2. Materials and Methods

As an agricultural country, Indonesia has a huge number of biomass fiber plantations, e.g., coconut (

Cocos nucifera), hemp (

Bohmeria nivea), and kenaf (

Hibiscus cannabinus). A study carried out by Narang revealed that lower density fiber boards yield better sound absorption behavior compared to similar high density boards [

30]. With regards to the use of cavity inclusion, they argued that the addition of a cavity to the metal frame could improve STL to a limit of 10 dB. Meanwhile, similar results reported by Ko et al. [

31] stated that aluminum foam material could have high sound transmission loss if it was treated with the addition of a cavity to the material structure. Furthermore, many researchers have proposed general acoustic tailoring by the use of additional resonators, porous layers and air back cavities. Setyowati et al. developed a unique strategy to improve the acoustic performance of materials by designing tailed cavity inclusion on seashell surface materials [

32]. Similar to previous studies, the present research implemented tail cavity inclusion in a resin reinforced biomass fiber for interior applications. Depending on the research by Ko et al., improvements in acoustic performance could be achieved by creating design innovation on either the surface or body of the material samples [

31]. The present research aims to create innovations by designing single and multiple tailed cavities in materials to improve sound absorption and insulation.

Finally, based on those theoretical reviews and references, this study also aims to observe the acoustic behavior of biomass fibers and deliver innovations for the application of tailed cavity inclusions. In this study, biomass fibers were first cleaned and dried in natural conditions within three days at 34–35 °C temperature and 80–85% relative humidity. After the drying process, the dried biomass fibers were then ground using a dish-mills machine and filtered to a size 250 microns. The mass of the specimens was measured, and an epoxy resin manufactured by the JUSTUS polyester resin 2522 was added. The biomass fibers reinforced epoxy resin JUSTUS 2522 had the composition of a natural fiber; polyester resin: catalyst as 25 grams; 200 mL and 20 mL respectively. The dough was manually stirred until it was thoroughly blended at a normal temperature and poured into tube-shaped moldings of 30 mm diameter. After 24 hours, the moldings were dismantled and massed for density.

Figure 1 illustrates three kinds of biomass fibers: coco-husk (

Cocos nucifera), hemp (

Bohmeria nivea), and kenaf (

Hibiscus cannabinus), as seen in

Figure 1a, and the treated specimens with either single or multiple tailed cavities in an effort to improve the acoustic performances of the biomass fibers (see

Figure 1b).

The three kinds of biomass fibers have four samples of two thicknesses, 15 mm and 30 mm in 30 mm diameter. Each thickness was represented by two samples, and the specimens were coded A to F, as listed in

Table 1. To observe the acoustic performances of the specimens, they were treated with eight holes of quarter wavelength resonators, hole-tailed cavity inclusions, additional fibrous Dacron layer, and a 10 mm air gap (see

Table 1). The 30 mm diameter tube specimens were measured in terms of their mass, volume, and density. The equation for density is:

where

is the material’s density in grams per cm

3, m is the weight in grams, and π, r, and t are pi, radius (cm), and the thickness of specimens (cm) respectively.

Table 2 shows the density of specimens:

Table 2 describes the average density of the biomass fibers. The differences of density between similar kinds of specimens occured due to the manual mixing process. The lowest density goes to the kenaf (

Hibiscus cannabinus) with 0.7670 g/cm

3, while the highest is indicated by the hemp (

Bohmeria nivea) at 0.9318 g/cm

3. Since previous studies indicated that density influenced the acoustic behavior of materials, including the absorption and the Sound Transmission Loss (STL), further discussion follows to compare one fiber to another in terms of surface material performances.

2.1. Sound Absorption Coefficient

The impedance tube test procedure using two microphones, ASTM E-1050 (DK-2850, Naerum, Denmark), was used to measure the sound absorption of specimens [

33]. The sound absorption behavior with frequencies up to 6400 Hz was measured by the 4206 series of B&K impedance tube equipped with a 30 mm diameter tube. The comparative measurement between 8-hole resonators and tailed-cavity inclusion samples on their sound absorption behavior was scrupulously observed. The treatments were conducted by drilling the samples to form both 3 mm diameter quarter wavelength resonators [

1] and 6 mm diameter single-multiple tailed cavity inclusions, as indicated in

Figure 1b.

