Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

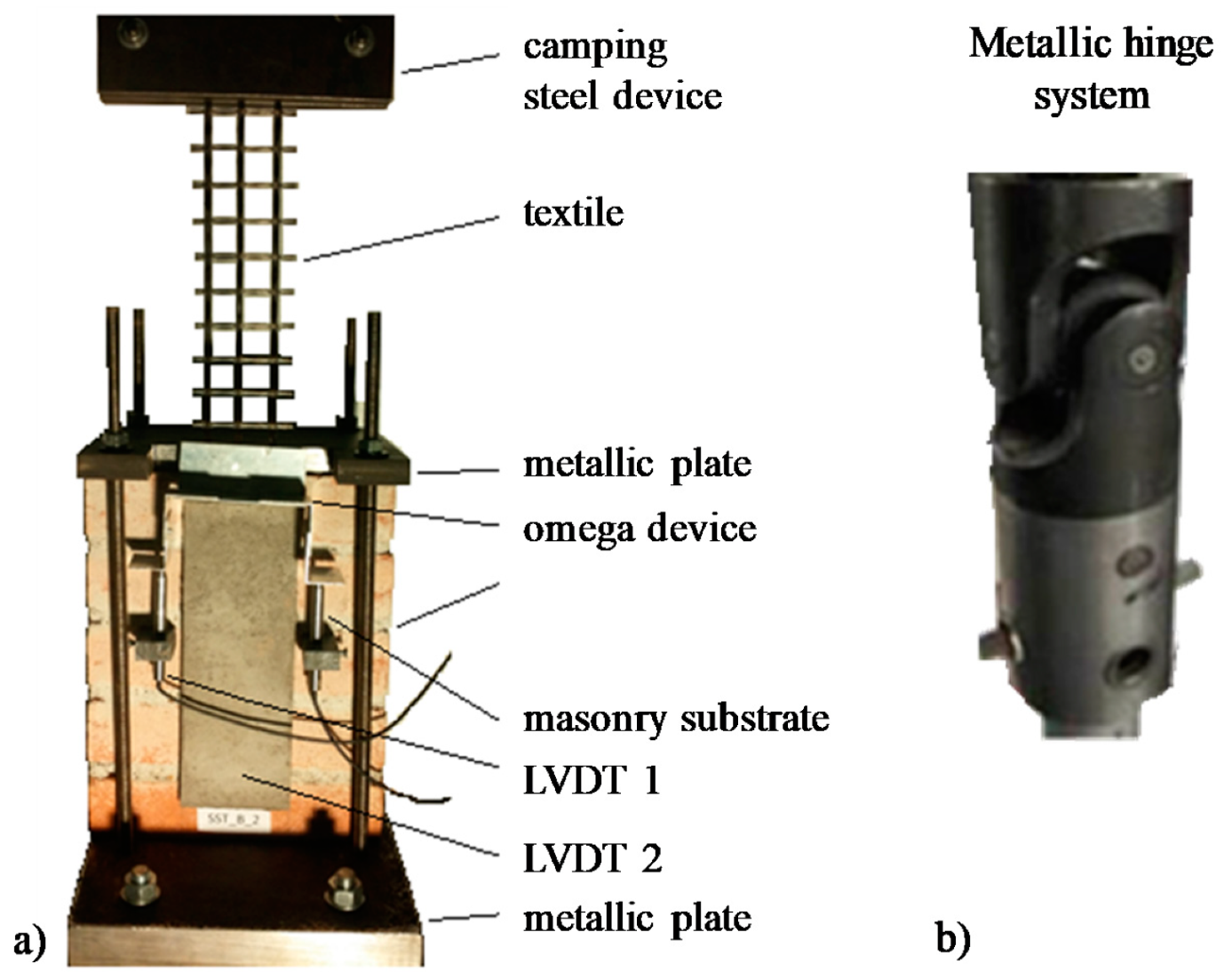

2.2. Methods

3. Results

4. Discussion

5. Comparison between Tensile and Shear Bond Responses

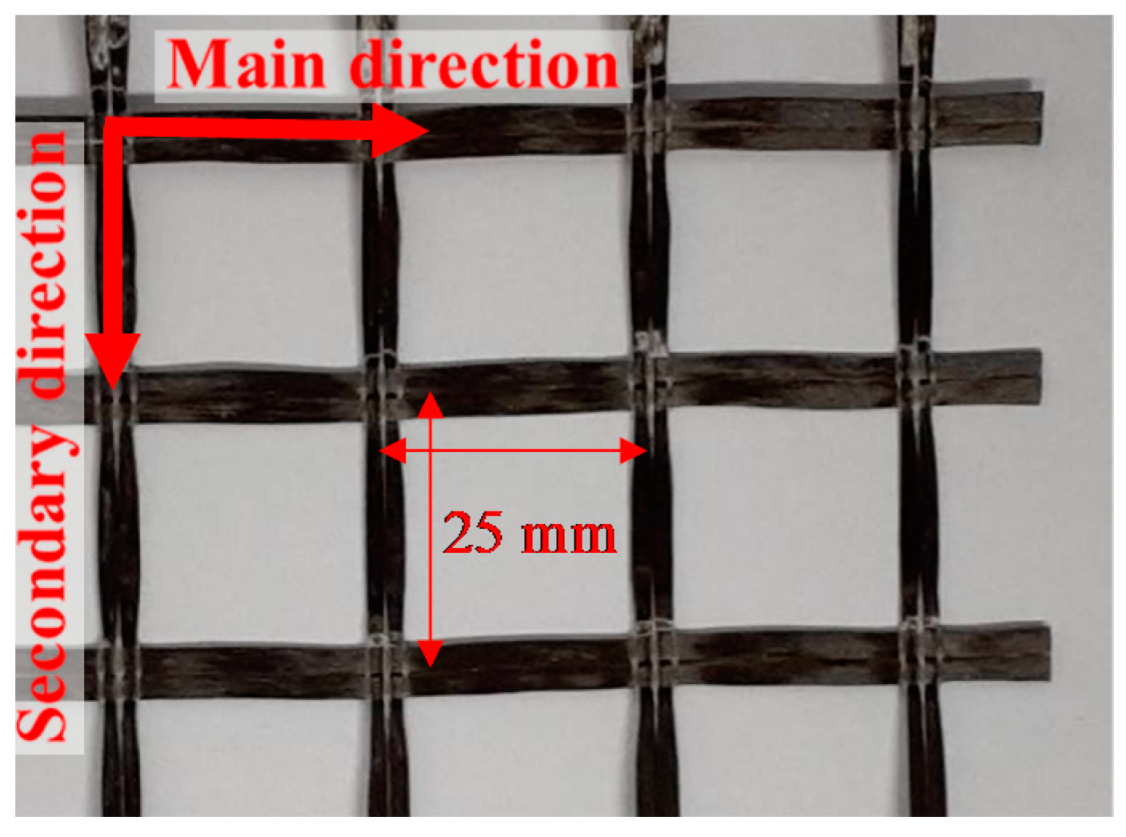

- Tensile Test with 1 ply of Textile (TT_T1): 5 specimens reinforced by a composite characterized by one ply of textile, and so by three basalt threads (Figure 3a), with a textile density of 220 g/m2 and a volumetric strengthening ratio of 0.5%;

- Tensile Test with 2 plies of Textile (TT_T2): Five specimens reinforced by a composite characterized by one ply of textile, and so by five basalt threads (Figure 3b), with a textile density of 367 g/m2 and a volumetric strengthening ratio of 0.9%.

6. Conclusions

- -

- B-TRM systems characterized by basalt density of 220 gr/m² (1 layer of textile) are characterized by a mechanical response in which the maximum capacity is mainly governed by the loss of adherence at the fiber-to-matrix interface;

- -

- The failure mode and the load capacity recorded show that a high density of textile in the middle of composite (two and three layers of textile, respectively 367 and 527 gr/m²) reduce the adherence between the upper and lower layer of mortar matrix. By looking at the results in terms of stress, the fiber loading resulted in being lower in specimens with higher amount of textile reinforcement;

- -

- the textile grid size and the manufacturing process play a key role in the definition of a TRM system in which an appropriate continuity of the matrix allows the system to correctly work as a composite material.

