyleHoque, Mohammad Bellal, Solaiman, A.B.M. Hafizul Alam, Hasan Mahmud, and Asiqun Nobi. 2018. "Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites" Fibers 6, no. 4: 94. https://doi.org/10.3390/fib6040094

APA StyleHoque, M. B., Solaiman, Alam, A. B. M. H., Mahmud, H., & Nobi, A. (2018). Mechanical, Degradation and Water Uptake Properties of Fabric Reinforced Polypropylene Based Composites: Effect of Alkali on Composites. Fibers, 6(4), 94. https://doi.org/10.3390/fib6040094