A personal computer with a material testing software controlled all the experiments using the tube installed with four LAN-XI Bruel & Kjaer analyzer channels. The tube’s power amplifier propagated the gratuitous sound energy as the sound fount scattered along pipe before hitting the specimen’s surface. Two 1/4-inch 4187 Bruel & Kjaer microphones using transfer function analysis captured both decaying incident and reflection waves. The sound absorption behavior of the samples was represented by the decomposed sound energy and the process of decay. The following equations represent the frequency response function H

1,2 and reflection coefficient R:

The two microphones (in position one and two) captured the sound pressure levels,

P1 and

P2; the wave number is represented by

k;

R is Reflectance coefficient, while the distance between the sample and the first microphone is expressed by

h; finally, the distance between the microphones is represented by

s.

α, the sound absorption coefficient, can be formulated as:

where

α is the absorption coefficient and

R is reflectance coefficient.

2.2. Sound Transmission Loss (STL)

As a number of studies conducted to determine the Sound Transmission Loss [

34], the four Bruel & Kjaer 4187 series microphones located in both bottom and upper tubes captured the noise energy scattered by a hard speaker installed on the bottom tube. Random noise was generated by an analyzer of spectrum (3160-A-042 series of B&K, DK-2850, Naerum, Denmark) and power amplifier (the 2716C series of B&K, DK-2850, Naerum, Denmark). After being captured by the microphone, the sound was then analyzed by the module of spectrum analyzer (see

Figure 2).

To reach a high frequency test for sound dumping, a shorter tube was used. Specimens of 15 and 30 mm thickness were applied for the anechoic termination in the lower tube. The devising codes of A and B indicated the incidents and components reflected in the lower pipe, while the devising codes of C and D were emitted and reflected in the lower tube (see

Figure 2). To simplify the formulation of sound transmission loss, the distance between the two microphones was then considered equal and the calculation of STL was represented in Equation (4):

As such, the transfer function of sound pressure at positions 1 and 2 is represented by

H1,2, while that at positions 3 and 4 is represented by

H3,4, and

is the ratio between the auto spectrum in both the upper and lower tubes [

35].

2.3. Surface Morphology

The acoustic performances of natural fiber materials depend on the porosity of the natural fiber contained in the materials. A number of studies used a SEM to obtain the surface morphology of various materials in terms of acoustic performance. In this research, a SEM instrument of JEOL JSM-6510 LA (JEOL Co., Ltd., Tokyo, Japan) was used to observe the porosity and to analyze the different appearance of the morphology of the specimen’s surfaces [

36,

37,

38]. Sambu et al. used the porosity with SEM procedure to observe the Hibiscus cannabinus composed of latex in various compositions in terms of sound absorption capability. Unlike Sambu et al., Nath and Mishra and Sei discussed the performance of the sound absorption of porous materials observed with SEM analyses in macro discussions [

39,

40]. Meanwhile, Mahzan et al. observed the viability of coconut coir fiber composed using recycled rubber in terms of its sound absorption performance using SEM analyses [

37]. Further studies were carried out by Peng et al. [

41], Renouard et al. [

42], Bonnafous et al. [

43], and Cao et al [

38]. They evaluated the correlation between the compound of carbon within materials and acoustic behavior based on both the sound absorption and the transmission loss. The absorption coefficient and the sound transmission loss (STL) findings influenced by the surface morphology of biomass fibers are described in the following section.

3. Results and Discussions

The effects of single and multiple tailed cavity inclusion on the sound absorption behavior are described in

Figure 3. The sound absorption performance of the six specimens before treatment is presented in continuous lines (A

0, C

0, and E

0 indicate untreated, 15 mm thickness coco-husk, hemp, and kenaf respectively, while B

0, D

0, and F

0 indicate untreated, 30 mm thickness coco-husk, hemp, and kenaf respectively), while the treatments are shown in the dash-dot lines (A1H-Tailed, C1H-Tailed, and E1H-Tailed indicate 15 mm coco-husk, hemp, and kenaf respectively with single tailed cavity treatments, while B2H-Tailed, D2H-Tailed, and F2H-Tailed indicates 30 mm coco-husk, hemp and kenaf respectively with multiple tailed cavities). The hemp and kenaf fibers with thicknesses of 30 mm are indicated as C and E respectively, while the 15 mm hemp and kenaf are represented as D and F respectively. Before treatments, the entire four specimens show similar sound absorption coefficients in middle frequencies (1.5–3.0 kHz), except for the the coco-husk fiber. However, discrepancies occur in low and high frequencies, especially for the 30 mm hemp sample and the 15 mm kenaf sample. The 30 mm hemp showed the best performance at high frequencies, with a peak of 0.95 at 5.4 kHz, while the 15 mm kenaf in low frequencies reaching up to 0.46 at 750 Hz. These findings were in agreement with the results of Cao et al [

38] and Lim et al. [

5]; nevertheless, the coco-husk fiber showed its superiority, producing the highest sound absorption in middle frequencies for the 15 mm specimens and in the low frequencies for the 30 mm specimens.