- -

- the comparison between tensile and shear bond response emphasizes the importance of shear tests to investigate the adhesion behavior otherwise not shown by only characterizing the material in tension.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tetta, Z.C.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fiber-reinforced polymers (FRP) in shear strengthening of concrete beams. Compos. Part B Eng. 2015, 77, 338–348. [Google Scholar] [CrossRef]

- Bisby, L.; Stratford, T.; Smith, J.; Halpin, S. Comparative performance of fibre reinforced polymer and fibre reinforced cementitious mortar strengthening systems in elevated temperature service environments. In Proceedings of the Structural Faults and Repair 2010, Edinburgh, UK, 15–17 June 2010; Engineering Technics Press: Edinburgh, UK, 2010. [Google Scholar]

- ACI 549.4R-13, Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures; ACI Committee 549: Farmington Hills, MI, USA, 2013.

- AC434, Acceptance Criteria for Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composite Systems; ICC Evaluation Service, LLC: Birmingham, AL, USA, 2018.

- RILEM Technical Committee 232-TDT (Wolfgang Brameshuber). Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete. Uniaxial tensile test: Test method to determine the load bearing behaviour of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- de Felice, G.; Aiello, M.A.; Caggegi, C.; Ceroni, F.; De Santis, S.; Garbin, E.; Gattesco, N.; Hojdas, Ł.; Krajewski, P.; Kwiecień, A.; et al. Recommendation of RILEM Technical Committee 250-CSM: Test method for textile reinforced mortar to substrate bond characterization. Mater. Struct. 2018, 51, 95. [Google Scholar] [CrossRef]

- Linea Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti; Consiglio Superior dei Lavori Pubblici—Servizio Tecnico Centrale: Rome, Italy, 2018.

- CNR-DT 215/2018, Istruzioni per la Progettazione, L’esecuzione ed il Controllo di Interventi di Consolidamento Statico Mediante L’utilizzo di Compositi Fibrorinforzati a Matrice Inorganica; CNR Commissione di Studio per la Predisposizione e L’analisi di Norme Tecniche Relative Alle Costruzioni: Rome, Italy, 2018.

- De Santis, S.; de Felice, G. Tensile behaviour of mortar-based composites for externally bonded reinforcement systems. Compos. Part B 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Poggi, C. Mechanical properties and debonding strength of Fabric Reinforced Cementitious Matrix (FRCM) systems for masonry strengthening. Compos. Part B 2015, 70, 215–230. [Google Scholar] [CrossRef]

- Arboleda, D.; Carozzi, F.G.; Nanni, A.; Poggi, C. Testing procedures for the uniaxial tensile characterization of fabric reinforced cementitious matrix (FRCM) composites. J. Compos. Constr. 2016, 20, 04015063. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Saidi, M.; Gabor, A. Use of distributed optical fibre as a strain sensor in textile reinforced cementitious matrix composites. Measurement 2019, 140, 323–333. [Google Scholar] [CrossRef]

- Nobili, A. Durability assessment of impregnated Glass Fabric Reinforced Cementitious Matrix (GFRCM) composites in the alkaline and saline environments. Constr. Build. Mater. 2016, 105, 465–471. [Google Scholar] [CrossRef]

- Nobili, A.; Signorini, C. On the effect of curing time and environmental exposure on impregnated Carbon Fabric Reinforced Cementitious Matrix (FRCM) composite with design considerations. Compos. Part B 2017, 112, 300–313. [Google Scholar] [CrossRef]

- Donnini, J.; De Caso y Basalo, F.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behaviour at high-temperature: Experimental and numerical results. Compos. Part B 2017, 108, 108–121. [Google Scholar] [CrossRef]

- Tran, M.T.; Hong Vu, X.; Ferrier, E. Experimental and analytical analysis of the effect of fibre treatment on the thermomechanical behaviour of continuous carbon textile subjected to simultaneous elevated temperature and uniaxial loadings. Constr. Build. Mater. 2018, 183, 32–45. [Google Scholar] [CrossRef]