There is no significant influence in terms of the additional holes and slits as single and multiple tailed cavity inclusions, except that the phenomenon occurred in the 30 mm-thick hemp specimens. The bare 30 mm hemp sample delineated by the red continuous line shifted its absorption performance towards lower frequencies after the treatments (see

Figure 3b). The 30 mm coco-husk specimens showed better performance after it was treated by multiple-tailed cavities, as represented by a black-dash dot line in

Figure 3b; it had two peaks of 0.60 and 1.0 at 3.0 kHz and 1.2 kHz respectively. The most promising performance occured when the 30 mm hemp sample was treated by multiple tailed cavity inclusions represented as D2HTailed with the red dash-dot line. Its sound absorption coefficient reached a high point of 0.63 at 2000 Hz and had a wide broadband frequency, which signifies the multiple tailed cavity inclusion creating a substantial effect on sound absorption improvement.

Nevertheless, the negative absorption values reveal that the material tends to be reflective at certain frequencies, but in fact, in reference to the statistical data described in

Table 3 and

Table 4, the biomass fiber materials have sound transmission loss performances in positive values.

Table 3 and

Table 4 show that the additional tailed cavity could increase the sound absorption performance.

Comparing

Figure 3,

Table 3, and

Table 4, although there are negative values in absorption performance due to the instrument’s sensitivity, the average sound absorption of all materials are in positive values. To emphasize the findings,

Table 3 describes the sound absorption increments as a result of the additional single tailed cavity. Similar to the findings of by Narang [

30] and Ko et al. [

31], it was indicated that part of sound energy had been successfully trapped in the new structure of the tailed cavity inclusion. For example, when the sound absorption of

A0 (15 mm bared coco-husk) was 0.1885, the increment sound absorption increased at 0.2422 when a single tailed cavity was added in materials. Similar conditions occured in other specimens,

C (15 mm thick hemp) and

E (15 mm thick Kenaf) respecively (see the ‘average’ column of

Table 3). Like

Table 3,

Table 4 reveals that the sound absorption increased when multiple tailed cavities were added.

B,

D, and

F stand for 30 mm Coco-husk, Hemp and Kenaf respectively, while B

2HTailed, D

2HTailed and F

2HTailed indicated the 30 mm, Hemp, and Kenaf with multiple tailed cavities respectively.

The effectiveness of single-multiple tailed cavity inclusion is described in

Figure 4. The tailed cavity both reflects and blocks the sound energy, in that it can easily reduce the sound intensity due to the reflecting, blocking and decaying. This findings agree with studies conducted by Narang [

30] and Ko et al [

31]. The tailed cavity inclusion was designed to trap the sound energy. As illustrated in

Figure 4a, the sample was fitted in the B&K impedance tube and strengthened the sound energy released from the speaker. The generic method was applied covering additional resonators, the fibrous layer, and the air gap behind the sample. The sound energy hit the material surface, propagated within the material, and was trapped by the tailed cavity inclusion. As a result of the event of the sound capture in the tailed inclusion structure, the sound became gradually decreased, due not only to trapped sound energy, but also because viscous damping occured in this process.

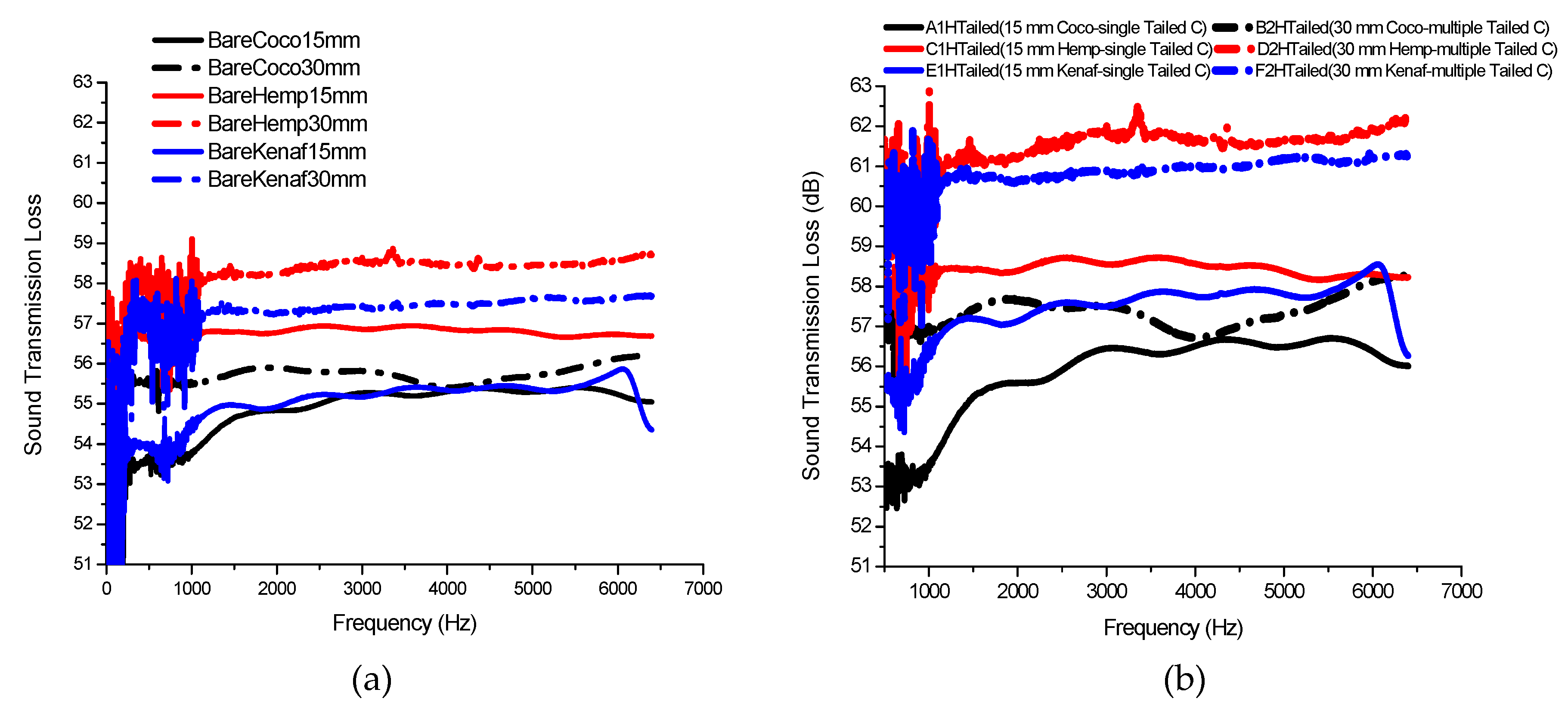

Moreover, it was also found that the sound transmission loss represented the ability of the material to obstruct and remove sound energy. The transmission loss of Coco-Husk, Hemp, and Kenaf fiber reinforced

polyester epoxy is described in

Figure 5. In

Figure 5,

A1H-Tailed,

C1H-Tailed, and

E1H-Tailed denote the 15 mm coco-husk, hemp, and kenaf respectively, with the single tailed cavity treatments, while the

B2H-Tailed,

D2H-Tailed and

F2H-tailed indicate the 30 mm coco-husk, hemp, and kenaf respectively with the multiple tailed cavities treatments. The graph shows that the Sound Transmission Loss of either hemp or kenaf specimen with 30 mm thickness has better performance than that with the thickness of 15 mm (see

Figure 5). The best performance is shown by the 30 mm thickness of hemp specimen with the STL increases starting from 61 dB at 1 kHz. Unlike the hemp and kenaf, the STL behavior of coco-husk looks different, due to the distinctive fiber structure and pattern of coco-husk.

Figure 5a illustrates the sound transmission loss of untreated biomass fiber. In

Figure 5b, the hemp specimens have at least 61.5 dB at a 30 mm thickness and at least 58.2 dB at 15 mm, while the kenaf specimens have at least 60.8 and 58.0 dB at 30 mm and 15 mm thickness, respectively. Compared to the density data in

Table 1, the data show that the STL values agree with the density of the materials. It can be concluded that the thicker the specimens and the higher the densities, the better the sound transmission loss of materials. To make clearer the discussion of the sound transmission loss improvements due to the additional tailed cavity inclusion,

Table 3 shows the sound transmission loss differences of the bare biomass fiber specimens, samples with single tailed cavities, and samples with multiple tailed cavities.

Table 5 shows that the sound transmission loss performance increases due to both the additional single and multiple cavities. The highest increment percentage is indicated by the 30 mm thickness of the kenaf specimens by as much as 5.8538%, while the lowest increment percentage was indicated by the 15 mm thickness of coco-husk at 1.4468%.