- De Munck, M.; El Kadi, M.; Tsangouri, E.; Vervloet, J.; Verbruggen, S.; Wastiels, J.; Tysmans, T.; Remi, O. Influence of environmental loading on the tensile and cracking behaviour of textile reinforced cementitious composites. Constr. Build. Mater. 2018, 181, 325–334. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; Di Prisco, M. Tensile behavior of textile reinforced concrete subjected to freezing-thawing cycles in un-cracked and cracked regimes. Cem. Concr. Res. 2015, 73, 169–183. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental and analytical investigation on bond between Carbon-FRCM materials and masonry. Compos. Part B 2013, 46, 15–20. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Milani, G.; Poggi, C. Mechanical Properties and numerical modeling of Fabric Reinforced Cementitious Matrix (FRCM) systems for strengthening of masonry structures. Compos. Struct. 2014, 107, 711–725. [Google Scholar] [CrossRef]

- De Felice, G.; De Santis, S.; Germendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenço, P.B.; Oliveira, D.V.; Paolacci, F.; Papanicolaou, C.G. Mortar-based systems for externally bonded strengthening of masonry. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B 2016, 88, 220–228. [Google Scholar] [CrossRef]

- D’Antino, T.; Gonzalez, J.; Pellegrino, C.; Carloni, C.; Sneed, L.H. Experimental investigation of glass and carbon FRCM composite materials applied onto concrete supports. Appl. Mech. Mater. 2016, 847, 60–67. [Google Scholar] [CrossRef]

- Bencardino, F.; Condello, A.; Ashour, A.F. Single-lap shear bond tests on Steel Reinforced Geopolymeric Matrix-concrete joints. Compos. Part B 2017, 110, 62–71. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for strengthening of masonry. Compos. Part B 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Olivito, R.S.; Cevallos, O.A.; Carrozzini, A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater. Des. 2014, 57, 258–268. [Google Scholar] [CrossRef]

- Olivito, R.S.; Codispoti, R.; Cevallos, O.A. Bond behaviour of Flax-FRCM and PBO-FRCM composites applied on clay bricks: Experimental and theoretical study. Compos. Struct. 2016, 146, 221–231. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Influence of an impregnation treatment on the morphology and mechanical behaviour of flax yarns embedded in hydraulic lime mortar. Fibers 2019, 7, 30. [Google Scholar] [CrossRef]

- Ferrara, G.; Coppola, B.; Di Maio, L.; Incarnato, L.; Martinelli, E. Tensile strength of flax fabrics to be used as reinforcement in cement-based composites: Experimental tests under different environmental exposures. Compos. Part B 2019, 168, 511–523. [Google Scholar] [CrossRef]

- D’Antino, T.; Sneed, L.H.; Carloni, C.; Pellegrino, C. Influence of the substrate characteristics on the bond behaviour of PBO FRCM concrete joints. Constr. Build. Mater. 2015, 101, 838–850. [Google Scholar] [CrossRef]

- Caggegi, C.; Carozzi, F.G.; De Santis, S.; Fabbroncino, F.; Focacci, F.; Hojdys, Ł.; Lanoye, E.; Zuccarino, L. Experimental analysis on tensile and bond properties of PBO and aramid fabric reinforced cementitious matrix for strengthening masonry structures. Compos. Part B 2017, 127, 175–195. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; Poggi, C. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B 2017, 128, 100–119. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecien, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round Robin Test on tensileand bond behaviour of Steel Reinforced Grout systems. Compos. Part B 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B 2017, 127, 196–214. [Google Scholar] [CrossRef]

- Ascione, L.; De Felice, G.; De Santis, S. A qualification method for externally bonded fibre reinforced cementitious matrix (FRCM) strengthening systems. Compos. Part B 2015, 78, 497–506. [Google Scholar] [CrossRef]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis Group, LLC, Abington: Oxfordshire, UK, 2006. [Google Scholar]