Figure 6 describes how this research compares to previous research conducted by Setyowati et al. [

1]. The graph compares sound absorption performance according to the different treatments between the additional quarter wavelength resonators and single-multiple tailed cavity inclusions on three kinds of biomass fibers reinforced with a polyester resin. In

Figure 6, the codes of

A8Hresonator and

B8Hresonator stand for the coco-husk treated with eight holes resonator in 15 mm and 30 mm thicknesses, respectively. The codes of

C1HTailed and

E1HTailed stand for 15 mm hemp and kenaf specimens, which were respectively treated with single tailed cavity, while the codes of

D2HTailed and

F2HTailed indicate 30 mm hemps and kenaf specimens with multiple tailed cavity inclusions. The continuous lines show the 30 mm thick specimens, while the dash-dot lines depict the 15 mm thick samples.

Although the quarter wavelength resonators treatment impacts sound absorption to a much greater extent, the single-multiple tailed cavity treatments on the specimen causes lower frequencies in their sound absorption performances. The promising performance in terms of sound absorption of tailed cavity inclusion is delineated by the 30 mm thickness of hemp sample that has a lower frequency at its peak and a wider broadband frequency performance.

Several methods could be adopted to analyze the effectiveness of the single-multiple tailed cavity method compared to the previous traditional method, such as additional hole resonators. First, we compared the present methods to the previous quarter wavelength resonator methods.

Figure 7 shows coconut husk fiber reinforced polyester resin in term of its comparison between a quarter wavelength resonators and single-multiple tailed cavity inclusion method. In

Figure 7, the codes of AH8Resonator and BH8Resonator stand for the coco-husk with eight-hole resonator treatment in 15 mm and 30 mm thickness respectively, while the codes of A1H-TailedCav and B2H-TailedCav indicate coco-husk treated with single and multiple tailed cavity inclusions respectively into which the 10 mm air gap was added.

Ultimately, the present methods can shift sound absorption performance toward lower frequencies than the previous ones. For example, the 30 mm thickness coco-husks previously showed 0.95 at 2.6 kHz with the old method, but after treatment with the present method, the material had better performance at lower frequencies, with peaks on 0.99 and 0.60 at 1.0 kHz and 3.0 kHz respectively; this was due to its two-hole tailed cavities. Like the 30 mm thick samples, the 15 mm coco-husk with a single tailed cavity had absorption performance with a peak in 0.85 at 2.0 kHz, lower than the previous method of quarter wavelength resonators. Due to the cavity functioning like a Helmholtz resonator, such a finding is in agreement with previous studies by Setyowati et al., Echeverria et al. and Wang et al. [

32,

44,

45]. Second, as

Figure 8 indicates, we compared specimens treated with the present methods to the previous study observing coco-husks treated with quarter wavelength resonators and 10 mm air gaps.

In

Figure 8a,b, 15mmCoco-Husk8HC10mm means that the 15 mm coco-husk specimen was treated with eight hole resonators and a 10 mm air gap; 30mmRamie2HtailedFC10mm indicates the 30 mm Hemp specimen treated with multiple tailed cavities inclusions, an additional fibrous layer, and additional 10 mm air gap; finally, 15mmKenaf1HtailedFC10mm indicates the 15 mm kenaf specimen which was treated with multiple tailed cavity inclusions, an additional fibrous layer, and additional 10 mm air gap. Furthermore, on the red line, 15mmCoco-husk1H-TailedC10mm stands for the 15 mm coco-husk specimen that was treated with single tailed cavity and additional 10 mm air gap. The results shown in

Figure 8 is that all of treatments reach wide broadband frequencies, although the kenaf and hemp treated with tailed cavity are still much lower than the coco-husk treated with quarter wavelength eight-resonators in previous research. It means that the present improvement methods can be considered as treatments of biomass fiber composites due to their ability in terms of sound absorption in wide broadband frequencies (see

Figure 8a). In

Figure 8b, unlike the coco-husk with quarter wavelength 8 resonators (the black-dash dot line), the coco-husk with a single tailed cavity inclusion (the red-dash dot line) appeared in lower performance and did not have a wide broadband frequencies, although it has its highest peak at 0.99 at 1.0 kHz. This means that the coco-husk with an eight-hole resonator was still much better than that with a single tailed cavity due to having wideband frequencies.

The other result following the absorption and STL is the surface morphology of hemp and kenaf observed by SEM. The observation of surface morphology was needed to obtain the porosity appearance of hemp and kenaf fibers. The differences of SEM results between Hemp and Kenaf fibers are shown in

Figure 9 and

Figure 10:

SEM is an analytical technique to observe the surface morphology of materials.

Figure 9 and

Figure 10 show various specimen magnifications, i.e., 1000x, 3000x and 5000x. The figures show that the hemp fiber has few pores and that its channels are largely invisible compared to those in the kenaf fiber. The kenaf fiber tends to have larger pores and channels appearing frequently on its surface (see

Figure 9 and

Figure 10 above). The results provide the answers to the question of why the Transmission Loss of hemp is much higher than that of kenaf fiber in both the 30 and 15 mm thick samples.

In contrast with the sound transmission loss test, the sound absorption performance of kenaf fiber appears to be significantly higher in frequencies below 1 kHz, while that of of hemp fiber increases starting at 2.7 kHz and reaches a peak at 0.95 at 5.4 kHz. Such a phenomenon occurs because kenaf fiber has big pores and large channels that are clearly visible, giving rise to the ability to absorb and to reflect sound energy much more rapidly than the hemp fiber (see

Figure 9 and

Figure 10). SEM images of coco-husk fiber samples look like sheets that curl or overlap each other, which causes the formation of small and long channels with the greatest absorption of sound energy compared to hemp and kenaf fiber samples (see

Figure 11). In the SEM images, hemp fibers showed a tight morphology, i.e., large rods stacked so that they appear to have large channels. For the samples of kenaf fiber, the morphology has many pores of various sizes. The sound absorption of hemp fiber shows greater value compared to kenaf fiber, due to the large channels present in the hemp fiber.

The analyses were consistent with other studies [

5,

36,

37,

38,

39,

40,

41,

42,

43]. The SEM analysis is also comparable with the absorption coefficient analysis where the coco-husk sample has the largest absorption coefficient value, followed by hemp fiber and kenaf fiber samples. Each sample has wide broadband with an absorption coefficient above 0.2, which shows the good sound absorption of each test sample. In the STL analysis, hemp fiber samples had the highest sound absorption values compared to coco-husk and kenaf samples. This is due to the fact that hemp fiber has a high density (as seen from SEM images) compared to the other fiber samples. The morphological appearance of this finding can reflect sound absorption more quickly; in contrast, the small and long channels in coco fiber and pores on kenaf fiber have a reflection time from the sound absorbed which is longer, as indicated by their STL value.

Table 6 describes the Oxide content of coco-husk (Cocos nucifera), in which it comprises mostly carbon (C) mass, i.e., about 93.56%. The other contents are 0.42% sodium oxide (Na

2O), 0.21% magnesium oxide (MgO), 3.06% potassium oxide (K

2O), and 1.34% platinum dioxide (PtO

2).

Table 7 reveals that the

Bohmeria nivea (Hemp) comprises mostly carbon (

C), i.e., as much as 80.45%, with aluminum oxide (Al

2O

3) at about 0.50%, 0.38% silicon dioxide (SiO

2), 1.30% sulfur trioxide (SO

3), 10.30% calcium oxide (CaO), 2.11% copper oxide (CuO), 1.32% zinc oxide (ZnO) and 3.64% zirconium oxide (ZrO

2).

Table 8 describes the compound of

Hibiscus cannabinus (kenaf) as containing mostly carbon, i.e., as much as 87.43% of the entire mass, with 0.61% magnesium oxide (MgO), 2.28% sulfur trioxide (SO

3), 1.39% chloride (Cl), 4.64% potassium oxide (K

2O), 2.26% copper oxide (CuO) and 1.39% zinc oxide (ZnO).

Table 6,

Table 7 and

Table 8 describe the compound of coco-husk, hemp, and kenaf respectively. The percentage of carbon in coco-husk is 93.56%, while the carbon compound in hemp and kenaf are 80.45% and 87.43% respectively. If we consider the findings in sound absorption performances of the biomass fiber in

Figure 8a, it can be understood that the highest sound absorption performance is the coco-husks, while that of hemp and kenaf tend to be identical. This means that the higher the carbon compound is in biomass fiber, the higher the sound absorption performance. These findings agree with studies carried out by Sambu et al., Mahzan et al., and Cao et al. [

36,

37,

38] as well as studies by Nath and Mishra and Sei [

39,

40]. However, based on

Figure 8a, all of the biomass fibers show good sound absorption behavior due to their wide broadband frequencies. Based on the biomass fiber composites made in this present study,

Figure 12 illustrates the SEM of the specimens in which the polymeric resin was reinforced with the biomass fibers consisting of coco-husk, hemp, and kenaf respectively (see

Figure 12A–C).