- Ombres, L. Analysis of the bond between Fabric Reinforced Cementitious Mortar (FRCM) strengthening systems and concrete. Compos. Part B 2015, 69, 418–426. [Google Scholar] [CrossRef]

- De Santis, S.; De Felice, G. Steel reinforced grout systems for the strengthening of masonry structures. Compos. Struct. 2015, 134, 533–548. [Google Scholar] [CrossRef]

- Deàk, T.; Czigàny, T. Chemical composition and mechanical properties of basalt and glass fibres: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characterisation of basalt fibres as a strengthening material for concrete structures. Compos. Part B 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valena, A. A review on basalt fibre and its composites. Compos. Part B 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; De Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Pellegrino, A.; et al. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; Biscaia, H.C.; San-José, J.T. Experimental and numerical modeling of basalt textile reinforced mortar behaviour under uniaxial tensile stress. Mater. Design 2014, 55, 66–74. [Google Scholar] [CrossRef]

- Marcari, G.; Basili, M.; Vestroni, F. Experimental investigation of tuff masonry panels reinforced with surface bonded basalt textile-reinforced mortar. Compos. Part B 2017, 108, 131–142. [Google Scholar] [CrossRef]

- Harajli, M.; Elkhatib, H.; San-José, J.T. Static and cyclic out-of-plane response of masonry walls strengthened using textile-mortar system. J. Mater. Civ. Eng. 2010, 22, 1171–1180. [Google Scholar] [CrossRef]

- Caggegi, C.; Lanoye, E.; Djama, K.; Bassil, A.; Gabor, A. Tensile behavior of a basalt TRM strengthening system: Influence of mortar and reinforcing textile ratios. Compos. Part B 2017, 130, 90–120. [Google Scholar] [CrossRef]

- De Felice, G.; Aiello, M.A.; Bellini, A.; Ceroni, F.; De Santis, S.; Garbin, E.; Leone, M.; Lignola, G.P.; Malena, M.; Mazzotti, C.; et al. Experimental characterisation of composite-to-brick masonry shear bond. Mater. Struct. 2015, 49, 2581–2596. [Google Scholar] [CrossRef]

- San Marco Terreal Company Website. Available online: https://www.sanmarco.it/ (accessed on 14 May 2019).

- EN 196-1:1994. Methods of Testing Cement—Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 1994.

- Fyfe Company Website. Available online: https://www.aegion.com/about/our-brands/fyfe (accessed on 14 May 2019).

- Caggegi, C.; Sciuto, D.; Cuomo, M. Experimental study on effective bond length of basalt textile reinforced mortar strengthening system: Contribution of digital image correlation. Measurement 2018, 129, 119–127. [Google Scholar] [CrossRef]

| fc (N/mm2) | ft (N/mm2) | Ec (N/mm2) | |||||

|---|---|---|---|---|---|---|---|

| Masonry substrate | Bricks * | 17.89 | (5%) | 2.46 | (11%) | 5756 | (5%) |

| Mortar | 10.93 | (7%) | 3.08 | (6%) | - | ||

| TRM system | Cementitious matrix | 20.56 | (16%) | 5.46 | (12%) | ||

| Basalt textile ** | - | 1089 | 55,825 | ||||

| fc = compressive strength, ft = tensile strength, Ec = elastic modulus in compression | |||||||

| Series of Specimens | Number of Specimens | Number of Threads | Textile Cross Section mm2 | Textile Density g/m2 | Volumetric Strength Ratio |

|---|---|---|---|---|---|

| SST-T1 | 5 | 3 | 4.83 | 220 | 0.53% |

| SST-T2 | 4 | 5 | 8.05 | 367 | 0.89% |

| SST-T3 | 6 | 7 | 11.27 | 513 | 1.25% |

| Specimen | Pu | s* | ko | σ* | σ*/ft | Γel | Γin | Failure | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | mm | N/mm | N/mm2 | J | J | mode | ||||||||||