The SEM analysis on the three composites shows that each composite has a porous surface morphology. In

Figure 12A (coco), it can be seen that the pore of the coco-husk composite is very large; in the hemp composite, the pore morphology looks small but has a long canal structure, whereas in kenaf, the composite morphology looks almost uniform/regular. The SEM results of the three composites show that the natural fibers of coco and hemp are not homogeneously mixed with polyester resins, as indicated by the results of both SEMs that still appear to have pore morphology. On the other hand, in kenaf composites the morphological structure looks irregular; this shows that the kenaf biomass from the preparation has a smooth material structure in that when mixed with resin to form a composite, the resulting composite will have a high density or little or almost no pores. The SEM analysis on the three composites supports analysis of absorption coefficient and STL, on coco composites where the coco husk filler/biomass pores still have a sound absorption role, apart from the role of cavity which is manually created. The same property is also present in hemp composites, in which pores in the filler/biomass hemp have the role of sound adsorption, apart from the role of cavity which is made manually. On the other hand, in kenaf composites, the acoustical value is in the lowest order compared to the two composite samples, which is caused by the density in morphology (SEM analysis results) looking very tight or having a high density. Accordingly, the ability of absorption and transmission of loss to sound is only influenced by cavity that is created manually.

Table 9,

Table 10 and

Table 11 describe the EDX analysis of the three composites that show other contents in the Coco and Hemp composites that cover over the presence of K

2O in the Coco and Al

2O

3 composites and CaO in the Hemp composites in addition to the carbon content in each composite. The results show that the Coco and Hemp biomass are not homogeneously mixed with the polyester resin so that the contents of both composites are still detected in the EDX analyses. The identification of the contents was due to the inhomogeneous composing between the polyester resin and either of the Coco fiber or the Hemp fiber (see

Table 9 and

Table 10). As a result, there are pores in the Coco-husk and Hemp biomass composites; in contrast, in the Kenaf composite, the EDX analysis result showed 100% carbon content without other compounds. It occurred because the polyester resin and the Kenaf fiber were mixed homogeneously indicated by such high carbon compound. It can be concluded that there are no gaps and pores in the Kenaf biomass composite. The analyses support the performance of absorption coefficient and STL, where the Coco and the Hemp composites have higher absorption and STL coefficient values than that of the Kenaf composites.

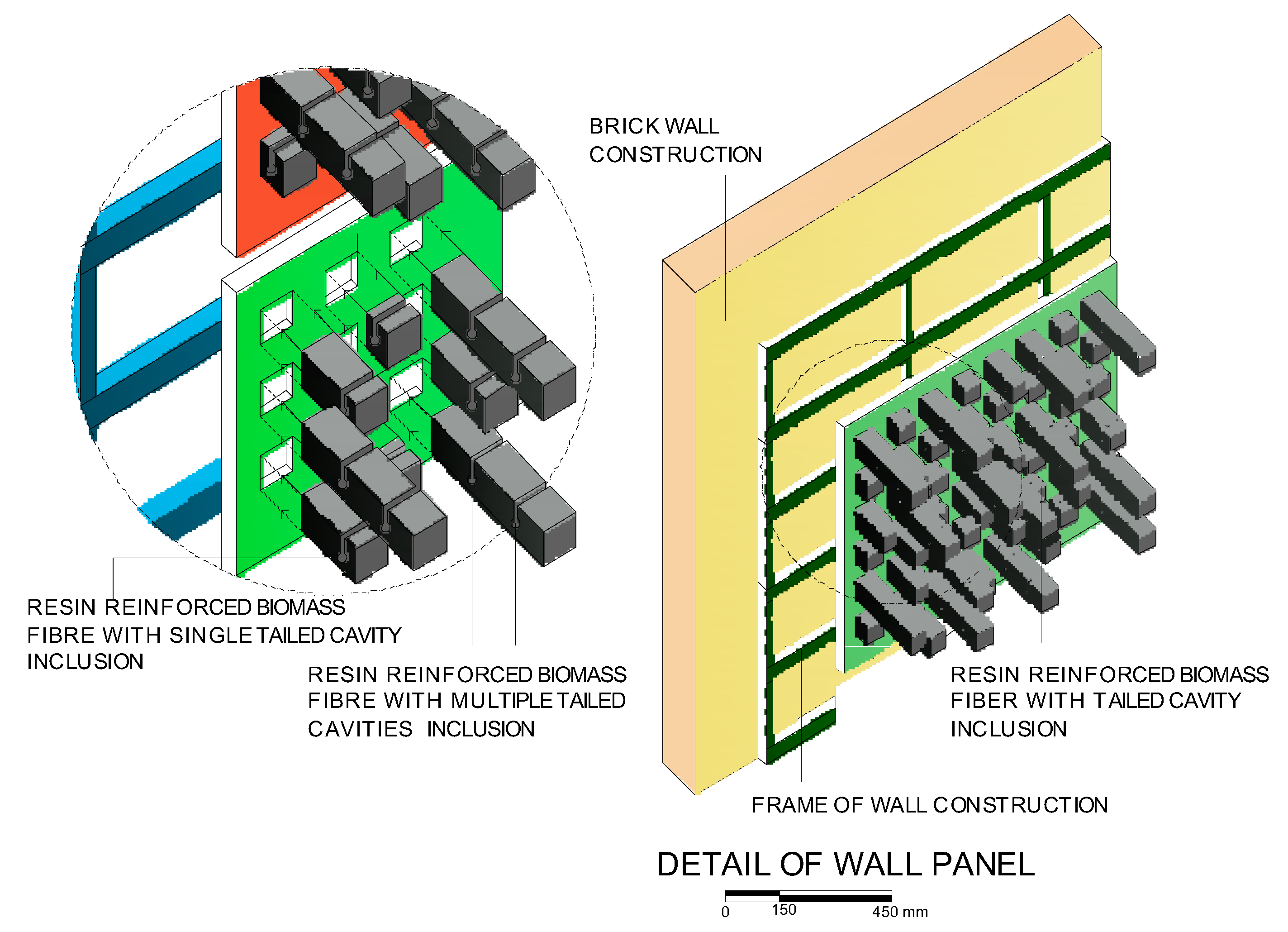

The materials demonstrated incremental performances on both in sound absorption and sound insulation; therefore, the materials can be considered as acoustic elements in buildings. The tailed cavity inclusion design in the specimen was tested as a sound damper, as stated in the results and discussion session. Hence, the application of these findings can be implemented in building interiors. The rough surface design of the diffuser-absorber proposed in the current research consists of either tubular or cubical elements in an acoustic panel comprising the proposed tailed cavity inclusions. This emphasizes how the panel structure can be made by ordering the tubular or cubical elements having tailed cavities inclusion and how the surface design of the panel can support the diffusivity (see

Figure 13,

Figure 14 and

Figure 15).

Figure 13 shows the diffusivity of the surface design of the panel consisting of either tubular or cubical types of panel element having the proposed single and multiple cavities.

To emphasize the term of diffusivity and reflection,

Figure 14 and

Table 12 describe the reflection performances of the biomass fibers in this current research.

Figure 14 illustrates that by the addition of either single and multiple tailed cavities in the specimens, the reflection performance decreased gradually. For example, the 30 mm thick of untreated hemp had a reflection of 0.7778, after the multiple tailed cavities were added, the reflection decreased to be 0.7653. Like hemp, the reflection capability of the 30 mm thick kenaf also decreased from 0.9669 to 0.9271 after multiple tailed cavities were added (see the ‘average’ column of

Table 12).

The graph in

Figure 14 shows the reflection coefficient of hemp and kenaf representing the biomass fibers, while

Table 12 shows the average reflection coefficient of the biomass fibers. The most reflective biomass fiber are 30 mm untreated kenaf followed by 15 mm untreated hemp. The additional tailed cavities in materials cause the reflection performance decrease as seen in average column in the table. This means that the tailed cavity caught a part of the sound energy and insulated it. Due to this phenomenon, it can be concluded that the tailed cavities helped the materials to reduce part of the sound; therefore, the role of the tailed cavity can be considered for materials as a sound damper in many applications.

The findings agree with the previous research [

32] and should be considered in interior design in buildings where acoustic performance is a priority. The biomass fibers studied in this research, i.e., coco-husk, hemp, and kenaf, are acceptable as acoustic materials.

Figure 15 shows the structural application of the materials as diffuser-absorbers in interior purposes with aluminum frame fitted in the wall.

Figure 15 in detail illustrates the details of tubular shaped diffuser absorber. Due to its good acoustic performance in previous research, biomass fibers could be considered as wall treatments in buildings. Combined with a tailed cavity diffuser above it, the panel structure could be an effective wall treatment design to address acoustic failures in building interiors.