| SST-T1 | 1 | 4301 | 3.45 | 2433 | 890.4 | 0.85 | 7.4 | 17.6 | D + F* | |||||||

| SST-T1 | 2 | 2613 | 1.39 | 1322 | 541.0 | 0.51 | 2.6 | 22.0 | D | |||||||

| SST-T1 | 3 | 3772 | 1.95 | 3607 | 781.0 | 0.74 | 4.5 | 18.9 | D + F | |||||||

| SST-T1 | 4 | 4672 | 2.49 | 1991 | 967.3 | 0.92 | 7.2 | 34.9 | D + F* | |||||||

| SST-T1 | 5 | 4353 | 1.8 | 5767 | 901.2 | 0.86 | 5.4 | 15.6 | D + F* | |||||||

| Mean (Co.V. %) | 3942 | (21) | 2.22 | (36) | 3024 | (58) | 816.2 | (21) | 0.78 | (21) | 5.4 | (36) | 21.8 | (35) | - | |

| SST-T2 | 1 | 2728 | 0.5 | 5387 | 338.9 | 0.32 | 0.9 | - | B + C | |||||||

| SST-T2 | 2 | 2731 | 0.64 | 3319 | 339.3 | 0.32 | 1.2 | - | B | |||||||

| SST-T2 | 3 | 4225 | 2.16 | 3379 | 524.8 | 0.50 | 6.7 | 35.6 | E | |||||||

| SST-T2 | 4 | 3619 | 1.51 | 2733 | 449.5 | 0.43 | 4.0 | 26.0 | E | |||||||

| Mean (Co.V. %) | 3326 | (22) | 1.20 | (65) | 3705 | (31) | 413.1 | (22) | 0.39 | (22) | 3.2 | (85) | 30.8 | (22) | - | |

| SST-T3 | 1 | 5650 | 1.75 | 4985 | 501.3 | 0.48 | 6.8 | 27.1 | E | |||||||

| SST-T3 | 2 | 3956 | 1.17 | 3105 | 351.0 | 0.33 | 2.7 | - | C | |||||||

| SST-T3 | 3 | 2938 | 0.87 | 3529 | 260.6 | 0.25 | 1.4 | - | C | |||||||

| SST-T3 | 4 | 6250 | 1.99 | 6979 | 554.6 | 0.53 | 8.6 | 44.2 | E | |||||||

| SST-T3 | 5 | 3041 | 1.24 | 2454 | 269.8 | 0.26 | 2.5 | 20.7 | E | |||||||

| SST-T3 | 6 | 2656 | 0.71 | 3179 | 253.7 | 0.22 | 1.3 | - | C | |||||||

| Mean (Co.V. %) | 4082 | (37) | 1.29 | (38) | 4038 | (41) | 362.2 | (37) | 0.34 | (37) | 3.9 | (80) | 30.7 | (40) | - | |

| Pu = peak load, s* = displacement at peak load, ko = initial stiffness, σ* = stress at peak load, ft = basalt tensile strength, Γel = elastic energy, Γin = inelastic energy. | ||||||||||||||||

| Tensile Tests | σ*/ft | (Co.V.) | Single Shear | σ*/ft | (Co.V.) |

|---|---|---|---|---|---|

| % | % | Tests | % | % | |

| TT-T1 | 87 | (10) | SST-T1 | 78 | (21) |

| TT-T2 | 76 | (6) | SST-T2 | 39 | (22) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrara, G.; Caggegi, C.; Gabor, A.; Martinelli, E. Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density. Fibers 2019, 7, 103. https://doi.org/10.3390/fib7120103

Ferrara G, Caggegi C, Gabor A, Martinelli E. Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density. Fibers. 2019; 7(12):103. https://doi.org/10.3390/fib7120103

Chicago/Turabian StyleFerrara, Giuseppe, Carmelo Caggegi, Aron Gabor, and Enzo Martinelli. 2019. "Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density" Fibers 7, no. 12: 103. https://doi.org/10.3390/fib7120103

APA StyleFerrara, G., Caggegi, C., Gabor, A., & Martinelli, E. (2019). Experimental Study on the Adhesion of Basalt Textile Reinforced Mortars (TRM) to Clay Brick Masonry: The Influence of Textile Density. Fibers, 7(12), 103. https://doi.org/10.3390/fib7120103